Building Orientation and Post Processing of Ti6Al4V Produced by Laser Powder Bed Fusion Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of the Ti6Al4V Samples

2.2. Post-Processing of the Ti6Al4V Samples

2.2.1. Anodization

2.2.2. Etching

2.3. Characterization of the Ti6Al4V Samples

2.3.1. Surface Wettability

2.3.2. Optical Microscopy: Three-Dimensional Surface Reconstruction and Roughness Analysis

2.3.3. Scanning Electron Microscopy: Surface Topography Analysis

2.3.4. Statistical Analysis

2.4. Biocompatibility Test, and Mineralization Assay

2.4.1. Cell Line

2.4.2. Biocompatibility Tests: Direct and Indirect ATP Cell Viability Assay

2.4.3. Mineralization Evaluation by Osteogenic Gene Expression Analysis

3. Results

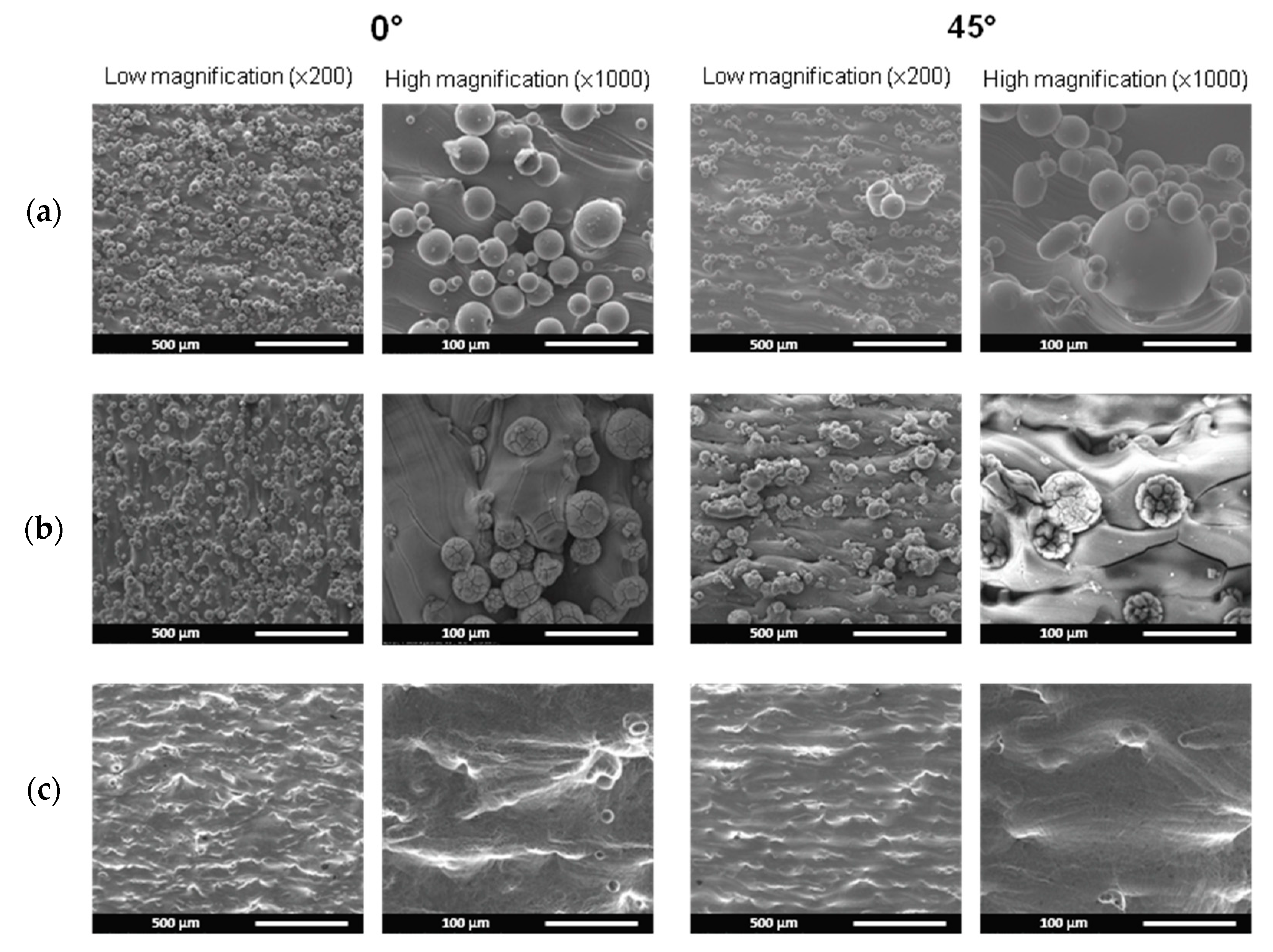

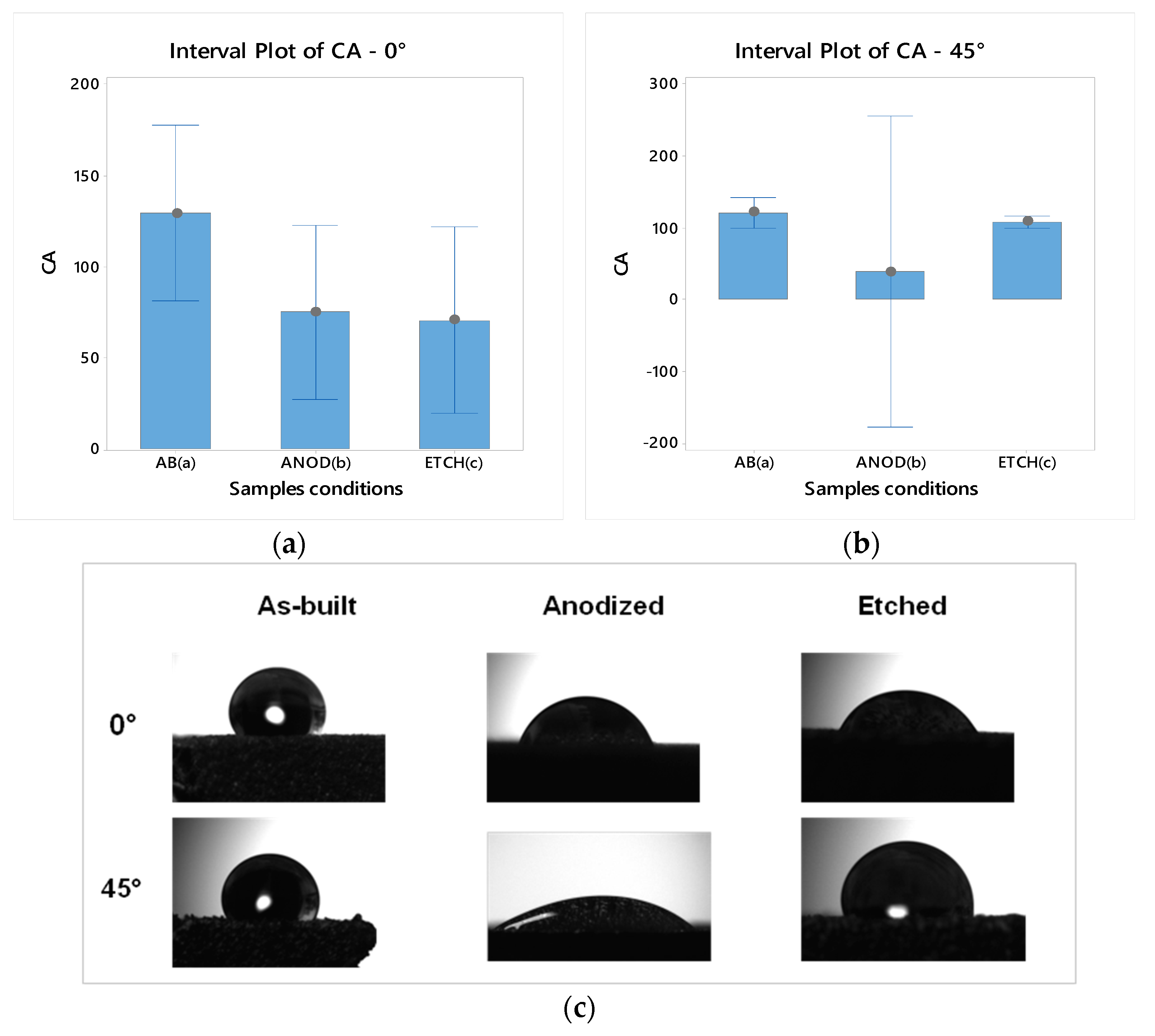

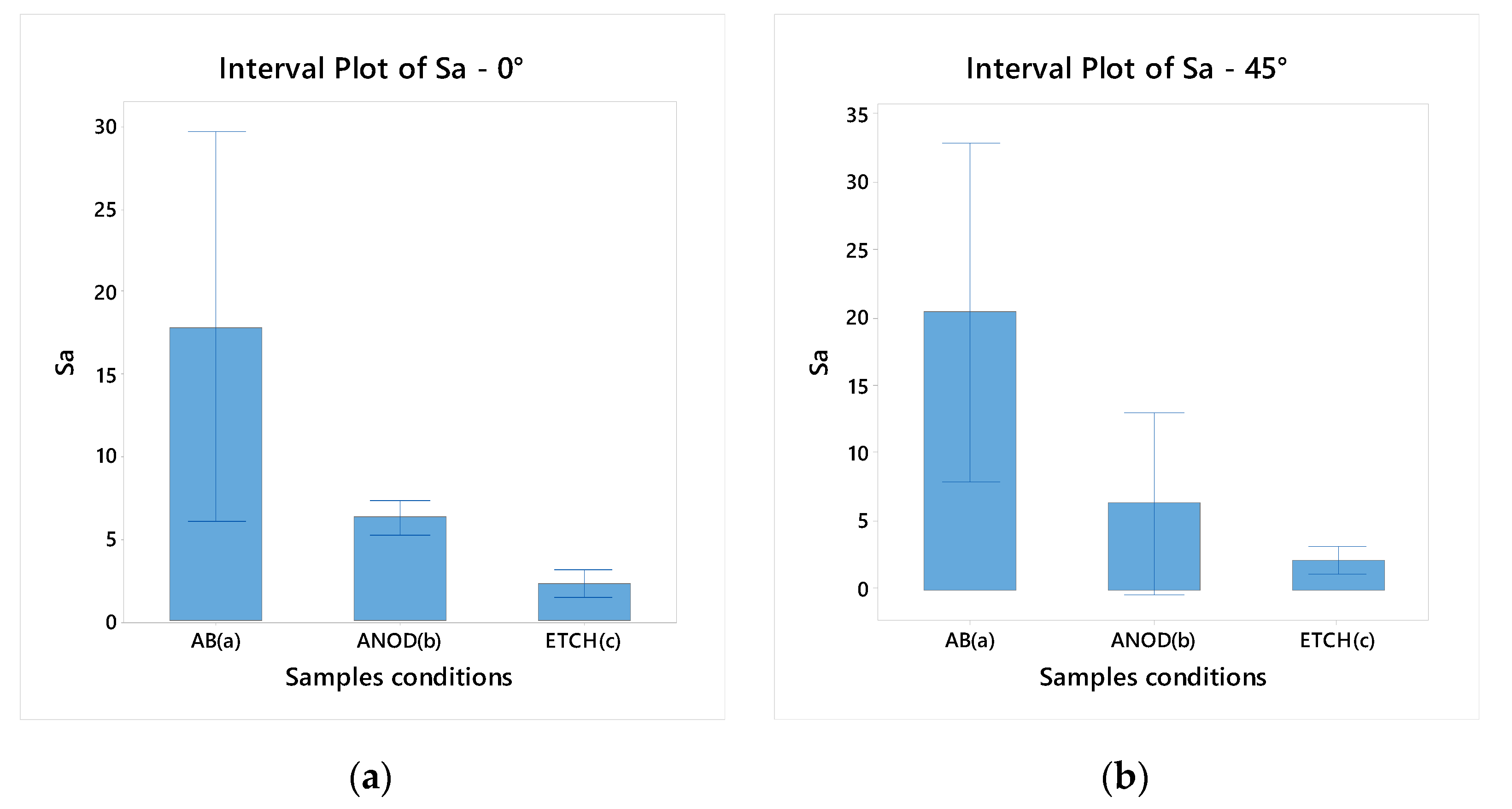

3.1. Surface Topography of the Titanium Samples

3.2. Biocompatibility of Titanium Scaffolds

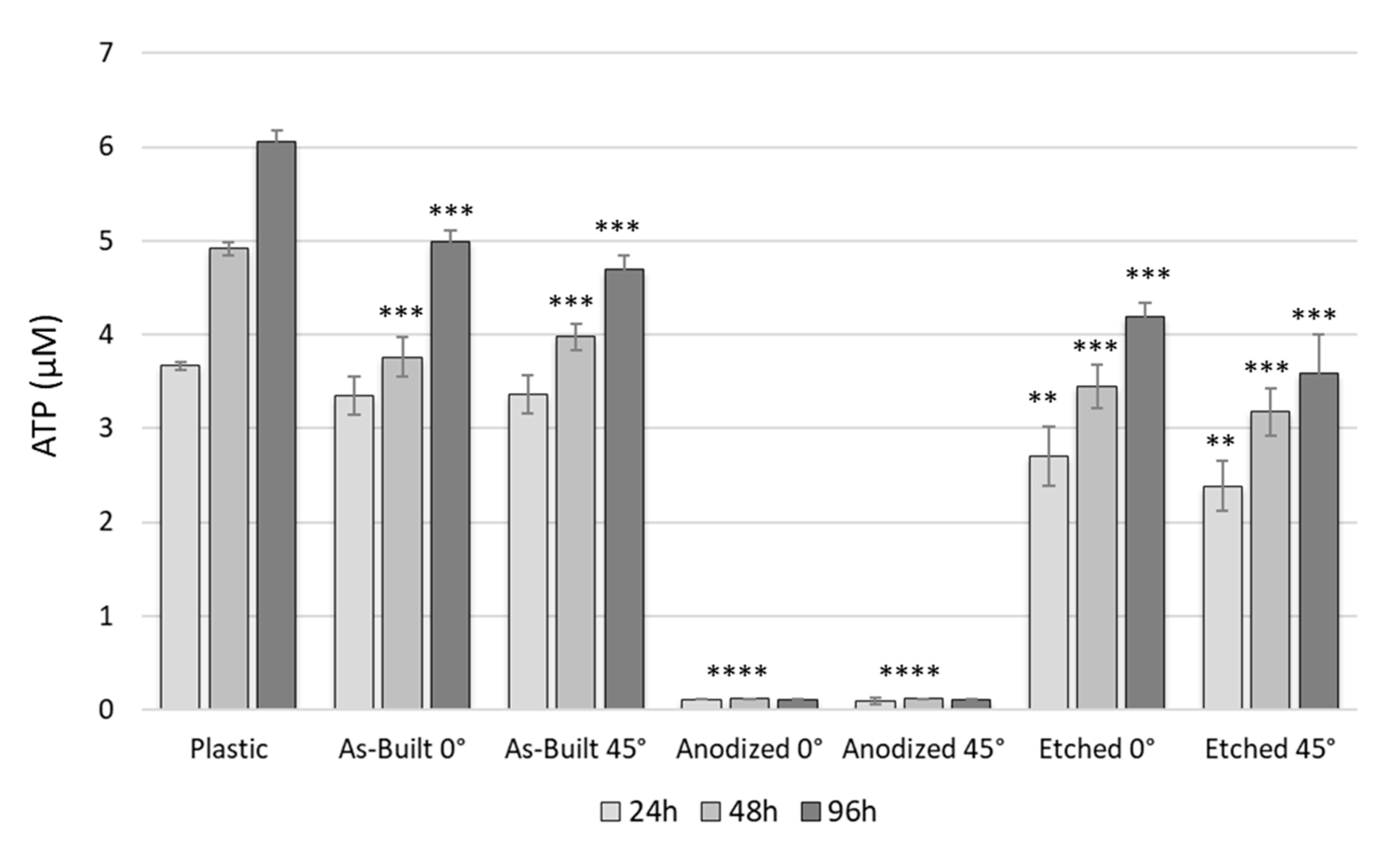

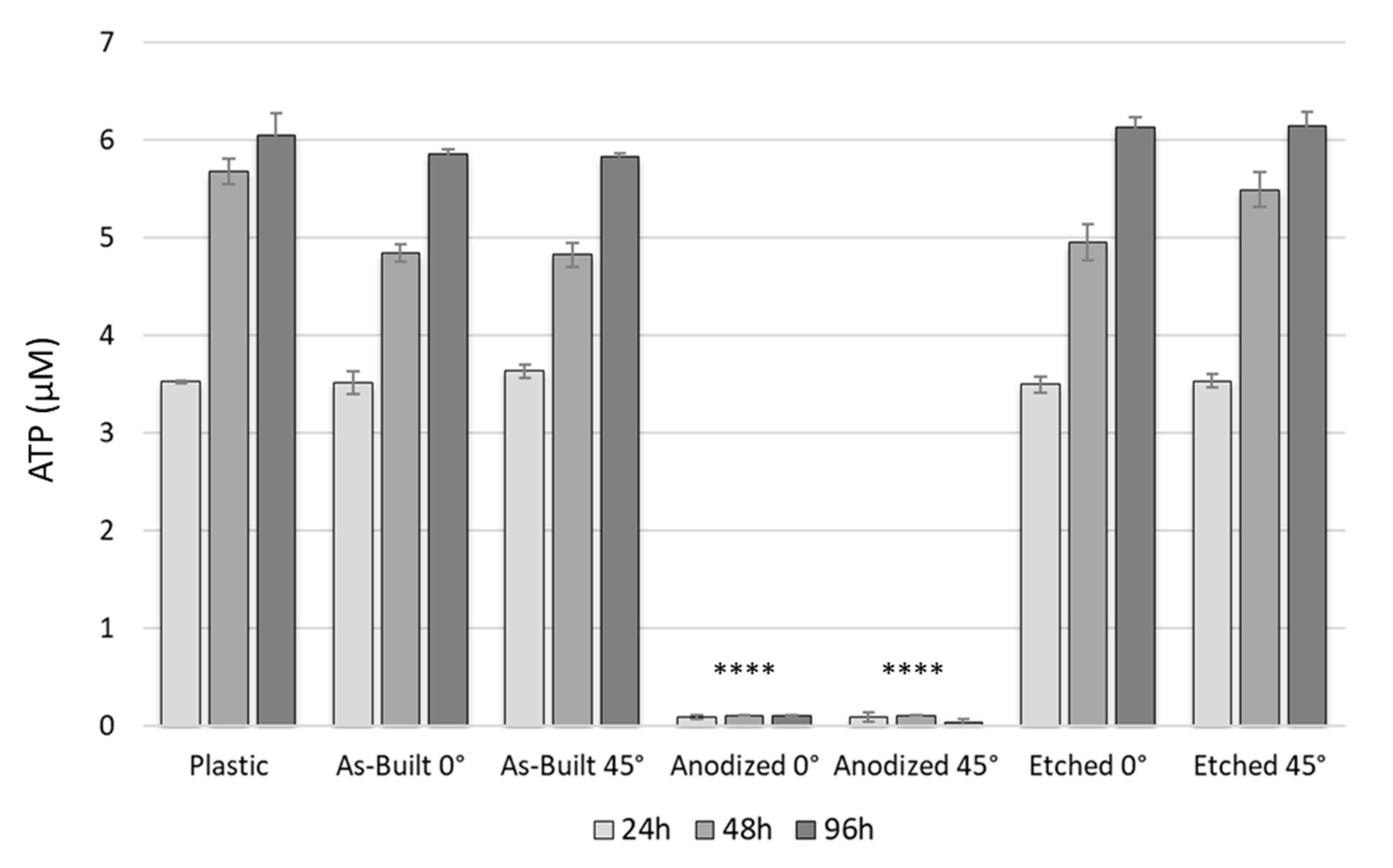

3.2.1. Direct rATP Assay

3.2.2. Indirect rATP Assay

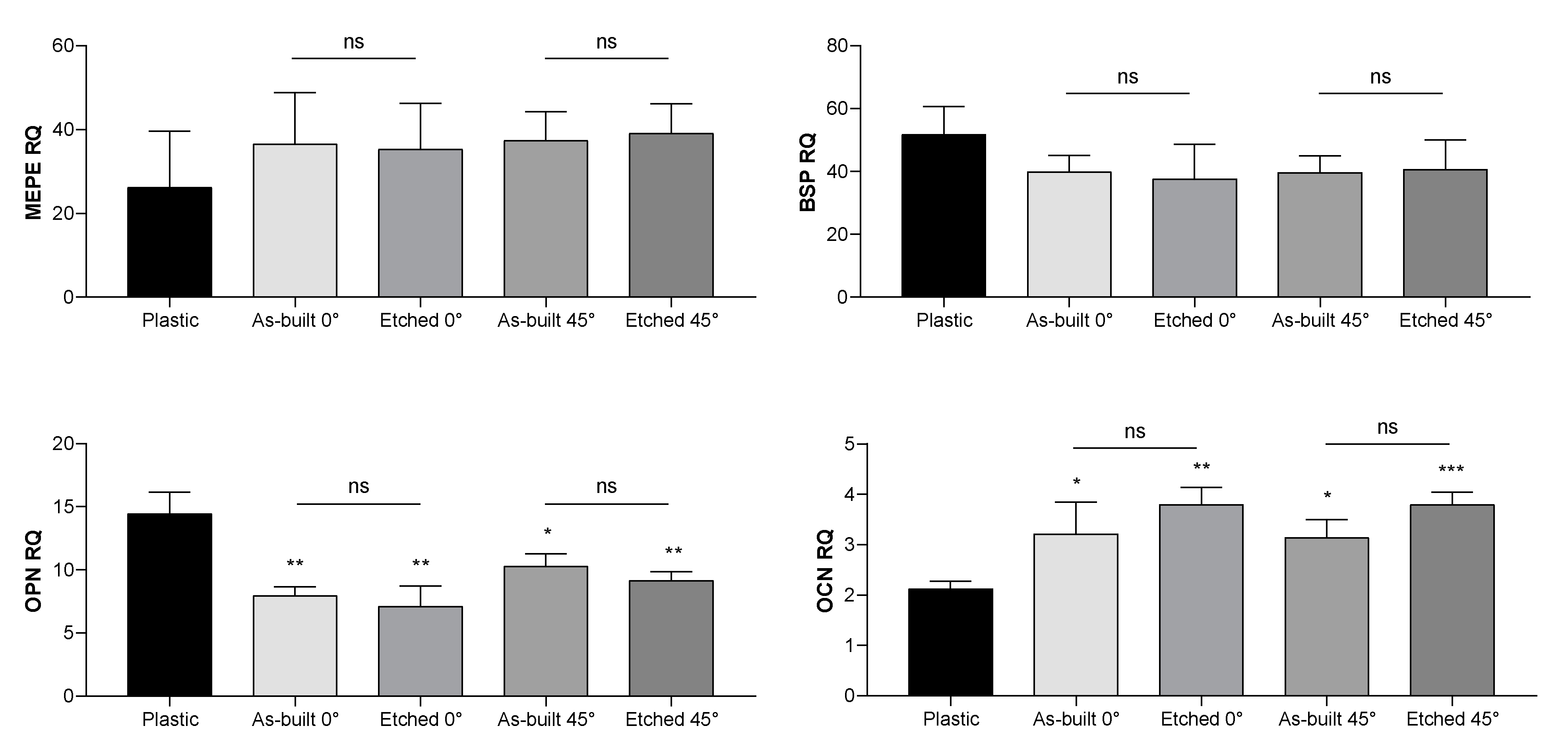

3.2.3. Osteogenic Differentiation and Mineralization on Titanium Scaffolds

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Velu, R.; Calais, T.; Jayakumar, A.; Raspall, F. A Comprehensive Review on Bio-Nanomaterials for Medical Implants and Feasibility Studies on Fabrication of Such Implants by Additive Manufacturing Technique. Materials 2020, 13, 92. [Google Scholar] [CrossRef] [PubMed]

- Ginestra, P.; Ceretti, E.; Fiorentino, A. Potential of modeling and simulations of bioengineered devices: Endoprostheses, prostheses and orthoses. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2016, 230, 607–638. [Google Scholar] [CrossRef] [PubMed]

- Bayata, F.; Yildiz, C. The effects of design parameters on mechanical failure of Ti-6Al-4V implants using finite element analysis. Eng. Fail. Anal. 2020, 110, 104445. [Google Scholar] [CrossRef]

- Doliveux, S.; Jamjoom, F.Z.; Nadra, M.; Gallucci, G.O.; Hamilton, A. Fabrication technique for a custom implant emergence profile on 3D printed casts. J. Prosthet. Dent. 2020, 123, 571–575. [Google Scholar] [CrossRef] [PubMed]

- Angelats, D.; Ginestra, P. Cell Bioprinting: The 3D-Bioplotter™ Case. Materials 2019, 12, 4005. [Google Scholar] [CrossRef] [PubMed]

- Lowther, M.; Cox, S.C.; Davey, A.; Hussain, A.; Ginestra, P.; Carter, L.; Eisenstein, N.; Grover, L.M.; Cox, S.C. Clinical, industrial, and research perspectives on powder bed fusion additively manufactured metal implants. Addit. Manuf. 2019, 28, 565–584. [Google Scholar] [CrossRef]

- Tilton, M.; Lewis, G.S.; Wee, H.B.; Armstrong, A.; Hast, M.W.; Manogharan, G. Additive manufacturing of fracture fixation implants: Design, material characterization, biomechanical modeling and experimentation. Addit. Manuf. 2020, 33, 101137. [Google Scholar] [CrossRef]

- Li, C.-H.; Wu, C.-H.; Lin, C.-L. Design of a patient-specific mandible reconstruction implant with dental prosthesis for metal 3D printing using integrated weighted topology optimization and finite element analysis. J. Mech. Behav. Biomed. Mater. 2020, 105, 103700. [Google Scholar] [CrossRef]

- Ni, J.; Ling, H.; Zhang, S.; Wang, Z.; Peng, Z.; Benyshek, C.; Zan, R.; Miri, A.K.; Li, Z.; Zhang, X.; et al. Three-dimensional printing of metals for biomedical applications. Mater. Today Bio 2019, 3, 100024. [Google Scholar] [CrossRef]

- Nirish, M.; Rajendra, R. Suitability of metal additive manufacturing processes for part topology optimization—A comparative study. Mater. Today Proc. 2020, 27, 1601–1607. [Google Scholar] [CrossRef]

- Zhao, D.; Han, C.; Li, Y.; Li, J.; Zhou, K.; Wei, Q.; Liu, J.; Shi, Y. Improvement on mechanical properties and corrosion resistance of titanium-tantalum alloys in-situ fabricated via selective laser melting. J. Alloy. Compd. 2019, 804, 288–298, ISSN 0925-8388. [Google Scholar] [CrossRef]

- Makhetha, W.M.I.; Becker, T.H.; Sacks, N. Post-Processing Framework for As-Built LPBF Ti-6Al-4V Parts Towards Meeting Industry Functional Requirements. JOM 2022, 74, 764–776. [Google Scholar] [CrossRef]

- Grover, T.; Pandey, A.; Kumari, S.T.; Awasthi, A.; Singh, B.; Dixit, P.; Singhal, P.; Saxena, K. Role of titanium in bio implants and additive manufacturing: An overview. Mater. Today Proc. 2020, 26, 3071–3080. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Chen, L.-Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef]

- Khorasani, A.M.; Goldberg, M.; Doeven, E.H.; Littlefair, G. Titanium in Biomedical Applications—Properties and Fabrication: A Review. J. Biomater. Tissue Eng. 2015, 5, 593–619. [Google Scholar] [CrossRef]

- Sidhu, S.S.; Gepreel, M.A.-H.; Bahraminasab, M. Advances in titanium bio-implants: Alloy design, surface engineering and manufacturing processes. J. Mater. Res. 2022, 37, 2487–2490. [Google Scholar] [CrossRef]

- Balasubramanian Gayathri, Y.K.; Kumar, R.L.; Ramalingam, V.V.; Priyadharshini, G.S.; Kumar, K.S.; Prabhu, T.R. Additive Manufacturing of Ti-6Al-4V alloy for Biomedical Applications. J. Bio Tribo. Corros. 2022, 8, 98. [Google Scholar] [CrossRef]

- Murr, L.E. Metallurgy principles applied to powder bed fusion 3D printing/additive manufacturing of personalized and optimized metal and alloy biomedical implants: An overview. J. Mater. Res. Technol. 2020, 9, 1087–1103. [Google Scholar] [CrossRef]

- Bhanupratap, G.; Deepak, S.; Rupesh, G.; Ravi, B. Ti6Al4V scaffolds fabricated by laser powder bed fusion with hybrid volumetric energy density. Rapid Prototyp. J. 2023, 29, 67–79, ISSN 1355-2546. [Google Scholar]

- Aufa, A.N.; Zaki Hassan, M.; Ismail, Z. Recent advances in Ti-6Al-4V additively manufactured by selective laser melting for biomedical implants: Prospect development. J. Alloy. Compd. 2022, 896, 163072, ISSN 0925-8388. [Google Scholar] [CrossRef]

- Buhairi, M.A.; Foudzi, F.M.; Jamhari, F.I.; Sulong, A.B.; Radzuan, N.A.M.; Muhamad, N.; Mohamed, I.F.; Azman, A.H.; Harun, W.S.W.; Al-Furjan, M.S.H. Review on volumetric energy density: Influence on morphology and mechanical properties of Ti6Al4V manufactured via laser powder bed fusion. Prog. Addit. Manuf. 2022. [Google Scholar] [CrossRef]

- Eskandari, H.; Lashgari, H.R.; Zangeneh, S.; Kong, C.; Ye, L.; Eizadjou, M.; Wang, H. Microstructural characterization and mechanical properties of SLM-printed Ti–6Al–4V alloy: Effect of build orientation. JMatR 2022, 37, 2645. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Fredriksson, G.; Yadroitsava, I.; Kazantseva, N.; Du Plessis, A.; Yadroitsev, I. Deformation behavior and microstructure of Ti6Al4V manufactured by SLM. Phys. Procedia 2016, 83, 778–788. [Google Scholar] [CrossRef]

- NEW Mukalay, T.A.; Johan Trimble, J.A.; Mpofu, K.; Muvunzi, R. A systematic review of process uncertainty in Ti6Al4V-selective laser melting. CIRP J. Manuf. Sci. Technol. 2022, 36, 185–212, ISSN 1755-5817. [Google Scholar] [CrossRef]

- Carter, L.N.; Villapún, V.M.; Grover, L.; Cox, S.C. Exploring the duality of powder adhesion and underlying surface roughness in laser powder bed fusion processed Ti-6Al-4V. J. Manuf. Process. 2022, 81, 14–26, ISSN 1526-6125. [Google Scholar] [CrossRef]

- Dos Santos, L.C.P.; Malheiros, F.C.; Guarato, A.Z. Surface parameters of as-built additive manufactured metal for intraosseous dental implants. J. Prosthet. Dent. 2020, 124, 217–222. [Google Scholar] [CrossRef]

- Rodriguez, G.M.; Bowen, J.; Zelzer, M.; Stamboulis, A. Selective modification of Ti6Al4V surfaces for biomedical applications. RSC Adv. 2020, 10, 17642–17652. [Google Scholar] [CrossRef]

- Zhou, W.; Peng, X.; Ma, Y.; Hu, Y.; Wu, Y.; Lan, F.; Weir, M.D.; Li, M.; Ren, B.; Oates, T.W.; et al. Two-staged time-dependent materials for the prevention of implant-related infections. Acta Biomater. 2020, 101, 128–140. [Google Scholar] [CrossRef]

- Sarker, A.; Tran, N.; Rifai, A.; Brandt, M.; A Tran, P.; Leary, M.; Fox, K.; Williams, R. Rational design of additively manufactured Ti6Al4V implants to control Staphylococcus aureus biofilm formation. Materialia 2019, 5, 100250. [Google Scholar] [CrossRef]

- Xie, K.; Guo, Y.; Zhao, S.; Wang, L.; Wu, J.; Tan, J.; Yang, Y.; Wu, W.; Jiang, W.; Hao, Y. Partially Melted Ti6Al4V Particles Increase Bacterial Adhesion and Inhibit Osteogenic Activity on 3D-printed Implants: An In Vitro Study. Clin. Orthop. Relat. Res. 2019, 477, 2772–2782. [Google Scholar] [CrossRef]

- Ren, B.; Wan, Y.; Liu, C.; Wang, H.; Yu, M.; Zhang, X.; Huang, Y. Improved osseointegration of 3D printed Ti-6Al-4V implant with a hierarchical micro/nano surface topography: An in vitro and in vivo study. Mat. Sci. Eng. C-Mater. 2021, 118, 111505. [Google Scholar] [CrossRef] [PubMed]

- Ginestra, P.; Fiorentino, A.; Ceretti, E. Micro-structuring of Titanium Collectors by Laser Ablation Technique: A Promising Approach to Produce Micro-patterned Scaffolds for Tissue Engineering Applications. Procedia CIRP 2017, 65, 19–24. [Google Scholar] [CrossRef]

- Ginestra, P.; Pandini, S.; Fiorentino, A.; Benzoni, P.; Dell’Era, P.; Ceretti, E. Microstructured scaffold for guided cellular orientation: Poly(ε-caprolactone) electrospinning on laser ablated titanium collector. CIRP J. Manuf. Sci. Technol. 2017, 19, 147–157. [Google Scholar] [CrossRef]

- Malik, A.; Rouf, S.; Ul Haq, M.I.; Raina, A.; Valerga Puerta, A.P.; Sagbas, B.; Ruggiero, A. Tribo-corrosive behavior of additive manufactured parts for orthopaedic applications. J. Orthop. 2022, 34, 49–60. [Google Scholar] [CrossRef] [PubMed]

- Erwin, N.; Sur, D.; Basim, G.B. Remediation of machining medium effect on biocompatibility of titanium-based dental implants by chemical mechanical nano-structuring. J. Mater. Res. 2022, 37, 2686–2697. [Google Scholar] [CrossRef]

- Dwivedi, S.; Dixit, A.R.; Das, A.K.; Adamczuk, K. Additive texturing of metallic implant surfaces for improved wetting and biotribological performance. J. Mater. Res. Technol. 2022, 20, 2650–2667, ISSN 2238-7854. [Google Scholar] [CrossRef]

- Zhang, D.J.; Zhao, C.; Sheng, R.; Lin, K.; Wang, X.; Zhang, S. Construction of a Hierarchical Micro-/Submicro-/Nanostructured 3D-Printed Ti6Al4V Surface Feature to Promote Osteogenesis: Involvement of Sema7A through the ITGB1/FAK/ERK Signaling Pathway. ACS Appl. Mater. Interfaces 2022, 14, 30571–30581. [Google Scholar] [CrossRef]

- Wang, H.; Liu, J.; Wang, C.; Shen, S.C.; Wang, X.; Lin, K. The synergistic effect of 3D-printed microscale roughness surface and nanoscale feature on enhancing osteogenic differentiation and rapid osseointegration. J. Mater. Sci. Technol. 2021, 63, 18–26, ISSN 1005-0302. [Google Scholar] [CrossRef]

- Stepanovska, J.; Matejka, R.; Otahal, M.; Rosina, J.; Bacakova, L. The Effect of Various Surface Treatments of Ti6Al4V on the Growth and Osteogenic Differentiation of Adipose Tissue-Derived Stem Cells. Coatings 2020, 10, 762. [Google Scholar] [CrossRef]

- Ginestra, P.; Ferraro, R.M.; Zohar-Hauber, K.; Abeni, A.; Giliani, S.; Ceretti, E. Selective Laser Melting and Electron Beam Melting of Ti6Al4V for Orthopedic Applications: A Comparative Study on the Applied Building Direction. Materials 2020, 13, 5584. [Google Scholar] [CrossRef]

- Izmir, M.; Ercan, B. Anodization of titanium alloys for orthopedic applications. Front. Chem. Sci. Eng. 2019, 13, 28–45. [Google Scholar] [CrossRef]

- Manjaiah, M.; Laubscher, R.F. Effect of anodizing on surface integrity of Grade 4 titanium for biomedical applications. Surf. Coat. Technol. 2017, 310, 263–272, ISSN 0257-8972. [Google Scholar] [CrossRef]

- Hung, K.-Y.; Lin, Y.-C.; Feng, H.-P. The Effects of Acid Etching on the Nanomorphological Surface Characteristics and Activation Energy of Titanium Medical Materials. Materials 2017, 10, 1164. [Google Scholar] [CrossRef]

- Surmeneva, M.A.; Khrapov, D.; Prosolov, K.; Kozadayeva, M.; Koptyug, A.; Volkova, A.; Paveleva, A.; Surmenev, R.A. The influence of chemical etching on porous structure and mechanical properties of the Ti6AL4V Functionally Graded Porous Scaffolds fabricated by EBM. Mater. Chem. Phys. 2022, 275, 125217, ISSN 0254-0584. [Google Scholar] [CrossRef]

- Bright, R.; Hayles, A.; Wood, J.; Ninan, N.; Palms, D.; Visalakshan, R.M.; Burzava, A.; Brown, T.; Barker, D.; Vasilev, K. Bio-Inspired Nanostructured Ti-6Al-4V Alloy: The Role of Two Alkaline Etchants and the Hydrothermal Processing Duration on Antibacterial Activity. Nanomaterials 2022, 12, 1140. [Google Scholar] [CrossRef]

- ASTM B214-16; Standard Test Method for Sieve Analysis of Metal Powders. ASTM: West Conshohocken, PA, USA, 2016; Volume 02.05.

- ASTM F2924-14; Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium with Powder Bed Fusion. ASTM: West Conshohocken, PA, USA, 2014; Volume 10.04.

- ASTM F1472-08; Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications. ASTM: West Conshohocken, PA, USA, 2008; Volume 10.15.

- Yazid, F.; Kay, A.N.M.; Qin, W.Y.; Luchman, N.A.; Wahab, R.M.A.; Ariffin, S.H.Z. Morphology and Osteogenic Capability of MC3T3-E1 Cells on Granular Hydroxyapatite Scaffold. J. Biol. Sci. 2019, 19, 201–209. [Google Scholar] [CrossRef]

- Jimenez, E.H.; Kreitcberg, A.; Moquin, E.; Brailovski, V. Influence of Post-Processing Conditions on the Microstructure, Static, and Fatigue Resistance of Laser Powder Bed Fused Ti-6Al-4V Components. J. Manuf. Mater. Process. 2022, 6, 85. [Google Scholar] [CrossRef]

- Chen, A.; Li, Y.; Zhao, X.; He, H.; Sun, G.; Li, W.; Wang, X. Spray-deposited Ag nanoparticles on micro/nano structured Ti6Al4V surface for enhanced bactericidal property and cytocompatibility. Surf. Coat. Technol. 2022, 431, 128010, ISSN 0257-8972. [Google Scholar] [CrossRef]

- Obeidi, M.A.; Mussatto, A.; Dogu, M.N.; Sreenilayam, S.P.; McCarthy, E.; Ul Ahad, I.; Keaveney, S.; Brabazon, D. Laser surface polishing of Ti-6Al-4V parts manufactured by laser powder bed fusion. Surf. Coat. Technol. 2022, 434, 128179, ISSN 0257-8972. [Google Scholar] [CrossRef]

- Damiati, L.; Eales, M.G.; Nobbs, A.H.; Su, B.; Tsimbouri, P.; Salmeron-Sanchez, M.; Dalby, M. Impact of surface topography and coating on osteogenesis and bacterial attachment on titanium implants. J. Tissue Eng. 2018, 9, 2041731418790694. [Google Scholar] [CrossRef] [PubMed]

- Ginestra, P.; Ceretti, E.; Lobo, D.; Lowther, M.; Cruchley, S.; Kuehne, S.; Villapun, V.; Cox, S.; Grover, L.; Shepherd, D.; et al. Post Processing of 3D Printed Metal Scaffolds: A Preliminary Study of Antimicrobial Efficiency. Procedia Manuf. 2020, 47, 1106–1112. [Google Scholar] [CrossRef]

| Particle Size Analysis 1 | Powder Density 2 | Chemical Composition 3 | ||||||

|---|---|---|---|---|---|---|---|---|

| (μm) | (g/cm3) | (wt %) | ||||||

| d10 | d50 | d90 | 2.31 | Al | V | O | Fe | Ti |

| 27.79 | 38.18 | 54.45 | 5.92 | 4.04 | 0.13 | 0.20 | Bal. | |

| Angle SLM | Mean Value [°] | p-Value | ||

|---|---|---|---|---|

| As-Built | Anodized | Etched | ||

| 0° | 129.64 ± 5.32 | 75.48 ± 5.31 | 70.64 ± 5.70 | 0.003 |

| 45° | 120.91 ± 2.32 | 38.8 ± 24.1 | 108.48 ± 0.993 | 0.018 |

| Angle SLM | Mean Value [°] | p-Value | ||

|---|---|---|---|---|

| As-Built | Anodized | Etched | ||

| 0° | 17.84 ± 4.76 | 6.29 ± 0.399 | 2.307 ± 0.326 | 0.001 |

| 45° | 20.40 ± 5.02 | 6.35 ± 2.71 | 2.200 ± 0.416 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rovetta, R.; Ginestra, P.; Ferraro, R.M.; Zohar-Hauber, K.; Giliani, S.; Ceretti, E. Building Orientation and Post Processing of Ti6Al4V Produced by Laser Powder Bed Fusion Process. J. Manuf. Mater. Process. 2023, 7, 43. https://doi.org/10.3390/jmmp7010043

Rovetta R, Ginestra P, Ferraro RM, Zohar-Hauber K, Giliani S, Ceretti E. Building Orientation and Post Processing of Ti6Al4V Produced by Laser Powder Bed Fusion Process. Journal of Manufacturing and Materials Processing. 2023; 7(1):43. https://doi.org/10.3390/jmmp7010043

Chicago/Turabian StyleRovetta, Rosaria, Paola Ginestra, Rosalba Monica Ferraro, Keren Zohar-Hauber, Silvia Giliani, and Elisabetta Ceretti. 2023. "Building Orientation and Post Processing of Ti6Al4V Produced by Laser Powder Bed Fusion Process" Journal of Manufacturing and Materials Processing 7, no. 1: 43. https://doi.org/10.3390/jmmp7010043

APA StyleRovetta, R., Ginestra, P., Ferraro, R. M., Zohar-Hauber, K., Giliani, S., & Ceretti, E. (2023). Building Orientation and Post Processing of Ti6Al4V Produced by Laser Powder Bed Fusion Process. Journal of Manufacturing and Materials Processing, 7(1), 43. https://doi.org/10.3390/jmmp7010043