Enhancing the Microhardness of Coatings Produced by Cold Gas Dynamic Spraying through Multi-Reinforcement with Aluminum Powders Containing Fullerenes and Aluminum Nitride

Abstract

:1. Introduction

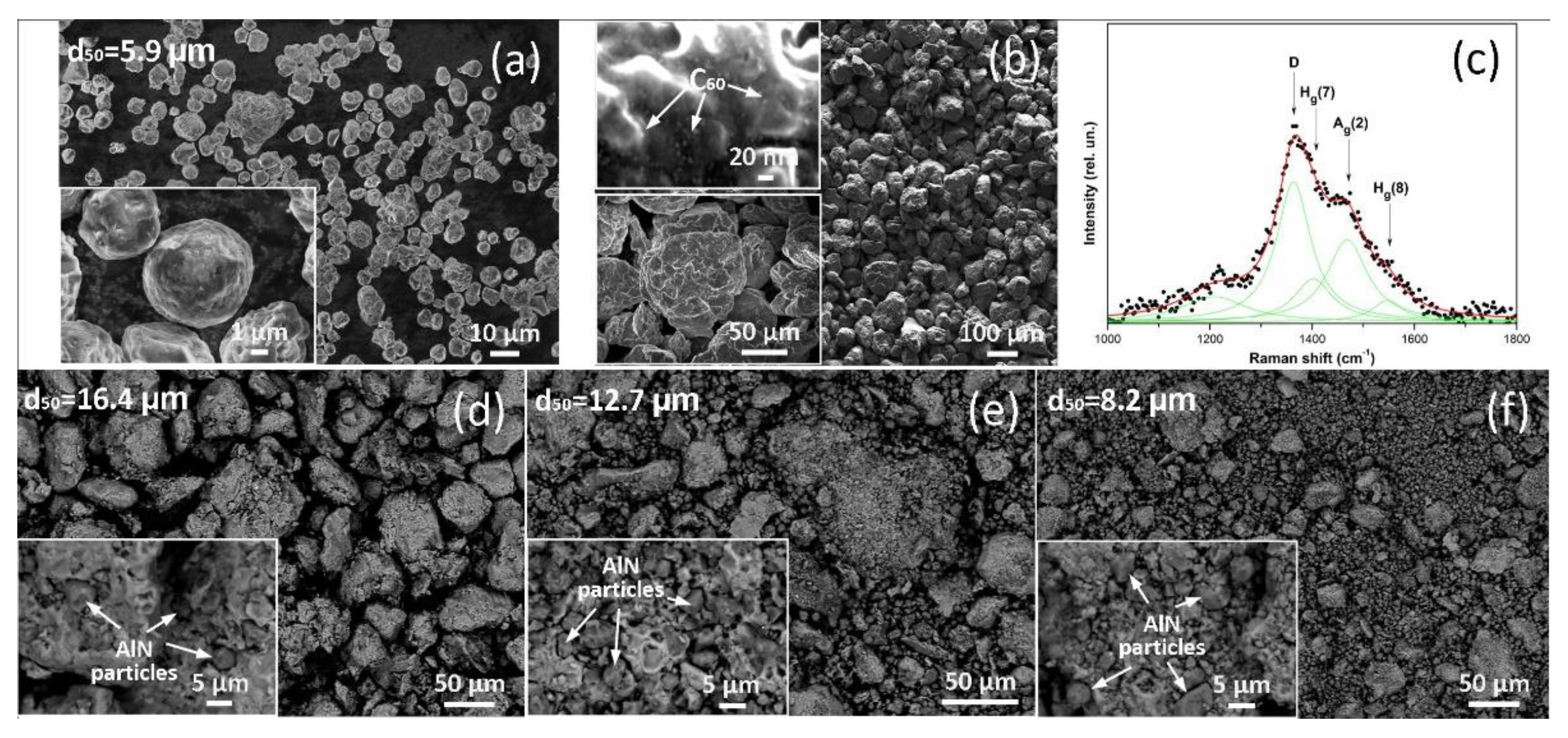

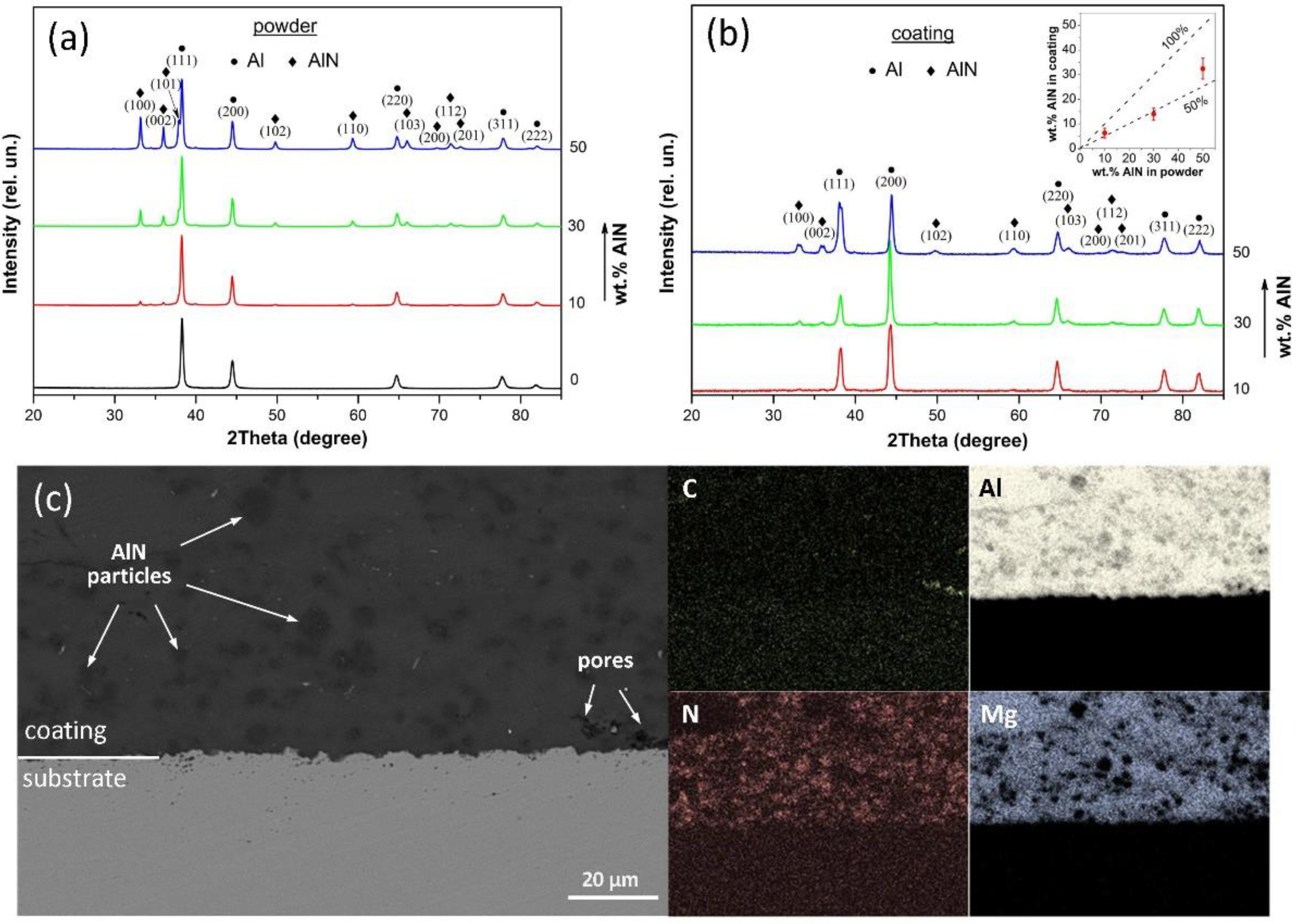

2. Materials and Methods

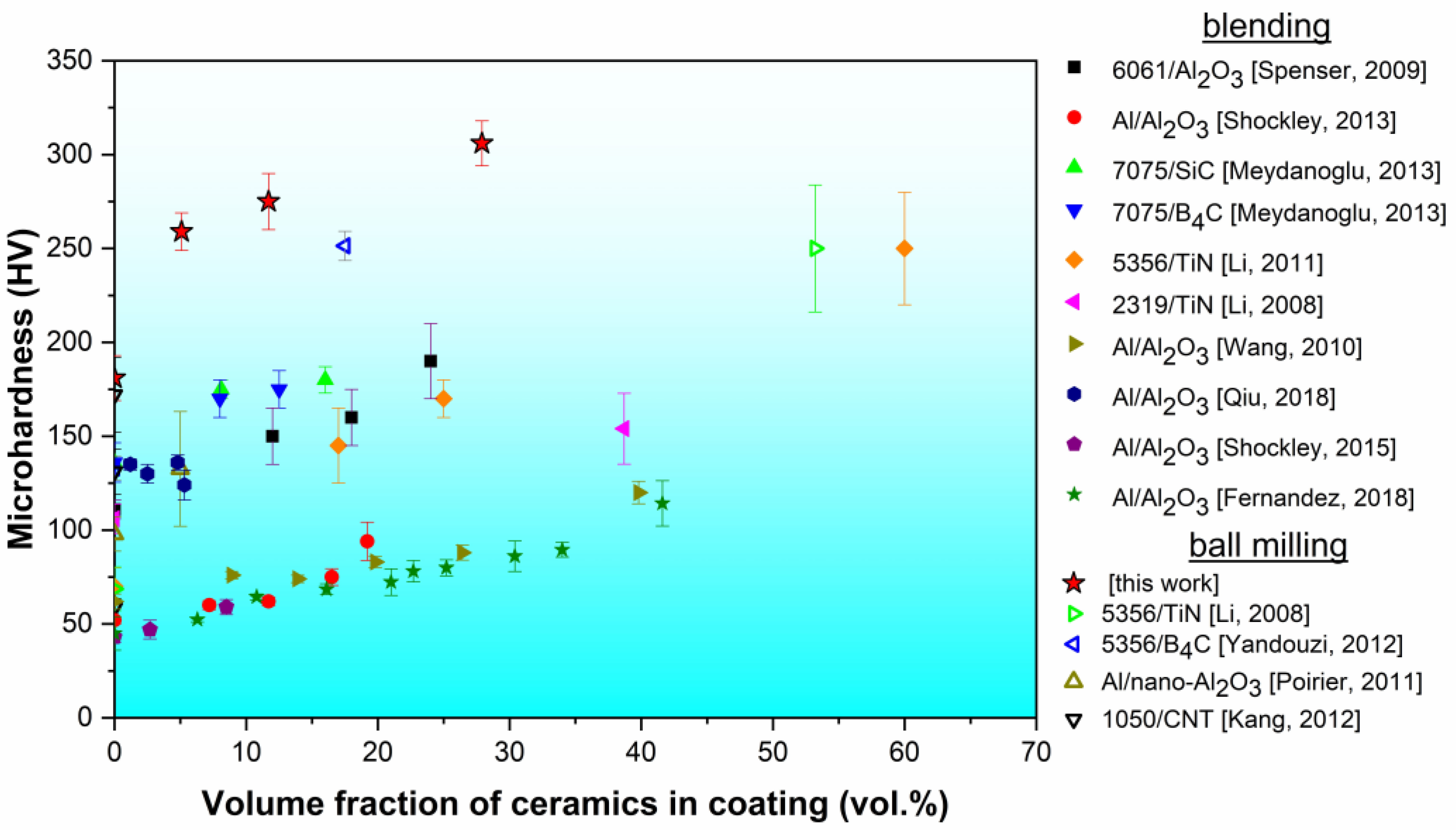

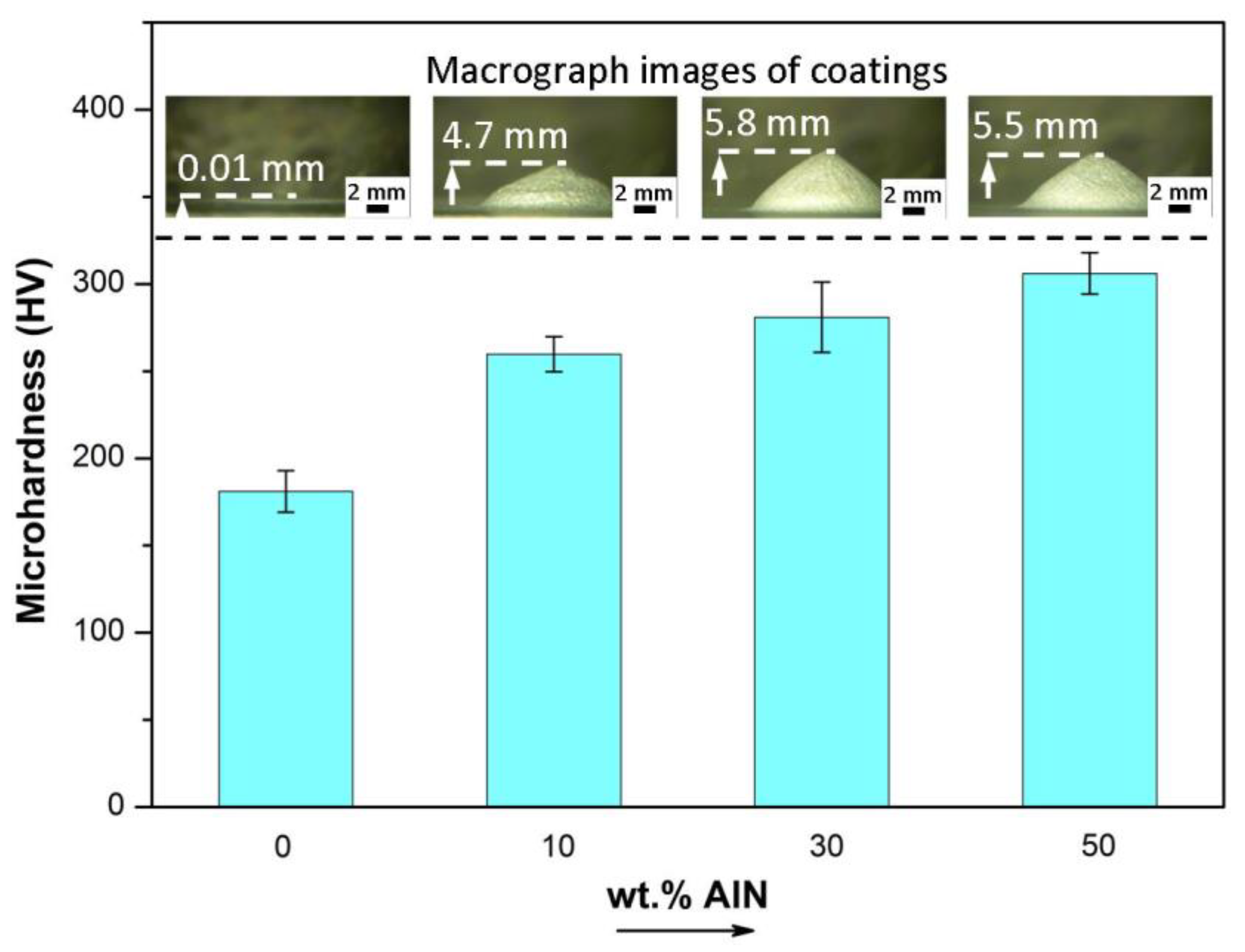

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Raoelison, R.N.; Xie, Y.; Sapanathan, T.; Planche, M.P.; Kromer, R.; Costil, S.; Langlade, C. Cold gas dynamic spray technology: A comprehensive review of processing conditions for various technological developments till to date. Addit. Manuf. 2018, 19, 134–159. [Google Scholar] [CrossRef]

- Perna, A.S.; Viscusi, A.; Gatta, R.D.; Astarita, A. Cold spraying on polymer-based composites: Understanding the single-particle adhesion. Surf. Coat. Technol. 2022, 447, 128837. [Google Scholar] [CrossRef]

- Perna, A.S.; Viscusi, A.; Astarita, A.; Boccarusso, L.; Caraviello, A.; Carrino, L.; Durante, M.; Sansone, R. Experimental Study of Functionalized Polymer Matrix Composite with Multi-Material Metal Coatings Produced by Means of Cold Spray Technology. Key Eng. Mater. 2019, 813, 267–272. [Google Scholar] [CrossRef]

- Gyansah, L.; Tariq, N.H.; Tang, J.R.; Qiu, X.; Feng, B.; Huang, J.; Du, H.; Wang, J.Q.; Xiong, T.Y. Cold spraying SiC/Al metal matrix composites: Effects of SiC contents and heat treatment on microstructure, thermophysical and flexural properties. Mater. Res. Express. 2018, 5, 026523. [Google Scholar] [CrossRef]

- Kumar, S.; Reddy, S.K.; Joshi, S.V. Microstructure and performance of cold sprayed Al-SiC composite coatings with high fraction of particulates. Surf. Coat. Technol. 2017, 318, 62–71. [Google Scholar] [CrossRef]

- Qiu, X.; Tariq, N.U.H.; Qi, L.; Tang, J.; Cui, X.; Wang, J.; Xiong, T. Influence of particulate morphology on microstructure and tribological properties of cold sprayed A380/Al2O3 composite coatings. J. Mater. Sci. Technol. 2020, 44, 9–18. [Google Scholar] [CrossRef]

- Kosarev, V.F.; Klinkov, S.V.; Shikalov, V.S.; Chesnokov, A.E. A Study of the Neutron Absorbing Properties of Al + B4C and Al + B Coatings Formed by Cold Gas-Dynamic Spraying. Phys. Met. Metallogr. 2023, 124, 308–314. [Google Scholar] [CrossRef]

- Tariq, N.H.; Gyansah, L.; Wang, J.; Feng, B.; Siddiquee, M.T.; Xiong, T. Cold spray additive manufacturing: A viable strategy to fabricate thick B4C/Al composite coatings for neutron shielding applications. Surf. Coat. Technol. 2018, 339, 224–236. [Google Scholar] [CrossRef]

- Wu, C.; Lu, Y.; Luo, G.; Shen, Q.; Gan, Z.; Liu, J. Influence of particulate B4C size on microstructural evolution and mechanical behavior in nanostructured Al matrix during heat treatment. Powder Technol. 2020, 374, 274–282. [Google Scholar] [CrossRef]

- Martin, J.; Maizeray, A.; da Silva Tousch, C.; Marcos, G.; Czerwiec, T.; Henrion, G. A new strategy to prepare alumina-zirconia composite or multilayered coatings by combining cold-spray deposition and plasma electrolytic oxidation. Mater. Today Commun. 2023, 36, 106676. [Google Scholar] [CrossRef]

- Chen, C.; Xie, Y.; Yan, X.; Ahmed, M.; Lupoi, R.; Wang, J.; Ren, Z.; Liao, H.; Yin, S. Tribological properties of Al/diamond composites produced by cold spray additive manufacturing. Addit. Manuf. 2020, 36, 101434. [Google Scholar] [CrossRef]

- Chen, H.; Pala, Z.; Hussain, T.; McCartney, D. Fabrication and microstrain evolution of Al-TiB2 composite coating by cold spray deposition. Proc. Inst. Mech. Eng. L 2019, 233, 1044–1052. [Google Scholar] [CrossRef]

- Woo, D.J.; Heer, F.C.; Brewer, L.N.; Hooper, J.P.; Osswald, S. Synthesis of nanodiamond-reinforced aluminum metal matrix composites using cold-spray deposition. Carbon 2015, 86, 15–25. [Google Scholar] [CrossRef]

- Loganathan, A.; Rengifo, S.; Hernandez, A.F.; Zhang, C.; Agarwal, A. Effect of nanodiamond reinforcement and heat-treatment on microstructure, mechanical and tribological properties of cold sprayed aluminum coating. Surf. Coat. Technol. 2021, 412, 127037. [Google Scholar] [CrossRef]

- Xie, X.; Yin, S.; Raoelison, R.; Chen, C.; Verdy, C.; Li, W.; Ji, G.; Ren, Z.; Liao, H. Al matrix composites fabricated by solid-state cold spray deposition: A critical review. J. Mater. Sci. Technol. 2021, 86, 20–55. [Google Scholar] [CrossRef]

- Li, W.; Assadi, H.; Gaertner, F.; Yin, S. A Review of Advanced Composite and Nanostructured Coatings by Solid-State Cold Spraying Process. Crit. Rev. Solid State Mater. Sci. 2018, 44, 109–156. [Google Scholar] [CrossRef]

- Jodoin, B.; Ajdelsztajn, L.; Sansoucy, E.; Zúñiga, A.; Richer, P.; Lavernia, E.J. Effect of particle size, morphology, and hardness on cold gas dynamic sprayed aluminum alloy coatings. Surf. Coat. Technol. 2006, 201, 3422–3429. [Google Scholar] [CrossRef]

- Meyer, M.; Caruso, F.; Lupoi, R. Particle velocity and dispersion of high Stokes number particles by PTV measurements inside a transparent supersonic Cold Spray nozzle. Int. J. Multiph. Flow. 2018, 106, 296–310. [Google Scholar] [CrossRef]

- Koithara, L.; Raoelison, R.; Costil, S. Flow phenomenon of micron-sized particles during cold spray additive manufacturing: High-speed optic observation and characterization. Adv. Powder Technol. 2020, 31, 1060–1079. [Google Scholar] [CrossRef]

- Aborkin, A.; Alymov, M.; Arkhipov, V.; Khrenov, D. Formation of Heterogeneous Powder Coatings with a Two-Level Micro-and Nanocomposite Structure under Gas-Dynamic Spraying Conditions. Dokl. Phys. 2018, 63, 50–54. [Google Scholar] [CrossRef]

- Evdokimov, I.; Perfilov, S.; Pozdnyakov, A.; Blank, V.; Bagramov, R.; Perezhogin, I.; Kulnitsky, B.; Kirichenko, A.; Aksenenkov, V. Nanostructured Composite Materials Based on Al–Mg Alloy Modified with Fullerene C60. Inorg. Mater. Appl. Res. 2018, 9, 472–477. [Google Scholar] [CrossRef]

- Nam, S.; Lee, S.; Roh, A.; Son, H.; Kim, M.; Choi, H. Role of supersaturated Al-C phases in mechanical properties of Al/fullerene composites. Sci. Rep. 2021, 11, 13143. [Google Scholar] [CrossRef]

- Reshetniak, V.; Reshetniak, O.; Aborkin, A.; Nederkin, V.; Filippov, A. Effect of the Interface on the Compressibility of Substances with Spherical Nano-Inhomogeneities on the Example of Al/C60. Nanomaterials 2022, 12, 2045. [Google Scholar] [CrossRef]

- Aborkin, A.; Arkhipov, V.; Sachkova, N.; Sychev, A.; Alymov, M. Effect of Al2O3 on the Microhardness of AMg2/Graphite Nanocomposite Powder Gas Dynamic Coatings on Aluminum Alloys. Met. Sci. Heat Treat. 2019, 61, 360–365. [Google Scholar] [CrossRef]

- Fernandez, R.; Jodoin, B. Cold Spray Aluminum–Alumina Cermet Coatings: Effect of Alumina Content. J. Therm. Spray Technol. 2018, 27, 603–623. [Google Scholar] [CrossRef]

- Sun, X.; Hao, X.; Nie, J.; Fan, Y.; Chen, Y.; Liu, S.; Liu, X.; Zhao, Y. Microstructure and enhanced cryogenic tensile property of a heterostructured Al-AlN/Al-Mg composite fabricated by accumulative roll bonding (ARB). J. Mater. Res. Technol. 2022, 21, 532–545. [Google Scholar] [CrossRef]

- Dorner-Reisel, A.; Ritter, U.; Moje, J.; Freiberger, E.; Scharff, P. Effect of fullerene C60 thermal and tribomechanical loading on Raman signals. Diam. Relat. Mater. 2022, 126, 109036. [Google Scholar] [CrossRef]

- Popov, V. X-ray micro-absorption enhancement for non-agglomerated nanodiamonds in mechanically alloyed aluminium matrix composites. Phys. Status Solidi A 2015, 212, 2722–2726. [Google Scholar] [CrossRef]

- Aborkin, A.; Alymov, M.; Sobol’kov, A.; Khor’kov, K.; Babin, D. Effect of the Thermomechanical Treatment Conditions on the Consolidation, the Structure, and the Mechanical Properties of Bulk Al–Mg–C Nanocomposites. Russ. Metall. Met. 2018, 7, 625–632. [Google Scholar] [CrossRef]

- Aborkin, A.; Alymov, M.; Kireev, A.; Elkin, A.; Sobol’kov, A. Mechanically Synthesized Composite Powder Based on AMg2 Alloy with Graphite Additives: Particle Size Distribution and Structural-Phase Composition. Nanotechnol. Russ. 2017, 12, 395–399. [Google Scholar] [CrossRef]

- Spencer, K.; Fabijanic, D.M.; Zhang, M.X. The use of Al–Al2O3 cold spray coatings to improve the surface properties of magnesium alloys. Surf. Coat. Technol. 2009, 204, 336–344. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, J.; Tang, J.; Gyansah, L.; Zhao, Z.; Xiong, T. Microstructure, microhardness and tribological behavior of Al2O3 reinforced A380 aluminum alloy composite coatings prepared by cold spray technique. Surf. Coat. Technol. 2018, 350, 391–400. [Google Scholar] [CrossRef]

- Yandouzi, M.; Richer, P.; Jodoin, B. SiC particulate reinforced Al–12Si alloy composite coatings produced by the pulsed gas dynamic spray process: Microstructure and properties. Surf. Coat. Technol. 2009, 203, 3260–3270. [Google Scholar] [CrossRef]

- Li, W.Y.; Yang, C.; Liao, H. Effect of vacuum heat treatment on microstructure and microhardness of cold-sprayed TiN particle-reinforced Al alloy-based composites. Mater. Des. 2011, 32, 388–394. [Google Scholar] [CrossRef]

- Ajdelsztajn, L.; Schoenung, J.M.; Jodoin, B.; Kim, G. Cold spray deposition of nanocrystalline aluminum alloys. Met. Mater. Trans. A Phys. Met. Mater. Sci. 2005, 36, 657–666. [Google Scholar] [CrossRef]

- Rokni, M.; Widener, C.; Nardi, A.; Champagne, V. Nano crystalline high energy milled 5083 Al powder deposited using cold spray. Appl. Surf. Sci. 2014, 305, 797–804. [Google Scholar] [CrossRef]

- Hall, A.; Brewer, L.; Roemer, T. Preparation of aluminum coatings containing homogenous nanocrystalline microstructures using the cold spray process. J. Therm. Spray Technol. 2008, 17, 352–359. [Google Scholar] [CrossRef]

- Shockley, J.; Strauss, H.; Chromik, R.; Brodusch, N.; Gauvin, R.; Irissou, E.; Legoux, J. In situ tribometry of cold-sprayed Al-Al2O3 composite coatings. Surf. Coat. Technol. 2013, 215, 350–356. [Google Scholar] [CrossRef]

- Meydanoglu, O.; Jodoin, B.; Kayali, E.S. Microstructure, mechanical properties and corrosion performance of 7075 Al matrix ceramic particle reinforced composite coatings produced by the cold gas dynamic spraying process. Surf. Coat. Technol. 2013, 235, 108–116. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, G.; Liao, H.L.; Coddet, C. Characterizations of cold sprayed TiN particle reinforced Al2319 composite coating. J. Mater. Process. Technol. 2008, 202, 508–513. [Google Scholar] [CrossRef]

- Wang, Q.; Spencer, K.; Birbilis, N.; Zhang, M.X. The influence of ceramic particles on bond strength of cold spray composite coatings on AZ91 alloy substrate. Surf. Coat. Technol. 2010, 205, 50–56. [Google Scholar] [CrossRef]

- Shockley, J.; Descartes, S.; Vo, P.; Irissou, E.; Chromik, R. The influence of Al2O3 particle morphology on the coating formation and dry sliding wear behavior of cold sprayed Al–Al2O3 composites. Surf. Coat. Technol. 2015, 270, 324–333. [Google Scholar] [CrossRef]

- Li, W.Y.; Zhang, G.; Zhang, C.; Elkedim, O.; Liao, H.; Coddet, C. Effect of ball milling of feedstock powder on microstructure and properties of TiN particle-reinforced Al alloy-based composites fabricated by cold spraying. J. Therm. Spray Technol. 2008, 17, 316–322. [Google Scholar] [CrossRef]

- Yandouzi, M.; Bu, H.; Brochu, M.; Jodoin, B. Nanostructured al-based metal matrix composite coating production by pulsed gas dynamic spraying process. J. Therm. Spray Technol. 2012, 21, 609–619. [Google Scholar] [CrossRef]

- Poirier, D.; Legoux, J.; Drew, R.; Gauvin, R. Consolidation of Al2O3/Al Nanocomposite Powder by Cold Spray. J. Therm. Spray Technol. 2011, 20, 275–284. [Google Scholar] [CrossRef]

- Kang, K.; Bae, G.; Won, J.; Lee, C. Mechanical property enhancement of kinetic sprayed Al coatings reinforced by multi-walled carbon nanotubes. Acta Mater. 2012, 60, 5031–5039. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aborkin, A.; Babin, D.; Belyaev, L.; Bokaryov, D. Enhancing the Microhardness of Coatings Produced by Cold Gas Dynamic Spraying through Multi-Reinforcement with Aluminum Powders Containing Fullerenes and Aluminum Nitride. J. Manuf. Mater. Process. 2023, 7, 203. https://doi.org/10.3390/jmmp7060203

Aborkin A, Babin D, Belyaev L, Bokaryov D. Enhancing the Microhardness of Coatings Produced by Cold Gas Dynamic Spraying through Multi-Reinforcement with Aluminum Powders Containing Fullerenes and Aluminum Nitride. Journal of Manufacturing and Materials Processing. 2023; 7(6):203. https://doi.org/10.3390/jmmp7060203

Chicago/Turabian StyleAborkin, Artemiy, Dmitry Babin, Leonid Belyaev, and Dmitry Bokaryov. 2023. "Enhancing the Microhardness of Coatings Produced by Cold Gas Dynamic Spraying through Multi-Reinforcement with Aluminum Powders Containing Fullerenes and Aluminum Nitride" Journal of Manufacturing and Materials Processing 7, no. 6: 203. https://doi.org/10.3390/jmmp7060203

APA StyleAborkin, A., Babin, D., Belyaev, L., & Bokaryov, D. (2023). Enhancing the Microhardness of Coatings Produced by Cold Gas Dynamic Spraying through Multi-Reinforcement with Aluminum Powders Containing Fullerenes and Aluminum Nitride. Journal of Manufacturing and Materials Processing, 7(6), 203. https://doi.org/10.3390/jmmp7060203