Evaluation of Microstructure–Porosity–Hardness of Thermal Plasma-Sprayed NiTi Coating Layers

Abstract

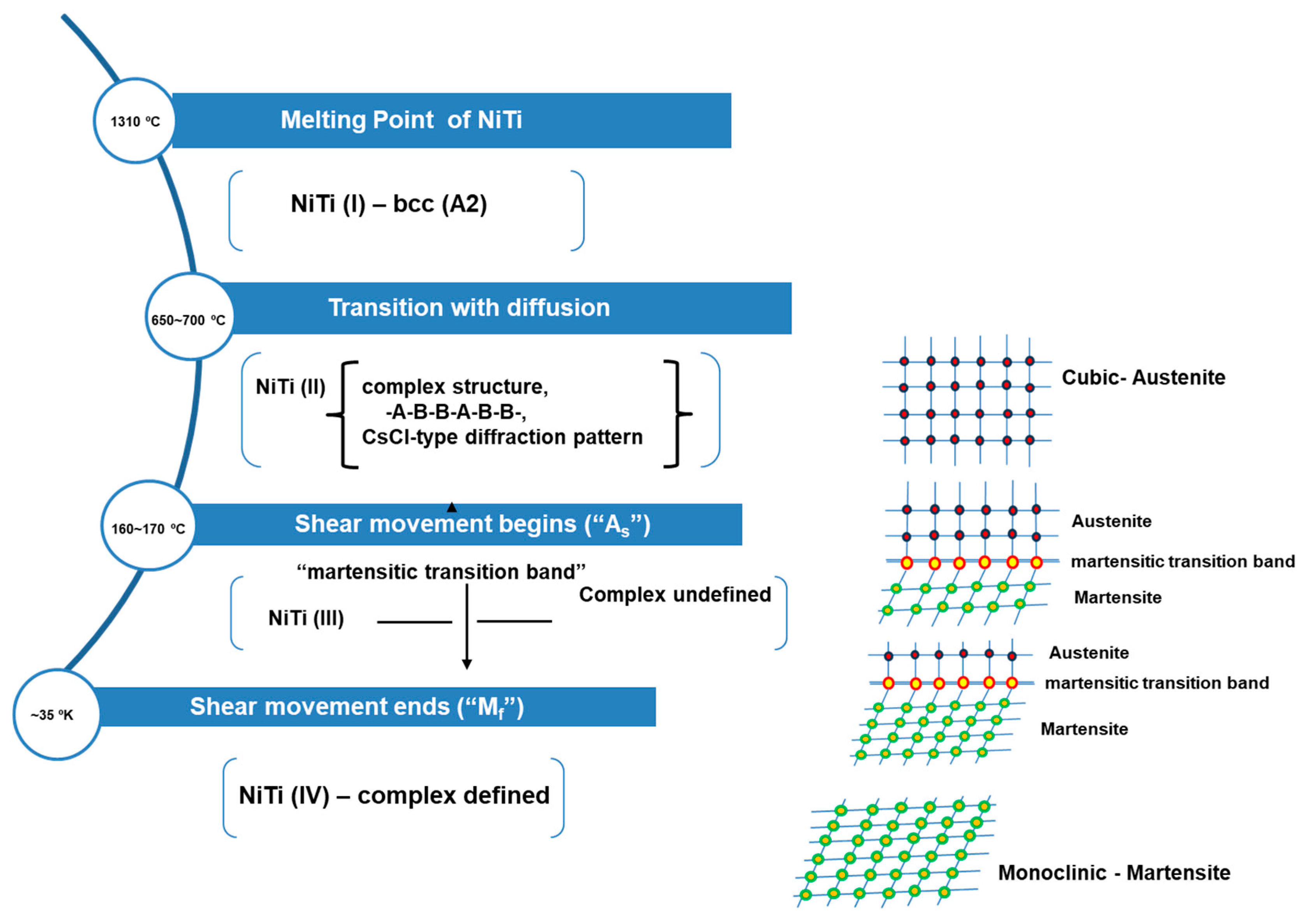

:1. Introduction

2. Materials and Method

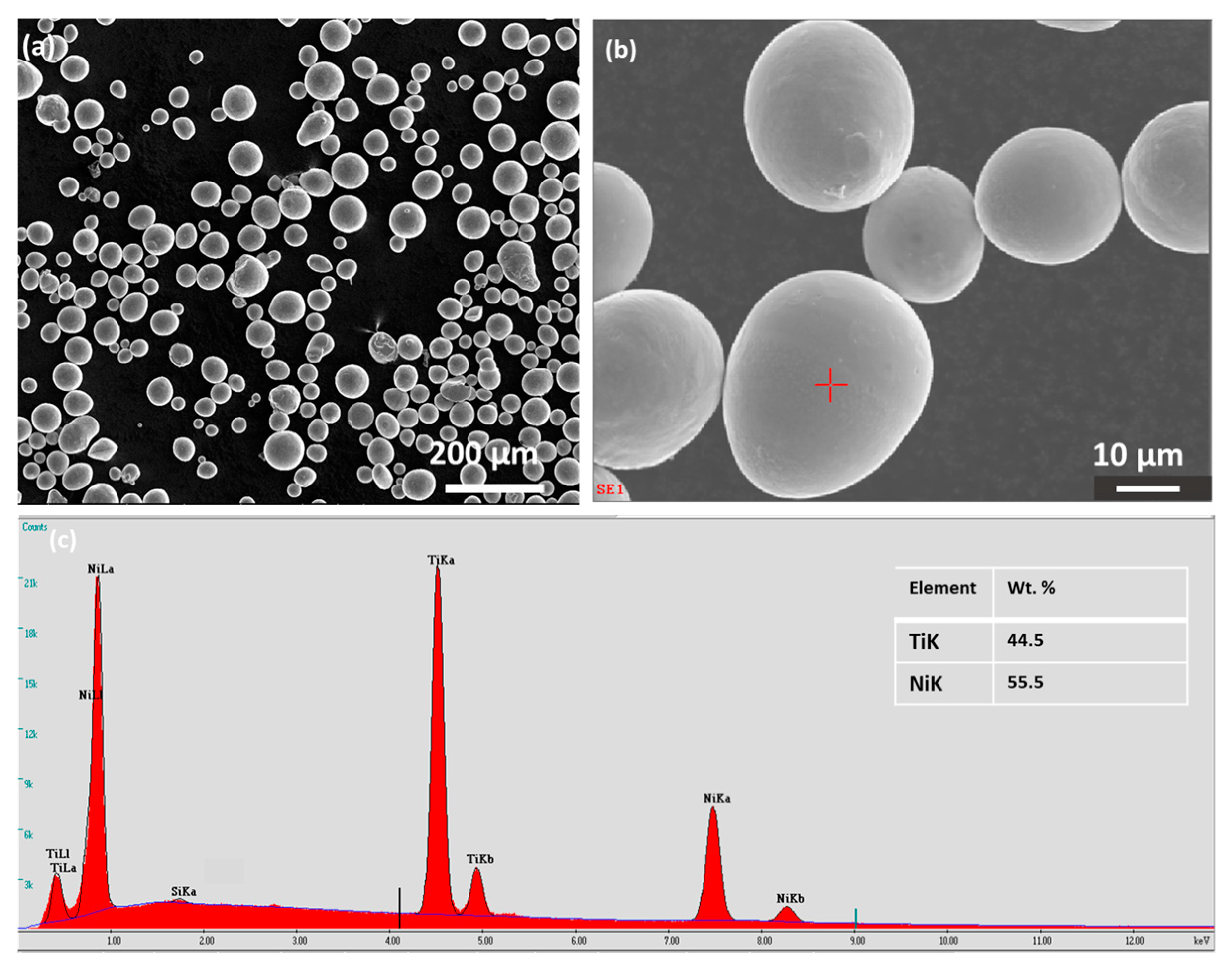

2.1. Feedstock Powder of NiTi for Spraying

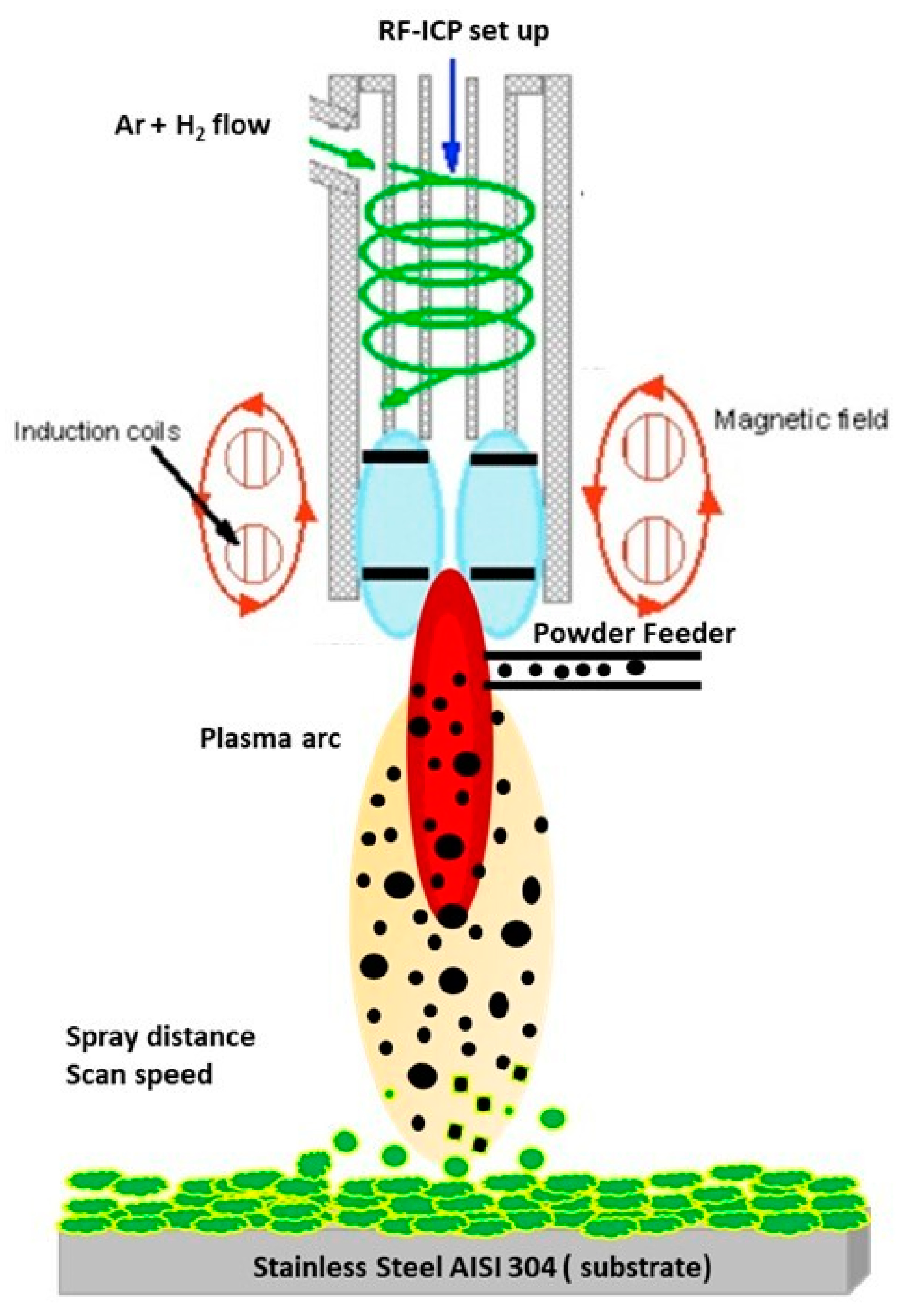

2.2. Plasma-Spraying Process and Process Parameters for Sample Preparation

2.3. Characterization of Plasma Coating Samples

3. Results

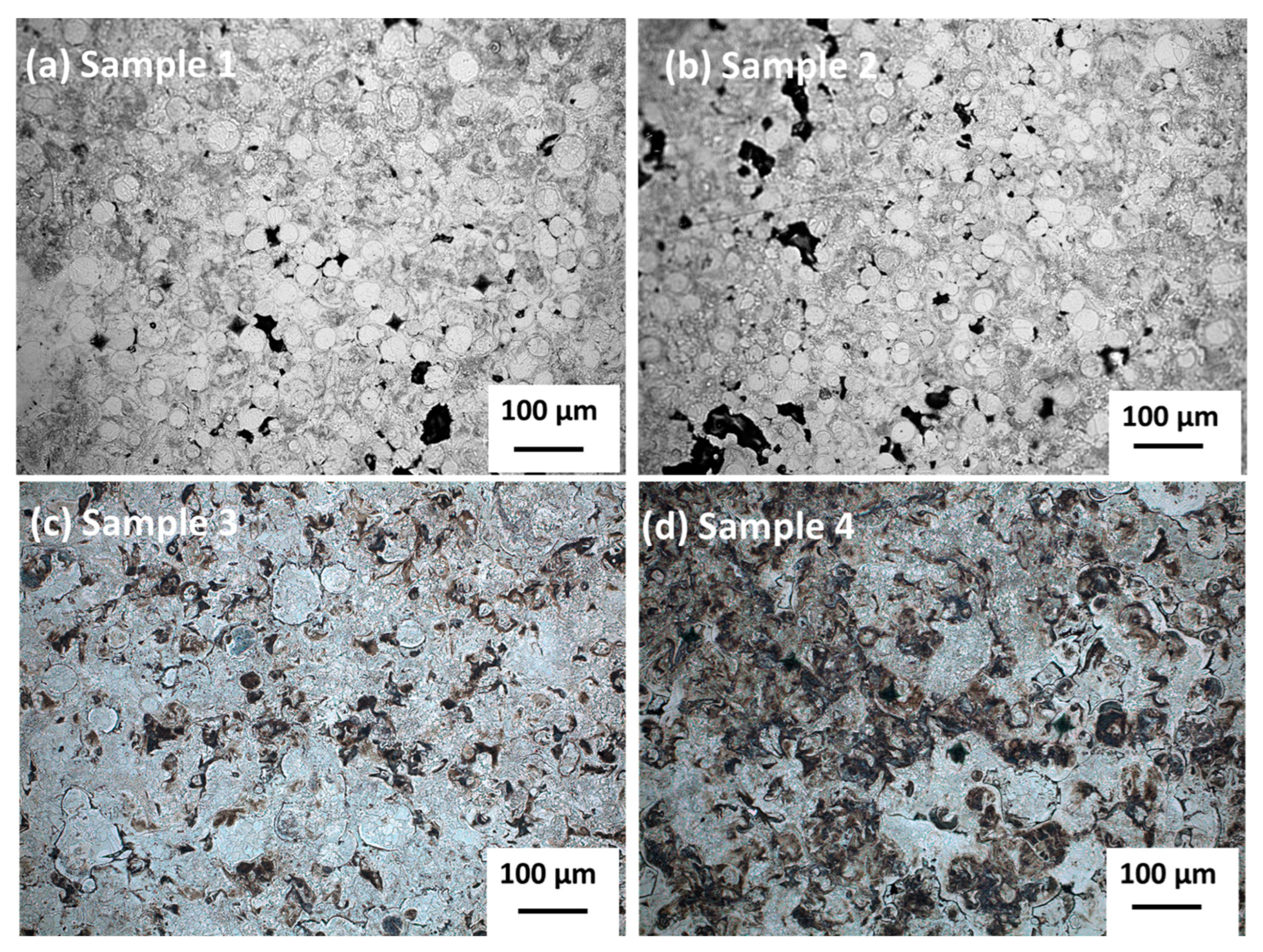

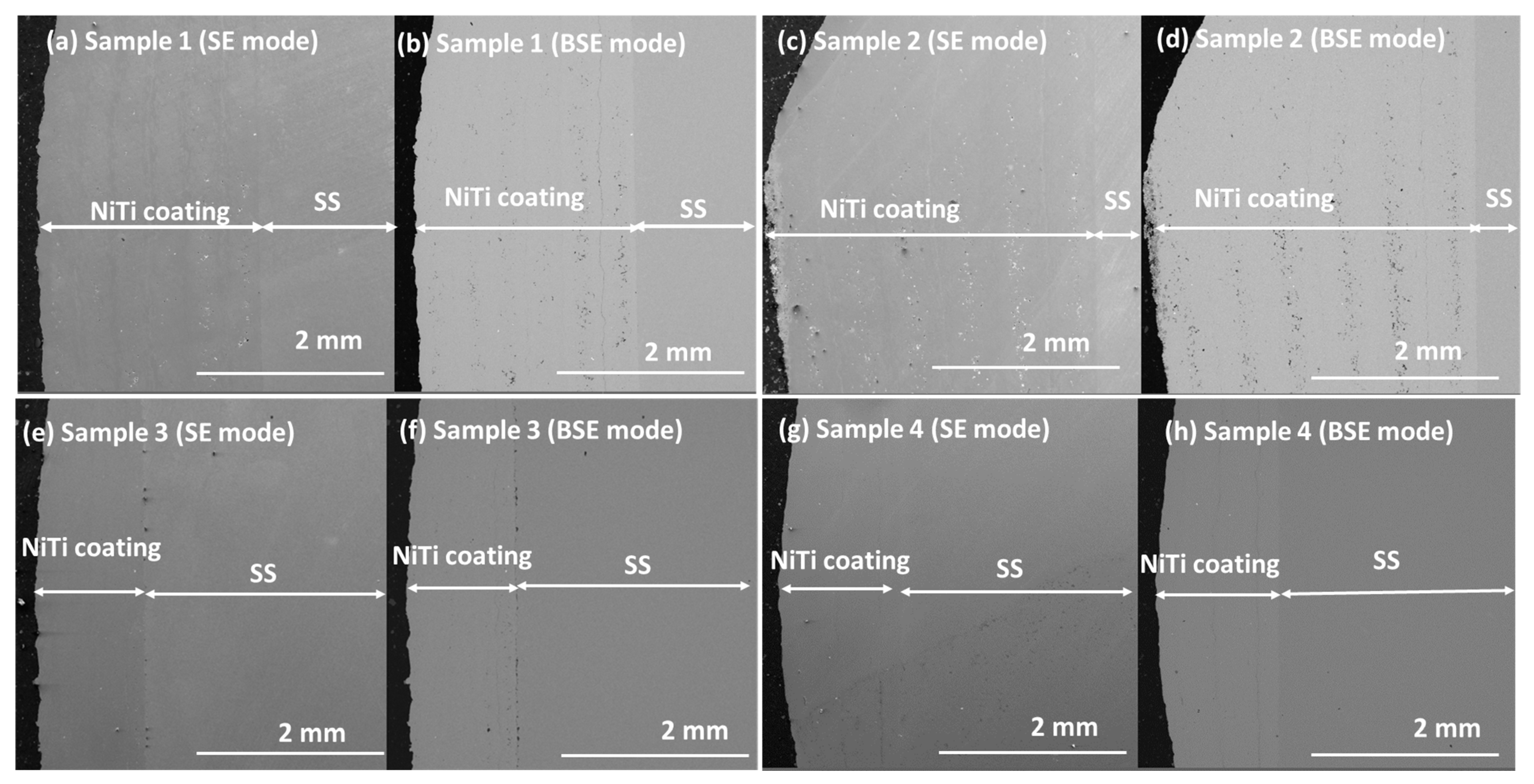

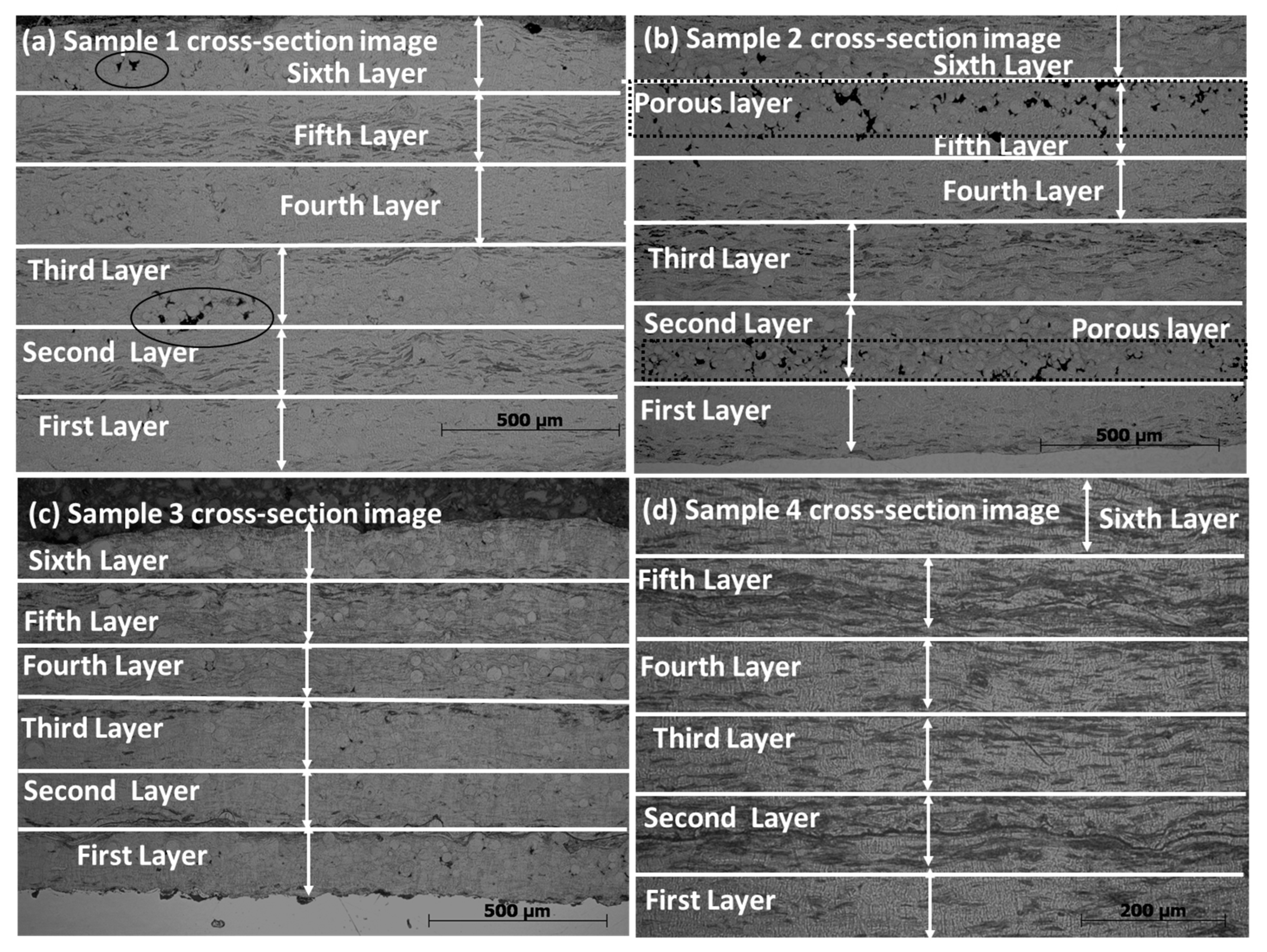

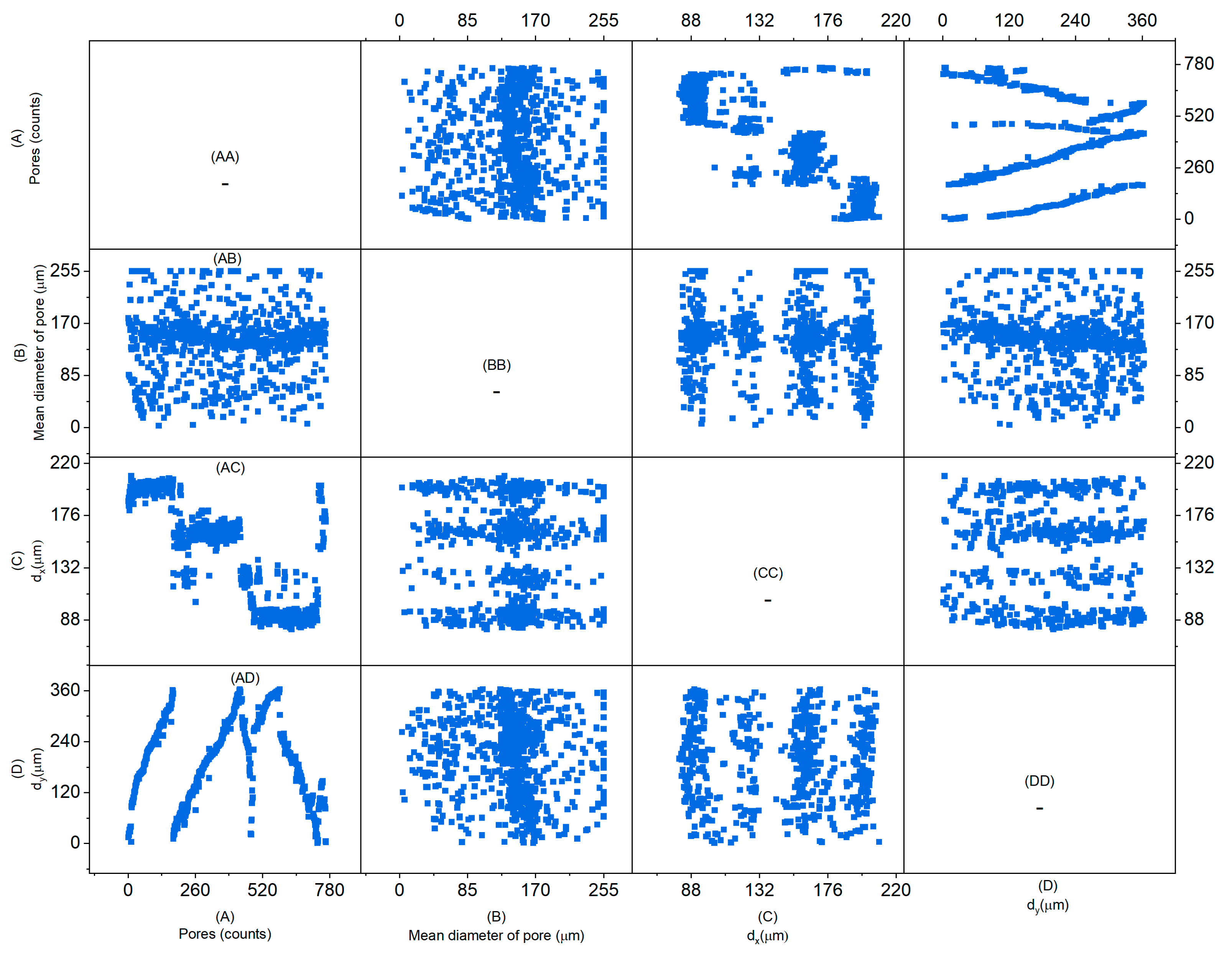

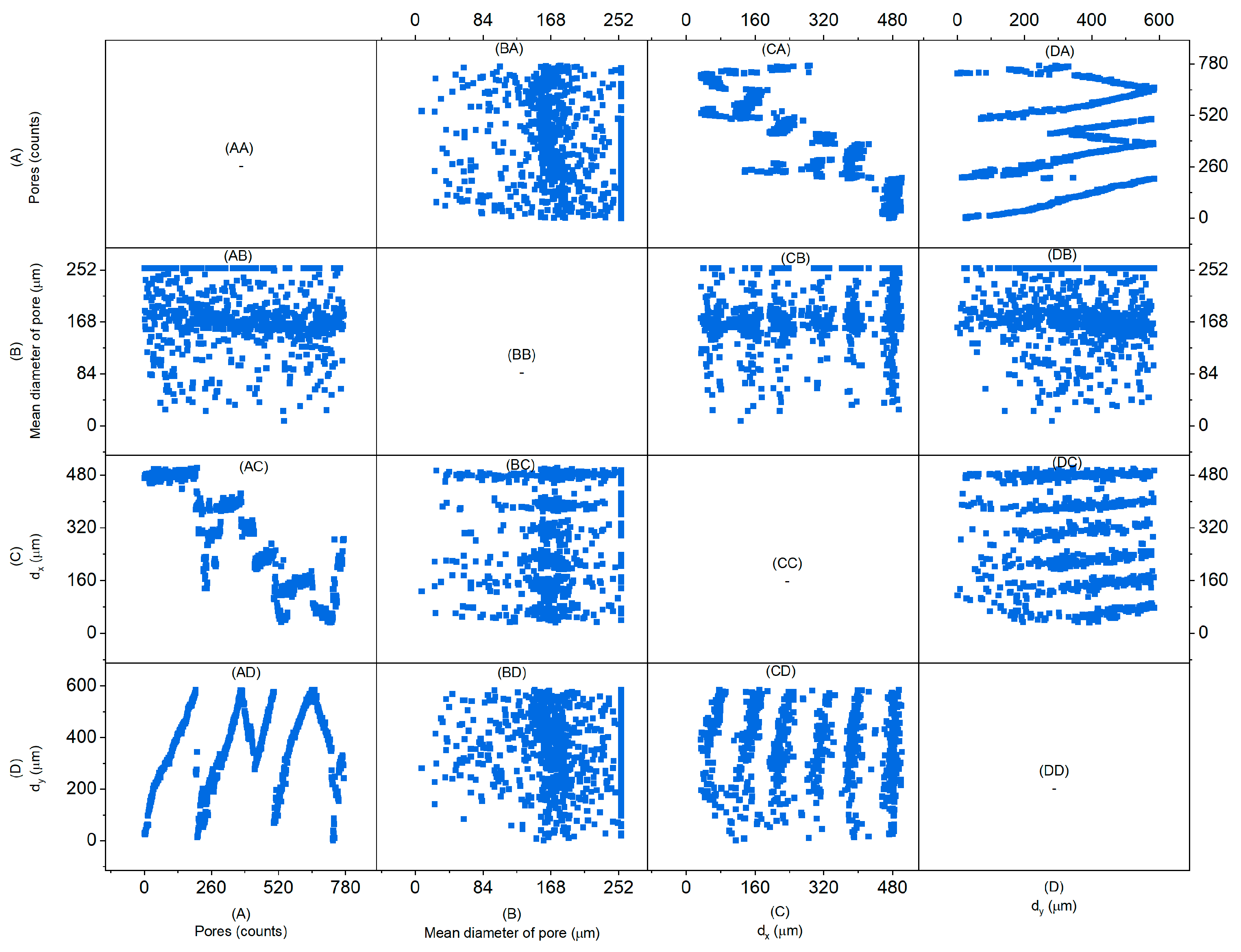

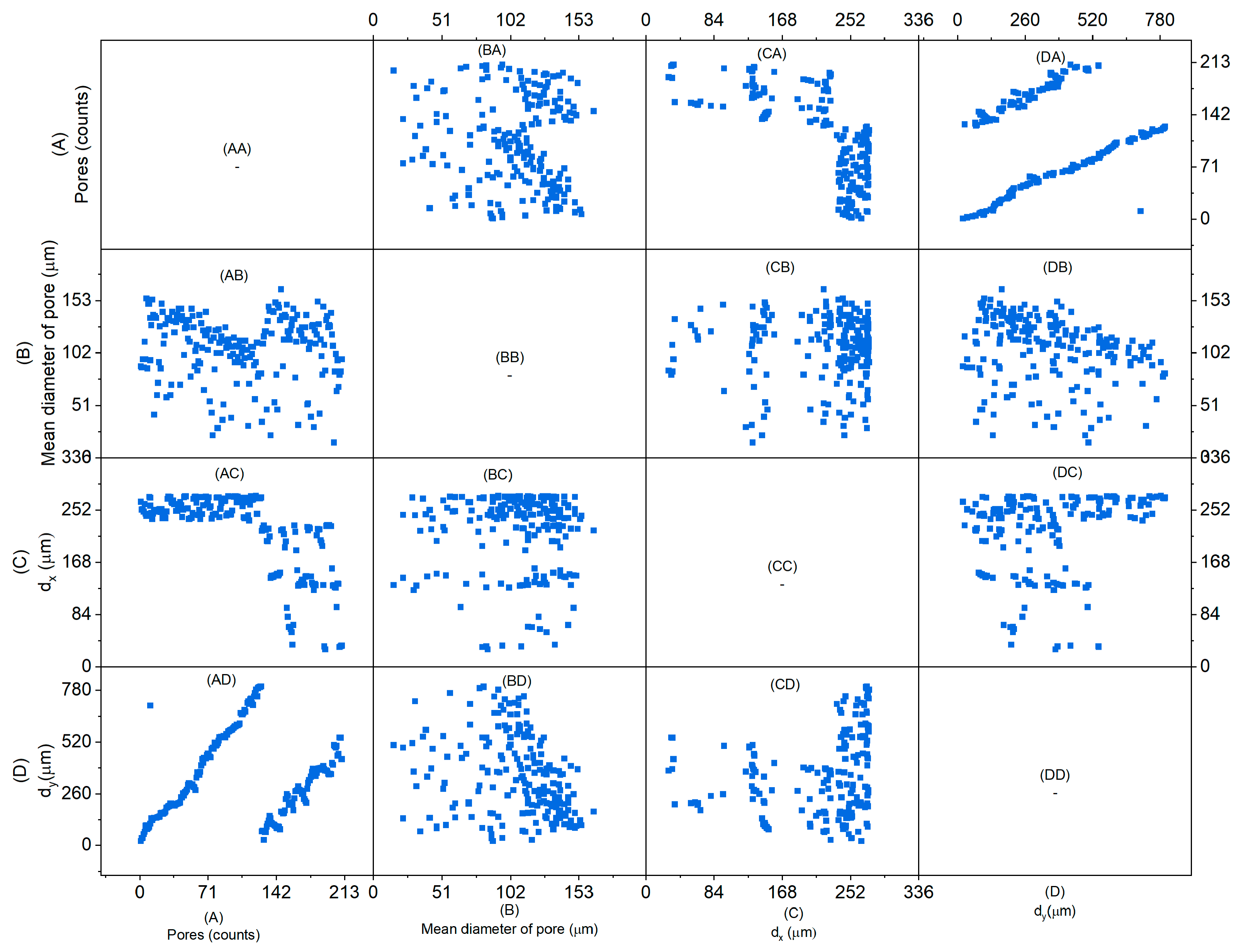

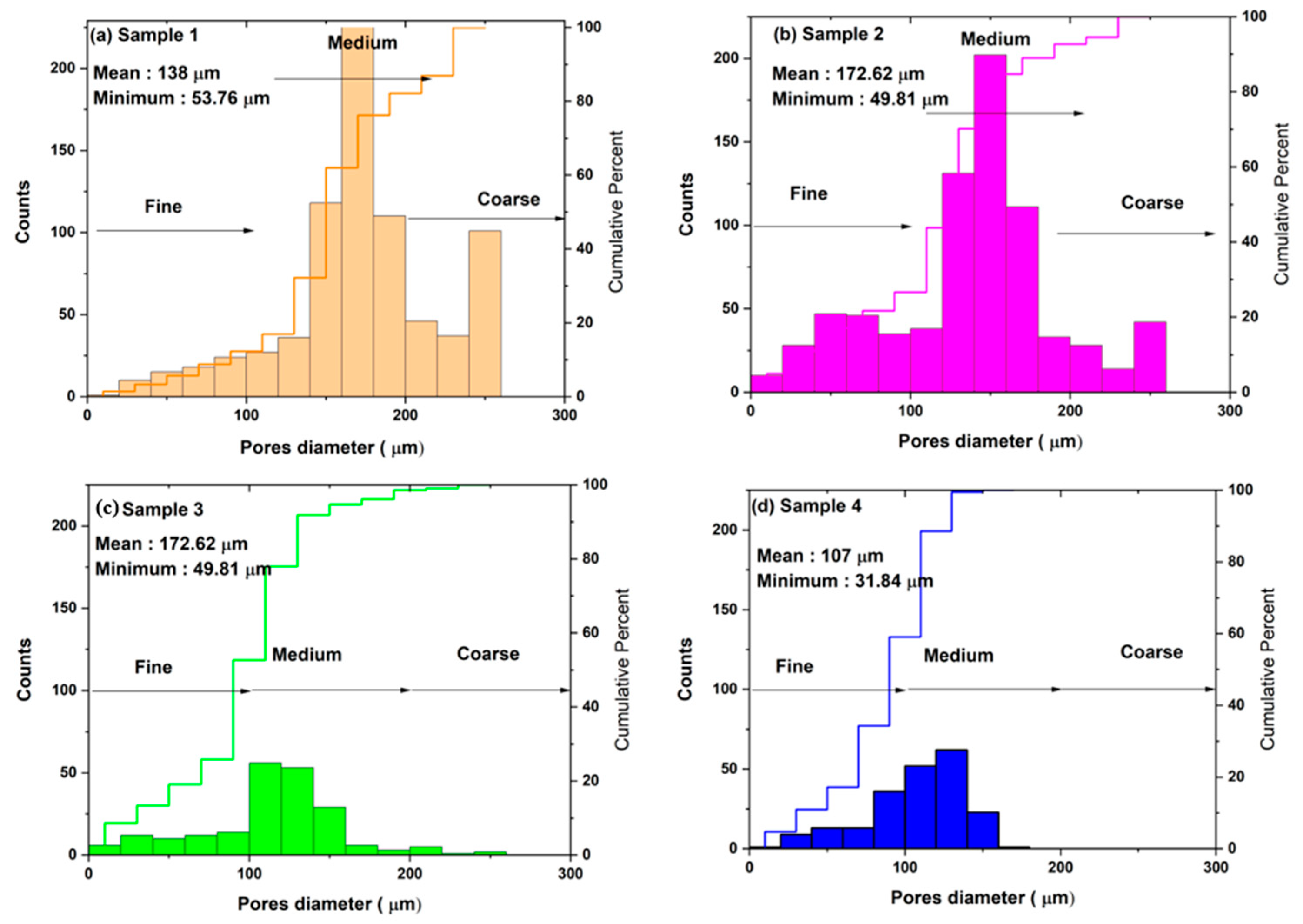

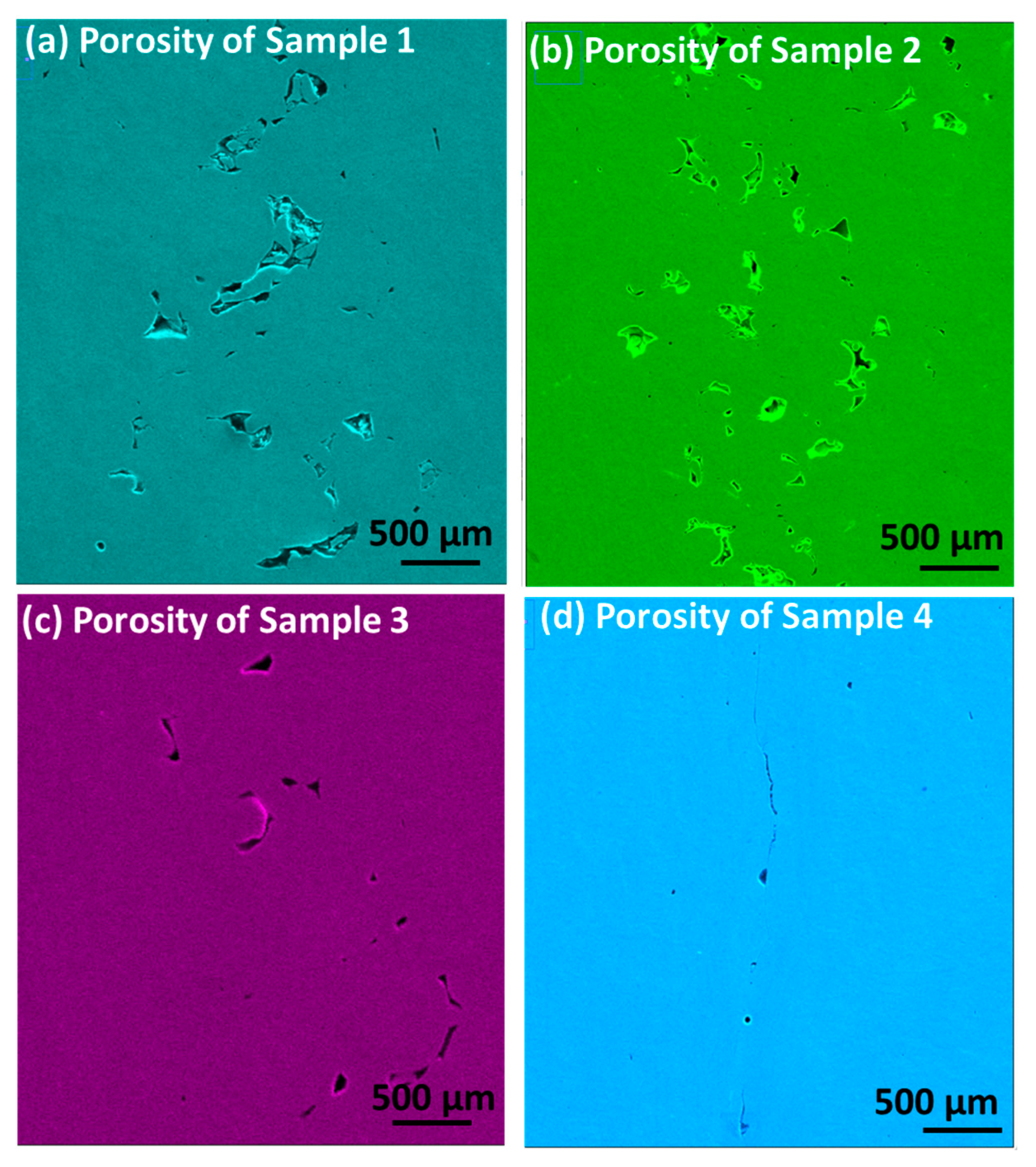

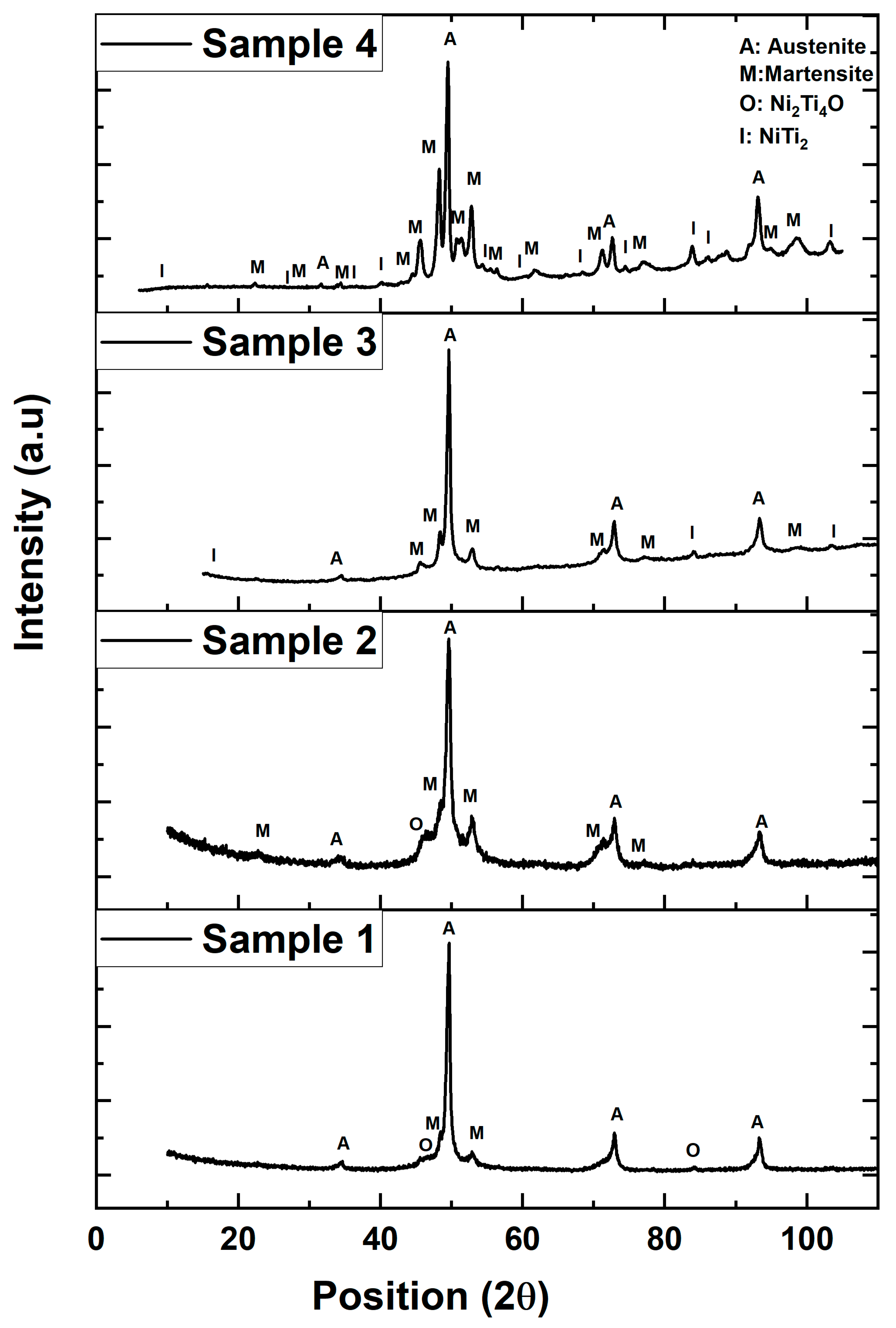

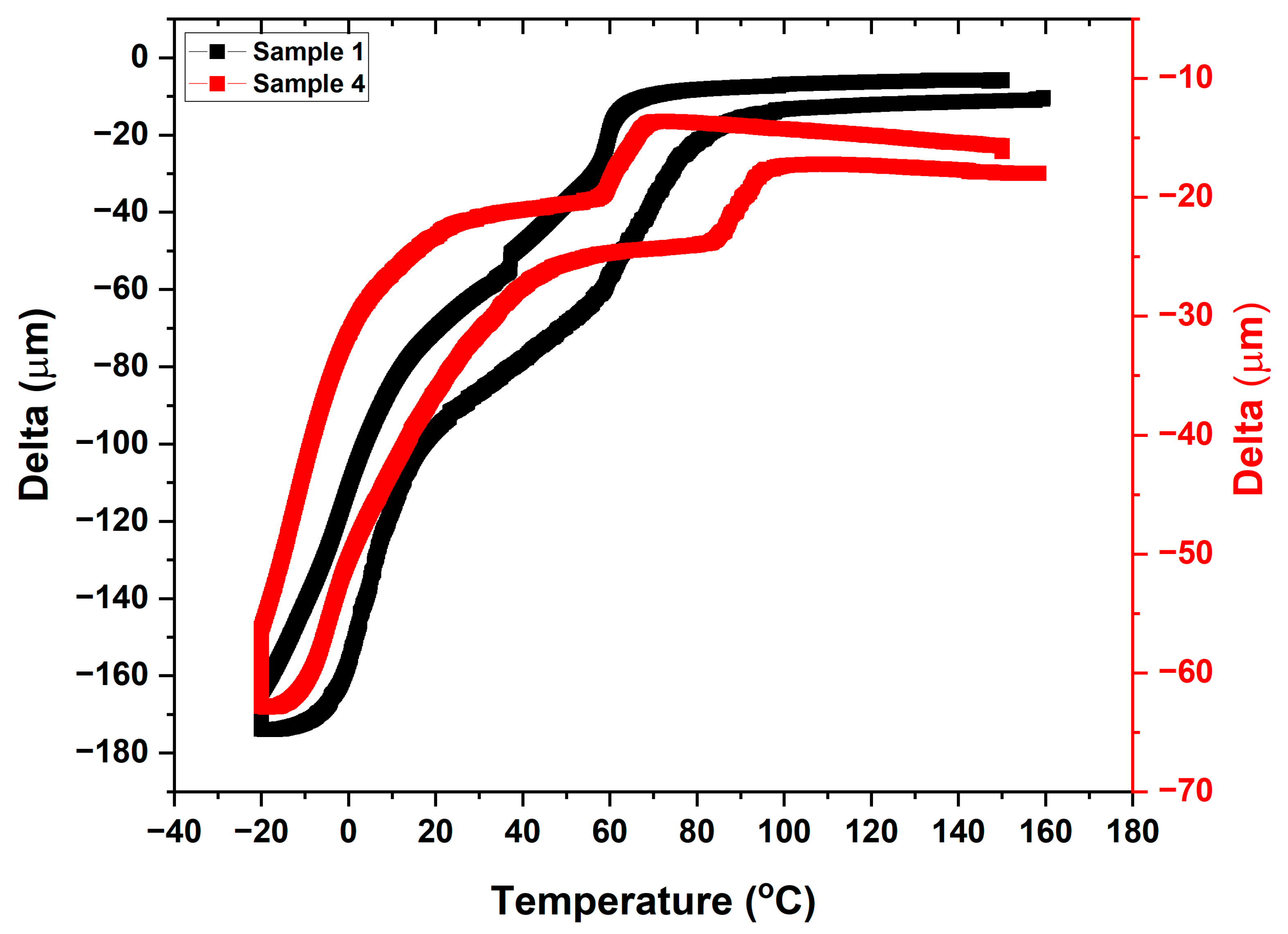

Microstructural Images of the Plasma-Sprayed Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Richman, R.H.; Rao, A.S.; Hodgson, D.E. Cavitation erosion of two NiTi alloys. Wear 1992, 157, 401–407. [Google Scholar] [CrossRef]

- Richman, R.H.; Rao, A.S.; Kung, D. Cavitation erosion of NiTi explosively welded to steel. Wear 1995, 181–183, 80–85. [Google Scholar] [CrossRef]

- Bram, M.; Ahmad-Khanlou Buchkremer, H.P.; Stöver, D. Vaccum plasma spraying of NiTi protection layers. Mater. Lett. 2002, 57, 647–651. [Google Scholar] [CrossRef]

- Samal, S.; Zeman, J.; Kopeček, J.; Šittner, P. The Microstructure, Hardness, Phase Transformation and Mechanical Properties of a NiTi Coating Applied to Graphite Substrate via a Plasma Spraying Process. Coatings 2023, 13, 1174. [Google Scholar] [CrossRef]

- Samal, S.; Tyc, O.; Cizek, J.; Klecka, J.; Lukáč, F.; Molnárová, O.; de Prado, E.; Weiss, Z.; Kopeček, J.; Heller, L.; et al. Fabrication of Thermal Plasma Sprayed NiTi Coatings Possessing Functional Properties. Coatings 2021, 11, 610. [Google Scholar] [CrossRef]

- Swain, B.; Mallick, P.; Gupta Ram, K.; Mohapatra, S.S.; Yasin, G.; Nguyen, T.A.; Ajit, B. Mechanical and tribological properties evaluation of plasma-sprayed shape memory alloy coating. J. Alloys Compd. 2021, 863, 158599. [Google Scholar] [CrossRef]

- Zhao, Y.; Wen, J.; Peyraut, F.; Planche, M.-P.; Misra, S.; Lenoir, B.; Ilavsky, J.; Liao, H.; Montavon, G. Porous architecture and thermal properties of thermal barrier coatings deposited by suspension plasma spray. Surf. Coat. Technol. 2020, 386, 125462. [Google Scholar] [CrossRef]

- Samal, S. Thermal plasma processing of materials: High-temperature applications. In Reference Module in Materials Science and Materials Engineering; Elesvier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Özel, S.; Vural, E. The microstructure and hardness properties of plasma-sprayed Cr2O3/Al2O3 coatings. J. Optoelectron. Adv. Mater. 2016, 18, 1052–1056. [Google Scholar]

- Odhiambo, J.G.; Li, W.; Zhao, Y.; Li, C. Porosity and Its Significance in Plasma-Sprayed Coatings. Coatings 2019, 9, 460. [Google Scholar] [CrossRef]

- Ian, M.; Bernard, G.; Michael, B.; William, M.B.; Alyssa, C.; Kelvin, X.; Winson, K.; Winson, K.; Jonah, E. Self-Organized High-Hardness Thermal Spray Coatings. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3793930 (accessed on 27 October 2023).

- Zhang, Y.; Wang, Q.; Ramachandran, C.S.; Guo, P.; Wang, A. Microstructure and Performance of High-Velocity Oxygen-Fuel Coupled Physical Vapor Deposition (HVOF-PVD) Duplex Protective Coatings: A Review. Coatings 2022, 12, 1395. [Google Scholar] [CrossRef]

- Daroonparvar, M.; Azizi Mat Yajid, M.; Yusof, N.M.; Sakhawat Hussain, M. Improved thermally grown, oxide scale in air plasma-sprayed NiCrAlY/Nano-YSZ coatings. J. Nanomater. 2013, 2013, 520104. [Google Scholar] [CrossRef]

- Samal, S.; Kopeček, J.; Šittner, P. Interfacial Adhesion of Thick NiTi Coating on Substrate Stainless Steel. Materials 2022, 15, 8598. [Google Scholar] [CrossRef]

- Pilch, J.; Šittner, P. A Method of Heat Treatment and/or Inspection of Functional Mechanical Properties, Particularly Transformation Strain and/or Strength, of Shape Memory Alloy Wires and Apparatus for the Application of This Method. U.S. Patent 20120018413A1, 26 January 2012. [Google Scholar]

- Fauchais, P.; Vardelle, M.; Vardelle, A.; Bianchi, L. Plasma spray: Study of the coating generation. Ceram. Int. 1996, 22, 295–303. [Google Scholar] [CrossRef]

- Curry, N.; Leitner, M.; Körner, K. High-Porosity Thermal Barrier Coatings from High-Power Plasma Spray Equipment—Processing, Performance and Economics. Coatings 2020, 10, 957. [Google Scholar] [CrossRef]

- Gan, J.A.; Berndt, C.C. Effects of standoff distance on porosity, phase distribution and mechanical properties of plasma sprayed Nd–Fe–B coatings. Surf. Coat. Technol. 2013, 216, 127–138. [Google Scholar] [CrossRef]

- Samal, S. Study of porosity on titania slag obtained by conventional sintering and thermal plasma process. JOM 2016, 68, 3000–3005. [Google Scholar] [CrossRef]

- Wang, Y.; Adrien, J.; Normand, B. Porosity Characterization of Cold Sprayed Stainless Steel Coating Using Three-Dimensional X-ray Microtomography. Coatings 2018, 8, 326. [Google Scholar] [CrossRef]

- Zdravkov, B.; Čermák, J.; Šefara, M.; Janků, J. Pore clasification in the characterization of porous materials: A perspective. Cent. Eur. J. Commun. 2007, 5, 385–395. [Google Scholar] [CrossRef]

- Sobhanverdi, R.; Akbari, A. Porosity and microstructural features of plasma sprayed Yttria stabilized Zirconia thermal barrier coatings. Ceram. Int. 2015, 41, 14517–14528. [Google Scholar] [CrossRef]

- Gerald, O.J.; Wenge, L.; Tao, Z.Y.; Long, L.C.; Qiang, L. Influence of plasma spraying current on the microstructural characteristics and tribological behaviour of plasma sprayed Cr2O3 coating. Boletín de La Soc. Española de Cerámica y Vidr. 2021, 60, 338–346. [Google Scholar] [CrossRef]

- Vaßen, R.; Bakan, E.; Sebold, D.; Sohn, Y.J. Correlation of Process Conditions, Porosity Levels and crystallinity in Atmospherically Plasma Sprayed Yb2Si2O7 Environmental Barrier Coatings. J. Compos. Sci. 2021, 5, 198. [Google Scholar] [CrossRef]

- Amit, B.; Felix, E.; Balla, V.K.; Bose, S.; Ohgami, Y.; Davies, N.M. Influence of porosity on mechanical properties and In Vivo response of Ti6Al4V implants. Acta Biomater. 2010, 6, 1640–1648. [Google Scholar] [CrossRef]

- Oh, I.H.; Nomura, N.; Masahashi, N.; Hanada, S. Mechanical properties of porous titanium compacts prepared by powder sintering. Scr. Mater 2003, 49, 1197–1202. [Google Scholar] [CrossRef]

- Daure, J.L.; Voisey, K.T.; Shipway, P.H.; Stewart, D.A. The effect of coating architecture and defects on the corrosion behaviour of a PVD multilayer Inconel 625/Cr coating. Surf. Coat. Technol. 2017, 324, 403–412. [Google Scholar] [CrossRef]

- Holleck, H.; Lahres, M.; Woll, P. Multilayer coatings—Influence of fabrication parameters on constitution and properties. Surf. Coat. Technol. 1990, 41, 179–190. [Google Scholar] [CrossRef]

- Kabir, M.S.; Zhou, Z.; Xie, Z.; Munroe, P. Designing multilayer diamond like carbon coatings for improved mechanical properties. J. Mater. Sci. Technol. 2021, 65, 108–117. [Google Scholar] [CrossRef]

- Samal, S.; Sulovský, M.; Kopeček, J.; Šittner, P. Deposition and characterization of plasma sprayed NiTi powder on stainless steel and graphite substrate. Mater. Chem. Phys. 2023, 307, 128146. [Google Scholar] [CrossRef]

- Ali, R.; Sebastiani, M.; Bemporad, E. Influence of Ti–TiN multilayer PVD-coatings design on residual stresses and adhesion. Mater. Des. 2015, 75, 47–56. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Sun, X.-W.; Wang, L.; Yang, Y.; Ren, X.-X.; Ma, Y.-D.; Cui, Y.-H.; Sun, W.-W.; Wang, X.-Y.; Dong, Y.-C. Microstructure and properties of CrB2-Cr3C2 composite coatings prepared by plasma spraying. Surf. Coat. Technol. 2021, 425, 127693. [Google Scholar] [CrossRef]

- Chicot, D.; Ageorges, H.; Voda, M.; Louis, G.; Dhia, M.A.; Palacio, C.C.; Kossman, A. Hardness of thermal sprayed coatings: Relevance of the scale of measurement. Surf. Coat. Technol. 2015, 268, 173–179. [Google Scholar] [CrossRef]

- Xu, H.; Jiri, N.; Bin, Z.; Ramirez, A.G. Nanoindentation of NiTi shape memory thin films at elevated temperatures. Int. J. Smart Nano Mater. 2011, 2, 39–49. [Google Scholar] [CrossRef]

- Buehler, W.; Wang, F. A summary of recent research on the nitinol alloys and their potential application in ocean engineering. Ocean. Eng. 1968, 1, 105–120. [Google Scholar] [CrossRef]

- Milan, H. Thermal Plasma Generators with Water Stabilized Arc. Open Plasma Phys. J. 2009, 2, 99–104. [Google Scholar]

- Davide, M.; Shimizu, Y.; Sasaki, T.; Koshizaki, N. Gas temperature and electron temperature measurements. J. Appl. Phys. 2007, 101, 013307. [Google Scholar] [CrossRef]

| Sample Name | Power (kW) | Feeding Rate (g/min) | Moving Speed (mm/s) | Net Powder Spray Time (s) | Microhardness in the Cross-Section of the Coating (HV) | Microhardness on the Surface of the Coating (HV) |

|---|---|---|---|---|---|---|

| Sample 1 | 9 | 4.1 | 2 | 30 × 6 = 180 | 289.6 | 328.6 |

| Sample 2 | 9 | 4.1 | 1 | 60 × 6 = 360 | 283 | 302.6 |

| Sample 3 | 9 | 2.1 | 2 | 25 × 6 = 150 | 273 | 259.8 |

| Sample 4 | 12 | 2.1 | 2 | 25 × 6 = 150 | 218 | 293.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samal, S.; Zeman, J.; Habr, S.; Pacherová, O.; Chandra, M.; Kopeček, J.; Šittner, P. Evaluation of Microstructure–Porosity–Hardness of Thermal Plasma-Sprayed NiTi Coating Layers. J. Manuf. Mater. Process. 2023, 7, 198. https://doi.org/10.3390/jmmp7060198

Samal S, Zeman J, Habr S, Pacherová O, Chandra M, Kopeček J, Šittner P. Evaluation of Microstructure–Porosity–Hardness of Thermal Plasma-Sprayed NiTi Coating Layers. Journal of Manufacturing and Materials Processing. 2023; 7(6):198. https://doi.org/10.3390/jmmp7060198

Chicago/Turabian StyleSamal, Sneha, Jakub Zeman, Stanislav Habr, Oliva Pacherová, Mohit Chandra, Jaromír Kopeček, and Petr Šittner. 2023. "Evaluation of Microstructure–Porosity–Hardness of Thermal Plasma-Sprayed NiTi Coating Layers" Journal of Manufacturing and Materials Processing 7, no. 6: 198. https://doi.org/10.3390/jmmp7060198

APA StyleSamal, S., Zeman, J., Habr, S., Pacherová, O., Chandra, M., Kopeček, J., & Šittner, P. (2023). Evaluation of Microstructure–Porosity–Hardness of Thermal Plasma-Sprayed NiTi Coating Layers. Journal of Manufacturing and Materials Processing, 7(6), 198. https://doi.org/10.3390/jmmp7060198