Residual Stresses in a High- and a Medium-Entropy Alloy due to TIG and Friction Stir Welding

Abstract

1. Introduction

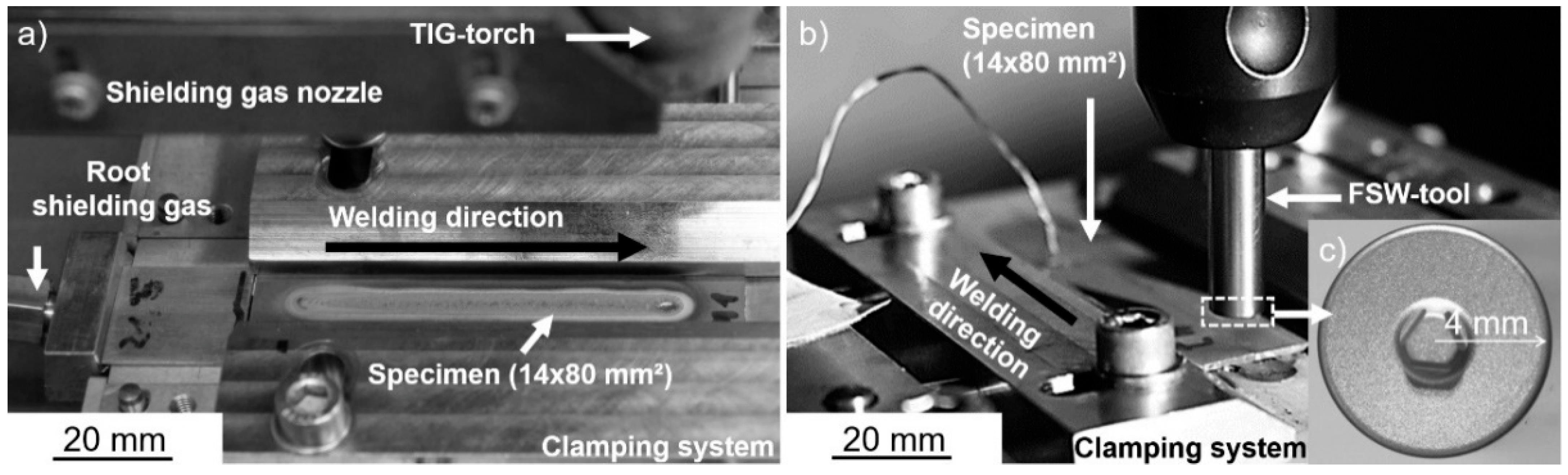

2. Materials and Methods

3. Results

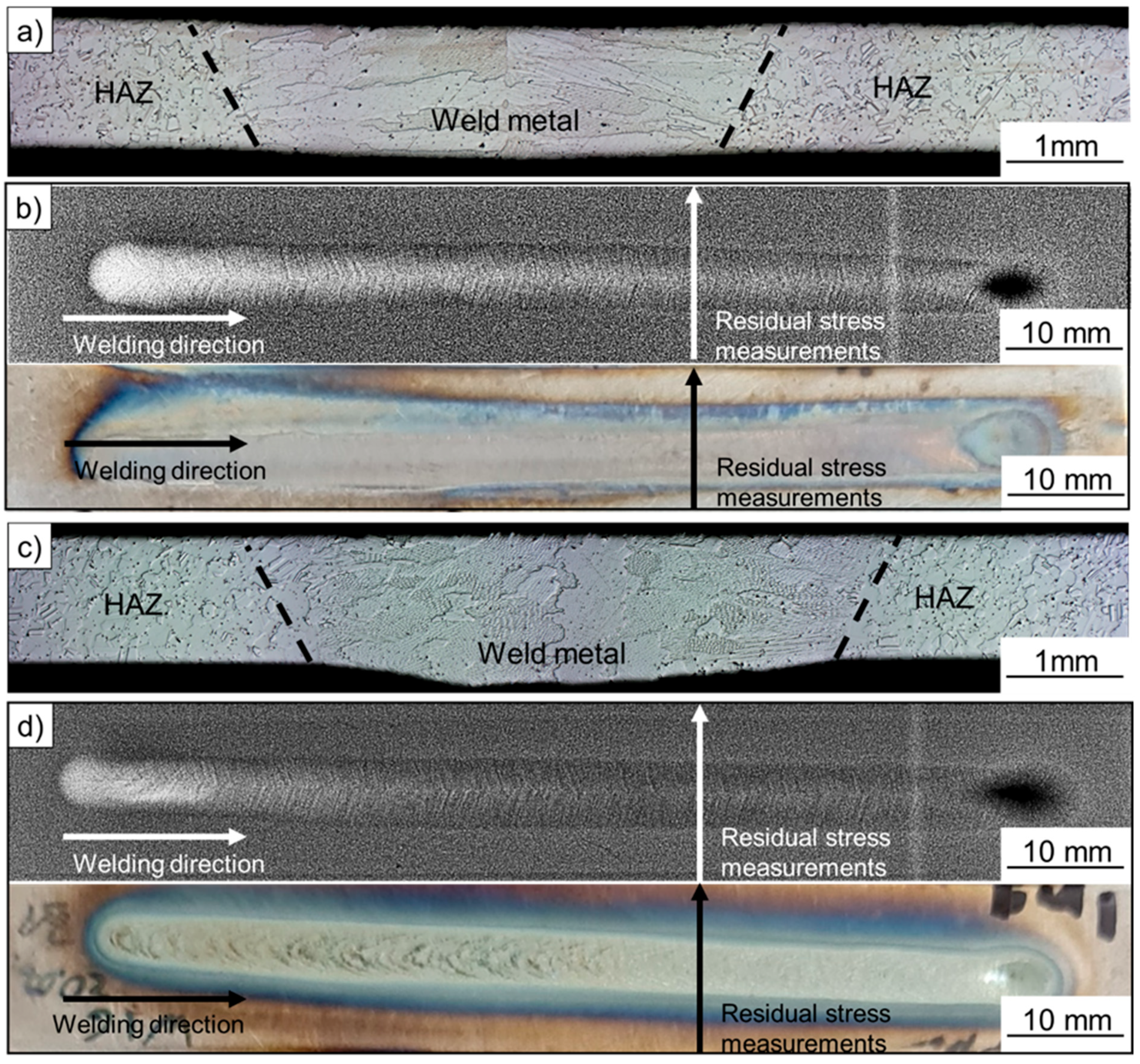

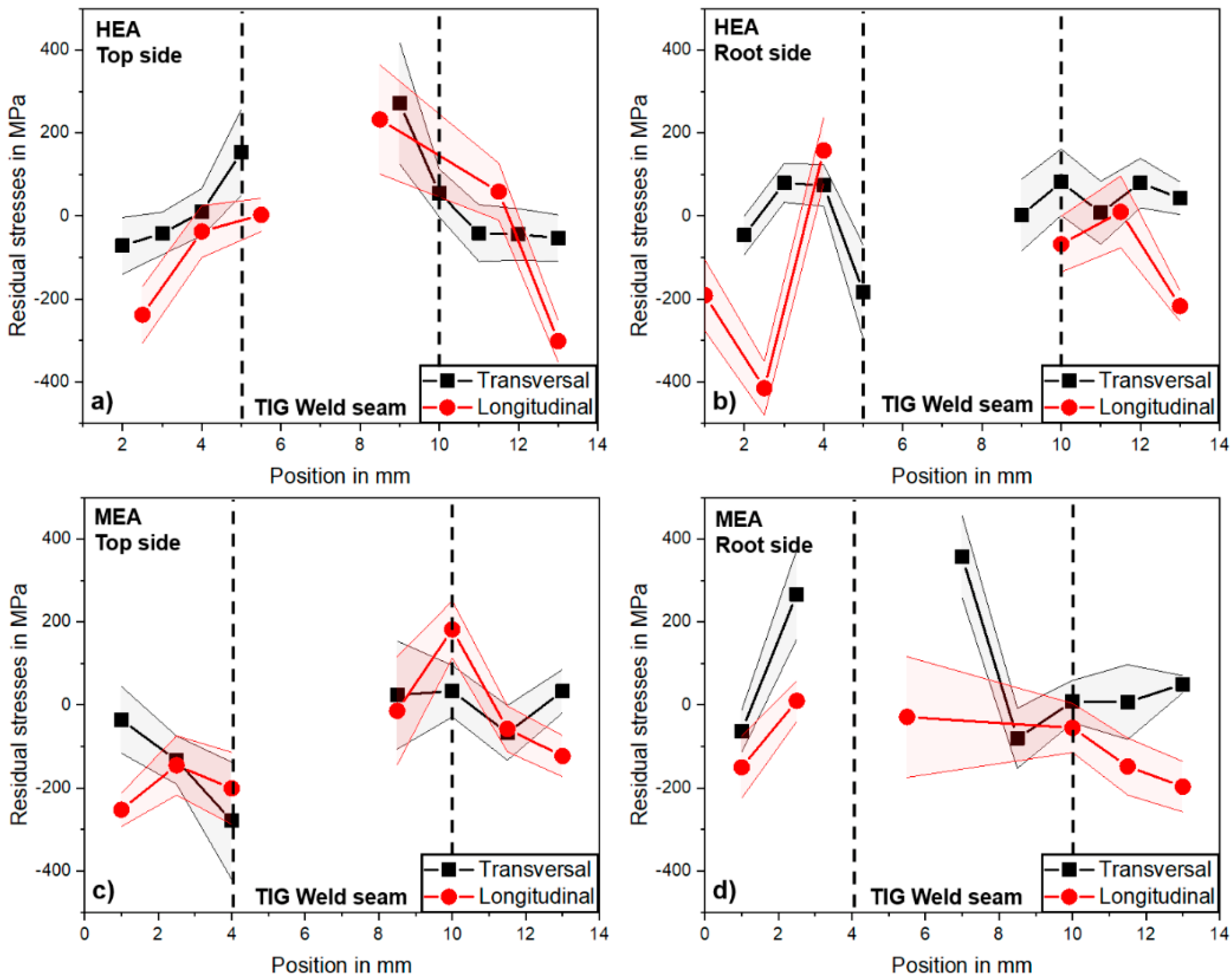

3.1. TIG Welding Experiments

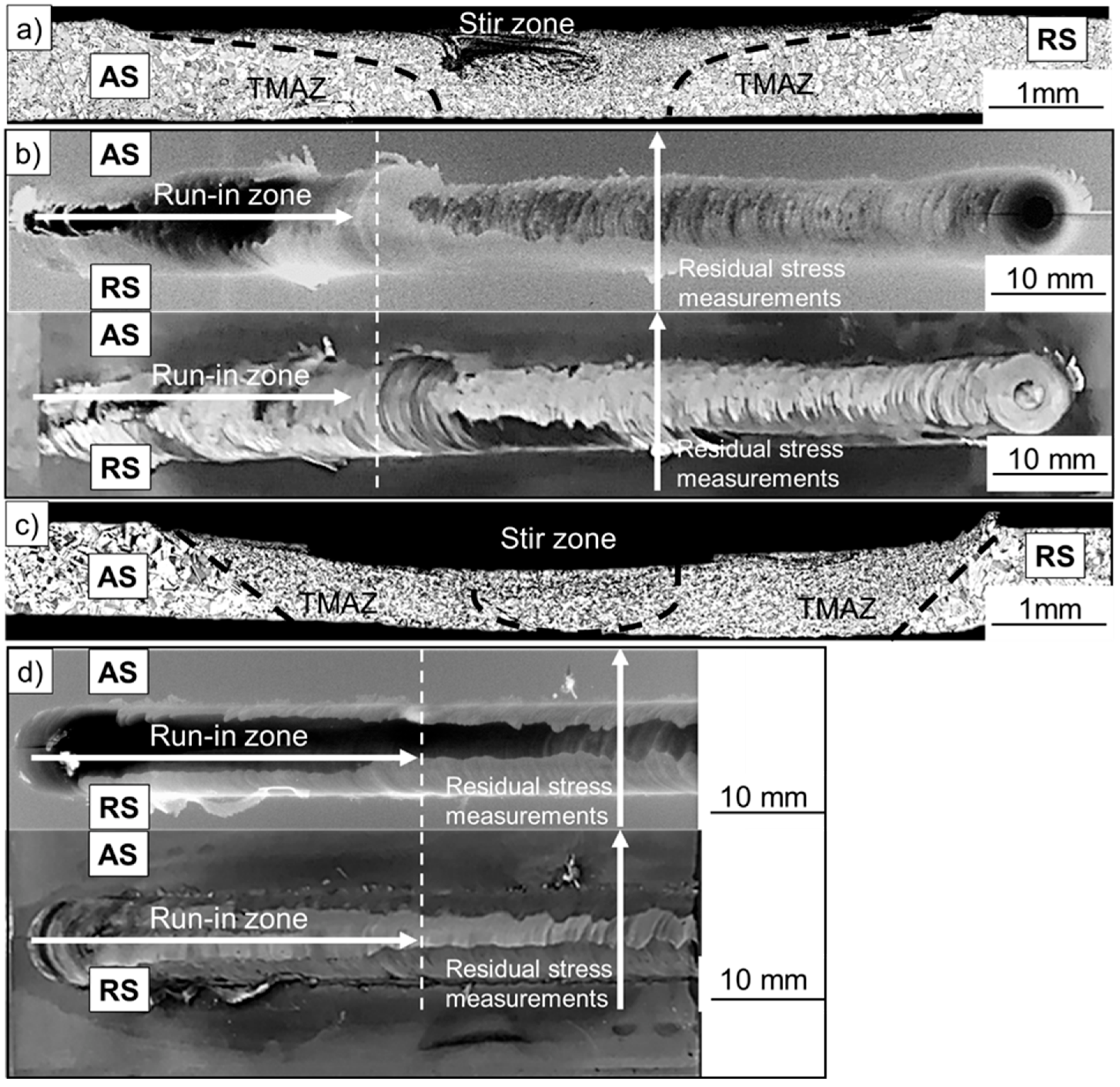

3.2. FSW Experiments

4. Summary and Conclusions

- (1)

- The results basically show that with the selected tool, process, and parameters, CoCrFeMnNi HEA and CoCrNi MEA welds can be produced that do not show any impermissible defects upon visual inspection and light microscopic examination of the transverse sections. In summary, both alloys showed good weldability using the TIG and FSW process, as stated in other studies.

- (2)

- Defect-free welds were obtained with specimens with considerable dimension and restraint conditions, allowing residual stress analyses to be carried out at the weld seams.

- (3)

- The columnar dendritic solidification (large, oriented grains) did not allow a proper determination of residual stresses by XRD in TIG WM. The high compensating longitudinal residual compressive stresses in the HAZ and the base metal indicate high tensile stresses up to the material strength in the TIG WM area of HEA and MEA; meanwhile, the transverse residual stresses in the base metal were low (approx. 0 MPa), and increased at the top side in the weld area and decreased on the root side into compression (HEA), or vice versa (MEA).

- (4)

- The fine-grained structure of friction stir WM allowed accurate residual stress analysis. The longitudinal FSW-generated residual stresses for both MEA and HEA were similar to the TIG welds, with compressive stresses (base material) and tensile stresses in yield strength level (WM). The higher force for FSW processing of the harder MEA resulted in a significantly wider residual stress profile, transverse to the welding direction. In contrast to the TIG, the transverse residual stresses (WM) were close to 0 MPa, and increased in the direction of the base metal, in the MEA, up to the yield strength level.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Manzoni, A.M.; Glatzel, U. High-Entropy Alloys: Balancing Strength and Ductility at Room Temperature. Ref. Modul. Mater. Sci. Mater. Eng. 2020, 2, 441–453. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Rhode, M.; Richter, T.; Schroepfer, D.; Manzoni, A.M.; Schneider, M.; Laplanche, G. Welding of high-entropy alloys and compositionally complex alloys-an overview. Weld. World 2021, 65, 1645–1659. [Google Scholar] [CrossRef]

- Laplanche, G.; Kostka, A.; Reinhart, C.; Hunfeld, J.; Eggeler, G.; George, E.P. Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 2017, 128, 292–303. [Google Scholar] [CrossRef]

- Park, S.; Nam, H.; Na, Y.; Kim, H.; Moon, Y.; Kang, N. Effect of Initial Grain Size on Friction Stir Weldability for Rolled and Cast CoCrFeMnNi High-Entropy Alloys. Met. Mater. Int. 2020, 26, 641–649. [Google Scholar] [CrossRef]

- Park, S.; Park, C.; Na, Y.; Kim, H.-S.; Kang, N. Effects of (W, Cr) carbide on grain refinement and mechanical properties for CoCrFeMnNi high entropy alloys. J. Alloys Compd. 2019, 770, 222–228. [Google Scholar] [CrossRef]

- Richter, T.; Giese, M.; Rhode, M.; Schroepfer, D.; Michael, T.; Fritsch, T. Influence of Surface Preparation on Cracking Phenomena in TIG-Welded High and Medium Entropy Alloys. J. Manuf. Mater. Process. 2021, 6, 5. [Google Scholar] [CrossRef]

- Nam, H.; Park, S.; Chun, E.-J.; Kim, H.; Na, Y.; Kang, N. Laser dissimilar weldability of cast and rolled CoCrFeMnNi high-entropy alloys for cryogenic applications. Sci. Technol. Weld. Join. 2019, 25, 127–134. [Google Scholar] [CrossRef]

- ISO/TR 581:2005; Weldability—Metallic materials—General Principles. Beuth publishing: Berlin, Germany, 2005.

- Xu, N.; Song, Q.; Bao, Y. Microstructure evolution and mechanical properties of friction stir welded FeCrNiCoMn high-entropy alloy. Mater. Sci. Technol. 2019, 35, 577–584. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.P.; Robson, J.D.; et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2020, 117, 100752. [Google Scholar] [CrossRef]

- DIN EN ISO 6520—2; Einteilung von Geometrischen Unregelmäßigkeiten an Metallen, Pressschweißungen. Beuth Verlag GmbH: Berlin, Germany, 2001.

- Nitschke-Pagel, T.; Wohlfahrt, H. Residual Stresses in Welded Joints—Sources and Consequences. Mater. Sci. Forum 2002, 404–407, 215–226. [Google Scholar] [CrossRef]

- Zerbst, U. Application of fracture mechanics to welds with crack origin at the weld toe—A review. Part 2: Welding residual stresses. Residual and total life assessment. Weld. World 2019, 64, 151–169. [Google Scholar] [CrossRef]

- Reynolds, A.P.; Tang, W.; Gnaupel-Herold, T.; Prask, H. Structure, properties, and residual stress of 304 L stainless steel friction stir welds. Scr. Mater. 2003, 48, 1289–1294. [Google Scholar] [CrossRef]

- Zhu, X.K.; Chao, Y.J. Numerical simulation of transient temperature and residual stresses in friction stir welding of 304 L stainless steel. J. Mater. Process. Technol. 2004, 146, 263–272. [Google Scholar] [CrossRef]

- Singh, K.; Singh, G.; Singh, H. Review on friction stir welding of magnesium alloys. J. Magnes. Alloy. 2018, 6, 399–416. [Google Scholar] [CrossRef]

- Richter, T.; Schröpfer, D.; Rhode, M.; Börner, A. Rührreibschweißen von Hoch- und Mittelentropie-Legierungen. In Tagungsband 4. Symposium Material Technik; Clausthaler Znetrum für Materialtechnik: Clausthal Zellerfeld, Germany, 2021; p. 974. [Google Scholar]

- ISO 6507-1:2018; Metallische Werkstoffe– Härteprüfung nach Vickers—Teil 1: Prüfverfahren. Beuth Verlag GmbH: Berlin, Germany, 2018.

- Richter, T.; Schroepfer, D.; Rhode, M.; Boerner, A.; Neumann, R.S.; Schneider, M.; Laplanche, G. Influence of machining on the surface integrity of high- and medium-entropy alloys. Mater. Chem. Phys. 2022, 275, 125271. [Google Scholar] [CrossRef]

- Laplanche, G.; Volkert, U.F.; Eggeler, G.; George, E.P. Oxidation Behavior of the CrMnFeCoNi High-Entropy Alloy. Oxid. Met. 2016, 85, 629–645. [Google Scholar] [CrossRef]

- Withers, P.J.; Turski, M.; Edwards, L.; Bouchard, P.J.; Buttle, D.J. Recent advances in residual stress measurement. Int. J. Press. Vessel. Pip. 2008, 85, 118–127. [Google Scholar] [CrossRef]

- Zaddach, A.J.; Niu, C.; Koch, C.C.; Irving, D.L. Mechanical Properties and Stacking Fault Energies of NiFeCrCoMn High-Entropy Alloy. Jom 2013, 65, 1780–1789. [Google Scholar] [CrossRef]

- Laplanche, G.; Gadaud, P.; Bärsch, C.; Demtröder, K.; Reinhart, C.; Schreuer, J.; George, E.P. Elastic moduli and thermal expansion coefficients of medium-entropy subsystems of the CrMnFeCoNi high-entropy alloy. J. Alloys Compd. 2018, 746, 244–255. [Google Scholar] [CrossRef]

- Wu, Z.; David, S.A.; Leonard, D.N.; Feng, Z.; Bei, H. Microstructures and mechanical properties of a welded CoCrFeMnNi high-entropy alloy. Sci. Technol. Weld. Join. 2018, 23, 585–595. [Google Scholar] [CrossRef]

| at.% | Co | Cr | Fe | Mn | Ni | HV0.5 |

|---|---|---|---|---|---|---|

| HEA | 19.7 | 20.7 | 19.7 | 20.1 | 19.9 | 130 ± 3 |

| MEA | 33.0 | 34.3 | - | - | 32.7 | 187 ± 6 |

| Basic Current | Peak Current | Arc Voltage | Shielding Gas |

|---|---|---|---|

| 35 A | 90 A | 10 V | I1-Ar/25 l × min−1 |

| Pulse frequency | Welding speed | Heat input | Root shielding gas |

| 4 Hz | 300 mm × min−1 | 0.133 kJ × mm−1 | R1-ArH-7.5 |

| Electrode type | Electrode diameter | Arc length | |

| WR02 | 2.4 mm | 2.5 mm | |

| Rotation Speed | Welding Speed | Inclination Angle |

|---|---|---|

| 3000 min−1 | 100 mm × min−1 | 2° |

| Test implementation | Shielding gas | Tool material |

| Position controlled | No shielding gas | W-alloy with 1.5 wt% La2O3 |

| Measuring Mode | Radiation | Detector | Diffraction Line | 2Θ Angle |

|---|---|---|---|---|

| sin2ψ | Mn-Kα | Linear solid-state | (311) | 156° |

| Collimator ᴓ | Tube power | ψ–tilting | ψ-step | Measuring time |

| 3 mm | 30 kV/6.7 mA | 0° bis ± 45° | 9 | 2 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richter, T.; Schroepfer, D.; Rhode, M. Residual Stresses in a High- and a Medium-Entropy Alloy due to TIG and Friction Stir Welding. J. Manuf. Mater. Process. 2022, 6, 147. https://doi.org/10.3390/jmmp6060147

Richter T, Schroepfer D, Rhode M. Residual Stresses in a High- and a Medium-Entropy Alloy due to TIG and Friction Stir Welding. Journal of Manufacturing and Materials Processing. 2022; 6(6):147. https://doi.org/10.3390/jmmp6060147

Chicago/Turabian StyleRichter, Tim, Dirk Schroepfer, and Michael Rhode. 2022. "Residual Stresses in a High- and a Medium-Entropy Alloy due to TIG and Friction Stir Welding" Journal of Manufacturing and Materials Processing 6, no. 6: 147. https://doi.org/10.3390/jmmp6060147

APA StyleRichter, T., Schroepfer, D., & Rhode, M. (2022). Residual Stresses in a High- and a Medium-Entropy Alloy due to TIG and Friction Stir Welding. Journal of Manufacturing and Materials Processing, 6(6), 147. https://doi.org/10.3390/jmmp6060147