Tribological Behavior of Additively Manufactured Metal Components

Abstract

:1. Introduction

2. Metal AM Methods

3. Materials of Interest for AM and Their Mechanical Properties

4. Tribological Behavior of AM Components

5. Post-Processing of AM Components to Improve the Tribological Performance

6. Outlook and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ralls, A.M.; Kumar, P.; Menezes, P.L. Tribological Properties of Additive Manufactured Materials for Energy Applications: A Review. Processes 2021, 9, 31. [Google Scholar] [CrossRef]

- Hashemi, S.M.; Parvizi, S.; Baghbanijavid, H.; Tan, A.T.L.; Nematollahi, M.; Ramazani, A.; Fang, N.X.; Elahinia, M. Computational modelling of process–structure–property–performance relationships in metal additive manufacturing: A review. Int. Mater. Rev. 2022, 67, 1–46. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Guan, K.; Wang, Z.; Gao, M.; Li, X.; Zeng, X. Effects of processing parameters on tensile properties of selective laser melted 304 stainless steel. Mater. Des. (1980–2015) 2013, 50, 581–586. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; van Humbeeck, J.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Kanagarajah, P.; Brenne, F.; Niendorf, T.; Maier, H.J. Inconel 939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading. Mater. Sci. Eng. A 2013, 588, 188–195. [Google Scholar] [CrossRef]

- Kumar, S.; Pityana, S. Laser-Based Additive Manufacturing of Metals. AMR 2011, 227, 92–95. [Google Scholar] [CrossRef]

- Kumar, S. Selective laser sintering: Recent advances. In Proceedings of the Pacific International Conference on Applications of Lasers and Optics, PICALO 2010: 4th Pacific International Conference on Laser Materials Processing, Micro, Nano and Ultrafast Fabrication, Wuhan, China, 23–25 March 2010; Laser Institute of America: Orlando, FL, USA, 2010; p. 607. ISBN 978-0-912035-56-7. [Google Scholar]

- Khan, M.; Dickens, P. Selective Laser Melting (SLM) of pure gold. Gold Bull. 2010, 43, 114–121. [Google Scholar] [CrossRef] [Green Version]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Matilainen, V.; Piili, H.; Salminen, A.; Syvänen, T.; Nyrhilä, O. Characterization of Process Efficiency Improvement in Laser Additive Manufacturing. Phys. Procedia 2014, 56, 317–326. [Google Scholar] [CrossRef] [Green Version]

- Qian, M.; Xu, W.; Brandt, M.; Tang, H.P. Additive manufacturing and postprocessing of Ti-6Al-4V for superior mechanical properties. MRS Bull. 2016, 41, 775–784. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Zhou, H.; Wang, C.; Zhou, L.; Yuan, S.; Zhang, W. A review of topology optimization for additive manufacturing: Status and challenges. Chin. J. Aeronaut. 2021, 34, 91–110. [Google Scholar] [CrossRef]

- Bourell, D.L.; Rosen, D.W.; Leu, M.C. The Roadmap for Additive Manufacturing and Its Impact. 3D Print. Addit. Manuf. 2014, 1, 6–9. [Google Scholar] [CrossRef]

- Frazier, W.E. Direct Digital Manufacturing of Metallic Components: Vision and Roadmap. In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 2010. [Google Scholar] [CrossRef]

- Campbell, I.; Bourell, D.; Gibson, I. Additive manufacturing: Rapid prototyping comes of age. Rapid Prototyp. J. 2012, 18, 255–258. [Google Scholar] [CrossRef] [Green Version]

- Kruth, J.-P.; Levy, G.; Klocke, F.; Childs, T. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann.-Manuf. Technol. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Cáceres, C.H.; Davidson, C.J.; Griffiths, J.R. The deformation and fracture behaviour of an AlSiMg casting alloy. Mater. Sci. Eng. A 1995, 197, 171–179. [Google Scholar] [CrossRef]

- Atzeni, E.; Salmi, A. Economics of additive manufacturing for end-usable metal parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- GE Additive. What Is Additive Manufacturing? Available online: https://www.ge.com/additive/additive-manufacturing (accessed on 22 September 2022).

- Brecher, C. Integrative Production Technology for High-Wage Countries; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-642-21066-2. [Google Scholar]

- Brandt, M. (Ed.) Laser Additive Manufacturing: Materials, Design, Technologies, and Applications; Elsevier/Woodhead Publishing (Woodhead Publishing is an imprint of Elsevier): Amsterdam, The Netherlands, 2017; ISBN 9780081004340. [Google Scholar]

- Zhang, S.; Wei, Q.; Cheng, L.; Li, S.; Shi, Y. Effects of scan line spacing on pore characteristics and mechanical properties of porous Ti6Al4V implants fabricated by selective laser melting. Mater. Des. (1980–2015) 2014, 63, 185–193. [Google Scholar] [CrossRef]

- Khaing, M.; Fuh, J.; Lu, L. Direct metal laser sintering for rapid tooling: Processing and characterisation of EOS parts. J. Mater. Process. Technol. 2001, 113, 269–272. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Shah, R.; Gashi, B.; Hoque, S.; Marian, M.; Rosenkranz, A. Enhancing mechanical and biomedical properties of protheses-Surface and material design. Surf. Interfaces 2021, 27, 101498. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Kelly, S.M.; Kampe, S.L. Microstructural evolution in laser-deposited multilayer Ti-6Al-4V builds: Part II. Thermal modeling. Met. Mat. Trans. A 2004, 35, 1869–1879. [Google Scholar] [CrossRef]

- Wang, P.; Nai, M.L.S.; Sin, W.J.; Wei, J. Effect of Building Height on Microstructure and Mechanical Properties of Big-Sized Ti-6Al-4V Plate Fabricated by Electron Beam Melting. MATEC Web Conf. 2015, 30, 2001. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Xu, J.; Jin, Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8, 221–300. [Google Scholar] [CrossRef]

- Zhu, Y.; Tian, X.; Li, J.; Wang, H. The anisotropy of laser melting deposition additive manufacturing Ti–6.5Al–3.5Mo–1.5Zr–0.3Si titanium alloy. Mater. Des. (1980–2015) 2015, 67, 538–542. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Tallman, C.; Duty, C.E.; Peter, W.H.; Yamamoto, Y.; Chen, W.; Blue, C.A. Case Study: Additive Manufacturing of Aerospace Brackets. Adv. Mater. Processes 2013, 171, 3. [Google Scholar]

- Patel, J.K.; Wilshire, B. The challenge to produce consistent mechanical properties in Nb-HSLA strip steels. J. Mater. Process. Technol. 2002, 120, 316–321. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Ur Rahman, N.; Matthews, D.T.A.; de Rooij, M.; Khorasani, A.M.; Gibson, I.; Cordova, L.; Römer, G. An Overview: Laser-Based Additive Manufacturing for High Temperature Tribology. Front. Mech. Eng. 2019, 5, 16. [Google Scholar] [CrossRef]

- Shah, R.; Woydt, M.; Huq, N.; Rosenkranz, A. Tribology meets sustainability. Ind Lubr. Tribol. 2021, 73, 430–435. [Google Scholar] [CrossRef]

- Special Issue on Tribology of Additive Manufacturing. J. Tribol. Trans. ASME 2021, 143, 05021. [CrossRef]

- Rao, B.S.; Rao, T.B. Mechanical and Tribological Properties of 3D printed Al-Si alloys and composites: A Review. Silicon 2022, 14, 5751–5782. [Google Scholar] [CrossRef]

- F42 Committee. Terminology for Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Kruth, J.-P.; Mercelis, P.; van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef] [Green Version]

- Panda, B.K.; Sahoo, S. Thermo-mechanical modeling and validation of stress field during laser powder bed fusion of AlSi10Mg built part. Results Phys. 2019, 12, 1372–1381. [Google Scholar] [CrossRef]

- Asgharzadeh, H.; Simchi, A. Effect of sintering atmosphere and carbon content on the densification and microstructure of laser-sintered M2 high-speed steel powder. Mater. Sci. Eng. A 2005, 403, 290–298. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Robert, P.M.; Nick, W. Laser engineered net shaping advances additive manufacturing and repair. Weld. J. 2007, 86, 44–48. [Google Scholar]

- Xue, L. Laser Consolidation-A One-Step Manufacturing Process for Making Net-Shaped Functional Aerospace Components. In SAE Technical Paper Series; Aerospace Manufacturing and Automated Fastening Conference and Exhibition, 11 September 2006; SAE International400 Commonwealth Drive: Warrendale, PA, USA, 2006. [Google Scholar]

- Li, Y.; Su, C.; Zhu, J. Comprehensive review of wire arc additive manufacturing: Hardware system, physical process, monitoring, property characterization, application and future prospects. Results Eng. 2022, 13, 100330. [Google Scholar] [CrossRef]

- Bi, X.; Li, R.; Hu, Z.; Gu, J.; Jiao, C. Microstructure and Texture of 2205 Duplex Stainless Steel Additive Parts Fabricated by the Cold Metal Transfer (CMT) Wire and Arc Additive Manufacturing (WAAM). Metals 2022, 12, 1655. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, G.; Peng, J.; Yu, Y.; Zhou, J. Path Generation Strategy and Wire Arc Additive Manufacturing of Large Aviation Die with Complex Gradient Structure. Materials 2022, 15, 6115. [Google Scholar] [CrossRef]

- Yu, Y.; Qu, Z.; Zhang, J.; Zhou, J. Influence of Surfacing Fe-Based Alloy Layers on Wire Arc Additive Manufactured Ni-Based Superalloys Material on Its Microstructure and Wear Properties. Materials 2022, 15, 6020. [Google Scholar] [CrossRef] [PubMed]

- Sales, A.; Kotousov, A.; Perilli, E.; Yin, L. Improvement of the Fatigue Resistance of Super Duplex Stainless-Steel (SDSS) Components Fabricated by Wire Arc Additive Manufacturing (WAAM). Metals 2022, 12, 1548. [Google Scholar] [CrossRef]

- Pinkerton, A.J. Laser direct metal deposition: Theory and applications in manufacturing and maintenance. In Advances in Laser Materials Processing; Elsevier: Amsterdam, The Netherlands, 2010; pp. 461–491. ISBN 9781845694746. [Google Scholar]

- Nasiri, M.T.; Movahhedy, M.R. A new design of continuous coaxial nozzle for direct metal deposition process to overcome the gravity effect. Prog. Addit. Manuf. 2022, 7, 173–186. [Google Scholar] [CrossRef]

- Caiazzo, F.; Caggiano, A. Laser Direct Metal Deposition of 2024 Al Alloy: Trace Geometry Prediction via Machine Learning. Materials 2018, 11, 444. [Google Scholar] [CrossRef] [Green Version]

- Samodurova, M.; Logachev, I.; Shaburova, N.; Samoilova, O.; Radionova, L.; Zakirov, R.; Pashkeev, K.; Myasoedov, V.; Trofimov, E. A Study of the Structural Characteristics of Titanium Alloy Products Manufactured Using Additive Technologies by Combining the Selective Laser Melting and Direct Metal Deposition Methods. Materials 2019, 12, 3269. [Google Scholar] [CrossRef] [Green Version]

- Erdakov, I.; Glebov, L.; Pashkeev, K.; Bykov, V.; Bryk, A.; Lezin, V.; Radionova, L. Effect of the Ti6Al4V Alloy Track Trajectories on Mechanical Properties in Direct Metal Deposition. Machines 2020, 8, 79. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal Alloys for Fusion-Based Additive Manufacturing. Adv. Eng. Mater. 2018, 20, 1700952. [Google Scholar] [CrossRef]

- Kumar, P.; Chandran, K.S.R. Strength–Ductility Property Maps of Powder Metallurgy (PM) Ti-6Al-4V Alloy: A Critical Review of Processing-Structure-Property Relationships. Met. Mat. Trans. A 2017, 48, 2301–2319. [Google Scholar] [CrossRef]

- Shi, X.; Lu, P.; Ye, X.; Ren, S.; Wang, Y.; Xie, Z.; Ma, Y.; Miao, X.; Wu, M. Study of mechanical and tribological properties of Ti–6Al–4V alloy fabricated by powder bed fusion laser beam. Powder Metall. 2022, 1–13. [Google Scholar] [CrossRef]

- Alvi, S.; Neikter, M.; Antti, M.-L.; Akhtar, F. Tribological performance of Ti6Al4V at elevated temperatures fabricated by electron beam powder bed fusion. Tribol. Int. 2021, 153, 106658. [Google Scholar] [CrossRef]

- Todai, M.; Nakano, T.; Liu, T.; Yasuda, H.Y.; Hagihara, K.; Cho, K.; Ueda, M.; Takeyama, M. Effect of building direction on the microstructure and tensile properties of Ti-48Al-2Cr-2Nb alloy additively manufactured by electron beam melting. Addit. Manuf. 2017, 13, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Lu, S.; Tang, H.; Qian, M.; Hong, Q.; Zeng, L.; StJohn, D.H. A yttrium-containing high-temperature titanium alloy additively manufactured by selective electron beam melting. J. Cent. South Univ. 2015, 22, 2857–2863. [Google Scholar] [CrossRef]

- Shen, S.; Wang, H.; He, B.; Zhang, S. Microstructure evolution and phase transformation behavior of Ti17 and γ-TiAl bimetallic structure fabricated by directed energy deposition. J. Alloys Compd. 2022, 907, 164571. [Google Scholar] [CrossRef]

- Khorev, A.I. Complex alloying and microalloying of titanium alloys. Weld. Int. 2011, 25, 56–63. [Google Scholar] [CrossRef]

- Zhu, Z.G.; An, X.H.; Lu, W.J.; Li, Z.M.; Ng, F.L.; Liao, X.Z.; Ramamurty, U.; Nai, S.M.L.; Wei, J. Selective laser melting enabling the hierarchically heterogeneous microstructure and excellent mechanical properties in an interstitial solute strengthened high entropy alloy. Mater. Res. Lett. 2019, 7, 453–459. [Google Scholar] [CrossRef] [Green Version]

- Qiu, Y.; Gibson, M.A.; Fraser, H.L.; Birbilis, N. Corrosion characteristics of high entropy alloys. Mater. Sci. Technol. 2015, 31, 1235–1243. [Google Scholar] [CrossRef]

- Huang, K.J.; Wang, Y.Y.; Lin, X. Microstructure and Wear Resistance of Cu0.9NiAlCoCrFe High Entropy Alloy Coating on AZ91D Magnesium Alloys by Laser Cladding. AMR 2014, 989–994, 246–250. [Google Scholar] [CrossRef]

- Prabu, G.; Duraiselvam, M.; Jeyaprakash, N.; Yang, C.-H. Microstructural Evolution and Wear Behavior of AlCoCrCuFeNi High Entropy Alloy on Ti–6Al–4V Through Laser Surface Alloying. Met. Mater. Int. 2021, 27, 2328–2340. [Google Scholar] [CrossRef]

- Rathod, H.J.; Nagaraju, T.; Prashanth, K.G.; Ramamurty, U. Tribological properties of selective laser melted Al 12Si alloy. Tribol. Int. 2019, 137, 94–101. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Debalina, B.; Wang, Z.; Gostin, P.F.; Gebert, A.; Calin, M.; Kühn, U.; Kamaraj, M.; Scudino, S.; Eckert, J. Tribological and corrosion properties of Al–12Si produced by selective laser melting. J. Mater. Res. 2014, 29, 2044–2054. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Elambasseril, J.; McMillan, M.; Chirent, T.; Sun, Y.; Qian, M.; Easton, M.; Brandt, M. Selective laser melting (SLM) of AlSi12Mg lattice structures. Mater. Des. 2016, 98, 344–357. [Google Scholar] [CrossRef]

- Li, Y.; Shi, Y. Microhardness, wear resistance, and corrosion resistance of AlxCrFeCoNiCu high-entropy alloy coatings on aluminum by laser cladding. Opt. Laser Technol. 2021, 134, 106632. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, J.; Luo, Z.-Y.; Wang, D. Accuracy and density optimization in directly fabricating customized orthodontic production by selective laser melting. Rapid Prototyp. J. 2012, 18, 482–489. [Google Scholar] [CrossRef]

- Carlton, H.D.; Haboub, A.; Gallegos, G.F.; Parkinson, D.Y.; MacDowell, A.A. Damage evolution and failure mechanisms in additively manufactured stainless steel. Mater. Sci. Eng. A 2016, 651, 406–414. [Google Scholar] [CrossRef] [Green Version]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 41101. [Google Scholar] [CrossRef]

- Ren, Y.; Liang, L.; Shan, Q.; Cai, A.; Du, J.; Huang, Q.; Liu, S.; Yang, X.; Tian, Y.; Wu, H. Effect of volumetric energy density on microstructure and tribological properties of FeCoNiCuAl high-entropy alloy produced by laser powder bed fusion. Virtual Phys. Prototyp. 2020, 15, 543–554. [Google Scholar] [CrossRef]

- Liu, H.; Sun, S.; Zhang, T.; Zhang, G.; Yang, H.; Hao, J. Effect of Si addition on microstructure and wear behavior of AlCoCrFeNi high-entropy alloy coatings prepared by laser cladding. Surf. Coat. Technol. 2021, 405, 126522. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, J.; Lin, X.; Huang, W. Study on microstructure and mechanical properties of laser rapid forming Inconel 718. Mater. Sci. Eng. A 2008, 478, 119–124. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Strondl, A.; Palm, M.; Gnauk, J.; Frommeyer, G. Microstructure and mechanical properties of nickel based superalloy IN718 produced by rapid prototyping with electron beam melting (EBM). Mater. Sci. Technol. 2011, 27, 876–883. [Google Scholar] [CrossRef]

- Saunders, M. How Process Parameters Drive Successful Metal AM Part Production, Metal Additive Manufacturing. Available online: https://www.metal-am.com/articles/70927-2/ (accessed on 22 September 2022).

- Bandyopadhyay, A.; Traxel, K.D. Invited Review Article: Metal-additive manufacturing-Modeling strategies for application-optimized designs. Addit. Manuf. 2018, 22, 758–774. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Y.F. Process parameters optimization for improving surface quality and manufacturing accuracy of binder jetting additive manufacturing process. Rapid Prototyp. J. 2016, 22, 527–538. [Google Scholar] [CrossRef]

- Dehoff, R.R.; Kirka, M.M.; Sames, W.J.; Bilheux, H.; Tremsin, A.S.; Lowe, L.E.; Babu, S.S. Site specific control of crystallographic grain orientation through electron beam additive manufacturing. Mater. Sci. Technol. 2015, 31, 931–938. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Zhao, S.; Yuan, K.; Guo, W.; He, Y.; Xu, Y.; Lin, X. A comparative study of laser metal deposited and forged Ti-6Al-4V alloy: Uniaxial mechanical response and vibration fatigue properties. Int. J. Fatigue 2020, 136, 105629. [Google Scholar] [CrossRef]

- Gratton, A. Comparison of Mechanical, Metallurgical Properties of 17-4PH Stainless Steel between Direct Metal Laser Sintering (DMLS) and Traditional Manufacturing Methods. In Proceedings of the National Conference of Undergraduate Research 2012, Ogden, UT, USA, 29–31 March 2012. [Google Scholar]

- Shellabear, M.; Nyrhila, O. Advances in Materials and Properties of Direct Metal Laser-Sintered Parts. Available online: https://rm-platform.com/downloads2/send/5-papers/255-paper-lane-2007-eos-shellabear (accessed on 24 September 2022).

- Jawade, S.A.; Joshi, R.; Desai, S.B. Comparative study of mechanical properties of additively manufactured aluminum alloy. Mater. Today Proc. 2021, 46, 9270–9274. [Google Scholar] [CrossRef]

- Laleh, M.; Hughes, A.E.; Yang, S.; Li, J.; Xu, W.; Gibson, I.; Tan, M.Y. Two and three-dimensional characterisation of localised corrosion affected by lack-of-fusion pores in 316L stainless steel produced by selective laser melting. Corros. Sci. 2020, 165, 108394. [Google Scholar] [CrossRef]

- Du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of defects on mechanical properties in metal additive manufacturing: A review focusing on X-ray tomography insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Mandal, A.; Tiwari, J.K.; AlMangour, B.; Sathish, N.; Kumar, S.; Kamaraj, M.; Ashiq, M.; Srivastava, A.K. Tribological behavior of graphene-reinforced 316L stainless-steel composite prepared via selective laser melting. Tribol. Int. 2020, 151, 106525. [Google Scholar] [CrossRef]

- Upadhyay, R.K.; Kumar, A. Scratch and wear resistance of additive manufactured 316L stainless steel sample fabricated by laser powder bed fusion technique. Wear 2020, 458–459, 203437. [Google Scholar] [CrossRef]

- Eliasu, A.; Duntu, S.H.; Hukpati, K.S.; Amegadzie, M.Y.; Agyapong, J.; Tetteh, F.; Czekanski, A.; Boakye-Yiadom, S. Effect of individual printing parameters on residual stress and tribological behaviour of 316L stainless steel fabricated with laser powder bed fusion (L-PBF). Int. J. Adv. Manuf. Technol. 2022, 119, 7041–7061. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Lim, D.; Chen, Y.; Yang, S.; Gao, N. Tribological behaviour of 316L stainless steel additively manufactured by laser powder bed fusion and processed via high-pressure torsion. J. Mater. Process. Technol. 2021, 290, 116985. [Google Scholar] [CrossRef]

- Yasa, E.; Ay, G.M.; Türkseven, A. Tribological and mechanical behavior of AISI 316L lattice-supported structures produced by laser powder bed fusion. Int. J. Adv. Manuf. Technol. 2022, 118, 1733–1748. [Google Scholar] [CrossRef]

- Li, H.; Ramezani, M.; Li, M.; Ma, C.; Wang, J. Effect of process parameters on tribological performance of 316L stainless steel parts fabricated by selective laser melting. Manuf. Lett. 2018, 16, 36–39. [Google Scholar] [CrossRef]

- Alvi, S.; Saeidi, K.; Akhtar, F. High temperature tribology and wear of selective laser melted (SLM) 316L stainless steel. Wear 2020, 448–449, 203228. [Google Scholar] [CrossRef]

- Bartolomeu, F.; Buciumeanu, M.; Pinto, E.; Alves, N.; Carvalho, O.; Silva, F.S.; Miranda, G. 316L stainless steel mechanical and tribological behavior—A comparison between selective laser melting, hot pressing and conventional casting. Addit. Manuf. 2017, 16, 81–89. [Google Scholar] [CrossRef]

- Li, H.; Ramezani, M.; Li, M.; Ma, C.; Wang, J. Tribological performance of selective laser melted 316L stainless steel. Tribol. Int. 2018, 128, 121–129. [Google Scholar] [CrossRef]

- Zhu, Y.; Zou, J.; Chen, X.; Yang, H. Tribology of selective laser melting processed parts: Stainless steel 316 L under lubricated conditions. Wear 2016, 350–351, 46–55. [Google Scholar] [CrossRef]

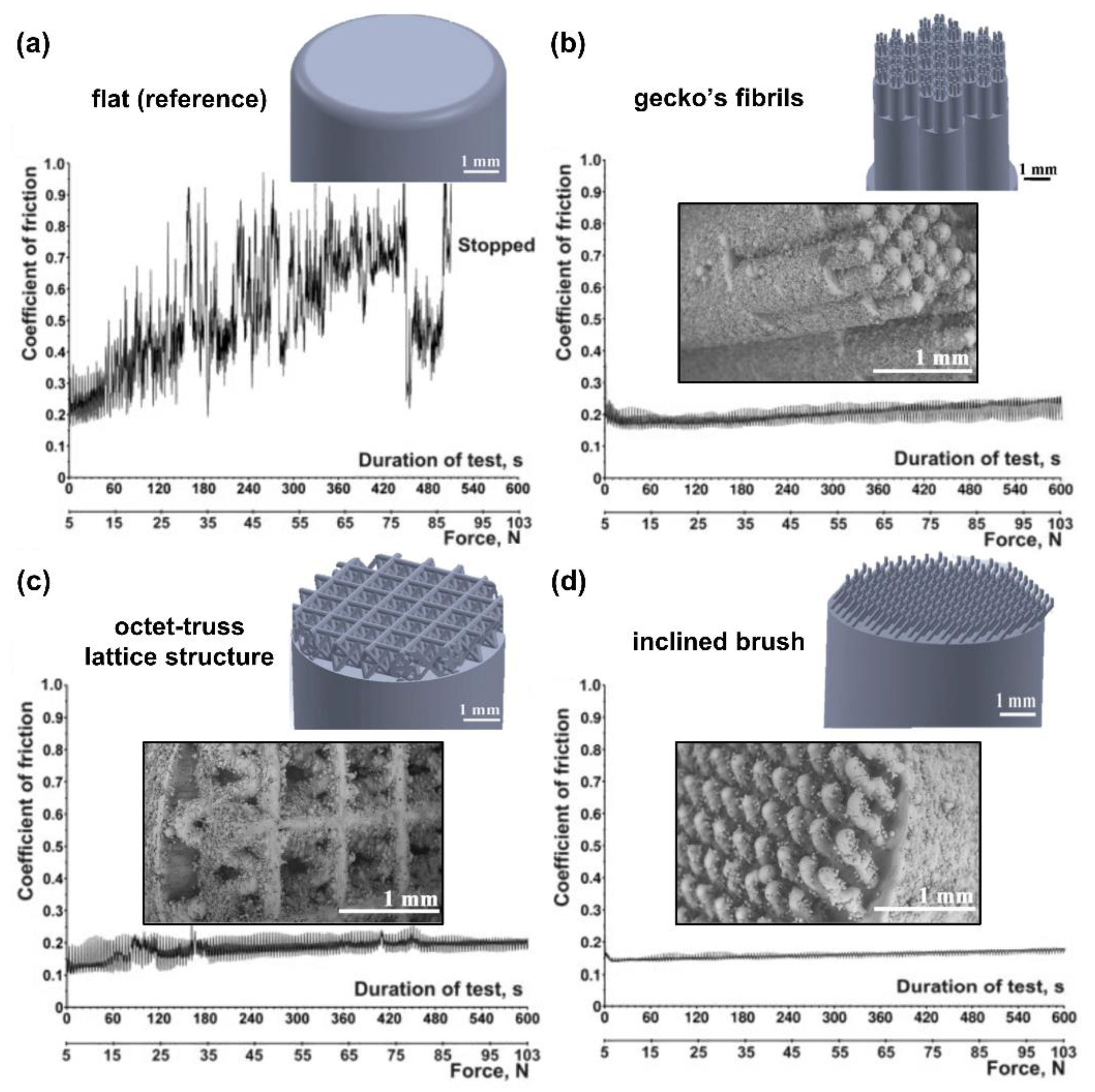

- Holovenko, Y.; Antonov, M.; Kollo, L.; Hussainova, I. Friction studies of metal surfaces with various 3D printed patterns tested in dry sliding conditions. Proc. IMechE 2018, 232, 43–53. [Google Scholar] [CrossRef] [Green Version]

- Lester, S.; Longfield, N.; Griffiths, J.; Cocker, J.; Staudenmaier, C.; Broadhead, G. New Systems for Laser Cladding. LTJ 2013, 10, 41–43. [Google Scholar] [CrossRef]

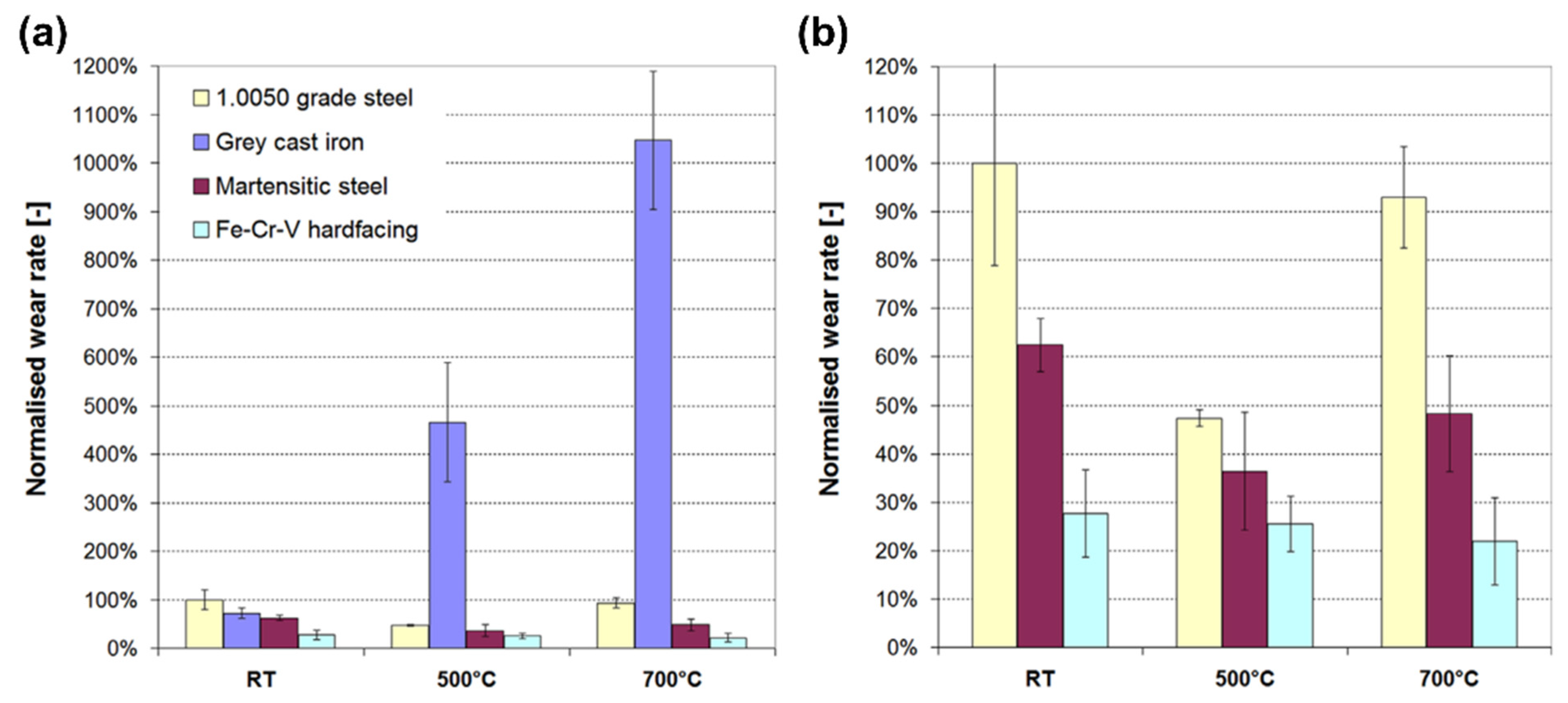

- Torres, H.; Varga, M.; Widder, F.; Cihak-Bayr, U.; Viskovic, O.; Ripoll, M.R. Experimental simulation of high temperature sliding contact of hot rolled steel. Tribol. Int. 2016, 93, 745–754. [Google Scholar] [CrossRef]

- Torres, H.; Varga, M.; Adam, K.; Ripoll, M.R. The role of load on wear mechanisms in high temperature sliding contacts. Wear 2016, 364–365, 73–83. [Google Scholar] [CrossRef]

- Sheng, W.; Liu, D.; Wang, H.M. Microstructure and high-temperature wear behavior of laser clad Ni–Ti–Si ternary metal silicide coatings. Surf. Coat. Technol. 2008, 202, 2871–2877. [Google Scholar] [CrossRef]

- Silva, R.G.N.; Pereira, A.d.S.P.; de Sousa, J.M.S.; Pereira, M.; Silva, R.H.G.e. Tribological comparison of Inconel 625 coatings deposited via laser metal deposition and tungsten inert gas welding process. J. Laser Appl. 2020, 32, 22034. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Smurov, I. Surface Morphology in Selective Laser Melting of Metal Powders. Phys. Procedia 2011, 12, 264–270. [Google Scholar] [CrossRef] [Green Version]

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2021, 37, 101619. [Google Scholar] [CrossRef]

- Pyka, G.; Kerckhofs, G.; Papantoniou, I.; Speirs, M.; Schrooten, J.; Wevers, M. Surface Roughness and Morphology Customization of Additive Manufactured Open Porous Ti6Al4V Structures. Materials 2013, 6, 4737–4757. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Scherillo, F. Chemical surface finishing of AlSi10Mg components made by additive manufacturing. Manuf. Lett. 2019, 19, 5–9. [Google Scholar] [CrossRef]

- Wysocki, B.; Idaszek, J.; Buhagiar, J.; Szlązak, K.; Brynk, T.; Kurzydłowski, K.J.; Święszkowski, W. The influence of chemical polishing of titanium scaffolds on their mechanical strength and in-vitro cell response. Mater. Sci. Eng. C Mater. Biol. Appl. 2019, 95, 428–439. [Google Scholar] [CrossRef]

- Worts, N.; Jones, J.; Squier, J. Surface structure modification of additively manufactured titanium components via femtosecond laser micromachining. Opt. Commun. 2019, 430, 352–357. [Google Scholar] [CrossRef]

- Hackel, L.; Rankin, J.R.; Rubenchik, A.; King, W.E.; Matthews, M. Laser peening: A tool for additive manufacturing post-processing. Addit. Manuf. 2018, 24, 67–75. [Google Scholar] [CrossRef]

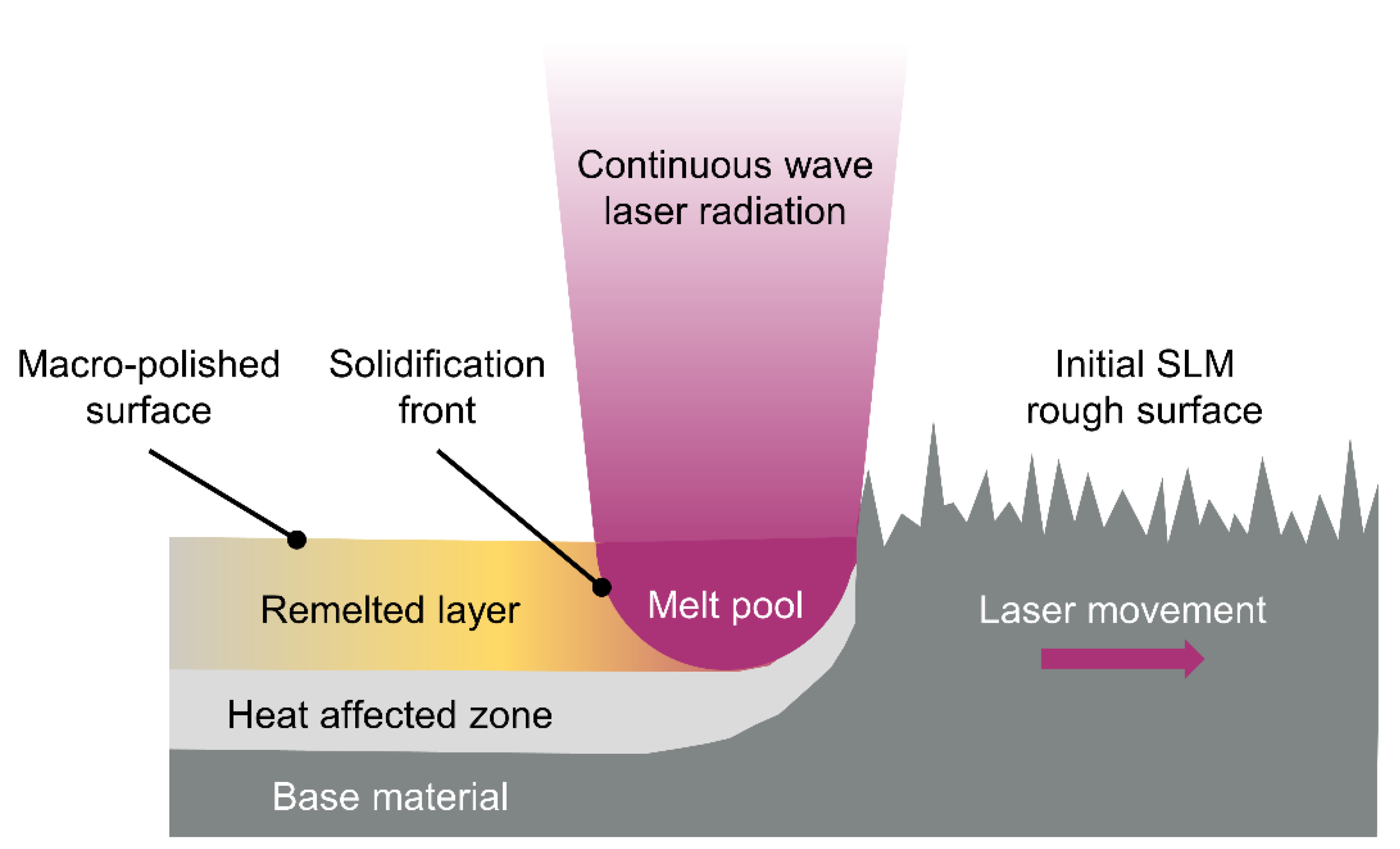

- Hofele, M.; Schanz, J.; Roth, A.; Harrison, D.K.; de Silva, A.; Riegel, H. Process parameter dependencies of continuous and pulsed laser modes on surface polishing of additive manufactured aluminium AlSi10Mg parts. Mat.-Wiss. U. Werkstofftech. 2021, 52, 409–432. [Google Scholar] [CrossRef]

- Balachandramurthi, A.R.; Moverare, J.; Dixit, N.; Pederson, R. Influence of defects and as-built surface roughness on fatigue properties of additively manufactured Alloy 718. Mater. Sci. Eng. A 2018, 735, 463–474. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti–6Al–4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

- Spierings, A.B.; Starr, T.L.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Sagbas, B. Post-Processing Effects on Surface Properties of Direct Metal Laser Sintered AlSi10Mg Parts. Met. Mater. Int. 2020, 26, 143–153. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Martina, F.; Roy, M.J.; Szost, B.A.; Terzi, S.; Williams, S.W.; Withers, P.J.; Jarvis, D. High Pressure Interpass Rolling of Wire + Arc Additively Manufactured Titanium Components. AMR 2014, 996, 694–700. [Google Scholar] [CrossRef] [Green Version]

- Martina, F.; Roy, M.J.; Szost, B.A.; Terzi, S.; Colegrove, P.A.; Williams, S.W.; Withers, P.J.; Meyer, J.; Hofmann, M. Residual stress of as-deposited and rolled wire+arc additive manufacturing Ti–6Al–4V components. Mater. Sci. Technol. 2016, 32, 1439–1448. [Google Scholar] [CrossRef] [Green Version]

- McAndrew, A.R.; Rosales, M.A.; Colegrove, P.A.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire + arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Donoghue, J.; Antonysamy, A.A.; Martina, F.; Colegrove, P.A.; Williams, S.W.; Prangnell, P.B. The effectiveness of combining rolling deformation with Wire–Arc Additive Manufacture on β-grain refinement and texture modification in Ti–6Al–4V. Mater. Charact. 2016, 114, 103–114. [Google Scholar] [CrossRef]

- Ye, C.; Zhang, C.; Zhao, J.; Dong, Y. Effects of Post-processing on the Surface Finish, Porosity, Residual Stresses, and Fatigue Performance of Additive Manufactured Metals: A Review. J. Mater. Eng. Perform. 2021, 30, 6407–6425. [Google Scholar] [CrossRef]

| System | Advantages | Disadvantages |

|---|---|---|

| Selective Laser Melting |

|

|

| Direct Metal Laser Sintering |

|

|

| Direct Energy Deposition/Laser Cladding |

|

|

| Wire arc additive manufacturing |

|

|

| Laser direct metal deposition |

|

|

| Post-Processing Method | Effect on Surface Finish | Effect on Porosity | Microstructure Changes |

|---|---|---|---|

| Laser polishing | Improves surface finish | Decreases porosity in the near-surface region | Refines the grains |

| Heat treatment | n/a | n/a | Decreases defect density and increases microstructure stability |

| Hot isostatic pressing | Increases surface roughness | n/a | Produces refined grains and high-density dislocations |

| Laser shock and shot peening | Increases surface roughness | n/a | Refines the grains |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, R.; Pai, N.; Rosenkranz, A.; Shirvani, K.; Marian, M. Tribological Behavior of Additively Manufactured Metal Components. J. Manuf. Mater. Process. 2022, 6, 138. https://doi.org/10.3390/jmmp6060138

Shah R, Pai N, Rosenkranz A, Shirvani K, Marian M. Tribological Behavior of Additively Manufactured Metal Components. Journal of Manufacturing and Materials Processing. 2022; 6(6):138. https://doi.org/10.3390/jmmp6060138

Chicago/Turabian StyleShah, Raj, Nikhil Pai, Andreas Rosenkranz, Khosro Shirvani, and Max Marian. 2022. "Tribological Behavior of Additively Manufactured Metal Components" Journal of Manufacturing and Materials Processing 6, no. 6: 138. https://doi.org/10.3390/jmmp6060138

APA StyleShah, R., Pai, N., Rosenkranz, A., Shirvani, K., & Marian, M. (2022). Tribological Behavior of Additively Manufactured Metal Components. Journal of Manufacturing and Materials Processing, 6(6), 138. https://doi.org/10.3390/jmmp6060138