Processing and Analysis of Hybrid Fiber-Reinforced Polyamide Composite Structures Made by Fused Granular Fabrication and Automated Tape Laying

Abstract

1. Introduction

2. Materials and Methods

2.1. Fiber-Reinforced Polyamide Composite Materials

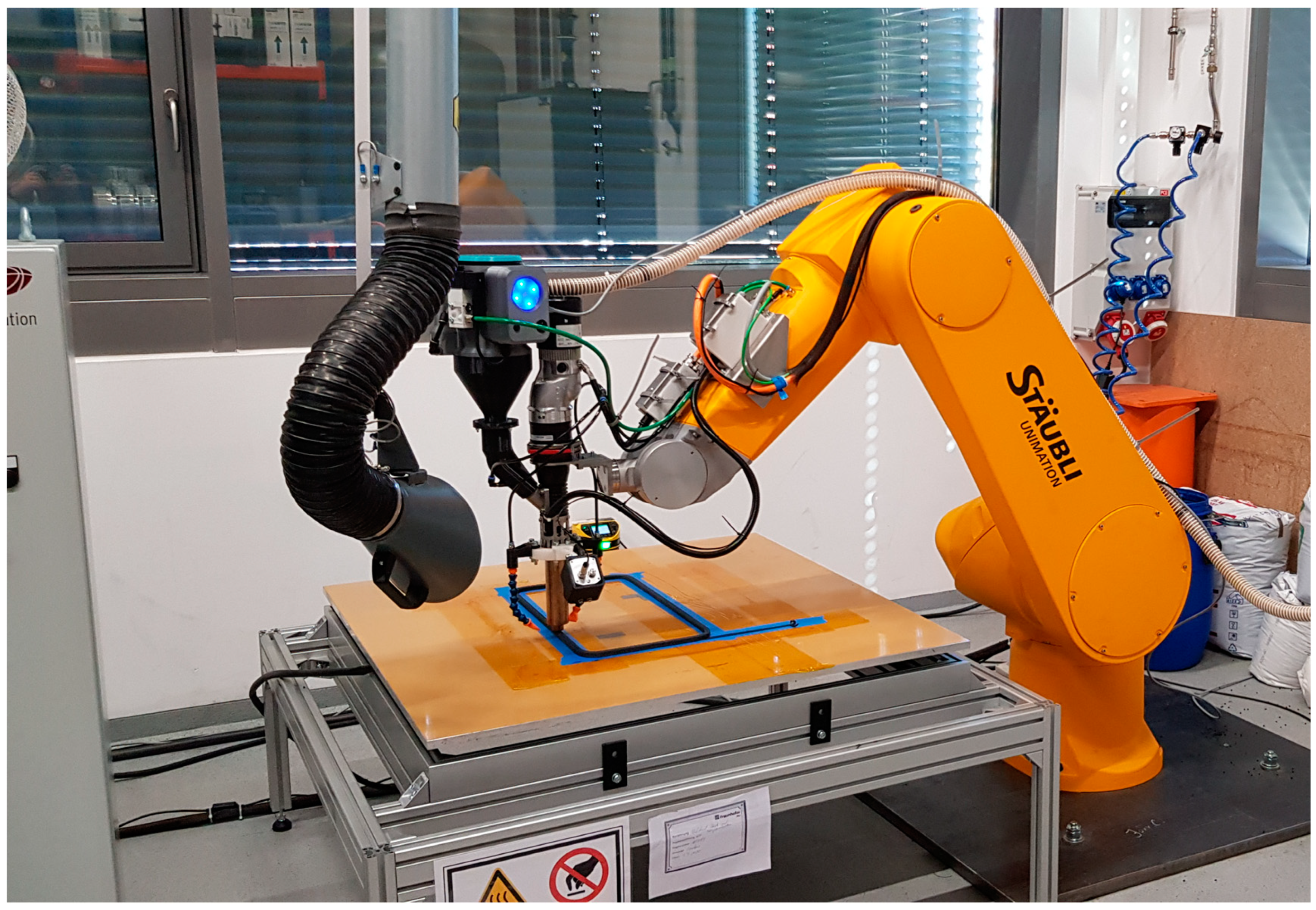

2.2. Fused Granular Fabrication

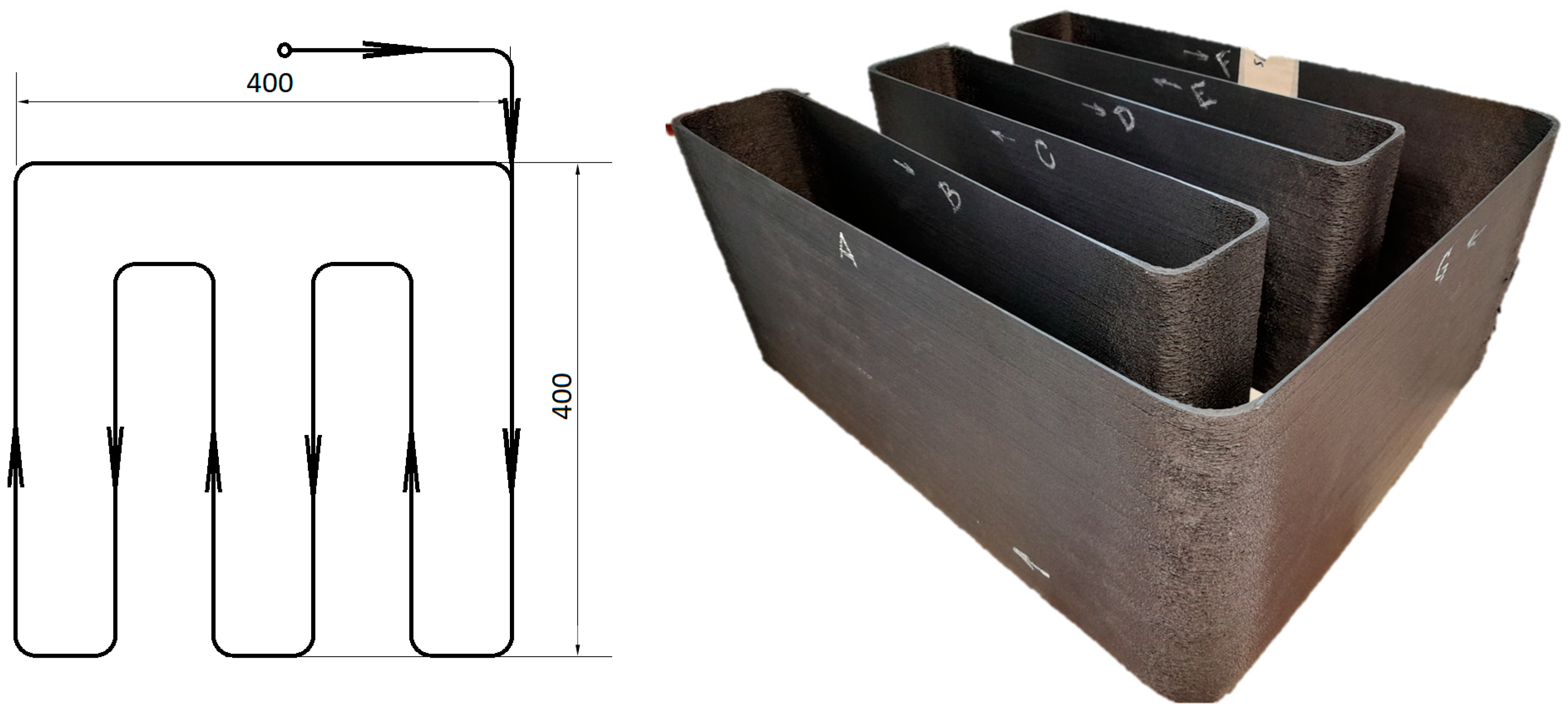

2.3. Preparation of Fused Granular Fabrication Test Specimen

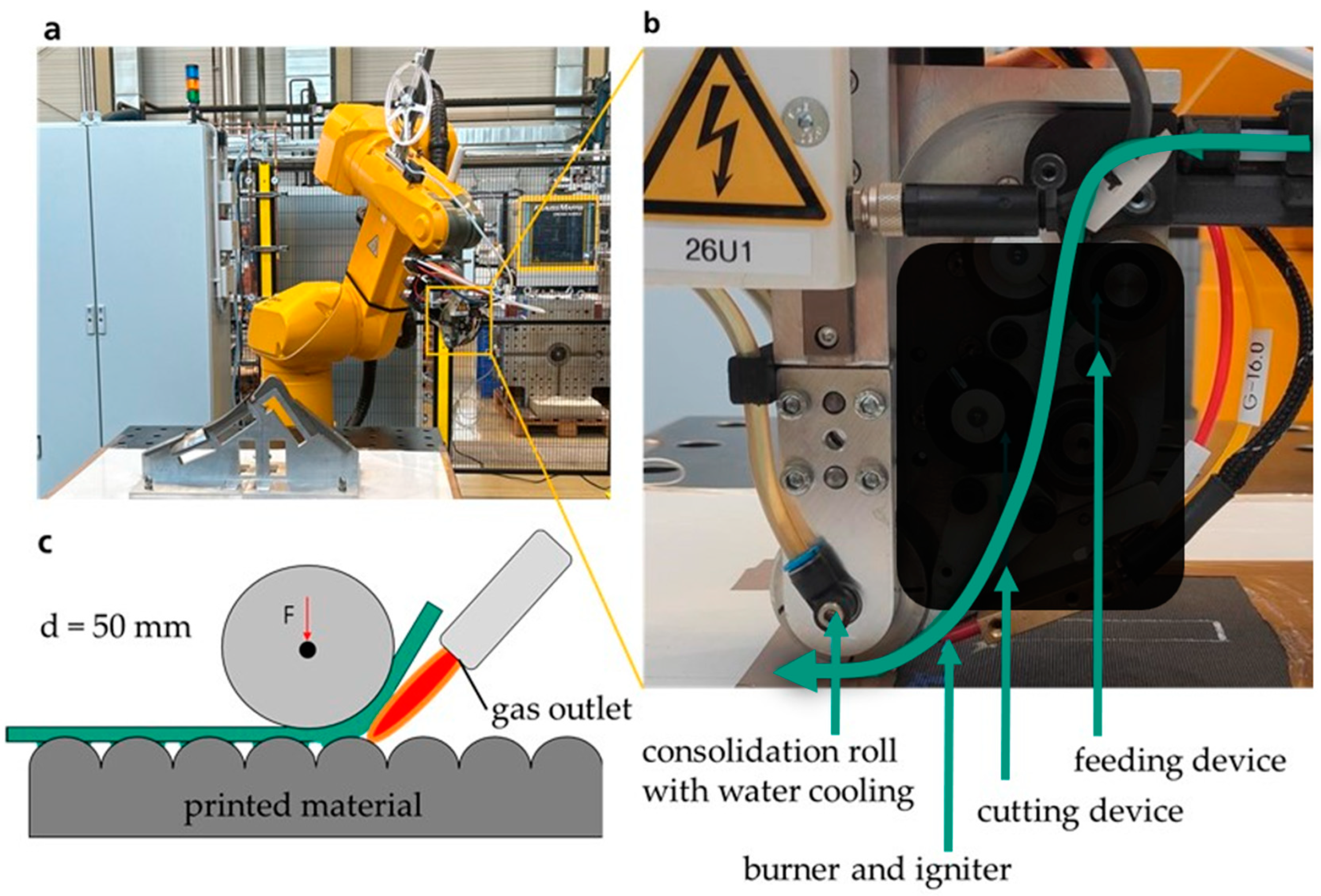

2.4. Automated Tape Laying

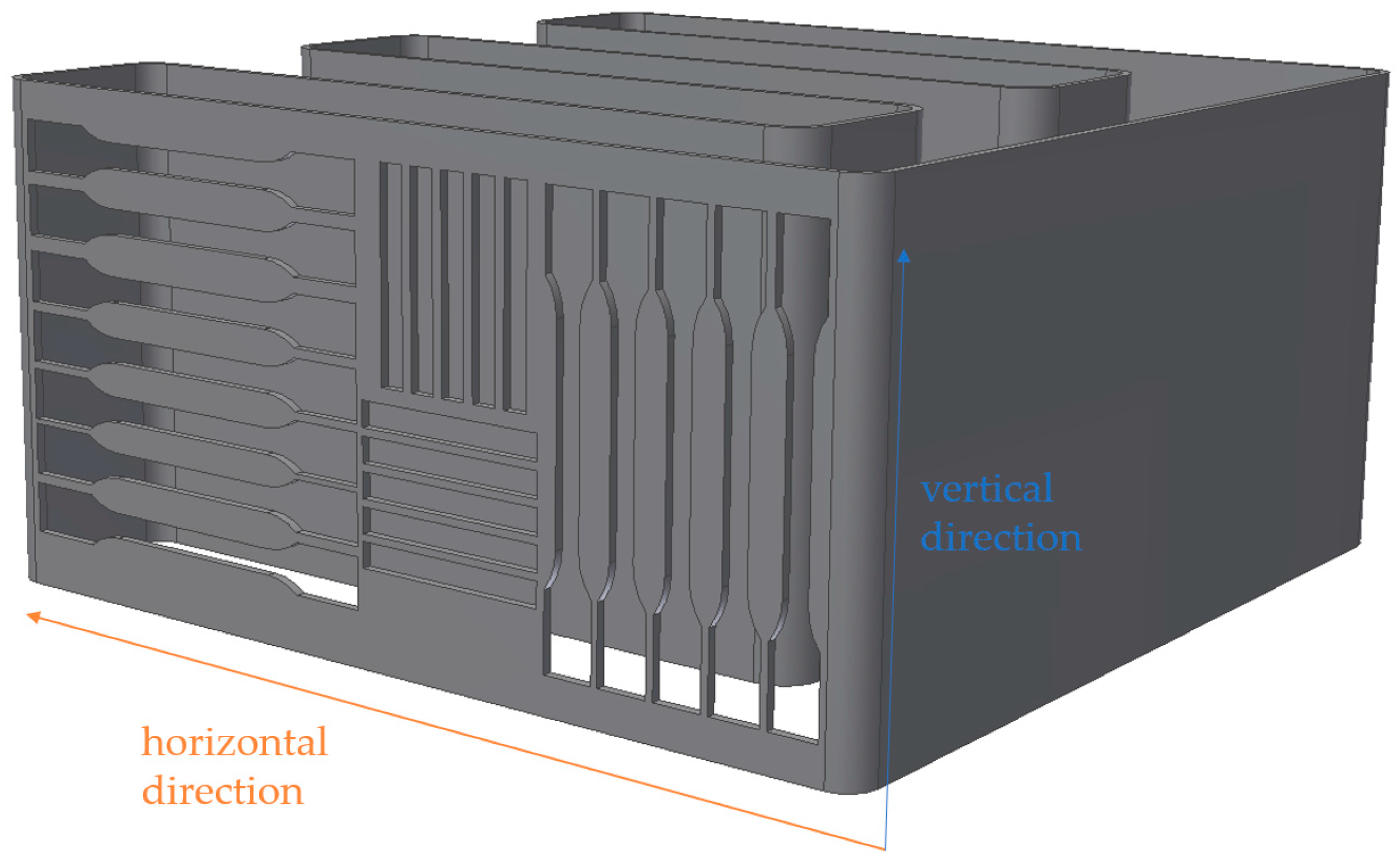

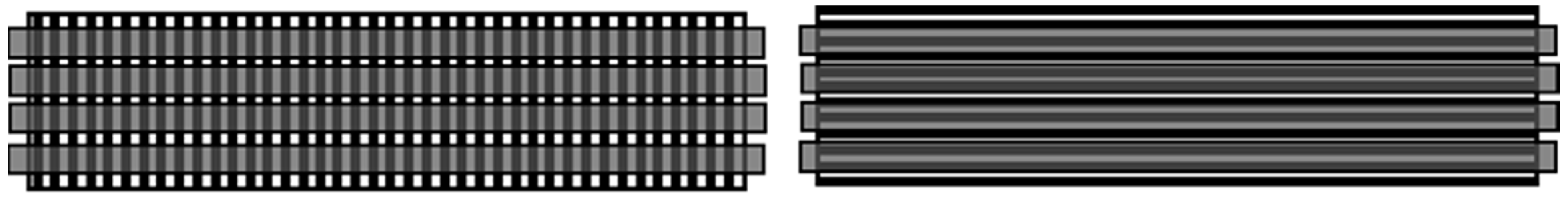

2.5. Preparation of Automated Tape-Laying Test Specimen

2.6. Morphological Analysis

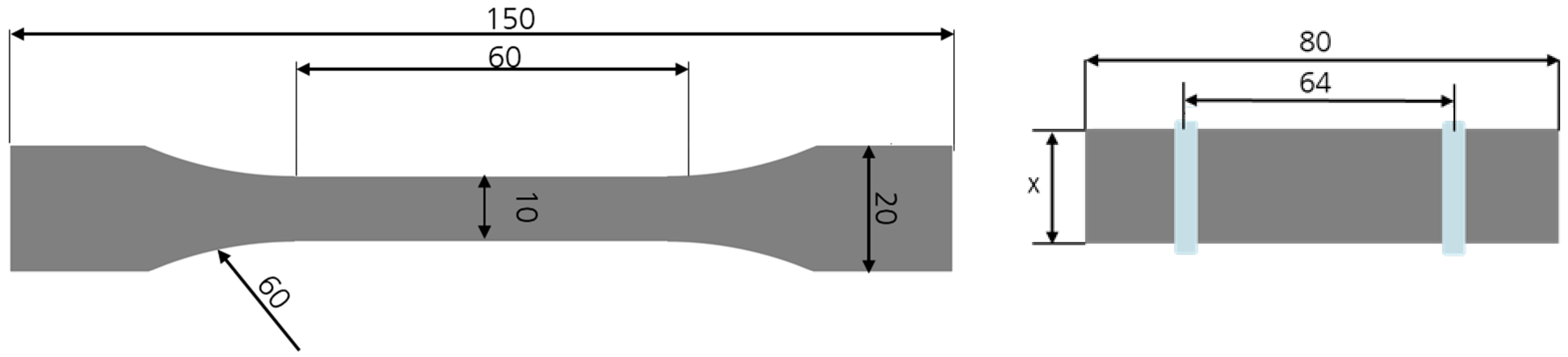

2.7. Mechanical Analysis

3. Results and Discussion

3.1. Composite Structures by Fused Granular Fabrication

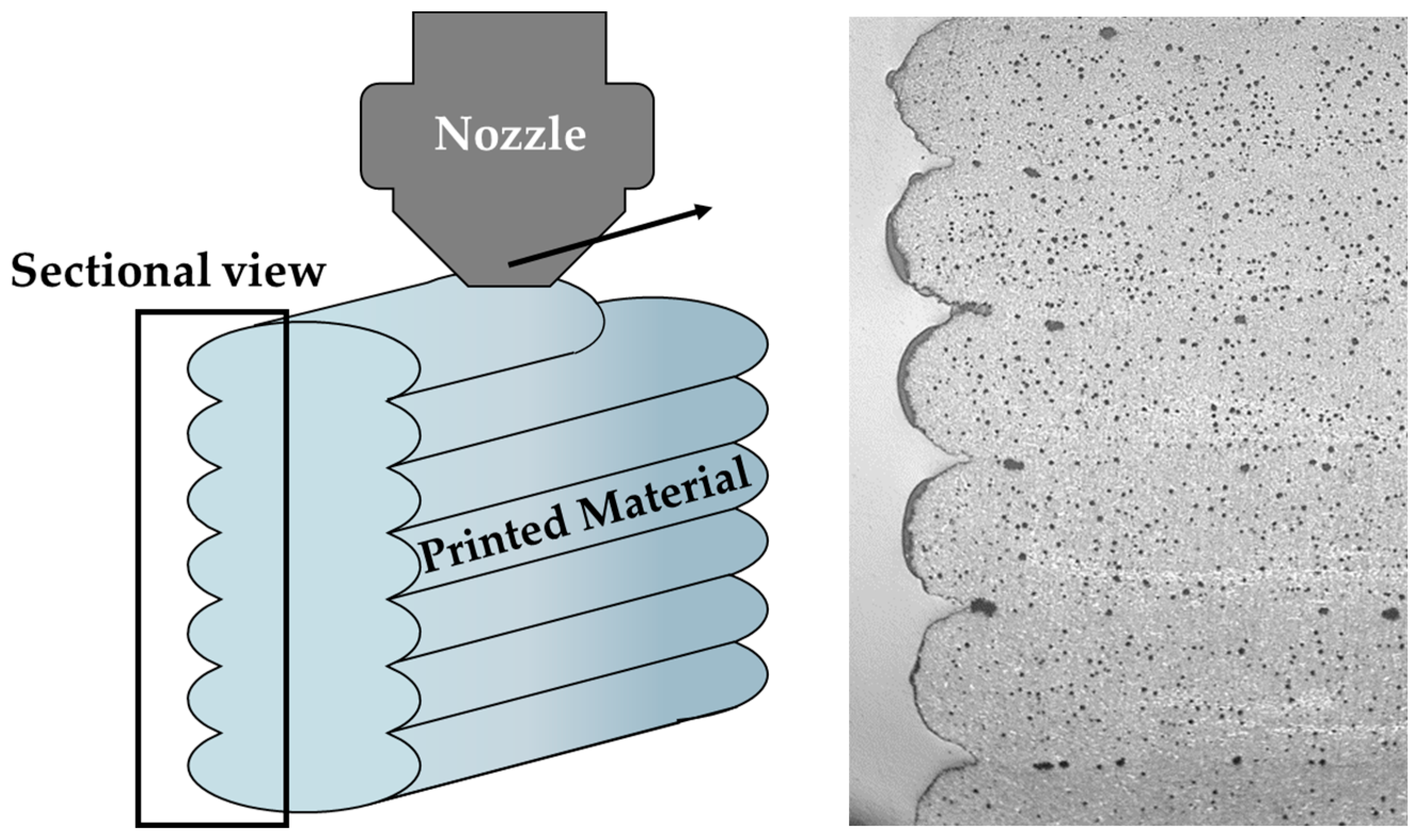

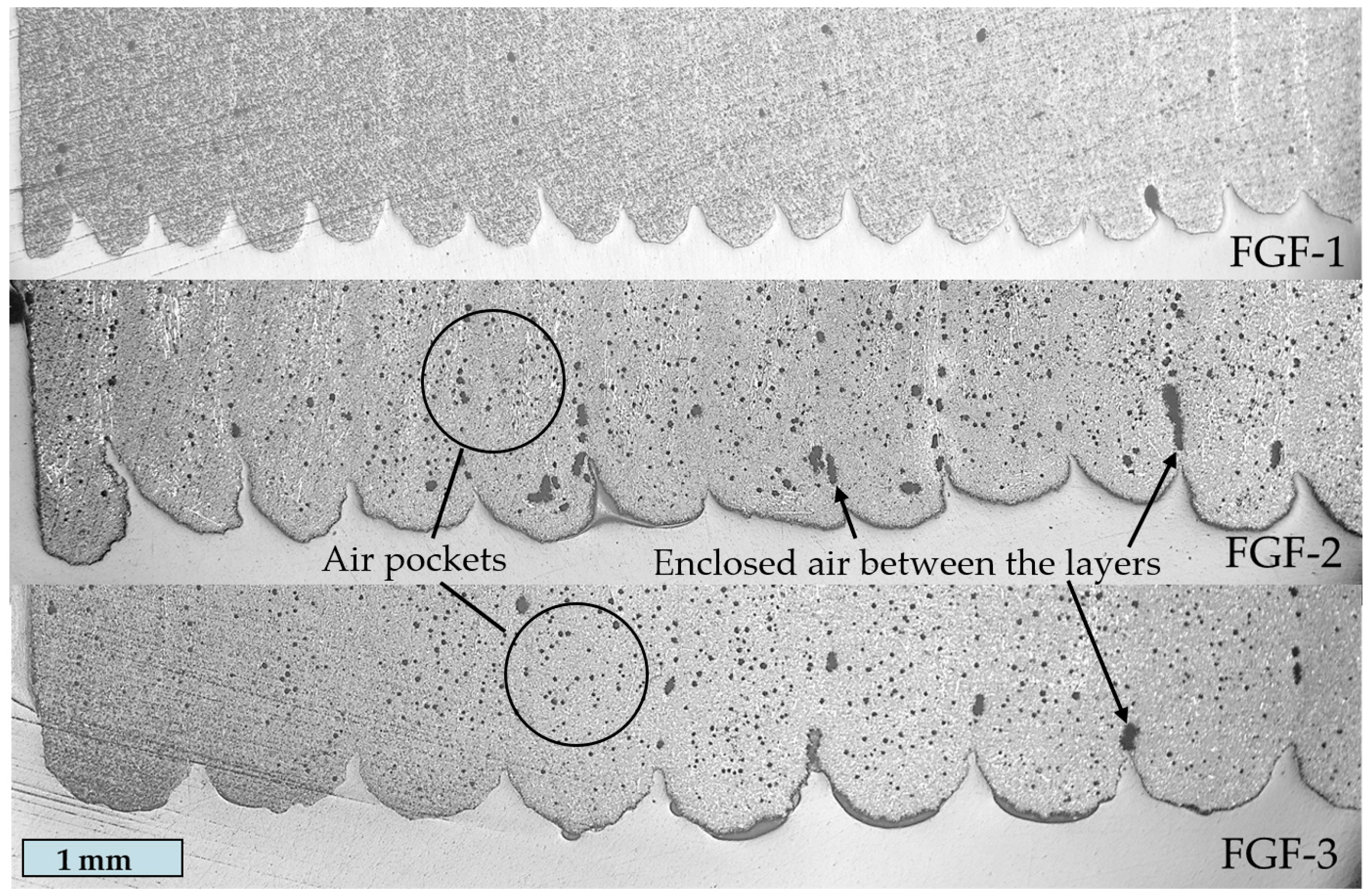

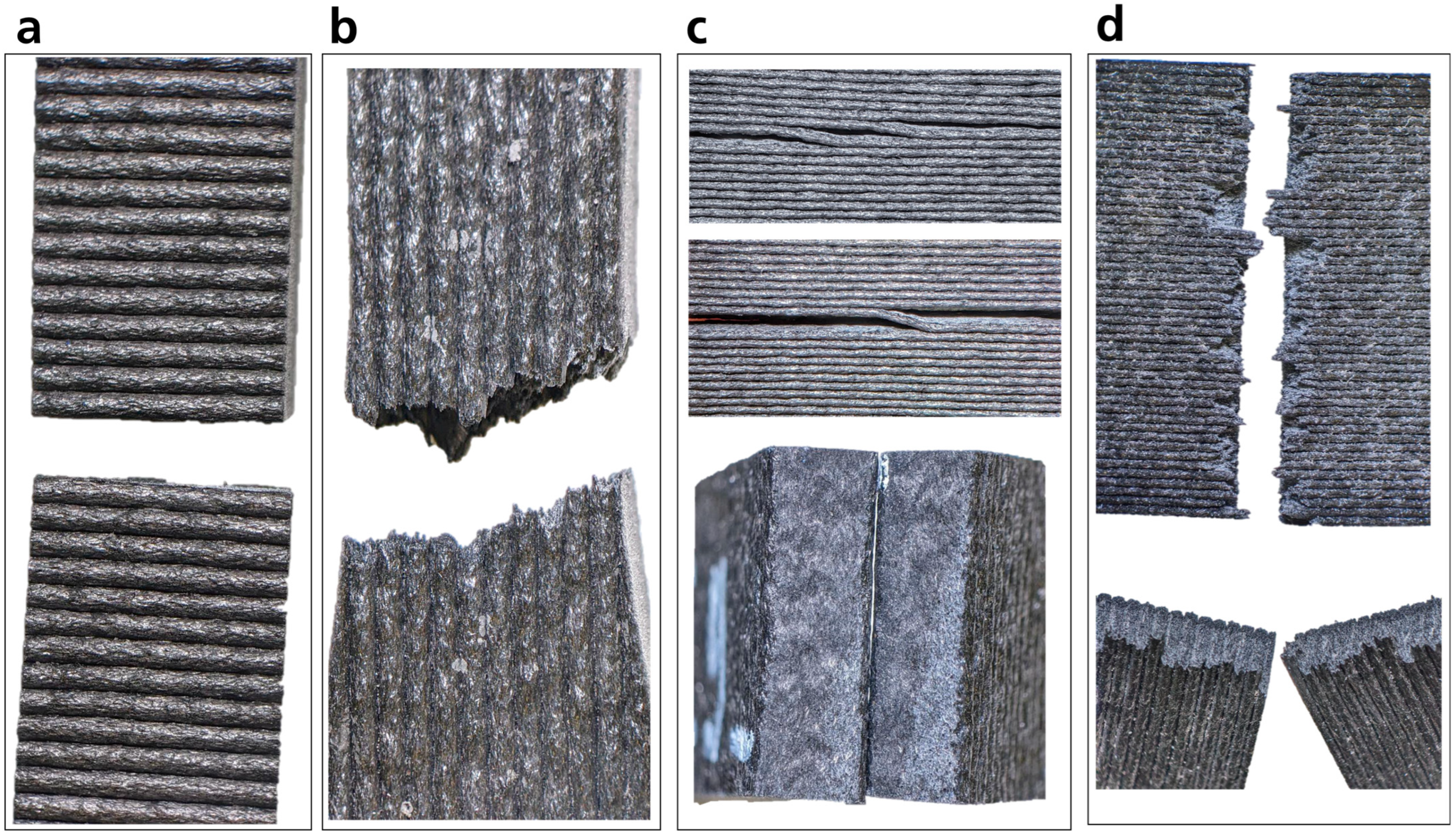

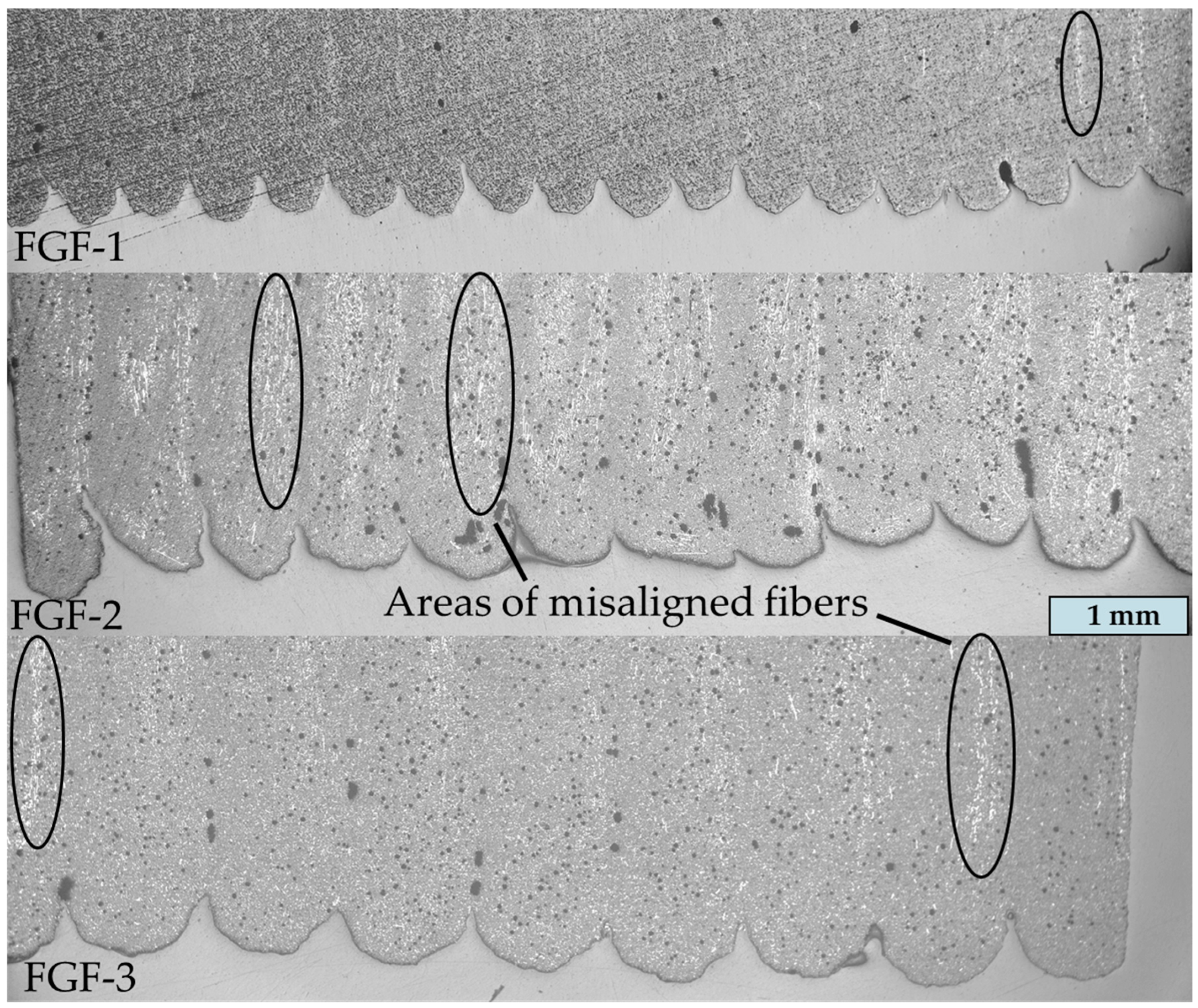

3.1.1. Morphological Analysis

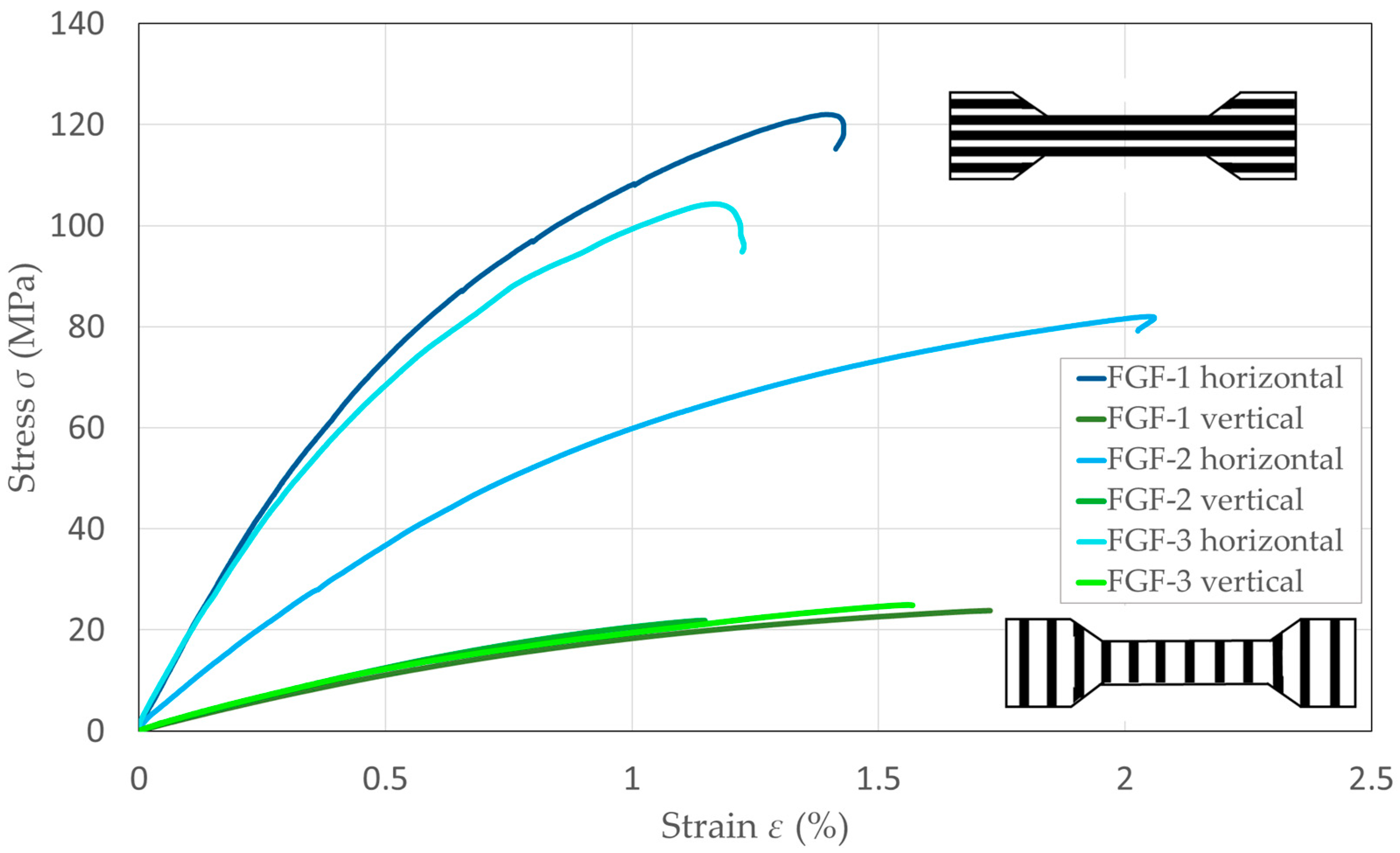

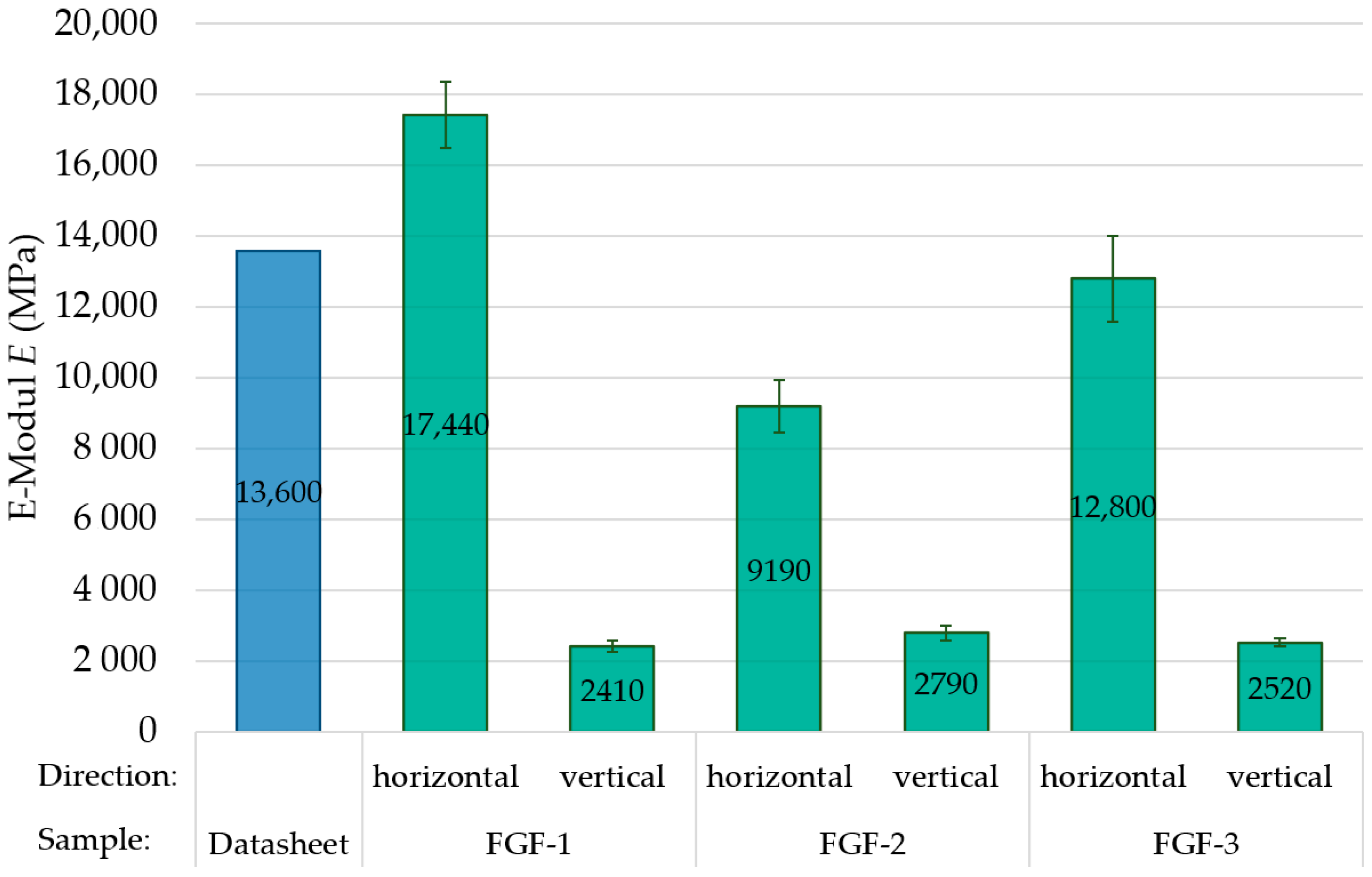

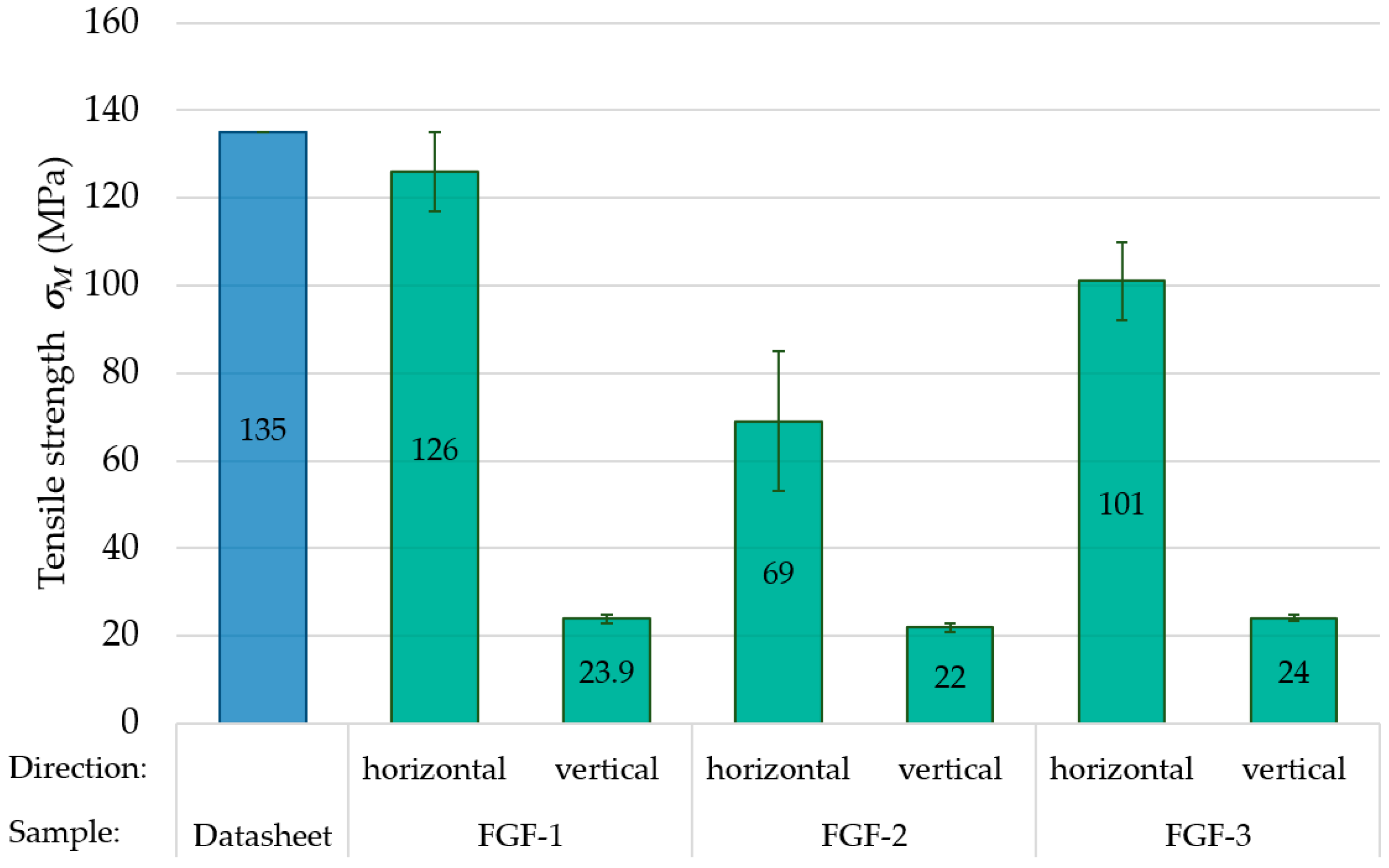

3.1.2. Mechanical Analysis

3.2. Hybrid Composite Structures from Fused Granular Fabrication and Automated Tape Laying

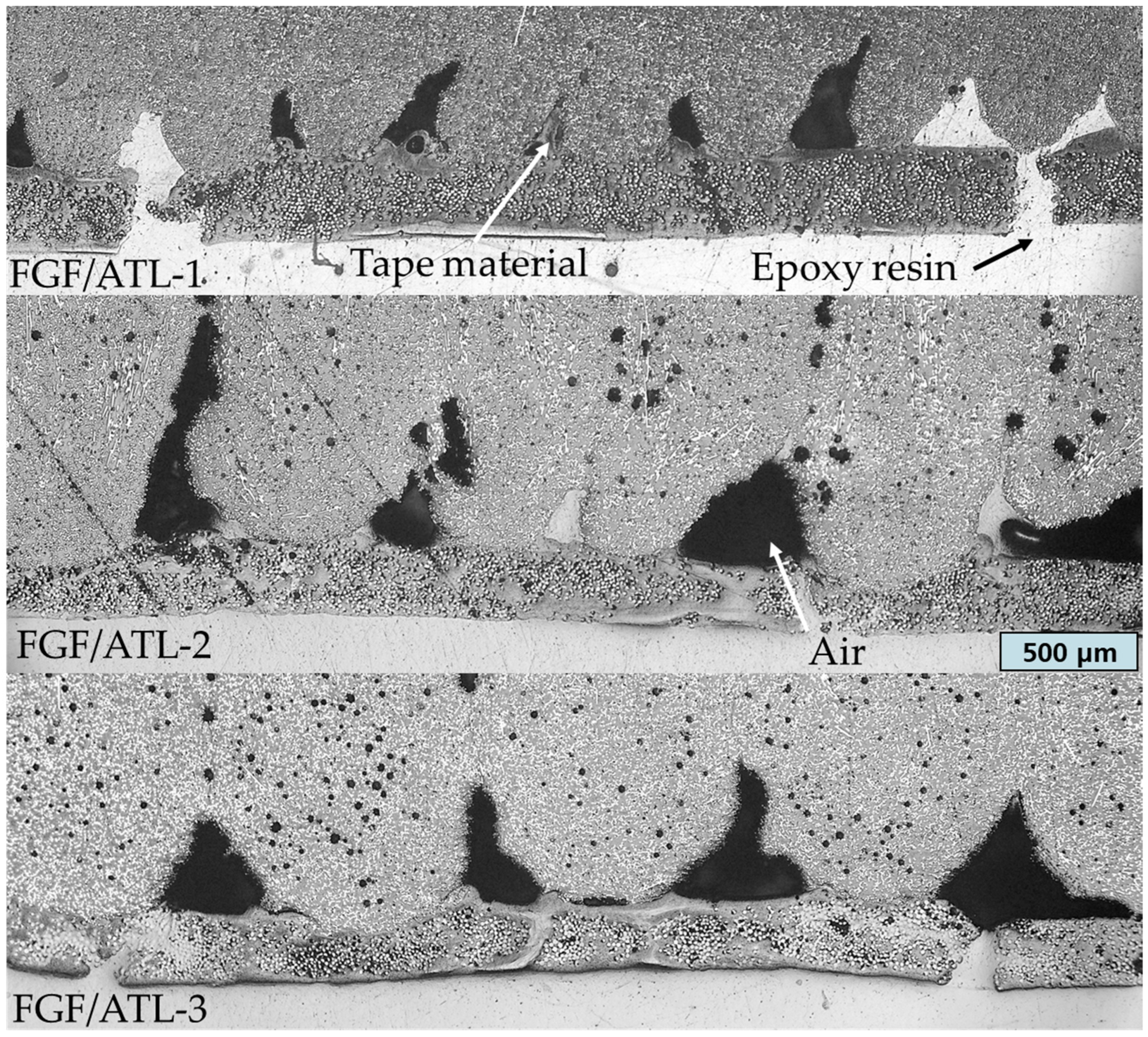

3.2.1. Morphological Analysis

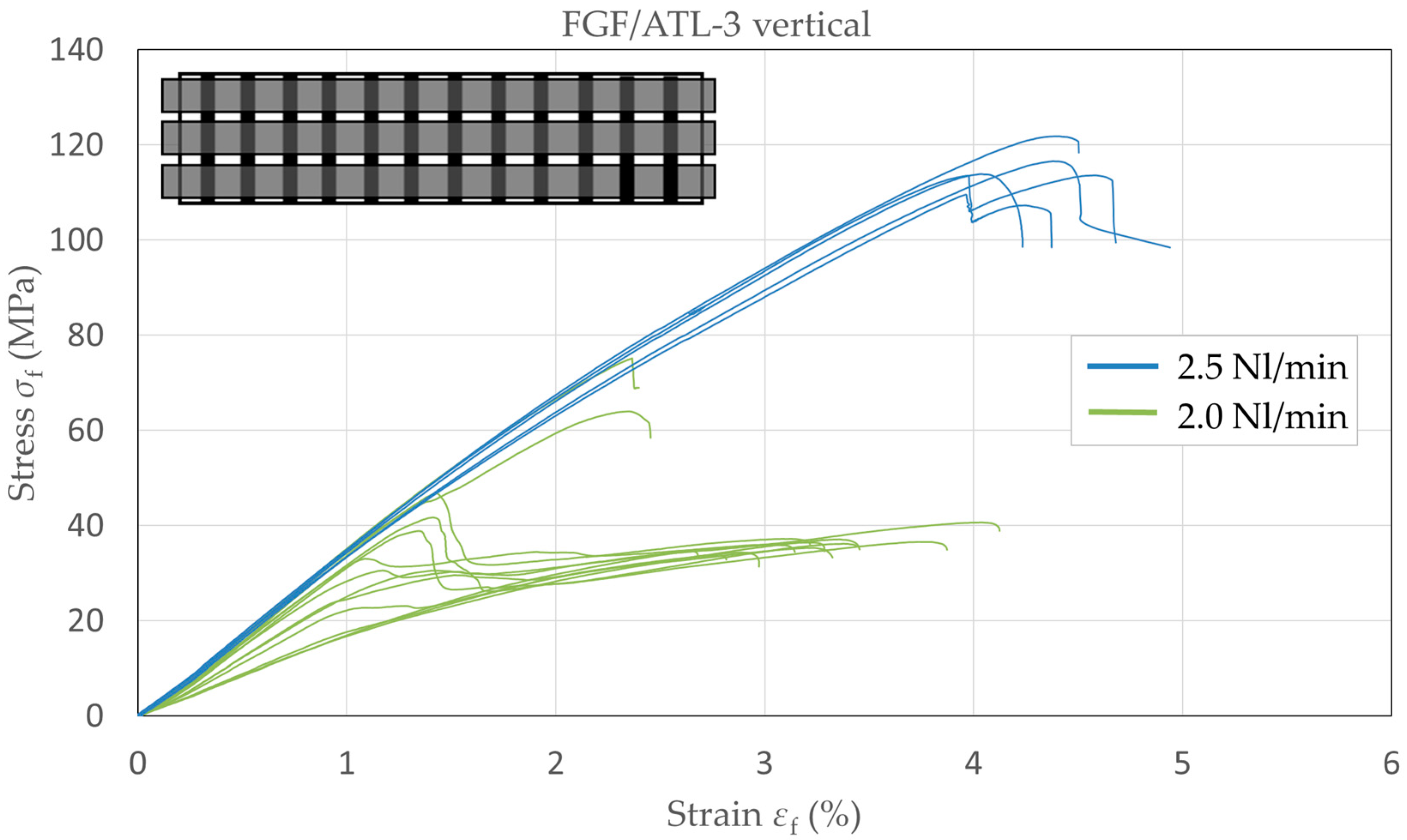

3.2.2. Analysis of Process Parameters

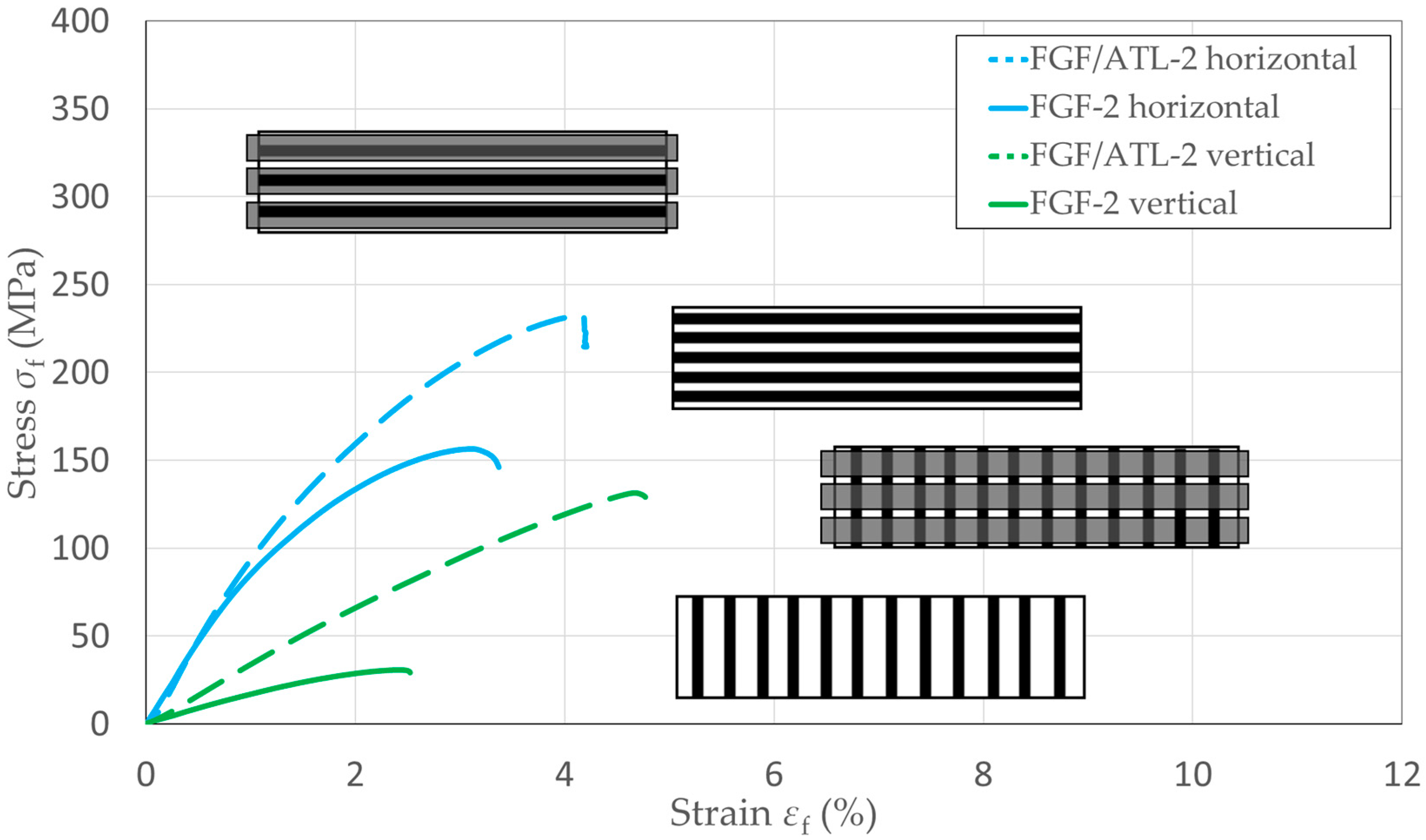

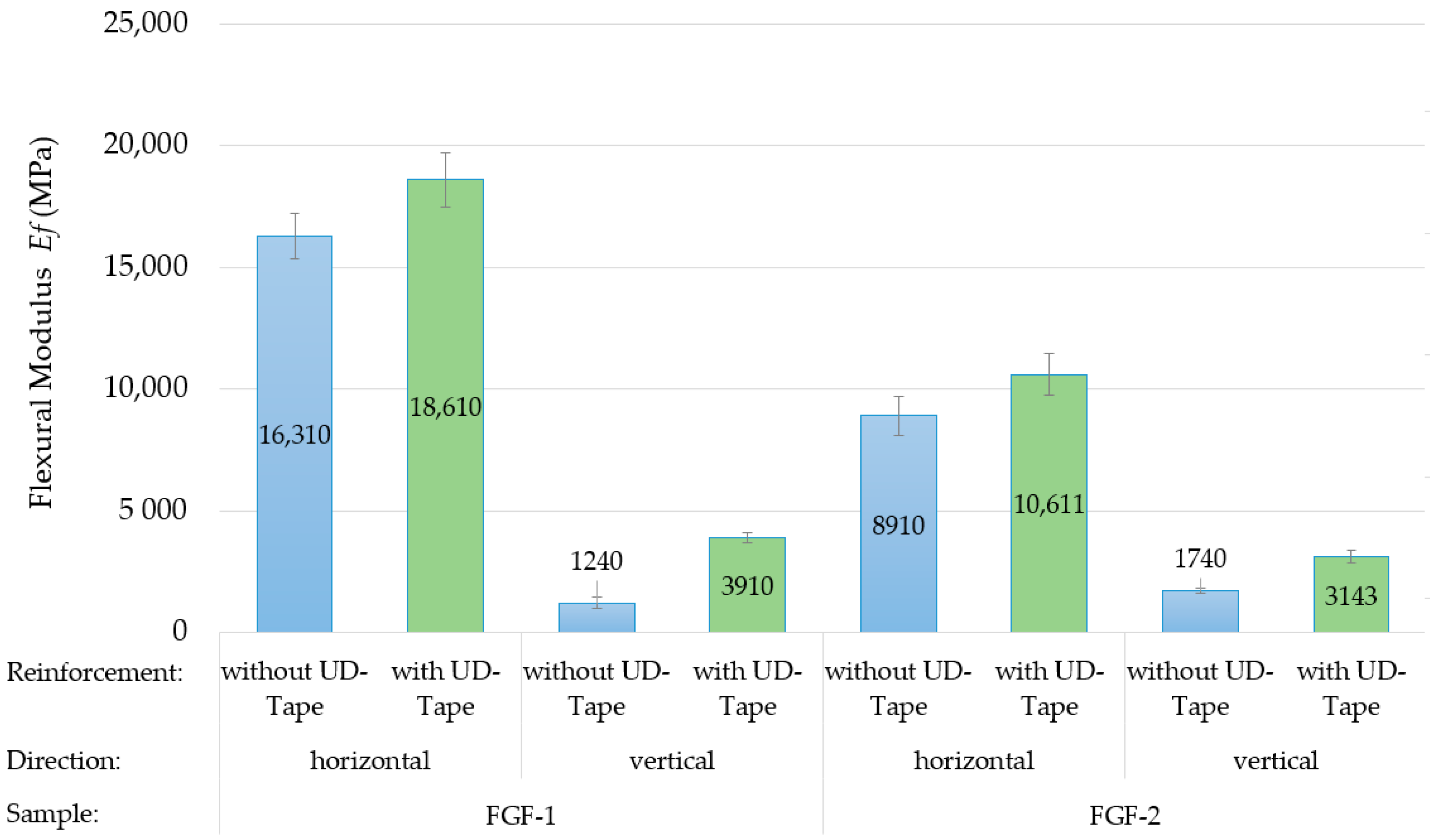

3.2.3. Mechanical Analysis

4. Conclusions

- ▪

- The process parameters have a strong influence on the surface roughness and mechanical properties. Especially the extrusion width, the layer height, and nozzle diameter ratios were found to be the essential factors affecting the regularity of printed geometry, surface quality, and misalignment of the reinforcing fibers in the FGF layers. This fact has a significant impact on the mechanical properties, particularly in the horizontal test direction, as found in the tensile tests of the FGF test samples.

- ▪

- By respecting optimal printing process parameters, comparable values for the elastic modulus and tensile strength of the manufactured FGF materials to the datasheet values from injection-molded samples could be achieved.

- ▪

- Additional automated tape laying (ATL) can significantly increase the mechanical properties of FGF structures, in some cases by several times. This was demonstrated by tape-laying glass-fiber-reinforced polyamide 6 UD tapes on the FGF plates.

- ▪

- For ATL using gas as the heat source, it is essential to find the optimum gas volume flow rate at a given speed and UD tape and FGF material combination. An amount of heat absorbed by UD tape that is too low does not ensure sufficient diffusion of the matrix polymers into the FGF structure. As a result, it does not lead to effective reinforcement of the FGF material as the adhesion to the UD tapes is too weak.

- ▪

- Lower surface roughness of the FGF materials leads to fewer gaps in the UD tape and therefore better stress transfer and higher mechanical values of resulting flexural modulus and strength, as demonstrated by the bending tests. Further improvement and analysis of the adhesion between the FGF materials and UD tapes are needed to determine optimal process parameters for both processes. Additionally, for multilayer components the tape–tape interface needs to be investigated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Ubaidillah, U.; Arifin, Z. A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Love, L.J.; Duty, C.E.; Post, B.K.; Lind, R.F.; Lloyd, P.D.; Kunc, V.; Peter, W.H.; Blue, C.A. Breaking Barriers in Polymer Additive Manufacturing. In Proceedings of the SAMPE Conference, Baltimore, MD, USA, 19–20 May 2015. [Google Scholar]

- Doshi, M.; Mahale, A.; Singh, S.K.; Deshmukh, S. Printing parameters and materials affecting mechanical properties of FDM-3D printed Parts: Perspective and prospects. Mater. Today Proc. 2022, 50, 2269–2275. [Google Scholar] [CrossRef]

- Ahuja, B.; Karg, M.; Schmidt, M. Additive manufacturing in production: Challenges and opportunities. In Proceedings of the SPIE LASE: Laser 3D Manufacturing II, San Francisco, CA, USA, 7–12 February 2015. [Google Scholar]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive Manufacturing: Current State, Future Potential, Gaps and Needs, and Recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Fleury, A.; Gregory, M.; Bennett, D. The future of manufacturing. J. Manuf. Technol. Manag. 2007, 18, 323–325. [Google Scholar] [CrossRef][Green Version]

- Pignatelli, F.; Percoco, G. An application- and market-oriented review on large format additive manufacturing, focusing on polymer pellet-based 3D printing. Prog. Addit. Manuf. 2022, 7, 1363–1377. [Google Scholar] [CrossRef]

- Post, B.K.; Lind, R.F.; Lloyd, P.D.; Kunc, V.; Linhal, J.M.; Love, L.J. The economics of big area additive manufacturing. In Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 8–10 August 2016. [Google Scholar]

- Duty, C.E.; Kunc, V.; Compton, B.; Post, B.; Erdman, D.; Smith, R.; Lind, R.; Lloyd, P.; Love, L. Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyp. J. 2017, 23, 181–189. [Google Scholar] [CrossRef]

- Silva, R.; Sereno, P.; Mateus, A.; Mitchell, G.R.; Carreira, P.; Santos, C.; Vitorino, J.; Domingues, J. Adaptive Platforms and Flexible Deposition System for Big Area Additive Manufacturing (BAAM). Appl. Mech. Mater. 2019, 890, 3–20. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Ghabezi, P.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Recovery of Particle Reinforced Composite 3D Printing Filament from Recycled Industrial Polypropylene and Glass Fibre Waste. In Proceedings of the 8th World Congress on Mechanical, Chemical, and Material Engineering MCM’22, Prague, Czech Republic, 31 July–2 August 2022. [Google Scholar]

- Sam-Daliri, O.; Ghabezi, P.; Steinbach, J.; Flanagan, T.; Finnegan, W.; Mitchell, S.; Harrison, N. Experimental study on mechanical properties of material extrusion additive manufactured parts from recycled glass fibre-reinforced polypropylene composite. Compos. Sci. Technol. 2023, 241, 110125. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Ajinjeru, C.; Kishore, V.; Lindahl, J.; Sudbury, Z.; Hassen, A.A.; Post, B.; Love, L.; Kunc, V.; Duty, C. The influence of dynamic rheological properties on carbon fiber-reinforced polyetherimide for large-scale extrusion-based additive manufacturing. Int. J. Adv. Manuf. Technol. 2018, 99, 411–418. [Google Scholar] [CrossRef]

- Ajinjeru, C.; Kishore, V.; Chen, X.; Hershey, C.; Lindhal, J.; Kunc, V.; Hassen, A.A.; Duty, C. Rheological survey of carbon fiber-reinforced high-temperature thermoplastics for big area additive manufacturing tooling applications. J. Thermoplast. Compos. Mater. 2021, 34, 1443–1461. [Google Scholar] [CrossRef]

- Billah, K.M.M.; Lorenzana, F.A.R.; Martinez, N.L.; Wicker, R.B.; Espalin, D. Thermomechanical characterization of short carbon fiber and short glass fiber-reinforced ABS used in large format additive manufacturing. Addit. Manuf. 2020, 35, 101299. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zohdi, N.; Yang, R. Material Anisotropy in Additively Manufactured Polymers and Polymer Composites: A Review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef]

- Haque, A.N.M.A.; Naebe, M. Tensile Properties of Natural Fibre-Reinforced FDM Filaments: A Short Review. Sustainability 2023, 15, 16580. [Google Scholar] [CrossRef]

- Liu, X.; Chi, B.; Jiao, Z.; Tan, J.; Liu, F.; Yang, W. A large-scale double-stage-screw 3D printer for fused deposition of plastic pellets. J. Appl. Polym. Sci. 2017, 134, 45147. [Google Scholar] [CrossRef]

- Chesser, P.; Post, B.; Roschli, A.; Carnal, C.; Lind, R.; Borish, M.; Love, L. Extrusion control for high quality printing on Big Area Additive Manufacturing (BAAM) systems. Addit. Manuf. 2019, 28, 445–455. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Raspall, F.; Velu, R.; Vaheed, N.M. Fabrication of complex 3D composites by fusing automated fiber placement (AFP) and additive manufacturing (AM) technologies. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 6–16. [Google Scholar] [CrossRef]

- Yassin, K.; Hojjati, M. Processing of thermoplastic matrix composites through automated fiber placement and tape laying methods: A review. J. Thermoplast. Compos. 2018, 31, 1676–1725. [Google Scholar] [CrossRef]

- Voelkl, H.; Kießkalt, A.; Wartzack, S. Design for Composites: Derivation of Manufacturable Geometries for Unidirectional Tape Laying. Proc. Des. Soc. Int. Conf. Eng. Des. 2019, 1, 2687–2696. [Google Scholar] [CrossRef]

- Kropka, M.; Muehlbacher, M.; Neumeyer, T.; Altstaedt, V. From UD-tape to Final Part—A Comprehensive Approach towards Thermoplastic Composites. Procedia CIRP 2017, 66, 96–100. [Google Scholar] [CrossRef]

- Brasington, A.; Sacco, C.; Halbritter, J.; Wehbe, R.; Harik, R. Automated fiber placement: A review of history, current technologies, and future paths forward. Compos. Part C 2021, 6, 100182. [Google Scholar] [CrossRef]

- Link, T.; Rosenberg, P.; Henning, F. Prediction of Gaps in Automated Tape Laying and Their Influence on Porosity in Consolidated Laminates. J. Compos. Sci. 2022, 6, 207. [Google Scholar] [CrossRef]

- Jayasekara, D.; Lai, N.Y.G.; Wong, K.-H.; Pawar, K.; Zhu, Y. Level of automation (LOA) in aerospace composite manufacturing: Present status and future directions towards industry 4.0. J. Manuf. Syst. 2022, 62, 44–61. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.; Pei, J.; Zhou, Y. Review of automated fibre placement and its prospects for advanced composites. J. Mater. Sci. 2020, 55, 7121–7155. [Google Scholar] [CrossRef]

- Dhinakaran, V.; Surendar, K.V.; Hasunfur Riyaz, M.S.; Ravichandran, M. Review on study of thermosetting and thermoplastic materials in the automated fiber placement process. Mater. Today Proc. 2020, 27, 812–815. [Google Scholar] [CrossRef]

- F3-Compositor Enables 3D Deposition and Simultaneous Joining of Thermoplastic UD Tape Semi-Finished Products. Available online: https://www.imws.fraunhofer.de/en/presse/pressemitteilungen/f3--compositor-enables-3d-deposition-and-simultaneous-joining-of.html (accessed on 9 November 2023).

- DIN EN ISO 178:2019-08; Plastics—Determination of Flexural Properties (ISO 178:2019). German version EN ISO 178:2019; ISO: Geneva, Switzerland, 2019.

- DIN EN ISO 1110:2019-09; Plastics—Polyamides—Accelerated Conditioning of Test Specimens (ISO 1110:2019). German version EN ISO 1110:2019; ISO: Geneva, Switzerland, 2019.

- DIN EN ISO 527-1:2019-12; Lastics—Determination of Tensile Properties—Part 1: General Principles (ISO 527-1:2019). German version EN ISO 527-1:2019; ISO: Geneva, Switzerland, 2019.

- Ahn, D.; Kweon, J.-H.; Kwon, S.; Song, J.; Lee, S. Representation of surface roughness in fused deposition modelling. J. Mater. Process. Technol. 2009, 209, 5593–5600. [Google Scholar] [CrossRef]

- Maier, R.; Bucaciuc, S.-G.; Mandoc, A.C. Reducing Surface Roughness of 3D Printed Short-Carbon Fiber Reinforced Composites. Materials 2022, 15, 7398. [Google Scholar] [CrossRef]

- Consul, P.; Beuerlein, K.; Luzha, G.; Drechsler, K. Effect of Extrusion Parameters on Short Fiber Alignment in Fused Filament Fabrication. Polymers 2021, 13, 2443. [Google Scholar] [CrossRef]

- Tagscherer, N.; Bär, A.; Zaremba, S.; Drechsler, K. Mechanical Analysis of Parameter Variations in Large-Scale Extrusion Additive Manufacturing of Thermoplastic Composites. J. Manuf. Process. 2022, 6, 36. [Google Scholar] [CrossRef]

- Barera, G.; Dul, S.; Pegoretti, A. Screw Extrusion Additive Manufacturing of Carbon Fiber Reinforced PA6 Tools. J. Mater. Eng. Perform. 2023, 32, 9579–9597. [Google Scholar] [CrossRef]

- König, M.; Diekmann, J.; Lahres, M.; Middendorf, P. Experimental investigation of process-structure effects on interfacial bonding strength of a short carbon fiber/polyamide composite fabricated by fused filament fabrication. Prog. Addit. Manuf. 2022, 7, 593–607. [Google Scholar] [CrossRef]

- Kepenekci, M.; Gharehpapagh, B.; Yaman, U.; Özerinc, S. Mechanical performance of carbon fiber-reinforced polymer cellular structures manufactured via fused filament fabrication. Polym. Compos. 2023, 44, 4654–4668. [Google Scholar] [CrossRef]

- Atzler, F.; Raps, L.; Freund, J.; Tröger, S.; Hümbert, S. Bonding of Low-Melting Polyaryletherketone onto Polyamide 6: A Concept for Molds for Automated Fiber Placement. J. Compos. Sci. 2023, 7, 371. [Google Scholar] [CrossRef]

- Janssen, H.; Peters, T.; Brecher, C. Efficient Production of Tailored Structural Thermoplastic Composite Parts by Combining Tape Placement and 3d Printing. Procedia CIRP 2017, 66, 91–95. [Google Scholar] [CrossRef]

| Composite Material | PA6/CF40 | PA6/GF60-UD |

|---|---|---|

| Grade | AKROMID® B3 ICF 40 black | Celstran® CFR-TP PA6-GF60 |

| Supplier | AKRO-PLASTIC GmbH | TICONA GmbH |

| Reinforcement | carbon fiber | glass fiber |

| Fiber Weight Content (%) | 40 | 60 |

| Density (g/cm3) | 1.31 | 1.69 |

| Tensile Modulus (GPa) | 32 (dry) 13.6 (conditioned) | 29.7 (dry) 27.5 (conditioned) |

| Tensile Strength (MPa) | 220 (dry) 135 (conditioned) | 679 (dry) 642 (conditioned) |

| Melting Temperature (°C) | 220 | 220 |

| Plate Type | Printing Speed v (mm/s) | Layer Height h (mm) | Nozzle Diameter d (mm) | Extrusion Width w (mm) | Ratio w/d (-) | Ratio h/d (-) |

|---|---|---|---|---|---|---|

| FGF-1 | 400 | 0.50 | 1.5 | 2.7 | 1.80 | 0.33 |

| FGF-2 | 200 | 0.75 | 1.5 | 4.3 | 2.87 | 0.5 |

| FGF-3 | 125 | 1.00 | 3.0 | 5.2 | 1.73 | 0.33 |

| Laying Speed v (mm/s) | Force on Tape F (N) | Gas Flow Rate V (Nl/min) | Gas Composition 2 H2 + O2 (%) | Roll Temperature T (°C) |

|---|---|---|---|---|

| 250 | 60 | 2.0/2.5 | 100 | 20 |

| Sample | Surface Roughness Ra (µm) | Surface Roughness Rz (µm) | Density ρ (g/cm3) |

|---|---|---|---|

| FGF-1 | 63 | 533 | 1.301 |

| FGF-2 | 95 | 1475 | 1.273 |

| FGF-3 | 95 | 703 | 1.277 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hirsch, P.; Scholz, S.; Borowitza, B.; Vyhnal, M.; Schlimper, R.; Zscheyge, M.; Kotera, O.; Stipkova, M.; Scholz, S. Processing and Analysis of Hybrid Fiber-Reinforced Polyamide Composite Structures Made by Fused Granular Fabrication and Automated Tape Laying. J. Manuf. Mater. Process. 2024, 8, 25. https://doi.org/10.3390/jmmp8010025

Hirsch P, Scholz S, Borowitza B, Vyhnal M, Schlimper R, Zscheyge M, Kotera O, Stipkova M, Scholz S. Processing and Analysis of Hybrid Fiber-Reinforced Polyamide Composite Structures Made by Fused Granular Fabrication and Automated Tape Laying. Journal of Manufacturing and Materials Processing. 2024; 8(1):25. https://doi.org/10.3390/jmmp8010025

Chicago/Turabian StyleHirsch, Patrick, Simon Scholz, Benjamin Borowitza, Moritz Vyhnal, Ralf Schlimper, Matthias Zscheyge, Ondrej Kotera, Michaela Stipkova, and Sebastian Scholz. 2024. "Processing and Analysis of Hybrid Fiber-Reinforced Polyamide Composite Structures Made by Fused Granular Fabrication and Automated Tape Laying" Journal of Manufacturing and Materials Processing 8, no. 1: 25. https://doi.org/10.3390/jmmp8010025

APA StyleHirsch, P., Scholz, S., Borowitza, B., Vyhnal, M., Schlimper, R., Zscheyge, M., Kotera, O., Stipkova, M., & Scholz, S. (2024). Processing and Analysis of Hybrid Fiber-Reinforced Polyamide Composite Structures Made by Fused Granular Fabrication and Automated Tape Laying. Journal of Manufacturing and Materials Processing, 8(1), 25. https://doi.org/10.3390/jmmp8010025