Numerical Modeling of Cutting Characteristics during Short Hole Drilling: Part 2—Modeling of Thermal Characteristics

Abstract

1. Introduction

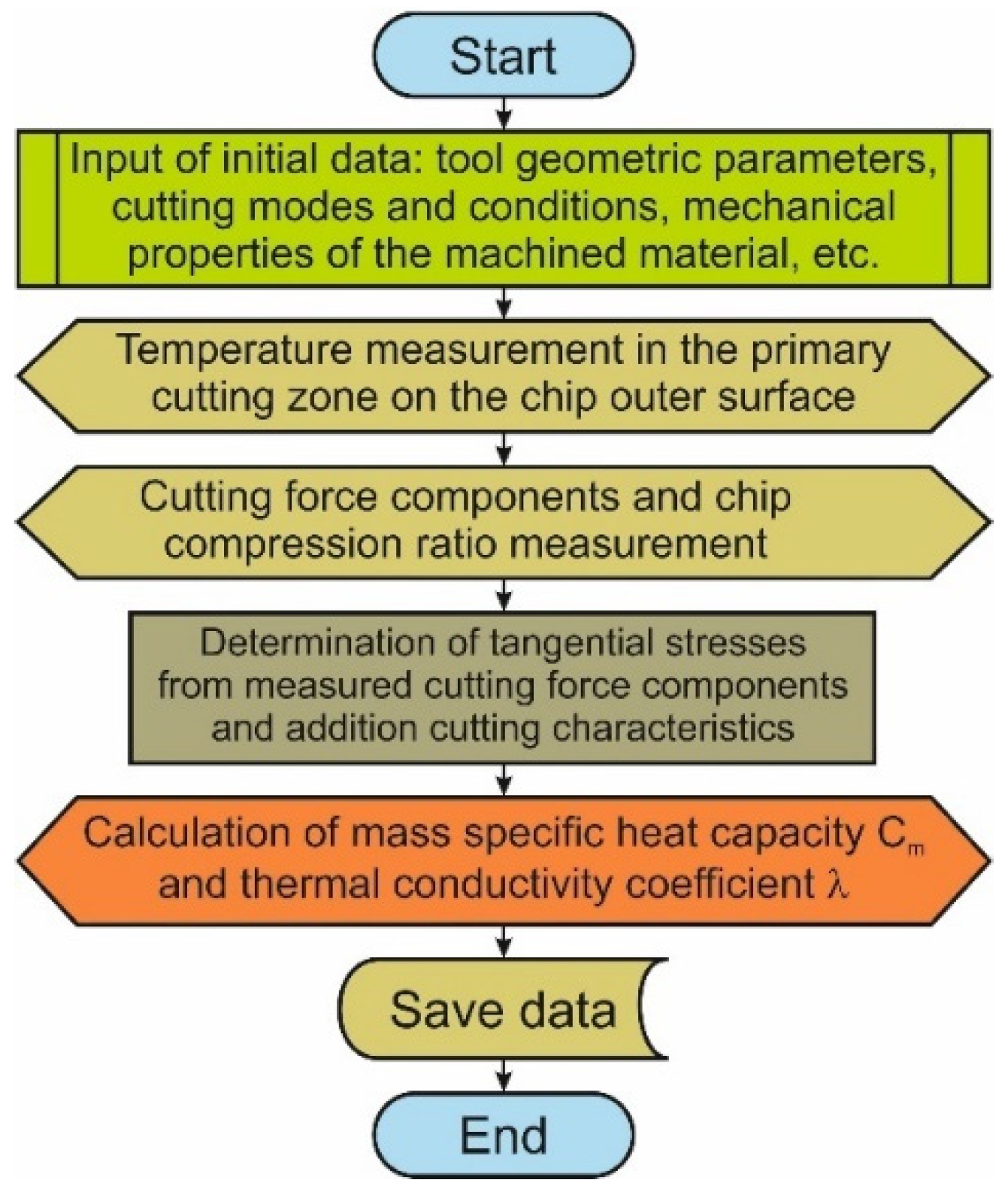

2. Methods for the Determination of Thermal Characteristics in Short Hole Drilling

3. Materials and Methods

3.1. Materials

3.1.1. Orthogonal Cutting

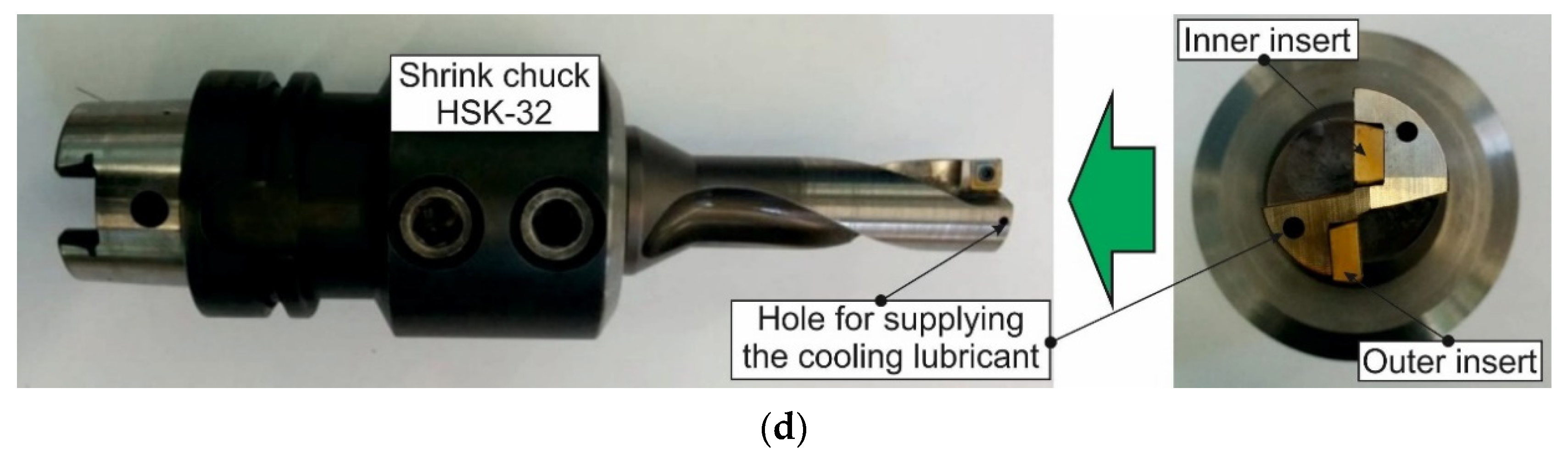

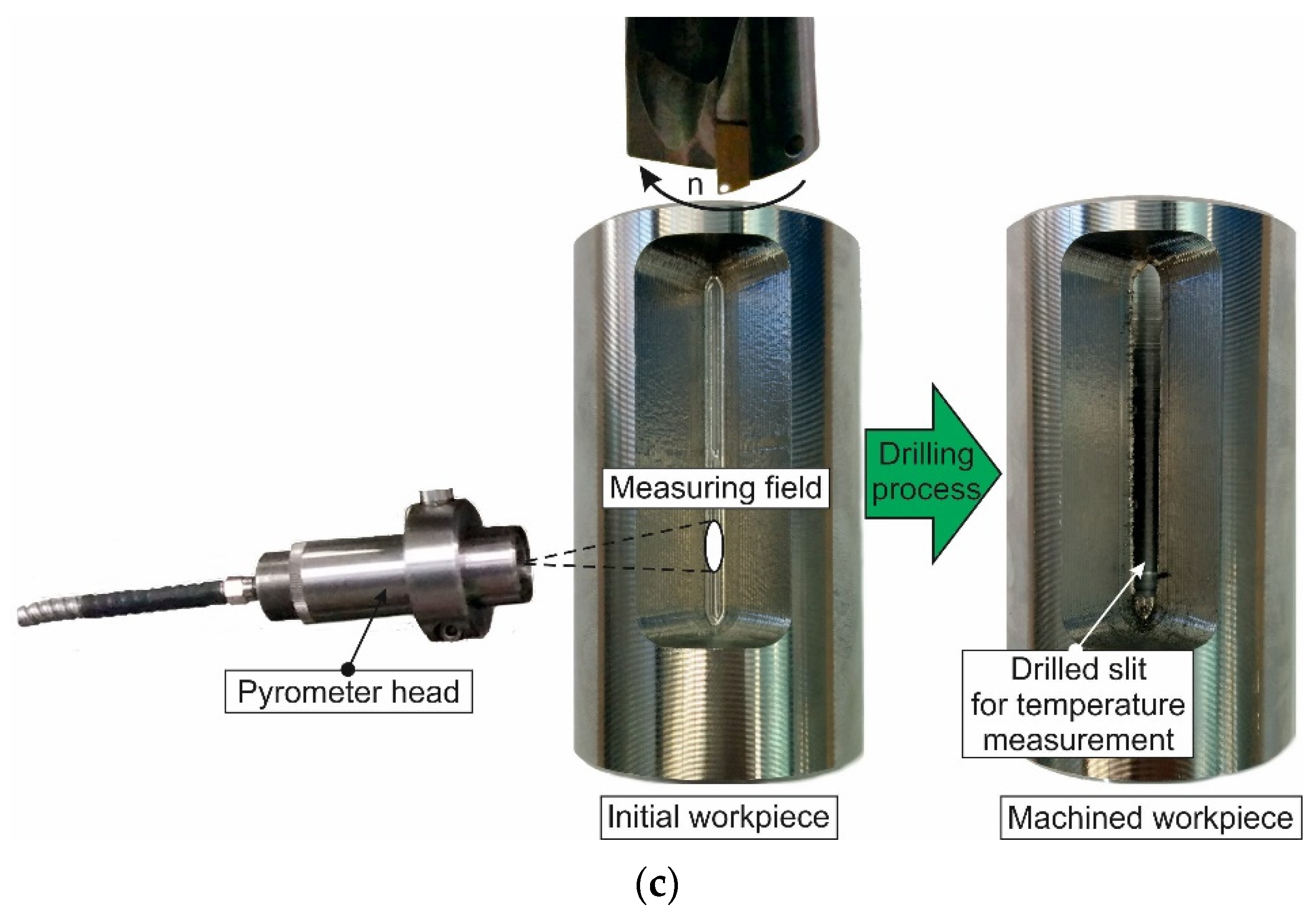

3.1.2. Short Hole Drilling

3.2. Methods

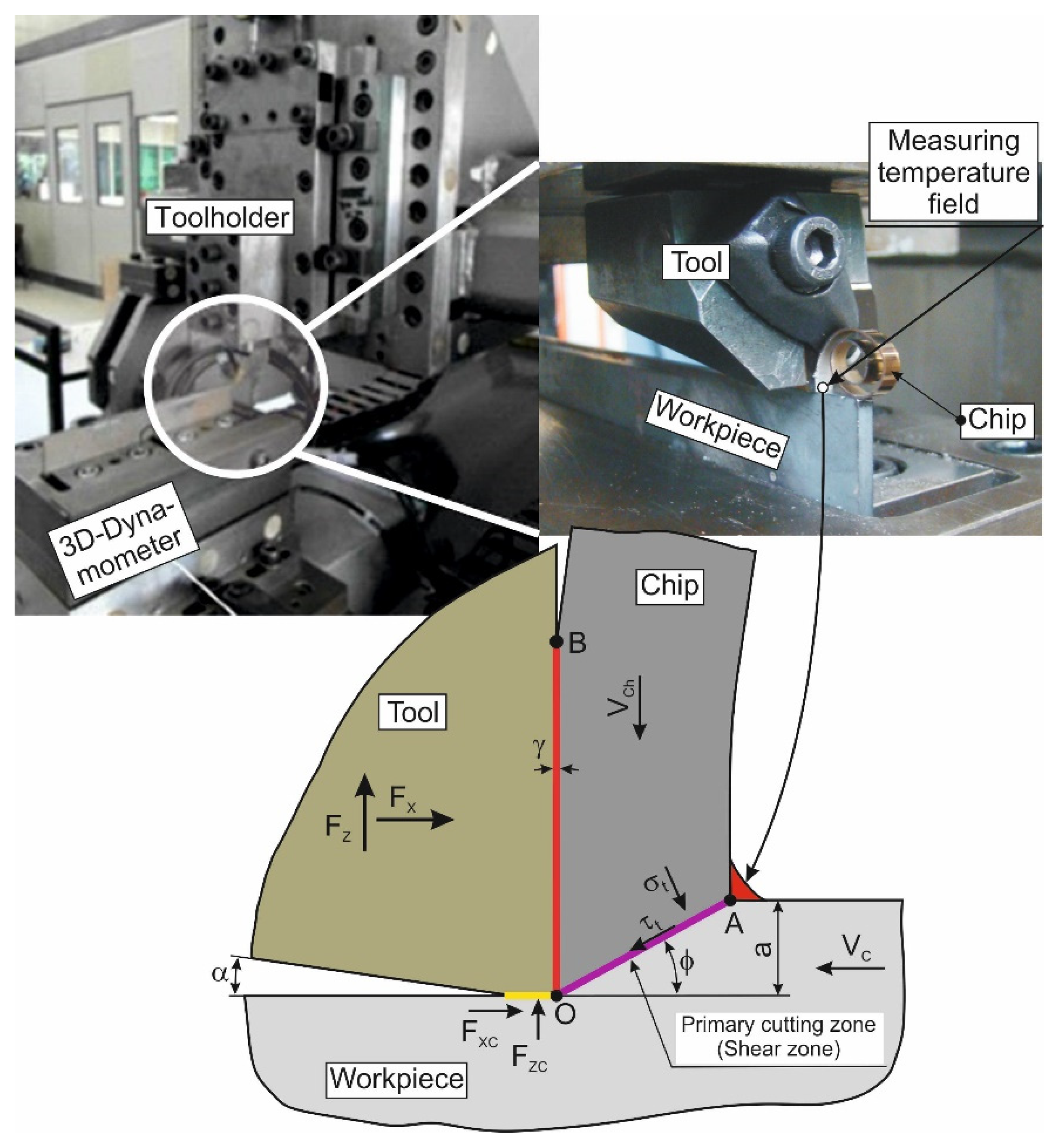

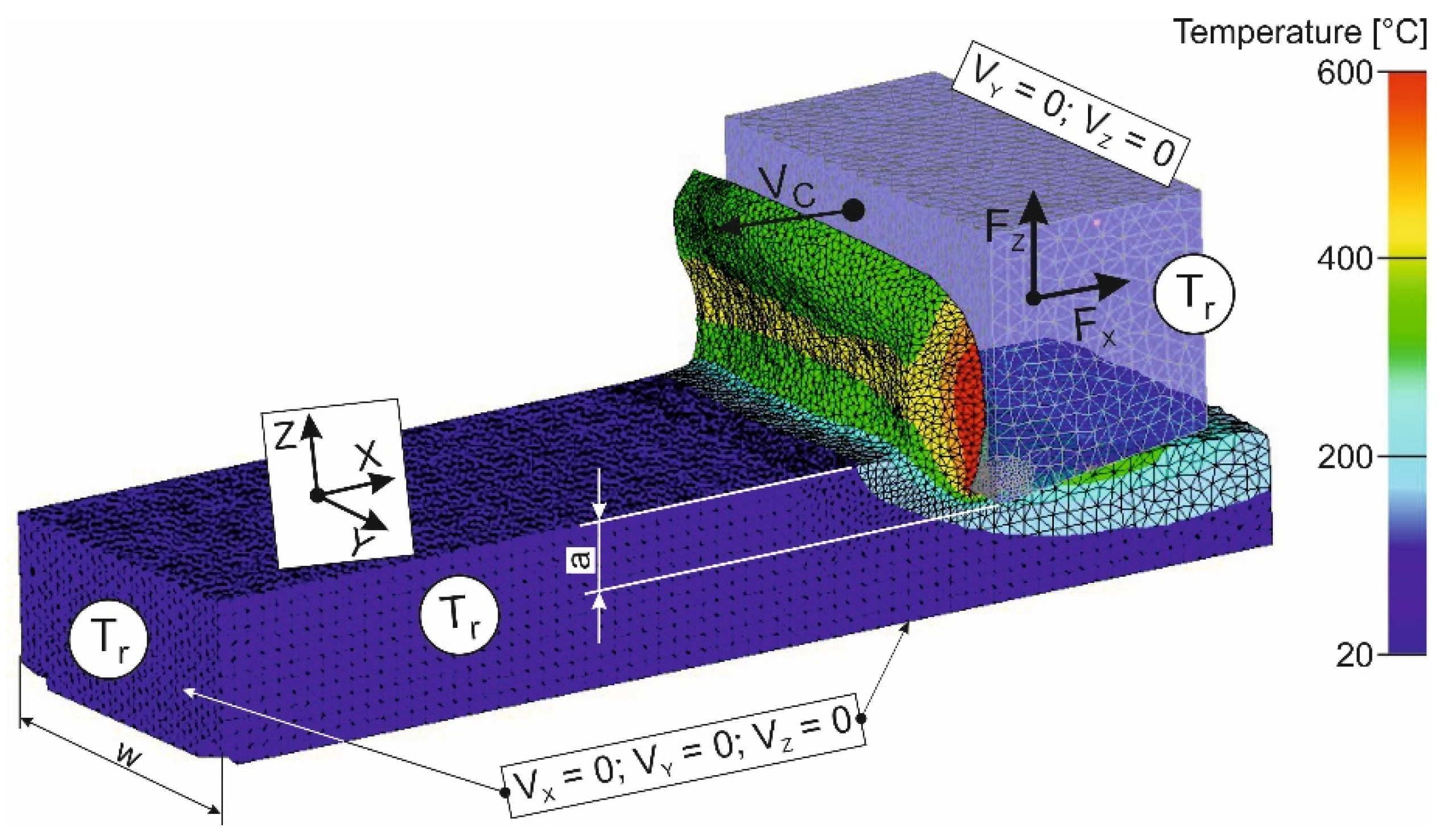

3.2.1. Orthogonal Cutting Process

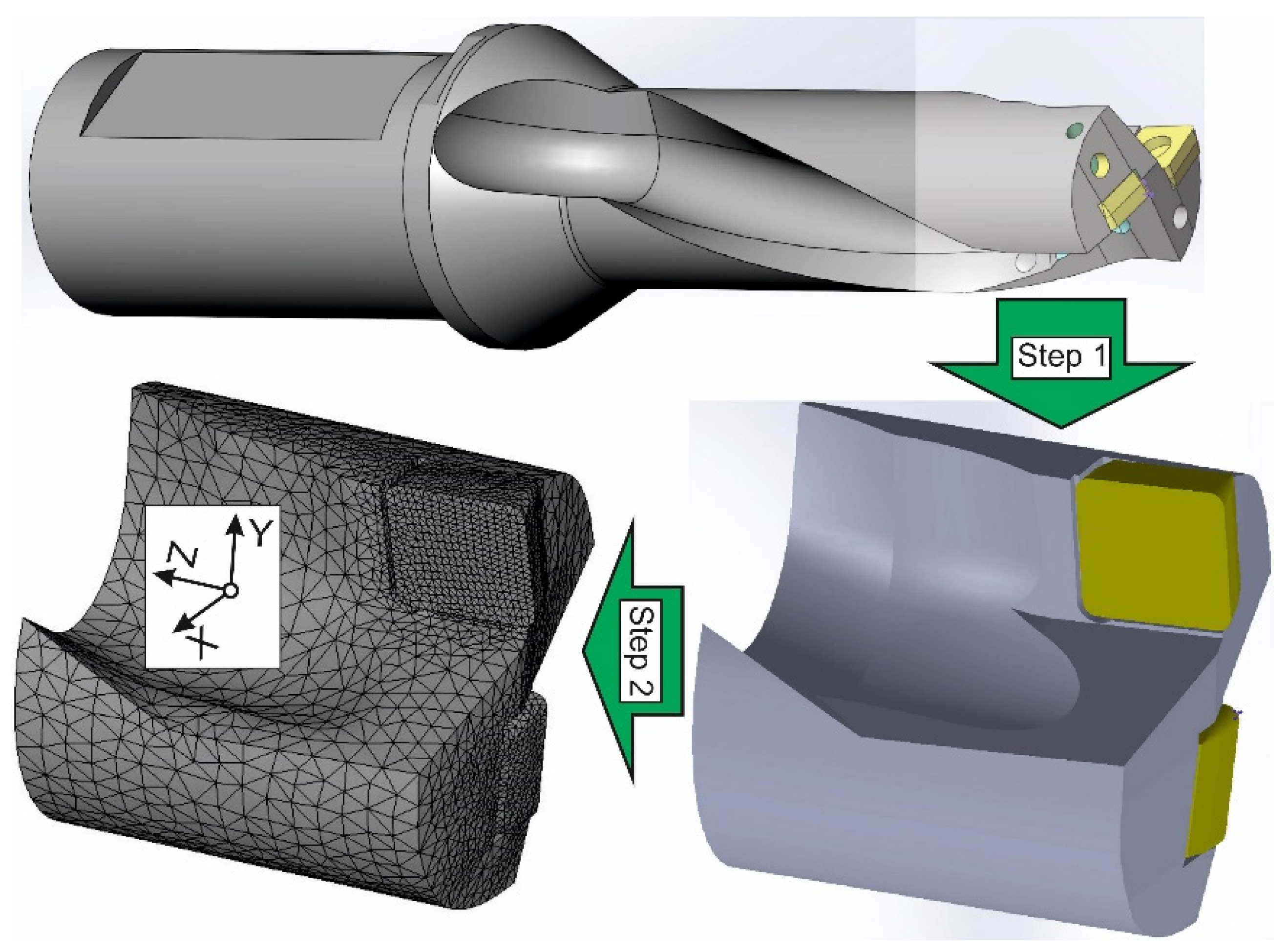

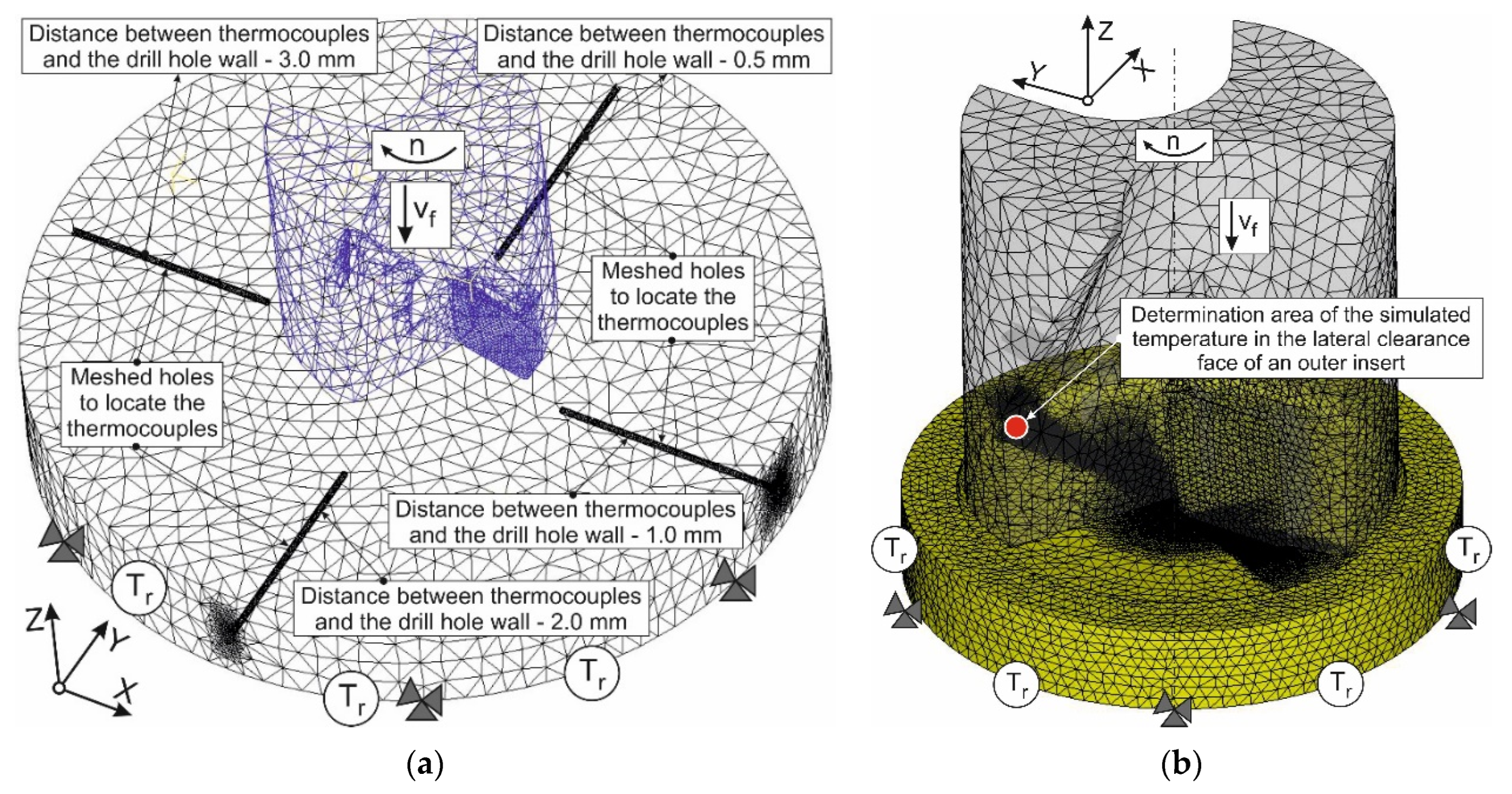

3.2.2. Short Hole Drilling

4. Results and Discussion

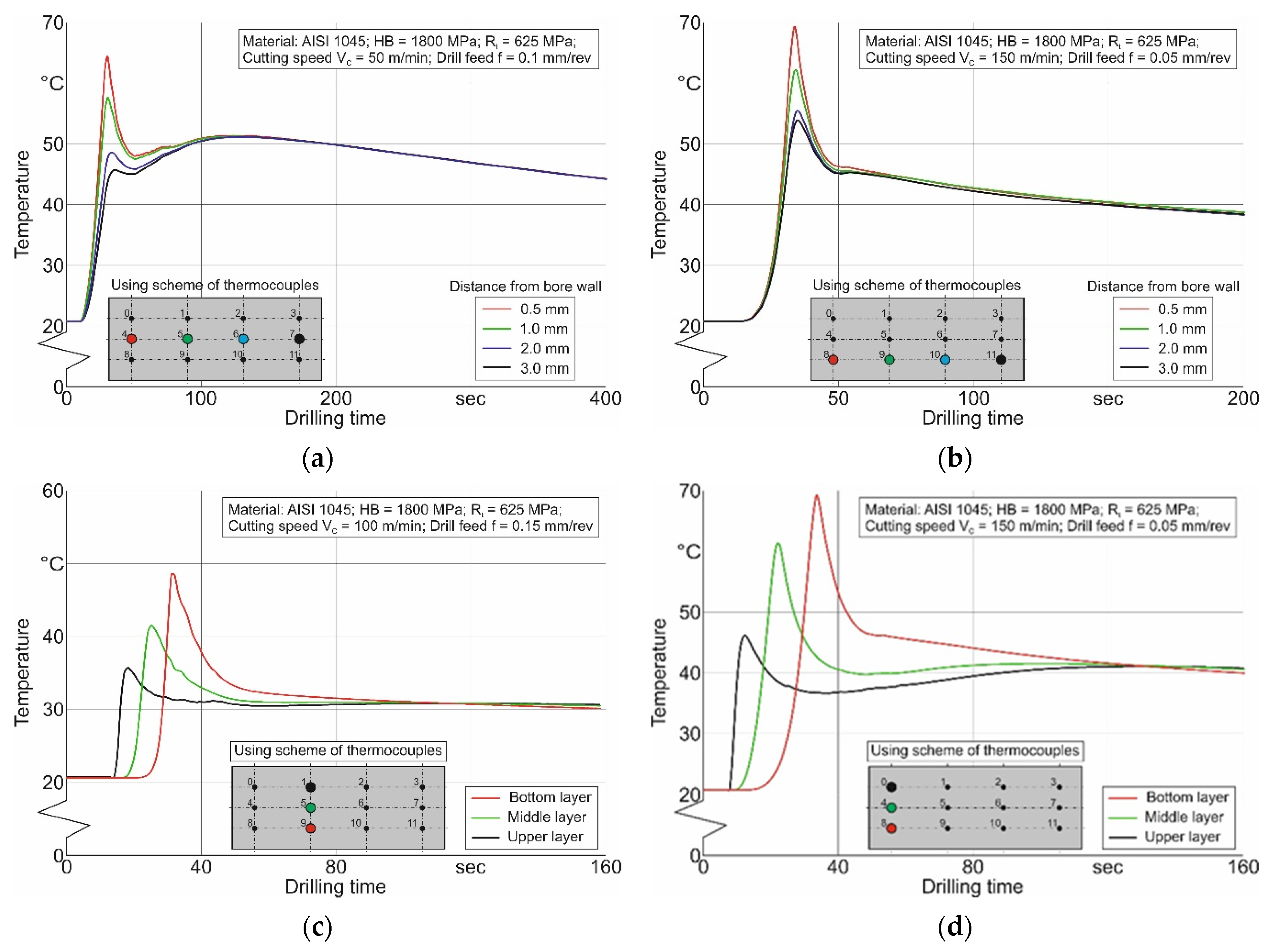

4.1. Orthogonal Cutting Process

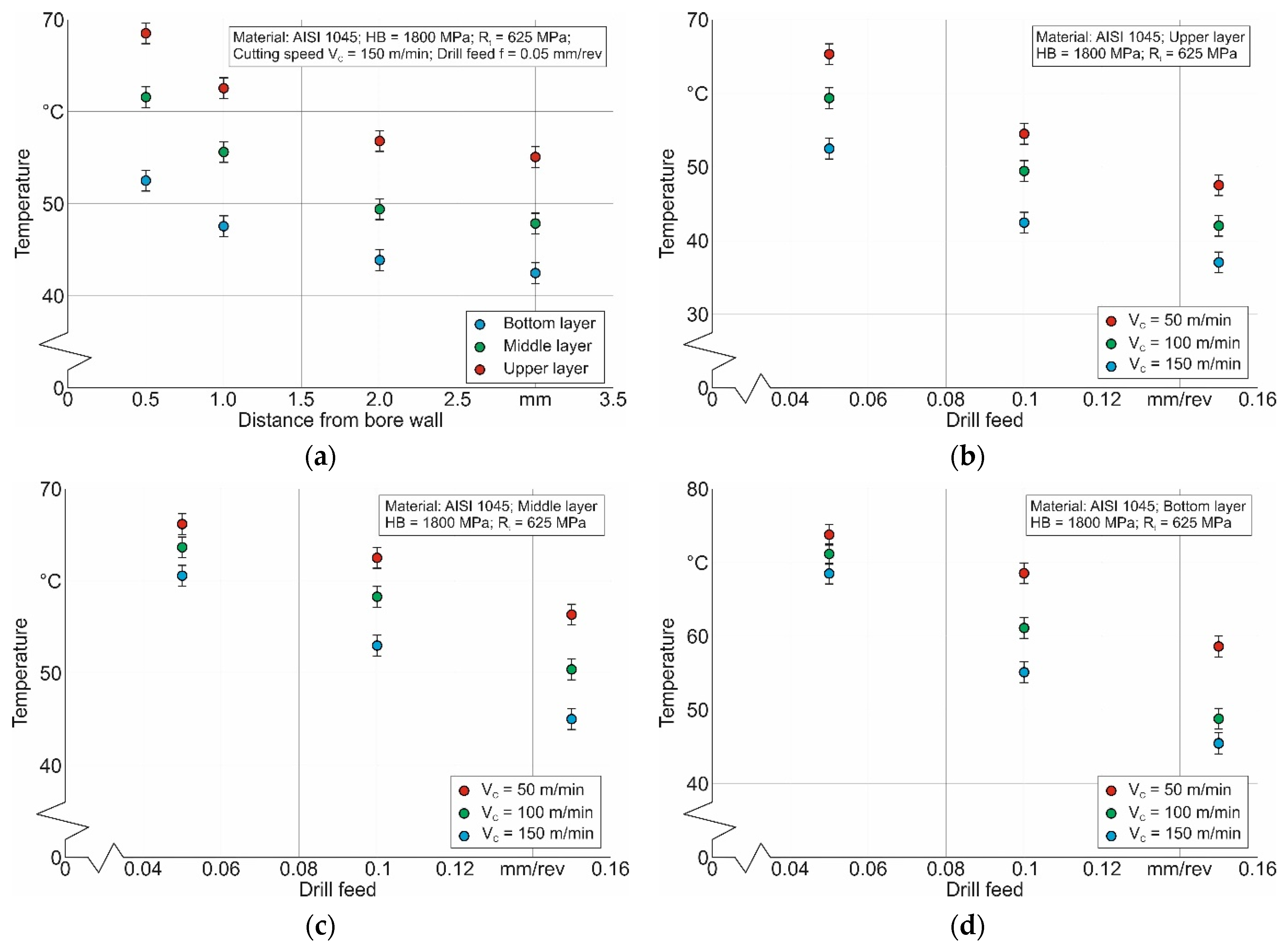

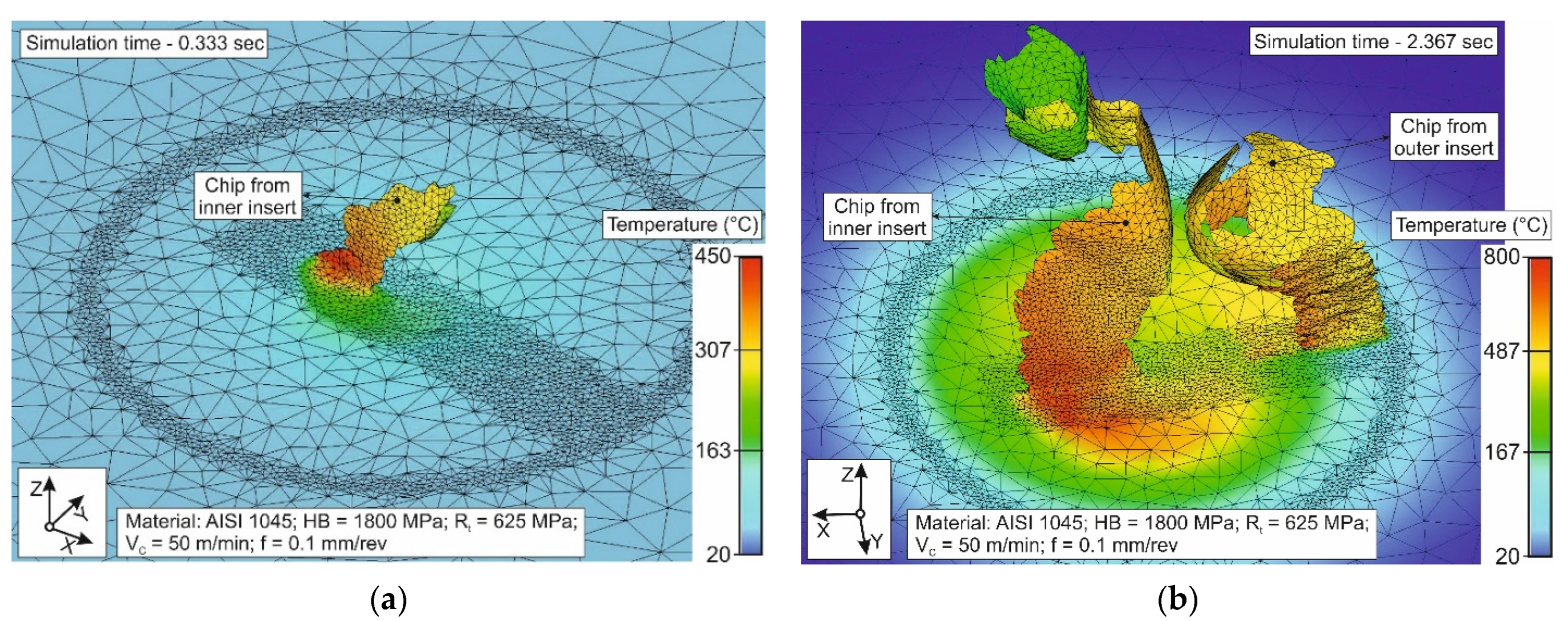

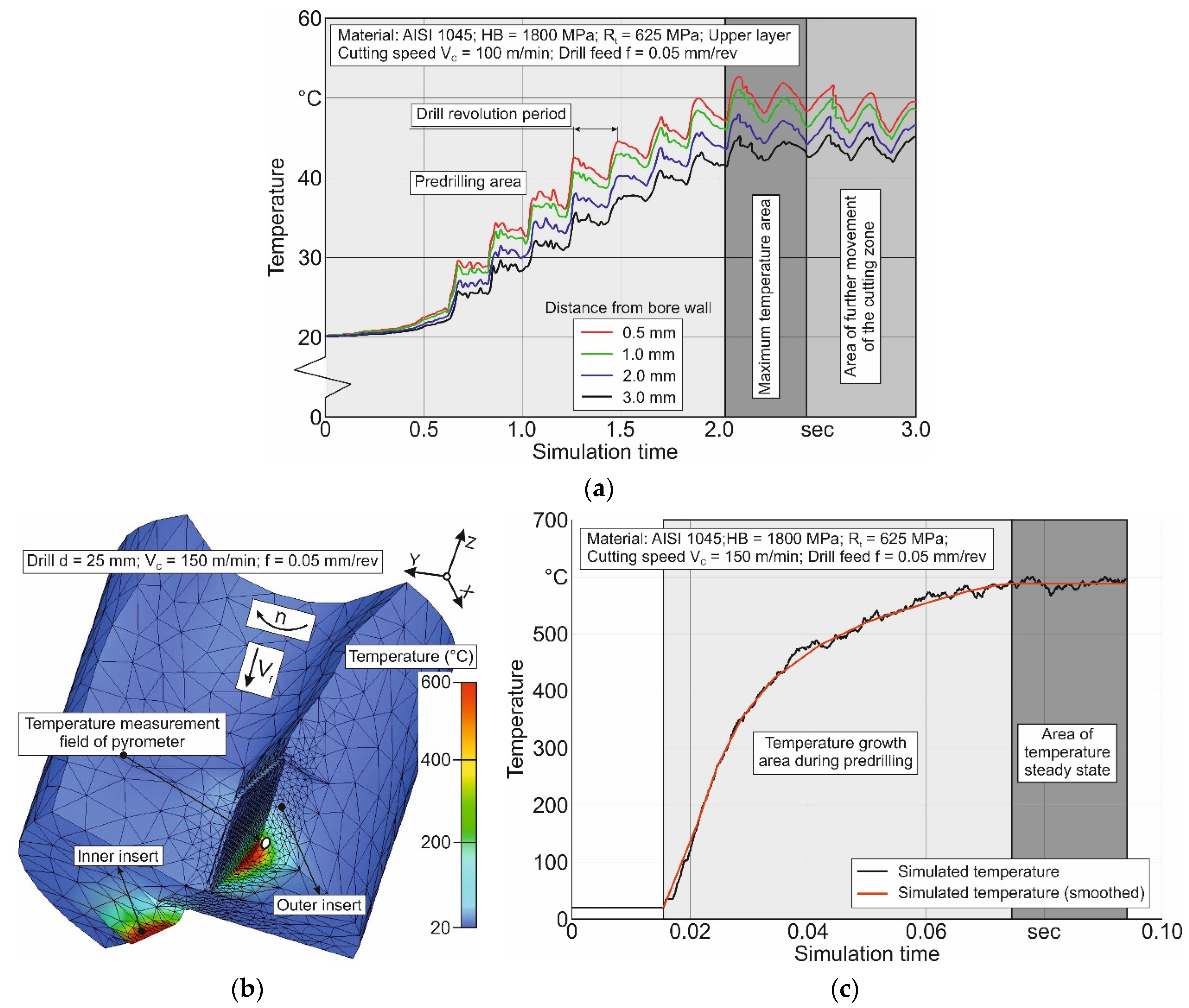

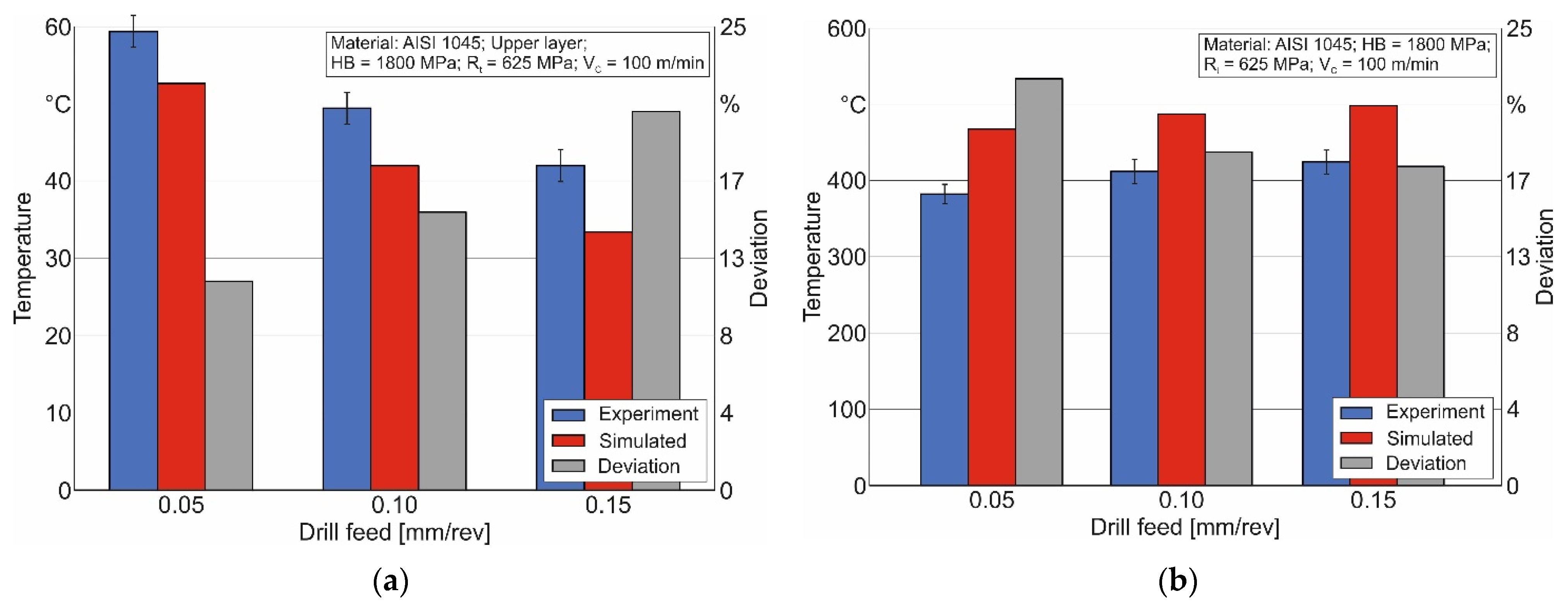

4.2. Short Hole Drilling

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- van Luttervelt, C.; Childs, T.; Jawahir, I.; Klocke, F.; Venuvinod, P.; Altintas, Y.; Armarego, E.; Dornfeld, D.; Grabec, I.; Leopold, J.; et al. Present Situation and Future Trends in Modelling of Machining Operations Progress Report of the CIRP Working Group ‘Modelling of Machining Operations’. CIRP Ann. 1998, 47, 587–626. [Google Scholar] [CrossRef]

- Arrazola, P.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I. Recent advances in modelling of metal machining processes. CIRP Ann. Manuf. Technol. 2013, 62, 695–718. [Google Scholar] [CrossRef]

- Mourtzis, D.; Doukas, M.; Bernidaki, D. Simulation in Manufacturing: Review and Challenges. Procedia CIRP 2014, 25, 213–229. [Google Scholar] [CrossRef]

- Melkote, S.; Liang, S.Y.; Ozel, T.; Jawahir, I.S.; Stephenson, D.A.; Wang, B. A Review of Advances in Modeling of Conventional Machining Processes: From Merchant to the Present. ASME J. Manuf. Sci. Eng. 2022, 144, 110801. [Google Scholar] [CrossRef]

- Ulutan, D.; Lazoglu, I.; Dinc, C. Three-dimensional temperature predictions in machining processes using finite difference method. J. Am. Acad. Dermatol. 2009, 209, 1111–1121. [Google Scholar] [CrossRef]

- Davim, J.P. Drilling Technology: Fundamentals and Recent Advances; De Gruyter Oldenbourg: Boston, MA, USA, 2018; 205p, ISBN 978-3110478631. [Google Scholar]

- Isbilir, O.; Ghassemieh, E. Finite Element Analysis of Drilling of Titanium Alloy. Procedia Eng. 2011, 10, 1877–1882. [Google Scholar] [CrossRef]

- Babichev, D.; Storchak, M. Synthesis of cylindrical gears with optimum rolling fatigue strength. Prod. Eng. 2015, 9, 87–97. [Google Scholar] [CrossRef]

- Davim, J.P. Machining of Complex Sculptured Surfaces; Springer: London, UK, 2012; 258p. [Google Scholar] [CrossRef]

- Patel, P.; Intwala, A.; Patel, D.; Gandhi, D.; Patel, N.; Patel, M. A Review Article on Effect of Cutting Parameter on Drilling Operation for Perpendicularity. J. Mech. Civ. Eng. 2014, 11, 11–18. [Google Scholar] [CrossRef]

- Risse, K. Einflüsse von Werkzeugdurchmesser und Schneidkantenverrundung beim Bohren mit Wendelbohrern in Stahl. Ph.D. Dissertation, Rheinisch-Westfälischen Technischen Hochschule Aachen, Aachen, Germany, 2006; 137p. ISBN: 978-3-8322-5252-6. Available online: http://publications.rwth-aachen.de/record/61346/files/Risse_Kai.pdf (accessed on 24 May 2023).

- Andersson, T.; Svensson, D.; Lassila, A.A. 3D-Simulation of Heat Flow in Indexable Drilling. Key Eng. Mater. 2023, 955, 53–62. [Google Scholar] [CrossRef]

- Okada, M.; Asakawa, N.; Sentoku, E.; M’saoubi, R.; Ueda, T. Cutting performance of an indexable insert drill for difficult-to-cut materials under supplied oil mist. Int. J. Adv. Manuf. Technol. 2014, 72, 475–485. [Google Scholar] [CrossRef]

- Jiang, A.; Liu, Z.; Wang, S.; Wen, J.; Li, Y.; Zhao, J. Optimized design of indexable insert drill based on radial cutting force balance. Int. J. Adv. Manuf. Technol. 2023, 128, 2029–2041. [Google Scholar] [CrossRef]

- Usui, E.; Shirakashi, T. Mechanics of Metal Cutting–From “Description” to “Predictive” Theory’, on the Art of Cutting Metals–75 Years Later; Production Engineering Division (PED): Phoenix, AZ, USA; ASME: New York, NY, USA, 1982; Volume 7, pp. 13–25. [Google Scholar]

- Ma, L.; Marusich, T.D.; Usui, S.; Wadell, J.; Marusich, K.; Zamorano, L.; Elangovan, H. Validation of Finite Element Modeling of Drilling Processes with Solid Tooling in Metals. Adv. Mater. Res. 2011, 223, 182–190. [Google Scholar] [CrossRef]

- Rowe, W.; Jin, T. Temperatures in High Efficiency Deep Grinding (HEDG). CIRP Ann. 2001, 50, 205–208. [Google Scholar] [CrossRef]

- Storchak, M.; Stehle, T.; Möhring, H.-C. Numerical Modeling of Cutting Characteristics during Short Hole Drilling: Modeling of Kinetic Characteristics. J. Manuf. Mater. Process. 2023, 7, 195. [Google Scholar] [CrossRef]

- Komanduri, R. Machining and Grinding: A Historical Review of the Classical Papers. Appl. Mech. Rev. 1993, 46, 80–132. [Google Scholar] [CrossRef]

- Tiffe, M.; Biermann, D. Modelling of Tool Engagement and FEM-Simulation of Chip Formation for Drilling Processes. Adv. Mater. Res. 2014, 1018, 183–188. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, J. Finite Element Modelling and Simulating of Drilling of Titanium Alloy. In Proceedings of the Second International Conference on Information and Computing Science, Manchester, UK, 21–22 May 2009; pp. 178–181. [Google Scholar] [CrossRef]

- Klocke, F.; Abouridouane, M.; Gerschwiler, K.; Lung, D. 3D Modelling and Simulation of Gun Drilling. Adv. Mater. Res. 2011, 223, 12–19. [Google Scholar] [CrossRef]

- Gyliene, V.; Ostasevicius, V.; Ubartas, M. Drilling Process using SPH. In Proceedings of the 9th European LS-Dyna Conference, Manchester, UK, 2–4 June 2013; 6p. Available online: https://www.google.de/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjm4KGViKiDAxXThv0HHXH1BXIQFnoECBIQAQ&url=https%3A%2F%2Fwww.dynalook.com%2Fconferences%2F9th-european-ls-dyna-conference%2Fdrilling-process-modelling-using-sph&usg=AOvVaw2eXV705TLft3Dt5R-C1HW0&opi=89978449 (accessed on 2 June 2023).

- Tajdari, M.; Tai, B.L. Modeling of Brittle and Ductile Materials Drilling Using Smoothed-Particle Hydrodynamics. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, WV, USA, 27 June–1 July 2016. 7p. [Google Scholar] [CrossRef]

- Türkes, E.; Erdem, M.; Gok, K.; Gok, A. Development of a new model for determine of cutting parameters in metal drilling processes. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 169. [Google Scholar] [CrossRef]

- Marusich, T.D.; Usui, S.; Stephenson, D. A Finite element modeling of drilling processes with solid and indexable tooling in metals and stack-ups. In Proceedings of the Procedia 10th CIRP, International Workshop on Modeling of Machining Operations, Reggio Calabria, Italy, 27–28 August 2007; pp. 51–58. Available online: https://www.google.de/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwjppZKEiaiDAxV3gv0HHXq9C28QFnoECBYQAQ&url=https%3A%2F%2Fthirdwavesys.com%2Fwp-content%2Fuploads%2F2019%2F10%2FFEM_Drilling_SolidIndexable_Metals_StackUps.pdf&usg=AOvVaw3PAzfcHjeHNL_blyKuJXL2&opi=89978449 (accessed on 27 August 2023).

- Anbarasan, M.; Senthilkumar, N.; Tamizharasan, T. Modelling and Simulation of Conventional Drilling Process using Deform 3D. Int. J. Mech. Dyn. Anal. 2019, 5, 9–16. Available online: https://www.google.de/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwj0g6q4iaiDAxVE_bsIHfehB18QFnoECBEQAQ&url=https%3A%2F%2Fmechanical.journalspub.info%2Findex.php%3Fjournal%3DJMDA%26page%3Darticle%26op%3Dview%26path%255B%255D%3D990&usg=AOvVaw3j3vCYRsU-KSQ5U9KV-S2B&opi=89978449 (accessed on 15 March 2023).

- Gardner, J.D.; Dornfeld, D. Finite Element Modeling of Drilling Using DEFORM; UC Berkeley: Laboratory for Manufacturing and Sustainability: Berkeley, CA, USA, 2006; 8p, Available online: https://escholarship.org/uc/item/9xg0g32g (accessed on 1 June 2023).

- Boldyrev, I.S.; Topolov, D.Y. Twist Drilling FEM Simulation for Thrust Force and Torque Prediction. In Proceedings of the 6th International Conference on Industrial Engineering (ICIE 2020), Lecture Notes in Mechanical Engineering, Sochi, Russia, 18–22 May 2020; Radionov, A.A., Gasiyarov, V.R., Eds.; pp. 946–952. [Google Scholar] [CrossRef]

- Ucun, I. 3D finite element modelling of drilling process of Al7075-T6 alloy and experimental validation. J. Mech. Sci. Technol. 2016, 30, 1843–1850. [Google Scholar] [CrossRef]

- Parida, A.K. Simulation and experimental investigation of drilling of Ti-6Al-4V alloy. Int. J. Light. Mater. Manuf. 2018, 1, 197–205. [Google Scholar] [CrossRef]

- Girinon, M.; Valiorgue, F.; Karaouni, H.; Feulvarch, É. 3D numerical simulation of drilling residual stresses. Comptes Rendus Mec. 2018, 346, 701–711. [Google Scholar] [CrossRef]

- Kheireddine, A.; Ammouri, A.; Lu, T.; Jawahir, I.; Hamade, R. An FEM Analysis with Experimental Validation to Study the Hardness of In-Process Cryogenically Cooled Drilled Holes in Mg AZ31b. Procedia CIRP 2013, 8, 588–593. [Google Scholar] [CrossRef][Green Version]

- Fandiño, D.; Guski, V.; Wegert, R.; Schmauder, S.; Möhring, H.-C. Numerical Investigations on Single Lip Deep Hole Drilling. Procedia CIRP 2021, 102, 132–137. [Google Scholar] [CrossRef]

- Nagaraj, M.; Ezilarasan, C.; John Presin Kumar, A.; Velayudham, A. A Review of Machining Characteristics in Mechanical Drilling of Super Alloys. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 579–588. Available online: https://www.tjprc.org/publishpapers/2-67-1538806991-64.IJMPERDFEB201864.pdf (accessed on 28 February 2023).

- Oezkaya, E.; Michel, S.; Biermann, D. Experimental and computational analysis of the coolant distribution considering the viscosity of the cutting fluid during machining with helical deep hole drills. Adv. Manuf. 2022, 10, 235–249. [Google Scholar] [CrossRef]

- Oezkaya, E.; Michel, S.; Biermann, D. Chip formation simulation and analysis of the mechanical loads during micro single-lip deep hole drilling of Inconel 718 with varying cooling lubricant pressure. Prod. Eng. 2021, 15, 299–309. [Google Scholar] [CrossRef]

- Abouridouane, M.; Klocke, F.; Lung, D.; Adams, O. A new 3D multiphase FE model for micro cutting ferritic–pearlitic carbon steels. CIRP Ann. 2012, 61, 71–74. [Google Scholar] [CrossRef]

- Kumar, A.; Bhardwaj, R.; Joshi, S.S. Thermal modeling of drilling process in titanium alloy (Ti-6Al-4V). Mach. Sci. Technol. 2020, 24, 341–365. [Google Scholar] [CrossRef]

- Bonnet, C.; Pottier, T.; Landon, Y. Development of a multi-scale and coupled cutting model for the drilling of Ti-6Al-4V. CIRP J. Manuf. Sci. Technol. 2021, 35, 526–540. [Google Scholar] [CrossRef]

- Bücker, M.; Oezkayaa, E.; Henslera, U.; Biermann, D. A New Flank Face Design Leading to an Improved Process Performance when Drilling High-Temperature Nickel-Base Alloys. In Proceedings of the 20th Machining Innovations Conference for Aerospace Industry 2020 (MIC 2020), Hannover, Germany, 2 December 2020; pp. 20–26. [Google Scholar] [CrossRef]

- Kolahdoozan, M.; Azimifar, F.; Rismani, Y.S. Finite Element Investigation and Optimization of Tool Wear in Drilling Process of Difficult-to-Cut Nickel-based Superalloy using Response Surface Methodology. Int. J. Adv. Des. Manuf. Technol. 2014, 7, 67–76. Available online: https://api.semanticscholar.org/CorpusID:59131374 (accessed on 13 August 2023).

- Li, R.; Shih, A.J. Spiral point drill temperature and stress in high-throughput drilling of titanium. Int. J. Mach. Tools Manuf. 2007, 47, 2005–2017. [Google Scholar] [CrossRef]

- Muhammad, R.; Ahmed, N.; Shariff, Y.M.; Silberschmidt, V.V. Finite-Element Analysis of Forces in Drilling of Ti-Alloys at Elevated Temperature. Solid State Phenom. 2012, 188, 250–255. [Google Scholar] [CrossRef]

- Patne, H.S.; Kumar, A.; Karagadde, S.; Joshi, S.S. Modeling of temperature distribution in drilling of titanium. Int. J. Mech. Sci. 2017, 133, 598–610. [Google Scholar] [CrossRef]

- Lazoglu, I.; Poulachon, G.; Ramirez, C.; Akmal, M.; Marcon, B.; Rossi, F.; Outeiro, J.C.; Krebs, M. Thermal analysis in Ti-6Al-4V drilling. CIRP Ann. 2017, 66, 105–108. [Google Scholar] [CrossRef]

- Kuzu, A.T.; Berenji, K.R.; Bakkal, M. Thermal and force modeling of CGI drilling. Int. J. Adv. Manuf. Technol. 2016, 82, 1649–1662. [Google Scholar] [CrossRef]

- Svensson, D.; Andersson, T.; Lassila, A.A. Coupled Eulerian–Lagrangian simulation and experimental investigation of indexable drilling. Int. J. Adv. Manuf. Technol. 2022, 121, 471–486. [Google Scholar] [CrossRef]

- Schmidt, A.O.; Roubik, J.R. Distribution of Heat Generated in Drilling. ASME J. Fluids Eng. 1949, 71, 245–248. [Google Scholar] [CrossRef]

- Leshock, C.E.; Shin, Y.C. Investigation on Cutting Temperature in Turning by a Tool-Work Thermocouple Technique. ASME J. Manuf. Sci. Eng. 1997, 119, 502–508. [Google Scholar] [CrossRef]

- Ueda, T.; Nozaki, R.; Hosokawa, A. Temperature Measurement of Cutting Edge in Drilling-Effect of Oil Mist. CIRP Ann. 2007, 56, 93–96. [Google Scholar] [CrossRef]

- Beno, T.; Hulling, U. Measurement of Cutting Edge Temperature in Drilling. Procedia CIRP 2012, 3, 531–536. [Google Scholar] [CrossRef]

- Heisel, U.; Krivoruchko, D.V.; Zaloha, W.A.; Storchak, M.; Stehle, T. Thermomechanical material models in the modeling of cutting processes. ZWF Zeitschrift fuer Wirtschaftlichen Fabrikbetrieb 2009, 104, 482–491. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain and high temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983; pp. 541–547. Available online: https://www.google.de/url?sa=t&rct=j&q=&esrc=s&source=web&cd=&cad=rja&uact=8&ved=2ahUKEwje5qKCiqiDAxVAgP0HHRYABz0QFnoECBEQAQ&url=https%3A%2F%2Fia800102.us.archive.org%2F9%2Fitems%2FAConstitutiveModelAndDataForMetals%2FA%2520constitutive%2520model%2520and%2520data%2520for%2520metals_text.pdf&usg=AOvVaw1OX7YT313yHJtCL1YUHCob&opi=89978449 (accessed on 27 August 2023).

- Uğur, L. A Numerical and Statistical Approach of Drilling Performance on Machining of ti–6al–4v alloy. Surf. Rev. Lett. 2022, 29, 2250168. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhu, Y.; Sun, X.; Gao, C.; Lin, Z.; He, B. 3D finite element simulation for tool temperature distribution and chip formation during drilling of Ti6Al4V alloy. Int. J. Adv. Manuf. Technol. 2022, 121, 5155–5169. [Google Scholar] [CrossRef]

- Wolf, T.; Fast, M.; Saelzer, J.; Brock, G.; Biermann, D.; Turek, S. Modeling and validation of a FEM chip formation simulation to expand the numerical work on discontinuous drilling of Inconel 718. Procedia CIRP 2023, 117, 32–37. [Google Scholar] [CrossRef]

- Kang, J.; Yao, E. Study on Burrs and Hole Quality of Drilling AA2024 Plates Based on FEM and Experimental Investigation. J. Appl. Sci. Eng. 2023, 26, 913–923. [Google Scholar] [CrossRef]

- Calamaz, M.; Coupard, D.; Girot, F. A new material model for 2D numerical simulation of serrated chip formation when machining titanium alloy Ti–6Al–4V. Int. J. Mach. Tools Manuf. 2008, 48, 275–288. [Google Scholar] [CrossRef]

- Cheng, W.; Outeiro, J.C. Modelling orthogonal cutting of Ti-6Al-4 V titanium alloy using a constitutive model considering the state of stress. Int. J. Adv. Manuf. Technol. 2022, 119, 4329–4347. [Google Scholar] [CrossRef]

- Jaspers, S.P.F.C.; Dautzenberg, J.H. Material behaviour in metal cutting: Strains, strain rates and temperatures in chip formation. J. Mater. Process. Technol. 2002, 121, 123–135. [Google Scholar] [CrossRef]

- Sima, M.; Özel, T. Modified material constitutive models for serrated chip formation simulations and experimental validation in machining of titanium alloy Ti–6Al–4V. Int. J. Mach. Tools Manuf. 2010, 50, 943–960. [Google Scholar] [CrossRef]

- Karpat, Y. Temperature dependent flow softening of titanium alloy Ti6Al4V: An investigation using finite element simulation of machining. J. Am. Acad. Dermatol. 2011, 211, 737–749. [Google Scholar] [CrossRef]

- Heisel, U.; Krivoruchko, D.V.; Zaloha, W.A.; Storchak, M.; Stehle, T. Thermomechanical exchange effects in machining. ZWF Zeitschrift fuer Wirtschaftlichen Fabrikbetrieb 2009, 104, 263–272. [Google Scholar] [CrossRef]

- Heisel, U.; Krivoruchko, D.V.; Zaloha, W.A.; Storchak, M.; Stehle, T. Breakage models for the modeling of cutting processes. ZWF Zeitschrift fuer Wirtschaftlichen Fabrikbetrieb 2009, 104, 330–339. [Google Scholar] [CrossRef]

- Yang, B.; Wang, H.; Fu, K.; Wang, C. Prediction of Cutting Force and Chip Formation from the True Stress–Strain Relation Using an Explicit FEM for Polymer Machining. Polymers 2022, 14, 189. [Google Scholar] [CrossRef] [PubMed]

- Fluhrer, J. Deform-User Manual Deform V12.0; SFTC: Columbus, OH, USA, 2019. [Google Scholar]

- Storchak, M.; Jiang, L.; Xu, Y.; Li, X. Finite element modeling for the cutting process of the titanium alloy Ti10V2Fe3Al. Prod. Eng. 2016, 10, 509–517. [Google Scholar] [CrossRef]

- Chen, G.; Ren, C.; Yang, X.; Jin, X.; Guo, T. Finite element simulation of high-speed machining of titanium alloy (Ti–6Al–4V) based on ductile failure model. Int. J. Adv. Manuf. Technol. 2011, 56, 1027–1038. [Google Scholar] [CrossRef]

- Gamboa, C.B.; Andersson, T.; Svensson, D.; Vilches, F.J.T.; Martín-Béjar, S.; Hurtado, L.S. Modeling of the fracture energy on the finite element simulation in Ti6Al4V alloy machining. Sci. Rep. 2021, 11, 18490. [Google Scholar] [CrossRef]

- Davies, M.; Ueda, T.; M’Saoubi, R.; Mullany, B.; Cooke, A. On the Measurement of Temperature in Material Removal Processes. CIRP Ann. 2007, 56, 581–604. [Google Scholar] [CrossRef]

- Storchak, M.; Kushner, V.; Möhring, H.-C.; Stehle, T. Refinement of temperature determination in cutting zones. J. Mech. Sci. Technol. 2021, 35, 3659–3673. [Google Scholar] [CrossRef]

- Grzesik, W. Modelling of heat generation and transfer in metal cutting: A short review. J. Mach. Eng. 2020, 20, 24–33. [Google Scholar] [CrossRef]

- Barzegar, Z.; Ozlu, E. Analytical prediction of cutting tool temperature distribution in orthogonal cutting including third deformation zone. J. Manuf. Process. 2021, 67, 325–344. [Google Scholar] [CrossRef]

- Osorio-Pinzon, J.C.; Abolghasem, S.; Casas-Rodriguez, J.P. Predicting the Johnson Cook constitutive model constants using temperature rise distribution in plane strain machining. Int. J. Adv. Manuf. Technol. 2019, 105, 279–294. [Google Scholar] [CrossRef]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Ebrahimi, S.M.; Araee, A.; Hadad, M. Investigation of the effects of constitutive law on numerical analysis of turning processes to predict the chip morphology, tool temperature, and cutting force. Int. J. Adv. Manuf. Technol. 2019, 105, 4245–4264. [Google Scholar] [CrossRef]

- Ribeiro-Carvalho, S.; Horovistiz, A.; Davim, J.P. Material model assessment in Ti6Al4V machining simulations with FEM. Proc. Inst. Mech. Eng. Part C: J. Mech. Eng. Sci. 2021, 235, 5500–5510. [Google Scholar] [CrossRef]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Published Lim.: Cambridge, UK, 2002; 244p. [Google Scholar]

- Craveiro, H.D.; Rodrigues, J.P.C.; Santiago, A.; Laím, L. Review of the high temperature mechanical and thermal properties of the steels used in cold formed steel structures—The case of the S280 Gd+Z steel. Thin-Walled Struct. 2015, 98, 154–168. [Google Scholar] [CrossRef]

- Fang, H.; Wong, M.B.; Bai, Y. Use of kinetic model for thermal properties of steel at high temperatures. Aust. J. Civ. Eng. 2015, 13, 40–47. [Google Scholar] [CrossRef]

- Franssen, J.M.; Real, P.V. Fire Design of Steel Structures, 2nd ed.; Wiley Ernst & Sohn: Berlin, Germany, 2015; 450p, ISBN 978-92-9147-124-9. [Google Scholar]

- Salame, C.; Malakizadi, A. An enhanced semi-analytical estimation of tool-chip interface temperature in metal cutting. J. Manuf. Process. 2023, 105, 407–430. [Google Scholar] [CrossRef]

- Gardner, L.; Bu, Y.; Francis, P.; Baddoo, N.; Cashell, K.; McCann, F. Elevated temperature material properties of stainless steel reinforcing bar. Constr. Build. Mater. 2016, 114, 977–997. [Google Scholar] [CrossRef]

- Fan, S.; Jia, L.; Lyu, X.; Sun, W.; Chen, M.; Zheng, J. Experimental investigation of austenitic stainless steel material at elevated temperatures. Constr. Build. Mater. 2017, 155, 267–285. [Google Scholar] [CrossRef]

- Díaz-Álvarez, J.; Tapetado, A.; Vázquez, C.; Miguélez, H. Temperature Measurement and Numerical Prediction in Machining Inconel 718. Sensors 2017, 17, 1531. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Liang, S. Cutting forces modeling considering the effect of tool thermal property—Application to CBN hard turning. Int. J. Mach. Tools Manuf. 2003, 43, 307–315. [Google Scholar] [CrossRef]

- Attanasio, A.; Umbrello, D. Abrasive and diffusive tool wear FEM simulation. Int. J. Mater. Form. 2009, 2, 543–546. [Google Scholar] [CrossRef]

- Storchak, M.; Drewle, K.; Menze, C.; Stehle, T.; Möhring, H.-C. Determination of the Tool–Chip Contact Length for the Cutting Processes. Materials 2022, 15, 3264. [Google Scholar] [CrossRef] [PubMed]

- Storchak, M.; Stehle, T.; Möhring, H.-C. Determination of thermal material properties for the numerical simulation of cutting processes. Int. J. Adv. Manuf. Technol. 2022, 118, 1941–1956. [Google Scholar] [CrossRef]

- Tsekhanov, J.; Storchak, M. Development of analytical model for orthogonal cutting. Prod. Eng. 2015, 9, 247–255. [Google Scholar] [CrossRef]

- Kushner, V.; Storchak, M. Determining mechanical characteristics of material resistance to deformation in machining. Prod. Eng. 2014, 8, 679–688. [Google Scholar] [CrossRef]

- Zorev, N.N. Metal Cutting Mechanics; Pergamon Press, GmbH: Frankfurt am Main, Germany, 1966; 526p, ISBN 978-0080107233. [Google Scholar]

- Oxley, P.L.B.; Shaw, M.C. Mechanics of Machining. An Analytical Approach to Assessing Machinability; Ellis Horwood: Chichester, UK, 1989; 242p. [Google Scholar] [CrossRef]

- Kushner, V.; Storchak, M. Determination of Material Resistance Characteristics in Cutting. Procedia CIRP 2017, 58, 293–298. [Google Scholar] [CrossRef]

- Heisel, U.; Storchak, M.; Krivoruchko, D. Thermal effects in orthogonal cutting. Prod. Eng. 2013, 7, 203–211. [Google Scholar] [CrossRef]

- Szwajka, K.; Zielińska-Szwajka, J.; Trzepiecinski, T. Experimental Study on Drilling MDF with Tools Coated with TiAlN and ZrN. Materials 2019, 12, 386. [Google Scholar] [CrossRef]

- Storchak, M.; Möhring, H.-C.; Stehle, T. Improving the friction model for the simulation of cutting processes. Tribol. Int. 2022, 167, 107376. [Google Scholar] [CrossRef]

| Insert | Constitutive Parameters | Friction Parameters in Cutting Zones | ||||||

|---|---|---|---|---|---|---|---|---|

| Secondary Zone | Tertiary Zone | |||||||

| A [MPa] | B [MPa] | n [-] | C [-] | m [-] | Plastic Area, fRFp [-] | Elastic Area, fRFe [-] | fCF [-] | |

| Outer | 532.7 | 654.2 | 0.2654 | 0.02135 | 0.85 | 0.653 | 0.324 | 0.562 |

| Inner | 475.9 | 592.6 | 0.2145 | 0.01812 | 0.92 | 0.724 | 0.392 | 0.637 |

| General | 518.5 | 632.4 | 0.2561 | 0.02048 | 0.87 | 0.678 | 0.347 | 0.587 |

| Insert | Thermal Properties of the Machined Material | |

|---|---|---|

| Mass Specific Heat Capacity Cm [J/(kg °C)] | Thermal Conductivity Coefficient λ [W/m °C] | |

| Outer | 685.4 | 19.8 |

| Inner | 635.7 | 17.6 |

| General | 663.2 | 18.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Storchak, M.; Stehle, T.; Möhring, H.-C. Numerical Modeling of Cutting Characteristics during Short Hole Drilling: Part 2—Modeling of Thermal Characteristics. J. Manuf. Mater. Process. 2024, 8, 13. https://doi.org/10.3390/jmmp8010013

Storchak M, Stehle T, Möhring H-C. Numerical Modeling of Cutting Characteristics during Short Hole Drilling: Part 2—Modeling of Thermal Characteristics. Journal of Manufacturing and Materials Processing. 2024; 8(1):13. https://doi.org/10.3390/jmmp8010013

Chicago/Turabian StyleStorchak, Michael, Thomas Stehle, and Hans-Christian Möhring. 2024. "Numerical Modeling of Cutting Characteristics during Short Hole Drilling: Part 2—Modeling of Thermal Characteristics" Journal of Manufacturing and Materials Processing 8, no. 1: 13. https://doi.org/10.3390/jmmp8010013

APA StyleStorchak, M., Stehle, T., & Möhring, H.-C. (2024). Numerical Modeling of Cutting Characteristics during Short Hole Drilling: Part 2—Modeling of Thermal Characteristics. Journal of Manufacturing and Materials Processing, 8(1), 13. https://doi.org/10.3390/jmmp8010013