Experimental Investigations and Optimization of Machining Parameters in CNC Turning of SS304 Using Coolant at 0 °C

Abstract

1. Introduction

2. Experimental Setup

2.1. Machine, Material, and Tooling Arrangements

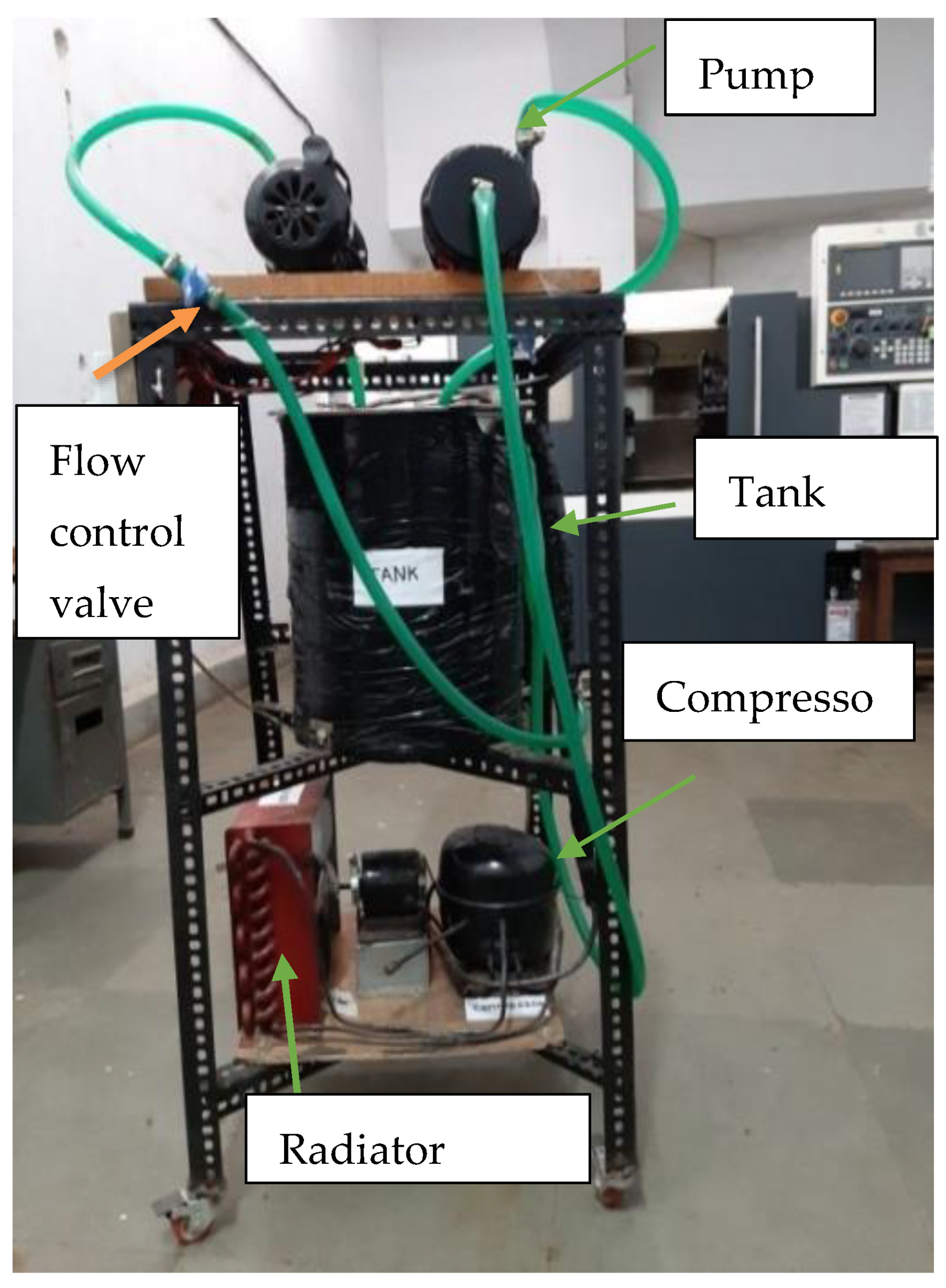

2.2. Refrigeration System

3. Research Methodology

3.1. Design of Experiment

3.2. Weight Assigning Using the Analytic Hierarchy Process (AHP)

3.3. Multi-Objective Optimization Using the TOPSIS Approach

3.4. Multi-Objective Optimization Using the GRG Technique

4. Results and Discussion

4.1. Verification of Results and Effectiveness of Low-Temperature Machining

4.2. Tool Wear Rate

4.3. Impact of Input Cutting Parameters on Surface Roughness

4.4. Chips Morphology

5. Conclusions

- The research work suggests that the parameters used on the turning CNC lathe for machining SS304 may be replaced with the recommended parameters, if possible, (machining with coolant at 0 °C, cutting velocity at 78 m/min, feed rate at 300 mm/min, and depth of cut at 1.0 mm), which will result in improvements in the tool life, surface finish, and material removal rate for the given machine conditions.

- The recommended input parameters are based on optimizing the input parameters and are duly verified by the TOPSIS and GRG preferential ranking techniques.

- Based on the examinations of the SEM images, it is verified physically that there is a considerable reduction in tool wear with the suggested input parameters compared with the conventional or traditional parameters currently being used.

- ANOVA revealed that temperature, cutting velocity, feed rate, and depth of cut have more significance as per their serial order mentioned above on machining of SS304.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bruschi, S.; Pezzato, L.; Ghiotti, A.; Dabalà, M.; Bertolini, R. Effectiveness of using low-temperature coolants in machining to enhance durability of AISI 316L stainless steel for reusable biomedical devices. J. Manuf. Process. 2019, 39, 295–304. [Google Scholar] [CrossRef]

- Venkatesh, V.; Swain, N.; Srinivas, G.; Kumar, P.; Barshilia, H. Review on the machining characteristics and research prospects of conventional microscale machining operations. Mater. Manuf. Process. 2016, 32, 235–262. [Google Scholar] [CrossRef]

- Tahmasebi, E.; Albertelli, P.; Lucchini, T.; Monno, M.; Mussi, V. CFD and experimental analysis of the coolant flow in cryogenic milling. Int. J. Mach. Tools Manuf. 2019, 140, 20–33. [Google Scholar] [CrossRef]

- Eltaggaz, A.; Zawada, P.; Hegab, H.A.; Deiab, I.; Kishawy, H.A. Coolant strategy influence on tool life and surface roughness when machining ADI. Int. J. Adv. Manuf. Technol. 2017, 94, 3875–3887. [Google Scholar] [CrossRef]

- Mizoue, Y.; Sencer, B.; Beaucamp, A. Identification and optimization of CNC dynamics in time-dependent machining processes and its validation to fluid jet polishing. Int. J. Mach. Tools Manuf. 2020, 159, 103648. [Google Scholar] [CrossRef]

- Bruno, G.; Genovese, A. Multi-Criteria Decision-Making: Advances in theory and applications—an introduction to the special issue. Soft Comput. 2018, 22, 7313–7314. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Govindan, K.; Antucheviciene, J.; Turskis, Z. Hybrid multiple criteria decision-making methods: A review of applications for sustainability issues. Econ. Res. Ekon. Istraž. 2016, 29, 857–887. [Google Scholar] [CrossRef]

- Godolphin, J. Two-level factorial and fractional factorial replicates in blocks of size two. Comput. Stat. Data Anal. 2018, 133, 120–137. [Google Scholar] [CrossRef]

- Chetan; Behera, B.; Ghosh, S.; Rao, P. Wear behavior of PVD TiN coated carbide inserts during machining of Nimonic 90 and Ti6Al4V superalloys under dry and MQL conditions. Ceram. Int. 2016, 42, 14873–14885. [Google Scholar] [CrossRef]

- Lin, C.; Kou, G. A heuristic method to rank the alternatives in the AHP synthesis. Appl. Soft Comput. 2020, 100, 106916. [Google Scholar] [CrossRef]

- Waris, M.; Panigrahi, S.; Mengal, A.; Soomro, M.I.; Mirjat, N.H.; Ullah, M.; Azlan, Z.S.; Khan, A. An Application of Analytic Hierarchy Process (AHP) for Sustainable Procurement of Construction Equipment: Multicriteria-Based Decision Framework for Malaysia. Math. Probl. Eng. 2019, 2019, 1–20. [Google Scholar] [CrossRef]

- Hu, C.-K.; Liu, F.-B. A Hybrid Fuzzy DEA/AHP Methodology for Ranking Units in a Fuzzy Environment. Symmetry 2017, 9, 273. [Google Scholar] [CrossRef]

- Mathew, M.; Chakrabortty, R.K.; Ryan, M.J. A novel approach integrating AHP and TOPSIS under spherical fuzzy sets for advanced manufacturing system selection. Eng. Appl. Artif. Intell. 2020, 96, 103988. [Google Scholar] [CrossRef]

- Yang, W. Ingenious Solution for the Rank Reversal Problem of TOPSIS Method. Math. Probl. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Girish, B.M.; Siddesh, H.S.; Satish, B.M. Taguchi grey relational analysis for parametric optimization of severe plastic deformation process. SN Appl. Sci. 2019, 1, 1–11. [Google Scholar] [CrossRef]

- Kumar T., S.; Ramanujam, R.; Vignesh, M.; Tamiloli, N.; Sharma, N.; Srivastava, S.; Patel, A. Comparative evaluation of performances of TiAlN, AlCrN, TiAlN/AlCrN coated carbide cutting tools and uncoated carbide cutting tools on turning Inconel 825 alloy using Grey Relational Analysis. Sens. Actuators A Phys. 2018, 279, 331–342. [Google Scholar] [CrossRef]

- Wu, W. Grey Relational Analysis Method for Group Decision Making in Credit Risk Analysis. Eurasia J. Math. Sci. Technol. Educ. 2017, 13, 7913–7920. [Google Scholar] [CrossRef]

- Kümmel, J.; Gibmeier, J.; Müller, E.; Schneider, R.; Schulze, V.; Wanner, A. Detailed analysis of microstructure of intentionally formed built-up edges for improving wear behaviour in dry metal cutting process of steel. Wear 2014, 311, 21–30. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Sun, S.; Kim, J.W.; Li, T.; Trimby, P.; Cairney, J. Effect of tool wear evolution on chip formation during dry machining of Ti-6Al-4V alloy. Int. J. Mach. Tools Manuf. 2018, 126, 13–17. [Google Scholar] [CrossRef]

- Alagan, N.T.; Hoier, P.; Zeman, P.; Klement, U.; Beno, T.; Wretland, A. Effects of high-pressure cooling in the flank and rake faces of WC tool on the tool wear mechanism and process conditions in turning of alloy 718. Wear 2019, 434–435, 102922. [Google Scholar] [CrossRef]

- Acayaba, G.M.A.; de Escalona, P.M. Prediction of surface roughness in low speed turning of AISI316 austenitic stainless steel. CIRP J. Manuf. Sci. Technol. 2015, 11, 62–67. [Google Scholar] [CrossRef]

- Tian, Y.; Zou, P.; Yang, X.; Kang, D. Study on chip morphology and surface roughness in ultrasonically assisted drilling of 304 stainless steel. Int. J. Adv. Manuf. Technol. 2020, 108, 2079–2090. [Google Scholar] [CrossRef]

- Davis, J.M.; Saei, M.; Mohanty, D.P.; Udupa, A.; Sugihara, T.; Chandrasekar, S. Cutting of tantalum: Why it is so difficult and what can be done about it. Int. J. Mach. Tools Manuf. 2020, 157, 103607. [Google Scholar] [CrossRef]

- Ahmed, Y.S.; Paiva, J.M.; Veldhuis, S.C. Characterization and prediction of chip formation dynamics in machining austenitic stainless steel through supply of a high-pressure coolant. Int. J. Adv. Manuf. Technol. 2019, 102, 1671–1688. [Google Scholar] [CrossRef]

| Elements | Cr | Ni | Mn | Si | C | Fe |

|---|---|---|---|---|---|---|

| (%) | 18.2 | 8.5 | 1 | 1 | 0.08 | Balance |

| Symbol | Process Parameter | Unit | Level | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| v | Cutting velocity | m/s | 78 | 160 | 235 |

| f | Feed rate | mm/min | 100 | 200 | 300 |

| t | Coolant temperature | °C | 15 | 10 | 0 |

| d | Depth of cut | mm | 0.5 | 1.0 | 1.5 |

| p | Coolant pressure | N/cm2 | 5 | 10 | 15 |

| Exp. Run | Controllable Input Process Parameters | Experimental Results | ||||||

|---|---|---|---|---|---|---|---|---|

| t | v | f | d | Ra (µm) | Fc (N) | TWR (µm) | MRR (gm/min) | |

| 1 | 15 | 78 | 100 | 0.5 | 2.5 | 660 | 154 | 51 |

| 2 | 15 | 78 | 200 | 1.0 | 2.62 | 690 | 156 | 56 |

| 3 | 15 | 78 | 300 | 1.5 | 2.76 | 720 | 162 | 62 |

| 4 | 15 | 160 | 100 | 1.0 | 2.38 | 760 | 158 | 61 |

| 5 | 15 | 160 | 200 | 1.5 | 2.48 | 780 | 165 | 67 |

| 6 | 15 | 160 | 300 | 0.5 | 2.30 | 790 | 184 | 78 |

| 7 | 15 | 235 | 100 | 1.5 | 2.02 | 930 | 190 | 73 |

| 8 | 15 | 235 | 200 | 0.5 | 2.2 | 945 | 198 | 75 |

| 9 | 15 | 235 | 300 | 1.0 | 2.12 | 985 | 232 | 80 |

| 10 | 8 | 78 | 100 | 1.0 | 2.26 | 685 | 157 | 68 |

| 11 | 8 | 78 | 200 | 1.5 | 2.5 | 725 | 150 | 60 |

| 12 | 8 | 78 | 300 | 0.5 | 2.32 | 698 | 156 | 68 |

| 13 | 8 | 160 | 100 | 1.5 | 1.92 | 760 | 162 | 70 |

| 14 | 8 | 160 | 200 | 0.5 | 1.96 | 760 | 176 | 76 |

| 15 | 8 | 160 | 300 | 1.0 | 2.09 | 810 | 182 | 83 |

| 16 | 8 | 235 | 100 | 0.5 | 2.0 | 875 | 172 | 68 |

| 17 | 8 | 235 | 200 | 1.0 | 1.9 | 970 | 190 | 76 |

| 18 | 8 | 235 | 300 | 1.5 | 2.32 | 985 | 220 | 91 |

| 19 | 0 | 78 | 100 | 1.5 | 2.1 | 685 | 146 | 78 |

| 20 | 0 | 78 | 200 | 0.5 | 1.8 | 685 | 150 | 80 |

| 21 | 0 | 78 | 300 | 1.0 | 1.5 | 795 | 158 | 80 |

| 22 | 0 | 160 | 100 | 0.5 | 1.5 | 795 | 165 | 74 |

| 23 | 0 | 160 | 200 | 1.0. | 1.7 | 785 | 175 | 80 |

| 24 | 0 | 160 | 300 | 1.5 | 1.75 | 829 | 215 | 86 |

| 25 | 0 | 235 | 100 | 1.0 | 1.7 | 868 | 186 | 86 |

| 26 | 0 | 235 | 200 | 1.5 | 1.72 | 990 | 212 | 87 |

| 27 | 0 | 235 | 300 | 0.5 | 1.78 | 950 | 200 | 88 |

| Attributes | Ra | Fc | TWR | MRR |

|---|---|---|---|---|

| Ra | 1 | 3 | 2 | 1 |

| Fc | 1/3 | 1 | 1/2 | 1/2 |

| TWR | 1/2 | 2 | 1 | 1/2 |

| MRR | 1 | 2 | 2 | 1 |

| Attributes | Assigned Weights |

|---|---|

| Ra | 0.35 |

| Fc | 0.13 |

| TWR | 0.20 |

| MRR | 0.32 |

| N | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

| Sr. No | Controllable Process Parameter | Experimental Results | TOPSIS | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| t | v | f | d | Ra (µm) | Fc (N) | TWR (µm) | MRR (gm/min) | Si+ | Si- | Pf | Rank | |

| 1 | 15 | 78 | 100 | 0.5 | 2.5 | 660 | 154 | 51 | 0.05 | 0.02 | 0.288 | 25 |

| 2 | 15 | 78 | 200 | 1.0 | 2.62 | 690 | 156 | 56 | 0.05 | 0.02 | 0.28 | 26 |

| 3 | 15 | 78 | 300 | 1.5 | 2.76 | 720 | 162 | 62 | 0.051 | 0.02 | 0.273 | 27 |

| 4 | 15 | 160 | 100 | 1.0 | 2.38 | 760 | 158 | 61 | 0.043 | 0.02 | 0.344 | 22 |

| 5 | 15 | 160 | 200 | 1.5 | 2.48 | 780 | 165 | 67 | 0.043 | 0.02 | 0.34 | 23 |

| 6 | 15 | 160 | 300 | 0.5 | 2.3 | 790 | 184 | 78 | 0.037 | 0.03 | 0.444 | 17 |

| 7 | 15 | 235 | 100 | 1.5 | 2.02 | 930 | 190 | 73 | 0.036 | 0.03 | 0.466 | 15 |

| 8 | 15 | 235 | 200 | 0.5 | 2.2 | 945 | 188 | 75 | 0.039 | 0.03 | 0.416 | 21 |

| 9 | 15 | 235 | 300 | 1.0 | 2.12 | 985 | 232 | 80 | 0.04 | 0.03 | 0.44 | 18 |

| 10 | 8 | 78 | 100 | 1.0 | 2.26 | 685 | 157 | 68 | 0.036 | 0.03 | 0.435 | 19 |

| 11 | 8 | 78 | 200 | 1.5 | 2.5 | 725 | 150 | 60 | 0.046 | 0.02 | 0.327 | 24 |

| 12 | 8 | 78 | 300 | 0.5 | 2.12 | 698 | 156 | 68 | 0.038 | 0.03 | 0.416 | 20 |

| 13 | 8 | 160 | 100 | 1.5 | 2.32 | 760 | 162 | 70 | 0.031 | 0.04 | 0.532 | 12 |

| 14 | 8 | 160 | 200 | 0.5 | 1.96 | 760 | 176 | 76 | 0.03 | 0.04 | 0.546 | 10 |

| 15 | 8 | 160 | 300 | 1.0 | 2.09 | 810 | 182 | 83 | 0.031 | 0.04 | 0.534 | 11 |

| 16 | 8 | 235 | 100 | 0.5 | 2.00 | 875 | 172 | 68 | 0.035 | 0.03 | 0.467 | 14 |

| 17 | 8 | 235 | 200 | 1.0 | 1.9 | 970 | 190 | 76 | 0.034 | 0.04 | 0.511 | 13 |

| 18 | 8 | 235 | 300 | 1.5 | 2.32 | 985 | 220 | 91 | 0.041 | 0.04 | 0.465 | 16 |

| 19 | 0 | 78 | 100 | 1.5 | 2.1 | 685 | 146 | 78 | 0.029 | 0.04 | 0.557 | 9 |

| 20 | 0 | 78 | 200 | 0.5 | 1.8 | 685 | 150 | 80 | 0.023 | 0.04 | 0.65 | 2 |

| 21 | 0 | 78 | 300 | 1.0 | 1.5 | 795 | 158 | 80 | 0.024 | 0.05 | 0.671 | 1 |

| 22 | 0 | 160 | 100 | 0.5 | 1.5 | 795 | 165 | 74 | 0.027 | 0.05 | 0.637 | 3 |

| 23 | 0 | 160 | 200 | 1.0. | 1.7 | 785 | 175 | 80 | 0.026 | 0.04 | 0.63 | 4 |

| 24 | 0 | 160 | 300 | 1.5 | 1.75 | 829 | 215 | 86 | 0.029 | 0.04 | 0.599 | 6 |

| 25 | 0 | 235 | 100 | 1.0 | 1.7 | 868 | 186 | 86 | 0.027 | 0.05 | 0.628 | 5 |

| 26 | 0 | 235 | 200 | 1.5 | 2.72 | 990 | 212 | 87 | 0.032 | 0.04 | 0.581 | 8 |

| 27 | 0 | 235 | 300 | 0.5 | 2.78 | 950 | 200 | 88 | 0.031 | 0.04 | 0.59 | 7 |

| Sr. No | Controllable Process Parameter | Experiment Results | Ranking | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| t | v | f | d | Ra (µm) | Fc (N) | TWR (µm) | MRR (gm/min) | GRG Value | Rank | |

| 1 | 15 | 78 | 100 | 0.5 | 2.5 | 660 | 154 | 51 | 0.405408 | 8 |

| 2 | 15 | 78 | 200 | 1.0 | 2.62 | 690 | 156 | 56 | 0.347549 | 18 |

| 3 | 15 | 78 | 300 | 1.5 | 2.76 | 720 | 162 | 62 | 0.329532 | 19 |

| 4 | 15 | 160 | 100 | 1.0 | 2.38 | 760 | 158 | 61 | 0.322827 | 20 |

| 5 | 15 | 160 | 200 | 1.5 | 2.48 | 780 | 165 | 67 | 0.30351 | 23 |

| 6 | 15 | 160 | 300 | 0.5 | 2.3 | 790 | 184 | 78 | 0.313928 | 21 |

| 7 | 15 | 235 | 100 | 1.5 | 2.02 | 930 | 190 | 73 | 0.274642 | 25 |

| 8 | 15 | 235 | 200 | 0.5 | 2.2 | 945 | 188 | 75 | 0.260159 | 27 |

| 9 | 15 | 235 | 300 | 1.0 | 2.12 | 985 | 232 | 80 | 0.265834 | 26 |

| 10 | 8 | 78 | 100 | 1.0 | 2.26 | 685 | 157 | 68 | 0.413587 | 6 |

| 11 | 8 | 78 | 200 | 1.5 | 2.5 | 725 | 150 | 60 | 0.3666 | 13 |

| 12 | 8 | 78 | 300 | 0.5 | 2.32 | 698 | 156 | 68 | 0.394966 | 10 |

| 13 | 8 | 160 | 100 | 1.5 | 1.92 | 760 | 162 | 70 | 0.361912 | 14 |

| 14 | 8 | 160 | 200 | 0.5 | 1.96 | 760 | 176 | 76 | 0.352312 | 15 |

| 15 | 8 | 160 | 300 | 1.0 | 2.09 | 810 | 182 | 83 | 0.351373 | 16 |

| 16 | 8 | 235 | 100 | 0.5 | 2.0 | 875 | 172 | 68 | 0.308119 | 22 |

| 17 | 8 | 235 | 200 | 1.0 | 1.9 | 970 | 190 | 76 | 0.291863 | 24 |

| 18 | 8 | 235 | 300 | 1.5 | 2.32 | 985 | 220 | 91 | 0.395687 | 9 |

| 19 | 0 | 78 | 100 | 1.5 | 2.1 | 685 | 146 | 78 | 0.502661 | 4 |

| 20 | 0 | 78 | 200 | 0.5 | 1.8 | 685 | 150 | 80 | 0.58433 | 2 |

| 21 | 0 | 78 | 300 | 1.0 | 1.5 | 795 | 158 | 80 | 0.611209 | 1 |

| 22 | 0 | 160 | 100 | 0.5 | 1.5 | 795 | 165 | 74 | 0.568309 | 3 |

| 23 | 0 | 160 | 200 | 1.0. | 1.7 | 785 | 175 | 80 | 0.422897 | 5 |

| 24 | 0 | 160 | 300 | 1.5 | 1.75 | 829 | 215 | 86 | 0.387907 | 11 |

| 25 | 0 | 235 | 100 | 1.0 | 1.7 | 868 | 186 | 86 | 0.408177 | 7 |

| 26 | 0 | 235 | 200 | 1.5 | 1.72 | 990 | 212 | 87 | 0.379891 | 12 |

| 27 | 0 | 235 | 300 | 0.5 | 1.78 | 950 | 200 | 88 | 0.348573 | 17 |

| Exp. run no | Temp (°C) | Velocity (m/min) | Feed (m/min) | Depth of Cut (mm) | TOPSIS Ranking | GRG Ranking |

|---|---|---|---|---|---|---|

| 19 | 0 | 78 | 100 | 1.5 | 9 | 4 |

| 20 | 0 | 78 | 200 | 0.5 | 2 | 2 |

| 21 | 0 | 78 | 300 | 1.0 | 1 | 1 |

| 22 | 0 | 160 | 100 | 0.5 | 3 | 3 |

| 23 | 0 | 160 | 200 | 1.0. | 4 | 5 |

| 24 | 0 | 160 | 300 | 1.5 | 6 | 11 |

| 25 | 0 | 235 | 100 | 1.0 | 5 | 7 |

| 26 | 0 | 235 | 200 | 1.5 | 8 | 12 |

| 27 | 0 | 235 | 300 | 0.5 | 7 | 17 |

| Parameters | Traditionally Used Parameter | Optimal Recommended Process Parameter | Parameter Change Due to Recommendation | |

|---|---|---|---|---|

| TOPSIS | GRG | TOPSIS/GRG | ||

| Temperature (°C) | Ambient temp (28) | 0 | 0 | −28 |

| Cutting velocity (m/min) | 60 | 78 | 78 | +18 |

| Feed rate (mm/min) | 200 | 300 | 300 | +100 |

| Depth of cut (mm) | 0.8 | 1.0 | 1.0 | +0.2 |

| Parameters with Its Unit | Results with Traditionally Used Parameters | Results with Recommended Optimal Process Parameters | Percentage Change in Result at the Optimum Cutting Conditions over Initial Parameter Setting |

|---|---|---|---|

| TOPSIS and GRG | TOPSIS and GRG | ||

| Fc (N) | 780 | 795 | 15% increase |

| Ra (µm) | 2.3 | 1.5 | 34% reduction |

| TWR (µm) | 165 | 158 | 4.2% reduction |

| MRR (gm/min) | 67 | 80 | 19.4% increase |

| Level | Cutting Velocity | Temperature | Feed Rate | Depth of Cut |

|---|---|---|---|---|

| 1 | 0.6265 | 0.7912 | 0.8354 | 0.8125 |

| 2 | 0.8230 | 0.8325 | 0.8232 | 0.7685 |

| 3 | 0.9012 | 0.6589 | 0.6925 | 0.6985 |

| Delta | 0.2747 | 0.1736 | 0.1429 | 0.1140 |

| Rank | 1 | 2 | 3 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patil, P.; Karande, P. Experimental Investigations and Optimization of Machining Parameters in CNC Turning of SS304 Using Coolant at 0 °C. J. Manuf. Mater. Process. 2022, 6, 128. https://doi.org/10.3390/jmmp6060128

Patil P, Karande P. Experimental Investigations and Optimization of Machining Parameters in CNC Turning of SS304 Using Coolant at 0 °C. Journal of Manufacturing and Materials Processing. 2022; 6(6):128. https://doi.org/10.3390/jmmp6060128

Chicago/Turabian StylePatil, Pravin, and Prasad Karande. 2022. "Experimental Investigations and Optimization of Machining Parameters in CNC Turning of SS304 Using Coolant at 0 °C" Journal of Manufacturing and Materials Processing 6, no. 6: 128. https://doi.org/10.3390/jmmp6060128

APA StylePatil, P., & Karande, P. (2022). Experimental Investigations and Optimization of Machining Parameters in CNC Turning of SS304 Using Coolant at 0 °C. Journal of Manufacturing and Materials Processing, 6(6), 128. https://doi.org/10.3390/jmmp6060128