Parametric Optimization of Selective Laser Melted 13Ni400 Maraging Steel by Taguchi Method

Abstract

1. Introduction

2. Materials and Methods

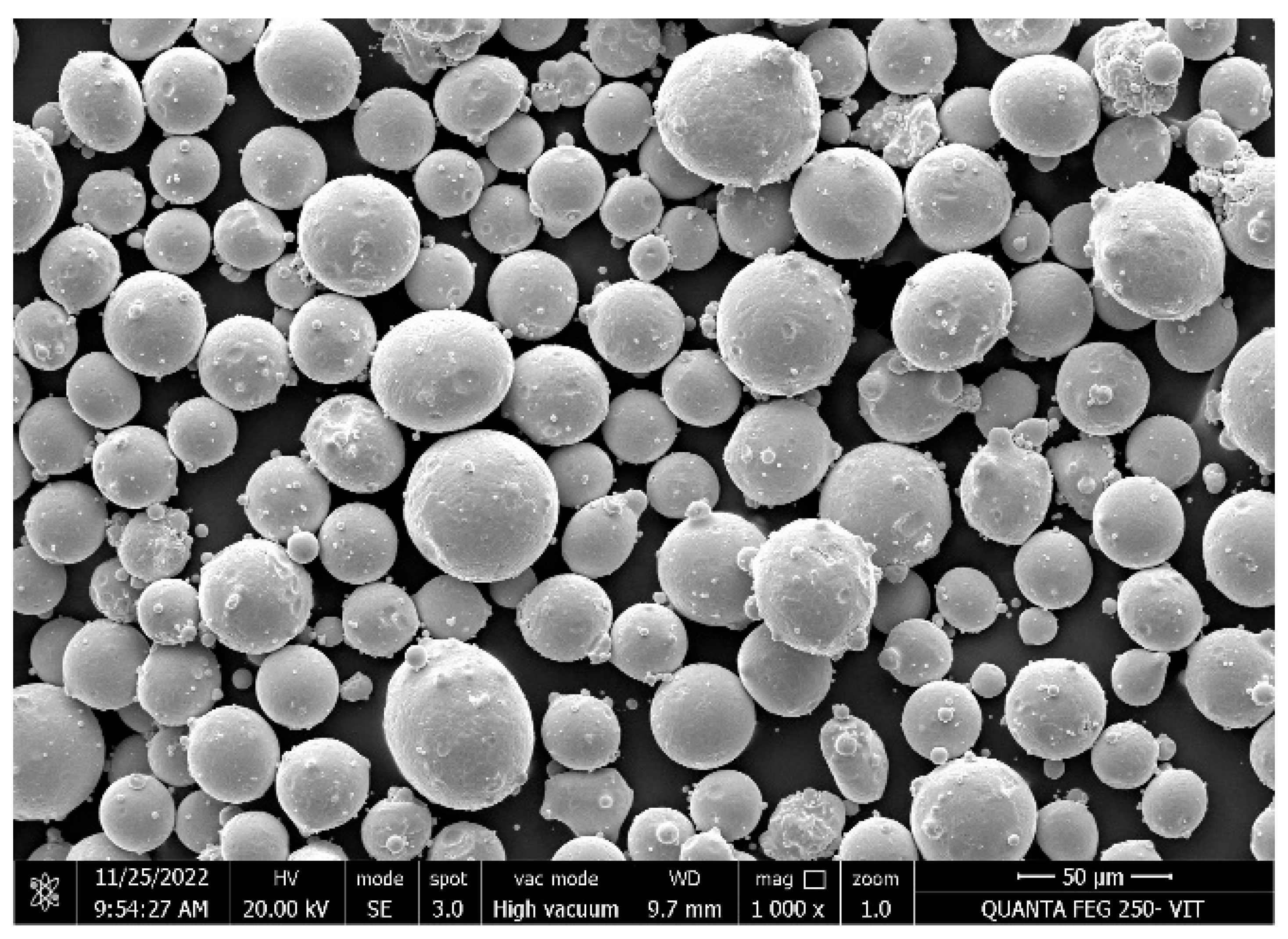

2.1. Materials

2.2. Selective Laser Melting Process

2.3. Experimental Design and Planning

2.4. Calculation of Performance Measures

2.4.1. Calculation of Energy Density (Ed)

2.4.2. Calculation of Relative Density (RD)

2.4.3. Calculation of Surface Roughness (Ra)

2.4.4. Calculation of Microhardness

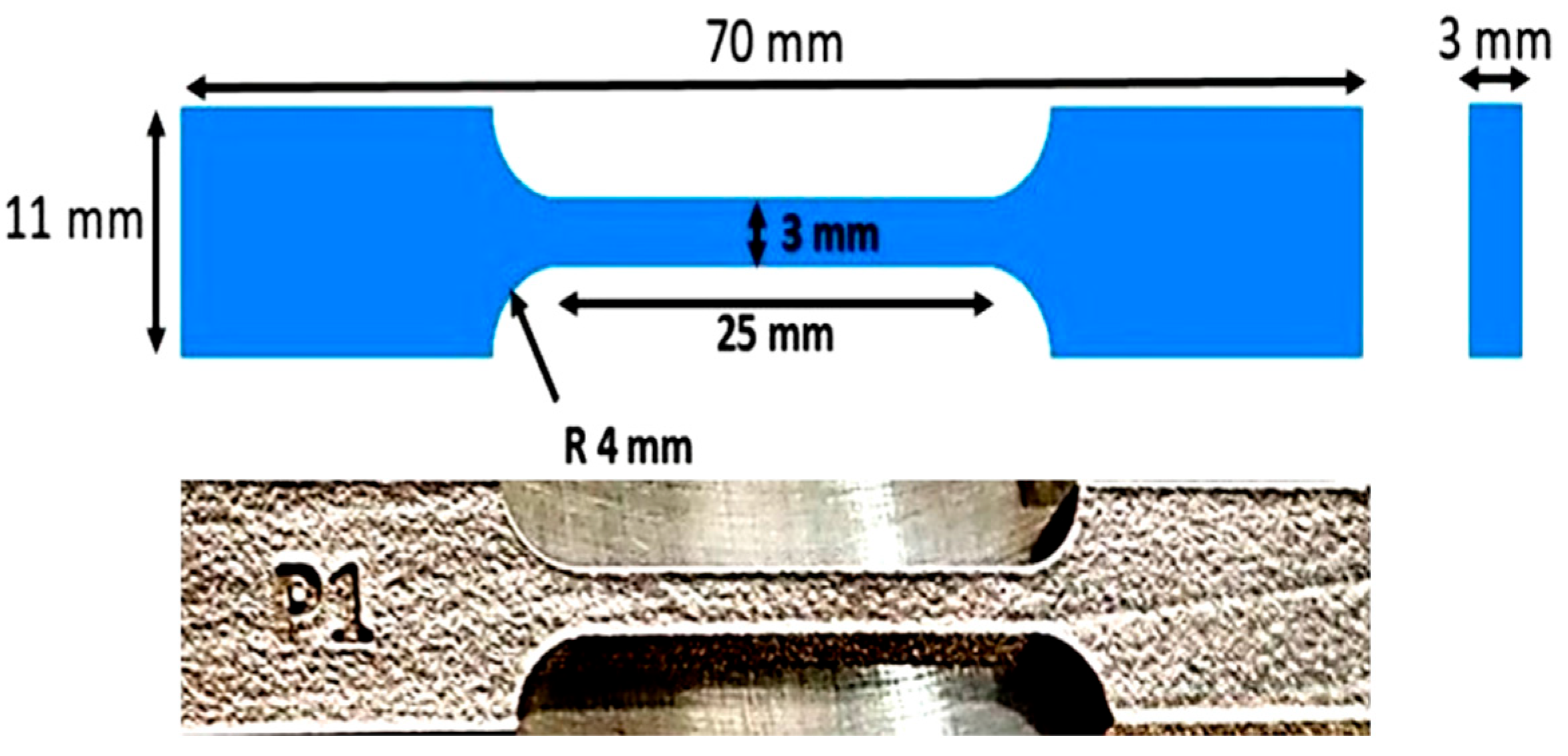

2.4.5. Calculation of Tensile Strength

3. Results and Discussion

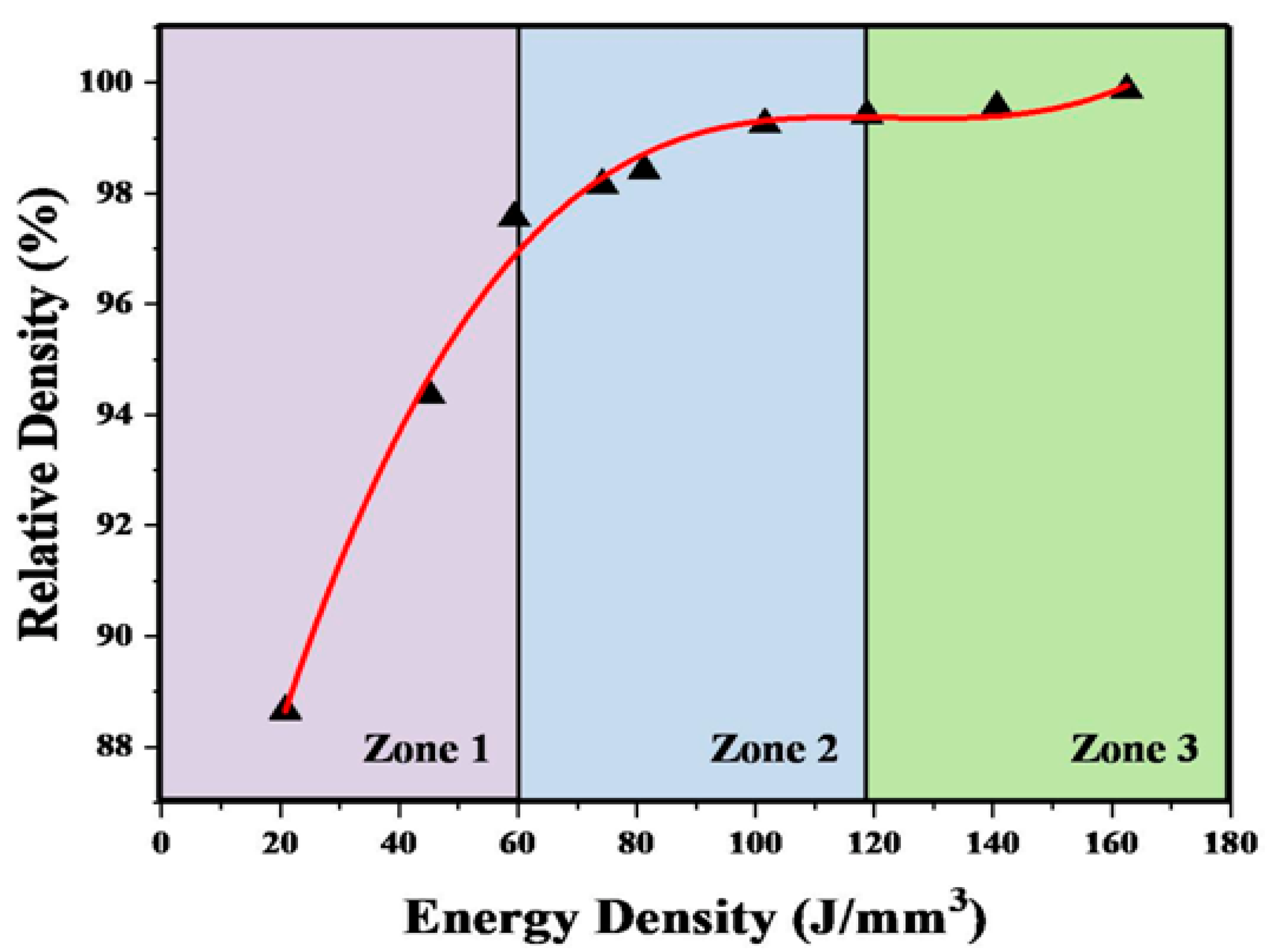

3.1. Relative Density

3.2. Surface Roughness

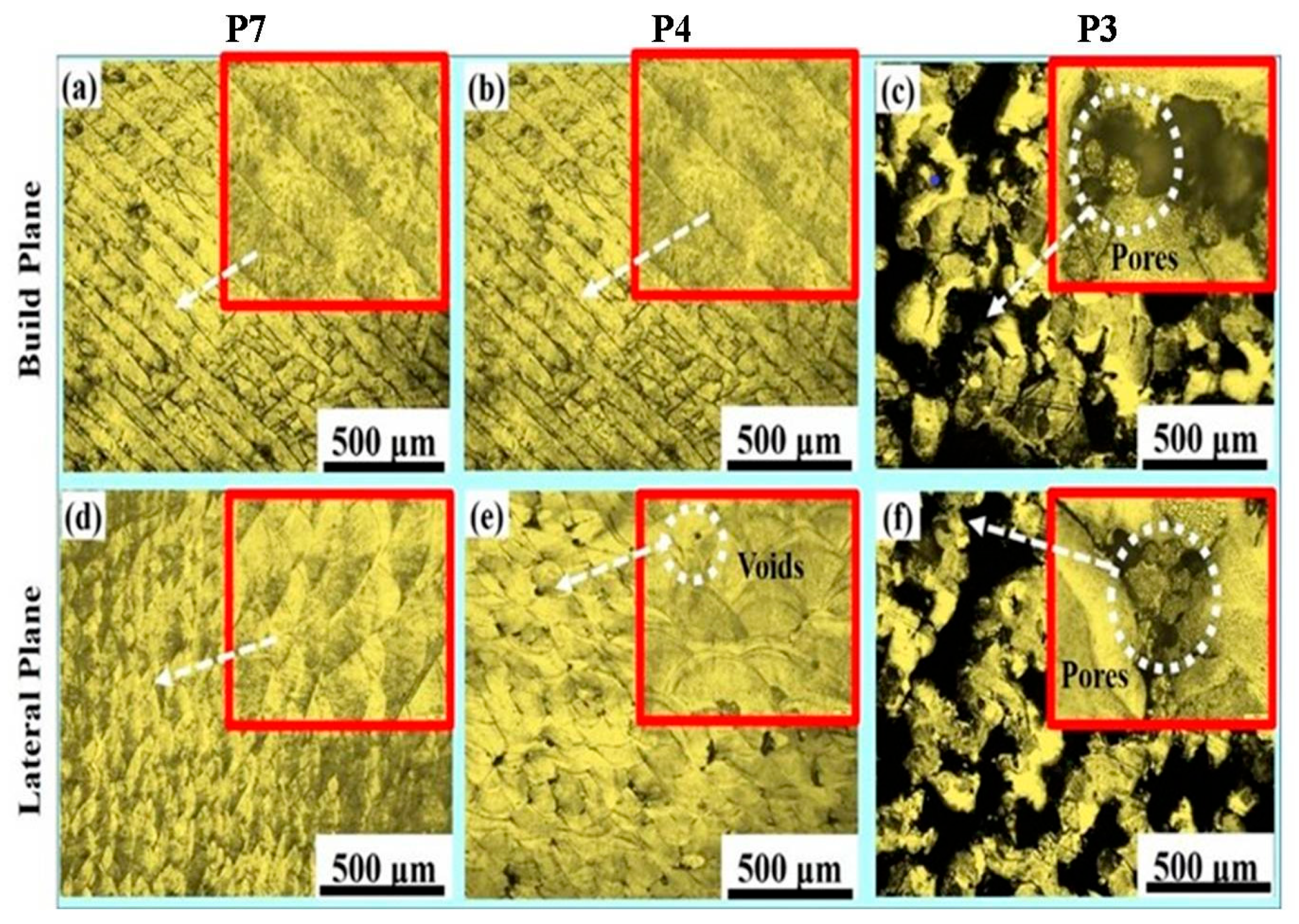

3.3. Microstructure

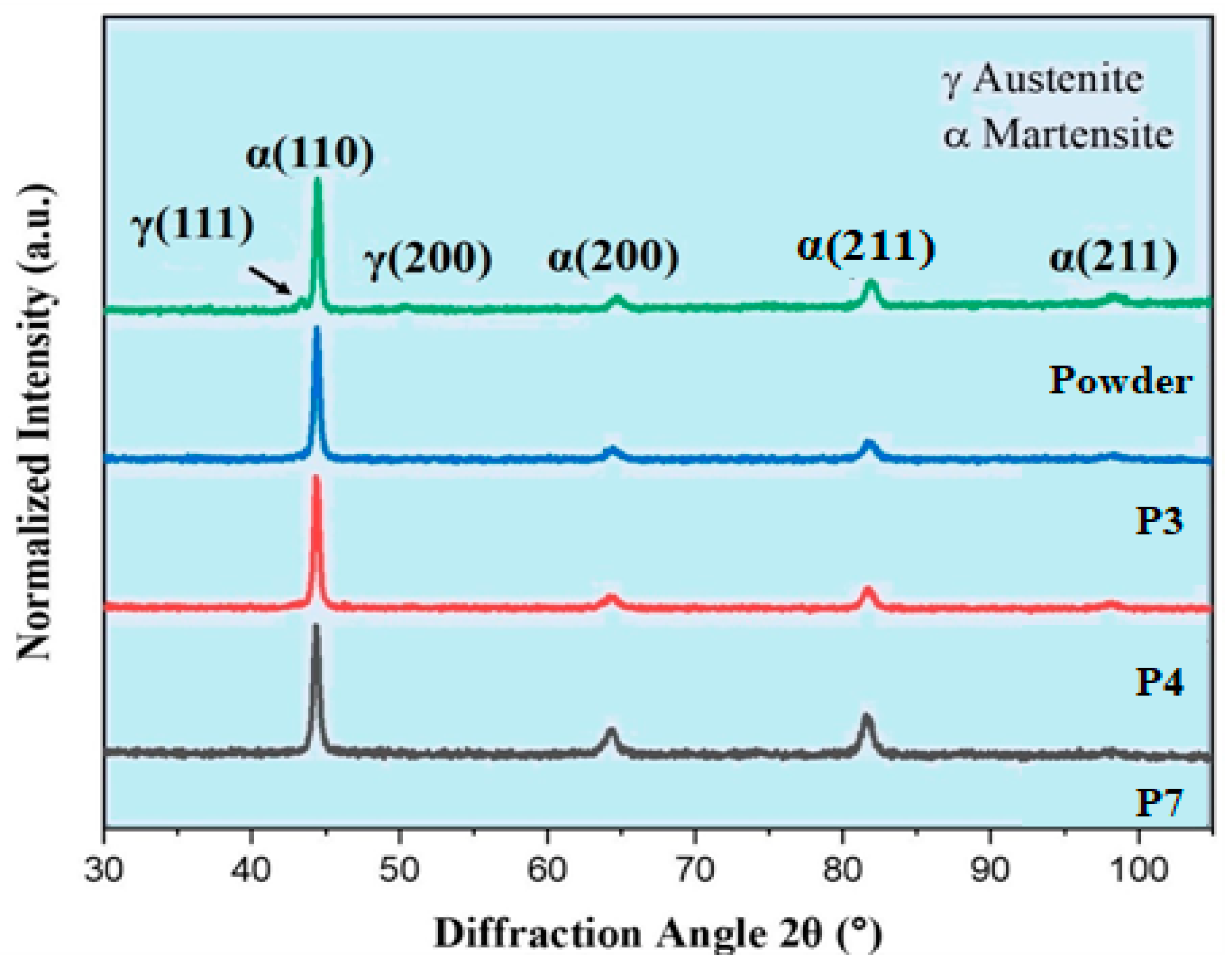

3.4. XRD Analysis

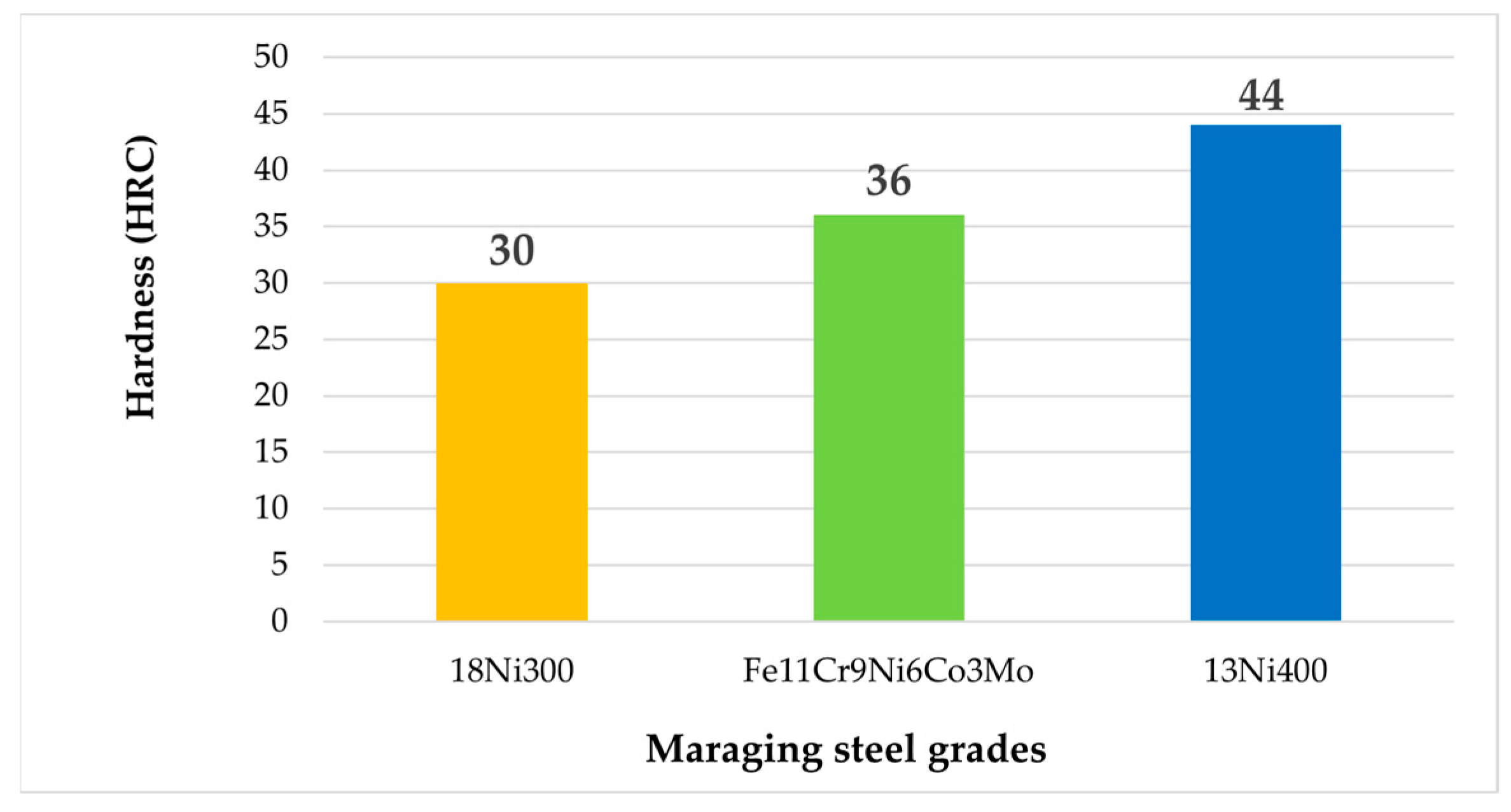

3.5. Microhardness

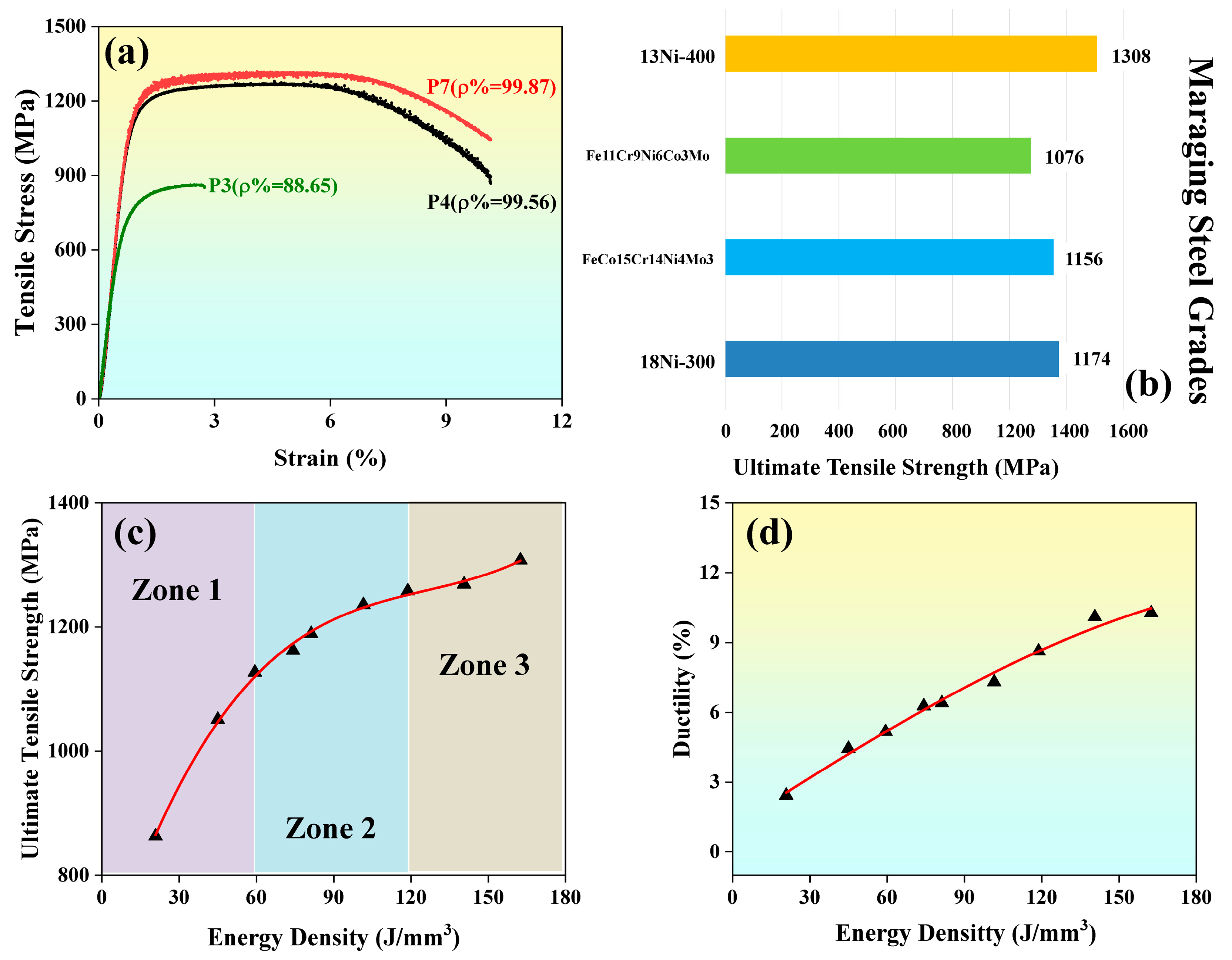

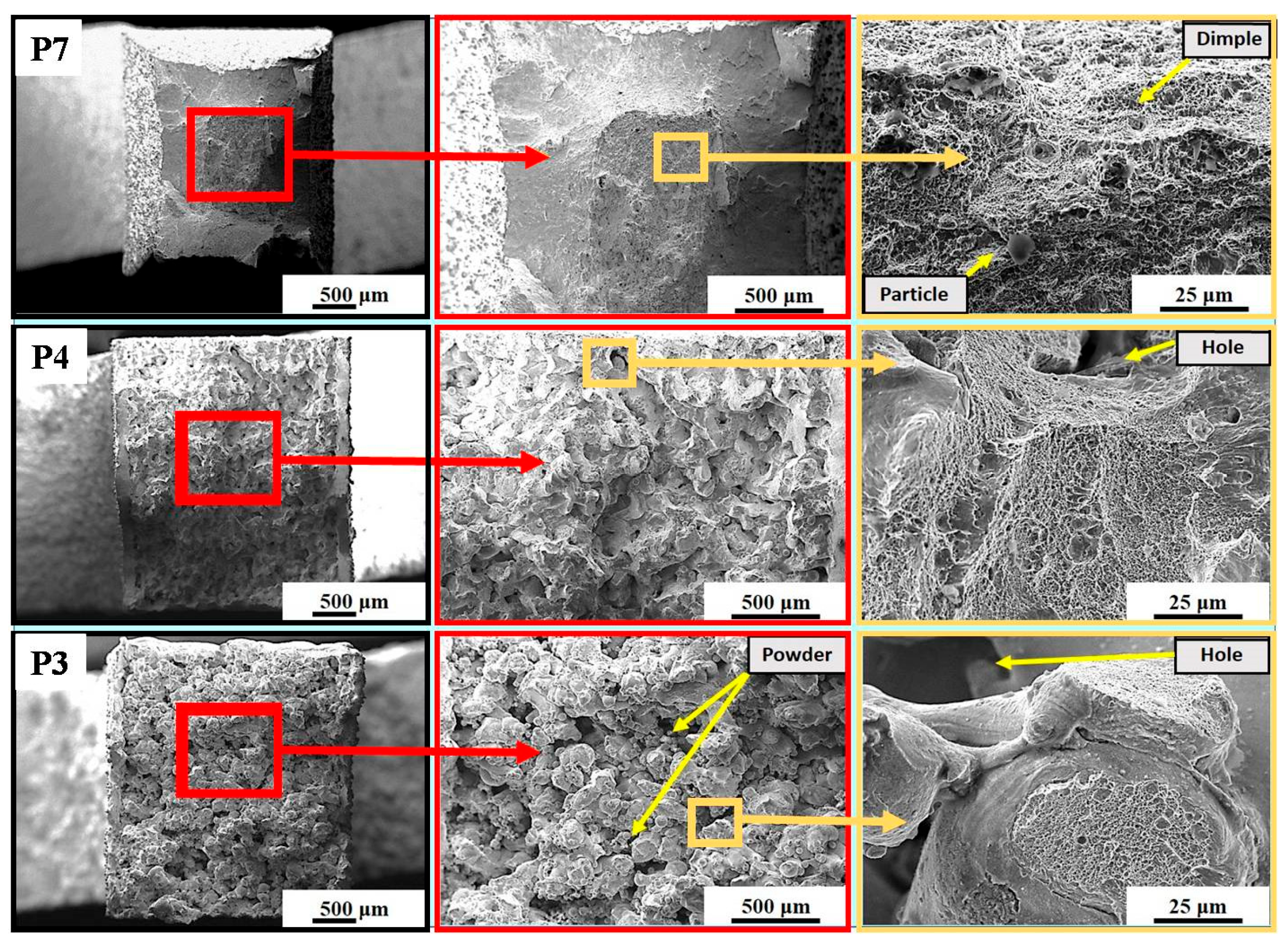

3.6. Tensile Test

3.7. Optimization of Independent Variables and Validation of the Proposed Work

4. Conclusions

- It is observed that relative density and microhardness initially increase rapidly as energy density increases from 19 to 60 J/mm3 and then tend to remain constant when energy densities increase from 60 to 120 J/mm3. The ANOVA results revealed that the energy density, layer thickness, and hatch spacing significantly influence the relative density of additively manufactured 13Ni400 maraging steel parts. It was found that higher energy density and smaller layer thickness positively contribute to achieving higher relative density. Additionally, increasing hatch spacing negatively affects relative density. This finding is crucial for achieving denser and defect-free components using SLM, which is essential for applications requiring high material integrity.

- The parts produced with an energy density greater than 162.50 J/mm3 have a relative density closer to 100% and a microhardness of 44 HRC. The ANOVA results demonstrated the significance of laser power and scan speed in determining the microhardness of the additively manufactured parts. Increasing laser power elevated the microhardness, whereas higher scan speeds had the opposite effect. Properly balancing these parameters is vital to achieving optimal microhardness and ensuring the components exhibit superior mechanical strength and wear resistance.

- The phase compositions of the specimen and powder are nearly identical. The martensite phase largely dominates the phase compositions of selectively laser-melted 13Ni400 samples, with very few traces of austenite. The austenite (γ) phase in the powder pattern (111) is unseen after forming in SLM. SLM produces components with a fine cellular structure and coarse granules. The crystal grain growth is reduced by the higher cooling rate, resulting in smaller crystal grains. The samples that possess a higher cooling rate result in a higher number of equiaxed crystals.

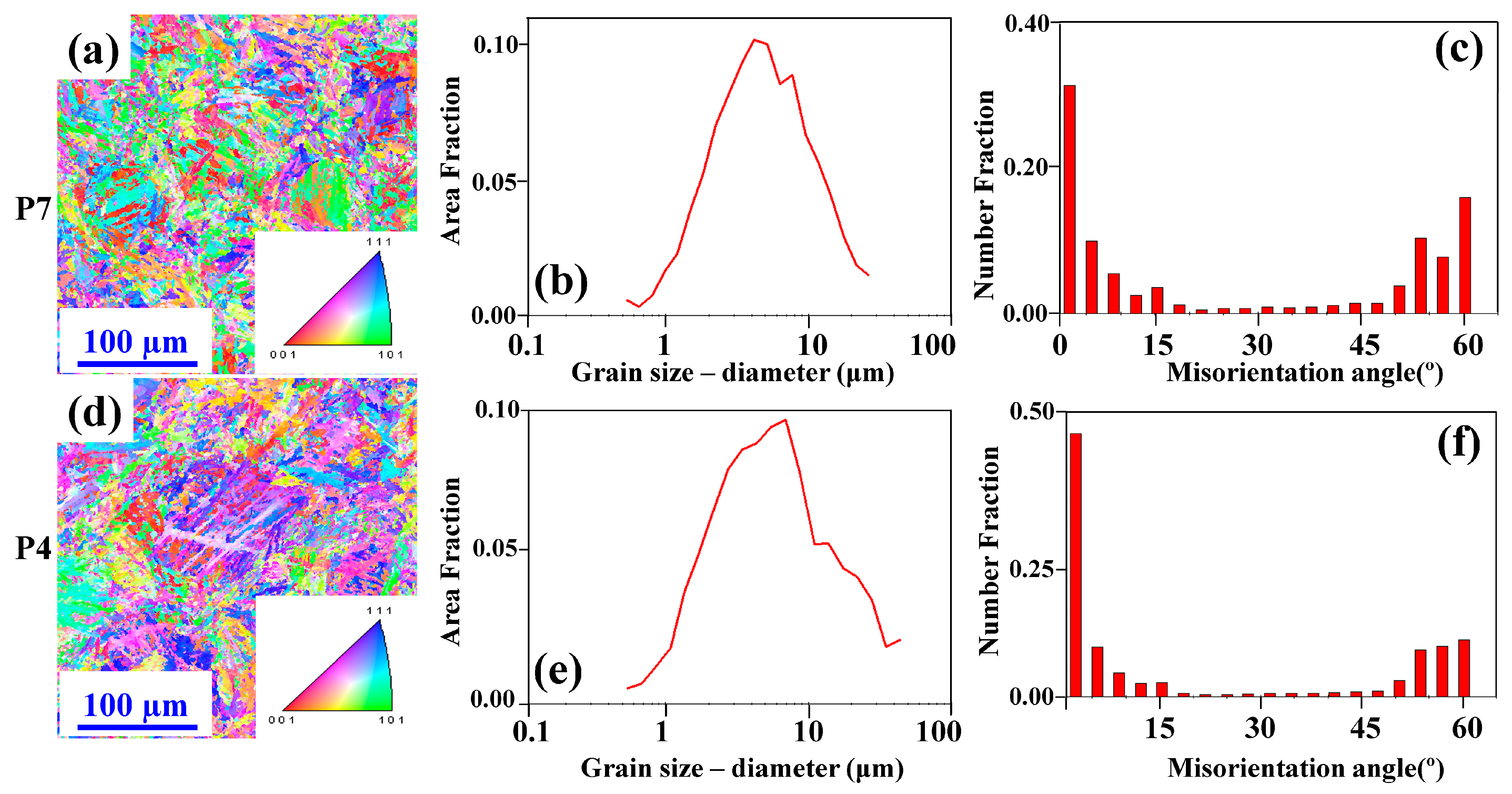

- The EBSD study of 13Ni400-grade maraging steel reveals significant differences in microstructure and grain boundaries between samples P7 and P4. Sample P7 exhibits a prevalence of fine grains with dominant orientations along the (111) and (101) planes, contributing to a more uniform stress distribution and improved mechanical performance. The smaller grain size and higher percentage of equiaxed grains in sample P7 result in enhanced material strength and hardness. Additionally, the presence of a higher fraction of high-angle grain boundaries in sample P7 impedes grain growth during processing and further strengthens the material.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Floreen, S. The physical metallurgy of maraging steels. Metall. Rev. 1968, 13, 115–128. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and Mechanical Properties of Al-12Si Produced by Selective Laser Melting: Effect of Heat Treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.D.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef]

- Habiby, F.; ul Haq, A.; Khan, A.Q. The Properties and Applications of 18% Nickel Maragi Ng Steels. Mater. Technol. 1994, 9, 246–252. [Google Scholar] [CrossRef]

- Lang, F.H.; Kenyon, N. Welding of Maraging Steels. Weld. Res. Counc. Bull. 1971, 11, 216–268. [Google Scholar]

- Zhao, C.; Wang, Z.; Li, D.; Kollo, L.; Luo, Z.; Zhang, W.; Prashanth, K.G. Cu-Ni-Sn Alloy Fabricated by Melt Spinning and Selective Laser Melting: A Comparative Study on the Microstructure and Formation Kinetics. J. Mater. Res. Technol. 2020, 9, 13097–13105. [Google Scholar] [CrossRef]

- Prashanth, K.; Scudino, S.; Chatterjee, R.; Salman, O.; Eckert, J. Additive Manufacturing: Reproducibility of Metallic Parts. Technologies 2017, 5, 8. [Google Scholar] [CrossRef]

- Salman, O.O.; Gammer, C.; Eckert, J.; Salih, M.Z.; Abdulsalam, E.H.; Prashanth, K.G.; Scudino, S. Selective Laser Melting of 316L Stainless Steel: Influence of TiB2 Addition on Microstructure and Mechanical Properties. Mater Today Commun. 2019, 21, 100615. [Google Scholar] [CrossRef]

- Shin, W.S.; Son, B.; Song, W.; Sohn, H.; Jang, H.; Kim, Y.J.; Park, C. Heat Treatment Effect on the Microstructure, Mechanical Properties, and Wear Behaviors of Stainless Steel 316L Prepared via Selective Laser Melting. Mater. Sci. Eng. A 2021, 806, 140805. [Google Scholar] [CrossRef]

- Liang, L.; Xu, M.; Chen, Y.; Zhang, T.; Tong, W.; Liu, H.; Wang, H.; Li, H. Effect of Welding Thermal Treatment on the Microstructure and Mechanical Properties of Nickel-Based Superalloy Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2021, 819, 141507. [Google Scholar] [CrossRef]

- Xu, G.G.; Jiang, W.G.; Sun, Y.Y.; Qin, Q.H.; Li, Q. Particle-Scale Computational Fluid Dynamics Simulation on Selective Parallel Dual-Laser Melting of Nickel-Based Superalloy. J. Manuf. Process 2022, 73, 197–206. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Damodaram, R.; Maity, T.; Wang, P.; Eckert, J. Friction Welding of Selective Laser Melted Ti6Al4V Parts. Mater. Sci. Eng. A 2017, 704, 66–71. [Google Scholar] [CrossRef]

- Kumar, D.; Shankar, G.; Prashanth, K.G.; Suwas, S. Control of Texture and Microstructure in Additive Manufacturing of Stainless Steel 316 L. J. Alloys Compd. 2023, 976, 173040. [Google Scholar] [CrossRef]

- Chen, H.; Kosiba, K.; Suryanarayana, C.; Lu, T.; Liu, Y.; Wang, Y.; Prashanth, K.G. Feedstock Preparation, Microstructures and Mechanical Properties for Laser-Based Additive Manufacturing of Steel Matrix Composites. Int. Mater. Rev. 2023, 68, 1192–1244. [Google Scholar] [CrossRef]

- Jagadeesh, B.; Duraiselvam, M.; Prashanth, K.G. Deformation Behavior of Metallic Lattice Structures with Symmetrical Gradients of Porosity Manufactured by Metal Additive Manufacturing. Vacuum 2023, 211, 111955. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical Behavior of Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Tensile, Fracture, and Fatigue Crack Growth Properties of a 3D Printed Maraging Steel through Selective Laser Melting. J. Alloys Compd. 2017, 725, 355–364. [Google Scholar] [CrossRef]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Corrigendum: “Selective Laser Melting of Stainless Steel 316L with Low Porosity and High Build Rates” (Materials and Design (2016) 104 (197–204) (S0264127516306372) (10.1016/j.Matdes.2016.05.035)). Mater. Des. 2017, 126, 359. [Google Scholar] [CrossRef]

- Alsalla, H.; Hao, L.; Smith, C. Fracture Toughness and Tensile Strength of 316L Stainless Steel Cellular Lattice Structures Manufactured Using the Selective Laser Melting Technique. Mater. Sci. Eng. A 2016, 669, 1–6. [Google Scholar] [CrossRef]

- Mao, Z.; Lu, X.; Yang, H.; Niu, X.; Zhang, L.; Xie, X. Processing Optimization, Microstructure, Mechanical Properties and Nanoprecipitation Behavior of 18Ni300 Maraging Steel in Selective Laser Melting. Mater. Sci. Eng. A 2022, 830, 142334. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, Z.; Tong, X.; Dong, S.; Cui, Z.; Wang, X.; Ren, L. Effects of Process Parameters on the Microstructure and Mechanical Properties of 24CrNiMo Steel Fabricated by Selective Laser Melting. Opt. Laser Technol. 2020, 128, 106262. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, S.; Zhang, C.; Chen, J.; Zhang, J.; Liu, Y. Optimization of Laser Energy Density and Scanning Strategy on the Forming Quality of 24CrNiMo Low Alloy Steel Manufactured by SLM. Mater. Charact. 2020, 170, 110718. [Google Scholar] [CrossRef]

- Cheng, Z.; Sun, S.; Du, X.; Tang, Q.; Shi, J.; Liu, X.; Jianrong, Q. Microstructural Evolution of a FeCo15Cr14Ni4Mo3 Maraging Steel with High Ductility Prepared by Selective Laser Melting. Mater. Today Commun. 2022, 31, 103243. [Google Scholar] [CrossRef]

- Vishwakarma, J.; Chattopadhyay, K.; Santhi Srinivas, N.C. Effect of Build Orientation on Microstructure and Tensile Behaviour of Selectively Laser Melted M300 Maraging Steel. Mater. Sci. Eng. A 2020, 798, 140130. [Google Scholar] [CrossRef]

- Bai, Y.; Zhao, C.; Zhang, Y.; Wang, H. Microstructure and Mechanical Properties of Additively Manufactured Multi-Material Component with Maraging Steel on CrMn Steel. Mater. Sci. Eng. A 2021, 802, 140630. [Google Scholar] [CrossRef]

- Gao, P.; Jing, G.; Lan, X.; Li, S.; Zhou, Y.; Wang, Y.; Yang, H.; Wei, K.; Wang, Z. Effect of Heat Treatment on Microstructure and Mechanical Properties of Fe–Cr–Ni–Co–Mo Maraging Stainless Steel Produced by Selective Laser Melting. Mater. Sci. Eng. A 2021, 814, 141149. [Google Scholar] [CrossRef]

- Contuzzi, N.; Campanelli, S.; Casalino, G.; Ludovico, A.D. Effect of Heat Treatment on Selective Laser Melted Steel Parts. In Proceedings of the 21st International DAAAM Symposium, Zadar, Croatia, 20–23 October 2010; Volume 21, pp. 1451–1452. [Google Scholar]

- Fel’dgandler, E.G.; Savkina, L.Y. Effect of Alloying on Hardening of Martensitic Stainless Steels of the Fe-Cr-Ni and Fe-Cr-Co Systems. Met. Sci. Heat Treat. 1975, 17, 758–762. [Google Scholar] [CrossRef]

- Michaud, P.; Delagnes, D.; Lamesle, P.; Mathon, M.H.; Levaillant, C. The Effect of the Addition of Alloying Elements on Carbide Precipitation and Mechanical Properties in 5% Chromium Martensitic Steels. Acta Mater. 2007, 55, 4877–4889. [Google Scholar] [CrossRef]

- Schnitzer, R.; Schober, M.; Zinner, S.; Leitner, H. Effect of Cu on the Evolution of Precipitation in an Fe-Cr-Ni-Al-Ti Maraging Steel. Acta Mater. 2010, 58, 3733–3741. [Google Scholar] [CrossRef]

- Zeisl, S.; Lassnig, A.; Hohenwarter, A.; Mendez-Martin, F. Precipitation Behavior of a Co-Free Fe-Ni-Cr-Mo-Ti-Al Maraging Steel after Severe Plastic Deformation. Mater. Sci. Eng. A 2022, 833, 142416. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Zhang, P.; Liu, M.; Kuang, T. Microstructural Evolution, Nanoprecipitation Behavior and Mechanical Properties of Selective Laser Melted High-Performance Grade 300 Maraging Steel. Mater. Des. 2017, 134, 23–34. [Google Scholar] [CrossRef]

- de Souza, A.F.; Al-Rubaie, K.S.; Marques, S.; Zluhan, B.; Santos, E.C. Effect of Laser Speed, Layer Thickness, and Part Position on the Mechanical Properties of Maraging 300 Parts Manufactured by Selective Laser Melting. Mater. Sci. Eng. A 2019, 767, 138425. [Google Scholar] [CrossRef]

- Patil, V.V.; Prashanth, K.G.; Mohanty, C.P. Spark Plasma Sintering of 13Ni-400 Maraging Steel: Enhancement of Mechanical Properties through Surface Modification. J. Alloys Compd. 2023, 960, 170734. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, M.; Ma, W.; Kuang, T. Microstructural Characterization and Properties of Selective Laser Melted Maraging Steel with Different Build Directions. Sci. Technol. Adv. Mater. 2018, 19, 746–758. [Google Scholar] [CrossRef]

- Conde, F.F.; Avila, J.A.; Oliveira, J.P.; Schell, N.; Oliveira, M.F.; Escobar, J.D. Effect of the As-Built Microstructure on the Martensite to Austenite Transformation in a 18Ni Maraging Steel after Laser-Based Powder Bed Fusion. Addit. Manuf. 2021, 46, 102122. [Google Scholar] [CrossRef]

- Ferreira, D.F.S.; Miranda, G.; Oliveira, F.J.; Oliveira, J.M. Predictive Models for an Optimized Fabrication of 18Ni300 Maraging Steel for Moulding and Tooling by Selective Laser Melting. J. Manuf. Process 2021, 70, 46–54. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, L.; Liu, T.; Wang, B.; Luo, L.; Zhao, J.; Wang, L.; Su, Y.; Guo, J.; Fu, H. Tuning Process Parameters to Optimize Microstructure and Mechanical Properties of Novel Maraging Steel Fabricated by Selective Laser Melting. Mater. Sci. Eng. A 2021, 823, 141740. [Google Scholar] [CrossRef]

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Experimental Investigation and Statistical Optimisation of the Selective Laser Melting Process of a Maraging Steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Mutua, J.; Nakata, S.; Onda, T.; Chen, Z.C. Optimization of Selective Laser Melting Parameters and Influence of Post Heat Treatment on Microstructure and Mechanical Properties of Maraging Steel. Mater. Des. 2018, 139, 486–497. [Google Scholar] [CrossRef]

- Yao, Y.; Huang, Y.; Chen, B.; Tan, C.; Su, Y.; Feng, J. Influence of Processing Parameters and Heat Treatment on the Mechanical Properties of 18Ni300 Manufactured by Laser Based Directed Energy Deposition. Opt. Laser Technol. 2018, 105, 171–179. [Google Scholar] [CrossRef]

- da Fonseca, D.P.M.; Melo Feitosa, A.L.; de Carvalho, L.G.; Plaut, R.L.; Padilha, A.F. A Short Review on Ultra-High-Strength Maraging Steels and Future Perspectives. Mater. Res. 2021, 24. [Google Scholar] [CrossRef]

- Mehmood, T.; Ahmed, A.; Ahmad, A.; Ahmad, M.S.; Sandhu, M.A. Optimization of Mixed Surfactants-Based β-Carotene Nanoemulsions Using Response Surface Methodology: An Ultrasonic Homogenization Approach. Food Chem. 2018, 253, 179–184. [Google Scholar] [CrossRef]

- Mehmood, T. Optimization of the Canola Oil Based Vitamin E Nanoemulsions Stabilized by Food Grade Mixed Surfactants Using Response Surface Methodology. Food Chem. 2015, 183, 1–7. [Google Scholar] [CrossRef]

- Sun, J.; Yang, Y.; Wang, D. Parametric Optimization of Selective Laser Melting for Forming Ti6Al4V Samples by Taguchi Method. Opt. Laser Technol. 2013, 49, 118–124. [Google Scholar] [CrossRef]

- Yang, D.; Li, X.; He, D.; Nie, Z.; Huang, H. Optimization of Weld Bead Geometry in Laser Welding with Filler Wire Process Using Taguchi’s Approach. Opt. Laser Technol. 2012, 44, 2020–2025. [Google Scholar] [CrossRef]

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M.S.J. Multi-Response Optimization of CO2 Laser-Welding Process of Austenitic Stainless Steel. Opt. Laser Technol. 2008, 40, 76–87. [Google Scholar] [CrossRef]

- Li, C.H.; Tsai, M.J.; Yang, C.D. Study of Optimal Laser Parameters for Cutting QFN Packages by Taguchi’s Matrix Method. Opt. Laser Technol. 2007, 39, 786–795. [Google Scholar] [CrossRef]

- Averardi, A.; Cola, C.; Zeltmann, S.E.; Gupta, N. Effect of Particle Size Distribution on the Packing of Powder Beds: A Critical Discussion Relevant to Additive Manufacturing. Mater. Today Commun. 2020, 24, 100964. [Google Scholar] [CrossRef]

- Patil, V.V.; Mohanty, C.P.; Prashanth, K.G. Selective Laser Melting of a Novel 13Ni400 Maraging Steel: Material Characterization and Process Optimization. J. Mater. Res. Technol. 2023, 27, 3979–3995. [Google Scholar] [CrossRef]

| Parameters | Levels | ||

|---|---|---|---|

| −1 | 0 | 1 | |

| Laser Power (W) | 180 | 285 | 390 |

| Layer Thickness (mm) | 0.02 | 0.04 | 0.06 |

| Hatch Spacing (mm) | 0.08 | 0.10 | 0.12 |

| Scanning Speed (mm/s) | 800 | 1000 | 1200 |

| Run | Input Parameters | Energy Density (J/mm3) | Response Values | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Part No. | Laser Power (W) | Layer Thickness (mm) | Hatch Spacing (mm) | Scan Speed (mm/s) | Relative Density (%) | Ultimate Tensile Strength (MPa) | Microhardness (HRC) | Surface Roughness (μm) | ||

| 1 | P1 | 180 | 0.02 | 0.08 | 800 | 140.63 | 99.56 | 1269 ± 15 | 41 | 2.41 |

| 2 | P2 | 180 | 0.04 | 0.1 | 1000 | 45.00 | 94.37 | 1051 ± 21 | 29 | 6.03 |

| 3 | P3 | 180 | 0.06 | 0.12 | 1200 | 20.83 | 88.65 | 863 ± 22 | 25 | 8.37 |

| 4 | P4 | 285 | 0.02 | 0.1 | 1200 | 118.75 | 99.41 | 1258 ± 30 | 40 | 2.64 |

| 5 | P5 | 285 | 0.04 | 0.12 | 800 | 74.22 | 98.15 | 1162 ± 27 | 37 | 4.23 |

| 6 | P6 | 285 | 0.06 | 0.08 | 1000 | 59.38 | 97.56 | 1127 ± 14 | 34 | 4.97 |

| 7 | P7 | 390 | 0.02 | 0.12 | 1000 | 162.50 | 99.87 | 1308 ± 18 | 44 | 2.31 |

| 8 | P8 | 390 | 0.04 | 0.08 | 1200 | 101.56 | 99.25 | 1236 ± 22 | 39 | 3.29 |

| 9 | P9 | 390 | 0.06 | 0.1 | 800 | 81.25 | 98.42 | 1189 ± 12 | 36 | 3.64 |

| Optimum Circumstances | Coded Level | Actual Level | ||

|---|---|---|---|---|

| Scan speed (mm/s) | 0.6 | 920 | ||

| Hatch spacing (mm) | 1 | 0.09 | ||

| Laser power (W) | 0.1333 | 311 | ||

| Layer thickness (mm) | −1 | 0.02 | ||

| Response | Predicted Values | Experimental Values | % Error | Average Error (%) |

| Relative density (%) | 99.95 | 99.90 | 0.0500 | 1.7983 |

| Surface roughness (mm) | 2.20 | 2.28 | 3.5088 | |

| Microhardness (HRC) | 45 | 44 | 2.2728 | |

| Tensile strength (MPa) | 1340 | 1322 | 1.3616 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patil, V.V.; Mohanty, C.P.; Prashanth, K.G. Parametric Optimization of Selective Laser Melted 13Ni400 Maraging Steel by Taguchi Method. J. Manuf. Mater. Process. 2024, 8, 52. https://doi.org/10.3390/jmmp8020052

Patil VV, Mohanty CP, Prashanth KG. Parametric Optimization of Selective Laser Melted 13Ni400 Maraging Steel by Taguchi Method. Journal of Manufacturing and Materials Processing. 2024; 8(2):52. https://doi.org/10.3390/jmmp8020052

Chicago/Turabian StylePatil, Viraj Vishwas, Chinmaya P. Mohanty, and K. G. Prashanth. 2024. "Parametric Optimization of Selective Laser Melted 13Ni400 Maraging Steel by Taguchi Method" Journal of Manufacturing and Materials Processing 8, no. 2: 52. https://doi.org/10.3390/jmmp8020052

APA StylePatil, V. V., Mohanty, C. P., & Prashanth, K. G. (2024). Parametric Optimization of Selective Laser Melted 13Ni400 Maraging Steel by Taguchi Method. Journal of Manufacturing and Materials Processing, 8(2), 52. https://doi.org/10.3390/jmmp8020052