Abstract

Powder bed fusion (PBF) process has been used successfully to produce 3D structures using single material properties. The current industrial demand is to use the technology to produce 3D structures of multimaterial properties. An electron beam melting (EBM) process has been used to produce 3D structures of multimaterial properties. However, due to the large beam size, the EBM process lacks geometrical accuracy, requiring a large machining allowance. A laser powder bed fusion (LPBF) process could be used to produce multimaterials with geometrical precision. However, the thermal gradient within the molten pool and the thermophysical difference between the multimaterials leads to defects (weak interfacial bonds, interlayer and intralayer cracks). Other challenges such as poor powder delivery system, powder cross-contamination, and lack of appropriate data processing software for producing 3D multimaterial structures are not yet fully resolved. Nonetheless, there have been encouraging results for producing the next generational multimaterial 3D components of intricate geometrical characteristics.

1. Introduction

Powder bed fusion (PBF) manufacturing technology has gained popularity as one of the most outstanding groups of the additive manufacturing (AM) process that has been extensively used for manufacturing 3D objects for engineering and biomedical applications []. The technology gains its dominance through the use of single materials to produce 3D objects layer-by-layer. The layer-wise manufacturing capability of the PBF process permits it to produce 3D structures with intricate geometrical characteristics with tailored configurations for a specific industrial application. The current demand in the manufacturing industry is to use the PBF technology to produce 3D structures with multimaterial properties [], thus manufacturing a single 3D object with different material properties in defined locations. This paradigm shift in the manufacturing industry aims to use different materials in one manufacturing cycle to produce a 3D structure with different material properties in strategic locations based on the functional requirements of the final products []. The multimaterial manufacturing capability of the PBF process would usher in monolithic manufacturing of complex 3D structures [] with a varied interface within the same material, as opposed to the multiple assembly steps of the conventional manufacturing methods (casting, forging, sheet forming, extrusion, etc.) [,]. Theoretically, with the multimaterial manufacturing capability of the PBF technology, it should be possible to produce 3D structures with embedded devices to optimize the functional capabilities of devices, such as [,,]:

- ➢

- Embedding optical properties in laser telecommunication systems;

- ➢

- Embedding resistors and sensors in electrical devices;

- ➢

- Embedding dielectric and magnetic properties in antenna and meta-materials;

- ➢

- Embedding thermal conductivity devices in conformal cooling channels;

- ➢

- Embedding wear resistance, vibration damping, thermal insulation coatings, high hardness, and high-temperature resistance properties in turbine engines;

- ➢

- Combing hot work steel and tungsten carbide/cobalt to increasing the lifetime and efficiency of tools used in abrasive wear environments.

The PBF process of manufacturing multimaterial fosters innovations and product optimizations [].

ISO/ASTM TR 52912 [] defined the multimaterial manufacturing process as “a layer-by-layer fabrication technique that intentionally modifies process parameters and gradationally varies the spatial of material(s) organization within one component to meet intended function”. Girnth et al. [] defined the multimaterial manufacturing strategy based on the geometrical dimensions in which the material is graded, and the number of different materials used. Accordingly, to their definition, a hybrid 3D component is produced when only two materials are used and a multimaterial component is produced when more than two different materials are used. The authors would like to align the definition of multimaterial in this article with ISO/ASTM TR 52912 definition.

Although all the additive manufacturing (AM) technologies (powder bed fusion, directed energy deposition, sheet lamination, photopolymer vat, material extrusion, material jetting, and binder jetting) [] have demonstrated their capabilities of manufacturing multiple materials for various applications, a thorough review of the literature [,,,,,,,] reveals that a lot of the previous 3D printed multimaterial components were manufactured with polymers using either sheet lamination, material extrusion, material jetting, binder jetting or photopolymer vat AM machines. This might be due to the mechanism (joining materials using adhesive or thermal bonding layer-by-layer or selectively curing polymers by using a laser, light or ultraviolet) the above AM machines used to print 3D multimaterial structures. It might be easier to bind different materials together layer-by-layer than delivering different powder particles on a powder bed from different nozzles to print a 3D multimaterial object using the PBF AM technology. As a result, not much has been reported using PBF AM printing systems to print multimaterials 3D structures.

The literature demonstrated that PBF technology is one of the most versatile AM technologies used to produce 3D structures for biomedical and engineering applications using a single material []. The PBF process is an eco-design topology optimization technology that permits the manufacturing of intricate 3D structures monolithically []. Technically, the technology provides almost unchallenged freedom of design and enables the manufacturing engineer to design and print 3D components according to the intended applications []. The layer-wise manufacturing approach reduces the multiple assembly steps and manufacturing time as opposed to the classical methods of manufacturing. Printing complex shapes leads to weight reduction, reduces fuel consumption, and improves performance reliability. Bewlay et al. [] demonstrated that the PBF technology could be used to print aerospace components (Boeing 787 and 747–8 low-pressure turbine blades) that performed better than prior engines in its class manufactured by the conventional method (gravity casting plus machining). The PBF-built aircraft engines demonstrated a 50% reduction in noise, a 20% reduction in fuel consumption, and an 80% reduction in NOx emissions. The operational capacity of the engines attests to the advantages offered by the PBF manufacturing strategy. In the medical industry, the technology has been used extensively to provide patient-specific implants (knee implants, hip implants, rib cages) with laudable success [].

Because the PBF manufacturing process has come to the fore as the most outstanding AM manufacturing system to produce 3D structures requiring intricate geometries with high resolution and rigorous build accuracy [], it is very prudent to review the literature to understand to what extent the PBF process has been used to manufacture multimaterials 3D structures, the current challenges and the success attained.

2. Methodology

To determine the extent to which PBF technology has been used to produce multimaterial 3D structures, current challenges, and the way forward; publications with high citation index [,,] that focused on PBF of multimaterial 3D structures were examined. Some relevant published documents were also accessed based on the snowball method (locating relevant documents based on the reference list in relevant articles). A general electronic database search was conducted through the Central University of Technology, library search database selector, and the following electronic resources were accessed: SAGE Research Methods, NETLAW, EBSCOHost, ASTM’s Digital Library, Clarivate Web of Science, Sabinet African Journals/SA e-Publications, Nexus: Current and Completed Research Projects, McGraw-Hill Access Engineering, Emerald, Taylor, and Francis Online. Google Scholar was also heavily used, and the Advanced Scholar Search feature in Google Scholar was used to set specific criteria in order to access only relevant publications. Electronic resources were used due to their limitless network and a large collection of information on the topic.

The approach of initially focusing on highly cited index articles that focus on LPBF manufacturing of 3D multimaterial structures gives guidance on the type of precise search words that could be used to search the electronic resources. The following are the main search terms: Additive manufacturing, 3D printing, powder bed fusion, laser powder bed fusion, selective laser melting, selective laser sintering, direct metal laser sintering, electron beam melting, selective electron beam melting, multimaterial, graded material, interfacial bond, powder delivery systems, powder cross-contamination, data preparation software, spatial distribution, and distribution of dissimilar materials. The selected search terms were combined using the Boolean search operator “AND” to narrow the search results to specific output (e.g., “laser powder bed fusion” AND “multimaterial”). The Boolean operator produces results that meet multiple criteria.

To ensure reliability, credibility, and validity, only peer-reviewed published articles were assessed. The abstract and the conclusion of the selected articles were first screened. The citation frequency of each article was used to select published articles that were deemed credible to be included in the current manuscript. Based on the citation index, articles that were not cited for more than half a decade were excluded from the studies. The selection of the articles was based on the quality of the content, the relevance of the topic to the current review, the credential of the source’s authors, and the year of publication (from 2000 to 2022). Some relevant documents from previous decades were also consulted to establish foundational concepts that continue to be used today. It is worth mentioning that only published articles in English were used, since most of the publications were written in English and the official language of the authors is the English language.

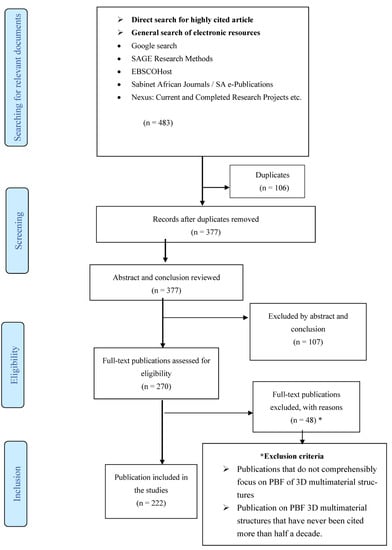

The inclusion and exclusion criteria used to select the relevant articles to establish the degree of success attained using the PBF technology to produce multimaterial 3D structures and the way forward is presented in Figure 1. A total of 483 articles were retrieved through various electronic databases. The abstracts and conclusions of the selected 483 articles were reviewed for eligibility. After the eligibility check, 107 articles that did not specifically focus on powder bed fusion of multimaterial 3D structures were excluded. A total of 270 full-text articles were read and 48 articles that did not comprehensively focus on the current research topic were excluded. A total of 222 articles were finally used for the studies.

Figure 1.

Flow chart for exclusion and inclusion of published articles (* explanation to the exclusion criteria).

3. Powder Bed Fusion

The powder bed fusion manufacturing technology mainly comprised the electron beam melting (EBM) manufacturing process and the laser powder bed manufacturing (LPBF) process []. The difference between the EBM and LPBF manufacturing processes is the difference between their energy source (electron beam and laser) and the different mechanism of manufacturing 3D objects layer-by-layer. The powder bed fusion manufacturing process is known as one of the earliest and the most flexible AM technologies that can process ceramics, metals, composites, and polymers []. Using the PBF process to produce multimaterial 3D structures offers several advantages including precision, narrow fusion zones, and narrow heat-affected zones, which cumulatively minimized part distortion as opposed to the classical methods of manufacturing (casting, forging, sheet forming, extrusion, etc.) []. When high energy-density beams are combined with the freedom of design and the monolithic manufacturing process offered by PBF manufacturing layer-wise strategy, it becomes possible to manufacture complex multimaterial 3D structures with improved interfacial bond characteristics and spatial distribution of the multimaterial properties at predefined locations due to the controlled process parameters.

3.1. Electron Beam Melting of Multilaterals 3D Structures

Terrazas et al. [] use the EBM technology to build multimaterial of Ti6Al4V and copper in the x and y direction. Powder particles of Ti6Al4V were delivered onto the powder bed to build the Ti6Al4V samples, after which the copper powder particles were delivered onto the powder bed to build the Cu section on the Ti6Al4V sample. The analysis reveals that the microstructure and the hardness values recorded were different from what is reported in the literature. The hardness profile was increasing for both materials closer to the Ti6Al4V/Cu interface. However, the hardness values begin to level off to those of the single material build component as measurements proceeded away from the Ti6Al4V/Cu interface. The authors indicated that the strategy of building Cu samples on Ti6Al4V could be used for the repair of metallic components. Hinojos et al. [] printed Inconel 718 on 316L stainless steel and vice versa. It was reported that there was a large decrease in the hardness value in the 316L SS area near the 316L SS/IN718 interface. Cracks were observed in the 316L SS/IN718 interface. The formation of the cracks was attributed to large thermal stresses, triggered by differences in the coefficient of thermal expansion between the materials. The IN718 substrate has high stiffness at higher temperatures; hence, the authors suggested the use of a solutionized substrate to prevent similar interfacial cracks. Nonetheless, the results of the investigation revealed EBM’s capability to produce a multimaterial with a high-quality metallurgical joint with minimized thermal damage to the surrounding material. Similar research work was conducted by Zhou [], who focused on producing functionally graded components using (TiAl) alloy and titanium alloy. The authors used an element evaporation concept based on electron beam powder bed fusion to produce the (TiAl) alloy and titanium alloy by irradiating different sub-regions of the powder bed with an electron beam energy input of different magnitude to greatly reduce the relative atomic ratio of aluminum from 47% to less than 10%. This has led to the successful manufacturing of (TiAl) alloy and titanium alloy with phase in the interfacial transition zone within the same powder layer on the build platform. The investigations revealed that increasing the overlap scan distance at the interfacial boundary would reduce the mechanical strength at the interfacial zone. Osipovich et al. [] used the electron beam additive manufacturing approach to print copper–steel multimaterial in the x–y direction. Five layers of SS 321 steel was printed on a 4.5 mm thick AISI 304 steel substrate. The SS 321 steel feedstock was replaced with C11000 copper, and five layers of copper were printed on SS 321 steel. The process was repeated to produce a multilayered multimaterial wall of alternating interlayers of SS–Cu–SS–Cu–SS with dimensions of 100 mm × 5 mm × 30 mm. The analysis reveals inhomogeneous printing of steel and copper in the boundary zone. Cu particles with an average size of 5 μm and Fe particles with an average size of 10 μm were present at the interfacial boundary of the SS–Cu multimaterial. The Cu and Fe particles at the interfacial boundary are solid solutions of Cu and Fe which were formed immediately near the sharp boundary of the boundary zones of Cu and Fe. Disc-shaped precipitations of steel denoting spinodal decomposition of alloying elements of steel were formed at the interfacial boundary of the SS–Cu multimaterial. A similar publication by the authors [] reveals the presence of austenite γ-Fe and coarse acicular δ-Fe in the form of lamellae at the boundary zone of SS–Cu. The printing of Cu-Ni bimetallic multimaterial was demonstrated by Chumaevskii et al. [] using an electron beam additive manufacturing system. The authors reported a smoother transition zone from copper to nickel alloy interface by employing more intensive heating of the substrate before printing the first layer. Gusarova et al. [] also used the additive electron beam technology to print copper and nickel multimaterial alloy. The results revealed a heterogeneous interfacial zone.

The EBM has been used successfully to print dissimilar materials. This could be due to the processing mechanism of the EBM systems. The EBM systems are equipped with a preheating system that elevated the temperature of the powder bed to over 1000 °C [], which reduces residual stresses in the built components. Besides the preheating systems, electromagnetic optics are used to focus and deflect the beam. The electron beams are focused and accelerated to approximately half the speed of light, which provides much higher scan speeds than laser-based systems []. Additionally, the absorptivity of the electron beam is higher than laser. Hence, the EBM mechanism of operations cumulatively ensures periodic scanning of the entire build plate [], thus maintaining an elevated temperature in the build chamber and virtually eliminating the effect of periodic cooling and heating as well as the need for thermal processing to solve residual stress issues. The cumulative effect of the elevated temperature in the build chamber reduces the thermal gradient in the chamber, which minimizes issues of weak interfacial bonds during multimaterial fabrication as compared to the LPBF systems [,]. The EBM manufacturing systems have more process control parameters (e.g., beam diameter, scanning velocity, beam power, beam focus, preheat temperatures, plate temperature) than the LPBF manufacturing system []. The process control parameters provide the manufacturing engineer with more manufacturing process control options to obtain the desired final built components. Due to the efficient energy source, the EBM manufacturing process can be used to process brittle materials that the LPBF process cannot manage []. As a result, the EBM system became a promising PBF system that could be used to produce multimaterials []. However, the EBM manufacturing systems lack geometrical accuracy due to the large beam size (Table 1). The large beam size produces large molten pools without geometrical precisions, making it difficult to produce intricate shapes with exact dimensions according to the CAD files [,]. The lack of geometrical precision of EBM build parts requires larger machining allowances to obtain the required final near-net-shape exact geometry. This inherent limitation of the EBM systems makes the post-processing stage of machining EBM built components to the final required geometry and surface quality a herculean task. Machining EBM products to the final precise dimensions would result in wasting of material, increase of total manufacturing lead time, and the cost of production. This characteristic undermined the original intent of the PBF process of manufacturing 3D structures with intricate geometries monolithically. The EBM manufacturing systems can only process a limited range of materials as compared to the LPBF process. The current market demand is to increase the materials database of the AM manufacturing systems [,]. The inherent limitations demonstrated by the EBM system prompt researchers to investigate the suitability of the LPBF manufacturing process of manufacturing multimaterials. The LPBF process has demonstrated a great geometrical accuracy in manufacturing intricate 3D structures with single materials [].

Table 1.

Comparison between EBM and LPBF.

3.2. Laser Powder Bed Fusion of Multilaterals’ 3D Structures

Due to the smaller laser spot size of LPBF process, enabling it to build 3D components of intricate geometries with high resolution and rigorous build accuracy, it has been increasingly applied to build complex 3D structures with a dimension error lower than 100 μm []. The degree of dimensional accuracy demonstrated by the LPBF process reveals that it could be used to build multimaterial components with the required near-net shape geometry. As the panorama for the current biomedical and engineering industry reveals a great demand for multimaterials 3D structures with spatial distributions of different materials precisely in strategic locations, industry practitioners and academics have tried to produce multimaterials using the superior manufacturing capability of the LPBF process.

Although the idea of using the LPBF to produce multimaterials was mentioned in the literature [], the work of Demir and Previtali [] was one of the first to practically demonstrate the manufacturing of multimaterials via the LPBF method. With a homemade powder delivery system, Fe/Al-12Si multimaterial was printed. Fe was first printed on a mild steel substrate, followed by printing Fe/Al-12Si composite layers, and finally printing Al-12Si layers on top. Twenty (20) layers of pure Fe were printed, 10 layers of Fe/Al-12Si, and 10 layers of Al-12Si multimaterial. The results indicated the presence of large cracks in the Fe/Al-12Si multimaterial layers due to the low compatibility and miscibility of the selected materials. The authors mentioned that although adhesion between consecutive layers was scarce, the process demonstrated could be improved to print 3D multimaterial structures with varying materials properties between consecutive layers.

Wang et al. [] investigated the probability of using the LPBF technology to produce bimetallic multimaterial of Al-12Si/Al-3.5Cu-1.5Mg-1Si and reported different successive zones (Al-12Si zone, a texture-strengthening zone, an interfacial zone, and an Al-Cu-Mg-Si zone) along the building direction. The authors described the interfacial bonds between the three interfaces as good metallurgical bonding, with a weak bond at sites in the Al-12Si base alloy due to unmelted powder particles. The authors explain that the success of obtaining a good metallurgical bonding in the three interfacial zones was due to the lessons learned in the previous work conducted by Demir and Previtali [] Fe/Al-12Si, Liu et al. [] 316L/C18400, Sing et al. [] Al-10Si-Mg/C18400, Tan et al. [] steel/Cu, Bartkowiak et al. [] Al-Si/Al-Cu and others [,,,], who attempted to produce multimaterials without being able to avoid the presence of pores or cracks. Although the work conducted by previous authors could not eliminate the presence of pores and cracks, the results indicated that the samples produced exhibited higher strength and lower corrosion rate than samples produce using the conventional methods of manufacturing multimaterials of metal–metal interface []. Li et al. [] recently used the LPBF method to produce micro-laminated CoCrFeMnNi-TiNp/CoCrFeMnNi multimaterial 3D structures of alternating coarse- and fine-grained layers. A homemade computerized powder delivery system was used to deliver the powders alternatively (CoCrFeMnNi-TiNp/CoCrFeMnNi) onto the powder bed. The authors aimed to produce a structurally hierarchical micro-laminate high-entropy alloy that can overcome the strength–ductility trade-off that is normally reported when producing high entropy alloys via the LPBF process []. Blending of TiNp (ceramic nano-particles) with the high entropy CoCrFeMnNi alloy minimized the strength ductility trade-off and improve the anti-impact performance of the CoCrFeMnNi-TiNp/CoCrFeMnNi multimaterial under high strain-rate compression deformation. The dynamic impact results reveal that the CoCrFeMnNi-TiNp/CoCrFeMnNi multimaterial alloy exhibited higher strength and deformability than the high entropy alloy (CoCrFeMnNi) alone without the dispersed ceramic nano-particles (TiNp). The authors noted that the success of the current investigations is a result of the preliminary research output reported [,].

Wang et al. [] demonstrated the possibility of manufacturing metal–ceramic multi-materials of TiB2/Ti6Al4 via LPBF process. The experimental results reveal that the interfacial microstructure consisted of unmelted TiB2 powders, columnar TiB crystals, and acicular TiB crystals. Many pores were present at the cross-sections of the TiB2/Ti6Al4 samples at lower laser powers (<350 W), as compared to samples produced at a higher laser power. A similar investigation by Cai et al. [] also reveals the presence of microspores randomly distribute in the TiB/Ti-6Al-4V metal–ceramic multimaterial matrix. The experimental results of Gu et al. [] TiB2/Ti6Al4V, Koopmann et al. [] 1.2367 tool steel/ZrO2 + Al2O3 and Wei et al. [] SiC/316L present similar results of micropores and unmelted zones and cracks at the interfacial zones and in the metal–ceramics matrix.

The investigation of Chueh et al. [] on metal–polymer 316L/CuSn10/polylactic acid (PLA) multimaterials reveals that, although it was possible to produce metal–polymer multimaterials, there were issues of high porosity and poor surface roughness which need to be overcome to advance the technology of manufacturing metal–polymer forward. The work of Chueh et al. [] on metal–polymer multimaterial (316L/CuSn10/PA11) also demonstrated the presence of nano-scale pores on the top surface of the samples. However, the authors mentioned that the surface roughness of the samples was ten times better than what is reported in the literature []. This was achieved by adjusting the composition of the polymer from Vol 30% to Vol 5%.

Metal–glass multimaterial was produced by Zhang et al. [] via LPBF process. The result indicated that the mechanical properties of the 316L/soda-lime change gradually from ductility (metal side) to brittleness (glass side). The 316L/soda-lime samples were weakest at the interface transition phase (the interface between the ductile and brittle phases) and there were micropores, although sound metal–glass interfaces were achieved from both vertical and horizontal directions because both metal and glass were fused by LPBF high energy density. The investigation of Zhang et al. [] reveals that the mechanism of printing metal–glass multimaterial (CuSn10/soda-lime) is the penetration of the glass into the base metal which anchored the glass phase during the printing process.

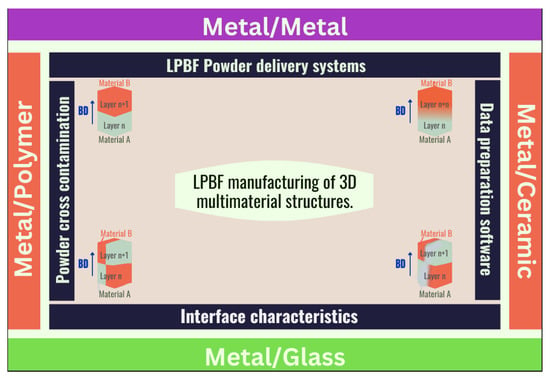

4. Distribution of Dissimilar Materials in LPBF 3D Structures

According to the distribution of dissimilar materials, the main materials that are used in the LPBF process for multimaterials fabrications are metals, polymers, ceramics and glasses. The use of multiples materials results in different material interfaces (e.g., metal–glass, metal–polymer, metal–metal, metal–ceramic, polymer–polymer, polymer–metal, polymer–glass, polymer–ceramic, ceramic–ceramic, glass–glass, etc.); therefore, different technological barriers need to be overcome for successful manufacturing of the various multimaterials structures. Each set of the multimaterials (e.g., metal–metal, metal–polymer) presents a unique interface challenge that needs to be overcome to enable the manufacturing of intricate 3D structures in which the directionality of the materials are controllable to vary the distribution of the various materials within a complex three-dimensional (3D) space [].

A thorough review of the literature reveals that, for the LPBF process, most researchers have focused on experimenting with the possibility of manufacturing 3D multimaterial structures of metal–metal interfaces [,] as opposed to other multimaterial interfaces. According to Wang et al. [], this could be due to the thermophysical difference (melting points, thermal absorptivity, specific heat capacity, thermal conductivity, density, coefficient of thermal expansion, phase transformation temperatures, etc.) [] between the various materials. Producing metal–ceramic, metal–polymer or metal–glass, or a combination of them, would be more complicated than producing metal–metal, polymer–polymer or ceramic–ceramic 3D multimaterial structures. Obtaining strong interfacial bonds between the different multimaterials is one of the main challenges of producing LPBF multimaterial structures for industrial applications. This challenge arises due to the different atomic bonding that exists among the different materials that are used to produce the multimaterial 3D structures additively. This difference in the inter-atomic bonding could lead to weak interlayer and intralayer bounding issues such as delamination, porosity at the boundaries of the dissimilar materials, coating defects, and interlayer and intralayer cracks. The current focus of many researchers is to overcome these boundary conditions to move the process of manufacturing intricate multimaterial structures via LPBF to the next stage [,].

Han and Lee [] reported that, to successfully manufactured multimaterial 3D structures via the LPBF process, it is very important to understand the fundamental scientific principles of materials science, reaction kinetics, mechanics, and the thermophysical difference that governs the laser–matter interaction between the various materials that are used to produce the 3D structures of multimaterials properties. Apart from the comprehensive understudying of the materials science at both micro and macro scales to overcome the interfacial bonding issues, there is a need to comprehensively understand the operational strategies of the LPBF process and how the material properties change during the manufacturing process. This is because one of the main barriers to the manufacturing of multimaterial 3D structures via the LPBF process is the inherent limitation of the LPBF systems to deliver multiple materials during one building cycle. [,]. Generally, the LPBF technology can deliver only one powder at a time—resulting in the manufacturing of 3D components of one material properties. By altering the powder delivery systems, multiple materials’ fabrication could be easily achieved. The review of the literature [,] has revealed that there are three main strategies for manufacturing multimaterial 3D components using the LPBF process:

- ➢

- The multimaterial is built in two printing sections. Half of the multimaterial 3D component is produced in the first phase of the production. In the second phase, the other half is produced directly on the previous part, which served as a substrate in the second phase of the production. This approach could only produce multimaterial variation in the x and y directions (Figure 2).

Figure 2. Challenges of distribution of multimaterial via LPBF.

Figure 2. Challenges of distribution of multimaterial via LPBF. - ➢

- Printing multimaterial 3D structures by changing the powders manually in a single printing process (variation in the x, y, and z directions) (Figure 2).

- ➢

- Modifying the powder-delivering systems to deliver more than one powder to enable the production of multimaterial 3D structures in one building cycle (variation in the x, y, and z directions) (Figure 2).

The last approach, of modifying the powder delivery systems, is the most promising strategy of precisely printing dissimilar materials with compositional gradients within layers. Several academic and industrial research works are vigorously in progress towards this end to create a geometrically complex component with graded or discrete material transition in a controlled manner [,,]. The potential ability to control the material composition and flow ability at an arbitrary interior point during the production process would yield the needed result of manufacturing multimaterial 3D structures with tailored materials composition in strategic locations (Figure 2).

5. Current Challenges and Encouraging Results

Despite the achievements made so far regarding the manufacturing of 3D multimaterial structures, there are pending challenges, such as cross-contamination of powders, poor scalability, poor surface quality, and limited material selection. All these challenges need to be addressed to build upon the already attainable strategies of building multimaterial 3D structures via the LPBF process. There is a constant effort to address the various challenges, which is yielding encouraging results.

5.1. Powder Delivery

Different approaches of delivering the powder to the powder bed have been proposed to deliver multimaterials. Wang et al. [] categorized the newly proposed multimaterial powder delivery systems into four, namely: ultrasonic-based powder delivery approach, ‘blade and ultrasonic’ hybrid powder delivery approach, electrophotographic-based powder delivery approach, and blade-based powder delivery approach. The various proposed powder delivery methods were used to fabricate multimaterial additively only in the interlayer plan (X and Y directions—variation of dissimilar materials in between the different layers) (Figure 2) []. Very recently, Zhang et al. [] modified the ultrasonic-based powder delivery systems by integrating an in situ powder mixing system and accurately changing different compositions of mixed powders in the X/Y/Z direction (varying of dissimilar materials within a layer and across other layers) (Figure 1). This technological breakthrough has demonstrated the beginning of the maturity of using the LPBF system to produce multimaterial components for unique industrial applications. Other notable research outputs [,,] have demonstrated the possibility of variations of dissimilar materials in the X/Y/Z directions using various integrations of the proposed powder delivery systems. The proposed powder bed fusion delivery systems were integrated with other AM delivery systems to produce multimaterials with interlayer and intralayer materials variations. Zhang et al. [] fabricated CuSn10/soda-lime glass multimaterial 3D structures with different proportions in X/Y/Z directions using a modified LPBF machine. Wei and Li [] used a hybrid machine by integrating an LPBF machine with blade and ultrasonic hybrid powder delivery approach with a fused filament fabrication (FFF) AM system to produce metal–polymer multimaterial parts with a relatively strong mechanical interlock (interfacial bonding) structure. The blade and ultrasonic powder delivery approach was used to print 316L stainless steel, In718 nickel alloy, and Cu10Sn copper alloy within a single build-up process []. The process involved delivering the main constituent powder on the powder bed, which is followed by ultrasonic-assisted powder dispensary that selectively deposits other powder feedstocks that occupy a small volume of the component []. The authors upgraded the blade and ultrasonic powder delivery system by adding a miniature vibration motor to the ultrasonic powder dispenser []. The high-frequency vibration process enables the dispenser to loosen tightly packed powder near the powder-feeding nozzle. Six ultrasonic powder dispensers were integrated into the powder delivery system. The multiple powder delivery system enables variation of the powder discretely in the X/Y/Z direction to produce a 316L–Cu10Sn turbine disk component []. It is reported that the ultrasonic vibration and blade powder delivery system produced multimaterial 3D components with strong interfacial bonds. Other advanced manufacturing strategies have been used to improve the interfacial bonding between the different fabricated multimaterials [,]. The Aerosint SA company in Belgium [] uses the LPBF system with electrophotographic-based powder delivery system to print metal, ceramic, and polymer parts with relatively high efficiency and strong interfacial bond. Schneck et al. [] use the manufacturing readiness level (MRL) [], which is similar to the technology readiness level (TRL) [] on a scale of 1 to 10 to estimate the readiness of using the powder delivery system to manufacture multimaterial structures. Their reports reveal that the current LPBF powder delivery systems have MRL between four and five, since the current LPBF powder delivery systems were able to produce some laboratory environment components (prototypes) [].

5.2. Interface Characteristics

The main challenge in manufacturing multimaterial 3D structures is the weak interfacial bond between the layers. Due to the different thermophysical properties (melting points, thermal absorptivity, specific heat capacity, thermal conductivity, density, coefficient of thermal expansion, phase transformation temperatures, etc.) [] of the various materials that are used to produce the multimaterials 3D structures, weak interlayer and intralayer bonding issues such as delamination, porosity at the boundaries of the dissimilar materials, coating defects, and interlayer and intralayer cracks have become the main focus of many researchers at present [,,,]. Most of the studies have focused on the various interlayer printing mechanisms to overcome the weak bonding between the different materials.

The stagger and island scanning strategies were adopted by Wang et al. [] to produce 316L/CuSn10 bimetallic structure. Wang et al. [] used the island and stagger scanning strategy to scan the interfacial layers. The authors reported ultimate strength of 423.3 MPa, which is higher than the ultimate strength of 150–300 MPa reported in the literature for steel–copper multimaterial components manufactured via the classical methods [,]. Wu et al. [] also use the interlayer printing strategy to produce CuSn10/4340 gear parts and reported good interlayer bonding. Koopmann et al. [] printed metal–ceramic 3D structures (1.2367 tool steel and ZrO2 + Al2O3) via LPBF process and reported an adhesion strength of 22 MPa. A Metal–glass multimaterial 3D part was printed by Zhang et al. []. The authors noted a discrete interface without oxidation at the interlayer phase.

The microstructure of dissimilar materials at the interface has a decisive effect on its interfacial mechanical properties [,]. If the atomic bonds at the interface of the materials are the same as the metal–metal interface, a fusion region is generated at the interface of the materials with a composition gradient variation []. The microstructure features, such as refined grains and composition gradient at the interfacial joints for metal–metal, could improve the interfacial bonds between different metals []. For materials of different atomic bonds such as metal–ceramic, metal–glass and metal–polymer, their interface strength depends upon mechanical interlocking between the materials []. Chueh et al. [] report on metal–polymer interface using PA11 and CuSn10. The authors noted that irregular interfaces between the two materials enhance the bonding strength through mechanical interlocking structures. The melted PA11 penetrates the CuSn10 and attaches along the rough side surface of CuSn10 during the scanning process, enabling the PA11 to adhere strongly to CuSn10 via mechanical interlocking.

5.3. Data Preparation Software

Data preparation is another possible stumbling block to the realization of using the LPBF process to manufacture multimaterials. The current available mainstream 3D models software—STL (standard tesselation language), AMF (additive manufacturing format), PLY (polygon file format) and OBJ (object file format)—files have the capacity to give information about the geometrical configuration of a part without its corresponding material information []. The newly emerging software such as FAV (fabricatable voxel), SVX (simple voxels) and 3MF (3D manufacturing), which does not only provide the geometrical information of a part but can also provide material gradient and micro-scale physical information, cannot be used to perform a solid modeling task with higher-order representations such as NURBS (non-uniform rational B-splines), BRep (boundary representation) and STEP (standard for the exchange of product model data) []. There is a need for a data preparation software interface file that has the capacity to provide the geometrical information and the corresponding material information simultaneously with the manufacturing process to predetermine the properties of the final printed multimaterial parts. The next generational data preparation software should have the capability to discretely vary the composition of the powder distribution and the directionality of the materials in 3D space in a Cartesian (x, y, z) coordinate. Thermodynamic calculation and process simulation using the phase field modeling approach and cellular automata approach leading to the understanding of formation mechanisms of the interface microstructures are currently designed for binary alloys or tertiary alloys; hence, limited superficial research activities have been conducted based on microscopic methods. The absence of comprehensive materials properties data based on the various multimaterials has worsened the situation, and as a result numerical simulation of multimaterials is still in its infancy [].

5.4. Powder Cross-Contamination

Powder cross-contamination during the building process poses another manufacturing challenge that needs to be overcome to obtain multimaterial 3D structures with unique properties for intended applications. To avoid cross-contaminating, it is obligatory to thoroughly remove unmelted powder particles after printing each layer. Powder cross-contamination could interfere with the material properties for the intended applications []. There is a need to upgrade the current AM system with powder clearing systems to remove powders that are not scanned within a printed layer, to ensure precise powder distribution in a 3D space. Cross-contamination impedes the generation of reliable results for further process optimization.

Surface quality of multimaterial LPBF 3D structures is another inherent technological challenge [,] that needs to be overcome to make the LPBF technology very agile for industries (e.g., medical and aerospace) that required high surface quality. For the medical industry, the surface quality of implanted medical devices must be of specific quality to enhance osseointegration (the direct and stable anchorage of an implant due to the formation of bony tissue around the implant) [,]. For the aerospace industry, surface quality is of high importance since it has direct effects on the failure of mechanical components such as crack initiation and propagation, rate of corrosion, fatigue, catastrophic failure of components, etc. [,]. Recently, Dzogbewu and Du Preez [,] have demonstrated that rescanning at an offset distance of 50% of the hatch distance can improve the surface quality of LPBF components by >50%.

Other areas of process optimization to produce porosity- and crack-free interfaces include process parameter optimization, exposure strategies, and suitable heat treatment procedures to yield the desired mechanical properties. As the effort of researchers have already led to the production of industrial prototypes of multimaterials components, the era of mass production of customized multimaterial 3D structures is almost at hand.

6. Conclusions

PBF technology has been used to produce multimaterial 3D structures with some degree of ‘success’. Due to the ability of LPBF technology to produce complex and finer structures as a result of its smaller laser spot size, it has become the most promising technology for manufacturing 3D structures with spatial distributions of different materials precisely in strategic locations. Despite the emerging encouraging results from various research and development establishments, issues of powder cross contamination, lack of appropriate data processing software, weak interfacial bonding, poor powder delivery systems, etc., are still not yet resolved. The current researchers need to focus on the optimization of powder delivery systems to deliver multimaterials simultaneously, innovative solid data processing software, simulation and thermodynamic calculations, and the avoidance of cross-contamination of powders. Based on research and industrial outputs, it is empirically proven that the era of manufacturing 3D multimaterials structures with specific geometrical configurations and discrete materials properties in predefined locations according to the intended applications is almost at hand.

Author Contributions

Conceptualization, T.C.D. and D.d.B.; methodology, T.C.D.; software, T.C.D.; validation, T.C.D. and D.d.B.; formal analysis, T.C.D. and D.d.B.; investigation, T.C.D.; resources, D.d.B.; data curation, T.C.D.; writing—original draft preparation, T.C.D.; writing—review and editing, T.C.D. and D.d.B.; visualization, T.C.D. and D.d.B.; supervision, D.d.B.; project administration, D.d.B.; funding acquisition, D.d.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Collaborative Program in Additive Manufacturing (Contract No. CSIR-NLC-CPAM-21-MOA-CUT-01).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data is available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Schneck, M.; Horn, M.; Schmitt, M.; Seidel, C.; Schlick, G.; Reinhart, G. Review on additive hybrid- and multi-material-manufacturing of metals by powder bed fusion: State of technology and development potential. In Progress in Additive Manufacturing; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2021; Volume 6, pp. 881–894. [Google Scholar] [CrossRef]

- Edri, E.; Armon, N.; Greenberg, E.; Moshe-Tsurel, S.; Lubotzky, D.; Salzillo, T.; Perelshtein, I.; Tkachev, M.; Girshevitz, O.; Shpaisman, H. Laser Printing of Multilayered Alternately Conducting and Insulating Microstructures. ACS Appl. Mater. Interfaces 2021, 13, 36416–36425. [Google Scholar] [CrossRef] [PubMed]

- Lu, B.-H.; Lan, H.-B.; Liu, H.-Z. Additive manufacturing frontier: 3D printing electronics. Opto Electron. Adv. 2018, 1, 17000401. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; Jnr, S.A.; Amoah, N.; Fianko, S.K.; de Beer, D. Additive Manufacturing Interventions during the COVID-19 Pandemic: South Africa. Appl. Sci. 2021, 12, 295. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; du Preez, W. Additive Manufacturing of Ti-Based Intermetallic Alloys: A Review and Conceptualization of a Next-Generation Machine. Materials 2021, 14, 4317. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Tuma, D.; Vaneker, T.; Afrasiabi, M.; Bambach, M.; Gibson, I. Multimaterial powder bed fusion techniques. Rapid Prototyp. J. 2022, 28, 1–19. [Google Scholar] [CrossRef]

- Han, D.; Lee, H. Recent advances in multi-material additive manufacturing: Methods and applications. Curr. Opin. Chem. Eng. 2020, 28, 158–166. [Google Scholar] [CrossRef]

- Wei, C.; Li, L.; Zhang, X.; Chueh, Y.-H. 3D printing of multiple metallic materials via modified selective laser melting. CIRP Ann. 2018, 67, 245–248. [Google Scholar] [CrossRef]

- Wang, D.; Liu, L.; Deng, G.; Deng, C.; Bai, Y.; Yang, Y.; Wu, W.; Chen, J.; Liu, Y.; Wang, Y.; et al. Recent progress on additive manufacturing of multi-material structures with laser powder bed fusion. Virtual Phys. Prototyp. 2022, 17, 329–365. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO/ASTM TR 52912:2020 Additive manufacturing—Design—Functionally graded additive manufacturing, 2020. Available online: https://www.iso.org/standard/71905.html (accessed on 2 May 2022).

- Girnth, S.; Koopmann, J.; Klawitter, G.; Waldt, N.; Niendorf, T. 3D hybrid-material processing in selective laser melting: Implementation of a selective coating system. Prog. Addit. Manuf. 2019, 4, 399–409. [Google Scholar] [CrossRef]

- International Organization for Standarization. ISO/ASTM 52900:2021 Additive Manufacturing—General Principles—Fundamentals and Vocabulary, 2021. Available online: https://www.iso.org/standard/74514.html?browse=tc (accessed on 18 June 2022).

- Zenani, A.; Dzogbewu, T.C.; Du Preez, W.B.; Yadroitsev, I. Optimum Process Parameters for Direct Metal Laser Sintering of Ti6Al Powder Blend. Univers. J. Mech. Eng. 2020, 8, 170–182. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Directed Energy Deposition Processes. Addit. Manuf. Technol. 2015, 245–268. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Sheet Lamination Processes. In Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2010; Available online: https://link.springer.com/chapter/10.1007/978-1-4419-1120-9_8 (accessed on 18 October 2021).

- Mirzababaei, S.; Pasebani, S. A Review on Binder Jet Additive Manufacturing of 316L Stainless Steel. J. Manuf. Mater. Process. 2019, 3, 82. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2020, 119, 100707. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef] [PubMed]

- Dzogbewu, T.C.; Fianko, S.K.; Amoah, N.; Jnr, S.A.; de Beer, D. Additive manufacturing in South Africa: Critical success factors. Heliyon 2022, 8, e11852. [Google Scholar] [CrossRef]

- Mashabela, M.; Maringa, M.; Dzogbewu, T. Nanoparticulate reinforced composites and their application to additively manufactured TI6AL4V for use in the aerospace sector. Manuf. Rev. 2022, 9, 29. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Rana, M.; Chui, C.H.; Wagner, M.; Zimmerer, R.; Rana, M.; Gellrich, N.-C. Increasing the Accuracy of Orbital Reconstruction with Selective Laser-Melted Patient-Specific Implants Combined With Intraoperative Navigation. J. Oral Maxillofac. Surg. 2015, 73, 1113–1118. [Google Scholar] [CrossRef] [PubMed]

- Dzogbewu, T.C.; Du Preez, W.B. Fused tracks and layers of Ti10Mo6Cu data obtained via laser powder bed fusion. Data Br. 2022, 46, 108775. [Google Scholar] [CrossRef] [PubMed]

- MacDonald, E.; Wicker, R. Multiprocess 3D printing for increasing component functionality. Science 2016, 353, Se2016. Available online: https://doi.org/10.1126/SCIENCE.AAF2093/ASSET/EBF82CEF-73AB-4A9D-8C88-548C0D6FA95D/ASSETS/GRAPHIC/353_AAF2093_FA.JPEG (accessed on 18 October 2022). [CrossRef] [PubMed]

- Wei, C.; Li, L. Recent progress and scientific challenges in multi-material additive manufacturing via laser-based powder bed fusion. Virtual Phys. Prototyp. 2021, 16, 347–371. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Terrazas, C.A.; Gaytan, S.M.; Rodriguez, E.; Espalin, D.; Murr, L.E.; Medina, F.; Wicker, R.B. Multi-material metallic structure fabrication using electron beam melting. Int. J. Adv. Manuf. Technol. 2013, 71, 33–45. [Google Scholar] [CrossRef]

- Hinojos, A.; Mireles, J.; Reichardt, A.; Frigola, P.; Hosemann, P.; Murr, L.E.; Wicker, R.B. Joining of Inconel 718 and 316 Stainless Steel using electron beam melting additive manufacturing technology. Mater. Des. 2016, 94, 17–27. [Google Scholar] [CrossRef]

- Zhou, J.; Li, H.; Yu, Y.; Firouzian, K.; Qian, Y.; Lin, F. Characterization of interfacial transition zone of functionally graded materials with graded composition from a single material in electron beam powder bed fusion. J. Alloys Compd. 2020, 832, 154774. [Google Scholar] [CrossRef]

- Osipovich, K.; Vorontsov, A.; Chumaevskii, A.; Gurianov, D.; Shamarin, N.; Savchenko, N.; Kolubaev, E. Characterization of a Bimetallic Multilayered Composite “Stainless Steel/Copper” Fabricated with Wire-Feed Electron Beam Additive Manufacturing. Metals 2021, 11, 1151. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Astafurova, E.G.; Chumaevskii, A.V.; Kalashnikov, K.N.; Astafurov, S.V.; Maier, G.G.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Tarasov, S.Y.; et al. Gradient transition zone structure in “steel–copper” sample produced by double wire-feed electron beam additive manufacturing. J. Mater. Sci. 2020, 55, 9258–9272. [Google Scholar] [CrossRef]

- Chumaevskii, A.V.; A Kalashnikova, T.; O Panfilov, A.; Gusarova, A.V.; O Knyazhev, E.; Kalashnikov, K.N.; Nikonov, S.Y. The Formation of Bimetallic Materials by the Electron-Beam Additive Manufacturing. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1079, p. 042014. [Google Scholar] [CrossRef]

- Gusarova, A.; Chumaevskii, A.; Gurianov, D.; Kalashnikova, T.; Zykova, A.P.; Panfilov, A.; Nikonov, S.; Osipovich, K. Obtaining of Copper- and Nickel-Based Polymetallic Gradient Products by Wire-Feed Electron Beam Additive Manufacturing. Mater. Sci. Forum 2022, 1049, 31–38. [Google Scholar] [CrossRef]

- Kan, W.; Chen, B.; Jin, C.; Peng, H.; Lin, J. Microstructure and mechanical properties of a high Nb-TiAl alloy fabricated by electron beam melting. Mater. Des. 2018, 160, 611–623. [Google Scholar] [CrossRef]

- Gamzina, D.; Luhmann, N.C.; Ledford, C.; Horn, T.; Karakaut, I.; Lin, L.; Frigola, P. Additive vacuum electronics: Electron beam melting of copper. In Proceedings of the IVEC 2017-18th International Vacuum Electronics Conference, London, UK, 24–26 April 2017. [Google Scholar] [CrossRef]

- Cakmak, E.; Nandwana, P.; Shin, D.; Yamamoto, Y.; Gussev, M.N.; Sen, I.; Seren, M.H.; Watkins, T.R.; Haynes, J.A. A comprehensive study on the fabrication and characterization of Ti–48Al–2Cr–2Nb preforms manufactured using electron beam melting. Materialia 2019, 6, 100284. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.A.; Satko, D.P.; Ackelid, U.; Semiatin, S.L.; Lewandowski, J.J. Effects of HIP on microstructural heterogeneity, defect distribution and mechanical properties of additively manufactured EBM Ti-48Al-2Cr-2Nb. J. Alloys Compd. 2017, 729, 1118–1135. [Google Scholar] [CrossRef]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive Manufacturing Processes: Selective Laser Melting, Electron Beam Melting and Binder Jetting—Selection Guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Aoyagi, K.; Yamanaka, K.; Chiba, A. Role of operating and environmental conditions in determining molten pool dynamics during electron beam melting and selective laser melting. Addit. Manuf. 2020, 36, 101559. [Google Scholar] [CrossRef]

- Loeber, L.; Biamino, S.; Ackelid, U.; Sabbadini, S.; Epicoco, P.; Fino, P.; Eckert, J. Comparison of selective laser and electron beam melted titanium aluminides. In 22nd Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, SFF 2011; University of Texas: Austin, TX, USA, 2011; pp. 547–556. [Google Scholar] [CrossRef]

- Murr, L.; Gaytan, S.; Ceylan, A.; Martinez, E.; Martinez, J.; Hernandez, D.; Machado, B.; Ramirez, D.; Medina, F.; Collins, S. Characterization of titanium aluminide alloy components fabricated by additive manufacturing using electron beam melting. Acta Mater. 2010, 58, 1887–1894. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Ramosena, L.A.; Dzogbewu, T.C.; du Preez, W. Direct Metal Laser Sintering of the Ti6Al4V Alloy from a Powder Blend. Materials 2022, 15, 8193. [Google Scholar] [CrossRef]

- Dzogbewu, T.C. Laser powder bed fusion of Ti6Al4V lattice structures and their applications. J. Met. Mater. Miner. 2020, 30, 68–78. [Google Scholar] [CrossRef]

- Lindhe, O.U. Rapid Manufacturing with Electron Beam Melting (EBM)—A Manufacturing Revolution? University of Texas: Austin, TX, USA, 2006. [Google Scholar] [CrossRef]

- Wang, P.; Lao, C.; Chen, Z.; Liu, Y.; Wang, H.; Wendrock, H.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of Al-12Si and Al-3.5Cu-1.5Mg-1Si bimetal fabricated by selective laser melting. J. Mater. Sci. Technol. 2019, 36, 18–26. [Google Scholar] [CrossRef]

- Dzogbewu, T.C. Laser powder bed fusion of Ti15Mo. Results Eng. 2020, 7, 100155. [Google Scholar] [CrossRef]

- Dall’Ava, L.; Hothi, H.; Di Laura, A.; Henckel, J.; Hart, A. 3D Printed Acetabular Cups for Total Hip Arthroplasty: A Review Article. Metals 2019, 9, 729. [Google Scholar] [CrossRef]

- Jakubenas, K.; Sanchez, J.; Marcus, H. Multiple material solid free-form fabrication by selective area laser deposition. Mater. Des. 1998, 19, 11–18. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Multi-material selective laser melting of Fe/Al-12Si components. Manuf. Lett. 2017, 11, 8–11. [Google Scholar] [CrossRef]

- Sing, S.; Lam, L.; Zhang, D.; Liu, Z.; Chua, C. Interfacial characterization of SLM parts in multi-material processing: Intermetallic phase formation between AlSi10Mg and C18400 copper alloy. Mater. Charact. 2015, 107, 220–227. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Min, L. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Bartkowiak, K.; Ullrich, S.; Frick, T.; Schmidt, M. New Developments of Laser Processing Aluminium Alloys via Additive Manufacturing Technique. Phys. Procedia 2011, 12, 393–401. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Wang, P.; Deng, L.; Prashanth, K.; Pauly, S.; Eckert, J.; Scudino, S. Microstructure and mechanical properties of Al-Cu alloys fabricated by selective laser melting of powder mixtures. J. Alloys Compd. 2018, 735, 2263–2266. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Qi, T.; Hu, Z.; Zeng, X. Selective laser melting of high strength Al–Cu–Mg alloys: Processing, microstructure and mechanical properties. Mater. Sci. Eng. A 2016, 656, 47–54. [Google Scholar] [CrossRef]

- Scaramuccia, M.G.; Demir, A.G.; Caprio, L.; Tassa, O.; Previtali, B. Development of processing strategies for multigraded selective laser melting of Ti6Al4V and IN718. Powder Technol. 2020, 367, 376–389. [Google Scholar] [CrossRef]

- Gharbi, O.; Jiang, D.; Feenstra, D.; Kairy, S.; Wu, Y.; Hutchinson, C.; Birbilis, N. On the corrosion of additively manufactured aluminium alloy AA2024 prepared by selective laser melting. Corros. Sci. 2018, 143, 93–106. [Google Scholar] [CrossRef]

- Li, B.; Zhang, W.; Shen, J.; Xuan, F. Micro-laminated CoCrFeMnNi−TiNp/CoCrFeMnNi high-entropy alloy matrix composite with bimodal grain structure via multi-material selective laser melting (MM-SLM) additive manufacturing. Compos. Commun. 2022, 36, 101366. [Google Scholar] [CrossRef]

- Li, B.; Zhang, L.; Xu, Y.; Liu, Z.; Qian, B.; Xuan, F. Selective laser melting of CoCrFeNiMn high entropy alloy powder modified with nano-TiN particles for additive manufacturing and strength enhancement: Process, particle behavior and effects. Powder Technol. 2019, 360, 509–521. [Google Scholar] [CrossRef]

- Li, B.; Qian, B.; Xu, Y.; Liu, Z.; Xuan, F. Fine-structured CoCrFeNiMn high-entropy alloy matrix composite with 12 wt% TiN particle reinforcements via selective laser melting assisted additive manufacturing. Mater. Lett. 2019, 252, 88–91. [Google Scholar] [CrossRef]

- Wang, R.; Gu, D.; Xi, L.; Lin, K.; Guo, M.; Zhang, H. Selective laser melted TiB2/Ti6Al4V graded materials and first-principle calculations. Mater. Lett. 2019, 254, 33–36. [Google Scholar] [CrossRef]

- Cai, C.; Radoslaw, C.; Zhang, J.; Yan, Q.; Wen, S.; Song, B.; Shi, Y. In-situ preparation and formation of TiB/Ti-6Al-4V nanocomposite via laser additive manufacturing: Microstructure evolution and tribological behavior. Powder Technol. 2018, 342, 73–84. [Google Scholar] [CrossRef]

- Gu, H.; Wei, C.; Li, L.; Han, Q.; Setchi, R.; Ryan, M.; Li, Q. Multi-physics modelling of molten pool development and track formation in multi-track, multi-layer and multi-material selective laser melting. Int. J. Heat Mass Transf. 2020, 151, 119458. [Google Scholar] [CrossRef]

- Koopmann, J.; Voigt, J.; Niendorf, T. Additive Manufacturing of a Steel–Ceramic Multi-Material by Selective Laser Melting. Met. Mater. Trans. B 2019, 50, 1042–1051. Available online: https://link.springer.com/article/10.1007/s11663-019-01523-1 (accessed on 18 October 2022). [CrossRef]

- Wei, C.; Chueh, Y.-H.; Zhang, X.; Huang, Y.; Chen, Q.; Li, L. Easy-To-Remove Composite Support Material and Procedure in Additive Manufacturing of Metallic Components Using Multiple Material Laser-Based Powder Bed Fusion. J. Manuf. Sci. Eng. 2019, 141, 1–18. [Google Scholar] [CrossRef]

- Chueh, Y.-H.; Wei, C.; Zhang, X.; Li, L. Integrated laser-based powder bed fusion and fused filament fabrication for three-dimensional printing of hybrid metal/polymer objects. Addit. Manuf. 2019, 31, 100928. [Google Scholar] [CrossRef]

- Chueh, Y.H.; Zhang, X.; Ke, J.R.; Li, Q.; Wei, C.; Li, L. Additive manufacturing of hybrid metal/polymer objects via multiple-material laser powder bed fusion. Addit. Manuf. 2020, 36, 101465. [Google Scholar]

- Zhang, X.; Chueh, Y.-H.; Wei, C.; Sun, Z.; Yan, J.; Li, L. Additive manufacturing of three-dimensional metal-glass functionally gradient material components by laser powder bed fusion with in situ powder mixing. Addit. Manuf. 2020, 33, 101113. [Google Scholar] [CrossRef]

- Zhang, X.; Wei, C.; Chueh, Y.-H.; Li, L. An Integrated Dual Ultrasonic Selective Powder Dispensing Platform for Three-Dimensional Printing of Multiple Material Metal/Glass Objects in Selective Laser Melting. J. Manuf. Sci. Eng. 2018, 141, 1–12. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; du Preez, W.B. In situ alloying of Ti10Mo fused tracks and layers via laser powder bed fusion. Manuf. Rev. 2022, 9, 23. [Google Scholar] [CrossRef]

- Cheng, B.; Chou, K. A numerical investigation of thermal property effects on melt pool characteristics in powder-bed electron beam additive manufacturing. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 232, 1615–1627. [Google Scholar] [CrossRef]

- Schneck, M.; Horn, M.; Schindler, M.; Seidel, C. Capability of Multi-Material Laser-Based Powder Bed Fusion—Development and Analysis of a Prototype Large Bore Engine Component. Metals 2021, 12, 44. [Google Scholar] [CrossRef]

- Jain, M.; Sadangi, R.; Cannon, W.; Kear, B. Processing of functionally graded WC/Co/diamond nanocomposites. Scr. Mater. 2001, 44, 2099–2103. [Google Scholar] [CrossRef]

- Goh, G.L.; Zhang, H.; Chong, T.H.; Yeong, W.Y. 3D Printing of Multilayered and Multimaterial Electronics: A Review. Adv. Electron. Mater. 2021, 7, 2100445. [Google Scholar] [CrossRef]

- Tan, P.; Shen, F.; Tey, W.S.; Zhou, K. A numerical study on the packing quality of fibre/polymer composite powder for powder bed fusion additive manufacturing. Virtual Phys. Prototyp. 2021, 16, S1–S18. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Muguruza, A.; Bo, J.B.; Gómez, A.; Minguella-Canela, J.; Fernandes, J.; Ramos, F.; Xuriguera, E.; Varea, A.; Cirera, A. Development of a multi-material additive manufacturing process for electronic devices. Procedia Manuf. 2017, 13, 746–753. [Google Scholar] [CrossRef]

- Wen, Y.; Zhang, B.; Narayan, R.L.; Wang, P.; Song, X.; Zhao, H.; Ramamurty, U.; Qu, X. Laser powder bed fusion of compositionally graded CoCrMo-Inconel 718. Addit. Manuf. 2021, 40, 101926. [Google Scholar] [CrossRef]

- Hall, C.W. Apparatus for production of three dimensional objects by stereolithography-Google Patents. Patent US6027324, 1984. Available online: https://patents.google.com/patent/US4575330A/en (accessed on 3 May 2022).

- Zhang, M.; Yang, Y.; Wang, D.; Song, C.; Chen, J. Microstructure and mechanical properties of CuSn/18Ni300 bimetallic porous structures manufactured by selective laser melting. Mater. Des. 2019, 165, 107583. [Google Scholar] [CrossRef]

- Wei, C.; Gu, H.; Li, Q.; Sun, Z.; Chueh, Y.-H.; Liu, Z.; Li, L. Understanding of process and material behaviours in additive manufacturing of Invar36/Cu10Sn multiple material components via laser-based powder bed fusion. Addit. Manuf. 2021, 37, 101683. [Google Scholar] [CrossRef]

- Wei, C.; Sun, Z.; Chen, Q.; Liu, Z.; Li, L. Additive Manufacturing of Horizontal and 3D Functionally Graded 316L/Cu10Sn Components via Multiple Material Selective Laser Melting. J. Manuf. Sci. Eng. 2019, 141, 1–14. [Google Scholar] [CrossRef]

- Toursangsaraki, M. A Review of Multi-material and Composite Parts Production by Modified Additive Manufacturing Methods, 2018. Available online: http://arxiv.org/abs/1808.01861 (accessed on 6 May 2022).

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-Material 3D and 4D Printing: A Survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Amestjr, M. Manufacturing Readiness Level (MRL) Deskbook Prepared by the OSD Manufacturing; DOD Manufacturing Technology Program: Washington, DC, USA, 2015. [Google Scholar]

- ISO. International Standard ISO/FDIS 16290: Space Systems. Definition of the Technology Readiness Levels (TRLs) and their criteria of assessment_Final Draft, 2013. Available online: https://www.iso.org/obp/ui/#iso:std:iso:16290:ed-1:v1:en (accessed on 7 May 2022).

- Wang, D.; Deng, G.-W.; Yang, Y.-Q.; Chen, J.; Wu, W.-H.; Wang, H.-L.; Tan, C.-L. Interface microstructure and mechanical properties of selective laser melted multilayer functionally graded materials. J. Central South Univ. 2021, 28, 1155–1169. [Google Scholar] [CrossRef]

- Garcia, D.; Wu, Z.; Kim, J.Y.; Yu, H.Z.; Zhu, Y. Heterogeneous materials design in additive manufacturing: Model calibration and uncertainty-guided model selection. Addit. Manuf. 2019, 27, 61–71. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial microstructure and mechanical properties of 316L /CuSn10 multi-material bimetallic structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, J.; Zhao, C.; Li, C.; Wang, H. Dual interfacial characterization and property in multi-material selective laser melting of 316L stainless steel and C52400 copper alloy. Mater. Charact. 2020, 167, 110489. [Google Scholar] [CrossRef]

- Loh, G.H.; Pei, E.; Harrison, D.; Monzón, M.D. An overview of functionally graded additive manufacturing. Addit. Manuf. 2018, 23, 34–44. [Google Scholar] [CrossRef]

- Tang, H.P.; Qian, M.; Liu, N.; Zhang, X.Z.; Yang, G.Y.; Wang, J. Effect of Powder Reuse Times on Additive Manufacturing of Ti-6Al-4V by Selective Electron Beam Melting. Jom 2015, 67, 555–563. [Google Scholar] [CrossRef]

- Dzogbewu, T.C.; Du Preez, W.B. Producing Ti5Mo-Fused Tracks and Layers via Laser Powder Bed Fusion. Metals 2022, 12, 950. [Google Scholar] [CrossRef]

- Subbiahdoss, G.; Kuijer, R.; Grijpma, D.W.; van der Mei, H.C.; Busscher, H.J. Microbial biofilm growth vs. tissue integration: “The race for the surface” experimentally studied. Acta Biomater. 2009, 5, 1399–1404. [Google Scholar] [CrossRef]

- Nhlapo, N.; Dzogbewu, T.C.; de Smidt, O. A systematic review on improving the biocompatibility of titanium implants using nanoparticles. Manuf. Rev. 2020, 7, 31. [Google Scholar] [CrossRef]

- Tennant, R. Mechanical Surface Finishing in the Aerospace Industry. Aircr. Eng. Aerosp. Technol. 1992, 64, 4–14. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).