Comprehensive Investigation of Hastelloy C-22 Powder Weld Overlay on SA 240 Type 316L Using Laser Beam Welding for Enhanced Performance

Abstract

:1. Introduction

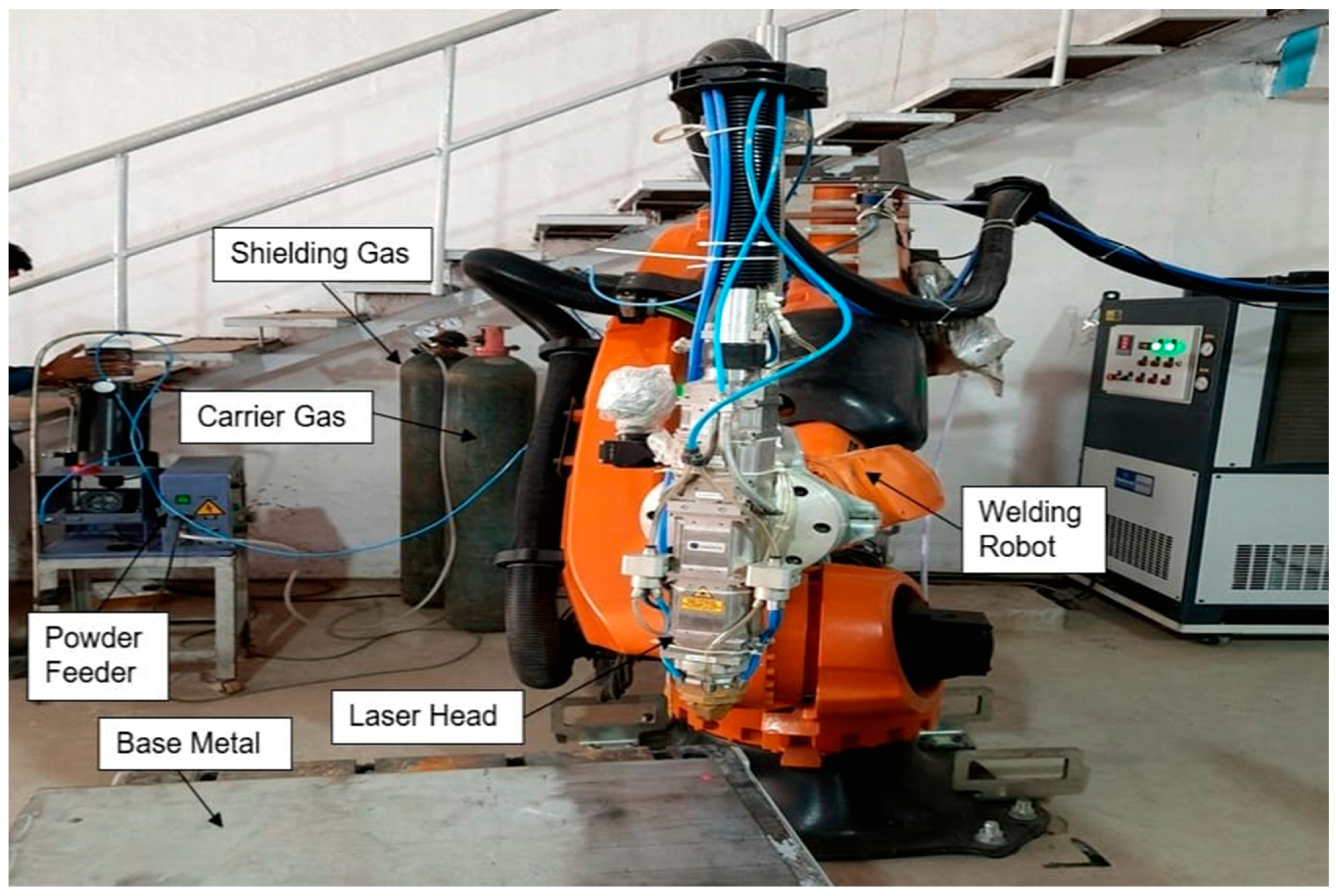

2. Experimental Process

2.1. Material

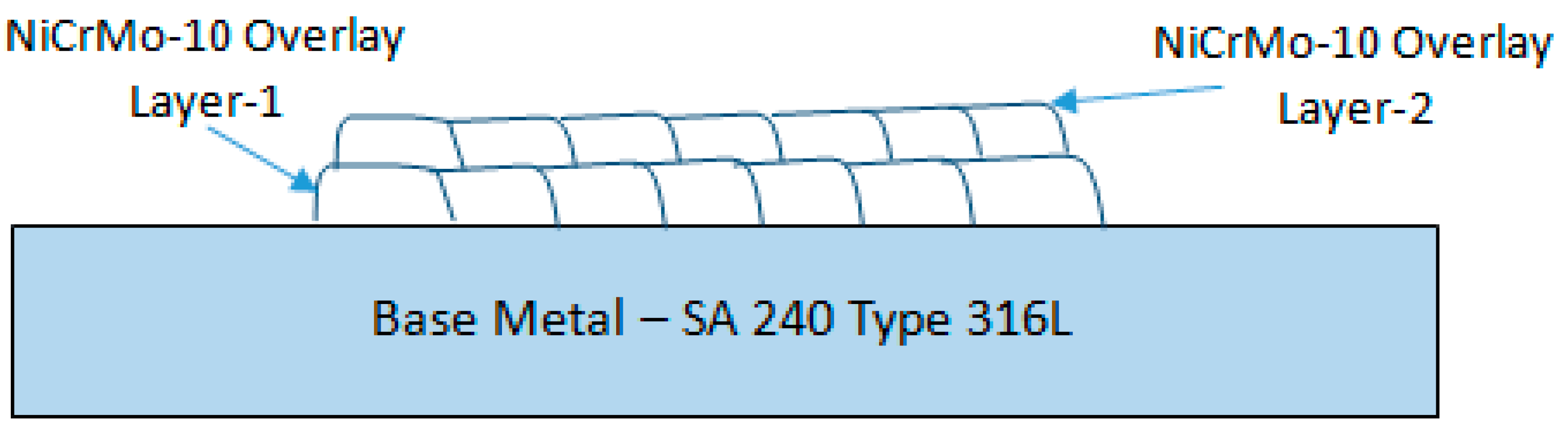

2.2. Method

2.2.1. Bend Test

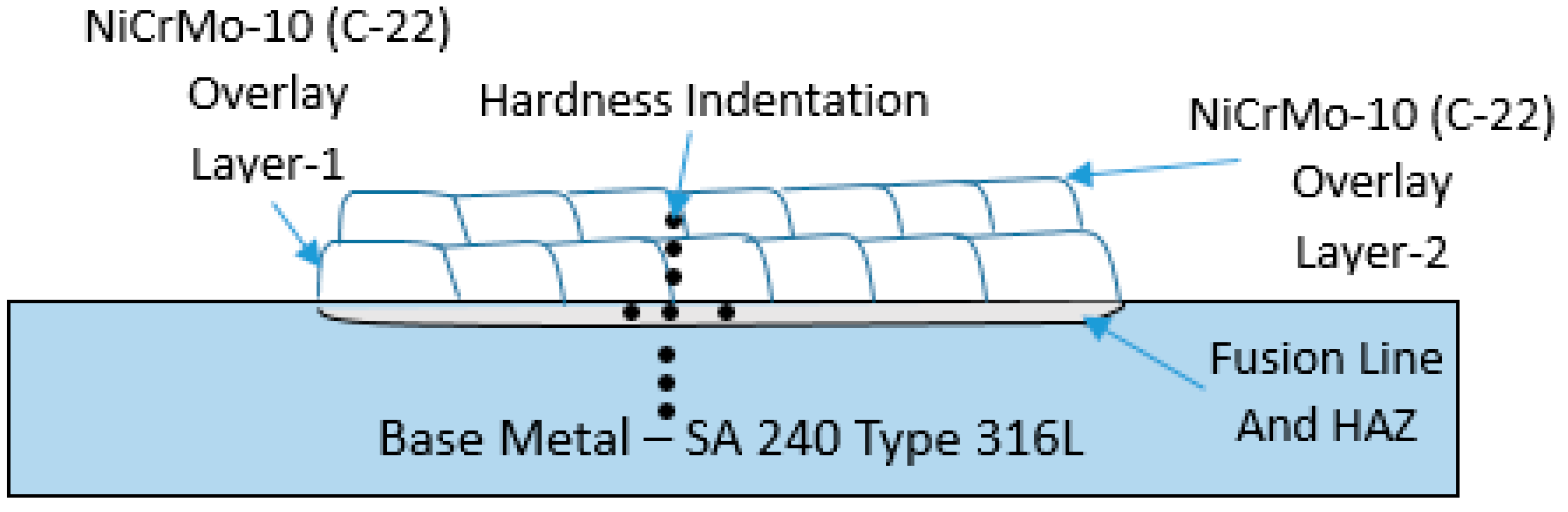

2.2.2. Hardness Test

2.2.3. Macro- and Microstructure Examination

2.2.4. Corrosion Resistance Using Potentiodynamic Polarization Technique

2.2.5. Chemical Composition Test

3. Results

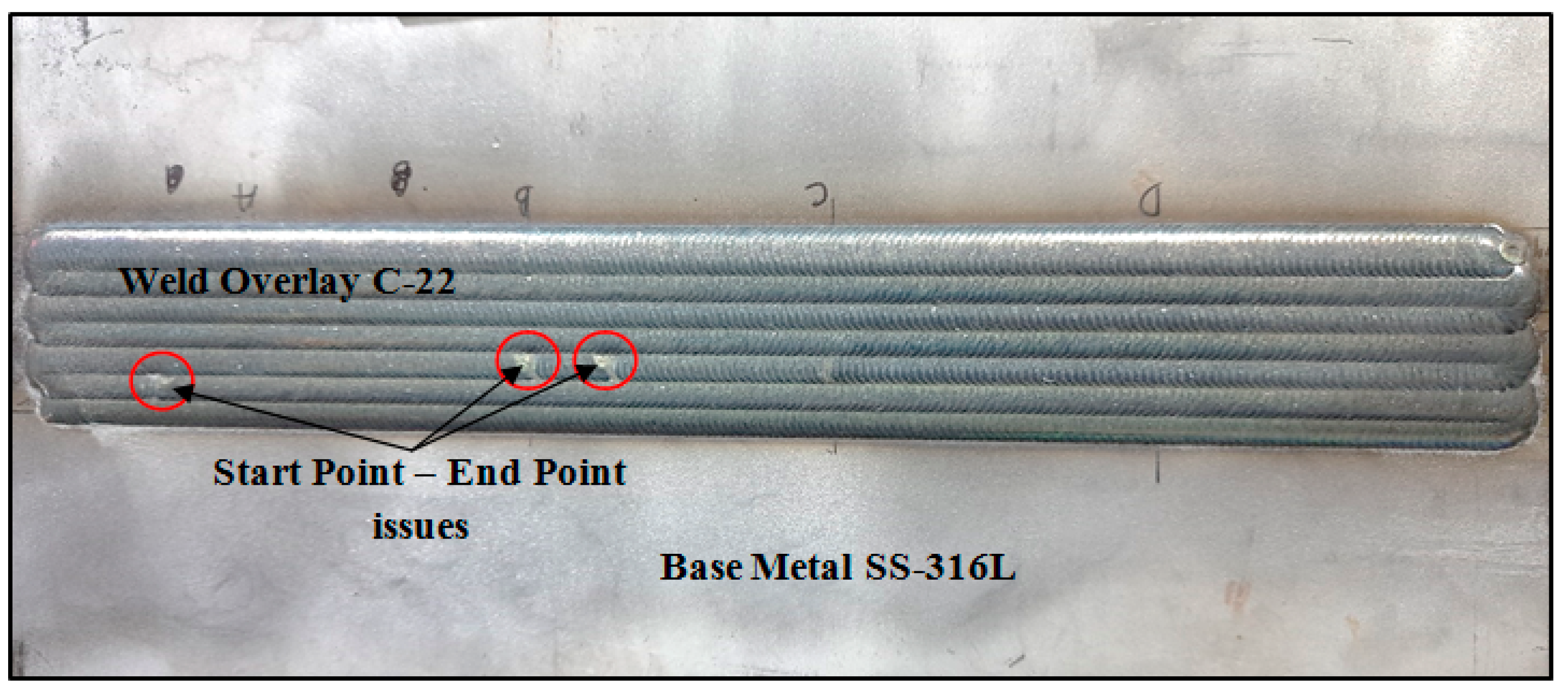

3.1. Visual Analysis

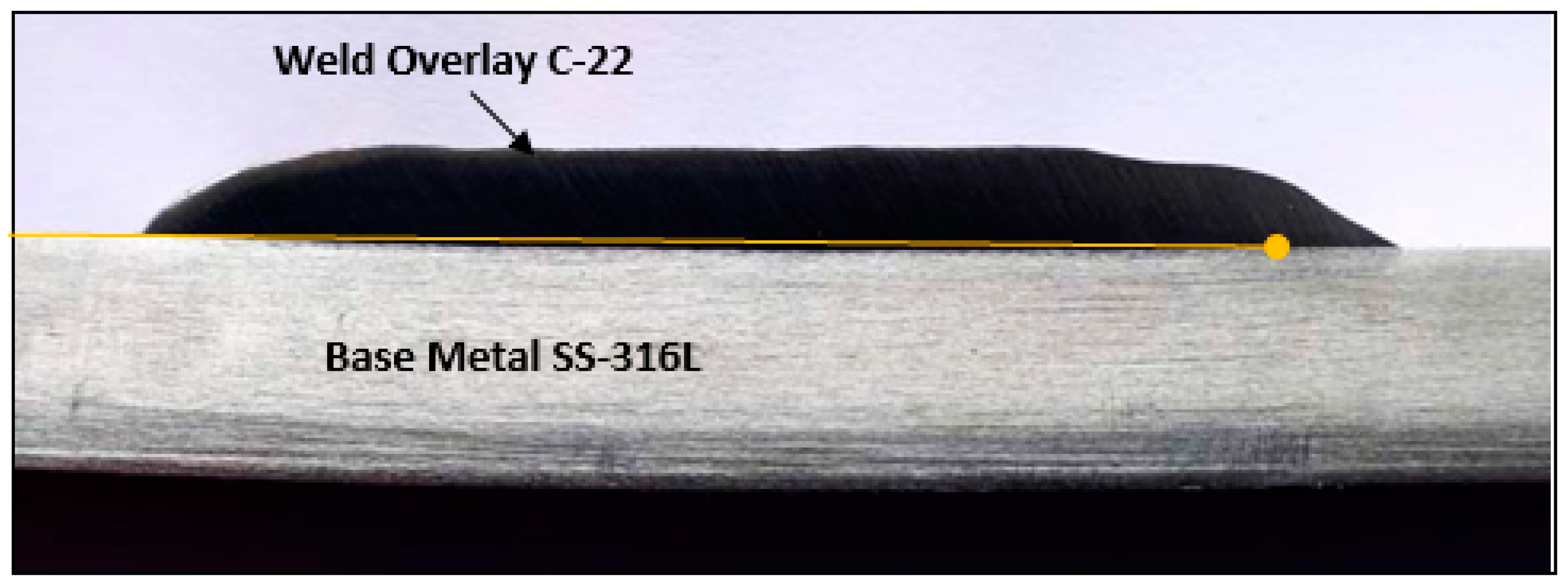

3.2. Macrostructure Examination

3.3. Bend Test Analysis

3.4. Hardness Testing

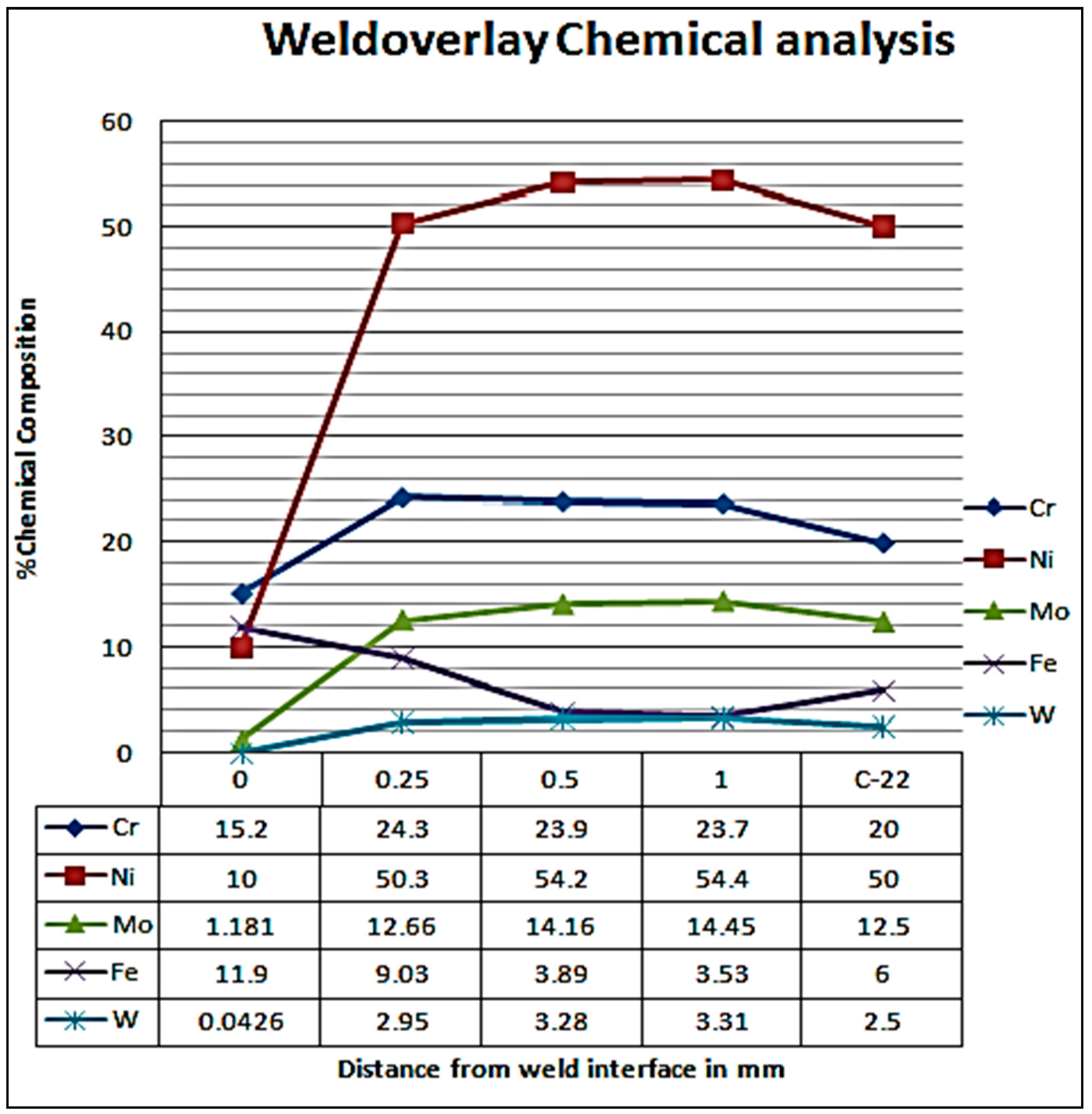

3.5. Chemical Composition

3.6. Microstructural Analysis

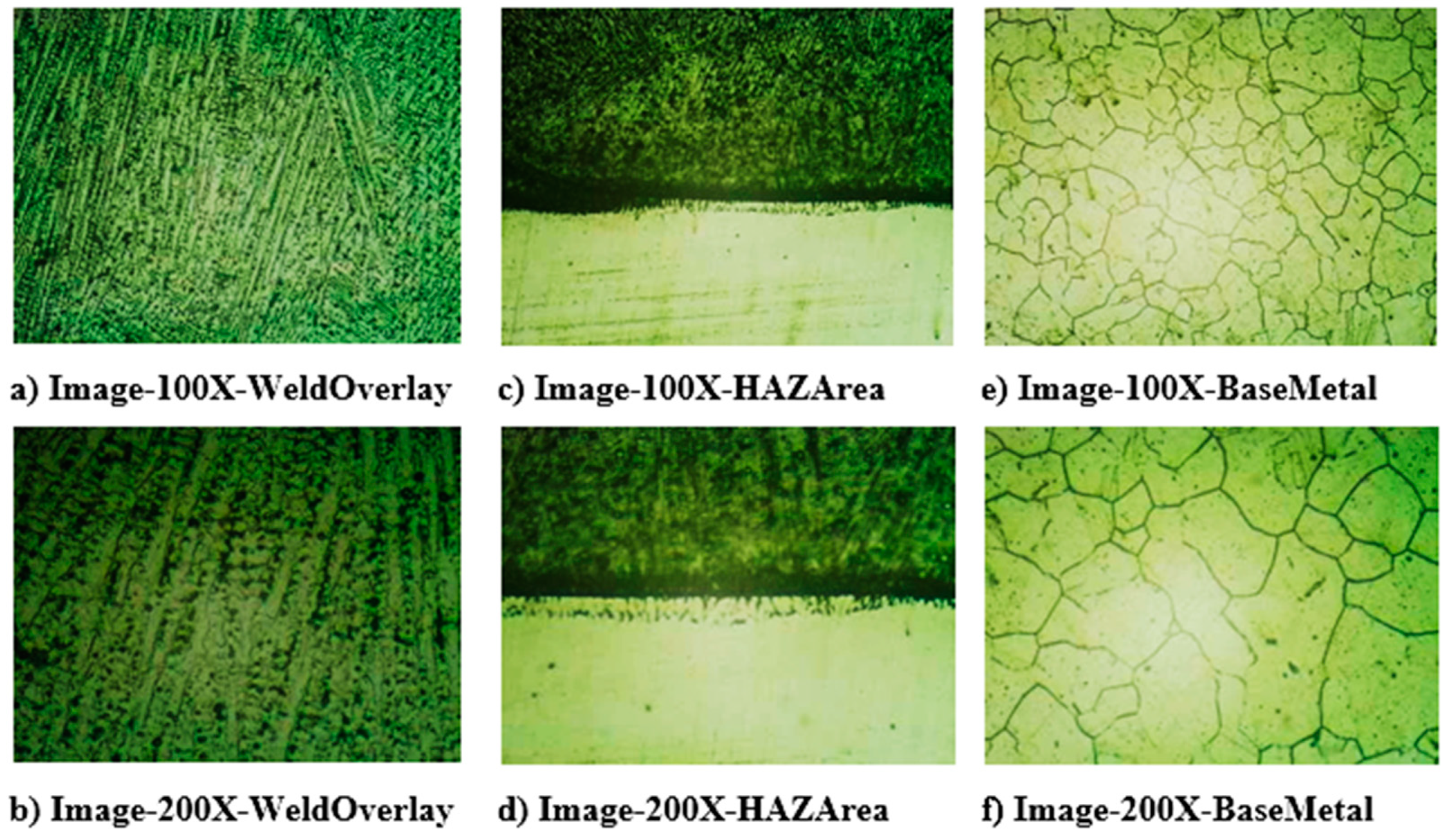

3.7. Corrosion Potential Test

4. Conclusions

- ➢

- The weld overlay of Hastelloy C-22 exhibited excellent weldability, as it displayed a clean surface without any welding flaws. However, some issues were observed at the starting and ending points of the automated welding process, which were attributed to setup problems in operational parameters. Overall, the surface quality of the weld overlay was deemed satisfactory.

- ➢

- The laser beam welding process achieved precise penetration of the Hastelloy weld overlay into the base metal, resulting in a defect-free weld overlay. This was confirmed through macro and visual examinations conducted on the weld overlay.

- ➢

- Bend test analysis confirmed the absence of cracks or holes in the welds, indicating the reliability and optimal parameters of the welding procedure. The integration between the cladding layer and the AISI 316L SS substrate was found to be satisfactory.

- ➢

- The hardness of the weld overlay increased compared to the base metal due to the development of a compact primary and secondary dendrite microstructure during welding. Hardness values in the heat-affected zone (HAZ) and at the interface were similar, indicating only a slight increase in hardness from the HAZ to the coating due to the small size of the HAZ.

- ➢

- Chemical composition analysis revealed that the weld overlay matched the desired composition of Hastelloy C-22 after a height of 0.5 mm from the base metal. At a height of 0.25 mm from the base metal, the composition of the weld overlay was similar to Hastelloy C-22, except for the Fe content in that region.

- ➢

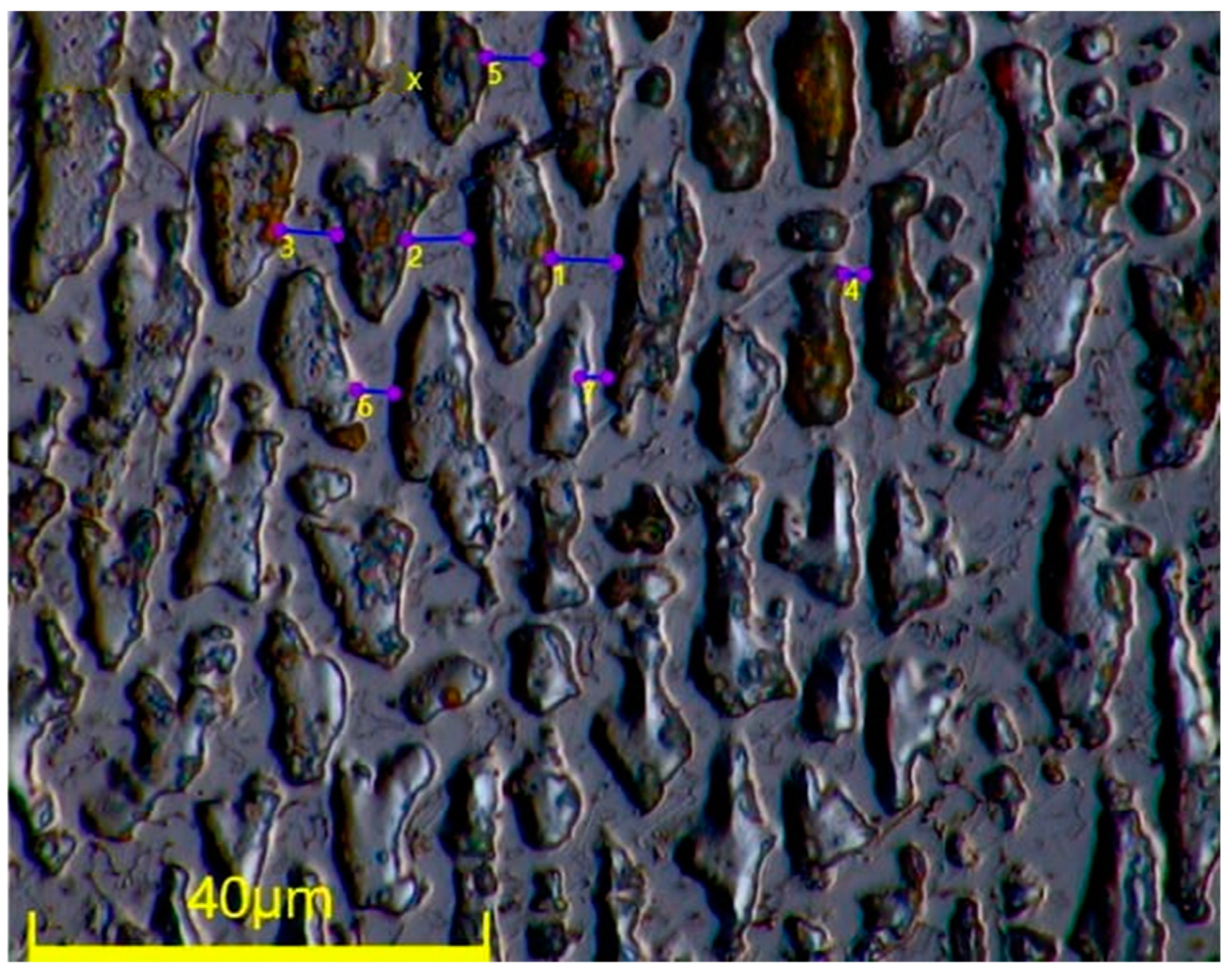

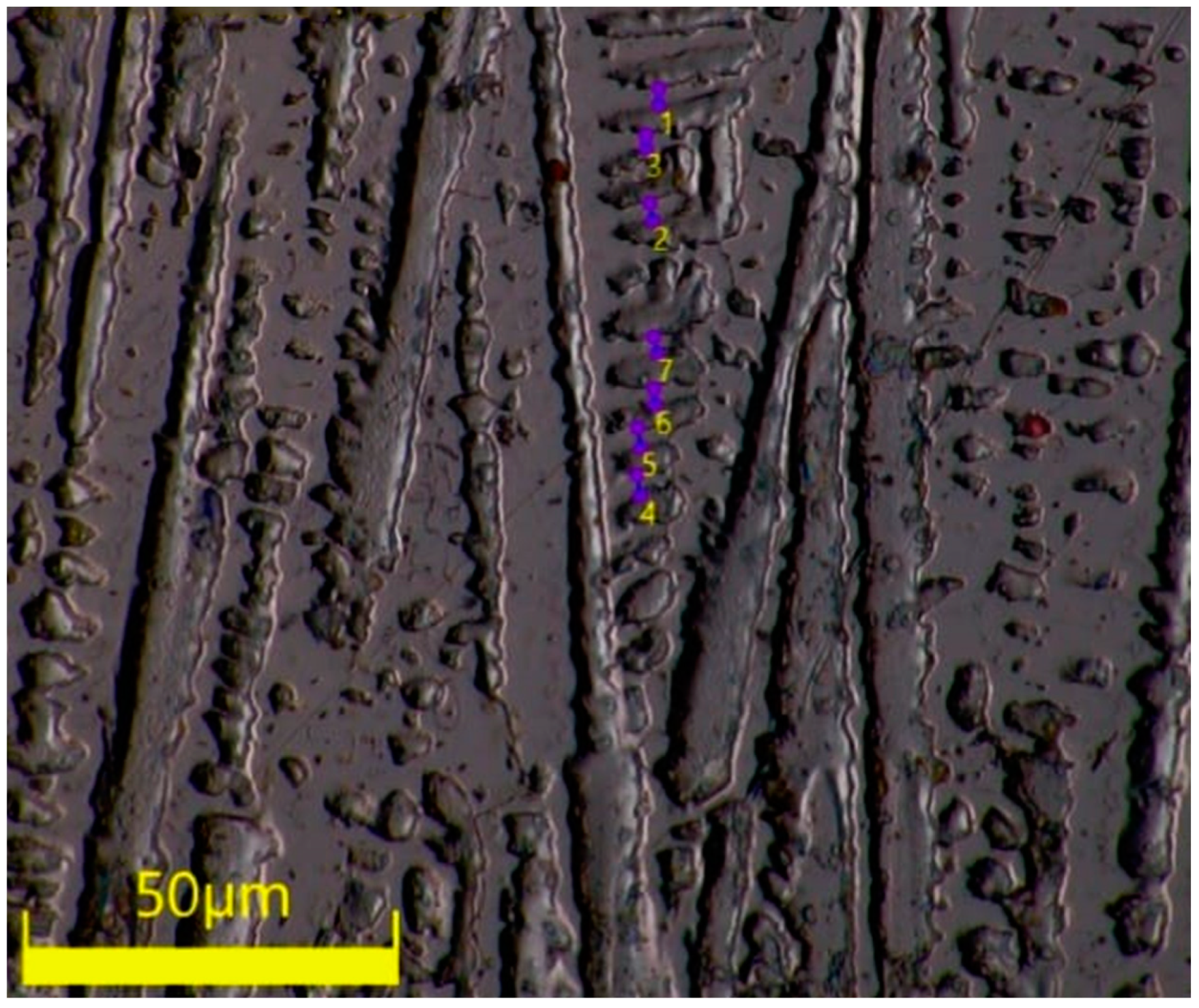

- Microstructure analysis showed a defect-free weld overlay and an unchanged microstructure of the base metal. The laser welding process resulted in a minimal heat-affected zone and a fine columnar interdendritic microstructure, with average primary and secondary arm spacing values of 3.981 µm and 2.289 µm, respectively.

- ➢

- Corrosion potential testing indicated that the average corrosion rate of the Hastelloy C-22 weld overlay on SS 316L achieved through laser beam welding was 1.20 mpy, owing to the proper and uniform distribution of the cladding phase in the weld overlay region.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mendes Da Mota, C.A.; Saldanha do Nascimento, A.; Neves Garcia, D.; Silva da Silva, D.A.; Ribeiro Teixeira, F.; Ferraresi, V.A. Nickel overlay deposited by MIG welding and cold wire MIG welding. Weld. Int. 2018, 32, 588–598. [Google Scholar] [CrossRef]

- Bray, J.W. Properties and Selection: Nonferrous Alloys and Special Purpose Materials; ASM Metals Handbook: Materials Park, OH, USA, 1990; Volume 92. [Google Scholar]

- Sharma, E.R.; Kumar, E.M.; Kamboj, D. Hastelloy C-276Weld overlay bySMAW process. Int. J. Eng. Res. Appl. 2017, 7, 86–91. [Google Scholar] [CrossRef]

- Lundin, C. Dissimilar metal welds-transition joints literature review. Weld. J. 1982, 61, 58–63. [Google Scholar]

- Scheid, A.; Oliveira, A.S.C.M.D. Analysis of PTA hardfacing with CoCrWC and CoCrMoSi alloys. Soldag. Inspeção 2013, 18, 322–328. [Google Scholar] [CrossRef]

- Gittos, M.; Gooch, T. Effect of iron dilution on corrosion resistance of Ni-Cr-Mo alloy cladding. Br. Corros. J. 1996, 31, 309–314. [Google Scholar] [CrossRef]

- Gatto, A.; Bassoli, E.; Fornari, M. Plasma Transferred Arc deposition of powdered high performances alloys: Process parameters optimisation as a function of alloy and geometrical configuration. Surf. Coat. Technol. 2004, 187, 265–271. [Google Scholar] [CrossRef]

- da Silva, M.M.; Batista, V.R.; Maciel, T.M.; dos Santos, M.A.; Brasileiro, T.L. Optimization of submerged arc welding process parameters for overlay welding. Weld. Int. 2018, 32, 122–129. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, B.; Liaw, P.K. Corrosion-resistant high-entropy alloys: A review. Metals 2017, 7, 43. [Google Scholar] [CrossRef]

- Chaudhari, R.; Bhatt, R.; Vaghasia, V.; Raja, B.D.; Patel, V.K.; Khanna, S.; Vora, J.; Patel, V.V. A parametric study and experimental investigations of microstructure and mechanical properties of multi-layered structure of metal core wire using wire arc additive manufacturing. J. Adv. Join. Process. 2023, 8, 100160. [Google Scholar] [CrossRef]

- Deshmukh, D.; Kalyankar, V. Deposition Characteristics of Multitrack Overlayby Plasma Transferred Arc Welding on SS316Lwith Co-Cr Based Alloy–Influence ofProcess Parameters. High Temp. Mater. Process. 2019, 38, 248–263. [Google Scholar] [CrossRef]

- Ferreira Filho, D.; Souza, D.; Gonçalves Júnior, J.L.; Reis, R.P.; Da Silva Junior, W.M.; Tavares, A.F. Influence of Substrate on the Tribological Behavior of Inconel 625 GMAW Overlays. Coatings 2023, 13, 1454. [Google Scholar] [CrossRef]

- Songya, T.; Saifan, A.; Pengqian, G.; Dawy, I.; Saleh, B. Development of an automatic welding system for the boiler tube walls weld overlay. Metals 2020, 10, 1241. [Google Scholar] [CrossRef]

- Ranjan, R.; Das, A.K. Protection from corrosion and wear by different weld cladding techniques: A review. Mater. Today Proc. 2022, 57, 1687–1693. [Google Scholar] [CrossRef]

- Sim, B.-M.; Hong, T.-S.; Hanim, M.A.-A.; Tchan, E.-J.N.; Talari, M.-K. The influence of post weld heat treatment precipitation on duplex stainless steels weld overlay towards pitting corrosion. Materials 2019, 12, 3285. [Google Scholar] [CrossRef]

- Chotěborský, R.; Navrátilová, M.; Hrabě, P. Effects of MIG process parameters on the geometry and dilution of the bead in the automatic surfacing. Res. Agric. Eng. 2011, 57, 56–62. [Google Scholar] [CrossRef]

- Palani, P.; Murugan, N. Optimization of weld bead geometry for stainless steel claddings deposited by FCAW. J. Mater. Process. Technol. 2007, 190, 291–299. [Google Scholar] [CrossRef]

- Sowrirajan, M.; Koshy Mathews, P.; Vijayan, S. Simultaneous multi-objective optimization of stainless steel clad layer on pressure vessels using genetic algorithm. J. Mech. Sci. Technol. 2018, 32, 2559–2568. [Google Scholar] [CrossRef]

- Kannan, T.; Yoganandh, J. Effect of process parameters on clad bead geometry and its shape relationships of stainless steel claddings deposited by GMAW. Int. J. Adv. Manuf. Technol. 2010, 47, 1083–1095. [Google Scholar] [CrossRef]

- Lin, C.-M.; Su, T.-L.; Wu, K.-Y. Effects of parameter optimization on microstructure and properties of GTAW clad welding on AISI 304L stainless steel using Inconel 52M. Int. J. Adv. Manuf. Technol. 2015, 79, 2057–2066. [Google Scholar] [CrossRef]

- Wang, Q.-Y.; Zhang, X.-S.; Zheng, H.-B.; Liu, T.-Y.; Dong, L.-J.; Zhang, J.; Xi, Y.-C.; Zeng, D.-Z.; Lin, Y.-H.; Luo, H. Intergranular corrosion mechanism of sub-grain in laser additive manufactured Hastelloy C22 induced by heat treatment. Appl. Surf. Sci. 2023, 608, 155140. [Google Scholar] [CrossRef]

- Prem Kumar, M.; Arivazhagan, N.; Chiranjeevi, C.; Raja Sekhar, Y.; Babu, N.; Manikandan, M. Effect of Molten Binary Salt on Inconel 600 and Hastelloy C-276 Superalloys for Thermal Energy Storage Systems: A Corrosion Study. J. Mater. Eng. Perform. 2023, 1–14. [Google Scholar] [CrossRef]

- Nowicki, R.; Świercz, R.; Oniszczuk-Świercz, D.; Rozenek, M. Experimental Investigation of Technological Indicators and Surface Roughness of Hastelloy C-22 after Electrical Discharge Machining Using POCO Graphite Electrodes. Materials 2022, 15, 5631. [Google Scholar] [CrossRef] [PubMed]

- Patel, D.; Jani, S.; Shah, D. Augmentation in depth of penetration of hastelloy C-22 by FATIG welding. Adv. Ind. Manuf. Eng. 2022, 4, 100081. [Google Scholar] [CrossRef]

- Zheng, C.; Liu, Z.; Liu, Q.; Li, Y.; Liu, C. Comparative investigation on corrosion behavior of laser cladding C22 coating, Hastelloy C22 alloy and Ti–6Al–4V alloy in simulated desulfurized flue gas condensates. J. Mater. Res. Technol. 2022, 18, 2194–2207. [Google Scholar] [CrossRef]

- Zhou, S.; Ma, G.; Dongjiang, W.; Chai, D.; Lei, M. Ultrasonic vibration assisted laser welding of nickel-based alloy and Austenite stainless steel. J. Manuf. Process. 2018, 31, 759–767. [Google Scholar] [CrossRef]

- Advaith, V.; Vaisikan, A.; Thirumalini, S.; Padmanaban, R.; Arivarasu, M.; Prabhu, T.R. Comparative studies on pulsed GTAW and AGTAW on dissimilar alloy C-22 and AISI 316L weldments. Mater. Today Proc. 2020, 27, 2886–2895. [Google Scholar] [CrossRef]

- Kumar, A.; Ramkumar, P.; Shukla, A.; Gupta, N. Prediction of Mechanical Properties in Rotational Moulding of LLDPE Using Machine Learning Model for the Given Oven Residence Time. In Proceedings of the Recent Advances in Mechanical Infrastructure: Proceedings of ICRAM 2020, Ahmedabad, India, 22–23 August 2020; pp. 3–12. [Google Scholar]

- Committee, A. Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications; ASTM International: Materials Park, OH, USA, 2023. [Google Scholar]

- Acherjee, B. Laser transmission welding of polymers–a review on welding parameters, quality attributes, process monitoring, and applications. J. Manuf. Process. 2021, 64, 421–443. [Google Scholar] [CrossRef]

- Yoon, B.H.; Ahn, Y.S.; Lee, C.H. The effect of dilution on HAZ liquation cracking in PTAW Ni-base superalloys overlay deposit. ISIJ Int. 2002, 42, 178–183. [Google Scholar] [CrossRef]

- Neyka, S.; Kusch, M.; Mayr, P. Progress in high performance hardfacing processes Tandem-Gas-Metal-Arc-Welding and Plasma-MIG Hybrid welding. In Proceedings of the 9th International Conference, Chicago, IL, USA, 11–14 August 2013. [Google Scholar]

- Chattopadhyay, P.; van der Mee, V.; Zhang, Z. Hybrid electroslag cladding (H-ESC): An innovation in high speed electroslag strip cladding. Weld. World 2019, 63, 663–672. [Google Scholar] [CrossRef]

- Deng, H.; Shi, H.; Tsuruoka, S. Influence of coating thickness and temperature on mechanical properties of steel deposited with Co-based alloy hardfacing coating. Surf. Coat. Technol. 2010, 204, 3927–3934. [Google Scholar] [CrossRef]

- Balasubramanian, V.; Varahamoorthy, R.; Ramachandran, C.; Muralidharan, C. Selection of welding process for hardfacing on carbon steels based on quantitative and qualitative factors. Int. J. Adv. Manuf. Technol. 2009, 40, 887–897. [Google Scholar] [CrossRef]

- Sudha, C.; Shankar, P.; Rao, R.S.; Thirumurugesan, R.; Vijayalakshmi, M.; Raj, B. Microchemical and microstructural studies in a PTA weld overlay of Ni–Cr–Si–B alloy on AISI 304L stainless steel. Surf. Coat. Technol. 2008, 202, 2103–2112. [Google Scholar] [CrossRef]

- Gontcharov, A.; Tian, Y.; Lowden, P.; Brochu, M. Mechanical properties and structure of laser beam and wide gap brazed joints produced using Mar M247–Amdry DF3 powders. J. Eng. Gas Turbines Power 2019, 141, 041031. [Google Scholar] [CrossRef]

- Prasath, N.E.; Selvabharathi, R. Influence of Plasma Transfer Arc Cladding of NiCrBFe filler powder on microstructure and tensile properties of Titanium Grade 2 and Ti 6Al-4V alloy dissimilar joint prepared by laser beam welding. Opt. Laser Technol. 2020, 128, 106206. [Google Scholar] [CrossRef]

- Vora, J.; Parmar, H.; Chaudhari, R.; Khanna, S.; Doshi, M.; Patel, V. Experimental investigations on mechanical properties of multi-layered structure fabricated by GMAW-based WAAM of SS316L. J. Mater. Res. Technol. 2022, 20, 2748–2757. [Google Scholar] [CrossRef]

- Chaudhari, R.; Parmar, H.; Vora, J.; Patel, V.K. Parametric study and investigations of bead geometries of GMAW-based wire–arc additive manufacturing of 316L stainless steels. Metals 2022, 12, 1232. [Google Scholar] [CrossRef]

- Vora, J.; Pandey, R.; Dodiya, P.; Patel, V.; Khanna, S.; Vaghasia, V.; Chaudhari, R. Fabrication of Multi-Walled Structure through Parametric Study of Bead Geometries of GMAW-Based WAAM Process of SS309L. Materials 2023, 16, 5147. [Google Scholar] [CrossRef]

- d’Oliveira, A.; Vilar, R.; Feder, C. High temperature behaviour of plasma transferred arc and laser Co-based alloy coatings. Appl. Surf. Sci. 2002, 201, 154–160. [Google Scholar] [CrossRef]

- Wang, Q.-Y.; Zhang, Y.-F.; Bai, S.-L.; Liu, Z.-D. Microstructures, mechanical properties and corrosion resistance of Hastelloy C22 coating produced by laser cladding. J. Alloys Compd. 2013, 553, 253–258. [Google Scholar] [CrossRef]

- Alvarães, C.P.; Madalena, F.C.A.; Souza, L.F.G.D.; Jorge, J.C.F.; Araújo, L.S.; Mendes, M.C. Performance of the INCONEL 625 alloy weld overlay obtained by FCAW process. Matéria 2019, 24. [Google Scholar] [CrossRef]

- Tahaei, A.; Vazquez, F.G.; Merlin, M.; Arizmendi-Morquecho, A.; Valdes, F.A.R.; Garagnani, G.L. Metallurgical characterization of a weld bead coating applied by the PTA process on the D2 tool steel. Soldag. Inspeção 2016, 21, 209–219. [Google Scholar] [CrossRef]

- Ahmad, M.; Akhter, J.; Akhtar, M.; Iqbal, M.; Ahmed, E.; Choudhry, M. Microstructure and hardness studies of the electron beam welded zone of Hastelloy C-276. J. Alloys Compd. 2005, 390, 88–93. [Google Scholar] [CrossRef]

- Xu, G.; Kutsuna, M.; Liu, Z.; Zhang, H. Characteristics of Ni-based coating layer formed by laser and plasma cladding processes. Mater. Sci. Eng. A 2006, 417, 63–72. [Google Scholar] [CrossRef]

- Antoszczyszyn, T.J.; Paes, R.M.G.; Oliveira, A.S.C.M.D.; Scheid, A. Impact of dilution on the microstructure and properties of Ni-based 625 alloy coatings. Soldag. Inspeção 2014, 19, 134–144. [Google Scholar] [CrossRef]

- Varghese, P.; Vetrivendan, E.; Dash, M.K.; Ningshen, S.; Kamaraj, M.; Mudali, U.K. Weld overlay coating of Inconel 617 M on type 316 L stainless steel by cold metal transfer process. Surf. Coat. Technol. 2019, 357, 1004–1013. [Google Scholar] [CrossRef]

- Toyserkani, E.; Khajepour, A.; Corbin, S.F. Laser Cladding; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Yaedu, A.; D’Oliveira, A. Cobalt based alloy PTA hardfacing on different substrate steels. Mater. Sci. Technol. 2005, 21, 459–466. [Google Scholar] [CrossRef]

- Miná, É.M.; Da Silva, Y.C.; Dille, J.; Silva, C.C. The effect of dilution on microsegregation in AWS ER NiCrMo-14 alloy welding claddings. Metall. Mater. Trans. A 2016, 47, 6138–6147. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | P | S | Cr | Mo | Ni | Fe | N | Co | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SA 240 Type 316L | 0.023 | 0.3 | 1.26 | 0.043 | 0.004 | 16.25 | 2.03 | 10.05 | Bal. | 0.038 | - | - |

| Hastelloy C-22 Powder | 0.007 | 0.1 | - | 0.01 | 0.01 | 23.5 | 14.84 | Bal. | 3.1 | 0.09 | 0.1 | 3.5 |

| Parameter | Layer-1 | Layer-2 |

|---|---|---|

| Power | 2.5 KW | 3.0 KW |

| Travel speed | 200 mm/min | 170 mm/min |

| Carrier gas flow | 6 LPM | 6 LPM |

| Shielding gas flow | 25 LPM | 25 LPM |

| Powder feed rate | 1.6 disc rpm | 1.6 disc rpm |

| Type of Weld | Weaving | Weaving |

| Carrier gas | Argon (99.99% purity) | Argon (99.99% purity) |

| Shielding gas | Argon (99.99% purity) | Argon (99.99% purity) |

| Welding position | 1 G (Flat) | 1 G (Flat) |

| Focus height | 25 mm | 25 mm |

| Laser spot size | 6 mm | 6 mm |

| No. of beads/layer | 7 | 7 |

| Sr. No | 1 | 2 | 3 | 4 | 5 | 6 | 7 | Average |

|---|---|---|---|---|---|---|---|---|

| Value (µm) | 5.711 | 5.289 | 5.026 | 1.809 | 4.454 | 3.212 | 2.365 | 3.981 |

| Sr. No | 1 | 2 | 3 | 4 | 5 | 6 | 7 | Average |

|---|---|---|---|---|---|---|---|---|

| Value (µm) | 2.087 | 2.358 | 1.731 | 2.739 | 2.745 | 2.086 | 2.278 | 2.289 |

| Parameter | Observation | ||

|---|---|---|---|

| Sample 1 | Sample 2 | Sample 3 | |

| Sample Size (cm) | 1 L × 1 W | 1 L × 1 W | 1 L × 1 W |

| Test Solution | Ferric Sulfate + Sulfuric Acid | Ferric Sulfate + Sulfuric Acid | Ferric Sulfate + Sulfuric Acid |

| Beta A (V/decade) | 217.7 × 10−3 | 335.0 × 10−3 | 277.2 × 10−3 |

| Beta C (V/decade) | 74.50 × 10−3 | 61.00 × 10−3 | 73.70 × 10−3 |

| Corrosion Current (Icorr) | 745.0 (nA) | 3.100 (µA) | 3.190 (µA) |

| Corrosion Potential (Ecorr) (mV) | 761.0 | 785.0 | 770.0 |

| Corrosion Rate (mpy) | 0.379 | 1.58 | 1.63 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehta, M.V.; Chaudhari, M.D.; Chaudhari, R.; Khanna, S.; Vora, J. Comprehensive Investigation of Hastelloy C-22 Powder Weld Overlay on SA 240 Type 316L Using Laser Beam Welding for Enhanced Performance. J. Manuf. Mater. Process. 2023, 7, 207. https://doi.org/10.3390/jmmp7060207

Mehta MV, Chaudhari MD, Chaudhari R, Khanna S, Vora J. Comprehensive Investigation of Hastelloy C-22 Powder Weld Overlay on SA 240 Type 316L Using Laser Beam Welding for Enhanced Performance. Journal of Manufacturing and Materials Processing. 2023; 7(6):207. https://doi.org/10.3390/jmmp7060207

Chicago/Turabian StyleMehta, Manish V., Mrunalkumar D. Chaudhari, Rakesh Chaudhari, Sakshum Khanna, and Jaykumar Vora. 2023. "Comprehensive Investigation of Hastelloy C-22 Powder Weld Overlay on SA 240 Type 316L Using Laser Beam Welding for Enhanced Performance" Journal of Manufacturing and Materials Processing 7, no. 6: 207. https://doi.org/10.3390/jmmp7060207

APA StyleMehta, M. V., Chaudhari, M. D., Chaudhari, R., Khanna, S., & Vora, J. (2023). Comprehensive Investigation of Hastelloy C-22 Powder Weld Overlay on SA 240 Type 316L Using Laser Beam Welding for Enhanced Performance. Journal of Manufacturing and Materials Processing, 7(6), 207. https://doi.org/10.3390/jmmp7060207