Determination of the Influence of the Tool Side Stress Superposition and Tool Geometry on the Cut Surface Quality during Precision Shear Cutting

Abstract

1. Introduction

1.1. Single-Stroke Shear Cutting and Its Characteristics

1.2. Cut Surface Characteristics and Influencing Factors

1.3. Superposition of Compression Stress

2. Materials and Methods

3. Results and Discussion

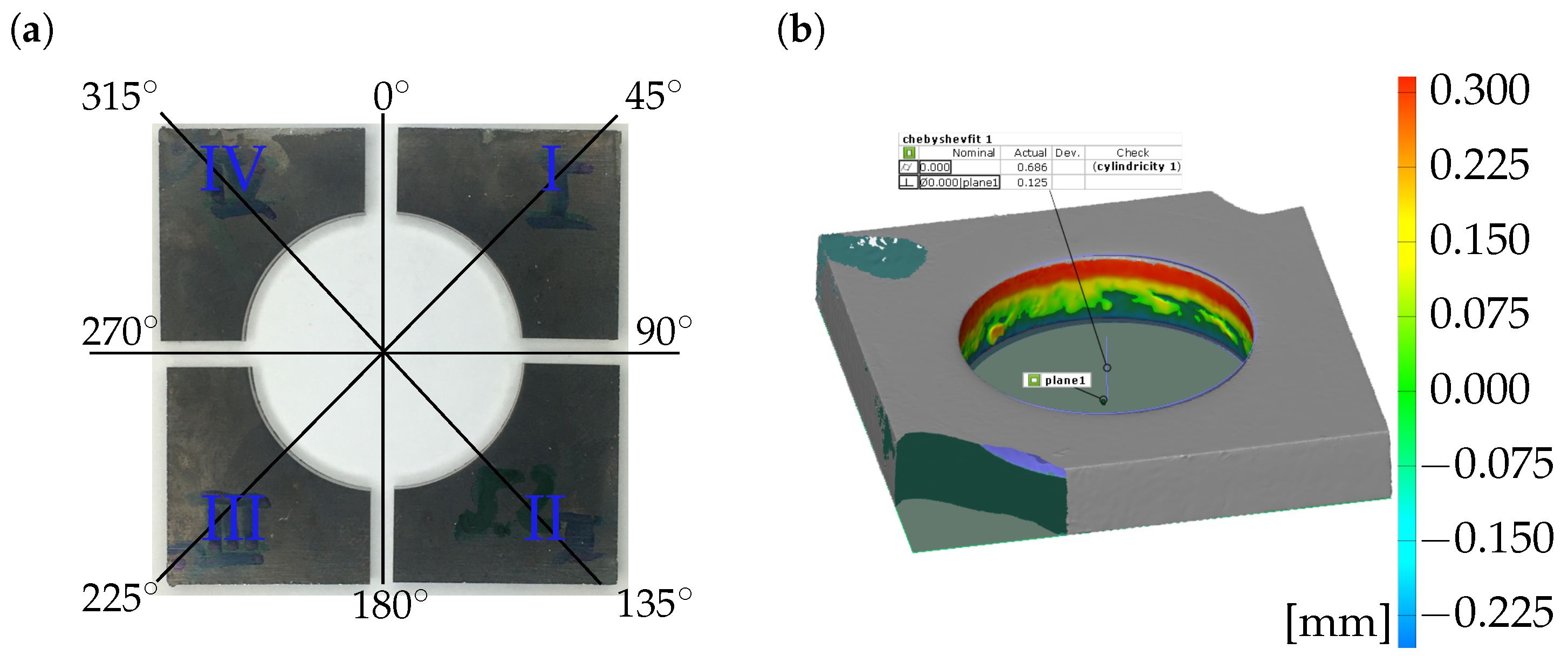

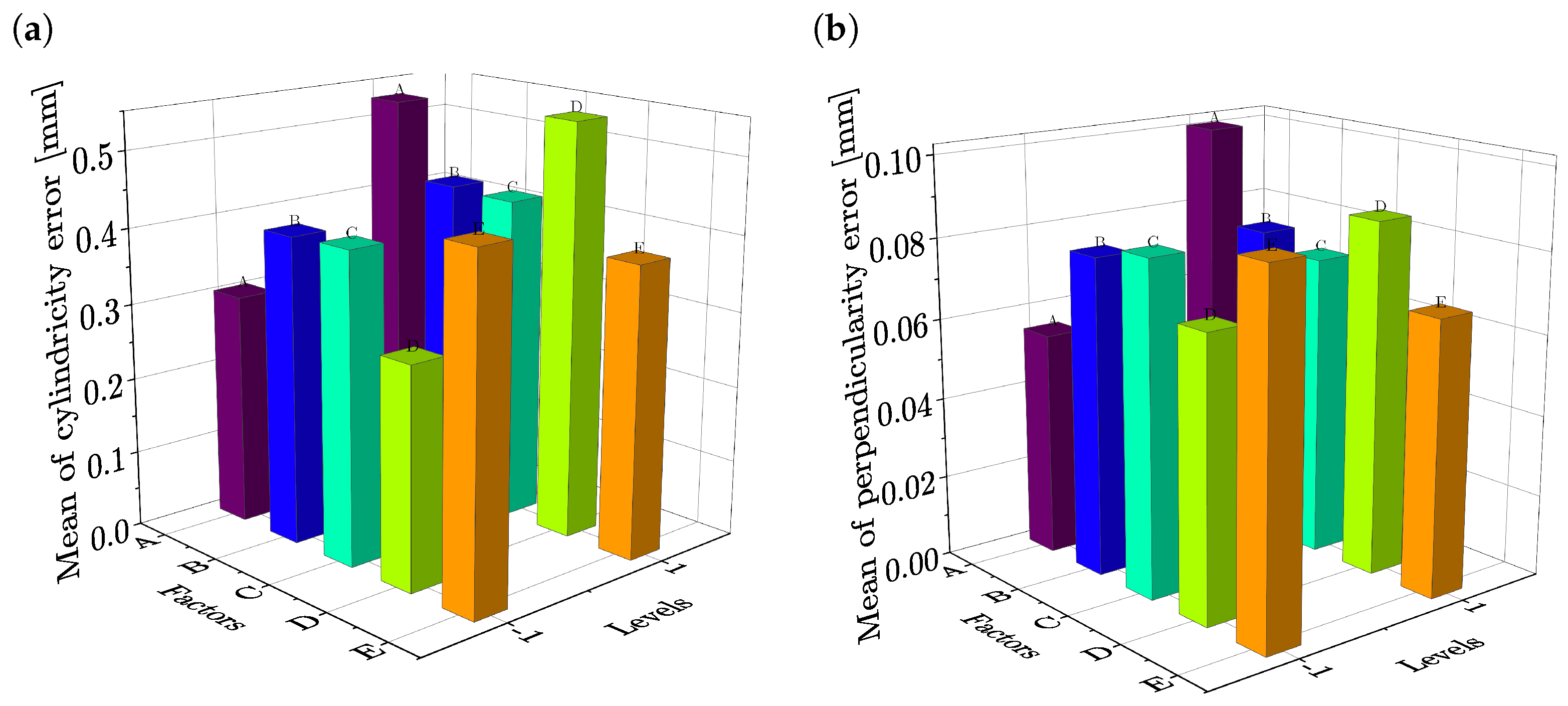

3.1. Influence on Cylindricity and Perpendicularity Error

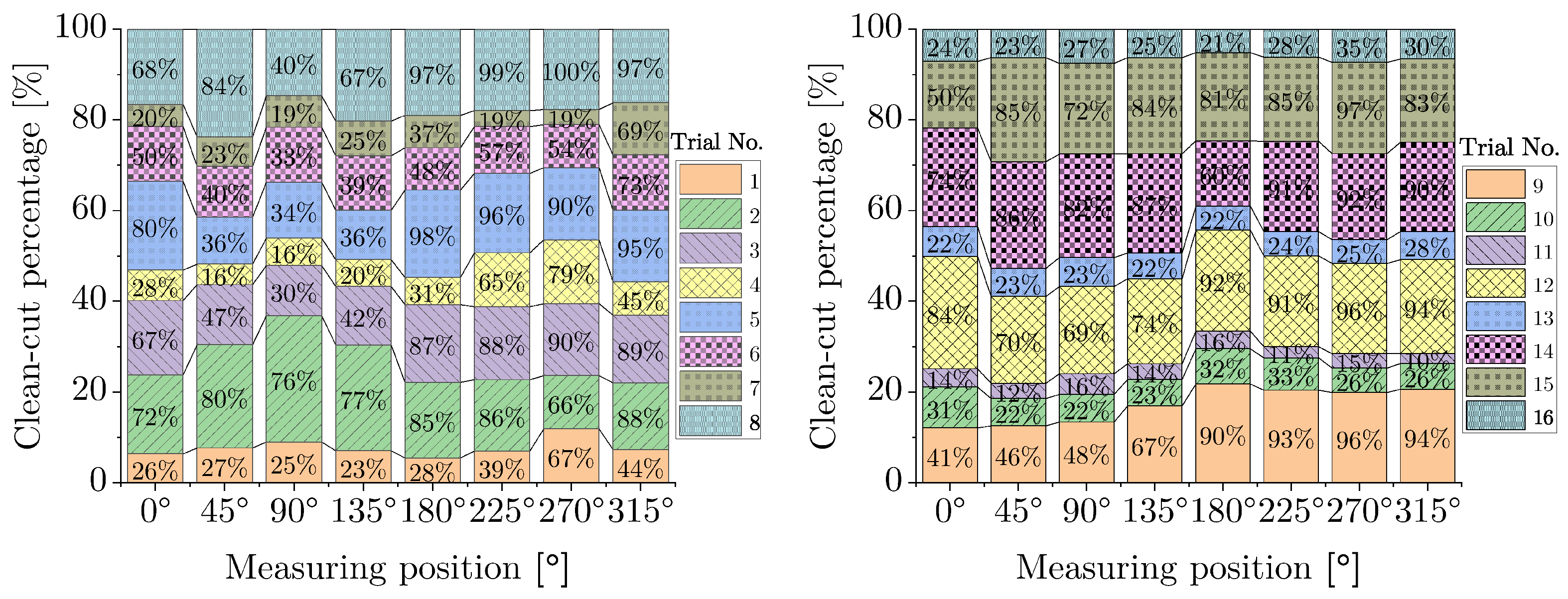

3.2. Influence on the Clean-Cut Zone

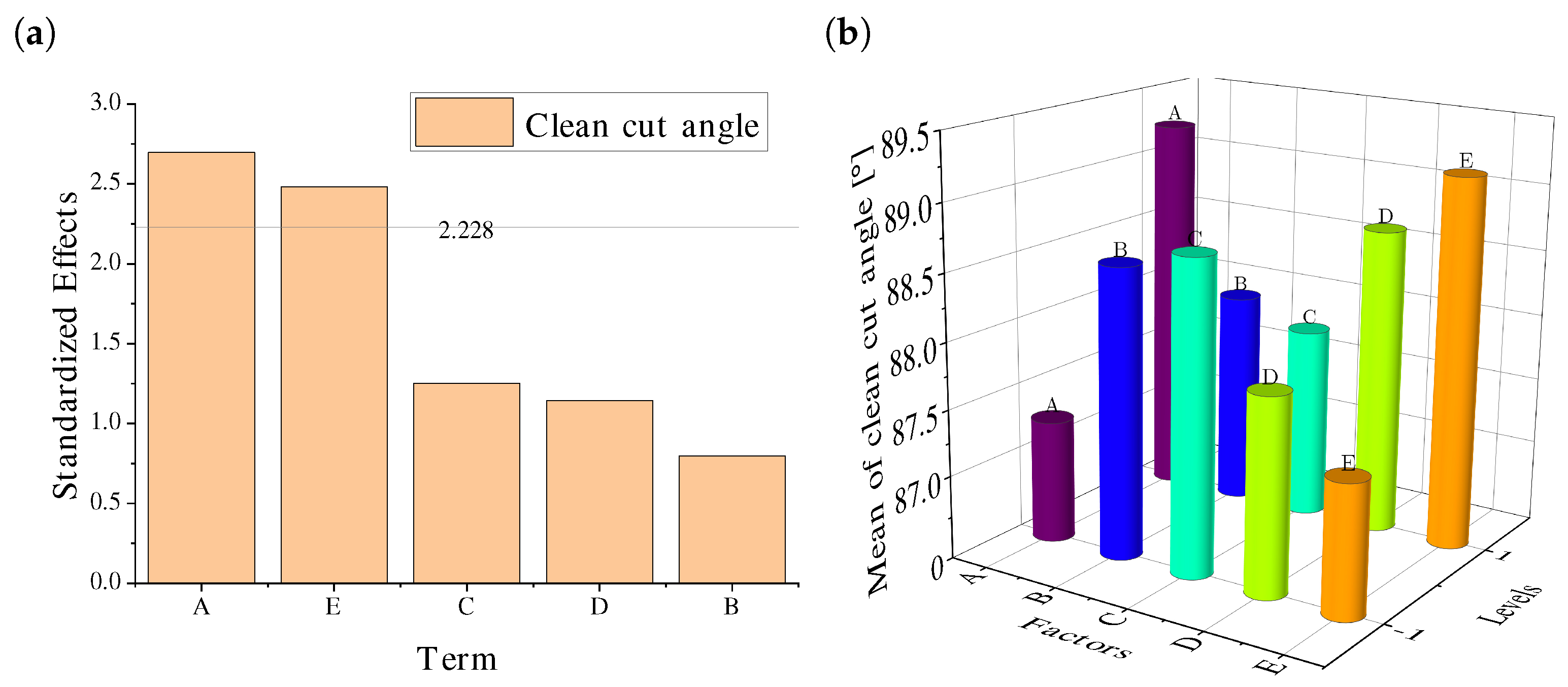

3.3. Influence on the Clean-Cut Angle and Fracture Surface Angle

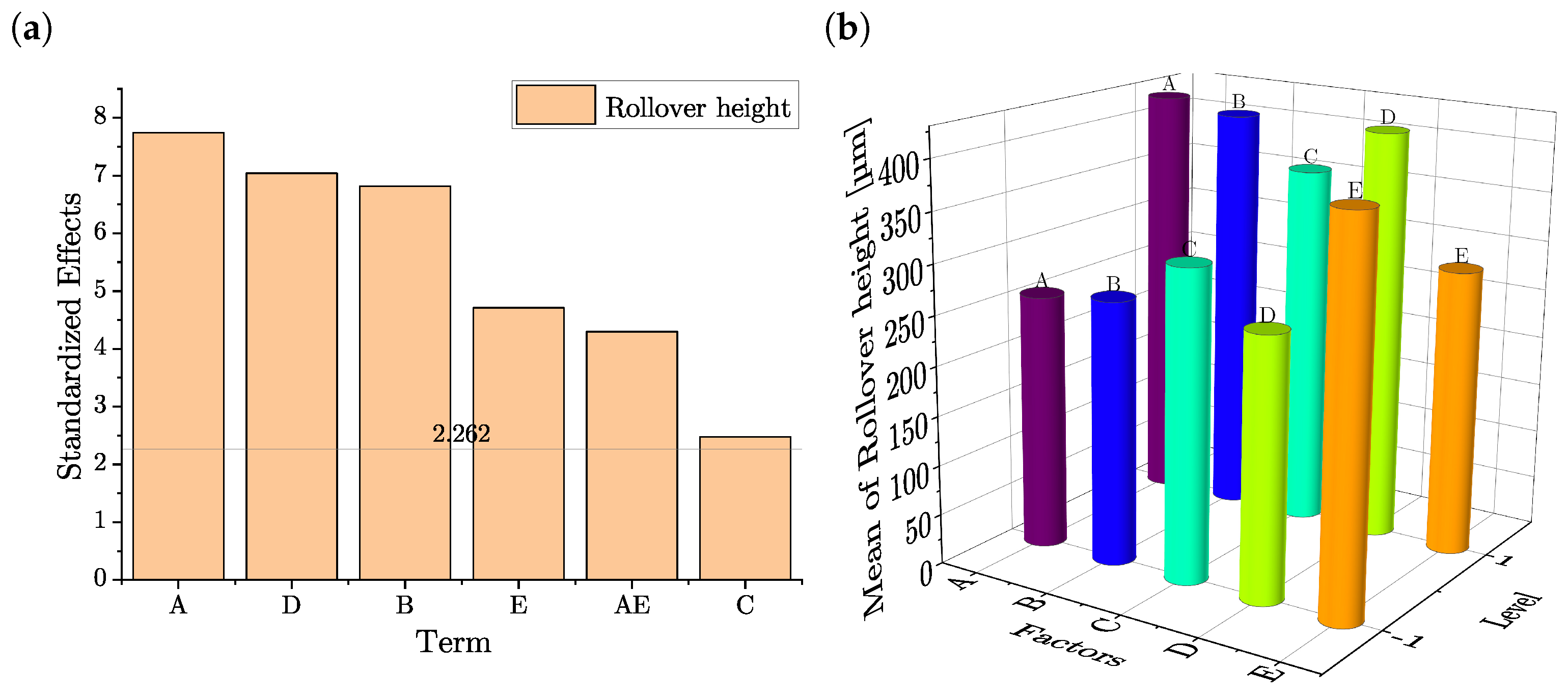

3.4. Influence on Rollover Height and Width

3.5. Influence on Shear Cutting and Retraction Force

4. Conclusions and Outlook

- The radial pre-stress decreases the cylindricity error and rollover height, and increases the perpendicularity of the clean-cut zone.

- In terms of the clean-cut zone, pre-stress has a significant interaction with the sheet thickness and clearance. In terms of rollover height, it has a significant interaction only with the sheet thickness and is of much importance when considering thicker sheets.

- The radial pre-stress increases the punch force but on the other hand, it helps in reducing tool wear causing retraction force.

- The perpendicularity error is solely dependent on the sheet thickness. This may be due to the absolute value of the fracture zone and its angle.

- Rollover height depends on every main factor and rollover width is dependent only on sheet thickness.

- In addition to rollover height, the cutting edge geometry is also important for the fracture surface angle, where a rounded edge was better than a sharp edge by around 6°.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AHSS | Advanced High Strength Steel |

| IT | ISO degree of Tolerance |

| UHSS | Ultra High Strength Steel |

| VDI | Association of German Engineers |

References

- Samodajev, N. Advanced High Strength Steel (AHSS) for Stronger, Lighter and Safer Cars. Available online: https://matmatch.com/blog/advanced-high-strength-steel-stronger-lighter-safer-cars/ (accessed on 22 September 2021).

- World Steel Association. Steel in Automotive. Available online: https://worldsteel.org/steel-topics/steel-markets/automotive/ (accessed on 22 September 2021).

- Levy, B.S.; van Tyne, C.J. Review of the Shearing Process for Sheet Steels and Its Effect on Sheared-Edge Stretching. J. Mater. Eng. Perform. 2012, 21, 1205–1213. [Google Scholar] [CrossRef]

- Mori, K.i.; Abe, Y.; Suzui, Y. Improvement of stretch flangeability of ultra high strength steel sheet by smoothing of sheared edge. J. Mater. Process. Technol. 2010, 210, 653–659. [Google Scholar] [CrossRef]

- Matsuno, T.; Kuriyama, Y.; Murakami, H.; Yonezawa, S.; Kanamaru, H. Effects of Punch Shape and Clearance on Hole Expansion Ratio and Fatigue Properties in Punching of High Strength Steel Sheets. Steel Res. Int. 2010, 81, 853–856. [Google Scholar]

- Neugebauer, R.; Kräusel, V.; Barthel, T.; Jesche, F.; Schönherr, J. Influence of a defined pre-load on the stress state in the precision cutting process. CIRP Ann. 2013, 62, 271–274. [Google Scholar] [CrossRef]

- Hoffmann, H. Handbuch Umformen; Edition Handbuch der Fertigungstechnik, Hanser Verlag: München, Germany, 2012. [Google Scholar]

- VDI 2906. Quality of Cut Faces of (Sheet) Metal Parts After Cutting, Blanking, Trimming or Piercing; Sheet 5: Fineblanking; VDI Verein Deutscher Ingenieure: Düsseldorf, Germany, 1994. [Google Scholar]

- VDI 2906. Quality of Cut Faces of (Sheet) Metal Parts After Cutting, Blanking, Trimming or Piercing Shearing, Form of Sheared Edge and Characteristic Values; Sheet 2: Shear Cutting; VDI Verein Deutscher Ingenieure: Düsseldorf, Germany, 1994. [Google Scholar]

- Chintamani, J.; Sriram, S. Sheared Edge Characterization of Steel Products used for Closure Panel Applications. In Proceedings of the SAE 2006 World Congress and Exhibition, SAE International, Detroit, MI, USA, 3–6 April 2006. [Google Scholar] [CrossRef]

- Kwak, T.S.; Kim, Y.J.; Bae, W.B. Finite element analysis on the effect of die clearance on shear planes in fine blanking. J. Mater. Process. Technol. 2002, 130–131, 462–468. [Google Scholar] [CrossRef]

- Han, S.S. Study for Sheared Edge Quality of High Strength Steel Sheet. Key Eng. Mater. 2014, 626, 252–257. [Google Scholar] [CrossRef]

- Klocke, F.; Sweeney, K.; Raedt, H. Improved tool design for fine blanking through the application of numerical modeling techniques. J. Mater. Process. Technol. 2001, 115, 70–75. [Google Scholar] [CrossRef]

- Nothhaft, K.; Suh, J.; Golle, M.; Picas, I.; Casellas, D.; Volk, W. Shear cutting of press hardened steel: Influence of punch chamfer on process forces, tool stresses and sheared edge qualities. Prod. Eng. 2012, 6, 413–420. [Google Scholar] [CrossRef]

- Ishiguro, T.; Yoshida, Y.; Yukawa, N.; Ishikawa, T. Deformation Analysis of Shearing Process Using Results of Notched Round Bar Tension Test. Mater. Trans. 2009, 50, 1671–1677. [Google Scholar] [CrossRef]

- Mori, K.; Abe, Y.; Kidoma, Y.; Kadarno, P. Slight clearance punching of ultra-high strength steel sheets using punch having small round edge. Int. J. Mach. Tools Manuf. 2013, 65, 41–46. [Google Scholar] [CrossRef]

- Kutuniva, K.; Karjalainen, J.A.; Mäntyjärvi, K. Effect of Convex Sheared Punch Geometry on Cutting Force of Ultra-High-Strength Steel. Key Eng. Mater. 2012, 504–506, 1359–1364. [Google Scholar] [CrossRef]

- Shaheen, W.; Kanapathipillai, S.; Mathew, P.; Prusty, B.G. Optimization of compound die piercing punches and double cutting process parameters using finite element analysis. PRoceedings Inst. Mech. Eng. Part J. Eng. Manuf. 2020, 234, 3–13. [Google Scholar] [CrossRef]

- Thipprakmas, S.; Jin, M.; Murakawa, M. An investigation of material flow analysis in fineblanking process. J. Mater. Process. Technol. 2007, 192–193, 237–242. [Google Scholar] [CrossRef]

- Fraunhofer IWU. High Speed Impact Cutting of Sheets and Tubes. Available online: https://www.iwu.fraunhofer.de/content/dam/iwu/en/documents/Infosheet/Infosheet-High-Speed-Impact-Cutting-Of-Sheets-And-Tubes.pdf (accessed on 24 October 2021).

- Gu, J.; Alamos, F.; Schoch, D.; Bornhorst, J.; Kim, H. A Study on Effects of the Press Speed on Sheared Edge Formability. IOP Conf. Ser. Mater. Sci. Eng. 2020, 967, 012064. [Google Scholar] [CrossRef]

- Krutz, P.; Leonhardt, A.; Graf, A.; Winter, S.; Rehm, M.; Kräusel, V.; Dix, M. Development and testing of a flexible test bench for high-speed impact shear-cutting with linear motors. In Proceedings of the SHEMET 2023—20th International Conference on Sheet Metal, Erlangen, Germany, 2–5 April 2023; MaterialsResearchForum LLC: Nuremberg, Germany, 2023; pp. 19–26. [Google Scholar] [CrossRef]

- Doege, E. Handbuch Umformtechnik: Grundlagen Technologien Maschinen; Springer eBook Collection Computer Science & Engineering, Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Hörmann, F. Einfluss der Prozessparameter auf einstufige Scherschneidverfahren zum Ausschneiden mit endkonturnaher Form. Ph.D. Thesis, Technische Universität München, München, Germany, 2008. [Google Scholar]

- Senn, S.; Liewald, M. Numerical investigation of a new sheet metal shear cutting tool design to increase the part quality by superposed compression stress. J. Phys. Conf. Ser. 2018, 1063, 012181. [Google Scholar] [CrossRef]

- Senn, S.; Liewald, M. Investigation of a new sheet metal shear cutting tool design to increase the part quality by superposed compression stress. IOP Conf. Ser. Mater. Sci. Eng. 2019, 651, 012088. [Google Scholar] [CrossRef]

- Briesenick, D.; Liewald, M.; Senn, S. Improvement of shear cutting process by stress superposition via cross-elastic partholder. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1238, 012027. [Google Scholar] [CrossRef]

- DIN EN ISO 12180-1; Geometrische Produktspezifikation (GPS)—Zylindrizität—Teil 1: Begriffe und Kenngrößen der Zylinderform. Beuth Verlag GmbH: Berlin, Germany, 2011.

- DIN EN ISO 12180-2; Geometrische Produktspezifikation (GPS)—Zylindrizität—Teil 2: Spezifikationsoperatoren. Beuth Verlag GmbH: Berlin, Germany, 2011.

- DIN EN ISO 1101; Geometrische Produktspezifikation (GPS)—Geometrische Tolerierung—Tolerierung von Form, Richtung, Ort und Lauf. Beuth Verlag GmbH: Berlin, Germany, 2017.

| Sheet Thickness [mm] | Rolling Direction [°] | Young’s Modulus [GPa] | Yield Strength [MPa] | Tensile Strength [MPa] | Elongation at Break [%] |

|---|---|---|---|---|---|

| 3 | 0 | 188 | 520 | 601 | 10.3 |

| 45 | 184 | 532 | 578 | 9.9 | |

| 90 | 249 | 574 | 612 | 9.1 | |

| 8 | 0 | 181 | 516 | 601 | 10.5 |

| 45 | 189 | 542 | 574 | 9.3 | |

| 90 | 221 | 576 | 625 | 8.8 |

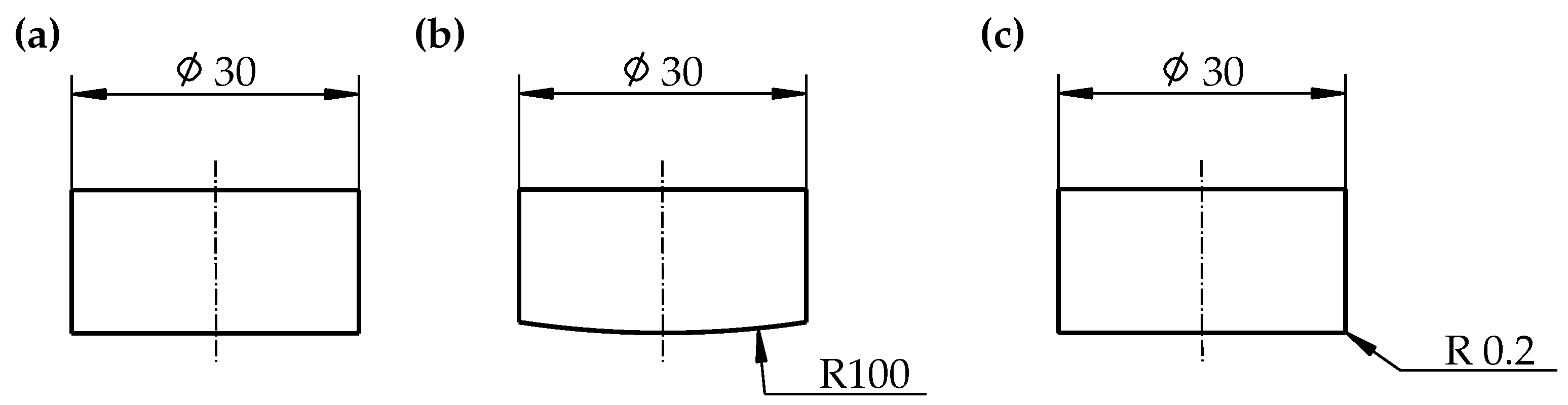

Levels | Sheet Thickness [mm] (A) | Punch Face Geometry (B) | Cutting Edge Geometry (C) | Cutting Clearance [% of ] (D) | Radial Pre-Stress [% of ] (E) |

|---|---|---|---|---|---|

| −1 | 3 | flat | sharp | 1.3 | 0 |

| 1 | 8 | konvex (R100) | radius (R0.2) | 10 | 45 |

| Trial No. | A | B | C | D | E |

|---|---|---|---|---|---|

| [mm] | [% of ] | [% of ] | |||

| 1 | 3 | flat | sharp | 10 | 0 |

| 2 | 3 | flat | radius | 1.3 | 0 |

| 3 | 3 | konvex | sharp | 1.3 | 0 |

| 4 | 3 | konvex | radius | 10 | 0 |

| 5 | 3 | flat | sharp | 1.3 | 45 |

| 6 | 3 | flat | radius | 10 | 45 |

| 7 | 3 | konvex | sharp | 10 | 45 |

| 8 | 3 | konvex | radius | 1.3 | 45 |

| 9 | 8 | flat | sharp | 1.3 | 0 |

| 10 | 8 | flat | radius | 10 | 0 |

| 11 | 8 | konvex | sharp | 10 | 0 |

| 12 | 8 | konvex | radius | 1.3 | 0 |

| 13 | 8 | flat | sharp | 10 | 45 |

| 14 | 8 | flat | radius | 1.3 | 45 |

| 15 | 8 | konvex | sharp | 1.3 | 45 |

| 16 | 8 | konvex | radius | 10 | 45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Graf, A.; Kräusel, V.; Weise, D.; Petrů, J.; Koziorek, J.; Bhandari, P. Determination of the Influence of the Tool Side Stress Superposition and Tool Geometry on the Cut Surface Quality during Precision Shear Cutting. J. Manuf. Mater. Process. 2023, 7, 145. https://doi.org/10.3390/jmmp7040145

Graf A, Kräusel V, Weise D, Petrů J, Koziorek J, Bhandari P. Determination of the Influence of the Tool Side Stress Superposition and Tool Geometry on the Cut Surface Quality during Precision Shear Cutting. Journal of Manufacturing and Materials Processing. 2023; 7(4):145. https://doi.org/10.3390/jmmp7040145

Chicago/Turabian StyleGraf, Alexander, Verena Kräusel, Dieter Weise, Jana Petrů, Jiří Koziorek, and Pravishan Bhandari. 2023. "Determination of the Influence of the Tool Side Stress Superposition and Tool Geometry on the Cut Surface Quality during Precision Shear Cutting" Journal of Manufacturing and Materials Processing 7, no. 4: 145. https://doi.org/10.3390/jmmp7040145

APA StyleGraf, A., Kräusel, V., Weise, D., Petrů, J., Koziorek, J., & Bhandari, P. (2023). Determination of the Influence of the Tool Side Stress Superposition and Tool Geometry on the Cut Surface Quality during Precision Shear Cutting. Journal of Manufacturing and Materials Processing, 7(4), 145. https://doi.org/10.3390/jmmp7040145