1. Introduction

The surfaces of plant and animal objects have been intensively studied in the last decades, as they provide several interesting insights and ideas that can eventually be translated into engineering practice. There are a large number of specific structures on the plant surface that provide plants with protection against water wetting and protection against excessive solar radiation or, on the contrary, improved water uptake and increased absorption of solar radiation [

1,

2,

3,

4].

Similarly, the surface of animal objects has specific structures that protect them and make it easier for them to exist in given climatic conditions. A characteristic feature of all-natural structures is their chemical composition and size. On the surface of plants, there are wax-based structures, which are often also silica-based. The surfaces of animal objects are largely equipped with protein-based structures—hairs, scrubs, scales, and others [

1,

2,

3,

5].

The common features are hierarchical structuring, the interconnection of organic and inorganic phases, and the possibility of self-repair and re-modeling. The functional structures that nature creates are usually very small, at micrometer to submicrometer levels. Replicating such structural formations with their specific properties is relatively difficult [

6,

7,

8].

Among the earliest techniques/technologies that were able to replicate surface structures were surface replication techniques using two-stage imprinting. The natural surface serves as a pattern on which a layer of silicone is applied. After the silicone is removed from the natural surface, a mold called the first or negative replica is created and used to prepare a second, called the positive replica, which is a copy of the natural surface. This technique gives very good results at the level of copying micrometer and nanometer surface structures. The replication process can achieve very good results over a relatively small area, usually a few square centimeters. The advantage of this technique is the possibility of achieving the formation of very fine structures. Another very challenging but precise technique to obtain fine-structured surfaces is the FIB method [

9,

10].

Given the current interest in the use of surfaces of this type with characteristic properties, such as non-wetting or low reflectivity, it is essential that the technology to create these structures is available and can form larger areas. Such techniques currently include laser machining and chip micromachining, specifically micro-milling [

11,

12].

The demand for miniaturized products and devices continues to grow, and the production of miniature products and microproducts, ranging in size from a few tens of nanometers to a few millimeters, is increasingly in demand. Due to the increased demand for this technology, there are more and more cases where individual manufacturing companies are using the available equipment for the possibility of applying micro-milling using conventional CNC machines instead of special single-purpose machines. Micro-milling is one of the most reliable micromanufacturing solutions, achieving high machined surface integrity and dimensional or geometric accuracy. Using multi-axis control, complex contours can be machined with excellent continuity of different pattern structures. Technological stability and relatively simple process control principles allow the use of micro-milling in the fields of medicine (production of chips for insulin pumps, various parts of implants, and dentistry), electrical engineering, and watchmaking [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25].

This article extends the knowledge of micromachining technology and the creation of functional natural microstructures using micro-milling. It then examines the dimensional and shape accuracies achieved compared with 3D fabrication data and a popular technology for fabricating surface structures—pulsed laser ablation (PLA) [

26].

2. Materials and Methods

The machined material of the 30 × 20 × 10 mm specimen was aluminum alloy EN AW 7075, and this alloy was chosen because of its excellent machinability, short chip formation, good availability, frequent occurrence in machining experiments, and recommendations in scientific publications [

14,

15]. EN AW 7075 alloy is hardenable, characterized by high strength Rm = 360 up to 540 MPa, hardness of 104 to 160 HBW, and very good polishability [

14,

15].

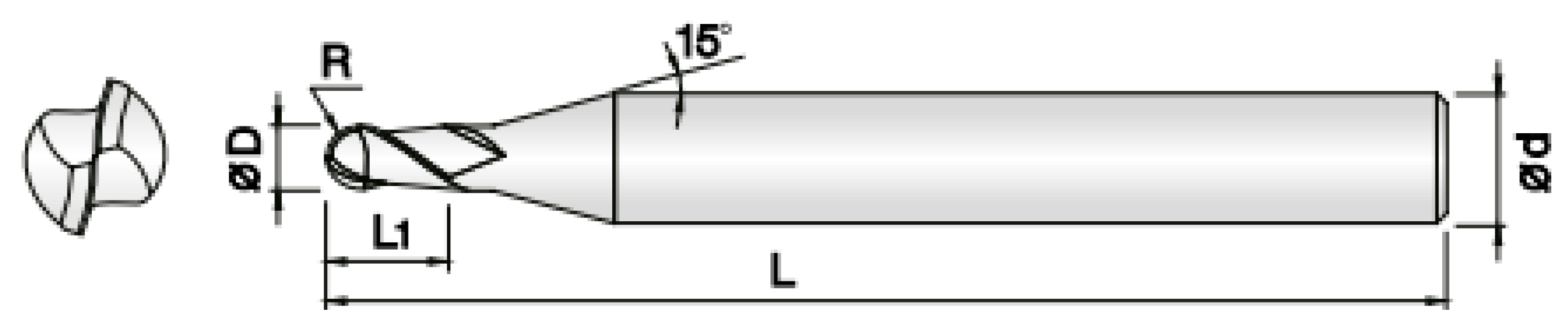

The machining tool was chosen to get as close as possible to the replicated natural morphology in terms of shape and dimension. According to the availability and the manufacturer’s recommendations, a double-edged ball cutter with a diameter of 0.1 mm, a cutting edge radius of 0.05 mm, and a functional cutting length of 0.2 mm was selected. A preview of the basic parameters of the ball milling cutter is shown in

Figure 1 and

Table 1, and a detail of the tool is shown in

Figure 2.

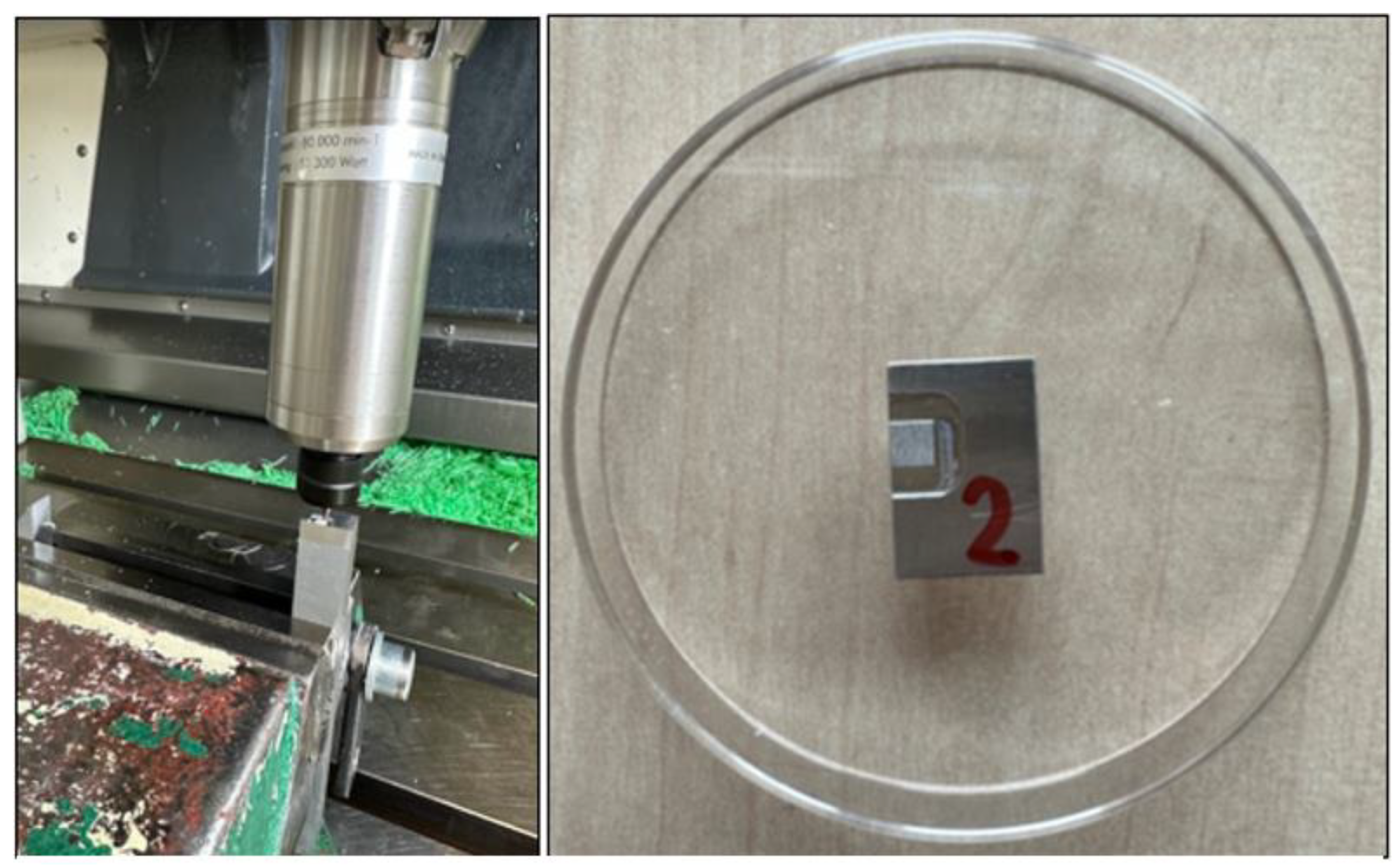

Milling was carried out on a 3-axis DMG MORI CMX 600 milling center (DMG Mori Seiki, Nagoja, Japan) with a high-speed electro spindle (Semaco, S/N 25849, Jesenik, Czech Republic) with a maximum rotation speed of 80,000 RPM using the SINUMERIK 840 D with a control system from Siemens. The instruments were clamped using an ER8 collete. The EN AW 7075 sample was fixed to the clamping device.

The electric spindle used, as seen in

Figure 3, was tube-shaped and air-cooled; the tool was cooled by 16 nozzles that were arranged around the circumference of the spindle. The total weight of the additional spindle without the clamped tool was 1.6 kg. The wiring diagram of the add-on system is shown in

Figure 4.

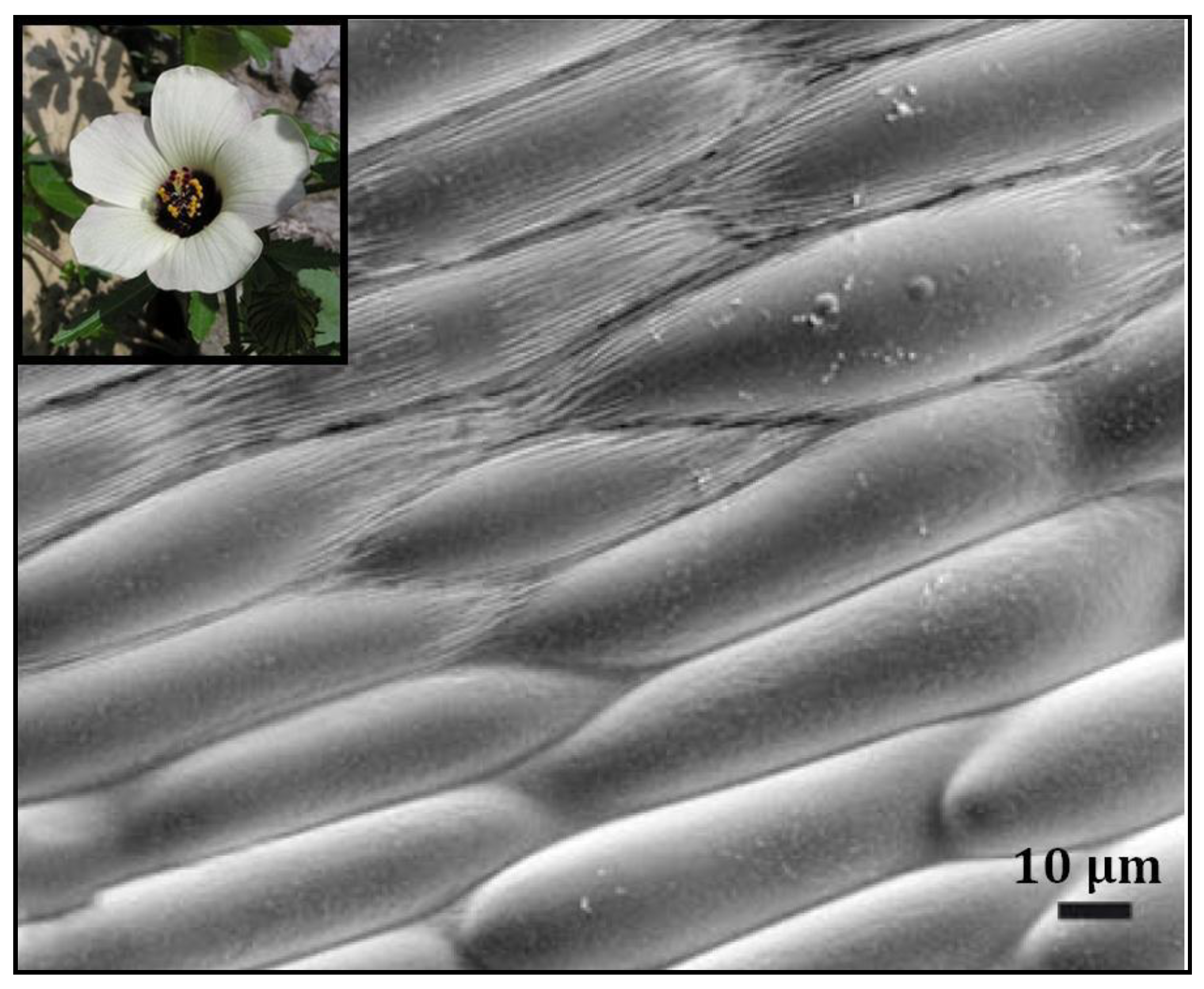

The choice of microstructure was based on information and knowledge from the science of biomimetics, which is dedicated to the study of natural objects and the subsequent imitation of their properties. A suitable microstructure for the planned experiment was inspired by the surface structure of the Hibiscus Trionum. The flower of the Hibiscus Trionum is distinguished by a surface structure that offers a surface easily cleaned by mere rain—the hydrophobic properties of the surface act as a diffraction grating. The particular shape and spacing of this cause constructive interference for different wavelengths of light in different directions, leading to angular color variation, also known as iridescence [

27,

28]. A detailed view of the natural structure can be seen in

Figure 5.

The CAD model of the microstructure of the sample was created in Autodesk Inventor Professional and then in Autodesk Fusion 360. Using the CAM software in Autodesk Fusion 360 (version 2.0.17954 x86_64), an NC program was created and transferred to the machine tool control system. Using the CAD model and the chosen parallel machining strategy, tool paths, traverse distances, safety distances, tool passes, and cutting conditions were precisely defined. For the subsequent replication of the specimens, the negative of the selected relief was first created and machined to produce a positive microstructure using the replication process [

5,

9,

10]. The dimensions of the relief were adjusted to suit the needs of the micro-milling technology, depending on the geometry of the selected cutting tool.

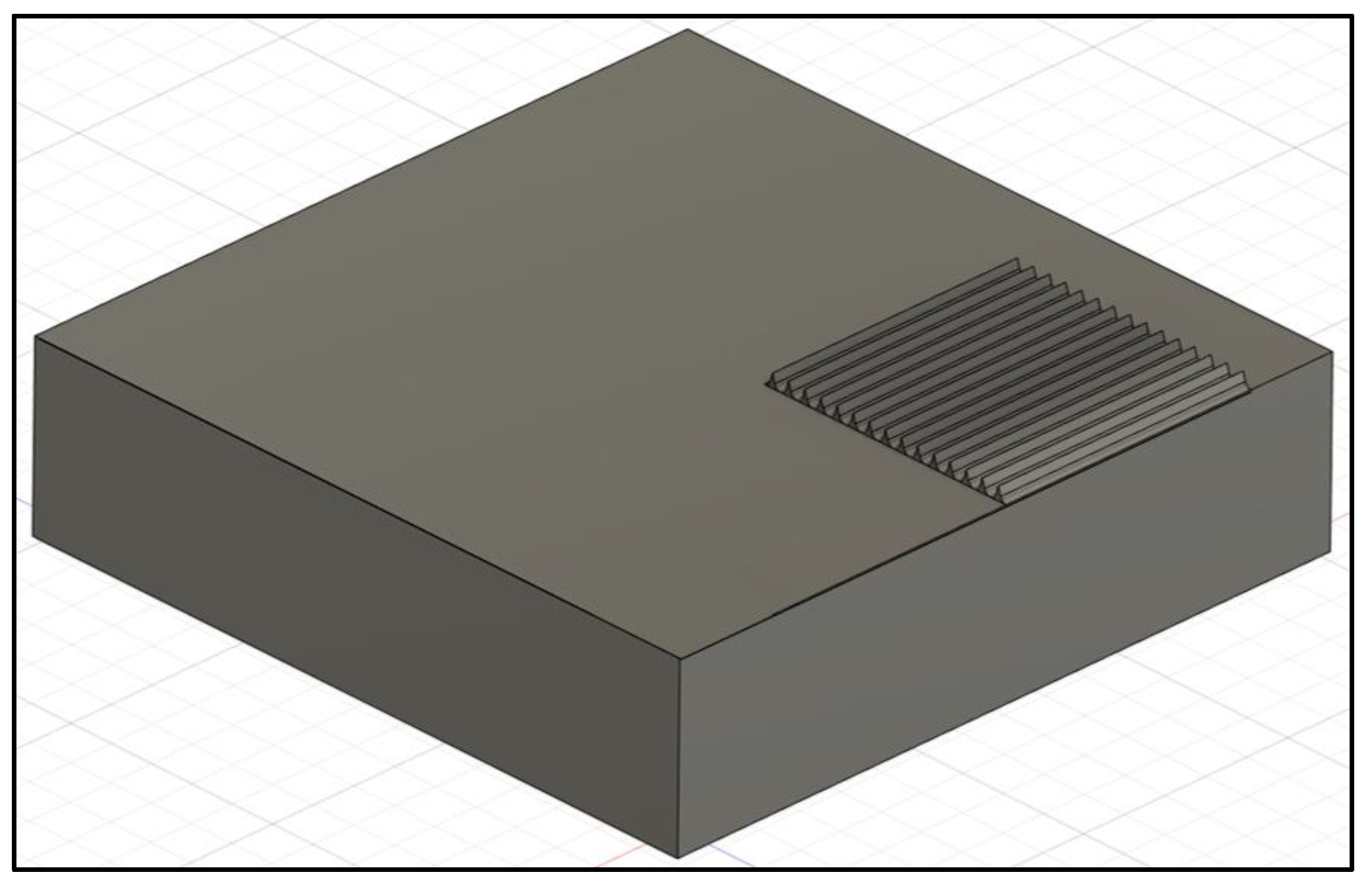

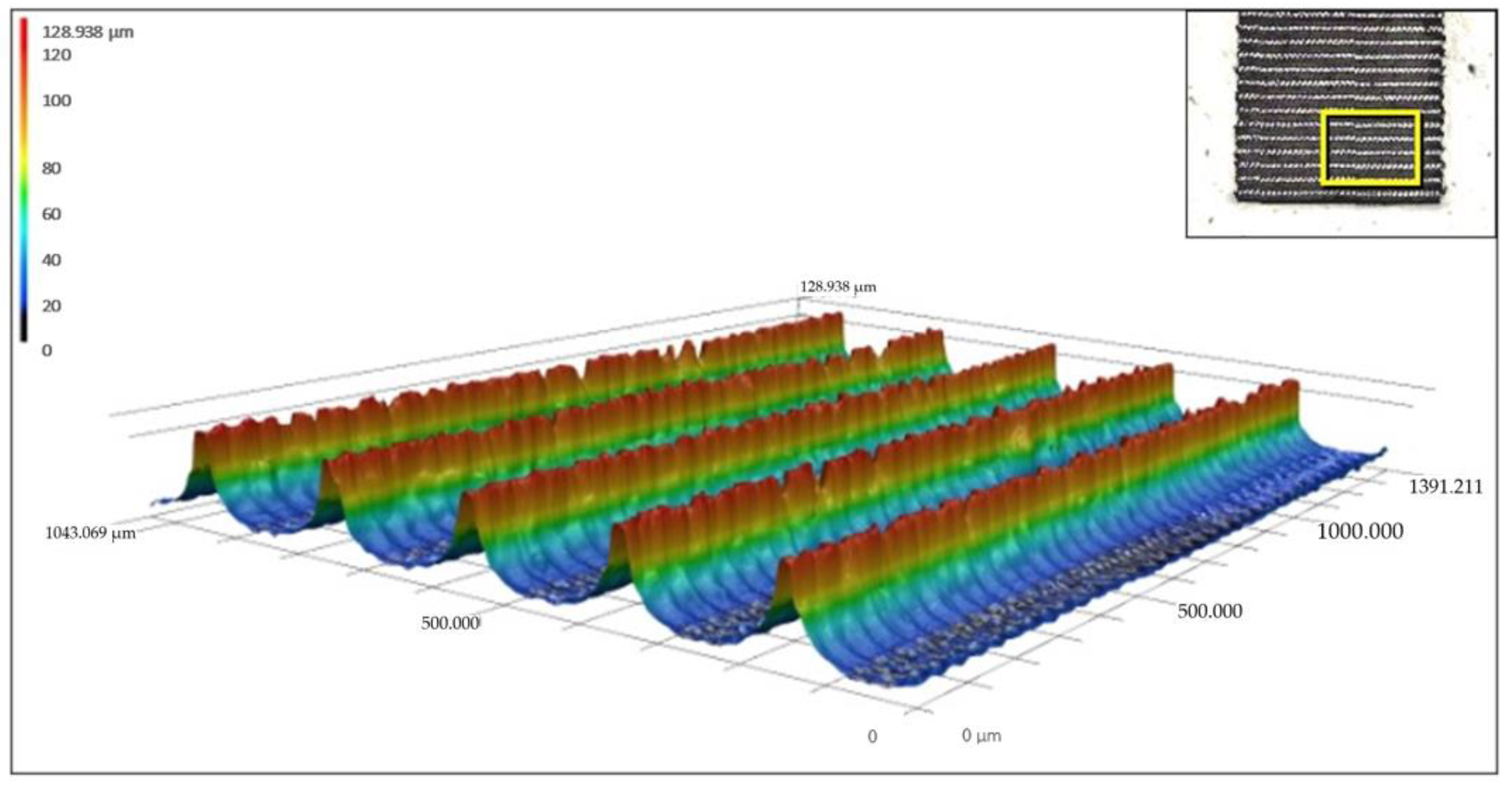

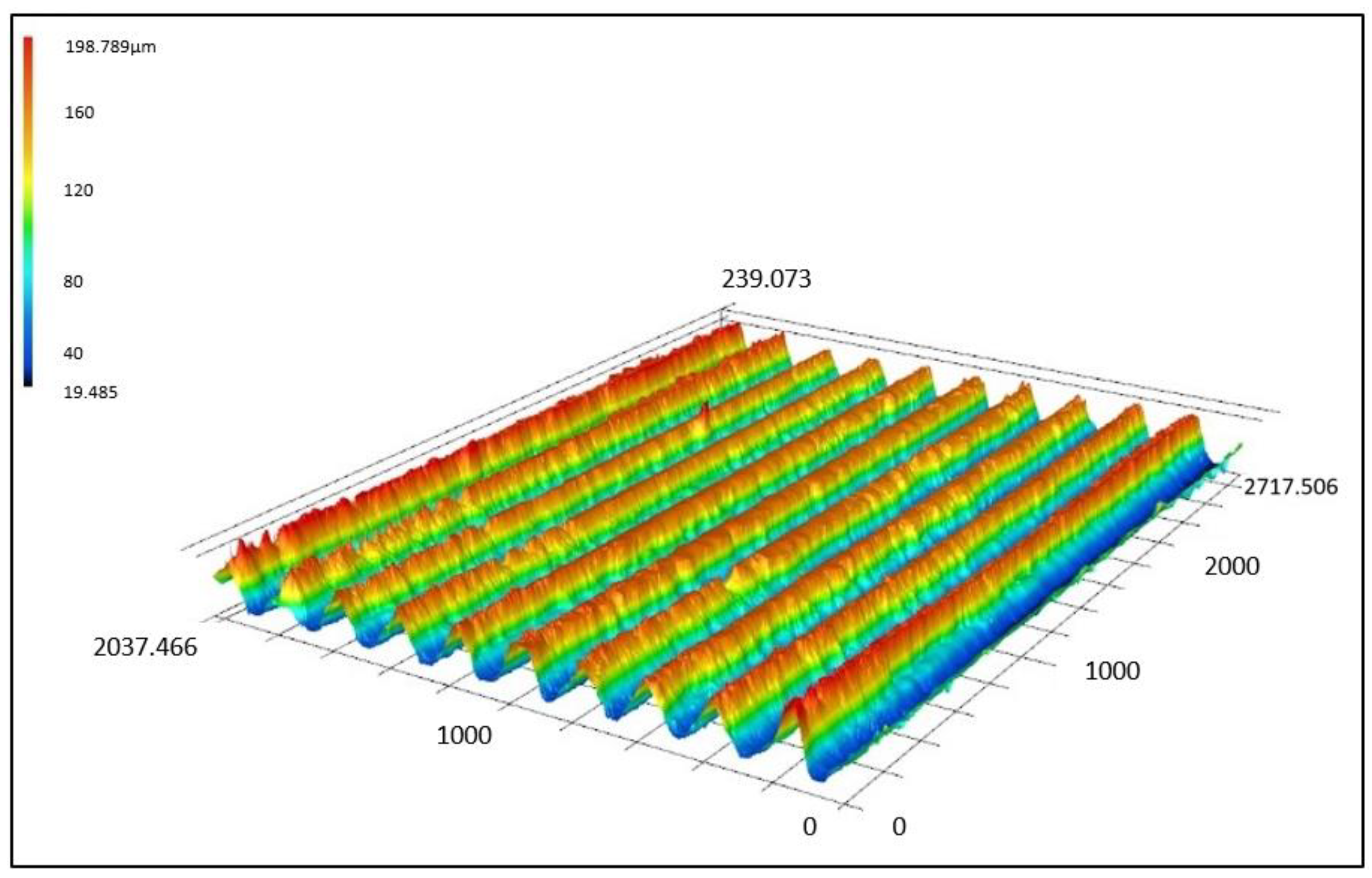

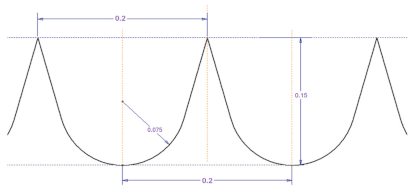

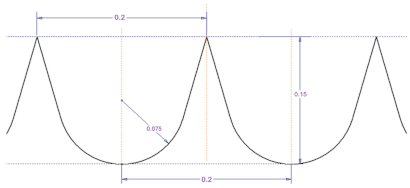

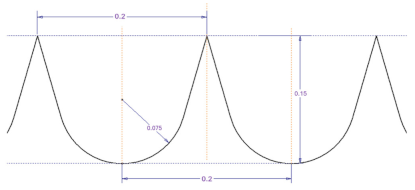

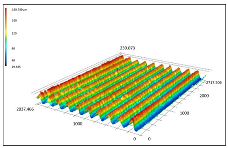

The simplified theoretical profile of the microstructure of the surface of the Hibiscus Trionum flower is formed by rows of arcuate formations that have been simplified for production—creating continuous lines. The negative of the theoretical profile is represented by a field made up of elongated lamellae of triangular cross-section with a sharp apical edge. The depth of the theoretical profile was chosen to be h = 0.15 mm, the spacing of the individual elements is p = 0.2 mm, and the radius of roundness of the profile base is r = 0.075 mm; see

Figure 6. The size of the machined sample was set to 3 × 3 mm due to manufacturing times and the subsequent replication process, and a detail of the 3D structure is shown in

Figure 7.

The set of cutting conditions used is the number of revolutions of the electric spindle of the machine n, feed per tooth f

z, feed speed v

f, depth of cut a

p, and width of cut a

e, which are shown in

Table 2. The design of the cutting conditions was based on the tool manufacturer’s recommendations.

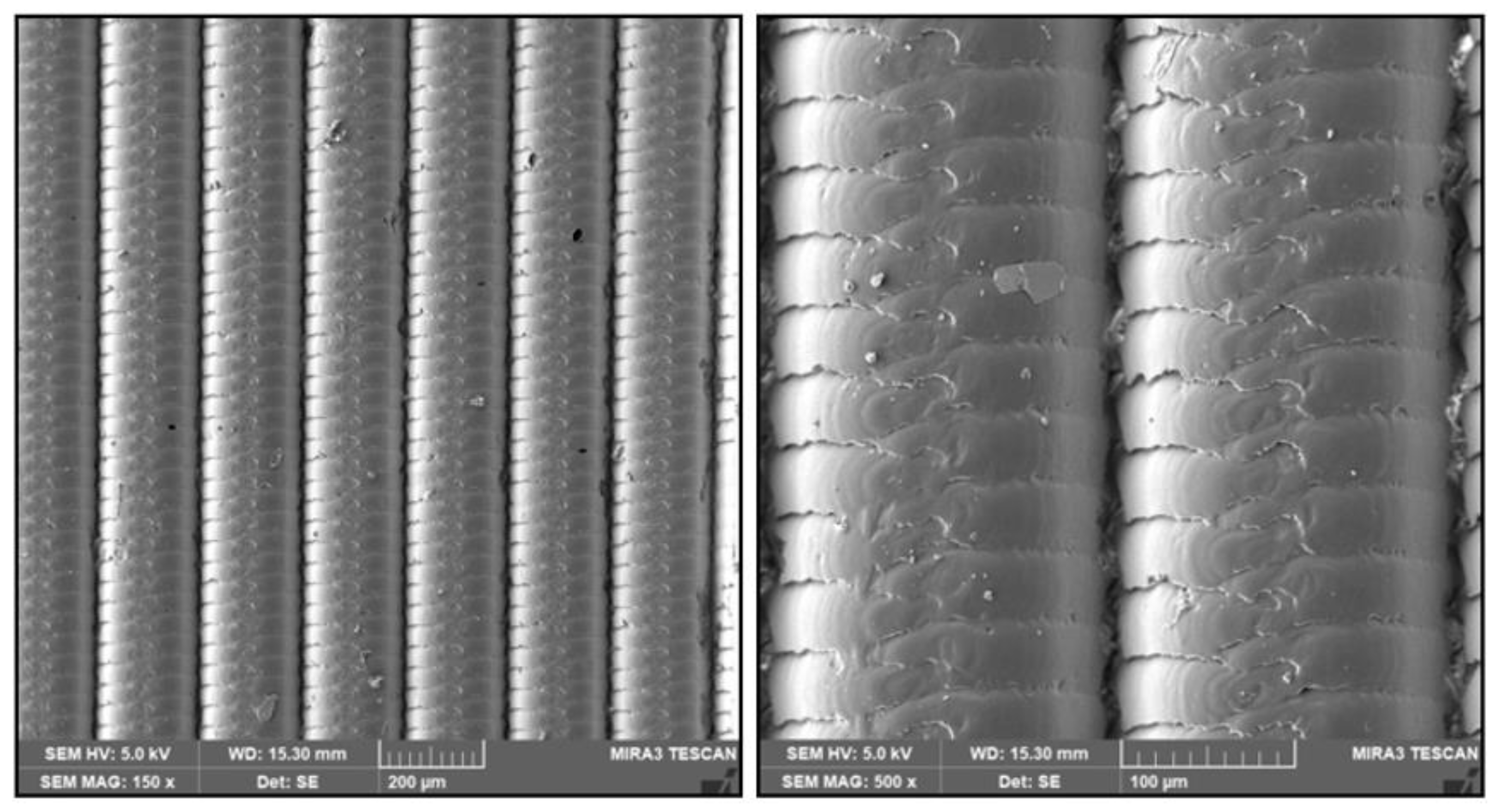

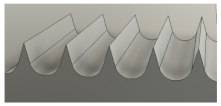

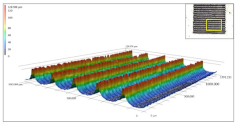

The sample was machined using a parallel strategy. During programming, one machined element (a triangular section slat) was programmed, and then the whole structure was fabricated using the linear array tool. The calculated machine time for the fabrication of the 1 × 1 mm array was set to 25 min. The total machine time for producing a 3 × 3 mm array was 240 min. A total of 1 cutting tool was used. Details of the machining process and finished surface structure are shown in

Figure 8.

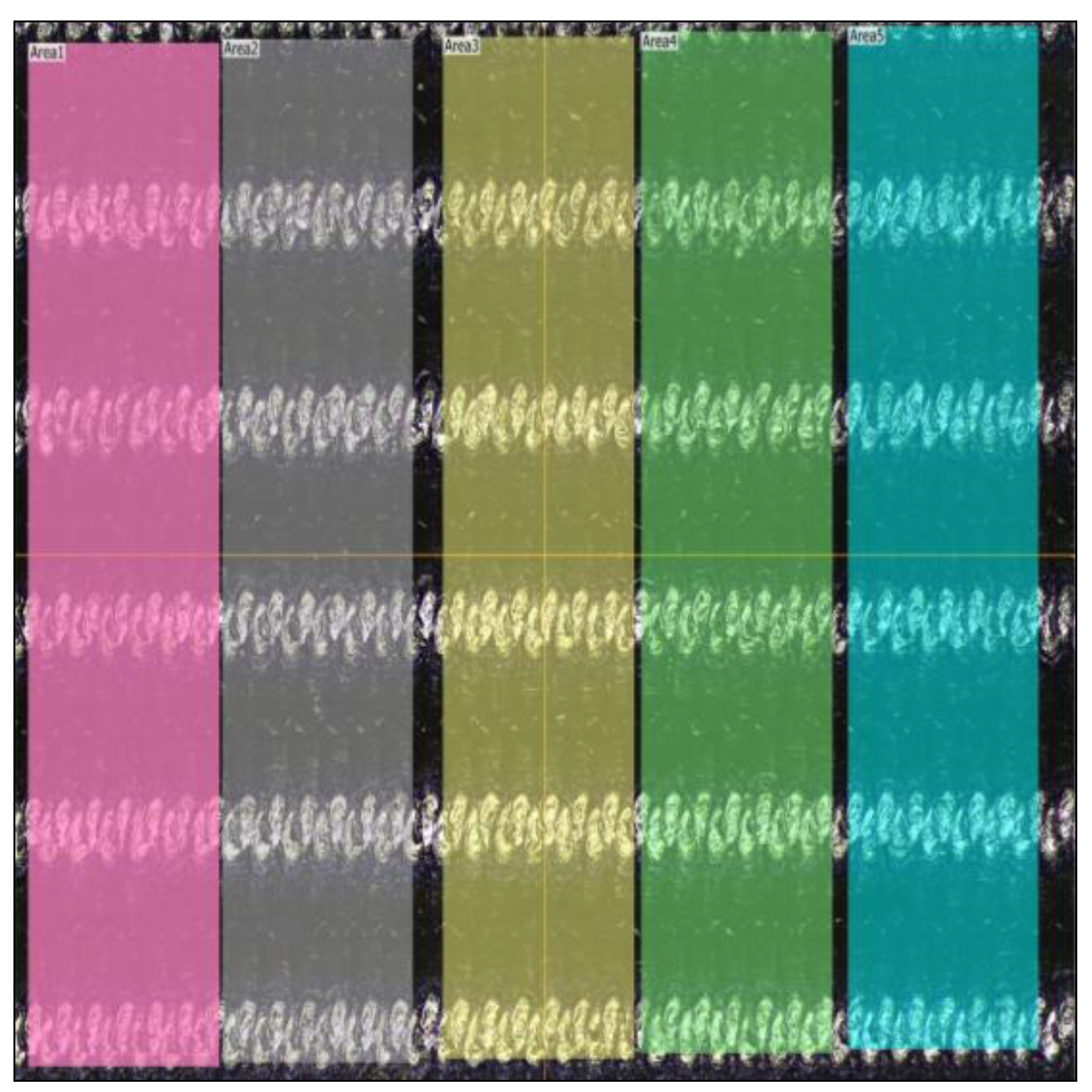

To investigate the quality achieved in the formation of the microstructure, the dimensional accuracy achieved, and the surface roughness of the microstructure formed, a non-contact measuring device, VK-X1000, from KEYENCE (Osaka, Japan), was used. This confocal microscope is equipped with a stage with driven axes and is capable of evaluating planar and profile parameters. The measured data were analyzed using the MultiFileAnalyzer software (VK-H1XMD, version 2.1.217), which was supplied by the manufacturer. A TESCAN MIRA 3 electron microscope would be used to investigate the size of burrs within the microstructure formation and also to monitor the microgeometry formed in the specimen produced by micro-milling.

4. Discussion

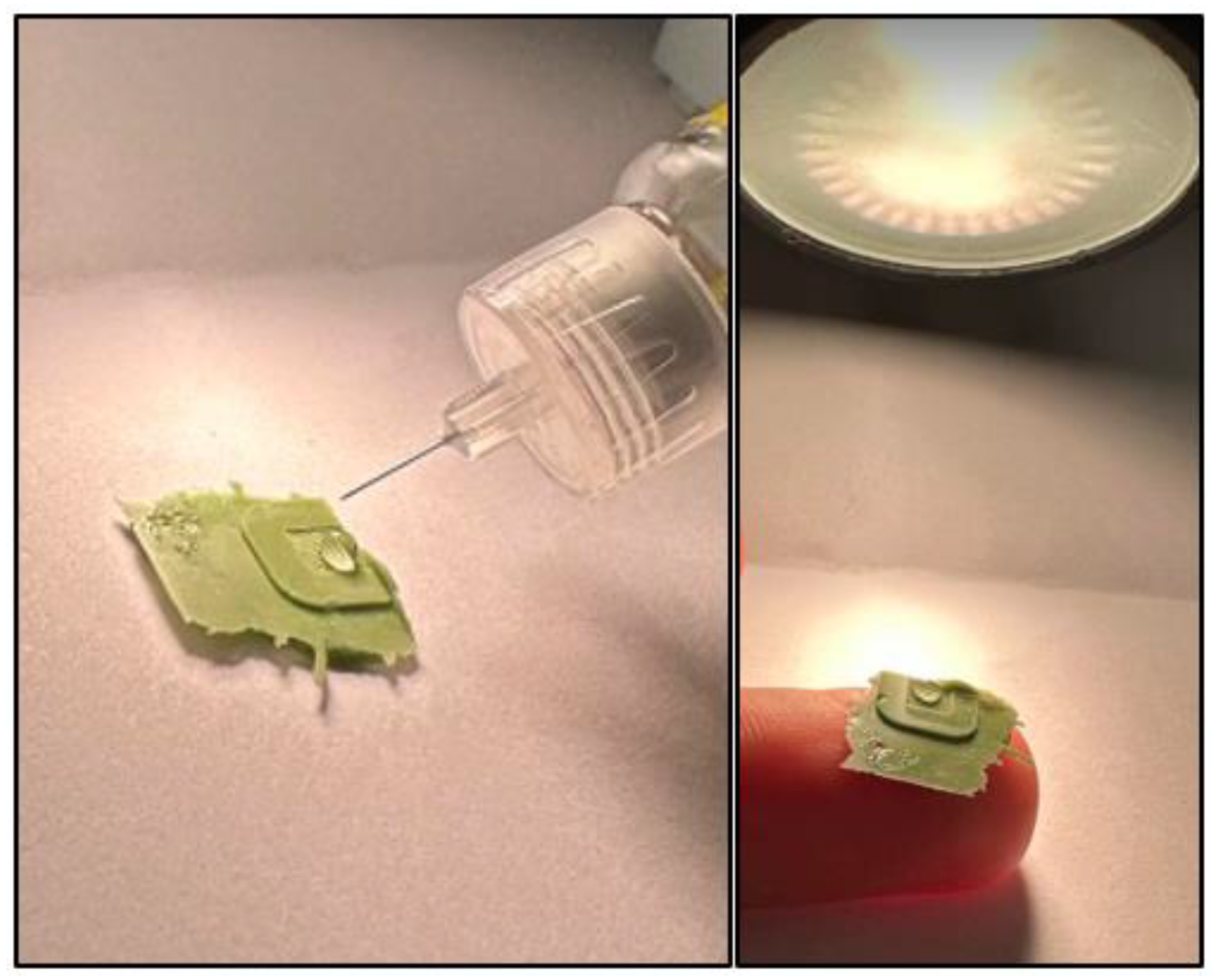

This paper was focused on the formation of natural surface microstructures with hydrophobic properties using micro-milling technology. To produce the desired microstructure, it was necessary to first design the microstructure, model it, fabricate it using micro-milling technology, and then replicate the structure. The choice of the microstructure was based on the knowledge of the scientific field of biomimetics, which is dedicated to the study of natural objects and the subsequent replication of their properties. A suitable microstructure for the planned experiment was inspired by the surface structure of the three-part hibiscus flower, which is notable for its hydrophobic structure, among other things. The machined material was aluminum alloy EN AW 7075. The tool was a double-edged ball mill with a diameter of 0.1 mm made of sintered carbide and coated with TiSiN. The cutting conditions were determined according to the tool manufacturer’s recommendations. For the subsequent replication of the specimen, a negative of the selected microstructure was created and machined, from which a positive microstructure was created by the replication process using a silicone impression compound to transfer the maximum amount of detail occurring on the surface of the machined structure.

The following findings can be summarized from the obtained results:

It was possible to produce the microstructure with a selected set of parameters (material to be machined, cutting tool, cutting conditions, dimensions of the structure).

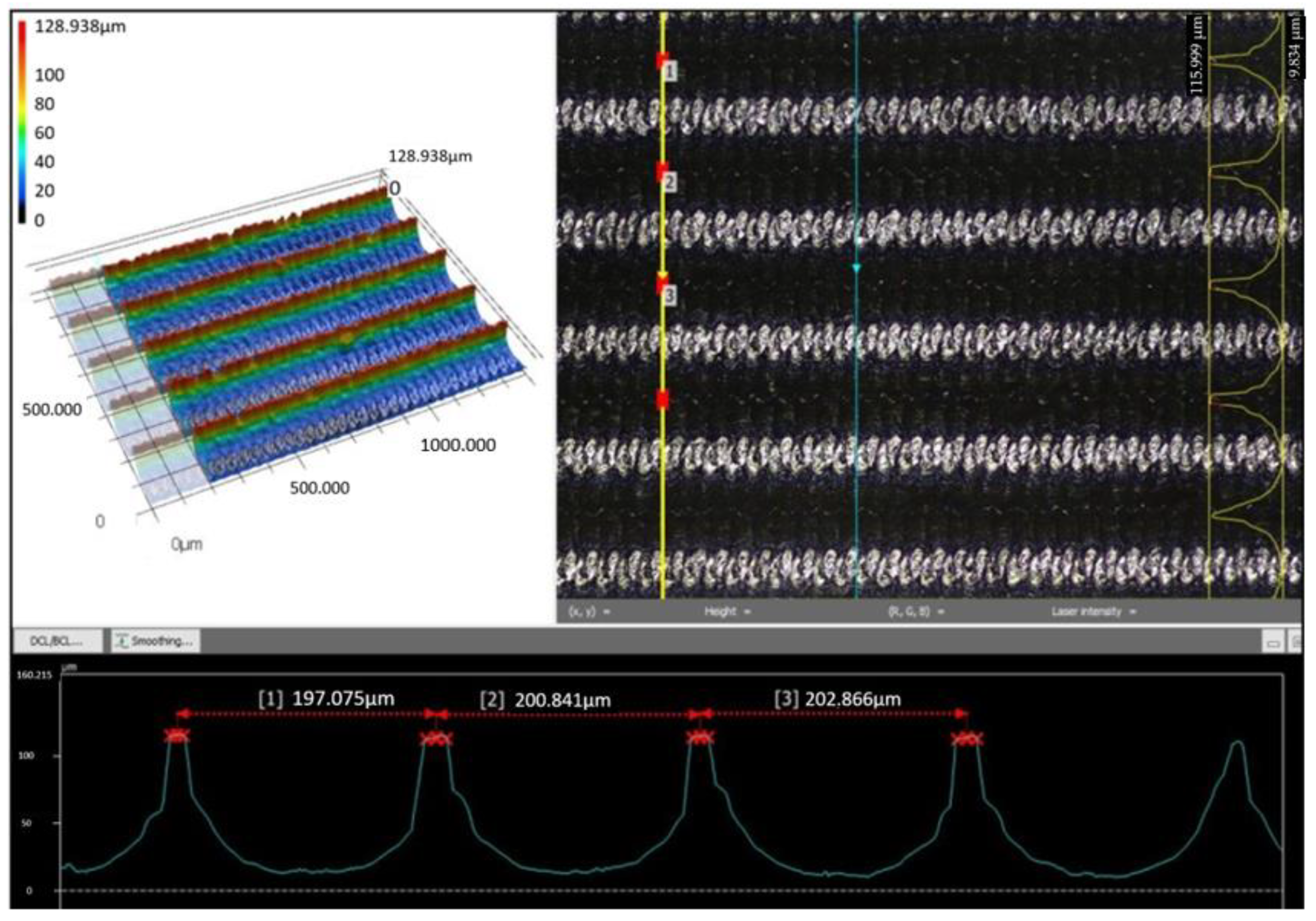

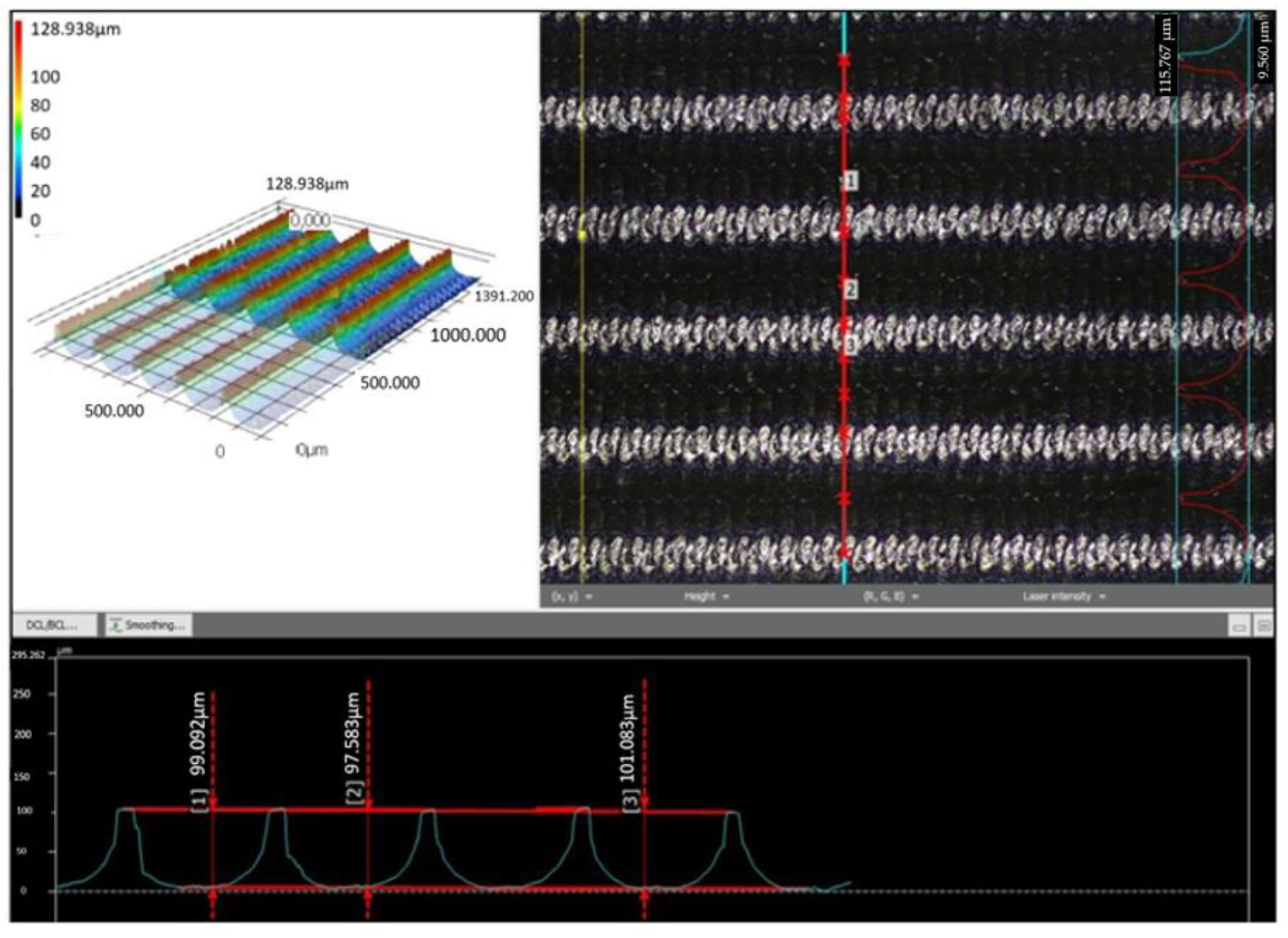

The structures inspired by the natural microstructure were created by micro-milling at a scale of 200 µm and achieved a dimensional accuracy of almost 70% for the profile depth parameter and almost 100% for the profile pitch parameter compared to the CAD master.

The replicated microstructure matched the production data 51% for the profile depth and nearly 100% for the observed profile pitch parameter.

The microstructure created by micro-milling compared to the microstructure created by the PLA method showed different accuracies for the observed parameters. A significant difference can be observed for the parameter pp.

It was further shown that the transferred relief dimensions did not change after multiple replications, and the replicated sample showed signs of hydrophobicity; see

Figure 17.

The quality of the transferred micro-dimensions between the CAD model, the microstructure created by micro-milling, the microstructure created by laser technology, and the resulting replication is summarized in

Table 12.

5. Conclusions

The present paper contributes to expanding the knowledge of the technological process of micro-milling and the fabrication of nature-inspired microstructures. This paper focused on the creation of a surface microstructure based on a template with hydrophobic properties, fabricated by micro-milling. For subsequent replication of the specimen, a negative of the chosen microstructure was created and machined, from which a positive microstructure was created through the replication process.

To produce the desired microstructure, it was necessary to first design the microstructure, model it, fabricate it with micro-milling technology, and then replicate the structure. This whole process is the subject of the paper. The research also included a comparison of the microstructure created by micro-milling with the same microstructure created by the PLA method.

From the extensive set of measurements and results obtained by micro-milling, the following can be formulated:

It is verified that the proposed natural microstructure can be produced by micro-milling. The resulting dimensional and shape accuracy of the structure is significantly related to the designed profile geometry or the mechanical strength of the profile (formation of burrs, elastic, and plastic deformations).

The microstructure created by micro-milling achieved a dimensional accuracy of almost 100% for the observed profile pitch parameter compared to the CAD master. The profile depth parameter of the structure will be significantly affected by the designed profile geometry. The difference between the production data and the fabricated structure concerning the observed profile depth parameter was 33% (approximately 50 μm).

The manufacturability of the designed structure was further verified using PLA technology. During the metrological control, a maximum deviation from the fabrication data of 2% (approximately 3 μm) was measured and found. The fabrication progress of the designed structure was significantly influenced by the choice of appropriate process conditions with suitable production times, geometric and dimensional accuracy, and surface quality. In the case of the fabrication of surface structures on planar surfaces, PLA technology appears to be a more accurate and faster technology. Significant limiting elements for the use of this technology are the application on general surfaces and the cost.

The microstructures produced can be replicated using a replication process. The replica using silicone impression material then faithfully matches the surface of the machined microstructure, even when the process is repeated several times. The quality of the achieved results is significantly influenced by the nature of the produced structure (geometric proportions, mechanical load-bearing capacity of the profile), the flow of the impression mass into the structure (venting of the structure, elimination of air pockets, open channels), and the choice of suitable impression material (formation of hierarchical structures, amount of transferred details).

Further research aims to modify the geometric parameters of the above structure using micro-milling in an attempt to obtain deviations from the production data in the order of percentages and to produce with subsequent replication other natural structures with functional properties (hydrophobicity, hydrophilicity, and others).