Impact Strength for 3D-Printed PA6 Polymer Composites under Temperature Changes

Abstract

1. Introduction

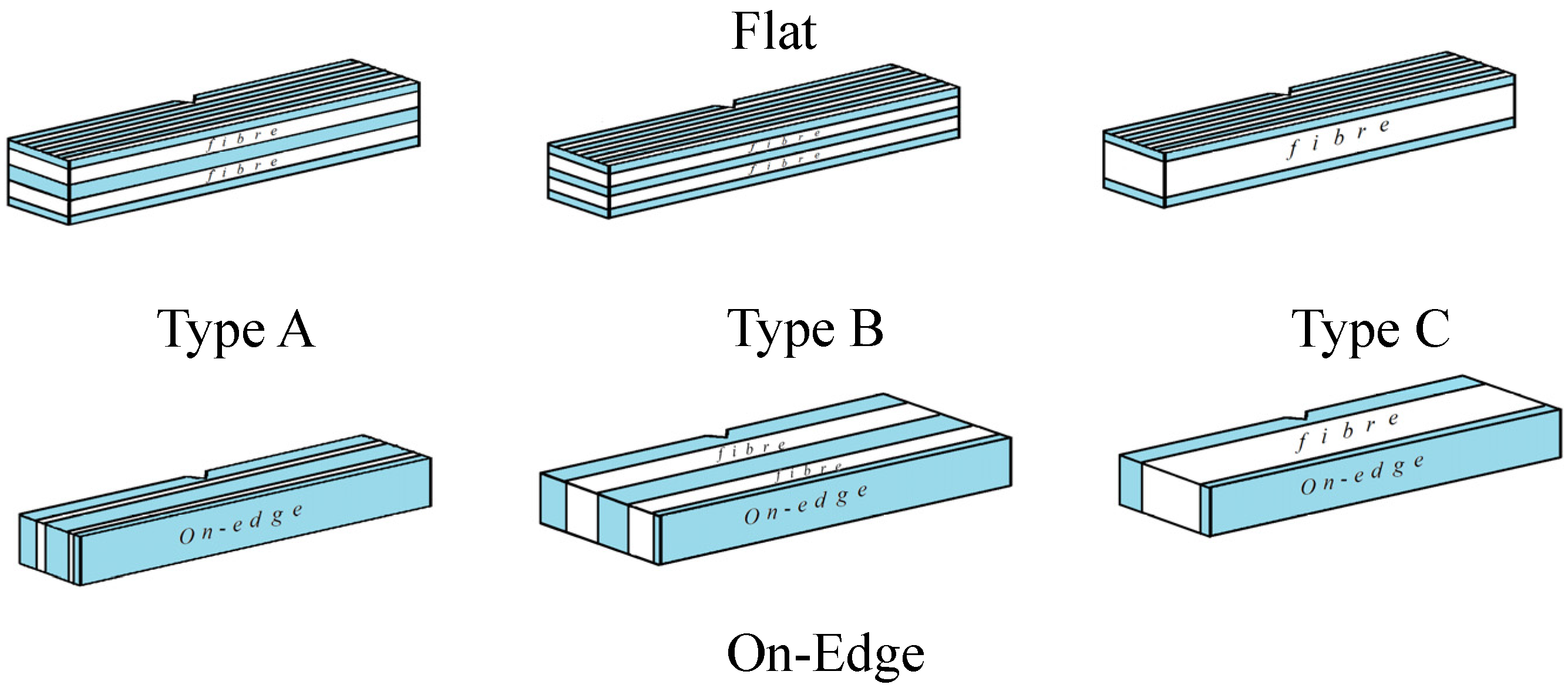

2. Material Extrusion

3. Materials and Methods

4. Results and Discussion

4.1. Impact Results

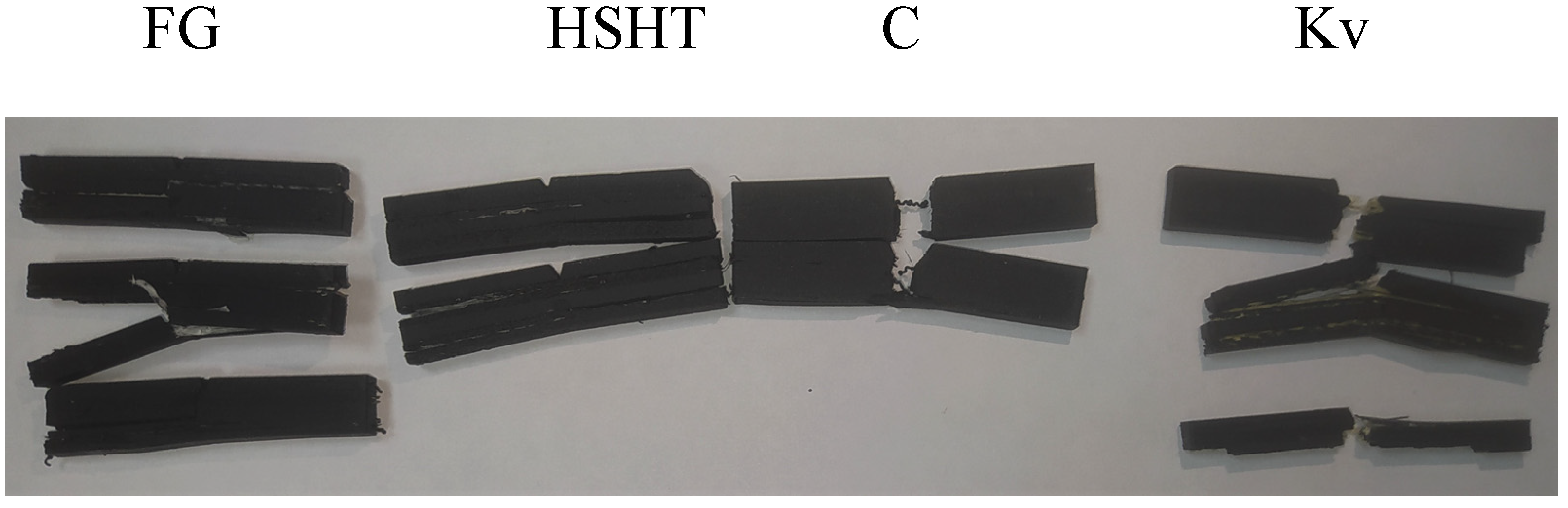

4.2. Failure Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Díaz-Rodríguez, J.G.; Pertúz-Comas, A.D.; González-Estrada, O.A. Mechanical Properties for Long Fibre Reinforced Fused Deposition Manufactured Composites. Compos. B Eng. 2021, 211, 108657. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact Damage Resistance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Compos. B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Beaumont, P.W.R. The Structural Integrity of Composite Materials and Long-Life Implementation of Composite Structures. Appl. Compos. Mater. 2020, 27, 449–478. [Google Scholar] [CrossRef]

- Castro, J.T.P.; Meggiolaro, M. Fatigue Design Techniques, 3rd ed.; CreateSpace: Scotts Valley, CA, USA, 2016; Volume I, ISBN 1530797365. [Google Scholar]

- Diaz, J.G.; Pertúz, A.D.; Ariza, C.J.; García, D.; Pinto, W. Monotonic Crack Propagation in a Notched Polymer Matrix Composite Reinforced with Continuous Fiber and Printed by Material Extrusion. J. Prog. Addit. Manuf. 2023, 8, 733–744. [Google Scholar] [CrossRef]

- Stoia, D.I.; Marsavina, L.; Linul, E. Mode I Critical Energy Release Rate of Additively Manufactured Polyamide Samples. Theor. Appl. Fract. Mech. 2021, 114, 102968. [Google Scholar] [CrossRef]

- Yasa, E. Anisotropic Impact Toughnness of Chopped Carbon Fiber Reinforced Nylon Fabricated by Material-Extrusion-Based Additive Manufacturing. Anadolu Univ. J. Sci. Technol.—A Appl. Sci. Eng. 2019, 20, 195–203. [Google Scholar] [CrossRef][Green Version]

- Sauer, J.M. Evaluation of the Mechanical Properties of 3D Printed Carbon Fiber Composites; South Dakota State University: Brookings, SD, USA, 2018. [Google Scholar]

- ISO ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. International Standard Organization: Geneva, Switzerland, 2021.

- Pertuz, A.D.; Díaz-Cardona, S.; González-Estrada, O.A. Static and Fatigue Behaviour of Continuous Fibre Reinforced Thermoplastic Composites Manufactured by Fused Deposition Modelling Technique. Int. J. Fatigue 2020, 130, 105275. [Google Scholar] [CrossRef]

- González-Estrada, O.A.; Pertuz Comas, A.D.; Díaz Rodríguez, J.G. Monotonic Load Datasets for Additively Manufactured Thermoplastic Reinforced Composites. Data Brief 2020, 29, 105295. [Google Scholar] [CrossRef]

- Prajapati, A.R.; Dave, H.K.; Raval, H.K. Impact Energy Absorption and Fracture Mechanism of FFF Made Fiberglass Reinforced Polymer Composites. Rapid Prototyp. J. 2023, 29, 275–287. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.-F.M. Impact Resistance and Failure Mechanism of 3D Printed Continuous Fiber-Reinforced Cellular Composites. J. Text. Inst. 2021, 112, 752–766. [Google Scholar] [CrossRef]

- Ojha, K.K.; Gugliani, G.; Francis, V. Impact and Tensile Performance of Continuous 3D-Printed Kevlar Fiber-Reinforced Composites Manufactured by Fused Deposition Modelling. Prog. Addit. Manuf. 2022. [Google Scholar] [CrossRef]

- Papa, I.; Manco, E.; Epasto, G.; Lopresto, V.; Squillace, A. Impact Behaviour and Non Destructive Evaluation of 3D Printed Reinforced Composites. Compos. Struct. 2022, 281, 115112. [Google Scholar] [CrossRef]

- Vaško, M.; Sága, M.; Majko, J.; Vaško, A.; Handrik, M. Impact Toughness of FRTP Composites Produced by 3D Printing. Materials 2020, 13, 5654. [Google Scholar] [CrossRef] [PubMed]

- Scrocco, M.; Chamberlain, T.; Chow, C.; Weinreber, L. Impact Testing of 3D Printed Kevlar-Reinforced Onyx Material. In Proceedings of the 29th Annual International Solid Freeform Fabrication Conference, Austin, TX, USA, 13–15 August 2018. [Google Scholar]

- Barbero, E.J. Finite Element Analysis of Composite Materials Using ANSYS, 2nd ed.; CRC Press: Boca Raton, Fl, USA, 2013. [Google Scholar]

- Roberson, D.A.; Torrado Perez, A.R.; Shemelya, C.M.; Rivera, A.; MacDonald, E.; Wicker, R.B. Comparison of Stress Concentrator Fabrication for 3D Printed Polymeric Izod Impact Test Specimens. Addit. Manuf. 2015, 7, 1–11. [Google Scholar] [CrossRef]

- Pyl, L.; Kalteremidou, K.A.; Van Hemelrijck, D. Exploration of Specimen Geometry and Tab Configuration for Tensile Testing Exploiting the Potential of 3D Printing Freeform Shape Continuous Carbon Fibre-Reinforced Nylon Matrix Composites. Polym. Test. 2018, 71, 318–328. [Google Scholar] [CrossRef]

- Pertuz-Comas, A.D.; Díaz, J.G.; Meneses-Duran, O.J.; Niño-Álvarez, N.Y.; León-Becerra, J. Flexural Fatigue in a Polymer Matrix Composite Material Reinforced with Continuous Kevlar Fibers Fabricated by Additive Manufacturing. Polymers 2022, 14, 3586. [Google Scholar] [CrossRef]

- Dickson, A.N.; Ross, K.-A.; Dowling, D.P. Additive Manufacturing of Woven Carbon Fibre Polymer Composites. Compos. Struct. 2018, 206, 637–643. [Google Scholar] [CrossRef]

- Angelidis, N.; Irving, P.E. Detection of Impact Damage in CFRP Laminates by Means of Electrical Potential Techniques. Compos. Sci. Technol. 2007, 67, 594–604. [Google Scholar] [CrossRef]

- Cantwell, W.J.; Morton, J. Detection of Impact Damage in CFRP Laminates. Compos. Struct. 1985, 3, 241–257. [Google Scholar] [CrossRef]

- Araya-Calvo, M.; López-Gómez, I.; Chamberlain-Simon, N.; León-Salazar, J.L.; Guillén-Girón, T.; Corrales-Cordero, J.S.; Sánchez-Brenes, O. Evaluation of Compressive and Flexural Properties of Continuous Fiber Fabrication Additive Manufacturing Technology. Addit. Manuf. 2018, 22, 157–164. [Google Scholar] [CrossRef]

- Van Der Klift, F.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D Printing of Continuous Carbon Fibre Reinforced Thermo-Plastic (CFRTP) Tensile Test Specimens. Open J. Compos. Mater. 2016, 06, 18–27. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Imeri, A.; Fidan, I.; Elkelany, M. 3D Printed Fiber Reinforced Polymer Composites—Structural Analysis. Compos. B Eng. 2019, 175, 107112. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of Continuous Carbon, Glass and Kevlar Fibre Reinforced Polymer Composites Using Additive Manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Dutra, T.A.; Ferreira, R.T.L.; Resende, H.B.; Guimarães, A. Mechanical Characterization and Asymptotic Homogenization of 3D-Printed Continuous Carbon Fiber-Reinforced Thermoplastic. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 133. [Google Scholar] [CrossRef]

- Heitkamp, T.; Girnth, S.; Kuschmitz, S.; Klawitter, G.; Waldt, N.; Vietor, T. Continuous Fiber-Reinforced Material Extrusion with Hybrid Composites of Carbon and Aramid Fibers. Appl. Sci. 2022, 12, 8830. [Google Scholar] [CrossRef]

- REV 5.0—08/01/2021 Markforged Composites Mechanical Properties. Available online: http://static.markforged.com/downloads/composites-data-sheet.pdf (accessed on 31 August 2022).

- Parrado-Agudelo, J.Z.; Narváez-Tovar, C. Mechanical Characterization of Polylactic Acid, Polycaprolactone and Lay-Fomm 40 Parts Manufactured by Fused Deposition Modeling, as a Function of the Printing Parameters. ITECKNE 2019, 16, 25–31. [Google Scholar] [CrossRef]

- León, B.J.; Díaz-Rodríguez, J.G.; González-Estrada, O.A. Daño En Partes de Manufactura Aditiva Reforzadas Por Fibras Continuas. Rev. UIS Ing. 2020, 19, 161–175. [Google Scholar] [CrossRef]

- Thomas, G.; Antoni, M.; Gozdz, S. Three Dimensional Printer with Composite Filament Fabrication. US9156205B2, 13 October 2015. [Google Scholar]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.M. A Critical Review on 3D Printed Continuous Fiber-Reinforced Composites: History, Mechanism, Materials and Properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties, 2nd ed.; Cambridge University Press: Cambridge, UK, 2014; ISBN 9781139878326. [Google Scholar]

- ASMT D-370; Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ASTM: West Conshohocken, PA, USA, 2019.

- Wallin, K.; Nevasmaa, P.; Planman, T.; Valo, M. Evolution of the Charpy-V Test from a Quality Control Test to a Materials Evaluation Tool for Structural Integrity Assessment. Eur. Struct. Integr. Soc. 2002, 30, 57–68. [Google Scholar]

| Type | A, Caminero [2] (kJ/m2) | B, Caminero [2] (kJ/m2) | C, Caminero [2] (kJ/m2) | C, Heitkamp [30] (kJ/m2) |

|---|---|---|---|---|

| f-CRTP | 22.21 | 33.21 | 57.5 | 12.6 |

| Vf | 0.0344 | 0.2494 | 0.5318 | 0.258 |

| f-KvRTP | 30.11 | 83.69 | 125.47 | 30.42 |

| Vf | 0.086 | 0.295 | 0.5606 | 0.258 |

| f-FGRTP | 74.16 | 206.66 | 271.19 | N/A |

| Vf | 0.084 | 0.2915 | 0.556 | N/A |

| e-CRTP | 24.73 | 59.76 | 82.26 | N/A |

| Vf | 0.0338 | 0.2482 | 0.3316 | N/A |

| e-KvRTP | 36.42 | 95.11 | 184.76 | N/A |

| Vf | 0.0782 | 0.2533 | 0.3465 | N/A |

| e-FGRTP | 86.3 | 246.19 | 280.95 | N/A |

| Vf | 0.0782 | 0.2968 | 0.343 | N/A |

| Material | E1 (GPa) | σ1 (MPa) | J (Izod) (N/m) | Relative Density |

|---|---|---|---|---|

| Onyx | 2.4 | 40 | 330 | 1.2 |

| Standard | ASTM D638 | ASTM D638 | ASTM D256 | NA |

| C | 60 | 800 | 960 | 1.4 |

| FG | 21 | 590 | 2600 | 1.5 |

| Kv | 27 | 610 | 2000 | 1.2 |

| HSHT | 21 | 600 | 3100 | 1.5 |

| Standard | ASTM D3039 | ASTM D3039 | ASTM D256 | NA |

| Group | A | B | C | D | E | |

|---|---|---|---|---|---|---|

| Temperature Medium | Liq N2 | Solid CO2 | T amb | Warm Glycerine | Hot Glycerine | |

| Temp, °C | −40 | ~−15 | 25 | ~50 | ~90 | |

| Sample ID | C | 3 | 3 | 3 | 3 | 3 |

| Fg | 4 | 3 | 3 | 3 | 3 | |

| Kv | 3 | 3 | 3 | 3 | 3 | |

| HSHT | 3 | 3 | 3 | 3 | 3 |

| T, °C | kJ/m2 | SD | |

|---|---|---|---|

| FG | 24.9 | 460.7 | 1.3 |

| −15.0 | 326.4 | 16.7 | |

| −40.0 | 178.6 | 47.3 | |

| 85.8 | 300.4 | 22.8 | |

| 51.0 | 349.2 | 11.5 | |

| HSHT | 25.5 | 362.1 | 7.2 |

| −18.7 | 316.6 | 26.5 | |

| −40.0 | 268.3 | 18.4 | |

| 94.3 | 172.5 | 51.3 | |

| 52.7 | 263.1 | 3.1 | |

| Kv | 25.3 | 236.2 | 16.7 |

| −19.3 | 110.0 | 9.9 | |

| −39.3 | 125.3 | 24.1 | |

| 91.3 | 206.6 | 98.3 | |

| 49.0 | 286.6 | 36.2 | |

| C | 25.2 | 40.9 | 3.2 |

| −18.7 | 12.2 | 1.5 | |

| −36.7 | 34.6 | 13.2 | |

| 81.7 | 100.0 | 4.8 | |

| 49.3 | 96.9 | 16.3 |

| Material\Constant | a | b | c | d | R2 |

|---|---|---|---|---|---|

| FG | 0.0004 | −0.0734 | 2.3096 | 4034.36 | 92.19 |

| HSHT | 0.0002 | −0.0436 | 0.2928 | 355.61 | 93.89 |

| Kv | −0.0006 | 0.0297 | 2.2783 | 151.63 | 99.79 |

| C | −0.0004 | 0.0317 | 0.9323 | 10.869 | 97.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz-Rodríguez, J.G.; Pertuz-Comas, A.D.; Bohórquez-Becerra, O.R. Impact Strength for 3D-Printed PA6 Polymer Composites under Temperature Changes. J. Manuf. Mater. Process. 2023, 7, 178. https://doi.org/10.3390/jmmp7050178

Díaz-Rodríguez JG, Pertuz-Comas AD, Bohórquez-Becerra OR. Impact Strength for 3D-Printed PA6 Polymer Composites under Temperature Changes. Journal of Manufacturing and Materials Processing. 2023; 7(5):178. https://doi.org/10.3390/jmmp7050178

Chicago/Turabian StyleDíaz-Rodríguez, Jorge Guillermo, Alberto David Pertuz-Comas, and Oscar Rodolfo Bohórquez-Becerra. 2023. "Impact Strength for 3D-Printed PA6 Polymer Composites under Temperature Changes" Journal of Manufacturing and Materials Processing 7, no. 5: 178. https://doi.org/10.3390/jmmp7050178

APA StyleDíaz-Rodríguez, J. G., Pertuz-Comas, A. D., & Bohórquez-Becerra, O. R. (2023). Impact Strength for 3D-Printed PA6 Polymer Composites under Temperature Changes. Journal of Manufacturing and Materials Processing, 7(5), 178. https://doi.org/10.3390/jmmp7050178