A Comprehensive Review of High-Pressure Laser-Induced Materials Processing, Part II: Laser-Driven Dynamic Compression within Diamond Anvil Cells

Abstract

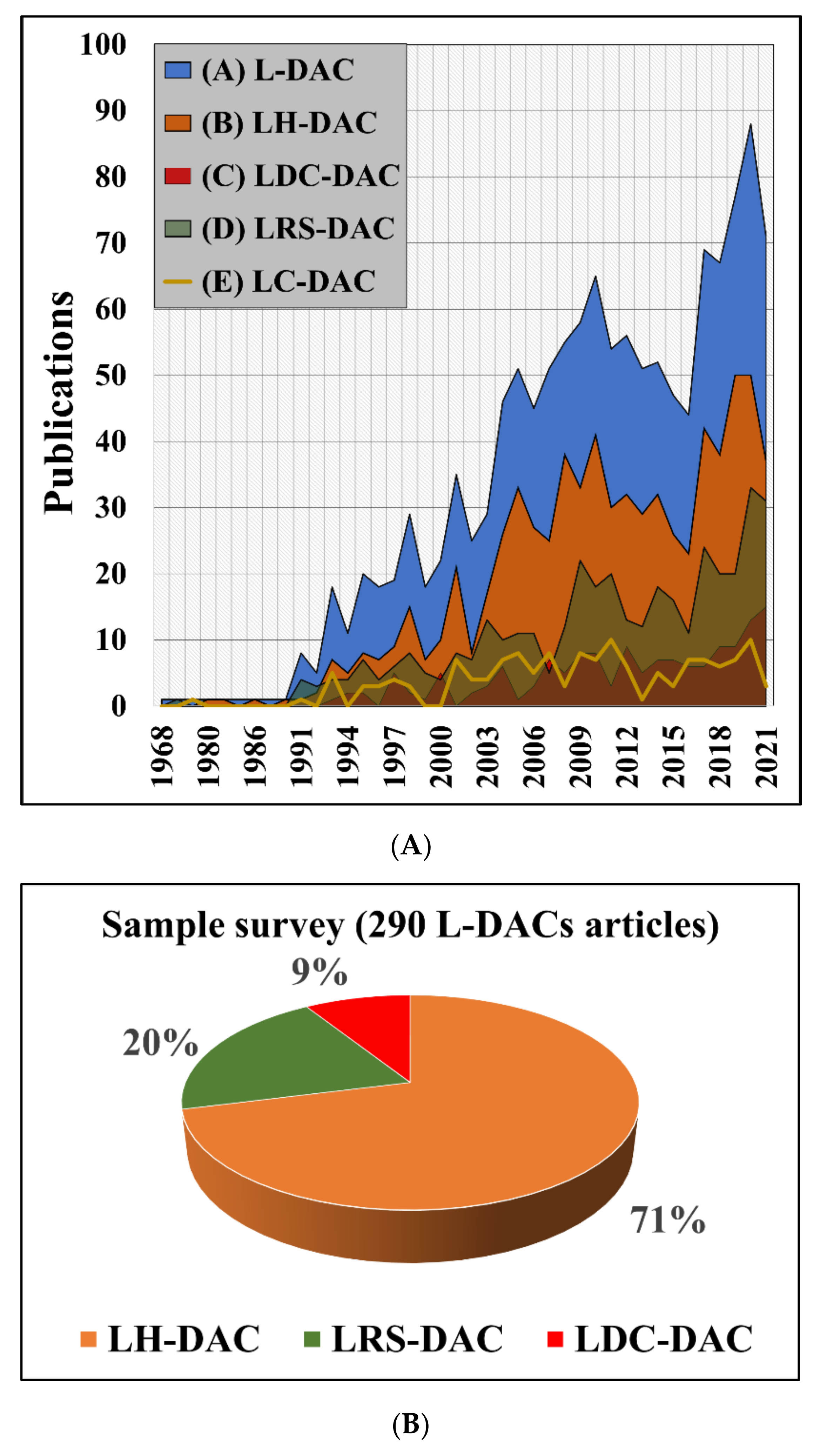

1. Introduction

2. Methodology

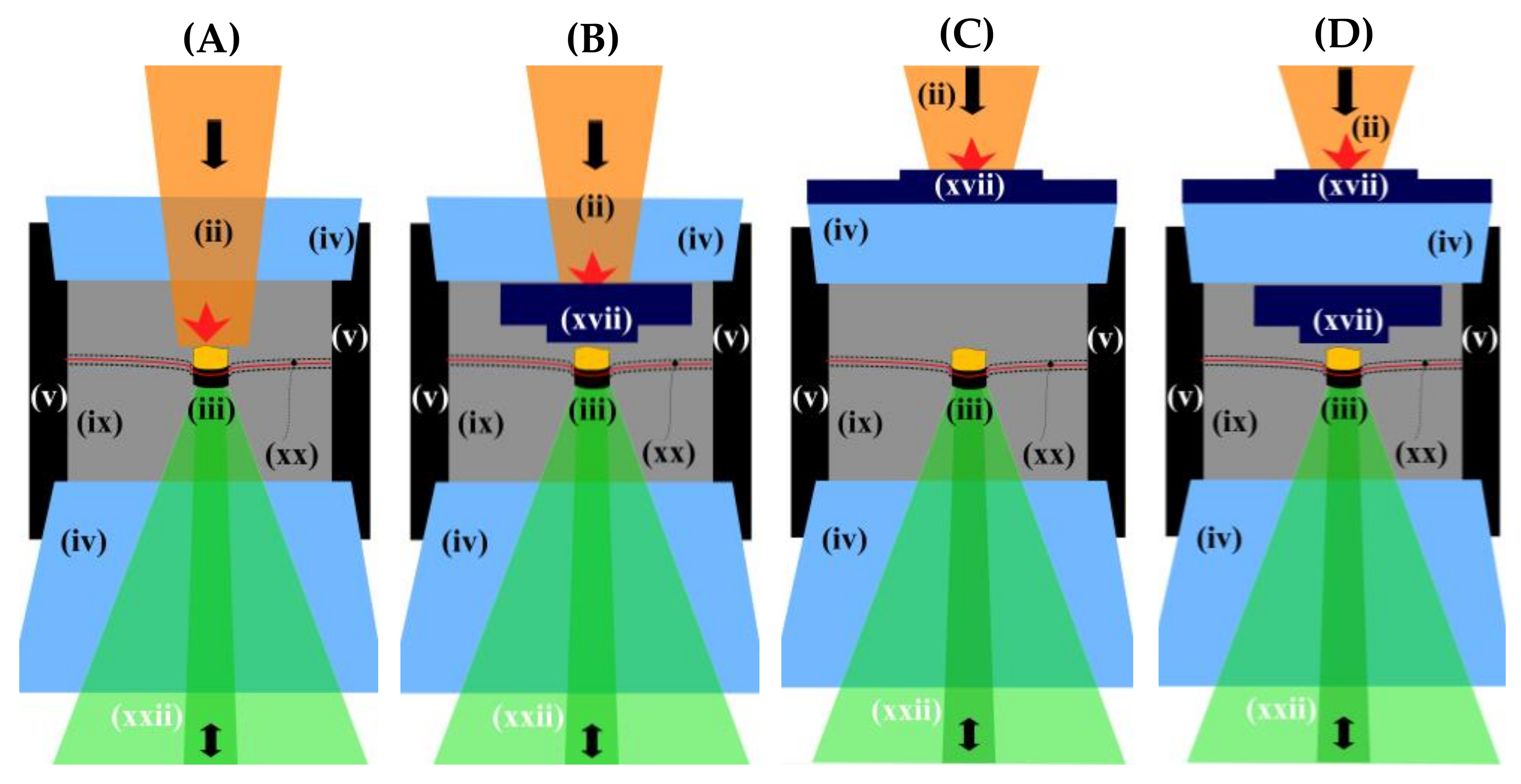

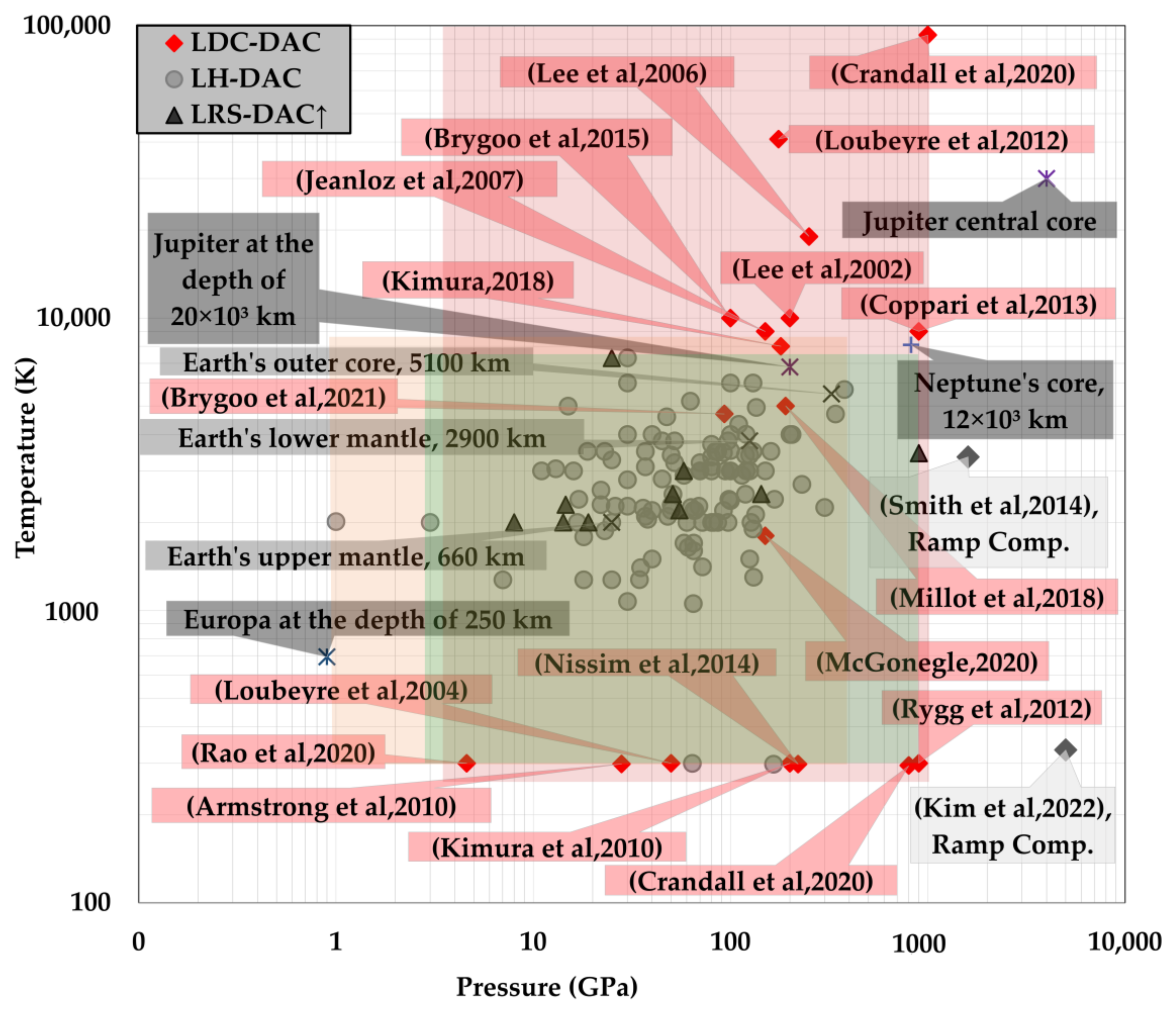

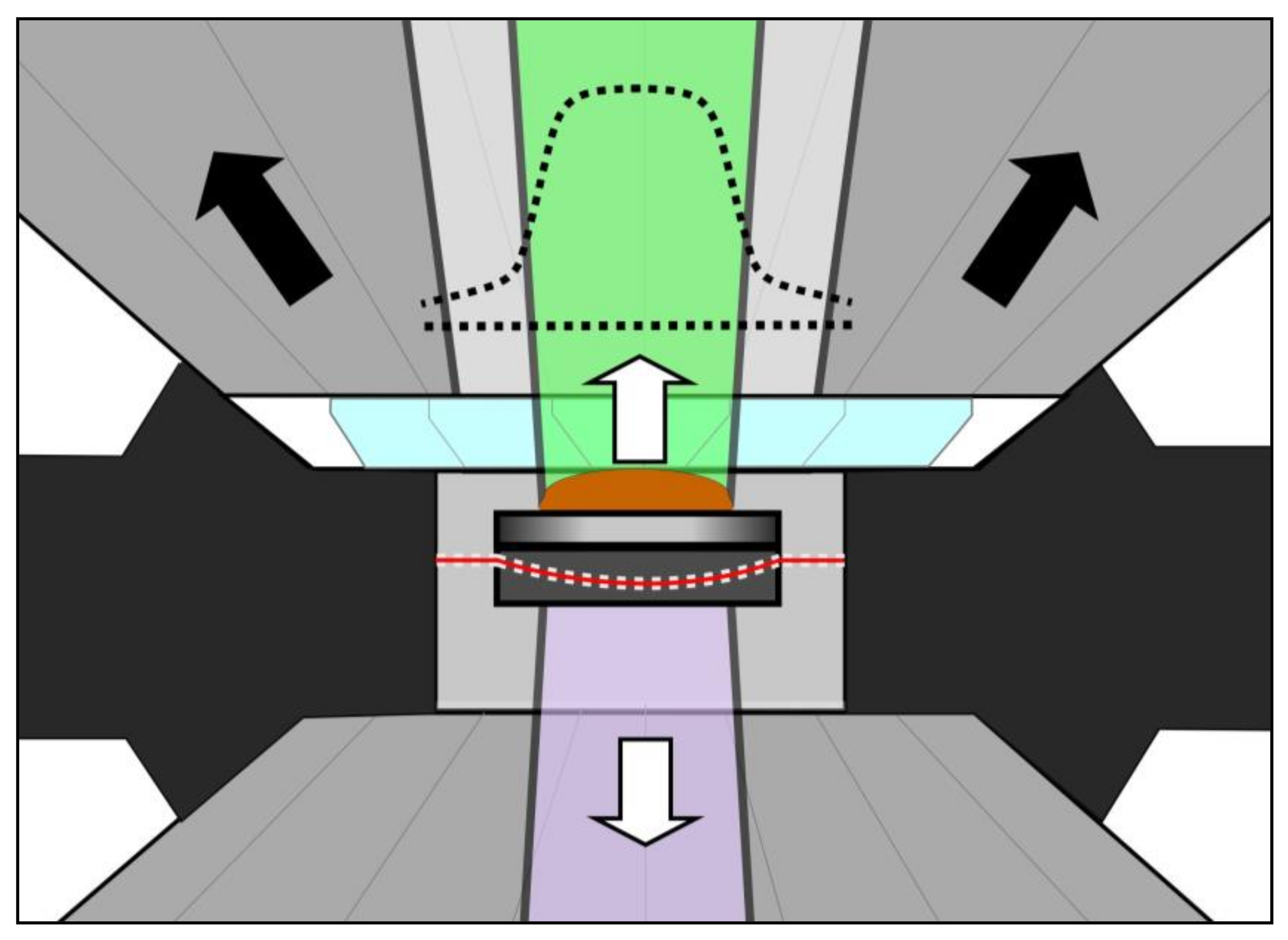

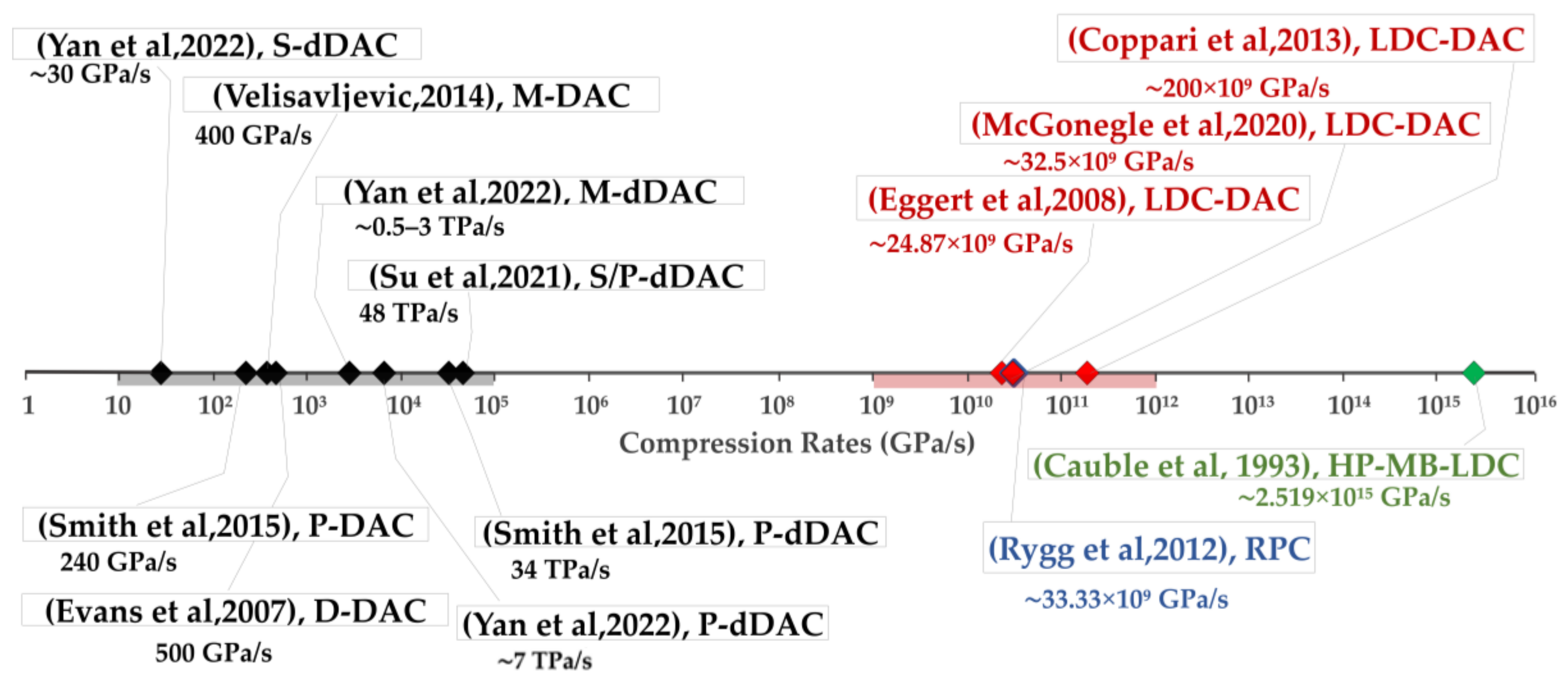

3. Overview of Laser Dynamic Compression in Diamond Anvil Cells (LDC–DACs)

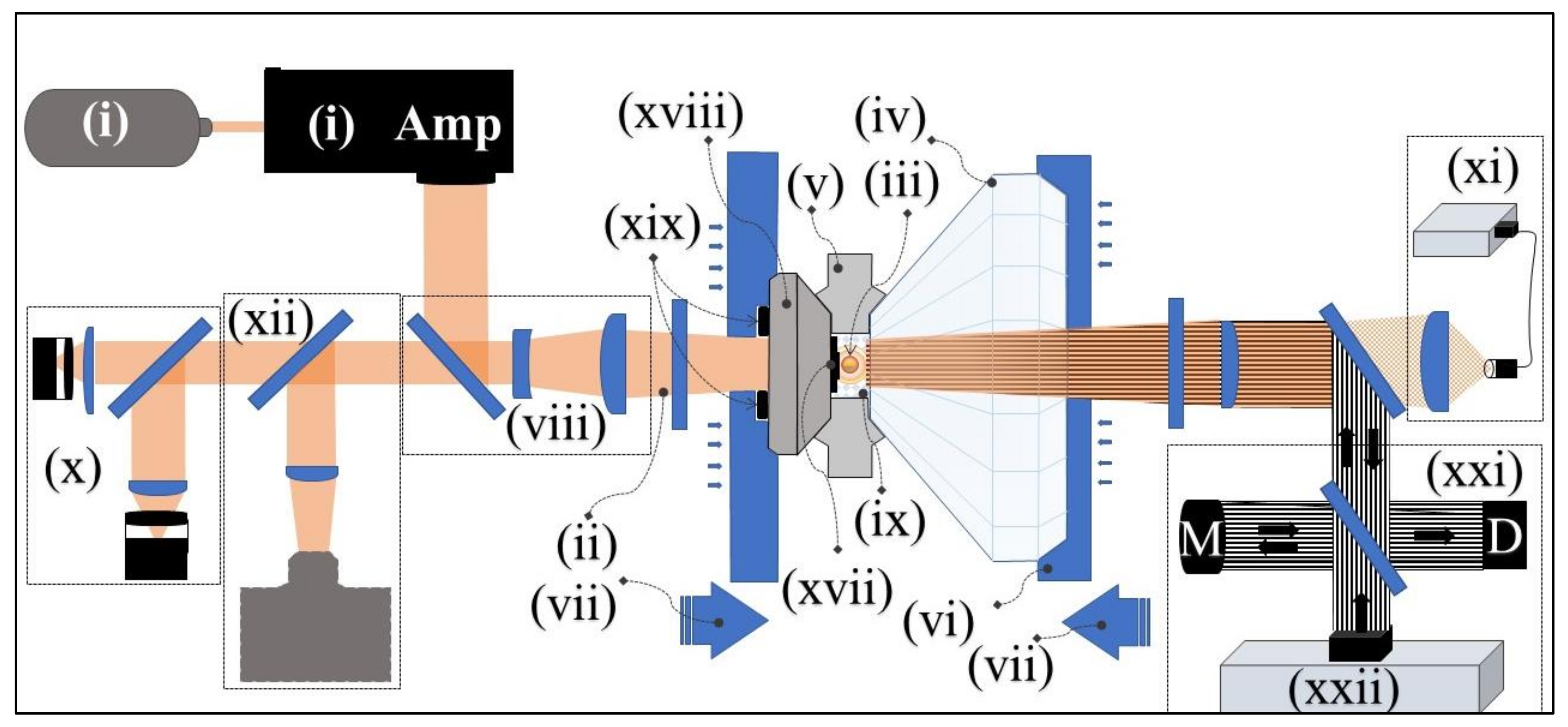

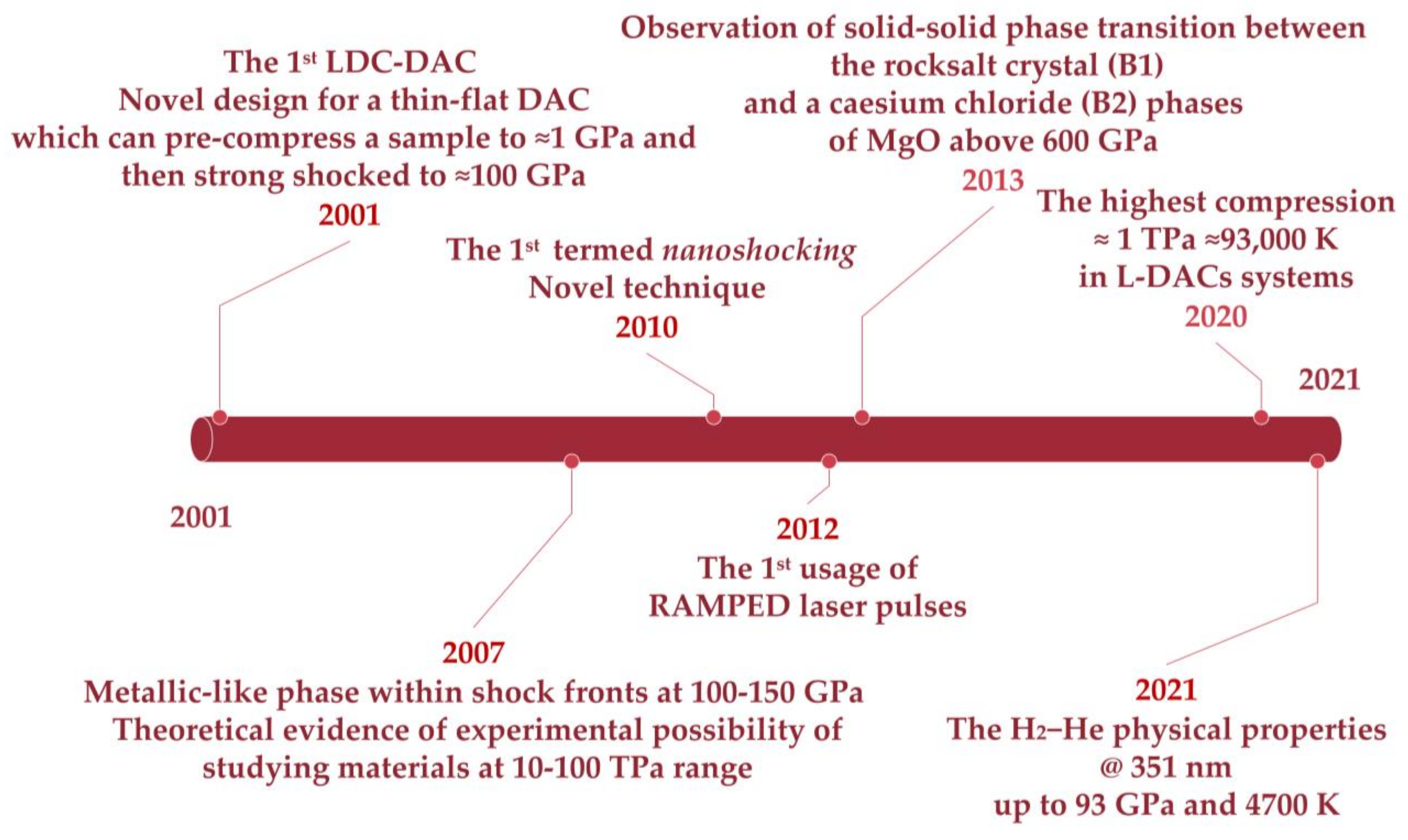

4. LDC–DACs: Physical Processes, Historical Development, and Key Experiments

4.1. LDC–DACs: Physical Processes

4.2. LDC–DAC: Historical Development and Key Experiments

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Keyword | ScienceDirect | Web of Science | Final Access Date | |

|---|---|---|---|---|

| Database/Date | ||||

| Diamond Anvil Cell | 8432 | 7294 | 2 August 2022 | |

| Laser diamond anvil cell | 1466 | 1369 | 2 August 2022 | |

| (ALL = (Laser diamond anvil cell)) NOT ALL = (synchrotron) | 1291 | 783 | 2 August 2022 | |

| Diamond anvil cell AND “Laser heated” | 703 | 766 | 2 August 2022 | |

| (ALL = (Laser diamond anvil cell AND (React * OR chemical reaction OR synthe *))) | 430 | 407 | 2 August 2022 | |

| (ALL = (Laser diamond anvil cell AND (shock * OR shockwave * OR pressure wave OR dynamic compression))) | 66 | 157 | 2 August 2022 | |

| (ALL = (Laser diamond anvil cell AND (spectroscop *)) NOT ALL = (X-ray)) | 163 | 150 | 2 August 2022 | |

References

- Bassett, W.A. The birth and development of laser heating in diamond anvil cells. Rev. Sci. Instrum. 2001, 72, 1270–1272. [Google Scholar] [CrossRef]

- Bridgman, P.W. Polymorphism, Principally of the Elements, up to 50,000 kg/cm2. Phys. Rev. 1935, 48, 893–906. [Google Scholar] [CrossRef]

- Hemley, R.J.; Percy, W. Bridgman’s second century. High Pressure Res. 2010, 30, 581–619. [Google Scholar] [CrossRef]

- Sahu, P.C.; Chandra Shekar, N.V. High pressure research on materials. Resonance 2007, 12, 49–64. [Google Scholar] [CrossRef]

- Ren, D.; Li, H. A Review of High-Temperature and High-Pressure Experimental Apparatus Capable of Generating Differential Stress. Front. Earth Sci. 2022, 10, 852403. [Google Scholar] [CrossRef]

- Bassett, W.A. Diamond anvil cell, 50th birthday. High Pressure Res. 2009, 29, 163–186. [Google Scholar] [CrossRef]

- Alabdulkarim, M.E.; Maxwell, W.D.; Thapliyal, V.; Maxwell, J.L. A Comprehensive Review of High-Pressure Laser-Induced Materials Processing, Part I: Laser-Heated Diamond Anvil Cells. J. Manuf. Mater. Process. 2022, 6, 111. [Google Scholar] [CrossRef]

- Saxena, S.K.; Dubrovinsky, L.S.; Häggkvist, P.; Cerenius, Y.; Shen, G.; Mao, H.K. Synchrotron X-Ray Study of Iron at High Pressure and Temperature. Science 1995, 269, 1703–1704. [Google Scholar] [CrossRef]

- Andrault, D.; Fiquet, G. Synchrotron radiation and laser heating in a diamond anvil cell. Rev. Sci. Instrum. 2001, 72, 1283–1288. [Google Scholar] [CrossRef]

- Hemley, R.J.; Mao, H.-K.; Struzhkin, V.V. Synchrotron radiation and high pressure: New light on materials under extreme conditions. J. Synchrotron Radiat. 2005, 12, 135–154. [Google Scholar] [CrossRef]

- Kavner, A.; Panero, W.R. Temperature gradients and evaluation of thermoelastic properties in the synchrotron-based laser-heated diamond cell. Phys. Earth Planet. Inter. 2004, 143–144, 527–539. [Google Scholar] [CrossRef]

- Duffy, T.S. Synchrotron facilities and the study of the Earth’s deep interior. Rep. Prog. Phys. 2005, 68, 1811–1859. [Google Scholar] [CrossRef]

- Boehler, R.; Musshoff, H.G.; Ditz, R.; Aquilanti, G.; Trapananti, A. Portable laser-heating stand for synchrotron applications. Rev. Sci. Instrum. 2009, 80, 045103. [Google Scholar] [CrossRef]

- Piermarini, G.J. High pressure X-ray crystallography with the diamond cell at NIST/NBS. J. Res. Nat. Inst. Stand. Technol. 2001, 106, 889. [Google Scholar] [CrossRef]

- Zimmerman, A.M. High-Pressure Studies in Cell Biology. In International Review of Cytology; Bourne, G.H., Danielli, J.F., Jeon, K.W., Eds.; Academic Press: Cambridge, MA, USA, 1971; Volume 30, pp. 1–47. [Google Scholar]

- O’Bannon, E.F.; Jenei, Z.; Cynn, H.; Lipp, M.J.; Jeffries, J.R. Contributed Review: Culet diameter and the achievable pressure of a diamond anvil cell: Implications for the upper pressure limit of a diamond anvil cell. Rev. Sci. Instrum. 2018, 89, 111501. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, M.; Xiao, G.; Zou, B. Thinking about the Development of High-Pressure Experimental Chemistry. J. Phys. Chem. Lett. 2020, 11, 7297–7306. [Google Scholar] [CrossRef]

- Akimoto, S.-i. High-Pressure Research in Geophysics: Past, Present and Future. In High-Pressure Research in Mineral Physics: A Volume in Honor of Syun-iti Akimoto; Terra Scientific Publishing Company: Tokyo, Japan, 1987; pp. 1–13. [Google Scholar]

- Falk, K. Experimental methods for warm dense matter research. High Power Laser Sci. Eng. 2018, 6, e59. [Google Scholar] [CrossRef]

- Duffy, T.S.; Smith, R.F. Ultra-High Pressure Dynamic Compression of Geological Materials. Front. Earth Sci. 2019, 7, 23. [Google Scholar] [CrossRef]

- Loubeyre, P.; Celliers, P.M.; Hicks, D.G.; Henry, E.; Dewaele, A.; Pasley, J.; Eggert, J.; Koenig, M.; Occelli, F.; Lee, K.M.; et al. Coupling static and dynamic compressions: First measurements in dense hydrogen. High Pressure Res. 2004, 24, 25–31. [Google Scholar] [CrossRef]

- Kimura, T.; Ozaki, N.; Okuchi, T.; Terai, T.; Sano, T.; Shimizu, K.; Sano, T.; Koenig, M.; Hirose, A.; Kakeshita, T.; et al. Significant static pressure increase in a precompression cell target for laser-driven advanced dynamic compression experiments. Phys. Plasma 2010, 17, 054502. [Google Scholar] [CrossRef]

- Dubrovinskaia, N.; Dubrovinsky, L.; Solopova Natalia, A.; Abakumov, A.; Turner, S.; Hanfland, M.; Bykova, E.; Bykov, M.; Prescher, C.; Prakapenka Vitali, B.; et al. Terapascal static pressure generation with ultrahigh yield strength nanodiamond. Sci. Adv. 2016, 2, e1600341. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, M.R.; Crowhurst, J.C.; Bastea, S.; Zaug, J.M. Ultrafast observation of shocked states in a precompressed material. J. Appl. Phys. 2010, 108, 023511. [Google Scholar] [CrossRef]

- Moon, S.J.; Cauble, R.; Collins, G.W.; Celliers, P.M.; Hicks, D.; Da Silva, L.B.; Mackinon, A.; Wallace, R.; Hammel, B.; Hsing, W.; et al. Experimental Design for Laser Produced Shocks in Diamond Anvil Cells; US Department of Energy (US): Atlanta, GA, USA, 2001. Available online: https://www.osti.gov/biblio/15002090 (accessed on 9 October 2022).

- Lee, K.K.M.; Benedetti, L.R.; Jeanloz, R.; Celliers, P.M.; Eggert, J.H.; Hicks, D.G.; Moon, S.J.; Mackinnon, A.; Da Silva, L.B.; Bradley, D.K.; et al. Laser-driven shock experiments on precompressed water: Implications for “icy” giant planets. J. Chem. Phys. 2006, 125, 014701. [Google Scholar] [CrossRef] [PubMed]

- Crandall, L.E.; Rygg, J.R.; Spaulding, D.K.; Boehly, T.R.; Brygoo, S.; Celliers, P.M.; Eggert, J.H.; Fratanduono, D.E.; Henderson, B.J.; Huff, M.F.; et al. Equation of State of CO2 Shock Compressed to 1 TPa. Phys. Rev. Lett. 2020, 125, 165701. [Google Scholar] [CrossRef] [PubMed]

- Loubeyre, P.; Brygoo, S.; Eggert, J.; Celliers, P.M.; Spaulding, D.K.; Rygg, J.R.; Boehly, T.R.; Collins, G.W.; Jeanloz, R. Extended data set for the equation of state of warm dense hydrogen isotopes. Phys. Rev. B: Condens. Matter 2012, 86, 144115. [Google Scholar] [CrossRef]

- Shu, H.; Li, J.; Tu, Y.; Ye, J.; Wang, J.; Zhang, Q.; Tian, H.; Jia, G.; He, Z.; Zhang, F.; et al. Measurement of the sound velocity of shock compressed water. Sci. Rep. 2021, 11, 6116. [Google Scholar] [CrossRef]

- Coppari, F.; Smith, R.F.; Eggert, J.H.; Wang, J.; Rygg, J.R.; Lazicki, A.; Hawreliak, J.A.; Collins, G.W.; Duffy, T.S. Experimental evidence for a phase transition in magnesium oxide at exoplanet pressures. Nat. Geosci. 2013, 6, 926–929. [Google Scholar] [CrossRef]

- McGonegle, D.; Heighway, P.G.; Sliwa, M.; Bolme, C.A.; Comley, A.J.; Dresselhaus-Marais, L.E.; Higginbotham, A.; Poole, A.J.; McBride, E.E.; Nagler, B.; et al. Investigating off-Hugoniot states using multi-layer ring-up targets. Sci. Rep. 2020, 10, 13172. [Google Scholar] [CrossRef]

- Rao, U.; Chaurasia, S.; Mishra, A.K.; Pasley, J. Phase transitions in benzene under dynamic and static compression. J. Raman Spectrosc. 2021, 52, 770–781. [Google Scholar] [CrossRef]

- Rapp, L.; Haberl, B.; Pickard, C.J.; Bradby, J.E.; Gamaly, E.G.; Williams, J.S.; Rode, A.V. Experimental evidence of new tetragonal polymorphs of silicon formed through ultrafast laser-induced confined microexplosion. Nat. Commun. 2015, 6, 7555. [Google Scholar] [CrossRef]

- Juodkazis, S.; Kohara, S.; Ohishi, Y.; Hirao, N.; Vailionis, A.; Mizeikis, V.; Saito, A.; Rode, A. Structural changes in femtosecond laser modified regions inside fused silica. J. Opt. 2010, 12, 124007. [Google Scholar] [CrossRef]

- Spaulding, D.K. Laser-Driven Shock Compression Studies of Planetary Compositions; ProQuest Dissertations Publishing: Ann Arbor, MI, USA, 2010. [Google Scholar]

- Lazicki, A.; McGonegle, D.; Rygg, J.R.; Braun, D.G.; Swift, D.C.; Gorman, M.G.; Smith, R.F.; Heighway, P.G.; Higginbotham, A.; Suggit, M.J.; et al. Metastability of diamond ramp-compressed to 2 terapascals. Nature 2021, 589, 532–535. [Google Scholar] [CrossRef]

- Smith, R.F.; Eggert, J.H.; Jeanloz, R.; Duffy, T.S.; Braun, D.G.; Patterson, J.R.; Rudd, R.E.; Biener, J.; Lazicki, A.E.; Hamza, A.V.; et al. Ramp compression of diamond to five terapascals. Nature 2014, 511, 330–333. [Google Scholar] [CrossRef]

- Kim, D.; Smith, R.F.; Ocampo, I.K.; Coppari, F.; Marshall, M.C.; Ginnane, M.K.; Wicks, J.K.; Tracy, S.J.; Millot, M.; Lazicki, A.; et al. Structure and density of silicon carbide to 1.5 TPa and implications for extrasolar planets. Nat. Commun. 2022, 13, 2260. [Google Scholar] [CrossRef]

- Bachmann, B.; Kritcher, A.L.; Benedetti, L.R.; Falcone, R.W.; Glenn, S.; Hawreliak, J.; Izumi, N.; Kraus, D.; Landen, O.L.; Le Pape, S.; et al. Using penumbral imaging to measure micrometer size plasma hot spots in Gbar equation of state experiments on the National Ignition Facility. Rev. Sci. Instrum. 2014, 85, 11D614. [Google Scholar] [CrossRef]

- Kritcher, A.L.; Döppner, T.; Swift, D.; Hawreliak, J.; Collins, G.; Nilsen, J.; Bachmann, B.; Dewald, E.; Strozzi, D.; Felker, S.; et al. Probing matter at Gbar pressures at the NIF. High Energy Density Phys. 2014, 10, 27–34. [Google Scholar] [CrossRef]

- Sistrunk, E.; Alessi, D.; Bayramian, A.J.; Chesnut, K.D.; Erlandson, A.C.; Galvin, T.C.; Gibson, D.; Nguyen, H.T.; Reagan, B.A.; Schaffers, K.I.; et al. Laser Technology Development for High Peak Power Lasers Achieving Kilowatt Average Power and Beyond. Proc. SPIE 2019, 11034, 1103407. [Google Scholar] [CrossRef]

- Crawford, D.; Thiagarajan, P.; Goings, J.; Caliva, B.; Smith, S.; Walker, R. Advancements of ultra-high peak power laser diode arrays. Proc. SPIE 2018, 10514, 105140H. [Google Scholar] [CrossRef]

- Xia, J.; Dong, X.; Yuan, H. Generation of High Peak Power Pulses With Controllable Repetition Rate in Doubly Q-Switched Laser With AOM/SnSe2. Front. Phys. 2022, 10, 213. [Google Scholar] [CrossRef]

- Chvykov, V. New Generation of Ultra-High Peak and Average Power Laser Systems; IntechOpen: London, UK, 2018. [Google Scholar]

- Brasch, J.W.; Melveger, A.J.; Lippincott, E.R. Laser excited Raman spectra of samples under very high pressures. Chem. Phys. Lett. 1968, 2, 99–100. [Google Scholar] [CrossRef]

- Crandall, L.E.; Rygg, J.R.; Spaulding, D.K.; Huff, M.F.; Marshall, M.C.; Polsin, D.N.; Jeanloz, R.; Boehly, T.R.; Zaghoo, M.; Henderson, B.J.; et al. Equation-of-state, sound speed, and reshock of shock-compressed fluid carbon dioxide. Phys. Plasma 2021, 28, 022708. [Google Scholar] [CrossRef]

- Eggert, J.; Brygoo, S.; Loubeyre, P.; McWilliams, R.S.; Celliers, P.M.; Hicks, D.G.; Boehly, T.R.; Jeanloz, R.; Collins, G.W. Hugoniot Data for Helium in the Ionization Regime. Phys. Rev. Lett. 2008, 100, 124503. [Google Scholar] [CrossRef]

- Boehly, T.R.; Hicks, D.G.; Celliers, P.M.; Collins, T.J.B.; Earley, R.; Eggert, J.H.; Jacobs-Perkins, D.; Moon, S.J.; Vianello, E.; Meyerhofer, D.D.; et al. Properties of fluid deuterium under double-shock compression to several Mbar. Phys. Plasma 2004, 11, L49–L52. [Google Scholar] [CrossRef]

- Rygg, J.R.; Eggert, J.H.; Lazicki, A.E.; Coppari, F.; Hawreliak, J.A.; Hicks, D.G.; Smith, R.F.; Sorce, C.M.; Uphaus, T.M.; Yaakobi, B.; et al. Powder diffraction from solids in the terapascal regime. Rev. Sci. Instrum. 2012, 83, 113904. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.K.M.; Benedetti, L.R.; Mackinnon, A.; Hicks, D.; Moon, S.J.; Loubeyre, P.; Occelli, F.; Dewaele, A.; Collins, G.W.; Jeanloz, R. Taking Thin Diamonds to Their Limit: Coupling Static-Compression and Laser-Shock Techniques to Generate Dense Water. AIP Conf. Proc. 2002, 620, 1363–1366. [Google Scholar] [CrossRef]

- Henry, E.; Brygoo, S.; Loubeyre, P.; Koenig, M.; Benuzzi-Mounaix, A.; Ravasio, A.; Vinci, T. Laser-driven shocks in precompressed water samples. J. Phys. IV France 2006, 133, 1093–1095. [Google Scholar] [CrossRef]

- Eggert, J.H.; Celliers, P.M.; Hicks, D.G.; Rygg, J.R.; Collins, G.W.; Brygoo, S.; Loubeyre, P.; McWilliams, R.S.; Spaulding, D.; Jeanloz, R.; et al. Shock Experiments on Pre-Compressed Fluid Helium. AIP Conf. Proc. 2009, 1161, 26–31. [Google Scholar] [CrossRef]

- LLNL; Bastea; Zaug, J. Shocking Results from Diamond Anvil Cell Experiments. Available online: https://www.llnl.gov/news/shocking-results-diamond-anvil-cell-experiments (accessed on 1 November 2022).

- Benuzzi-Mounaix, A.; Koenig, M.; Huser, G.; Faral, B.; Grandjouan, N.; Batani, D.; Henry, E.; Tomasini, M.; Hall, T.A.; Guyot, F. Generation of a double shock driven by laser. Phys. Rev. E Stat. Nonlin. Soft Matter Phys. 2004, 70, 045401. [Google Scholar] [CrossRef]

- Guarguaglini, M.; Hernandez, J.A.; Benuzzi-Mounaix, A.; Bolis, R.; Brambrink, E.; Vinci, T.; Ravasio, A. Characterizing equation of state and optical properties of dynamically pre-compressed materials. Phys. Plasma 2019, 26, 042704. [Google Scholar] [CrossRef]

- Sollier, A.; Auroux, E.; Vauthier, J.S.; Boustie, M.; He, H.; de Rességuier, T.; Berterretche, P.; Desbiens, N.; Bourasseau, E.; Maillet, J.B. A New Experimental Design for Laser-Driven Shocks On Precompressed And Preheated Water Samples. AIP Conf. Proc. 2007, 955, 1192–1195. [Google Scholar] [CrossRef]

- Jeanloz, R.; Celliers, P.M.; Collins, G.W.; Eggert, J.H.; Lee, K.K.M.; McWilliams, R.S.; Brygoo, S.; Loubeyre, P. Achieving high-density states through shock-wave loading of precompressed samples. Proc. Natl. Acad. Sci. USA 2007, 104, 9172–9177. [Google Scholar] [CrossRef]

- Nissim, N.; Eliezer, S.; Werdiger, M.; Perelmutter, L. Approaching the “cold curve” in laser-driven shock wave experiment of a matter precompressed by a partially perforated diamond anvil. Laser Part. Beams 2013, 31, 73–79. [Google Scholar] [CrossRef]

- Brygoo, S.; Millot, M.; Loubeyre, P.; Lazicki, A.E.; Hamel, S.; Qi, T.; Celliers, P.M.; Coppari, F.; Eggert, J.H.; Fratanduono, D.E.; et al. Analysis of laser shock experiments on precompressed samples using a quartz reference and application to warm dense hydrogen and helium. J. Appl. Phys. 2015, 118, 195901. [Google Scholar] [CrossRef]

- Brygoo, S.; Loubeyre, P.; Millot, M.; Rygg, J.R.; Celliers, P.M.; Eggert, J.H.; Jeanloz, R.; Collins, G.W. Evidence of hydrogen–helium immiscibility at Jupiter-interior conditions. Nature 2021, 593, 517–521. [Google Scholar] [CrossRef]

- Kimura, T. Application of Laser Technology for Static and Dynamic Compression Experiments. Rev. High Press. Sci. Technol. 2018, 28, 131–138. [Google Scholar] [CrossRef][Green Version]

- Neff, S.; Martinez, D.; Plechaty, C.; Stein, S.; Presura, R. Developing flyer plate impact experiments for shockwave interaction studies. In Proceedings of the 2010 Abstracts IEEE International Conference on Plasma Science, IEEE, Norfolk, VA, USA, 20–24 June 2010. [Google Scholar] [CrossRef][Green Version]

- Neff, S.; Presura, R. Simulation of shock waves in flyer plate impact experiments. Laser Part. Beams 2010, 28, 539–545. [Google Scholar] [CrossRef]

- Schram, D.C.; Mazouffre, S.; Engeln, R.; van de Sanden, M.C.M. The Physics of Plasma Expansion. In Atomic and Molecular Beams: The State of the Art 2000; Campargue, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2001; pp. 209–235. [Google Scholar]

- Eliezer, S. The Interaction of High-Power Lasers with Plasmas; Institute of Physics Publishing: Bristol, UK, 2002. [Google Scholar]

- Itoh, S. CHAPTER 3.2—Shock Waves in Liquids. In Handbook of Shock Waves; Ben-Dor, G., Igra, O., Elperin, T.O.V., Eds.; Academic Press: Burlington, NJ, USA, 2001; pp. 263–314. [Google Scholar]

- Sakakura, M.; Terazima, M.; Shimotsuma, Y.; Miura, K.; Hirao, K. Observation of pressure wave generated by focusing a femtosecond laser pulse inside a glass. Opt. Express 2007, 15, 5674–5686. [Google Scholar] [CrossRef]

- Henderson, L.R.F. CHAPTER 2—General Laws for Propagation of Shock Waves Through Matter. In Handbook of Shock Waves; Ben-Dor, G., Igra, O., Elperin, T.O.V., Eds.; Academic Press: Burlington, NJ, USA, 2001; pp. 143–183. [Google Scholar]

- Hamilton, B.W.; Sakano, M.N.; Li, C.; Strachan, A. Chemistry Under Shock Conditions. Annu. Rev. Mater. Res. 2021, 51, 101–130. [Google Scholar] [CrossRef]

- Williams, Q.; Knittle, E.; Jeanloz, R. The high-pressure melting curve of iron: A technical discussion. J. Geophys. Res. Solid Earth 1991, 96, 2171–2184. [Google Scholar] [CrossRef]

- Woollam, J.A.; Chu, C.W. High-Pressure and Low-Temperature Physics; Springer: New York, NY, USA, 2012. [Google Scholar]

- French, M.; Becker, A.; Lorenzen, W.; Nettelmann, N.; Bethkenhagen, M.; Wicht, J.; Redmer, R. Ab Initio Simulations for Material Properties Along the Jupiter Adiabat. Astrophys. J. Suppl. ApJS 2012, 202, 5. [Google Scholar] [CrossRef]

- Nissim, N.; Eliezer, S.; Werdiger, M. The sound velocity throughout the P-ρ phase-space with application to laser induced shock wave in matter precompressed by a diamond anvil cell. J. Appl. Phys. 2014, 115, 213503. [Google Scholar] [CrossRef]

- Millot, M.; Hamel, S.; Rygg, J.R.; Celliers, P.M.; Collins, G.W.; Coppari, F.; Fratanduono, D.E.; Jeanloz, R.; Swift, D.C.; Eggert, J.H. Experimental evidence for superionic water ice using shock compression. Nature Physics 2018, 14, 297–302. [Google Scholar] [CrossRef]

- Yoo, C.-S.; Wei, H.; Dias, R.; Shen, G.; Smith, J.; Chen, J.-Y.; Evans, W. Time-Resolved Synchrotron X-ray Diffraction on Pulse Laser Heated Iron in Diamond Anvil Cell. J. Phys. Conf. Ser. 2012, 377, 012108. [Google Scholar] [CrossRef]

- Dewaele, A.; Mezouar, M.; Guignot, N.; Loubeyre, P. High melting points of tantalum in a laser-heated diamond anvil cell. Phys. Rev. Lett. 2010, 104, 255701. [Google Scholar] [CrossRef]

- Andrault, D.; Fiquet, G.; Kunz, M.; Visocekas, F.; Häusermann, D. The Orthorhombic Structure of Iron: An in Situ Study at High-Temperature and High-Pressure. Science 1997, 278, 831–834. [Google Scholar] [CrossRef]

- Armstrong, L.S.; Walter, M.J. Tetragonal almandine pyrope phase (TAPP): Retrograde Mg-perovskite from subducted oceanic crust? Eur. J. Mineral. 2012, 24, 587–597. [Google Scholar] [CrossRef]

- Armstrong, L.S.; Walter, M.J.; Tuff, J.R.; Lord, O.T.; Lennie, A.R.; Kleppe, A.K.; Clark, S.M. Perovskite Phase Relations in the System CaO–MgO–TiO2–SiO2 and Implications for Deep Mantle Lithologies. J. Petrol. 2012, 53, 611–635. [Google Scholar] [CrossRef]

- Benedetti, L.R.; Loubeyre, P. Temperature gradients, wavelength-dependent emissivity, and accuracy of high and very-high temperatures measured in the laser-heated diamond cell. High Pressure Res. 2004, 24, 423–445. [Google Scholar] [CrossRef]

- Boehler, R. Melting of the FeFeO and the FeFeS systems at high pressure: Constraints on core temperatures. Earth Planet. Sci. Lett. 1992, 111, 217–227. [Google Scholar] [CrossRef]

- Boehler, R. Temperatures in the Earth’s core from melting-point measurements of iron at high static pressures. Nature 1993, 363, 534–536. [Google Scholar] [CrossRef]

- Boehler, R.; Ross, M.; Boercker, D.B. High-pressure melting curves of alkali halides. Phys. Rev. B Condens. Matter 1996, 53, 556–563. [Google Scholar] [CrossRef]

- Boehler, R.; Chopelas, A. A new approach to laser heating in high pressure mineral physics. Geophys. Res. Lett. 1991, 18, 1147–1150. [Google Scholar] [CrossRef]

- Boehler, R.; Ross, M.; Boercker, D.B. Melting of LiF and NaCl to 1 Mbar: Systematics of Ionic Solids at Extreme Conditions. Phys. Rev. Lett. 1997, 78, 4589–4592. [Google Scholar] [CrossRef]

- Bolfan-Casanova, N.; Andrault, D.; Amiguet, E.; Guignot, N. Equation of state and post-stishovite transformation of Al-bearing silica up to 100GPa and 3000K. Phys. Earth Planet. Inter. 2009, 174, 70–77. [Google Scholar] [CrossRef]

- Meade, C.; Mao, H.K.; Hu, J. High-Temperature Phase Transition and Dissociation of (Mg, Fe)SiO3 Perovskite at Lower Mantle Pressures. Science 1995, 268, 1743–1745. [Google Scholar] [CrossRef]

- Dewaele, A.; Mezouar, M.; Guignot, N.; Loubeyre, P. Melting of lead under high pressure studied using second-scale time-resolved x-ray diffraction. Phys. Rev. B Condens. Matter 2007, 76, 144106. [Google Scholar] [CrossRef]

- Dewaele, A.; Belonoshko, A.B.; Garbarino, G.; Occelli, F.; Bouvier, P.; Hanfland, M.; Mezouar, M. High-pressure—High-temperature equation of state of KCl and KBr. Phys. Rev. B Condens. Matter 2012, 85, 214105. [Google Scholar] [CrossRef]

- Dobson, D.P.; Hunt, S.A.; Ahmed, J.; Lord, O.T.; Wann, E.T.H.; Santangeli, J.; Wood, I.G.; Vočadlo, L.; Walker, A.M.; Thomson, A.R.; et al. The phase diagram of NiSi under the conditions of small planetary interiors. Phys. Earth Planet. Inter. 2016, 261, 196–206. [Google Scholar] [CrossRef]

- Dubrovinsky, L.S.; Saxena, S.K.; Lazor, P.; Ahuja, R.; Eriksson, O.; Wills, J.M.; Johansson, B. Experimental and theoretical identification of a new high-pressure phase of silica. Nature 1997, 388, 362–365. [Google Scholar] [CrossRef]

- Errandonea, D.; Schwager, B.; Ditz, R.; Gessmann, C.; Boehler, R.; Ross, M. Systematics of transition-metal melting. Phys. Rev. B Condens. Matter 2001, 63, 132104. [Google Scholar] [CrossRef]

- Errandonea, D.; Somayazulu, M.; Häusermann, D.; Mao, H.K. Melting of tantalum at high pressure determined by angle dispersive x-ray diffraction in a double-sided laser-heated diamond-anvil cell. J. Phys. Condens. Matter 2003, 15, 7635–7649. [Google Scholar] [CrossRef]

- Errandonea, D.; Boehler, R.; Japel, S.; Mezouar, M.; Benedetti, L.R. Structural transformation of compressed solid Ar: An x-ray diffraction study to 114 GPa. Phys. Rev. B Condens. Matter 2006, 73, 092106. [Google Scholar] [CrossRef]

- Errandonea, D.; MacLeod, S.G.; Burakovsky, L.; Santamaria-Perez, D.; Proctor, J.E.; Cynn, H.; Mezouar, M. Melting curve and phase diagram of vanadium under high-pressure and high-temperature conditions. Phys. Rev. B Condens. Matter 2019, 100, 094111. [Google Scholar] [CrossRef]

- Fedotenko, T.; Dubrovinsky, L.; Aprilis, G.; Koemets, E.; Snigirev, A.; Snigireva, I.; Barannikov, A.; Ershov, P.; Cova, F.; Hanfland, M.; et al. Laser heating setup for diamond anvil cells for in situ synchrotron and in house high and ultra-high pressure studies. Rev. Sci. Instrum. 2019, 90, 104501–104511. [Google Scholar] [CrossRef]

- Fiquet, G.; Andrault, D. Powder X-ray diffraction under extreme conditions of pressure and temperature. J. Synchrotron Radiat. 1999, 6, 81–86. [Google Scholar] [CrossRef]

- Fiquet, G.; Andrault, D.; Itié, J.P.; Gillet, P.; Richet, P. X-ray diffraction of periclase in a laser-heated diamond-anvil cell. Phys. Earth Planet. Inter. 1996, 95, 1–17. [Google Scholar] [CrossRef]

- Fiquet, G.; Dewaele, A.; Andrault, D.; Kunz, M.; Le Bihan, T. Thermoelastic properties and crystal structure of MgSiO3 perovskite at lower mantle pressure and temperature conditions. Geophys. Res. Lett. 2000, 27, 21–24. [Google Scholar] [CrossRef]

- Friedrich, A.; Morgenroth, W.; Bayarjargal, L.; Juarez-Arellano, E.A.; Winkler, B.; Konôpková, Z. In situ study of the high pressure high-temperature stability field of TaN and of the compressibilities of ϑ-TaN and TaON. High Pressure Res. 2013, 33, 633–641. [Google Scholar] [CrossRef]

- Golberg, D.; Bando, Y.; Eremets, M.; Takemura, K.; Kurashima, K.; Yusa, H. Nanotubes in boron nitride laser heated at high pressure. Appl. Phys. Lett. 1996, 69, 2045–2047. [Google Scholar] [CrossRef]

- Heinz, D.L.; Sweeney, J.S.; Miller, P. A laser heating system that stabilizes and controls the temperature: Diamond anvil cell applications. Rev. Sci. Instrum. 1991, 62, 1568–1575. [Google Scholar] [CrossRef]

- Hrubiak, R.; Meng, Y.; Shen, G. Microstructures define melting of molybdenum at high pressures. Nat. Commun. 2017, 8, 14562. [Google Scholar] [CrossRef]

- Huang, X.; Li, F.; Zhou, Q.; Meng, Y.; Litasov, K.D.; Wang, X.; Liu, B.; Cui, T. Thermal equation of state of Molybdenum determined from in situ synchrotron X-ray diffraction with laser-heated diamond anvil cells. Sci. Rep. 2016, 6, 19923. [Google Scholar] [CrossRef]

- Japel, S.; Schwager, B.; Boehler, R.; Ross, M. Melting of copper and nickel at high pressure: The role of d electrons. Phys. Rev. Lett. 2005, 95, 167801. [Google Scholar] [CrossRef]

- Kavner, A.; Duffy, T.S. Pressure–volume–temperature paths in the laser-heated diamond anvil cell. J. Appl. Phys. 2001, 89, 1907–1914. [Google Scholar] [CrossRef]

- Kesson, S.E.; Fitz Gerald, J.D. Partitioning of MgO, FeO, NiO, MnO and Cr2O3 between magnesian silicate perovskite and magnesiowüstite: Implications for the origin of inclusions in diamond and the composition of the lower mantle. Earth Planet. Sci. Lett. 1992, 111, 229–240. [Google Scholar] [CrossRef]

- Kesson, S.E.; Fitz Gerald, J.D.; Shelley, J.M.G. Mineral chemistry and density of subducted basaltic crust at lower-mantle pressures. Nature 1994, 372, 767–769. [Google Scholar] [CrossRef]

- Kiefer, B.; Duffy, T.S. Finite element simulations of the laser-heated diamond-anvil cell. J. Appl. Phys. 2005, 97, 114902. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Ming, L.C.; Manghnani, M.H. High-pressure phase transformations in a natural crystalline diopside and a synthetic CaMgSi2O6 glass. Phys. Earth Planet. Inter. 1994, 83, 67–79. [Google Scholar] [CrossRef]

- Kimura, T.; Kuwayama, Y.; Yagi, T. Melting temperatures of H2O up to 72 GPa measured in a diamond anvil cell using CO2 laser heating technique. J. Chem. Phys. 2014, 140, 074501. [Google Scholar] [CrossRef]

- Young-Ho, K.O.; Kyoung Hun, O.H.; Kwang Joo, K.I.M. Installation and Operation of a Double-Sided Laser Heating System for the Synthesis of Novel Materials Under Extreme Conditions. New Phys. Sae Mulli NPSM 2019, 69, 1107–1114. [Google Scholar] [CrossRef]

- Knittle, E.; Jeanloz, R. Synthesis and Equation of State of (Mg,Fe) SiO3 Perovskite to Over 100 Gigapascals. Science 1987, 235, 668–670. [Google Scholar] [CrossRef]

- Kumar, N.R.; Shekar, N.V.; Sekar, M.; Subramanian, N.; Mohan, P.C.; Srinivasan, M.P.; Parameswaran, P.; Sahu, P.C. Diamond and diamond-like carbon in laser heated diamond anvil cell at 16.5 GPa and above 2000 K from pyrolitic graphite. Indian J. Pure Appl. Phys. 2008, 46, 783–787. [Google Scholar]

- Kupenko, I.; Strohm, C.; McCammon, C.; Cerantola, V.; Glazyrin, K.; Petitgirard, S.; Vasiukov, D.; Aprilis, G.; Chumakov, A.I.; Rüffer, R.; et al. Time differentiated nuclear resonance spectroscopy coupled with pulsed laser heating in diamond anvil cells. Rev. Sci. Instrum. 2015, 86, 114501. [Google Scholar] [CrossRef] [PubMed]

- Lavina, B.; Dera, P.; Kim, E.; Meng, Y.; Downs Robert, T.; Weck Philippe, F.; Sutton Stephen, R.; Zhao, Y. Discovery of the recoverable high-pressure iron oxide Fe4O5. Proc. Natl. Acad. Sci. USA 2011, 108, 17281–17285. [Google Scholar] [CrossRef] [PubMed]

- Lazicki, A.; Dewaele, A.; Loubeyre, P.; Mezouar, M. High-pressure—Temperature phase diagram and the equation of state of beryllium. Phys. Rev. B Condens. Matter 2012, 86, 174118. [Google Scholar] [CrossRef]

- Lin, J.-F.; Santoro, M.; Struzhkin, V.V.; Mao, H.-k.; Hemley, R.J. In situ high pressure-temperature Raman spectroscopy technique with laser-heated diamond anvil cells. Rev. Sci. Instrum. 2004, 75, 3302–3306. [Google Scholar] [CrossRef]

- Lin, J.-F.; Sturhahn, W.; Zhao, J.; Shen, G.; Mao, H.-k.; Hemley, R.J. Absolute temperature measurement in a laser-heated diamond anvil cell. Geophys. Res. Lett. 2004, 31, L14611. [Google Scholar] [CrossRef]

- Lin, Y.; Hu, Q.; Zhu, L.; Meng, Y. Structure and Stability of Iron Fluoride at High Pressure–Temperature and Implication for a New Reservoir of Fluorine in the Deep Earth. Minerals 2020, 10, 783. [Google Scholar] [CrossRef]

- Liu, L.-G. A new high-pressure phase of spinel. Earth Planet. Sci. Lett. 1978, 41, 398–404. [Google Scholar] [CrossRef]

- Liu, L.-g. High pressure NaAlSiO4: The first silicate calcium ferrite isotype. Geophys. Res. Lett. 1977, 4, 183–186. [Google Scholar] [CrossRef]

- Liu, J.; Wang, C.; Lv, C.; Su, X.; Liu, Y.; Tang, R.; Chen, J.; Hu, Q.; Mao, H.-K.; Mao, W.L. Evidence for oxygenation of Fe-Mg oxides at mid-mantle conditions and the rise of deep oxygen. Natl. Sci. Rev. 2020, 8, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Lord, O.T.; Wann, E.T.H.; Hunt, S.A.; Walker, A.M.; Santangeli, J.; Walter, M.J.; Dobson, D.P.; Wood, I.G.; Vočadlo, L.; Morard, G.; et al. The NiSi melting curve to 70GPa. Phys. Earth Planet. Inter. 2014, 233, 13–23. [Google Scholar] [CrossRef]

- Lord, O.T.; Wood, I.G.; Dobson, D.P.; Vočadlo, L.; Wang, W.; Thomson, A.R.; Wann, E.T.H.; Morard, G.; Mezouar, M.; Walter, M.J. The melting curve of Ni to 1 Mbar. Earth Planet. Sci. Lett. 2014, 408, 226–236. [Google Scholar] [CrossRef]

- Meng, Y.; Shen, G.; Mao, H.K. Double-sided laser heating system at HPCAT for in situ x-ray diffraction at high pressures and high temperatures. J. Phys. Condens. Matter 2006, 18, S1097–S1103. [Google Scholar] [CrossRef]

- Ming, L.c.; Bassett, W.A. Laser heating in the diamond anvil press up to 2000°C sustained and 3000°C pulsed at pressures up to 260 kilobars. Rev. Sci. Instrum. 1974, 45, 1115–1118. [Google Scholar] [CrossRef]

- Miyagi, L.; Kanitpanyacharoen, W.; Raju, S.V.; Kaercher, P.; Knight, J.; MacDowell, A.; Wenk, H.-R.; Williams, Q.; Alarcon, E.Z. Combined resistive and laser heating technique for in situ radial X-ray diffraction in the diamond anvil cell at high pressure and temperature. Rev. Sci. Instrum. 2013, 84, 025118. [Google Scholar] [CrossRef]

- Nabiei, F.; Badro, J.; Boukaré, C.; Hébert, C.; Cantoni, M.; Borensztajn, S.; Wehr, N.; Gillet, P. Investigating Magma Ocean Solidification on Earth Through Laser-Heated Diamond Anvil Cell Experiments. Geophys. Res. Lett. 2021, 48, e2021GL092446. [Google Scholar] [CrossRef]

- Ohfuji, H.; Irifune, T.; Okada, T.; Yagi, T.; Sumiya, H. Laser heating in nano-polycrystalline diamond anvil cell. J. Phys. Conf. Ser. 2010, 215, 5. [Google Scholar] [CrossRef]

- Ohtaka, O.; Andrault, D.; Bouvier, P.; Schultz, E.; Mezouar, M. Phase relations and equation of state of ZrO2 to 100 GPa. J. Appl. Crystallogr. 2005, 38, 727–733. [Google Scholar] [CrossRef]

- Panero, W.R.; Jeanloz, R. Temperature gradients in the laser-heated diamond anvil cell. J. Geophys. Res. Solid Earth 2001, 106, 6493–6498. [Google Scholar] [CrossRef]

- Santamaría-Pérez, D.; Boehler, R. FeSi melting curve up to 70 GPa. Earth Planet. Sci. Lett. 2008, 265, 743–747. [Google Scholar] [CrossRef]

- Pigott, J.S.; Reaman, D.M.; Panero, W.R. Microfabrication of controlled-geometry samples for the laser-heated diamond-anvil cell using focused ion beam technology. Rev. Sci. Instrum. 2011, 82, 115106. [Google Scholar] [CrossRef] [PubMed]

- Pigott, J.S.; Velisavljevic, N.; Moss, E.K.; Draganic, N.; Jacobsen, M.K.; Meng, Y.; Hrubiak, R.; Sturtevant, B.T. Experimental melting curve of zirconium metal to 37 GPa. J. Phys. Condens. Matter 2020, 32, 355402. [Google Scholar] [CrossRef] [PubMed]

- Polvani, D.A.; Meng, J.F.; Hasegawa, M.; Badding, J.V. Measurement of the thermoelectric power of very small samples at ambient and high pressures. Rev. Sci. Instrum. 1999, 70, 3586–3589. [Google Scholar] [CrossRef]

- Prakapenka, V.B.; Kubo, A.; Kuznetsov, A.; Laskin, A.; Shkurikhin, O.; Dera, P.; Rivers, M.L.; Sutton, S.R. Advanced flat top laser heating system for high pressure research at GSECARS: Application to the melting behavior of germanium. High Pressure Res. 2008, 28, 225–235. [Google Scholar] [CrossRef]

- Prakapenka, V.B.; Shen, G.; Dubrovinsky, L.S. Carbon transport in diamond anvil cells. High Temp. High Press. 2003, 35/36, 237–249. [Google Scholar] [CrossRef]

- Raju, S.V.; Hrubiak, R.; Drozd, V.; Saxena, S. Laser-assisted processing of Ni-Al-Co-Ti under high pressure. Mater. Manuf. Processes 2017, 32, 1606–1611. [Google Scholar] [CrossRef]

- Ross, M.; Boehler, R.; Söderlind, P. Xenon Melting Curve to 80 GPa and 5p-d Hybridization. Phys. Rev. Lett. 2005, 95, 257801. [Google Scholar] [CrossRef]

- Runge, C.E.; Kubo, A.; Kiefer, B.; Meng, Y.; Prakapenka, V.B.; Shen, G.; Cava, R.J.; Duffy, T.S. Equation of state of MgGeO3 perovskite to 65 GPa: Comparison with the post-perovskite phase. Phys. Chem. Miner. 2006, 33, 699–709. [Google Scholar] [CrossRef]

- Sadovyi, B.; Wierzbowska, M.; Stelmakh, S.; Boccato, S.; Gierlotka, S.; Irifune, T.; Porowski, S.; Grzegory, I. Experimental and theoretical evidence of the temperature-induced wurtzite to rocksalt phase transition in GaN under high pressure. Phys. Rev. B Condens. Matter 2020, 102, 235109. [Google Scholar] [CrossRef]

- Saha, P.; Mukherjee, G.D. Temperature measurement in double-sided laser-heated diamond anvil cell and reaction of carbon. Indian J. Phys. 2021, 95, 621–628. [Google Scholar] [CrossRef]

- Saha, P.; Mazumder, A.; Mukherjee, G.D. Thermal conductivity of dense hcp iron: Direct measurements using laser heated diamond anvil cell. Geosci. Front. 2020, 11, 1755–1761. [Google Scholar] [CrossRef]

- Salem, R.; Matityahu, S.; Melchior, A.; Nikolaevsky, M.; Noked, O.; Sterer, E. Image analysis of speckle patterns as a probe of melting transitions in laser-heated diamond anvil cell experiments. Rev. Sci. Instrum. 2015, 86, 093907. [Google Scholar] [CrossRef]

- Santamaría-Pérez, D.; Ross, M.; Errandonea, D.; Mukherjee, G.D.; Mezouar, M.; Boehler, R. X-ray diffraction measurements of Mo melting to 119 GPa and the high pressure phase diagram. J. Chem. Phys. 2009, 130, 124509. [Google Scholar] [CrossRef]

- Schultz, E.; Mezouar, M.; Crichton, W.; Bauchau, S.; Blattmann, G.; Andrault, D.; Fiquet, G.; Boehler, R.; Rambert, N.; Sitaud, B.; et al. Double-sided laser heating system for in situ high pressure–high temperature monochromatic x-ray diffraction at the esrf. High Pressure Res. 2005, 25, 71–83. [Google Scholar] [CrossRef]

- Shen, G.; Mao, H.-k.; Hemley, R.J.; Duffy, T.S.; Rivers, M.L. Melting and crystal structure of iron at high pressures and temperatures. Geophys. Res. Lett. 1998, 25, 373–376. [Google Scholar] [CrossRef]

- Shen, G.; Rivers, M.L.; Wang, Y.; Sutton, S.R. Laser heated diamond cell system at the Advanced Photon Source for in situ x-ray measurements at high pressure and temperature. Rev. Sci. Instrum. 2001, 72, 1273–1282. [Google Scholar] [CrossRef]

- Shen, G.; Prakapenka, V.B.; Rivers, M.L.; Sutton, S.R. Structure of Liquid Iron at Pressures up to 58 GPa. Phys. Rev. Lett. 2004, 92, 185701. [Google Scholar] [CrossRef]

- Shen, G.; Mao, H.-k.; Hemley, R. Laser-Heated Diamond Anvil Cell Technique: Double-Sided Heating with Multimode Nd:YAG Laser. In Advanced Materials ’96 New Trends in High Pressure Research; Akaishi, M., Ed.; The Institute: Tsukuba, Japan, 1996. [Google Scholar]

- Shieh, S.R.; Duffy, T.S.; Shen, G. X-ray diffraction study of phase stability in SiO2 at deep mantle conditions. Earth Planet. Sci. Lett. 2005, 235, 273–282. [Google Scholar] [CrossRef]

- Shim, S.H.; Duffy, T.S.; Jeanloz, R.; Shen, G. Stability and crystal structure of MgSiO3 perovskite to the core-mantle boundary. Geophys. Res. Lett. 2004, 31. [Google Scholar] [CrossRef]

- Shukla, B.; Shekar, N.V.C.; Kumar, N.R.S.; Ravindran, T.R.; Sahoo, P.; Dhara, S.; Sahu, P.C. Twin chamber sample assembly in DAC and HPHT studies on GaN nano-particles. J. Phys. Conf. Ser. 2012, 377, 012014. [Google Scholar] [CrossRef]

- Singh, A.K.; Andrault, D.; Bouvier, P. X-ray diffraction from stishovite under nonhydrostatic compression to 70GPa: Strength and elasticity across the tetragonal→orthorhombic transition. Phys. Earth Planet. Inter. 2012, 208–209, 1–10. [Google Scholar] [CrossRef]

- Sinmyo, R.; Hirose, K. The Soret diffusion in laser-heated diamond-anvil cell. Phys. Earth Planet. Inter. 2010, 180, 172–178. [Google Scholar] [CrossRef]

- Sinmyo, R.; Pesce, G.; Greenberg, E.; McCammon, C.; Dubrovinsky, L. Lower mantle electrical conductivity based on measurements of Al, Fe-bearing perovskite under lower mantle conditions. Earth Planet. Sci. Lett. 2014, 393, 165–172. [Google Scholar] [CrossRef]

- Spiekermann, G.; Kupenko, I.; Petitgirard, S.; Harder, M.; Nyrow, A.; Weis, C.; Albers, C.; Biedermann, N.; Libon, L.; Sahle, C.J.; et al. A portable on-axis laser-heating system for near-90degrees X-ray spectroscopy: Application to ferropericlase and iron silicide. J. Synchrotron Radiat. 2020, 27, 414–424. [Google Scholar] [CrossRef] [PubMed]

- Stutzmann, V.; Dewaele, A.; Bouchet, J.; Bottin, F.; Mezouar, M. High-pressure melting curve of titanium. Phys. Rev. B Condens. Matter 2015, 92, 224110. [Google Scholar] [CrossRef]

- Auzende, A.-L.; Gillot, J.; Coquet, A.; Hennet, L.; Ona-Nguema, G.; Bonnin, D.; Esteve, I.; Roskosz, M.; Fiquet, G. Synthesis of amorphous MgO-rich peridotitic starting material for laser-heated diamond anvil cell experiments—Application to iron partitioning in the mantle. High Pressure Res. 2011, 31, 199–213. [Google Scholar] [CrossRef]

- Tateno, S.; Hirose, K.; Ohishi, Y.; Tatsumi, Y. The Structure of Iron in Earth’s Inner Core. Science 2010, 330, 359–361. [Google Scholar] [CrossRef]

- Watanuki, T.; Shimomura, O.; Yagi, T.; Kondo, T.; Isshiki, M. Construction of laser-heated diamond anvil cell system for in situ x-ray diffraction study at SPring-8. Rev. Sci. Instrum. 2001, 72, 1289–1292. [Google Scholar] [CrossRef]

- Weck, G.; Recoules, V.; Queyroux, J.-A.; Datchi, F.; Bouchet, J.; Ninet, S.; Garbarino, G.; Mezouar, M.; Loubeyre, P. Determination of the melting curve of gold up to 110 GPa. Phys. Rev. B Condens. Matter 2020, 101, 014106. [Google Scholar] [CrossRef]

- Yagi, T.; Susaki, J.-I. A Laser Heating System for Diamond Anvil Using CO2 Laser. In High-Pressure Research: Application to Earth and Planetary Sciences; Terra Scientific Publishing Company: Tokyo, Japan, 1992; pp. 51–54. [Google Scholar]

- Yang, L.; Karandikar, A.; Boehler, R. Flash heating in the diamond cell: Melting curve of rhenium. Rev. Sci. Instrum. 2012, 83, 063905. [Google Scholar] [CrossRef] [PubMed]

- Yoo, C.S.; Akella, J.; Moriarty, J.A. High-pressure melting temperatures of uranium: Laser-heating experiments and theoretical calculations. Phys. Rev. B Condens. Matter 1993, 48, 15529–15534. [Google Scholar] [CrossRef] [PubMed]

- Yoo, C.S.; Akella, J.; Campbell, A.J.; Mao, H.K.; Hemley, R.J. Phase Diagram of Iron by in Situ X-ray Diffraction: Implications for Earth’s Core. Science 1995, 270, 1473–1475. [Google Scholar] [CrossRef]

- Yoo, C.S.; Söderlind, P.; Moriarty, J.A.; Cambell, A.J. dhcp as a possible new ϵ′ phase of iron at high pressures and temperatures. Phys. Lett. A 1996, 214, 65–70. [Google Scholar] [CrossRef]

- Yusa, H.; Takemura, K.; Matsui, Y.; Morishima, H.; Watanabe, K.; Yamawaki, H.; Aoki, K. Direct transformation of graphite to cubic diamond observed in a laser-heated diamond anvil cell. Appl. Phys. Lett. 1998, 72, 1843–1845. [Google Scholar] [CrossRef]

- Zerr, A.; Boehier, R. Melting of (Mg, Fe)SiO3-Perovskite to 625 Kilobars: Indication of a High Melting Temperature in the Lower Mantle. Science 1993, 262, 553–555. [Google Scholar] [CrossRef]

- Zerr, A.; Miehe, G.; Serghiou, G.; Schwarz, M.; Kroke, E.; Riedel, R.; Fueß, H.; Kroll, P.; Boehler, R. Synthesis of cubic silicon nitride. Nature 1999, 400, 340–342. [Google Scholar] [CrossRef]

- Zhang, L.; Meng, Y.; Mao, H.-k. Unit cell determination of coexisting post-perovskite and H-phase in (Mg,Fe)SiO3 using multigrain XRD: Compositional variation across a laser heating spot at 119 GPa. Prog. Earth Planet. Sci. 2016, 3, 13. [Google Scholar] [CrossRef][Green Version]

- Zhang, D.; Jackson, J.M.; Zhao, J.; Sturhahn, W.; Alp, E.E.; Hu, M.Y.; Toellner, T.S.; Murphy, C.A.; Prakapenka, V.B. Temperature of Earth’s core constrained from melting of Fe and Fe0.9Ni0.1 at high pressures. Earth Planet. Sci. Lett. 2016, 447, 72–83. [Google Scholar] [CrossRef]

- Zinin, P.V.; Prakapenka, V.B.; Burgess, K.; Odake, S.; Chigarev, N.; Sharma, S.K. Combined laser ultrasonics, laser heating, and Raman scattering in diamond anvil cell system. Rev. Sci. Instrum. 2016, 87, 123908. [Google Scholar] [CrossRef]

- Zou, G.; Ma, Y.; Mao, H.-k.; Hemley, R.J.; Gramsch, S.A. A diamond gasket for the laser-heated diamond anvil cell. Rev. Sci. Instrum. 2001, 72, 1298–1301. [Google Scholar] [CrossRef]

- Weathers, M.S.; Bassett, W.A. Melting of carbon at 50 to 300 kbar. Phys. Chem. Miner. 1987, 15, 105–112. [Google Scholar] [CrossRef]

- Huang, D.; Siebert, J.; Badro, J. High pressure partitioning behavior of Mo and W and late sulfur delivery during Earth’s core formation. Geochim. Cosmochim. Acta 2021, 310, 19–31. [Google Scholar] [CrossRef]

- Kurnosov, A.; Marquardt, H.; Dubrovinsky, L.; Potapkin, V. A waveguide-based flexible CO2-laser heating system for diamond-anvil cell applications. C.R. Geosci. 2019, 351, 280–285. [Google Scholar] [CrossRef]

- Chidester, B.A.; Thompson, E.C.; Fischer, R.A.; Heinz, D.L.; Prakapenka, V.B.; Meng, Y.; Campbell, A.J. Experimental thermal equation of state of B2− KCl. Phys. Rev. B Condens. Matter 2021, 104, 094107. [Google Scholar] [CrossRef]

- Zhang, Y.; Tan, Y.; Geng, H.Y.; Salke, N.P.; Gao, Z.; Li, J.; Sekine, T.; Wang, Q.; Greenberg, E.; Prakapenka, V.B.; et al. Melting curve of vanadium up to 256 GPa: Consistency between experiments and theory. Phys. Rev. B Condens. Matter 2020, 102, 214104. [Google Scholar] [CrossRef]

- Gaida, N.A.; Niwa, K.; Sasaki, T.; Hasegawa, M. Phase relations and thermoelasticity of magnesium silicide at high pressure and temperature. J. Chem. Phys. 2021, 154, 144701. [Google Scholar] [CrossRef]

- Anzellini, S.; Burakovsky, L.; Turnbull, R.; Bandiello, E.; Errandonea, D. P–V–T Equation of State of Iridium Up to 80 GPa and 3100 K. Crystals 2021, 11, 452. [Google Scholar] [CrossRef]

- Liu, L.-g. Silicate perovskite from phase transformations of pyrope-garnet at high pressure and temperature. Geophys. Res. Lett. 1974, 1, 277–280. [Google Scholar] [CrossRef]

- Nishiyama, N.; Langer, J.; Sakai, T.; Kojima, Y.; Holzheid, A.; Gaida, N.A.; Kulik, E.; Hirao, N.; Kawaguchi, S.I.; Irifune, T.; et al. Phase relations in silicon and germanium nitrides up to 98 GPa and 2400°C. J. Am. Ceram. Soc. 2019, 102, 2195–2202. [Google Scholar] [CrossRef]

- Bassett, W.A.; Li-Chung, M. Disproportionation of Fe2SiO4 to 2FeO + SiO2 at pressures up to 250kbar and temperatures up to 3000 °C. Phys. Earth Planet. Inter. 1972, 6, 154–160. [Google Scholar] [CrossRef]

- Kavner, A.; Jeanloz, R. The high-pressure melting curve of Allende meteorite. Geophys. Res. Lett. 1998, 25, 4161–4164. [Google Scholar] [CrossRef]

- Boehler, R.; von Bargen, N.; Chopelas, A. Melting, thermal expansion, and phase transitions of iron at high pressures. J. Geophys. Res. Solid Earth 1990, 95, 21731–21736. [Google Scholar] [CrossRef]

- Wakamatsu, T.; Ohta, K.; Yagi, T.; Hirose, K.; Ohishi, Y. Measurements of sound velocity in iron–nickel alloys by femtosecond laser pulses in a diamond anvil cell. Phys. Chem. Miner. 2018, 45, 589–595. [Google Scholar] [CrossRef]

- Deemyad, S.; Sterer, E.; Barthel, C.; Rekhi, S.; Tempere, J.; Silvera, I.F. Pulsed laser heating and temperature determination in a diamond anvil cell. Rev. Sci. Instrum. 2005, 76, 125104. [Google Scholar] [CrossRef]

- Deemyad, S.; Silvera, I.F. Melting Line of Hydrogen at High Pressures. Phys. Rev. Lett. 2008, 100, 155701. [Google Scholar] [CrossRef]

- Yoo, C.S.; Akella, J.; Cynn, H.; Nicol, M. Direct elementary reactions of boron and nitrogen at high pressures and temperatures. Phys. Rev. B Condens. Matter 1997, 56, 140–146. [Google Scholar] [CrossRef]

- Serghiou, G.; Miehe, G.; Tschauner, O.; Zerr, A.; Boehler, R. Synthesis of a cubic Ge3N4 phase at high pressures and temperatures. J. Chem. Phys. 1999, 111, 4659–4662. [Google Scholar] [CrossRef]

- Sahu, P.C.; Takemura, K.; Yusa, H. Synthesis experiments on B-Sb, Ge-Sb, and Xe-Pd systems using a laser heated diamond anvil cell. High Pressure Res. 2001, 21, 41–50. [Google Scholar] [CrossRef]

- Sorb, Y.A.; Subramanian, N.; Ravindran, T.R.; Sahu, P.C. High Pressure in situ Micro-Raman Spectroscopy of Ge-Sn System Synthesized in a Laser Heated Diamond Anvil Cell. AIP Conf. Proc. 2011, 1349, 1305–1306. [Google Scholar] [CrossRef]

- Sanjay Kumar, N.R.; Chandra Shekar, N.V.; Chandra, S.; Basu, J.; Divakar, R.; Sahu, P.C. Synthesis of novel Ru2C under high pressure–high temperature conditions. J. Phys. Condens. Matter 2012, 24, 362202. [Google Scholar] [CrossRef]

- Fedotenko, T.; Dubrovinsky, L.; Khandarkhaeva, S.; Chariton, S.; Koemets, E.; Koemets, I.; Hanfland, M.; Dubrovinskaia, N. Synthesis of palladium carbides and palladium hydride in laser heated diamond anvil cells. J. Alloys Compd. 2020, 844, 156179. [Google Scholar] [CrossRef]

- Gréaux, S.; Andrault, D.; Gautron, L.; Bolfan-Casanova, N.; Mezouar, M. Compressibility of Ca3Al2Si3O12 perovskite up to 55 GPa. Phys. Chem. Miner. 2014, 41, 419–429. [Google Scholar] [CrossRef]

- Zerr, A.; Serghiou, G.; Boehler, R.; Ross, M. Decomposition of alkanes at high pressures and temperatures. High Pressure Res. 2006, 26, 23–32. [Google Scholar] [CrossRef]

- Vance, S.; Harnmeijer, J.; Kimura, J.; Hussmann, H.; deMartin, B.; Brown, J.M. Hydrothermal Systems in Small Ocean Planets. Astrobiology 2007, 7, 987–1005. [Google Scholar] [CrossRef]

- Helled, R.; Anderson, J.D.; Podolak, M.; Schubert, G. Interior Models of Uranus and Neptune. Astrophys. J. 2010, 726, 15. [Google Scholar] [CrossRef]

- Guillot, T.; Gautier, D. 10.13—Giant Planets. In Treatise on Geophysics; Schubert, G., Ed.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 439–464. [Google Scholar]

- Fossati, L.; Shulyak, D.; Sreejith, A.G.; Koskinen, T.; Young, M.E.; Cubillos, P.E.; Lara, L.M.; France, K.; Rengel, M.; Cauley, P.W.; et al. A data-driven approach to constraining the atmospheric temperature structure of the ultra-hot Jupiter KELT-9b. Astron. Astrophys. 2020, 643, A131. [Google Scholar] [CrossRef]

- Banerjee, A.; Bernoulli, D.; Zhang, H.; Yuen, M.-F.; Liu, J.; Dong, J.; Ding, F.; Lu, J.; Dao, M.; Zhang, W.; et al. Ultralarge elastic deformation of nanoscale diamond. Science 2018, 360, 300–302. [Google Scholar] [CrossRef]

- Ruoff, A.L. On the yield strength of diamond. J. Appl. Phys. 1979, 50, 3354–3356. [Google Scholar] [CrossRef]

- Reinhart, W.D.; Chhabildas, L.C.; Vogler, T.J. Investigating phase transitions and strength in single-crystal sapphire using shock–reshock loading techniques. Int. J. Impact Eng. 2006, 33, 655–669. [Google Scholar] [CrossRef]

- Bisschop, J.; den Brok, B.; Miletich, R. Brittle deformation of quartz in a diamond anvil cell. J. Struct. Geol. 2005, 27, 943–947. [Google Scholar] [CrossRef]

- Borg, J.P.; Vogler, T.J. Mesoscale simulations of a dart penetrating sand. Int. J. Impact Eng. 2008, 35, 1435–1440. [Google Scholar] [CrossRef]

- Dubrovinsky, L.; Khandarkhaeva, S.; Fedotenko, T.; Laniel, D.; Bykov, M.; Giacobbe, C.; Lawrence Bright, E.; Sedmak, P.; Chariton, S.; Prakapenka, V.; et al. Materials synthesis at terapascal static pressures. Nature 2022, 605, 274–278. [Google Scholar] [CrossRef] [PubMed]

- Mao, H.K.; Bell, P.M.; Shaner, J.W.; Steinberg, D.J. Specific volume measurements of Cu, Mo, Pd, and Ag and calibration of the ruby R1 fluorescence pressure gauge from 0.06 to 1 Mbar. J. Appl. Phys. 1978, 49, 3276–3283. [Google Scholar] [CrossRef]

- Mostovych, A.N.; Chan, Y.; Lehecha, T.; Phillips, L.; Schmitt, A.; Sethian, J.D. Reflected shock experiments on the equation-of-state properties of liquid deuterium at 100–600 GPa (1–6 Mbar). Phys. Plasma 2001, 8, 2281–2286. [Google Scholar] [CrossRef]

- Bonev, S.A.; Militzer, B.; Galli, G. Ab initio simulations of dense liquid deuterium: Comparison with gas-gun shock-wave experiments. Phys. Rev. B Condens. Matter 2004, 69, 014101. [Google Scholar] [CrossRef]

- Laboratory, L.L.N.; Bastea; Zaug, J. Material behavior insight comes as a nanoshock. Available online: https://www.llnl.gov/news/material-behavior-insight-comes-nanoshock (accessed on 1 November 2022).

- Campanella, B.; Legnaioli, S.; Pagnotta, S.; Poggialini, F.; Palleschi, V. Shock Waves in Laser-Induced Plasmas. Atoms 2019, 7, 57. [Google Scholar] [CrossRef]

- Urtiew, P.A. Effect of shock loading on transparency of sapphire crystals. J. Appl. Phys. 1974, 45, 3490–3493. [Google Scholar] [CrossRef]

- Celliers, P.M.; Loubeyre, P.; Eggert, J.H.; Brygoo, S.; McWilliams, R.S.; Hicks, D.G.; Boehly, T.R.; Jeanloz, R.; Collins, G.W. Insulator-to-Conducting Transition in Dense Fluid Helium. Phys. Rev. Lett. 2010, 104, 184503. [Google Scholar] [CrossRef]

- Bass, J.D.; Svendsen, B.; Ahrens, T.J. The Temperature of Shock Compressed Iron. In Elastic Properties and Equations of State; Wiley: Hoboken, NJ, USA, 1988; pp. 532–541. [Google Scholar]

- Pakhal, H.R.; Lucht, R.P.; Laurendeau, N.M. Spectral measurements of incipient plasma temperature and electron number density during laser ablation of aluminum in air. Appl. Phys. B 2008, 90, 15–27. [Google Scholar] [CrossRef]

- Nellis, W.J. Dynamic compression of materials: Metallization of fluid hydrogen at high pressures. Rep. Prog. Phys. 2006, 69, 1479–1580. [Google Scholar] [CrossRef]

- Babuel-Peyrissac, J.P.; Fauquignon, C.; Floux, F. Effect of powerful laser pulse on low Z solid material. Phys. Lett. A 1969, 30, 290–291. [Google Scholar] [CrossRef]

- Nellis, W.J. Adiabat-reduced isotherms at 100 GPa pressures. High Pressure Res. 2007, 27, 393–407. [Google Scholar] [CrossRef]

- Grujicic, M.; Runt, J.; Sr, J.T. Molecular Dynamics (MD) and Coarse Grain Simulation of High Strain-Rate Elastomeric Polymers (HSREP). In Elastomeric Polymers with High Rate Sensitivity; Barsoum, R.G., Ed.; William Andrew Publishing: Oxford, UK, 2015; pp. 187–232. [Google Scholar]

- Zhang, Q.B.; Braithwaite, C.H.; Zhao, J. Hugoniot equation of state of rock materials under shock compression. Phil. Trans. R. Soc. A 2017, 375, 20160169. [Google Scholar] [CrossRef]

- Celliers, P.M.; Bradley, D.K.; Collins, G.W.; Hicks, D.G.; Boehly, T.R.; Armstrong, W.J. Line-imaging velocimeter for shock diagnostics at the OMEGA laser facility. Rev. Sci. Instrum. 2004, 75, 4916–4929. [Google Scholar] [CrossRef]

- Cooper, M.A.; Specht, P.E.; Trott, W.M. Measuring three-dimensional deformation with surface-imaging ORVIS. J. Phys. Conf. Ser. 2014, 500, 182008. [Google Scholar] [CrossRef]

- Evans, W.J.; Yoo, C.-S.; Lee, G.W.; Cynn, H.; Lipp, M.J.; Visbeck, K. Dynamic diamond anvil cell (dDAC): A novel device for studying the dynamic-pressure properties of materials. Rev. Sci. Instrum. 2007, 78, 073904. [Google Scholar] [CrossRef]

- Su, L.; Shi, K.; Zhang, L.; Wang, Y.; Yang, G. Static and dynamic diamond anvil cell (s-dDAC): A bidirectional remote controlled device for static and dynamic compression/decompression. Matter Radiat. Extremes 2021, 7, 018401. [Google Scholar] [CrossRef]

- Yan, J.; Liu, X.; Gorelli, F.A.; Xu, H.; Zhang, H.; Hu, H.; Gregoryanz, E.; Dalladay-Simpson, P. Compression rate of dynamic diamond anvil cells from room temperature to 10 K. Rev. Sci. Instrum. 2022, 93, 063901. [Google Scholar] [CrossRef]

- Smith, J.S.; Sinogeikin, S.V.; Lin, C.; Rod, E.; Bai, L.; Shen, G. Developments in time-resolved high pressure x-ray diffraction using rapid compression and decompression. Rev. Sci. Instrum. 2015, 86, 072208. [Google Scholar] [CrossRef]

- Velisavljevic, N.; Sinogeikin, S.; Saavedra, R.; Chellappa, R.S.; Rothkirch, A.; Dattelbaum, D.M.; Konopkova, Z.; Liermann, H.P.; Bishop, M.; Tsoi, G.M.; et al. Time-resolved x-ray diffraction and electrical resistance measurements of structural phase transitions in zirconium. J. Phys. Conf. Ser. 2014, 500, 032020. [Google Scholar] [CrossRef]

- Cauble, R.; Phillion, D.W.; Hoover, T.J.; Holmes, N.C.; Kilkenny, J.D.; Lee, R.W. Demonstration of 0.75 Gbar planar shocks in x-ray driven colliding foils. Phys. Rev. Lett. 1993, 70, 2102–2105. [Google Scholar] [CrossRef]

- Zheng, X.; Song, Y.; Zhao, J.; Tan, D.; Yang, Y.; Liu, C. Nanosecond time-resolved Raman spectroscopy of molecular solids under laser-driven shock compression. Chem. Phys. Lett. 2010, 499, 231–235. [Google Scholar] [CrossRef]

- Duffy, T.S.; Ahrens, T.J. Sound velocities at high pressure and temperature and their geophysical implications. J. Geophys. Res. Solid Earth 1992, 97, 4503–4520. [Google Scholar] [CrossRef]

- Fratanduono, D.E.; Millot, M.; Kraus, R.G.; Spaulding, D.K.; Collins, G.W.; Celliers, P.M.; Eggert, J.H. Thermodynamic properties of MgSiO3 at super-Earth mantle conditions. Phys. Rev. B 2018, 97, 214105. [Google Scholar] [CrossRef]

- Ichiyanagi, K.; Takagi, S.; Kawai, N.; Fukaya, R.; Nozawa, S.; Nakamura, K.G.; Liss, K.-D.; Kimura, M.; Adachi, S.-i. Microstructural deformation process of shock-compressed polycrystalline aluminum. Sci. Rep. 2019, 9, 7604. [Google Scholar] [CrossRef]

- Johnson, J.D. Bound and estimate for the maximum compression of single shocks. Phys. Rev. E 1999, 59, 3727–3728. [Google Scholar] [CrossRef]

- Nellis, W.J.P.W. Bridgman’s contributions to the foundations of shock compression of condensed matter. J. Phys. Conf. Ser. 2010, 215, 012144. [Google Scholar] [CrossRef]

- Kadobayashi, H.; Ohnishi, S.; Ohfuji, H.; Yamamoto, Y.; Muraoka, M.; Yoshida, S.; Hirao, N.; Kawaguchi-Imada, S.; Hirai, H. Diamond formation from methane hydrate under the internal conditions of giant icy planets. Sci. Rep. 2021, 11, 8165. [Google Scholar] [CrossRef]

- Kraus, D.; Vorberger, J.; Pak, A.; Hartley, N.J.; Fletcher, L.B.; Frydrych, S.; Galtier, E.; Gamboa, E.J.; Gericke, D.O.; Glenzer, S.H.; et al. Formation of diamonds in laser-compressed hydrocarbons at planetary interior conditions. Nat. Astron 2017, 1, 606–611. [Google Scholar] [CrossRef]

- Benedetti, L.R.; Nguyen, J.H.; Caldwell, W.A.; Liu, H.; Kruger, M.; Jeanloz, R. Dissociation of CH4 at high pressures and temperatures: Diamond formation in giant planet interiors? Science 1999, 286, 100–102. [Google Scholar] [CrossRef] [PubMed]

- Hirai, H.; Konagai, K.; Kawamura, T.; Yamamoto, Y.; Yagi, T. Polymerization and diamond formation from melting methane and their implications in ice layer of giant planets. Phys. Earth Planet. Inter. 2009, 174, 242–246. [Google Scholar] [CrossRef]

- Showrilu, K.; Jyothirmai, C.; Sirisha, A.R.N.L.; Sivakumar, A.; Sahaya Jude Dhas, S.; Martin Britto Dhas, S.A. Shock wave-induced defect engineering on structural and optical properties of crown ether magnesium chloride potassium thiocyanate single crystal. J. Mater. Sci. Mater. Electron. 2021, 32, 3903–3911. [Google Scholar] [CrossRef]

- Paulus, W.S.; Rahman, I.A.; Jalar, A.; Othman, N.K.; Ismail, R.; Wan Yusoff, W.Y.; Abu Bakar, M. The Relationship between XRD Peak Intensity and Mechanical Properties of Irradiated Lead-Free Solder. Mater. Sci. Forum 2017, 888, 423–427. [Google Scholar] [CrossRef]

- Ahlam, M.A.; Ravishankar, M.N.; Vijayan, N.; Govindaraj, G.; Upadhyaya, V.; Prakash, A.P.G. The effect of Co-60 gamma irradiation on optical properties of some nonlinear optical (NLO) single crystals. J. Opt. 2012, 41, 158–166. [Google Scholar] [CrossRef]

- Sivakumar, A.; Victor, C.; Nayak, M.M.; Dhas, S.A.M.B. Structural, optical, and morphological stability of ZnO nano rods under shock wave loading conditions. Mater. Res. Express 2019, 6, 045031. [Google Scholar] [CrossRef]

- Thomas, R.; Davidson, P.; Rericha, A.; Recknagel, U. Discovery of Stishovite in the Prismatine-Bearing Granulite from Waldheim, Germany: A Possible Role of Supercritical Fluids of Ultrahigh-Pressure Origin. Geosciences 2022, 12, 196. [Google Scholar] [CrossRef]

- Ackerson, M.R. Trace and Minor Elements in Garnet and Quartz: Novel Approaches to Understanding Crustal Evolution. Ph.D. Thesis, Rensselaer Polytechnic Institute, Ann Arbor, MI, USA, 2015. [Google Scholar]

- Guarguaglini, M.; Hernandez, J.A.; Okuchi, T.; Barroso, P.; Benuzzi-Mounaix, A.; Bethkenhagen, M.; Bolis, R.; Brambrink, E.; French, M.; Fujimoto, Y.; et al. Laser-driven shock compression of “synthetic planetary mixtures” of water, ethanol, and ammonia. Sci. Rep. 2019, 9, 10155. [Google Scholar] [CrossRef]

- Arumugam, S.; Sathiyadhas, S.J.D.; Michael, J.; Pichan, K.; Muthu, S.P.; Perumalsamy, R.; Sathiyadhas Amalapusham, M.B.D. Investigation on the impact of xylenol orange dye on the growth and properties of unidirectional grown KDP crystals for photonic applications. J. Cryst. Growth 2019, 523, 125154. [Google Scholar] [CrossRef]

- Kohn, E. Harsh Environment Materials. In Comprehensive Microsystems; Gianchandani, Y.B., Tabata, O., Zappe, H., Eds.; Elsevier: Oxford, UK, 2008; pp. 131–181. [Google Scholar]

- Wackerle, J. Shock-Wave Compression of Quartz. J. Appl. Phys. 1962, 33, 922–937. [Google Scholar] [CrossRef]

- Kraus, D.; Ravasio, A.; Gauthier, M.; Gericke, D.O.; Vorberger, J.; Frydrych, S.; Helfrich, J.; Fletcher, L.B.; Schaumann, G.; Nagler, B.; et al. Nanosecond formation of diamond and lonsdaleite by shock compression of graphite. Nat. Commun. 2016, 7, 10970. [Google Scholar] [CrossRef]

- Kurdyumov, A.V.; Britun, V.F.; Yarosh, V.V.; Danilenko, A.I.; Zelyavskii, V.B. The influence of the shock compression conditions on the graphite transformations into lonsdaleite and diamond. J. Superhard Mater. 2012, 34, 19–27. [Google Scholar] [CrossRef]

- Thapliyal, V.; Alabdulkarim, M.E.; Whelan, D.R.; Mainali, B.; Maxwell, J.L. A concise review of the Raman spectra of carbon allotropes. Diamond Relat. Mater. 2022, 127, 109180. [Google Scholar] [CrossRef]

- Saha, P.; Annamalai, N.; Guha, A.K. Synthetic Quartz Production and Applications. Trans. Indian Ceram. Soc. 1991, 50, 129–135. [Google Scholar] [CrossRef]

- Knudson, M.D.; Desjarlais, M.P. Shock Compression of Quartz to 1.6 TPa: Redefining a Pressure Standard. Phys. Rev. Lett. 2009, 103, 225501. [Google Scholar] [CrossRef]

- Grieve, R.A.F.; Langenhorst, F.; Stöffler, D. Shock metamorphism of quartz in nature and experiment: II. Significance in geoscience*. Meteorit. Planet. Sci. 1996, 31, 6–35. [Google Scholar] [CrossRef]

- Hicks, D.G.; Boehly, T.R.; Celliers, P.M.; Bradley, D.K.; Eggert, J.H.; McWilliams, R.S.; Jeanloz, R.; Collins, G.W. High-precision measurements of the diamond Hugoniot in and above the melt region. Phys. Rev. B 2008, 78, 174102. [Google Scholar] [CrossRef]

- De Carli, P.S.; Milton, D.J. Stishovite: Synthesis by Shock Wave. Science 1965, 147, 144–145. [Google Scholar] [CrossRef]

- Beason, M.T.; Pauls, J.M.; Gunduz, I.E.; Rouvimov, S.; Manukyan, K.V.; Matouš, K.; Son, S.F.; Mukasyan, A. Shock-induced reaction synthesis of cubic boron nitride. Appl. Phys. Lett. 2018, 112, 171903. [Google Scholar] [CrossRef]

- Pan, Z.; Sun, H.; Zhang, Y.; Chen, C. Harder than Diamond: Superior Indentation Strength of Wurtzite BN and Lonsdaleite. Phys. Rev. Lett. 2009, 102, 055503. [Google Scholar] [CrossRef]

- Kennedy, J.P.; Williams, L.; Bridges, T.M.; Daniels, R.N.; Weaver, D.; Lindsley, C.W. Application of Combinatorial Chemistry Science on Modern Drug Discovery. J. Comb. Chem. 2008, 10, 345–354. [Google Scholar] [CrossRef] [PubMed]

| Modified Material and/or Property | Starting Material | Static Press. [GPa] | Shock Press. [GPa] | Laser Type [nm/µm] | Laser Parameters: Powers/Energies [W/J], Spots [], Ind. Temps [K] | Refs |

|---|---|---|---|---|---|---|

| Ionised H2O, EOS | H2O | ≈1 | ≈50–300 | Nd:YAG, 1.06 µm | Pulsed, 4 ns, ≤500 J, ≈5 × 1013 W/cm2, ≈300 μm | [25] |

| H2O, Sound velocity, Hugoniot Curves, EOS | H2O | a: 0.57 | a: 288–342 | a: Nd:YLF, 351 nm | a: Pulsed, 3 ns, 800–1500 J, 650 μm | a: [29] |

| b: ≈1–5 | b: 150 | b: Nd:YAG, 532 nm | b: Pulsed, ≈10–20 ns, 1–10 kJ, ≈200–500 μm, 6–9 × 103 K | b: [57] | ||

| c: 0.1–0.6 | c: 283 | c: Nd-glass laser | c: Pulsed, 1.5 ns, 1 kJ, Max 4 × 1014 W/cm2, 500 μm | c: [51] | ||

| d: ≈1 | d: ≈200 | d: Nd:glass laser | d: Seven Pulsed beams, 4 ns, 1013–1014 W/cm2, 104 K | d: [50] | ||

| e: ≈1 | e: 250 | e: Nd:glass laser | e: Pulsed,1–4 ns, ≈300 μm, 1014 W/cm2, 19 × 103 K | e: [26] | ||

| f: 1.33 | f: 200 | f: N/A | f: 800–1000 μm, 300 K | f: [22] | ||

| H2, Hugoniot curves | H2 | 0.7, 1.2 | ≈20 −50 | Nd:YAG, 1.06 µm | Pulsed, 1.2 ns, 1014 W/cm2, 400 μm, 300 K | [21] |

| H2, D2, EOS, Hugoniot Curves | a: H2 b: D2 | 0.16–1.6 | a: 104 b: 175 | Nd:glass laser, 351 nm | a: Pulsed, 1 ns, 6 kJ, 800 µm, ≈27.7 × 103 K b: Pulsed, 1 ns, 6 kJ, 800 µm, ≈40.9 × 103 K | [28] |

| He, Hugoniot Curves | He | 0.11–1.25 | 117 | Nd:glass laser, 351 nm | Pulsed, 10.6 ns, 3 kJ, 800 µm | [47] |

| He EOS, Hugoniot Curves, | He | 1.25 | 200 | Nd:glass laser, 351 nm | Pulsed, 1 ns | [52] |

| H2–He, EOS | H2–He | 4 | 93 | Nd: YAG laser, 351 nm | 4–6 kJ, 1 ns, 4700 K | [60] |

| He, H2, EOS | He, H2 | 5 | 100 | Nd:glass laser, 351 nm | Pulsed, ≈5–25 ns, 1–6 kJ, 800 µm, 10 × 103 K | [59] |

| Modified Material and/or Property | Starting Material | Static Press. [GPa] | Shock Press. [GPa] | Laser Type [nm/µm] | Laser Parameters: Powers/Energies [W/J], Spots [], Ind. Temps [K] | Refs |

|---|---|---|---|---|---|---|

| Ar, Shocked States | Ar | ≈7.8 | 28 | A Pulsed laser ≈ 300 ps, 800 nm center λ, 25 nm bandwidth pulse | ≈100–300 μJ, 20 μm to 50 μm, 298 K | [24] |

| C6H6, Phase transitions, Structures | C6H6 | N/A | 4.6 | Nd: YAG laser, 1064 nm | a: 0.7 J, 9–108 ns b: 0.1–1.3 J, 52 ns ≈2 J/7 ns, 1800 μm, 300 K | [32] |

| CO2, EOS | CO2 | 1.16 | 1000 | Nd:glass laser, 351 nm | 8 × 1014 W/cm2, 93 × 103 K | [27] |

| CO2, Sound velocity | CO2 | 0.36–1.16 | 800 | Nd:glass laser, 351 nm | 480 J/beam = 5670 J, 1.2–10 × 1014 W/cm2, 1 ns, 865 μm, 298 K | [46] |

| SiO2, EOS | SiO2 | 5 | 100 | Nd:glass laser, 351 nm | Pulsed, ≈5–25 ns, 1–6 kJ, 800 µm, 104 K | [59] |

| Al, Hugoniot Curves | Al | ≈50 | ≈200 | Pulsed laser | Pulsed, 1–2 ns, 1014 W/cm2, ≈500 μm | [58] |

| CsCl-type MgO, EOS, Structure | NaCl-type MgO | ≈60 | 600 to 900 | Nd:glass laser, 351 nm | ≈4.5 ns, up to 37 kJ UV, ≈300 μm, 4–9 × 103 K | [30] |

| Fe, Sn, Ta, Pb, and MgO, Structure | Fe, Sn, Ta, Pb, and MgO | N/A | 900 | Temporally shaped laser pulse | 1014 W/cm2, 800 μm, 300 K | [49] |

| Al, Ta, and W, Sound velocity Hugoniot Curves | Al, Ta, and W | N/A | 220 | Pulsed laser | Pulsed, 1–2 ns, 1014 W/cm2, ≈500 μm, 298 K | [73] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alabdulkarim, M.E.; Maxwell, W.D.; Thapliyal, V.; Maxwell, J.L. A Comprehensive Review of High-Pressure Laser-Induced Materials Processing, Part II: Laser-Driven Dynamic Compression within Diamond Anvil Cells. J. Manuf. Mater. Process. 2022, 6, 142. https://doi.org/10.3390/jmmp6060142

Alabdulkarim ME, Maxwell WD, Thapliyal V, Maxwell JL. A Comprehensive Review of High-Pressure Laser-Induced Materials Processing, Part II: Laser-Driven Dynamic Compression within Diamond Anvil Cells. Journal of Manufacturing and Materials Processing. 2022; 6(6):142. https://doi.org/10.3390/jmmp6060142

Chicago/Turabian StyleAlabdulkarim, Mohamad E., Wendy D. Maxwell, Vibhor Thapliyal, and James L. Maxwell. 2022. "A Comprehensive Review of High-Pressure Laser-Induced Materials Processing, Part II: Laser-Driven Dynamic Compression within Diamond Anvil Cells" Journal of Manufacturing and Materials Processing 6, no. 6: 142. https://doi.org/10.3390/jmmp6060142

APA StyleAlabdulkarim, M. E., Maxwell, W. D., Thapliyal, V., & Maxwell, J. L. (2022). A Comprehensive Review of High-Pressure Laser-Induced Materials Processing, Part II: Laser-Driven Dynamic Compression within Diamond Anvil Cells. Journal of Manufacturing and Materials Processing, 6(6), 142. https://doi.org/10.3390/jmmp6060142