Characterisation of Fibre Bundle Deformation Behaviour—Test Rig, Results and Conclusions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Specification

2.2. Evaluation Methods

3. Experimental Setup

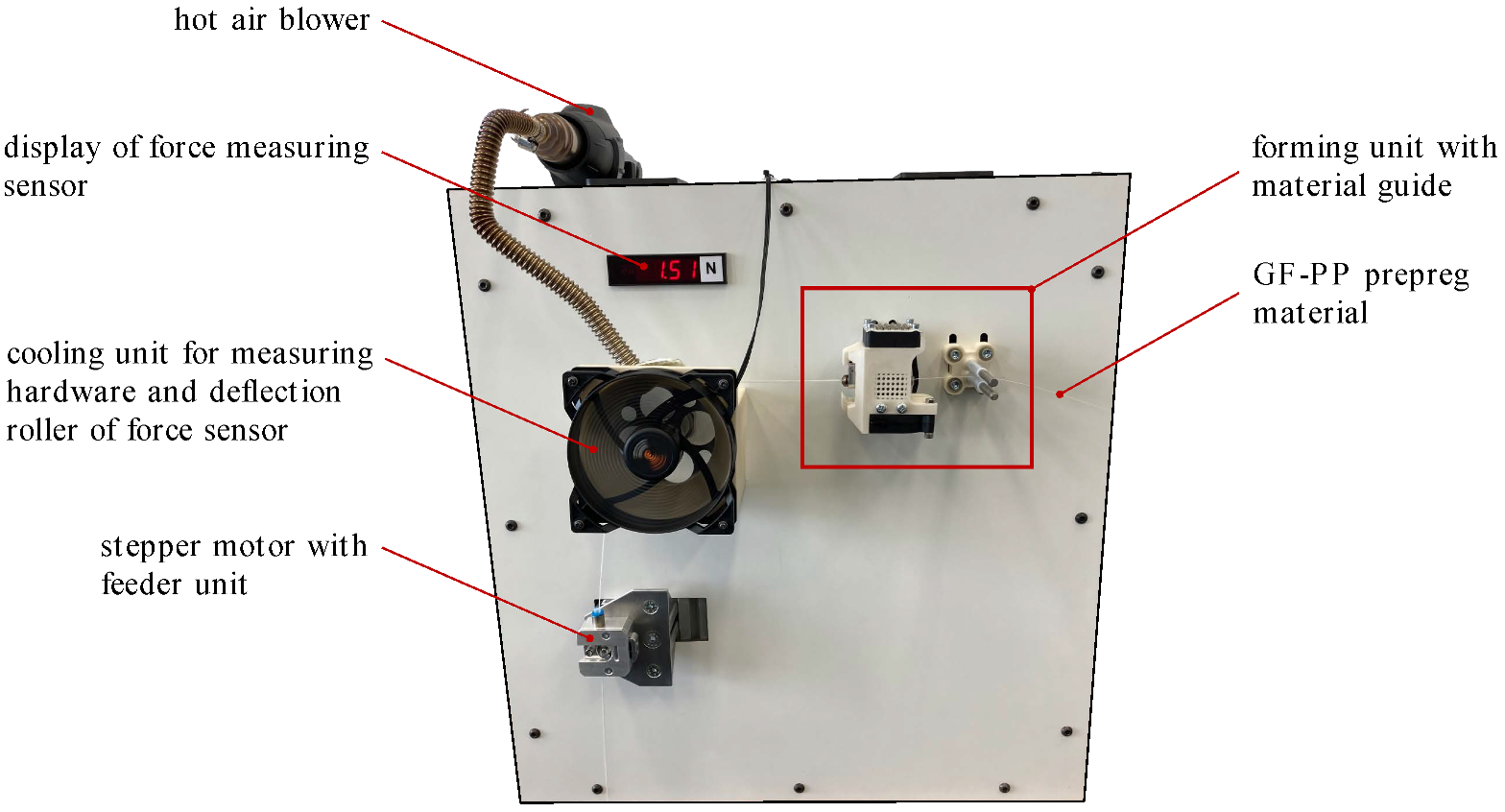

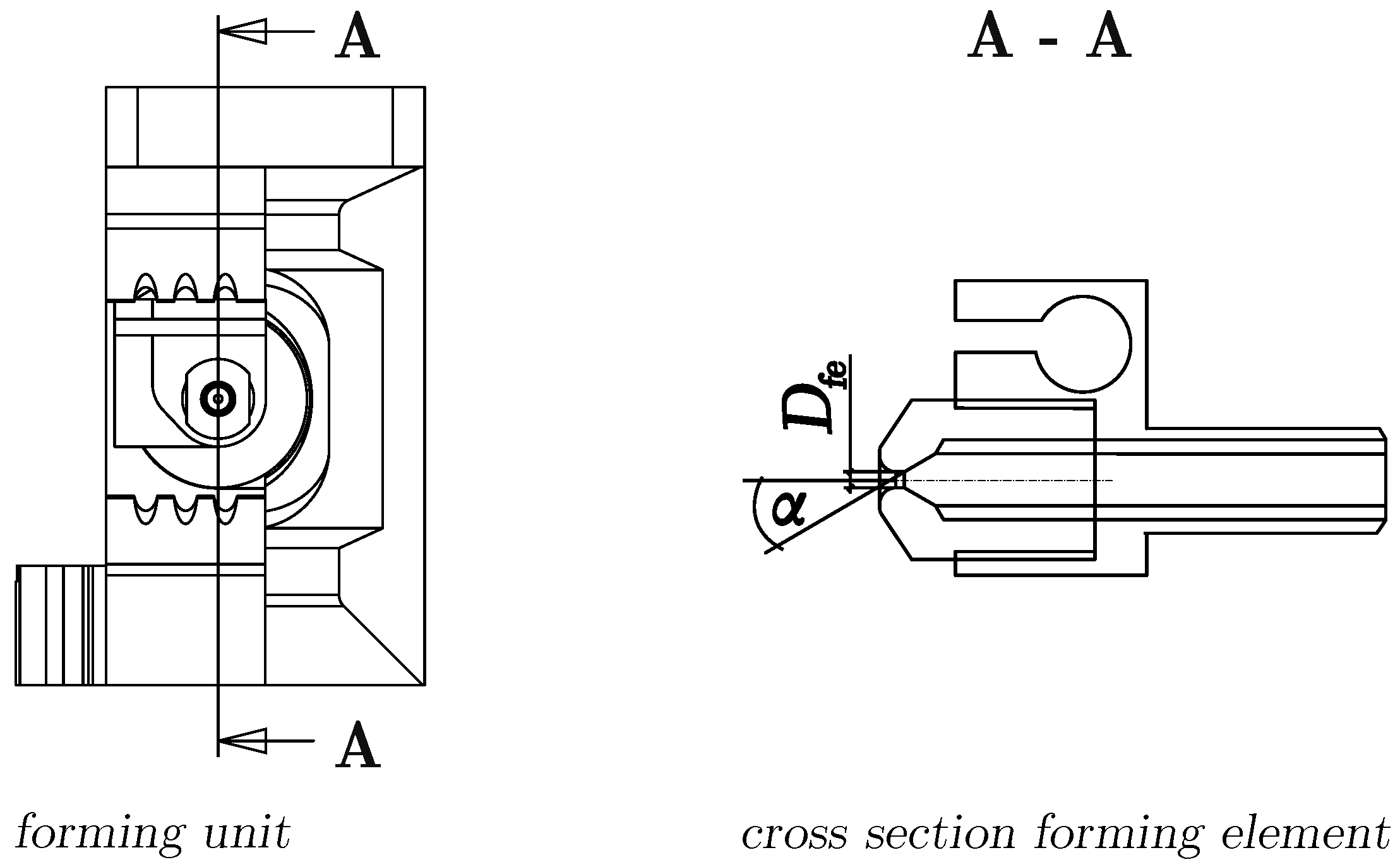

3.1. Equipment for Fibre Bundle Deformation Studies

3.2. Experimental Investigations

4. Results

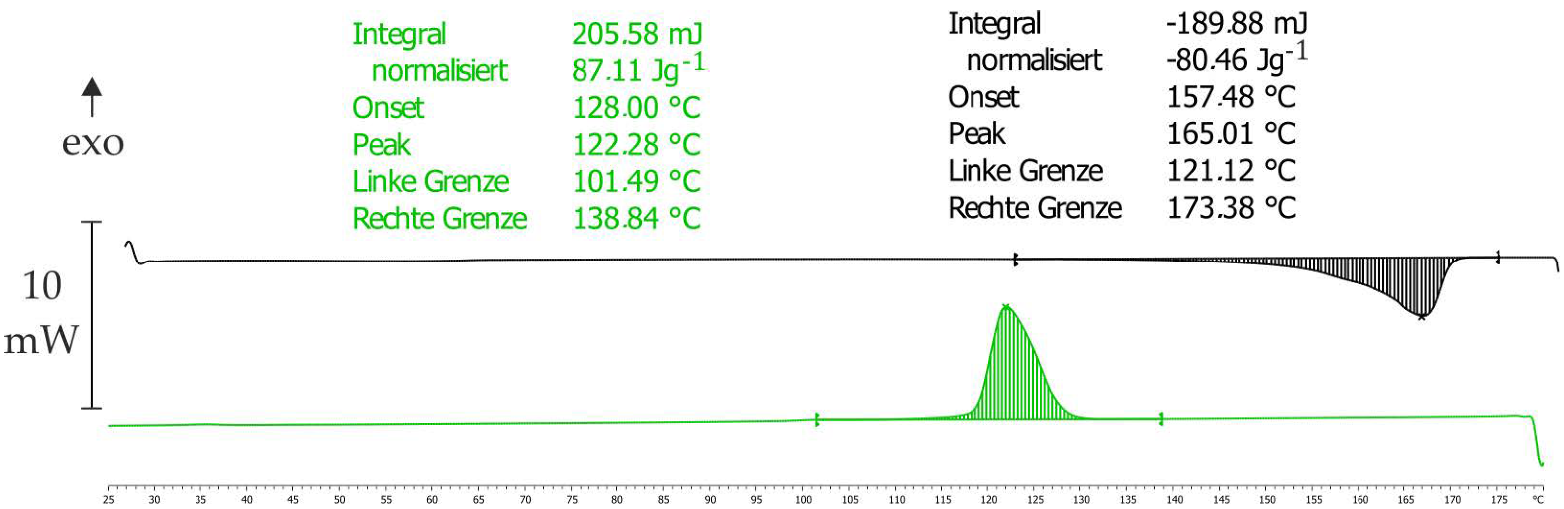

4.1. Characterization of the Thermoplastic PP Matrix

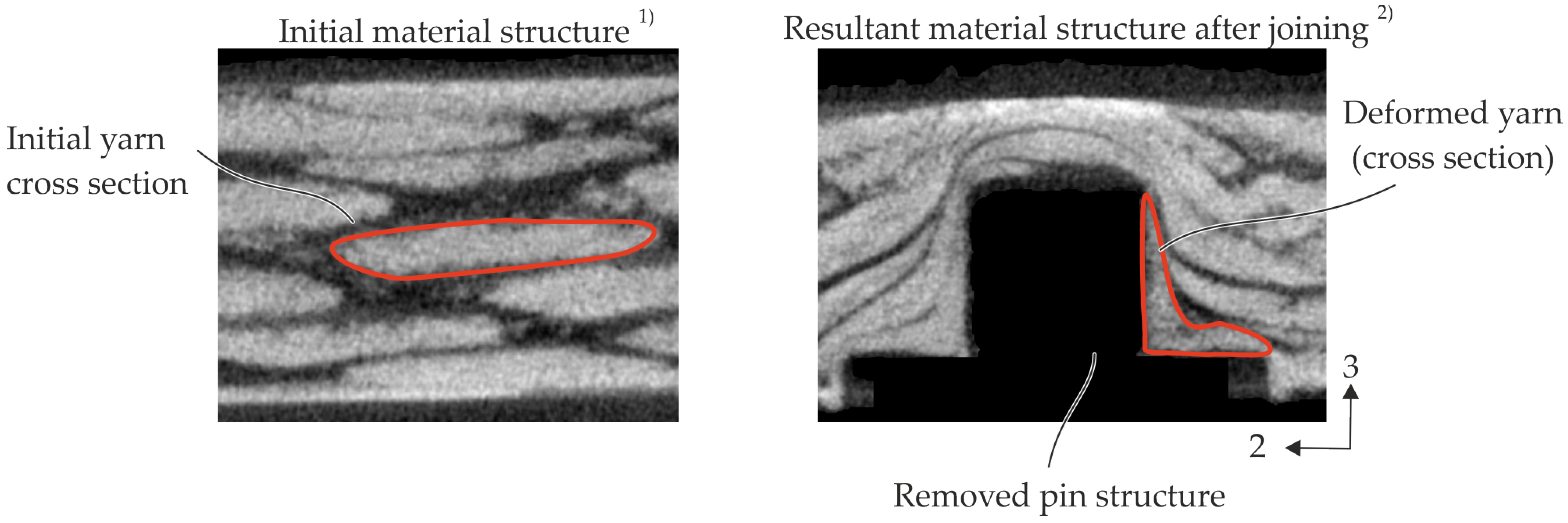

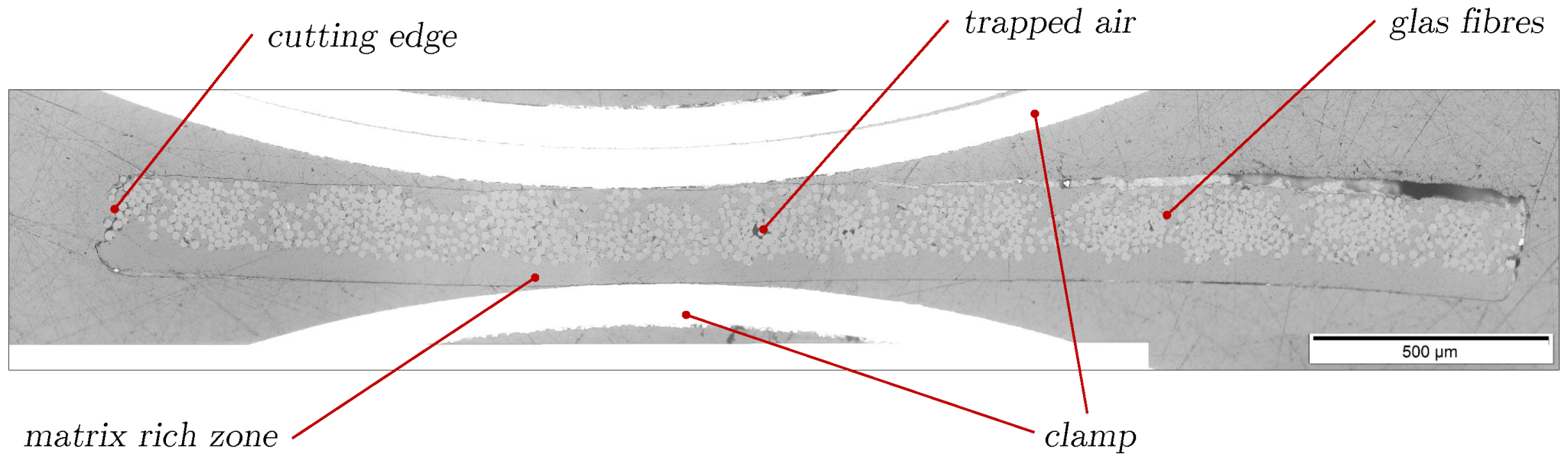

4.2. Evaluation of the Microscopy Image and CT Reconstruction Data of the Input Material

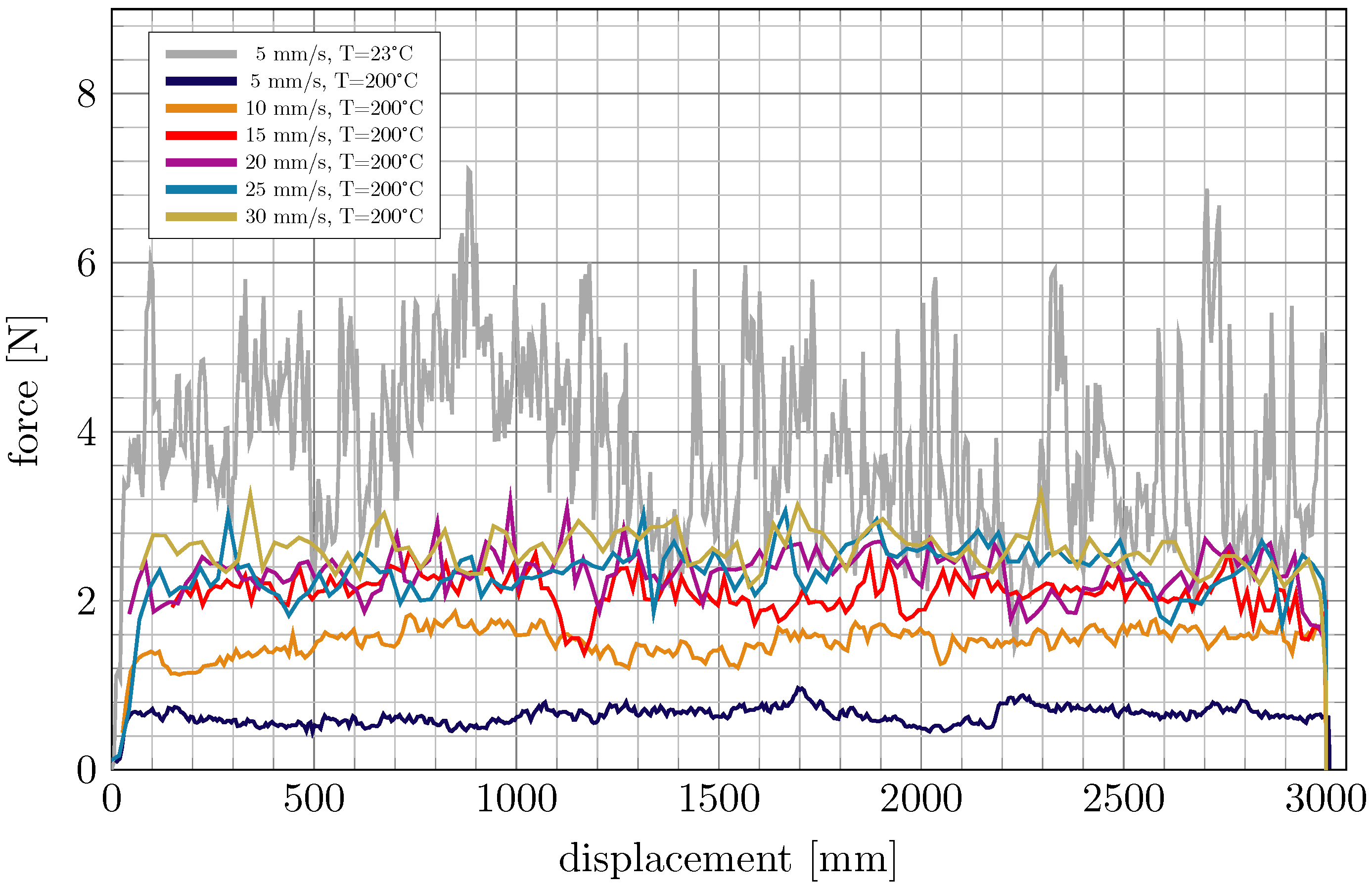

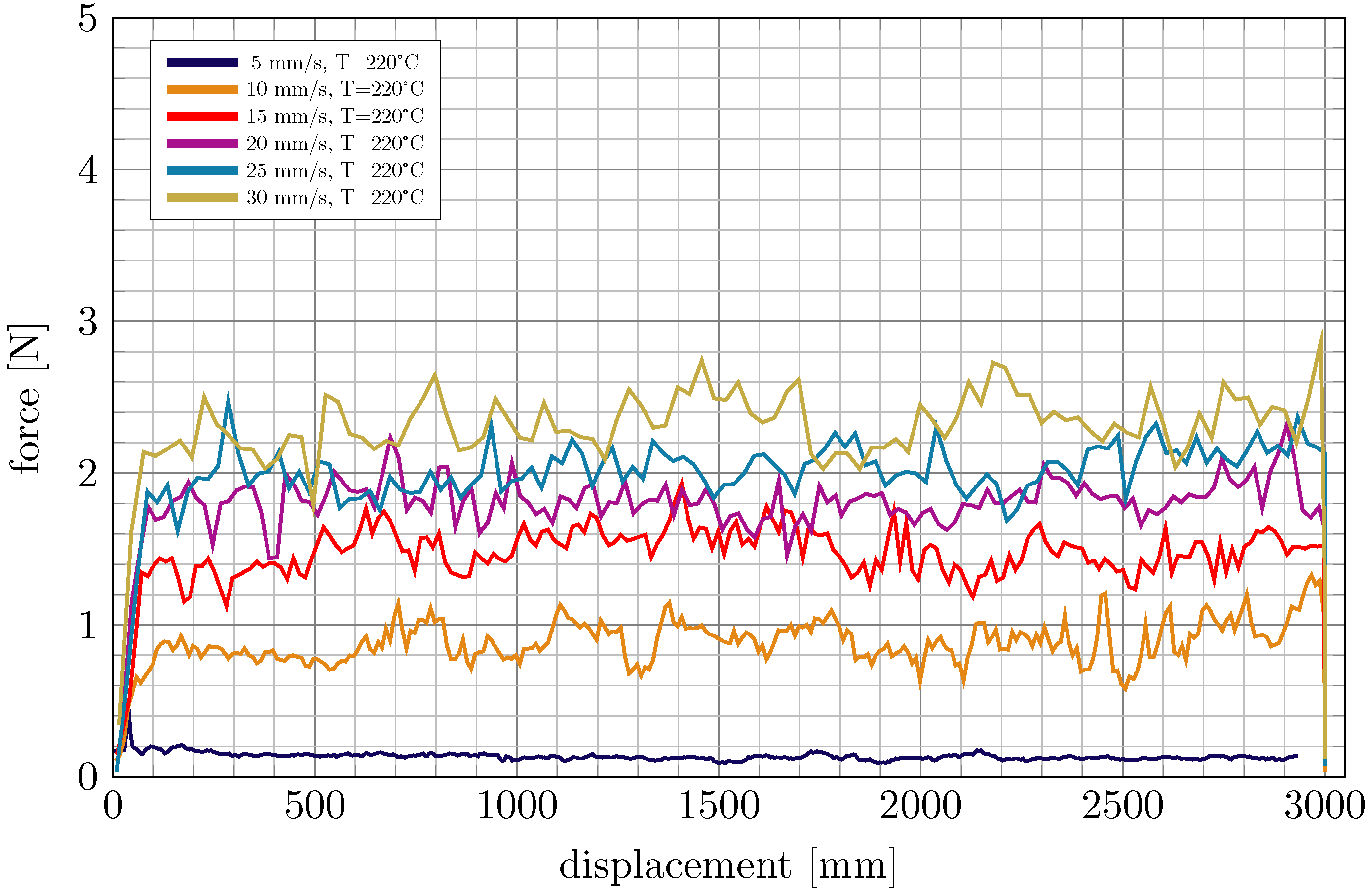

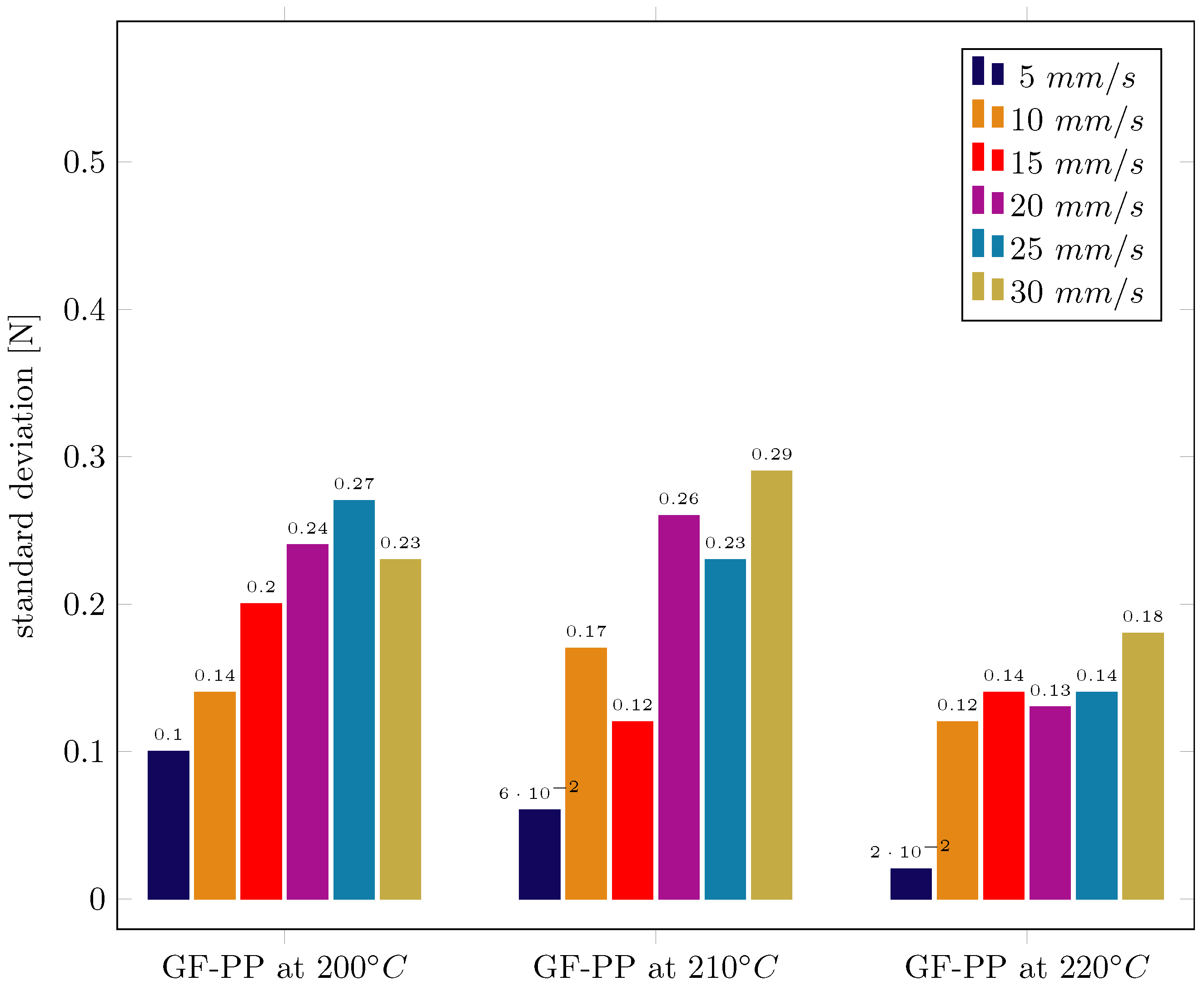

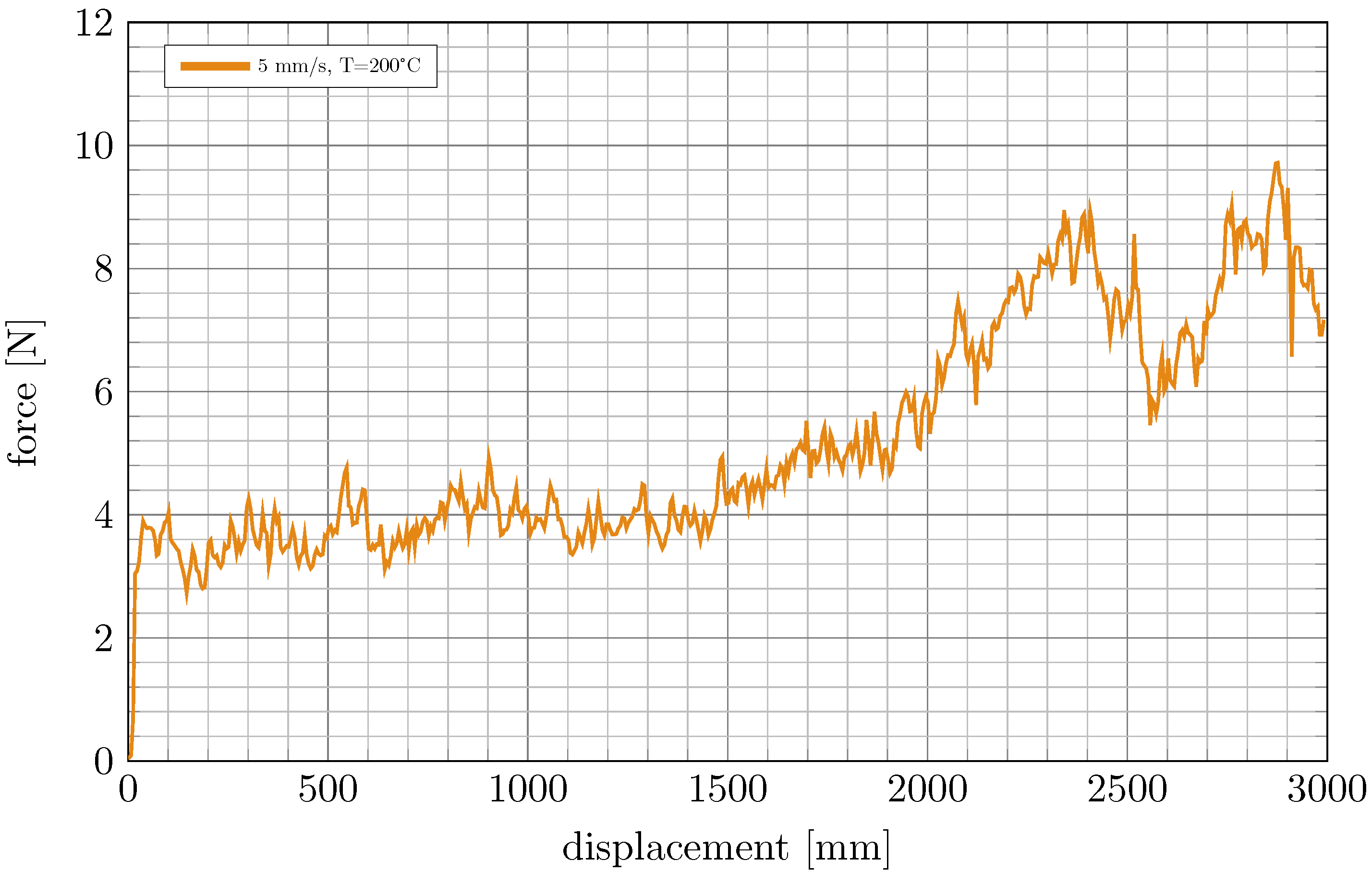

4.3. Results of the Forming Behaviour Using the Forming Element with Diameter 1.2 mm

4.4. Results of the Forming Behaviour Using the Forming Element with Diameter 0.9 mm

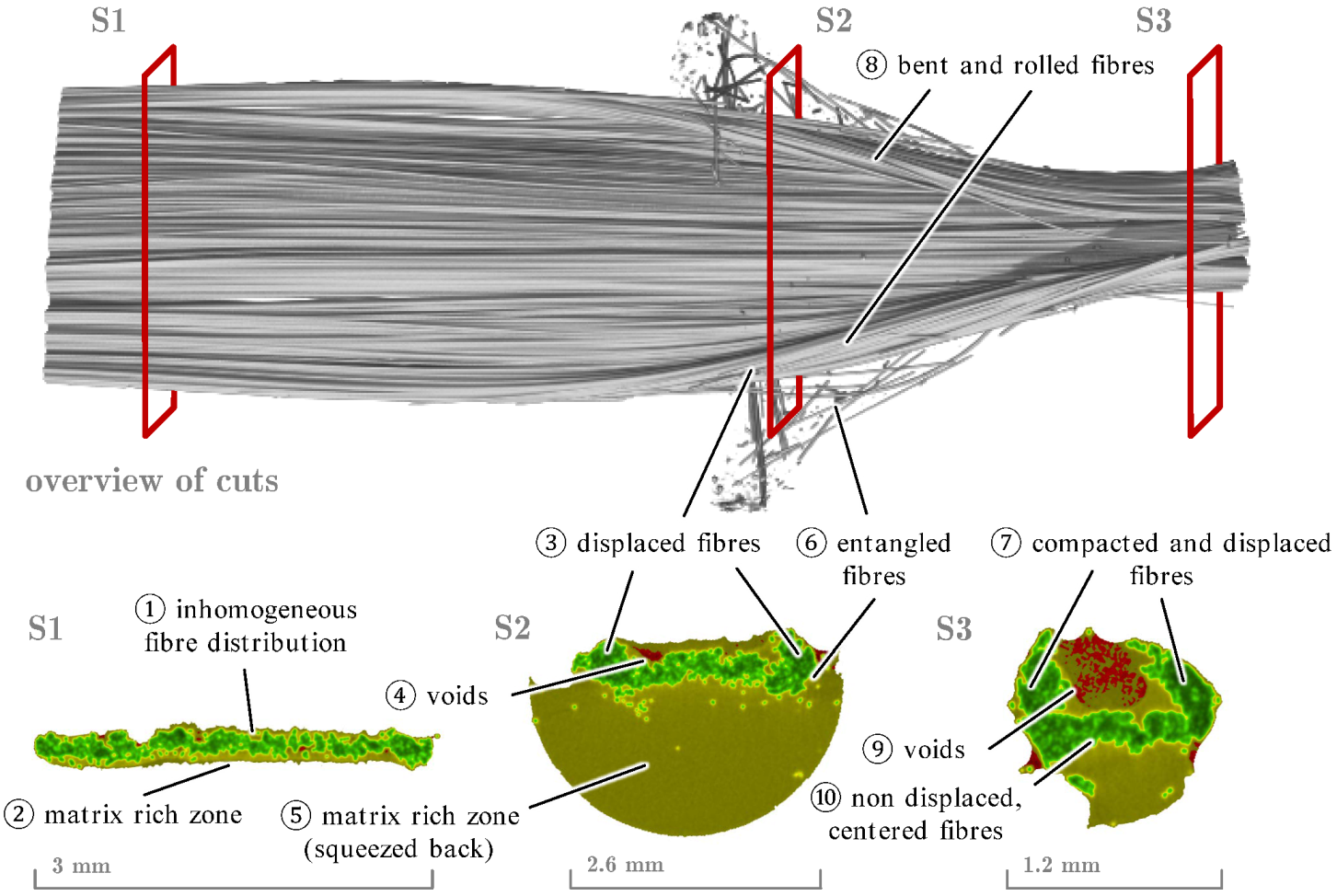

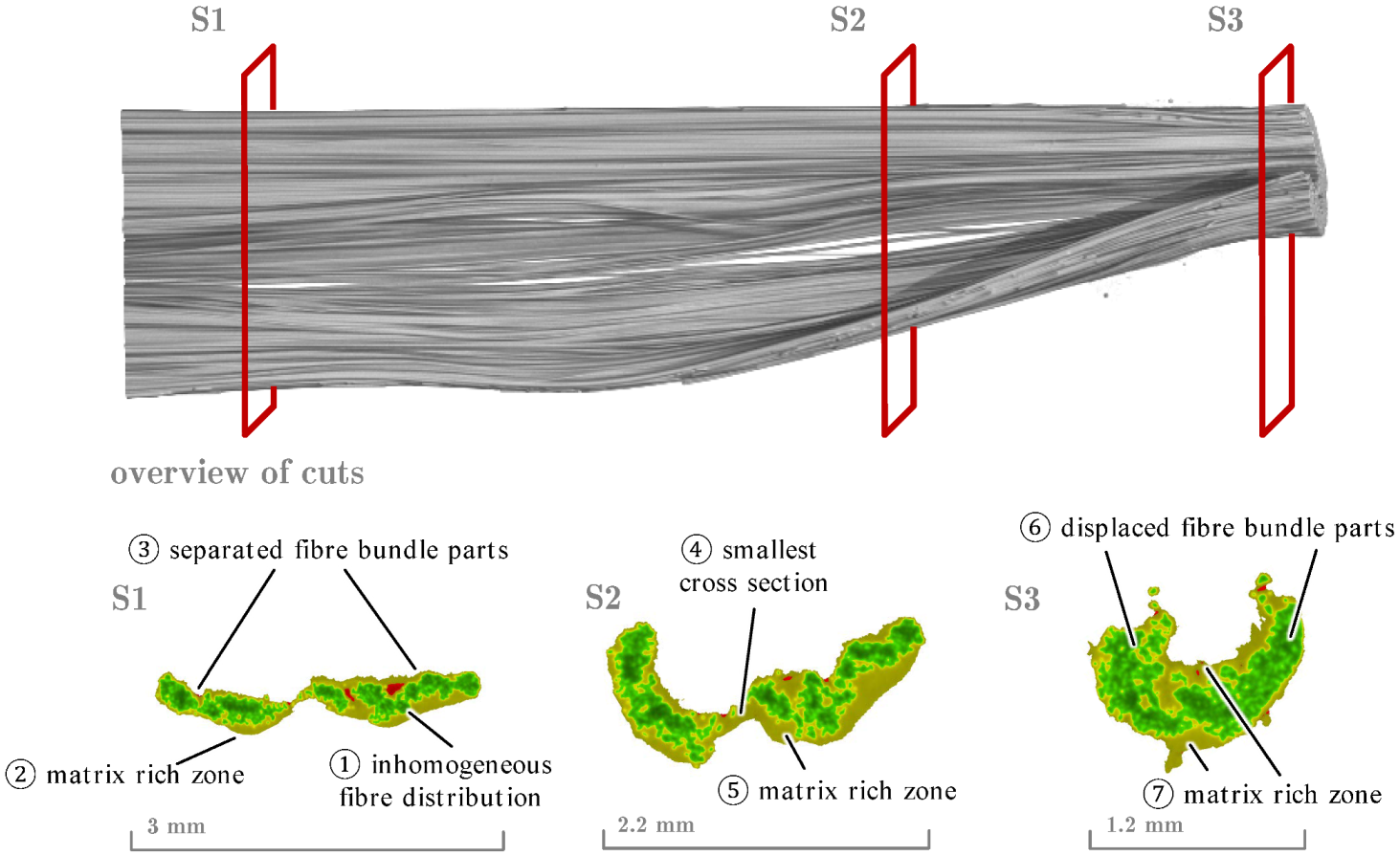

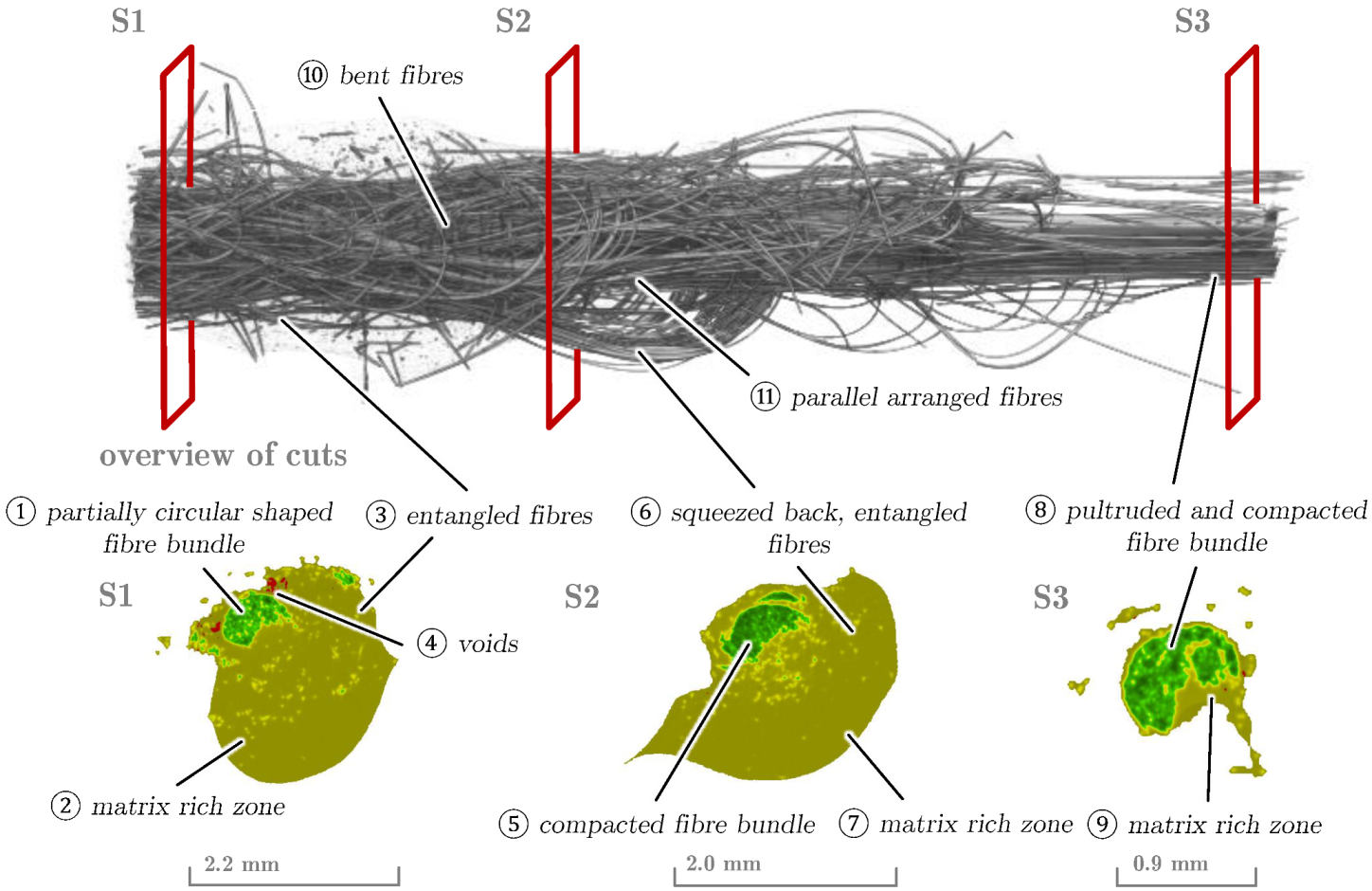

4.5. Material Structure Analysis with Computed Tomography

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PREPREG | Preimpregnated continuous fibre-reinforced material |

| FRP | Fibre-reinforced plastics |

| GF | Glass fibre |

| PP | Polypropylene |

| 3D | Three-dimensional |

| TPC | Thermoplastic composite |

| CT | Computed tomography |

| PPR | Parallel-plate rheometer |

| UD | Unidirectional |

| FFI | Fibre–fibre interaction |

| CF | Carbon fibre |

| PBT | Polybutylenterephthalate |

| PEEK | Polyetheretherketone |

| PA | Polyamide |

| PC | Polycarbonate |

| PEI | Polyetherimide |

| FVC | Fibre volume content |

| DSC | Differential scanning calorimetry |

References

- Van Oers, S.; Pfister, P.; Pichler, A.; Russell, L.; Spini, H.; Tanikawa, E.; van der Voet, H.; Weisz, J.; West, A.; Wiijkman, B.; et al. Assessing Global Resource Use: A Systems Approach to Resource Efficiency and Pollution Reduction; Technical Report; United Nations Environment Programme: Nairobi, Kenya, 2017. [Google Scholar]

- Priem, C.; Othman, R.; Rozycki, P.; Guillon, D. Experimental investigation of the crash energy absorption of 2.5D-braided thermoplastic composite tubes. Compos. Struct. 2014, 116, 814–826. [Google Scholar] [CrossRef] [Green Version]

- Gröger, B.; Troschitz, J.; Vorderbrüggen, J.; Vogel, C.; Kupfer, R.; Meschut, G.; Gude, M. Clinching of Thermoplastic Composites and Metals—A Comparison of Three Novel Joining Technologies. Materials 2021, 14, 2286. [Google Scholar] [CrossRef] [PubMed]

- Popp, J.; Kleffel, T.; Römisch, D.; Papke, T.; Merklein, M.; Drummer, D. Fiber Orientation Mechanism of Continuous Fiber Reinforced Thermoplastics Hybrid Parts Joined with Metallic Pins. Appl. Compos. Mater. 2021, 28, 951–972. [Google Scholar] [CrossRef]

- Galińska, A.; Galiński, C. Mechanical Joining of Fibre Reinforced Polymer Composites to Metals—A Review. Part II: Riveting, Clinching, Non-Adhesive Form-Locked Joints, Pin and Loop Joining. Polymers 2020, 12, 1681. [Google Scholar] [CrossRef] [PubMed]

- Troschitz, J.; Gröger, B.; Würfel, V.; Kupfer, R.; Gude, M. Joining Processes for Fibre-Reinforced Thermoplastics: Phenomena and Characterisation. Materials 2022, 15, 5454. [Google Scholar] [CrossRef]

- Troschitz, J.; Füßel, R.; Kupfer, R.; Gude, M. Damage Analysis of Thermoplastic Composites with Embedded Metal Inserts Using In Situ Computed Tomography. J. Compos. Sci. 2022, 6, 287. [Google Scholar] [CrossRef]

- Bussetta, P.; Correia, N. Numerical forming of continuous fibre reinforced composite material: A review. Compos. Part A Appl. Sci. Manuf. 2018, 113, 12–31. [Google Scholar] [CrossRef]

- Gröger, B.; Hornig, A.; Hoog, A.; Gude, M. Modelling of thermally supported clinching of fibre-reinforced thermoplastics: Approaches on mesoscale considering large deformations and fibre failure. In Proceedings of the ESAFORM 2021—24th International Conference on Material Forming, Liège, Belgium, 14–16 April 2021. [Google Scholar] [CrossRef]

- Liang, B.; Hamila, N.; Peillon, M.; Boisse, P. Analysis of thermoplastic prepreg bending stiffness during manufacturing and of its influence on wrinkling simulations. Compos. Part A Appl. Sci. Manuf. 2014, 67, 111–122. [Google Scholar] [CrossRef]

- Ropers, S.; Kardos, M.; Osswald, T.A. A thermo-viscoelastic approach for the characterization and modeling of the bending behavior of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 22–32. [Google Scholar] [CrossRef]

- Launay, J.; Hivet, G.; Duong, A.V.; Boisse, P. Experimental analysis of the influence of tensions on in plane shear behaviour of woven composite reinforcements. Compos. Sci. Technol. 2008, 68, 506–515. [Google Scholar] [CrossRef] [Green Version]

- Latil, P.; Orgéas, L.; Geindreau, C.; Dumont, P.; du Roscoat, S.R. Towards the 3D in situ characterisation of deformation micro-mechanisms within a compressed bundle of fibres. Compos. Sci. Technol. 2011, 71, 480–488. [Google Scholar] [CrossRef] [Green Version]

- Volk, M.; Yuksel, O.; Baran, I.; Hattel, J.H.; Spangenberg, J.; Sandberg, M. Cost-efficient, automated, and sustainable composite profile manufacture: A review of the state of the art, innovations, and future of pultrusion technologies. Compos. Part B Eng. 2022, 246, 110135. [Google Scholar] [CrossRef]

- Volk, M.; Wong, J.; Arreguin, S.; Ermanni, P. Pultrusion of large thermoplastic composite profiles up to ∅ 40 mm from glass-fibre/PET commingled yarns. Compos. Part B Eng. 2021, 227, 109339. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Safonov, A.; Akhatov, I. Thermoplastic Pultrusion: A Review. Polymers 2021, 13, 180. [Google Scholar] [CrossRef]

- Novo, P.; Silva, J.; Nunes, J.; Marques, A. Pultrusion of fibre reinforced thermoplastic pre-impregnated materials. Compos. Part B Eng. 2016, 89, 328–339. [Google Scholar] [CrossRef] [Green Version]

- Bechtold, G.; Wiedmer, S.; Friedrich, K. Pultrusion of Thermoplastic Composites - New Developments and Modelling Studies. J. Thermoplast. Compos. Mater. 2002, 15, 443–465. [Google Scholar] [CrossRef]

- Åström, B. Development and application of a process model for thermoplastic pultrusion. Compos. Manuf. 1992, 3, 189–197. [Google Scholar] [CrossRef]

- Carlsson, A.; Åström, B.T. Experimental investigation of pultrusion of glass fibre reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 585–593. [Google Scholar] [CrossRef]

- Kerbiriou, V.; Friedrich, K. Pultrusion of Thermoplastic Composites-Process Optimization and Mathematical Modeling. J. Thermoplast. Compos. Mater. 1999, 12, 96–120. [Google Scholar] [CrossRef]

- Evstatiev, M.; Angelov, I.; Friedrich, K. Structure and properties of microfibrillar-reinforced composites based on thermoplastic PET/LDPE blends after manufacturing by means of pultrusion. Polym. Eng. Sci. 2009, 50, 402–410. [Google Scholar] [CrossRef]

- Chen, K.; Jia, M.; Sun, H.; Xue, P. Thermoplastic Reaction Injection Pultrusion for Continuous Glass Fiber-Reinforced Polyamide-6 Composites. Materials 2019, 12, 463. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Åström, B.T.; Pipes, R.B. A modeling approach to thermoplastic pultrusion. II: Verification of models. Polym. Compos. 1993, 14, 184–194. [Google Scholar] [CrossRef]

- Safonov, A.A.; Carlone, P.; Akhatov, I. Mathematical simulation of pultrusion processes: A review. Compos. Struct. 2018, 184, 153–177. [Google Scholar] [CrossRef]

- Koubaa, S.; Corre, S.L.; Burtin, C. Thermoplastic pultrusion process: Modeling and optimal conditions for fibers impregnation. J. Reinf. Plast. Compos. 2013, 32, 1285–1294. [Google Scholar] [CrossRef]

- Duhovic, M.; Aswale, P.; Schommer, D.; Hausmann, J. Development of a process simulation model of a pultrusion line. In Proceedings of the 12th European LS-DYNA Users Conference, Koblenz, Germany, 14–16 May 2019. [Google Scholar]

- Wiedmer, S.; Manolesos, M. An Experimental Study of the Pultrusion of Carbon Fiber-Polyamide 12 Yarn. J. Thermoplast. Compos. Mater. 2006, 19, 97–112. [Google Scholar] [CrossRef] [Green Version]

- Gennaro, R.; Christmann, M.; Greco, A.; Rieber, G.; Mitschang, P.; Maffezzoli, A. Experimental measurement of transversal micro- and macro permeability during compression molding of PP/Glass composites. Polym. Compos. 2013, 35, 105–112. [Google Scholar] [CrossRef]

- Hexcel Corporation. HexFlow RTM6–Data Sheet; Hexcel Corporation: Stamford, CT, USA, 2018. [Google Scholar]

- Nakai, A.; Morino, K. Olding condition for shortening molding time during pultrusion molding of thermoplastic composites. In Proceedings of the ICCM International Conferences on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Eichenhofer, M.; Wong, J.C.; Ermanni, P. Continuous lattice fabrication of ultra-lightweight composite structures. Addit. Manuf. 2017, 18, 48–57. [Google Scholar] [CrossRef]

- Aegerter, N.; Volk, M.; Maio, C.; Schneeberger, C.; Ermanni, P. Pultrusion of hybrid bicomponent fibers for 3D printing of continuous fiber reinforced thermoplastics. Adv. Ind. Eng. Polym. Res. 2021, 4, 224–234. [Google Scholar] [CrossRef]

- Alsinani, N.; Ghaedsharaf, M.; Lebel, L.L. Effect of cooling temperature on deconsolidation and pulling forces in a thermoplastic pultrusion process. Compos. Part B Eng. 2021, 219, 108889. [Google Scholar] [CrossRef]

- BÜFA Thermoplastic Composites GmbH & Co. KG. Thermoplastic Unidirectional Tape PP GF 60. 2020. Available online: https://thermoplasticcomposites.de/de/wp-content/uploads/sites/2/2020/11/Preliminary-Dataheet_UD-Tape_GF-PP-natural_250%C2%B5m.pdf (accessed on 26 October 2022).

- Borealis AG. Polypropylene BJ100HP Polypropylene Copolymer; Borealis AG: Vienna, Austria, 2021. [Google Scholar]

- Gude, M.; Vogel, C.; Gröger, B. Simulation-aided development of a robust thermoclinching joining process for hybrid structures with textile reinforced thermoplastic composites and metallic components. Mater. Und Werkst. 2019, 50, 1027–1038. [Google Scholar] [CrossRef]

- Brown, N.; Worrall, C.; Ogin, S.; Smith, P. Investigation into the mechanical properties of thermoplastic composites containing holes machined by a thermally-assisted piercing (TAP) process. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 199–209. [Google Scholar] [CrossRef]

| Property | Unit | Abbreviation | Value |

|---|---|---|---|

| tensile modulus | GPa | 28 | |

| flexural modulus | GPa | 21 | |

| tensile strength | MPa | 720 | |

| flexural strength 0° | MPa | 436 | |

| thickness | mm | t | 0.25 |

| width | mm | w | 3 |

| fibre volume content | % | 35 | |

| melting temperature | °C | 165 | |

| processing temperature | °C | 180–220 |

| Parameter | Unit | Value |

|---|---|---|

| acceleration voltage | 60 | |

| tube current | 100 | |

| exposure time | 2000 | |

| X-ray projections | 1440 (4 per 1°) | |

| source object distance | 30 | |

| source image distance | 200 | |

| voxel size | 7.5 |

| Parameter | Unit | Value |

|---|---|---|

| acceleration voltage | 50 | |

| tube current | 180 | |

| exposure time | 1500 | |

| X-ray projections | 1440 (4 per 1°) | |

| source object distance | 30 | |

| source image distance | 200 | |

| voxel size | 7.5 |

| Series | Velocity mm/s | Temperature °C | Diameter D |

|---|---|---|---|

| 1 | 5 | 23 | 1.2 |

| 2 | 5, 10, 15, 20, 25, 30 | 200 | 1.2 |

| 3 | 5, 10, 15, 20, 25, 30 | 210 | 1.2 |

| 4 | 5, 10, 15, 20, 25, 30 | 220 | 1.2 |

| 5 | 5 | 200 | 0.9 |

| Temperature °C | Dynamic Viscosity in Pas |

|---|---|

| 200 | 328 |

| 210 | 257 |

| 220 | 225 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borowski, A.; Gröger, B.; Füßel, R.; Gude, M. Characterisation of Fibre Bundle Deformation Behaviour—Test Rig, Results and Conclusions. J. Manuf. Mater. Process. 2022, 6, 146. https://doi.org/10.3390/jmmp6060146

Borowski A, Gröger B, Füßel R, Gude M. Characterisation of Fibre Bundle Deformation Behaviour—Test Rig, Results and Conclusions. Journal of Manufacturing and Materials Processing. 2022; 6(6):146. https://doi.org/10.3390/jmmp6060146

Chicago/Turabian StyleBorowski, Andreas, Benjamin Gröger, René Füßel, and Maik Gude. 2022. "Characterisation of Fibre Bundle Deformation Behaviour—Test Rig, Results and Conclusions" Journal of Manufacturing and Materials Processing 6, no. 6: 146. https://doi.org/10.3390/jmmp6060146

APA StyleBorowski, A., Gröger, B., Füßel, R., & Gude, M. (2022). Characterisation of Fibre Bundle Deformation Behaviour—Test Rig, Results and Conclusions. Journal of Manufacturing and Materials Processing, 6(6), 146. https://doi.org/10.3390/jmmp6060146