SLA Resins Modification by Liquid Mixing with Ceramic Powders Aiming at Mechanical Property and Thermal Stability Enhancement for Rapid Tooling Applications

Abstract

:1. Introduction

- The refractive index (RI) of the ceramic powders has to present low variation from the one of the raw resins. Within UV spectrum range, Al2O3 and SiO2 ceramic powders have an RI near 1.7 and 1.56, respectively, while the majority of the resin monomers show an RI near 1.5. For that reason, ceramic powders with low or medium RI are recommended, such as silica and alumina.

- The median particle size of the ceramic powders should be smaller than the layer thickness, which lies between 25 and 100 μm. The smaller particle size improves the vertical resolution of the final 3D printed component. The optimum particle size is suggested to be around 0.05 μm and 10 μm.

- The reduction of the particle size affects the specific surface area consequently. Smaller and finer particles generate a lot of internal scattering events. In contrast, the internal scattering is decreased when larger particles are used, and more light is transmitted. Less internal scattering events lead to large scattering length. Scattering length is defined as the free distance that a photon can travel before its direction changes again and becomes randomised. A ceramic slurry with a large scattering length is considered to have the same cured profile as the conventional, unmodified resin.

2. Materials and Methods

2.1. Formulation Development and 3D Printing Process

- The selected SLA system was Form 2 by Formlabs with a self-heating resin tank up to 35 °C a 405 nm near UV (violet) diode laser with 250 mW power and 140 μm laser spot size. Layer thickness ranges from 25 to 100 μm

- Resin–ceramic particles composition and liquid mixing process: the hybrid ceramic materials that were produced during this process were 1% and 5% w/w Al2O3 and 1% and 5% w/w SiO2. For preprocessing of the powder a drying temperature of 110 °C was set, which is a few degrees above water boiling for 6–10 h to remove humidity residuals. Dispersion of ceramic powder within EtOH followed, using ultrasonic bath for 4 h and magnetic stirring for another 4 h for pre-mixing to ensure homogeneous dispersion and agglomeration reduction. Then, the EtOH-powder mixtures were poured within commercial selected resin followed by further ultrasonication and magnetic stirring. After mixing procedure, heating at a range of 40–60 °C is suggested for 1 h to remove EtOH.

- Printing process: Standard software-produced support structures were employed in order to ensure proper adhesion and scaffolding of the printed components to the build plate, taking into consideration the printing orientation. Support density values were set to 80% as per the slicer’s suggestion and touchpoint sizes were adjusted marginally from 0.7 mm to 0.8 mm to enhance retention capability and avoid support breakage during fabrication due to potentially increased part density induced from addition of the powder to the resin. Layer heights of 50 μm were selected towards the optimum combination between printing time and printed part quality. Due to the selected printing equipment’s restrictions, no alternative exposure times and laser scanning speeds could be investigated at this point.

- Post-processing: After 3D printing process, the fabricated specimens were treated with the material provider’s suggested post-processing protocol. The 3D printed components were washed with isopropanol (IPA, 99.8+% for analysis, from Acros-organics) for 6 min; supports removal was conducted followed by surface grinding to smoothly remove the support marks. Specimens were fully dried and photocured using FORM Cure at 80 °C for 120 min using 405 nm light source following the resin provider’s recommendations.

- Thermal treatment: High Temp Resin requires further heat treatment to reach its optimal mechanical properties and high heat deflection temperature (HDT), as also recommended by Formlabs. Therefore, the specimens were heat-treated in an oven for 180 min at 160 °C.

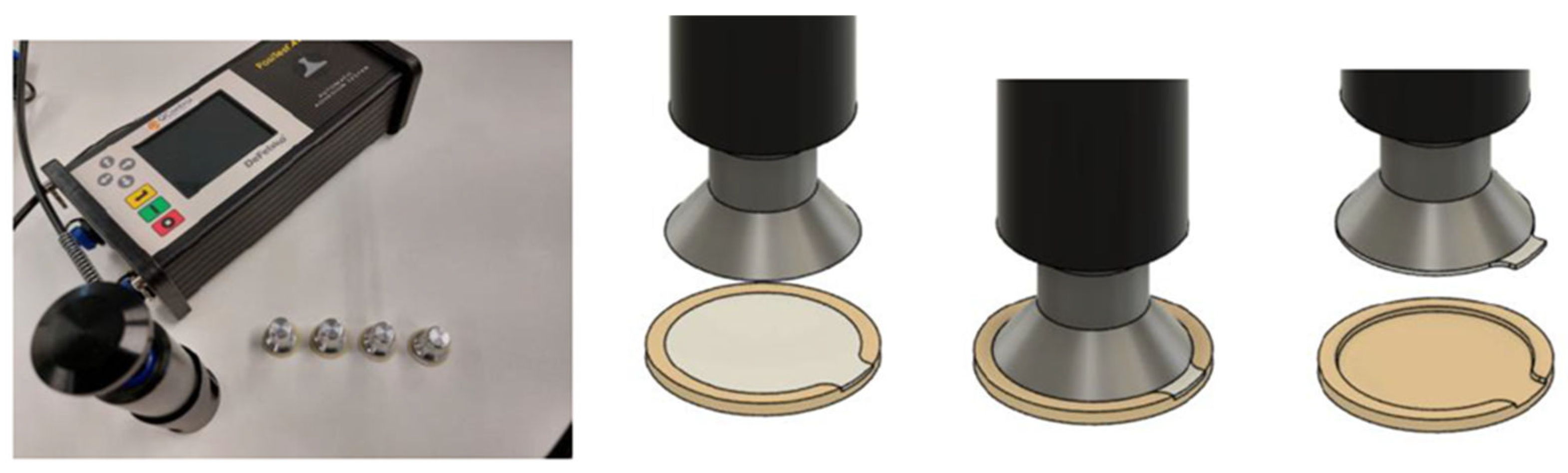

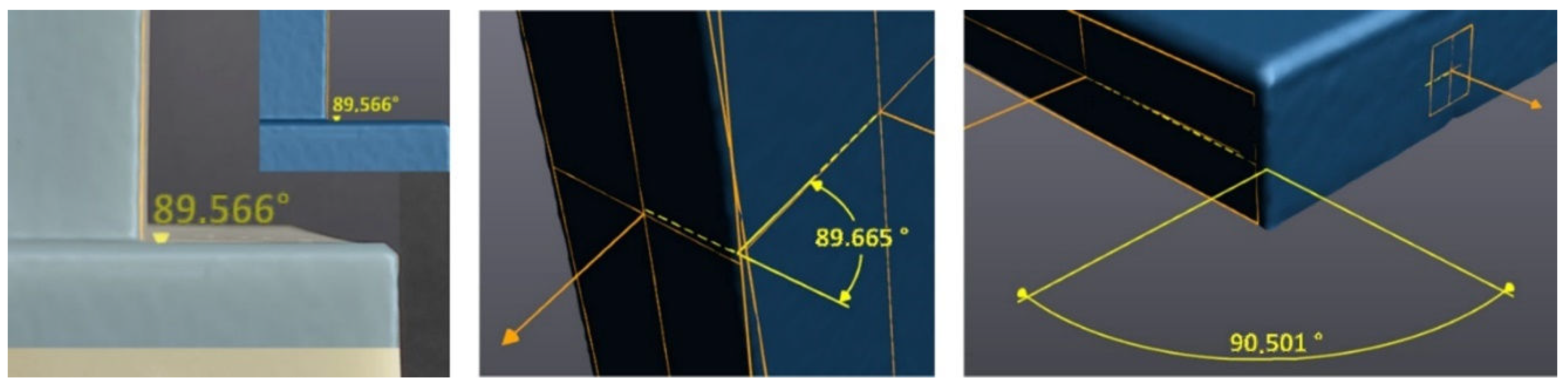

2.2. Dimensional Tolerance, Shrinkage Evaluation Protocol and Weight Loss Assessment

2.3. Mechanical Testing

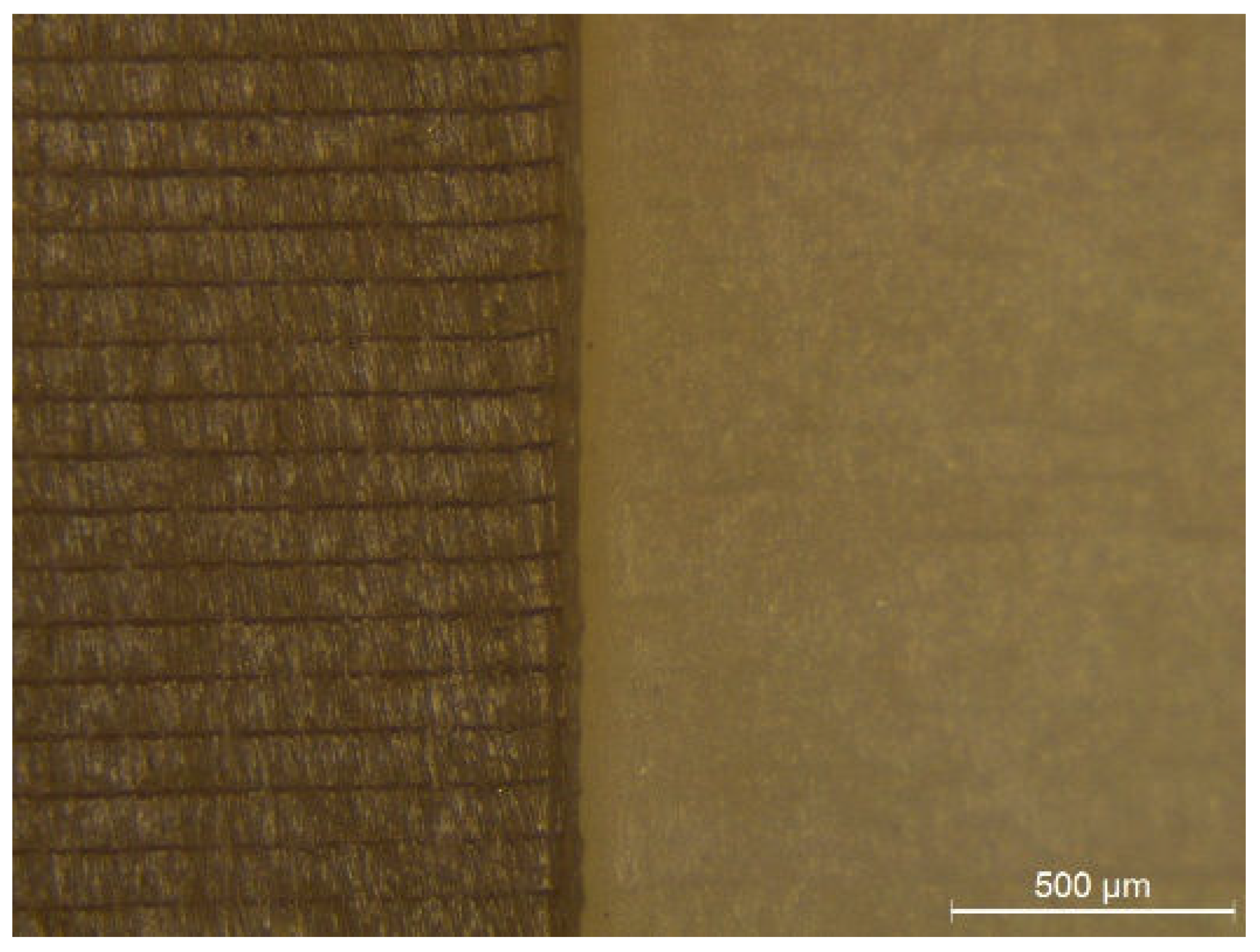

2.4. Surface Treatment and Adhesion Testing Protocol

- A set of untreated (as printed) coupons.

- A set of coupons that had undergone surface grinding. The coupons were procedurally processed by means of manual sanding, utilizing sandpaper with grit ranging from 120 to 2000. More specifically, dry sanding was employed up to 500 grits, whereas for higher grit values, wet sanding was appropriately applied.

- A set of sanded coupons, further dip coated with heated neat resin. The dip-coating process utilised neat resin heated up to 60 °C to decrease viscosity. The resin was placed in a borosilicate container and the coupons were submerged using a repurposed 3D printer motorised frame. This device was implemented into this process to ensure steady motion. The selected linear speed was set to 10 mm/min, the dwell time that the coupons spent in the liquid resin was set to 1 min and the retraction speed for the specimens to emerge from the resin was set to a lower value of 2 mm/min to avoid the formation of bubbles in the treated surface.

- A set of printed coupons with a commercial PTFE coating in spray form as a means to facilitate detachment during the trial. The PTFE was carefully applied indirectly using a cloth so as not to cause defects due to excess material droplets remaining on the surface of the part.

3. Results and Discussion

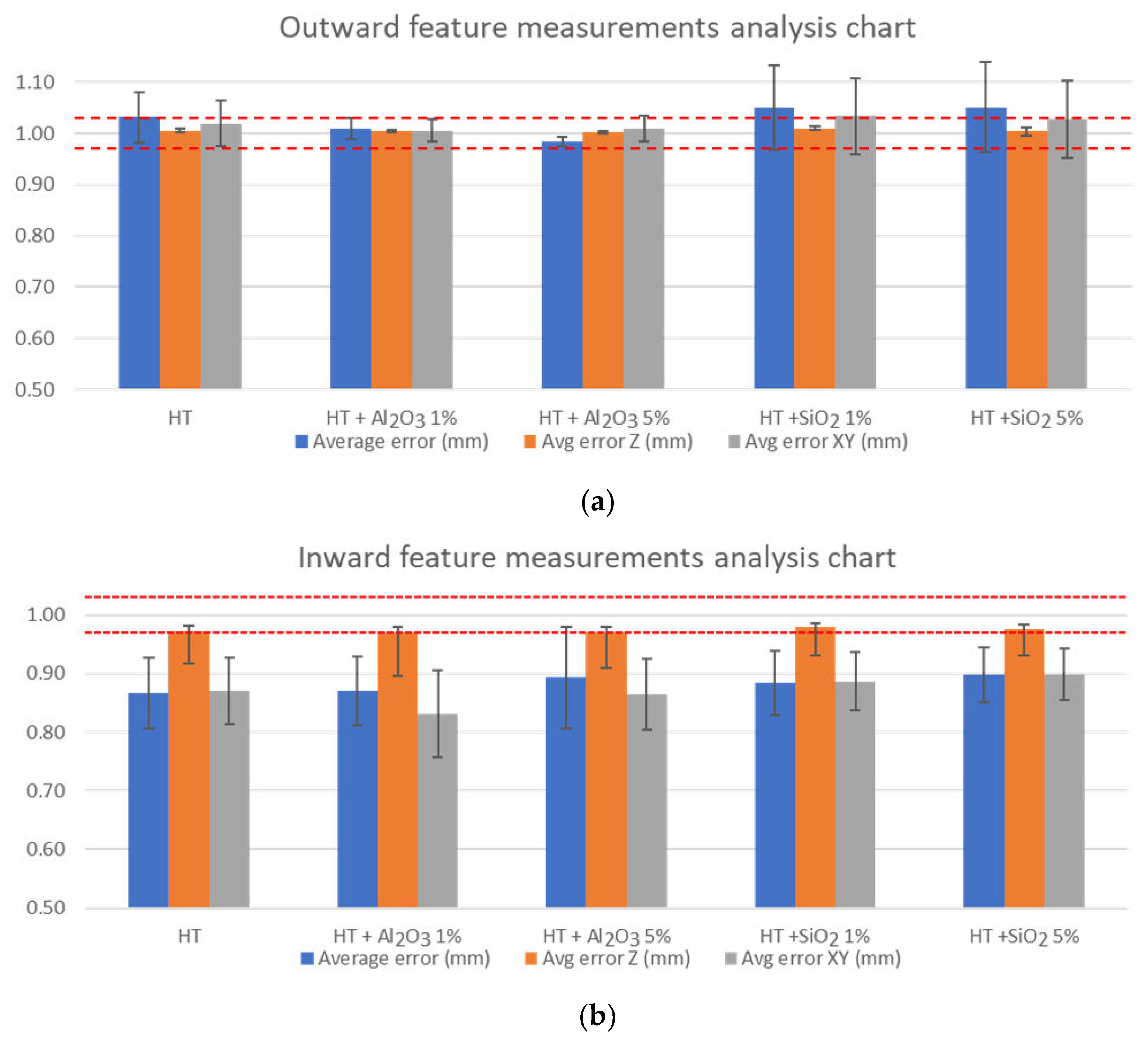

3.1. Dimensional Tolerances and Weight Loss Assessment

3.2. Mechanical Properties Results

3.3. Adhesion Testing in Different Surface Treatment Approaches

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| L1 | Nominal Value (mm) | HT | HT + Al2O3 1% | HT + Al2O3 5% | HT + SiO2 1% | HT +SiO2 5% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | ||

| 1.l | 8.00 | 8.06 | 8.08 | 8.10 | 8.07 | 8.06 | 8.02 | 8.04 | 8.04 | 8.01 | 8.12 | 8.15 | 8.14 | 8.09 | 8.10 | 8.08 |

| 1.w | 1.00 | 1.04 | 1.05 | 1.04 | 1.02 | 1.03 | 1.02 | 1.02 | 1.02 | 1.02 | 1.08 | 1.07 | 1.10 | 1.11 | 1.09 | 1.09 |

| 1.h | 2.00 | 1.91 | 1.92 | 1.91 | 1.90 | 1.94 | 1.91 | 2.02 | 1.94 | 1.94 | 1.96 | 1.89 | 1.92 | 1.86 | 1.79 | 1.86 |

| 2.l | 8.00 | 8.09 | 8.08 | 8.07 | 8.05 | 8.06 | 8.04 | 8.06 | 8.01 | 8.03 | 8.14 | 8.09 | 8.10 | 8.12 | 8.09 | 8.11 |

| 2.w | 2.00 | 2.03 | 2.05 | 2.02 | 2.00 | 2.01 | 2.03 | 2.03 | 2.01 | 2.06 | 2.05 | 2.03 | 2.01 | 2.07 | 2.07 | 2.06 |

| 2.h | 2.00 | 1.90 | 1.91 | 1.92 | 2.02 | 1.97 | 1.96 | 1.97 | 1.98 | 1.93 | 1.82 | 1.85 | 1.86 | 1.82 | 1.83 | 1.85 |

| 3.l | 8.00 | 8.06 | 8.10 | 8.07 | 8.04 | 8.01 | 8.05 | 8.10 | 8.02 | 8.06 | 8.11 | 8.10 | 8.12 | 8.11 | 8.08 | 8.10 |

| 3.w1 | 0.50 | 0.61 | 0.60 | 0.64 | 0.55 | 0.56 | 0.58 | 0.56 | 0.56 | 0.59 | 0.70 | 0.69 | 0.68 | 0.65 | 0.65 | 0.66 |

| 3.w2 | 1.00 | 1.03 | 1.05 | 1.06 | 1.01 | 1.03 | 1.04 | 1.01 | 1.03 | 1.04 | 1.08 | 1.05 | 1.06 | 1.07 | 1.06 | 1.05 |

| 3.h | 2.00 | 1.92 | 1.88 | 1.91 | 1.92 | 1.90 | 1.92 | 2.00 | 1.93 | 1.95 | 1.92 | 1.87 | 1.88 | 1.80 | 1.85 | 1.82 |

| 4.l | 8.00 | 8.06 | 8.08 | 8.06 | 8.06 | 8.06 | 8.07 | 8.07 | 8.01 | 8.05 | 8.15 | 8.14 | 8.08 | 8.09 | 8.11 | 8.09 |

| 4.w1 | 1.00 | 1.08 | 1.08 | 1.10 | 1.02 | 1.00 | 1.05 | 1.07 | 1.09 | 1.06 | 1.15 | 1.10 | 1.12 | 1.11 | 1.10 | 1.10 |

| 4.w2 | 1.50 | 1.52 | 1.54 | 1.53 | 1.53 | 1.55 | 1.54 | 1.51 | 1.54 | 1.52 | 1.55 | 1.50 | 1.53 | 1.57 | 1.54 | 1.54 |

| 4.h | 2.00 | 1.92 | 1.90 | 1.92 | 1.97 | 1.93 | 1.99 | 1.99 | 1.95 | 1.95 | 1.89 | 1.86 | 1.91 | 1.79 | 1.85 | 1.86 |

| 5.d | 1.00 | 1.04 | 1.08 | 1.06 | 1.02 | 1.03 | 1.02 | 1.03 | 1.02 | 1.01 | - | - | - | 1.10 | 1.16 | 1.13 |

| 5.h | 2.00 | 1.89 | 1.87 | 1.85 | 1.90 | 1.89 | 1.94 | 2.01 | 1.93 | 1.95 | 1.88 | 1.43 | 1.87 | |||

| 6.d | 2.00 | 2.13 | 2.11 | 2.11 | 2.02 | 2.01 | 2.03 | 2.04 | 2.02 | 2.02 | 2.05 | 2.03 | 3.03 | 2.06 | 2.09 | 2.03 |

| 6.h | 2.00 | 1.94 | 1.92 | 1.94 | 1.90 | 1.89 | 1.94 | 2.01 | 1.94 | 1.95 | 1.92 | 1.91 | 1.93 | 1.89 | 1.86 | 1.86 |

| 7.d | 3.00 | 3.03 | 3.05 | 3.05 | 3.00 | 3.03 | 3.02 | 3.01 | 3.03 | 3.03 | 3.05 | 3.04 | 3.07 | 3.03 | 3.05 | 3.04 |

| 7.h | 2.00 | 1.93 | 1.90 | 1.89 | 1.90 | 1.89 | 1.94 | 2.01 | 1.93 | 1.95 | 1.92 | 1.91 | 1.92 | 1.82 | 1.85 | 1.87 |

| 8.lb | 8.00 | 8.08 | 8.09 | 8.05 | 8.06 | 8.02 | 8.04 | 8.06 | 8.02 | 8.05 | 8.11 | 8.09 | 8.12 | 8.08 | - | 8.08 |

| 8.lt | 7.93 | 7.93 | 7.91 | 7.94 | 7.98 | 7.91 | 7.98 | 7.94 | 7.93 | 7.96 | 7.95 | 7.99 | 7.96 | 7.80 | - | 7.88 |

| 8.wb | 1.00 | 1.08 | 1.06 | 1.04 | 1.01 | 1.03 | 1.03 | 1.01 | 1.04 | 1.03 | 1.10 | 1.12 | 1.07 | 1.10 | - | 1.10 |

| 8.wt | 0.93 | 0.96 | 0.93 | 0.96 | 0.94 | 0.96 | 0.94 | 0.96 | 0.95 | 0.94 | 0.94 | 0.94 | 0.95 | 0.94 | - | 0.95 |

| 8.h | 2.00 | 1.91 | 1.89 | 1.89 | 1.96 | 1.96 | 1.96 | 1.93 | 1.94 | 1.95 | 1.82 | 1.79 | 1.83 | 1.79 | - | 1.82 |

| 9.lb | 8.00 | 8.10 | 8.09 | 8.07 | 8.03 | 8.06 | 8.04 | 8.07 | 8.06 | 8.05 | 8.10 | 8.09 | 8.11 | 8.09 | 8.11 | 8.12 |

| 9.lt | 7.93 | 7.91 | 7.94 | 7.92 | 7.94 | 7.93 | 7.92 | 7.93 | 7.91 | 7.97 | 7.94 | 7.93 | 7.96 | 7.93 | 7.90 | 7.90 |

| 9.wb | 2.00 | 2.06 | 2.08 | 2.06 | 2.05 | 2.03 | 2.04 | 2.06 | 2.06 | 2.02 | 2.03 | 2.04 | 2.03 | 2.04 | 2.17 | 2.14 |

| 9.wt | 1.93 | 1.94 | 1.95 | 1.97 | 1.95 | 1.96 | 1.94 | 1.96 | 1.95 | 1.93 | 1.96 | 1.91 | 1.95 | 1.91 | 1.98 | 1.95 |

| 9.h | 2.00 | 1.88 | 1.88 | 1.88 | 2.00 | 1.99 | 1.97 | 1.92 | 1.98 | 1.93 | 1.82 | 1.82 | 1.80 | 1.82 | 1.84 | 1.86 |

| 10.lb | 8.00 | 8.10 | 8.07 | 8.06 | 8.09 | 8.10 | 8.06 | 8.06 | 8.02 | 8.06 | 8.12 | - | 8.08 | 8.08 | 8.10 | 8.10 |

| 10.lt | 7.93 | 7.87 | 7.88 | 7.88 | 7.94 | 7.93 | 7.97 | 7.84 | 7.80 | 7.95 | 7.96 | - | 7.98 | 7.33 | 7.86 | 7.90 |

| 10.w1b | 0.50 | 0.62 | 0.62 | 0.61 | 0.56 | 0.54 | 0.58 | 0.58 | 0.58 | 0.58 | 0.70 | - | 0.70 | 0.74 | 0.71 | 0.69 |

| 10.w1t | 0.43 | 0.56 | 0.55 | 0.56 | 0.47 | 0.45 | 0.47 | 0.48 | 0.51 | 0.43 | 0.63 | - | 0.65 | 0.68 | 0.67 | 0.59 |

| 10.w2b | 1.00 | 1.02 | 1.05 | 1.06 | 1.01 | 1.01 | 1.02 | 1.00 | 1.01 | 0.98 | 1.08 | - | 1.07 | 1.07 | 1.08 | 1.08 |

| 10.w2t | 0.93 | 0.92 | 0.94 | 0.93 | 0.90 | 0.90 | 0.90 | 0.94 | 0.94 | 0.94 | 0.94 | - | 0.94 | 0.92 | 0.95 | 0.94 |

| 10.h | 2.00 | 1.93 | 1.93 | 1.91 | 1.99 | 1.92 | 1.97 | 1.94 | 1.96 | 1.90 | 1.87 | - | 1.87 | 1.85 | 1.85 | 1.87 |

| 11.lb | 8.00 | 8.03 | 8.05 | 8.07 | 8.06 | 8.01 | 8.05 | 8.08 | 8.02 | 8.05 | 8.09 | 8.06 | 8.08 | 8.06 | 8.03 | 8.05 |

| 11.lt | 7.93 | 7.97 | 7.97 | 7.94 | 7.94 | 7.95 | 7.93 | 7.96 | 7.90 | 7.96 | 7.98 | 8.01 | 7.97 | 8.01 | 7.94 | 7.96 |

| 11.w1b | 1.00 | 1.05 | 1.05 | 1.05 | 1.01 | 1.03 | 1.04 | 1.06 | 1.07 | 1.01 | 1.10 | 1.10 | 1.05 | 1.10 | 1.12 | 1.09 |

| 11.w1t | 0.93 | 1.00 | 1.00 | 0.97 | 0.90 | 0.92 | 0.94 | 0.97 | 0.95 | 0.97 | 0.97 | 1.06 | 0.96 | 1.06 | 0.99 | 1.02 |

| 11.w2b | 1.50 | 1.53 | 1.52 | 1.53 | 1.51 | 1.54 | 1.51 | 1.49 | 1.50 | 1.52 | 1.51 | 1.52 | 1.55 | 1.52 | 1.51 | 1.50 |

| 11.w2t | 1.43 | 1.46 | 1.47 | 1.43 | 1.46 | 1.46 | 1.48 | 1.45 | 1.43 | 1.44 | 1.45 | 1.43 | 1.45 | 1.43 | 1.45 | 1.46 |

| 11.h | 2.00 | 1.92 | 1.92 | 1.91 | 1.99 | 1.91 | 1.89 | 1.92 | 1.92 | 1.97 | 1.90 | 1.85 | 1.88 | 1.85 | 1.83 | 1.86 |

| 12.db | 1.00 | 1.03 | 1.04 | 1.05 | 1.03 | 1.03 | 1.02 | 1.01 | 1.00 | 0.99 | - | 1.08 | - | - | 1.08 | - |

| 12.dt | 0.93 | 0.90 | 0.94 | 0.94 | 0.93 | 0.94 | 0.94 | 0.91 | 0.92 | 0.90 | - | 0.90 | - | - | 0.90 | - |

| 12.h | 2.00 | 1.95 | 1.94 | 1.92 | 1.96 | 1.93 | 1.96 | 1.92 | 1.97 | 1.94 | - | 1.86 | - | - | 1.86 | - |

| 13.db | 2.00 | 2.03 | 2.02 | 2.01 | 2.00 | 2.00 | 2.01 | 2.00 | 2.02 | 1.99 | 2.06 | 2.09 | 2.07 | 2.06 | 2.04 | 2.04 |

| 13.dt | 1.93 | 1.96 | 1.93 | 1.95 | 1.92 | 1.95 | 1.91 | 1.93 | 1.93 | 1.92 | 1.93 | 1.93 | 1.95 | 1.95 | 1.97 | 1.97 |

| 13.h | 2.00 | 1.91 | 1.91 | 1.93 | 1.96 | 1.93 | 1.96 | 1.92 | 1.97 | 1.94 | 1.91 | 1.88 | 1.86 | 1.83 | 1.87 | 1.87 |

| 14.db | 3.00 | 3.01 | 3.03 | 3.00 | 3.02 | 3.01 | 3.02 | 3.01 | 3.01 | 3.00 | 3.03 | 3.05 | 3.04 | 3.05 | 3.00 | 3.00 |

| 14.dt | 2.93 | 2.96 | 2.92 | 2.96 | 2.94 | 2.94 | 2.95 | 2.93 | 2.95 | 2.93 | 2.96 | 2.94 | 2.96 | 2.93 | 2.90 | 2.90 |

| 14.h | 2.00 | 1.91 | 1.92 | 1.89 | 1.96 | 1.93 | 1.96 | 1.92 | 1.96 | 1.94 | 1.91 | 1.88 | 1.87 | 1.85 | 1.87 | 1.87 |

| L2 | Nominal Value (mm) | HT | HT + Al2O3 1% | HT + Al2O3 5% | HT +SiO2 1% | HT +SiO2 5% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | ||||

| 1.l | 8.00 | 7.66 | 7.78 | 7.80 | 7.67 | 7.66 | 7.62 | 7.74 | 7.68 | 7.71 | 7.72 | 7.85 | 7.84 | 7.69 | 7.70 | 7.68 | ||

| 1.w | 1.00 | 0.74 | 0.85 | 0.74 | 0.82 | 0.83 | 0.82 | 0.84 | 0.79 | 0.85 | 0.78 | 0.77 | 0.75 | 0.81 | 0.79 | 0.79 | ||

| 2.l | 8.00 | 7.76 | 7.78 | 7.70 | 7.67 | 7.66 | 7.62 | 7.74 | 7.74 | 7.71 | 7.82 | 7.85 | 7.74 | 7.79 | 7.80 | 7.78 | ||

| 2.w | 2.00 | 1.73 | 1.75 | 1.62 | 1.60 | 1.67 | 1.63 | 1.63 | 1.61 | 1.66 | 1.75 | 1.73 | 1.61 | 1.77 | 1.77 | 1.76 | ||

| 2.h | 2.00 | 2.00 | 2.01 | 1.99 | 1.99 | 1.99 | 2.01 | 1.99 | 2.01 | 2.01 | 2.01 | 2.00 | 2.01 | 1.99 | 2.00 | 2.01 | ||

| 3.l | 8.00 | 7.66 | 7.68 | 7.80 | 7.67 | 7.66 | 7.62 | 7.74 | 7.68 | 7.71 | 7.82 | 7.75 | 7.74 | 7.79 | 7.70 | 7.78 | ||

| 3.w1 | 0.50 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 3.w2 | 1.00 | 0.84 | 0.75 | 0.74 | 0.82 | 0.83 | 0.82 | 0.72 | 0.72 | 0.75 | 0.88 | 0.87 | 0.90 | 0.81 | 0.89 | 0.89 | ||

| 4.l | 8.00 | 7.76 | 7.68 | 7.70 | 7.77 | 7.76 | 7.72 | 7.68 | 7.74 | 7.71 | 7.82 | 7.85 | 7.84 | 7.69 | 7.80 | 7.68 | ||

| 4.w1 | 1.00 | 0.74 | 0.75 | 0.84 | 0.82 | 0.83 | 0.82 | 0.77 | 0.77 | 0.82 | 0.88 | 0.87 | 0.80 | 0.81 | 0.79 | 0.89 | ||

| 4.w2 | 1.50 | 1.22 | 1.14 | 1.13 | 1.23 | 1.25 | 1.28 | 1.21 | 1.24 | 1.22 | 1.25 | 1.20 | 1.13 | 1.17 | 1.24 | 1.24 | ||

| 4.h | 2.00 | 2.00 | 2.01 | 1.99 | 1.99 | 1.99 | 2.01 | 1.99 | 2.01 | 2.01 | 2.01 | 2.00 | 2.01 | 1.99 | 2.00 | 2.01 | ||

| 7.d | 3.00 | 2.73 | 2.65 | 2.65 | 2.70 | 2.73 | 2.62 | 2.71 | 2.73 | 2.73 | 2.75 | 2.64 | 2.77 | 2.63 | 2.65 | 2.74 | ||

| 7.h | 2.00 | 2.01 | 1.99 | 2.00 | 1.99 | 0.84 | 0.65 | 2.01 | 1.99 | 2.01 | 2.00 | 2.00 | 2.01 | 2.00 | 2.00 | 1.99 | ||

| 8.lb | 8.00 | 7.76 | 7.78 | 7.80 | 7.77 | 7.76 | 7.72 | 7.74 | 7.74 | 7.68 | 7.72 | 7.75 | 7.84 | 7.79 | 7.80 | 7.68 | ||

| 8.wb | 1.00 | 0.84 | 0.85 | 0.74 | 0.82 | 0.78 | 0.79 | 0.72 | 0.72 | 0.72 | 0.88 | 0.87 | 0.80 | 0.91 | 0.89 | 0.79 | ||

| 9.lb | 8.00 | 7.76 | 7.68 | 7.70 | 7.67 | 7.66 | 7.72 | 7.74 | 7.74 | 7.71 | 7.82 | 7.85 | 7.74 | 7.79 | 7.80 | 7.68 | ||

| 9.wb | 2.00 | 1.63 | 1.75 | 1.72 | 1.70 | 1.71 | 1.63 | 1.73 | 1.71 | 1.66 | 1.75 | 1.63 | 1.61 | 1.77 | 1.77 | 1.76 | ||

| 9.h | 2.00 | 1.99 | 2.00 | 2.00 | 2.00 | 2.01 | 2.00 | 1.99 | 1.99 | 1.99 | 2.00 | 1.99 | 1.99 | 1.99 | 2.01 | 1.99 | ||

| 10.lb | 8.00 | 7.66 | 7.68 | 7.80 | 7.67 | 7.76 | 7.62 | 7.74 | 7.64 | 7.61 | 7.72 | 7.85 | 7.84 | 7.79 | 7.70 | 7.78 | ||

| 10.w1b | 0.50 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 10.w1t | 0.43 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 10.w2b | 1.00 | 0.74 | 0.85 | 0.74 | 0.82 | 0.73 | 0.82 | 0.72 | 0.82 | 0.82 | 0.78 | 0.87 | 0.80 | 0.81 | 0.89 | 0.89 | ||

| 11.lb | 8.00 | 7.66 | 7.78 | 7.70 | 7.77 | 7.76 | 7.72 | 7.74 | 7.74 | 7.61 | 7.82 | 7.85 | 7.84 | 7.79 | 7.80 | 7.78 | ||

| 11.w1b | 1.00 | 0.74 | 0.75 | 0.84 | 0.82 | 0.73 | 0.72 | 0.72 | 0.82 | 0.72 | 0.78 | 0.77 | 0.80 | 0.91 | 0.79 | 0.89 | ||

| 11.w2b | 1.50 | 1.12 | 1.14 | 1.23 | 1.23 | 1.25 | 1.24 | 1.21 | 1.14 | 1.12 | 1.25 | 1.20 | 1.23 | 1.17 | 1.24 | 1.14 | ||

| 11.h | 2.00 | 1.99 | 2.01 | 2.00 | 2.00 | 1.99 | 2.00 | 2.01 | 1.99 | 2.00 | 2.00 | 1.99 | 1.99 | 1.99 | 2.01 | 2.00 | ||

| 12.db | 1.00 | 0.84 | 0.85 | 0.74 | 0.72 | 0.83 | 0.82 | 0.82 | 0.72 | 0.82 | 0.78 | 0.77 | 0.90 | 0.81 | 0.79 | 0.89 | ||

| 14.db | 3.00 | 2.63 | 2.65 | 2.75 | 2.60 | 2.63 | 2.72 | 2.71 | 2.63 | 2.63 | 2.65 | 2.64 | 2.67 | 2.73 | 2.75 | 2.74 | ||

| 14.h | 2.00 | 1.99 | 1.99 | 2.01 | 1.99 | 0.50 | 0.61 | 2.00 | 1.99 | 2.00 | 2.01 | 2.00 | 2.00 | 2.00 | 1.99 | 1.99 | ||

References

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP- stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Janssen, R.; Scheppokat, S.; Claussen, N. Tailor-made ceramic-based componentsadvantages. Eur. Ceram. Soc. 2018, 28, 1369–1379. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Wang, X.; Hu, Y.; Huang, C.; Xue, K. Fabrication and characterization of SiC whiskers toughened Al2O3 paste for stereolithography 3D printing applications. J. Alloys Compd. 2020, 828, 154347. [Google Scholar] [CrossRef]

- Geisler, E.; Lecompère, M.; Soppera, O. 3D printing of optical materials by processes based on photopolymerization: Materials, technologies, and recent advances. Photonics Res. 2022, 10, 1344–1360. [Google Scholar] [CrossRef]

- Kalsoom, U.; Nesterenko, P.N.; Paull, B. Recent developments in 3D printable composite. RSC Adv. 2016, 6, 60355. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A comprehensive review of the photopolymerization of ceramic resins used in stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Shuai, X.; Zeng, Y.; Li, P.; Chen, J. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. Ceramics 2020, 55, 6771–6782. [Google Scholar] [CrossRef]

- Bove, A.; Calignano, F.; Galati, M.; Iuliano, L. Protopolymerization of ceramic resins by stereolithography process: A review. Appl. Sci. 2022, 12, 3591. [Google Scholar] [CrossRef]

- Liu, H.; Mo, J. Study on nanosilicaa reinforced stereolithography resins. J. Reinf. Plast. Compos. 2010, 29, 909–920. [Google Scholar]

- Sprenger, S. Nanosilica-toughened epoxy resins. Polymers 2020, 12, 1777. [Google Scholar] [CrossRef]

- Hafkamp, T.; van Baars, G.; de Jager, B.; Etman, P. A feasibility study on process monitoring and control in vat photopolymerization of ceramics. Mechatronics 2018, 56, 220–241. [Google Scholar] [CrossRef]

- Ryu, K.; Kim, J.; Choi, J.; Kim, U. The 3D Printing Behavior of Photocurable Ceramic/Polymer Composite Slurries Prepared with Different Particle Sizes. Nanomaterials 2022, 12, 2631. [Google Scholar] [CrossRef] [PubMed]

- Griffith, M.L.; Halloran, J.W. Scattering of ultraviolet radiation in turbid suspensions. Appl. Phys. 1997, 81, 2538–2546. [Google Scholar] [CrossRef] [Green Version]

- Chartier, T.; Chaput, C.; Doreau, F.; Loiseau, M. Stereolithography of structural complex ceramic parts. Mater. Sci. 2002, 37, 3141–3147. [Google Scholar] [CrossRef]

- Licciulli, A.; Corcione, C.E.; Greco, A.; Amicarelli, V.; Maffezzoli, A. Laser stereolithography of ZrO2 toughened Al2O3. J. Eur. Ceram. Soc. 2005, 25, 1581–1589. [Google Scholar] [CrossRef]

- Wu, X.; Lian, Q.; Li, D.; He, X.; Meng, J.; Liu, X.; Jin, Z. Influence of boundary masks on dimensions and surface roughness using segmented exposure in ceramic 3D printing. Ceram. Int. 2019, 45, 3687–3697. [Google Scholar] [CrossRef]

- Liu, Y.; Zhan, L.; Wen, L.; Cheng, L.; He, Y.; Xu, B.; Wu, Q.; Liu, S. Effects of particle size and color on photocuring performance of Si3N4 ceramic slurry by stereolithography. Eur. Ceram. Soc. 2021, 41, 2386–2394. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, C.; Wang, G.; He, R.; Ding, G.; Wang, M.; Dai, D.; Fang, D. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceram. Int. 2019, 45, 203–208. [Google Scholar] [CrossRef]

- Azarmi, F.; Amiri, A. Microstructural evolution during fabrication of alumina via laser stereolithography technique. Ceram. Int. 2019, 45, 271–278. [Google Scholar] [CrossRef]

- Zheng, T.; Wang, W.; Sun, J.; Liu, J.; Bai, J. Development and evaluation of Al2O3–ZrO2 composite processed by digital light 3D printing. Ceram. Int. 2020, 46, 8682–8688. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Lai, Q.; Huang, X.; Chen, Q.; Fu, X.; Shi, Z. Preparation and characterization of UV curable Al2O3 suspensions applying for stereolithography 3D printing ceramic microcomponent. Powder Technol. 2018, 338, 153–161. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Park, M.S.; Lee, J.W.; Yun, J.S. A Study on the Rheological and Mechanical Properties of Photo-Curable Ceramic/Polymer Composites with Different Silane Coupling Agents for SLA 3D Printing Technology. Nanomaterials 2018, 8, 93. [Google Scholar]

| Height (Nominal Value: 30 mm) | Width (Nominal Value: 50 mm) | Thickness (Nominal Value: 3 mm) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| HT | SG | CL | HT | SG | CL | HT | SG | CL | |

| Mean Value average (mm) | 30.14 | 29.97 | 30.06 | 49.94 | 50.04 | 49.82 | 2.98 | 3.01 | 2.98 |

| Standard Deviation average (mm) | 0.06 | 0.09 | 0.05 | 0.05 | 0.04 | 0.02 | 0.03 | 0.02 | 0.01 |

| Standard error average (mm) | 0.04 | 0.05 | 0.03 | 0.03 | 0.02 | 0.01 | 0.01 | 0.01 | 0.00 |

| Dimension Upper Limit (mm) | 30.18 | 30.03 | 30.09 | 49.97 | 50.07 | 49.83 | 2.99 | 3.02 | 2.98 |

| Dimension Lower Limit (mm) | 30.11 | 29.92 | 30.04 | 49.91 | 50.02 | 49.81 | 2.97 | 3.01 | 2.97 |

| HT | HT Al2O3 1% | HT Al2O3 5% | HT SiO2 1% | HT SiO2 5% | |

|---|---|---|---|---|---|

| Height (nominal value: 30 mm) | |||||

| Mean Value aver. (mm) | 30.14 | 30.08 | 30.02 | 30.20 | 30.18 |

| Standard Deviation aver. (mm) | 0.06 | 0.03 | 0.04 | 0.08 | 0.04 |

| Standard error aver. (mm) | 0.04 | 0.02 | 0.02 | 0.05 | 0.03 |

| Dimension Upper Limit (mm) | 30.18 | 30.10 | 30.04 | 30.25 | 30.20 |

| Dimension Lower Limit (mm) | 30.11 | 30.06 | 30.00 | 30.15 | 30.15 |

| Width (nominal value: 50 mm) | |||||

| Mean Value aver. (mm) | 49.94 | 49.99 | 49.99 | 49.92 | 49.92 |

| Standard Deviation avg. (mm) | 0.05 | 0.03 | 0.04 | 0.03 | 0.03 |

| Standard error avg. (mm) | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 |

| Dimension Upper Limit (mm) | 49.97 | 50.01 | 50.02 | 49.93 | 49.93 |

| Dimension Lower Limit (mm) | 49.91 | 49.97 | 49.97 | 49.90 | 49.90 |

| Thickness (nominal value 3 mm) | |||||

| Mean Value avg. (mm) | 2.98 | 3.00 | 3.01 | 3.04 | 3.06 |

| Standard Deviation avg. (mm) | 0.03 | 0.03 | 0.02 | 0.04 | 0.05 |

| Standard error avg. (mm) | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| Dimension Upper Limit (mm) | 2.99 | 3.01 | 3.02 | 3.05 | 3.08 |

| Dimension Lower Limit (mm) | 2.97 | 2.99 | 3.01 | 3.03 | 3.05 |

| HT | HT + Al2O3 1% | HT + Al2O3 5% | HT + SiO2 1% | HT + SiO2 5% | |

|---|---|---|---|---|---|

| Average error (mm) | −0.03 | −0.01 | 0.02 | −0.05 | −0.05 |

| Average deviation (mm) | 0.09 | 0.04 | 0.02 | 0.14 | 0.15 |

| Avg. error Z (mm) | −0.01 | 0.00 | 0.00 | −0.01 | 0.00 |

| Avg. error dev Z (mm) | 0.01 | 0.00 | 0.00 | 0.00 | 0.01 |

| Avg. error XY (mm) | −0.02 | −0.01 | −0.01 | −0.03 | −0.03 |

| Avg. error dev XY (mm) | 0.08 | 0.04 | 0.04 | 0.13 | 0.13 |

| HT | HT + Al2O3 1% | HT + Al2O3 5% | HT + SiO2 1% | HT + SiO2 5% | |

|---|---|---|---|---|---|

| Average error (mm) | 0.13 | 0.13 | 0.11 | 0.12 | 0.10 |

| Average deviation (mm) | 0.10 | 0.10 | 0.15 | 0.09 | 0.08 |

| Avg. error Z (mm) | 0.03 | 0.03 | 0.03 | 0.02 | 0.02 |

| Avg. error dev Z (mm) | 0.01 | 0.02 | 0.02 | 0.01 | 0.01 |

| Avg. error XY (mm) | 0.13 | 0.17 | 0.14 | 0.11 | 0.10 |

| Avg. error dev XY (mm) | 0.10 | 0.13 | 0.10 | 0.09 | 0.08 |

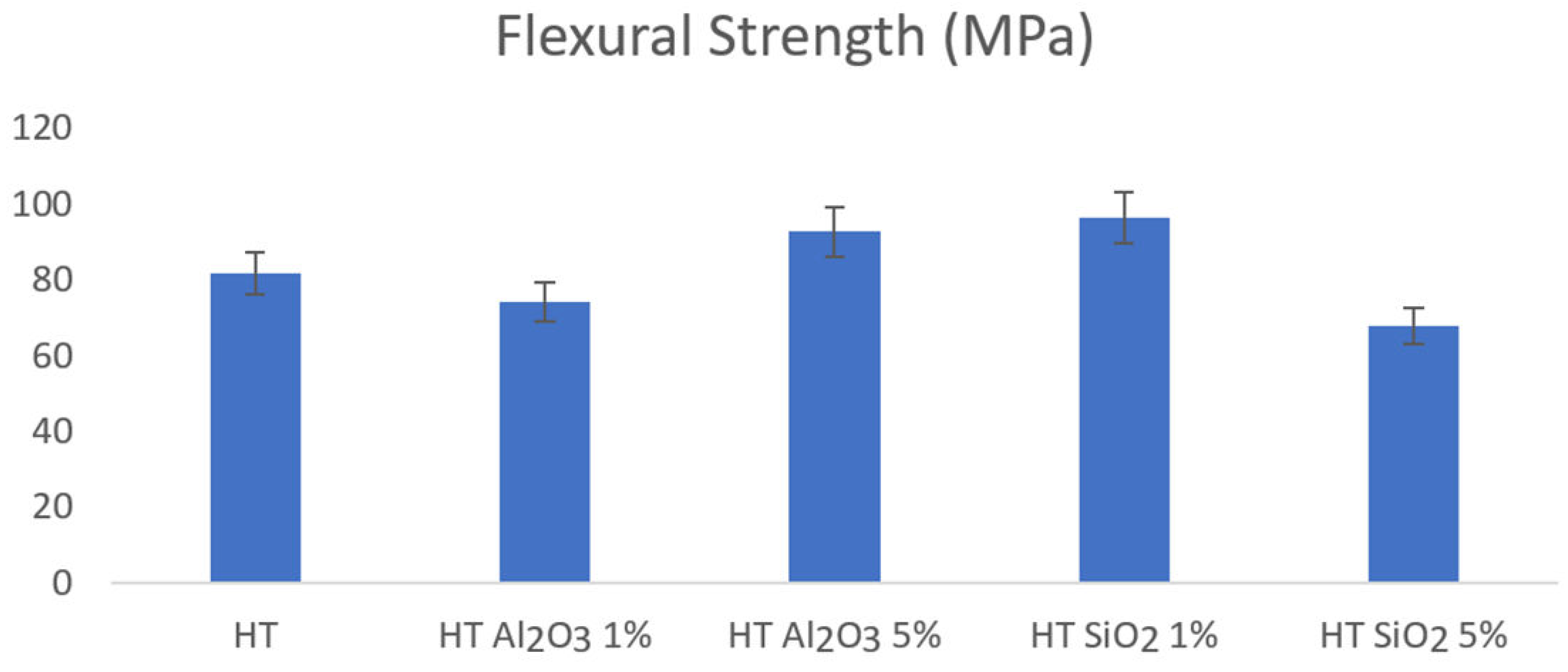

| Maximum Stress (MPa) | Flexural Strain at Max Stress (%) | Flexural Modulus (GPa) | |

|---|---|---|---|

| HT | 81.59 ± 22.86 | 4.95% | 2.74 ± 0.16 |

| HT Al2O3 1% | 74.16 ± 11.15 | 4.95% | 2.50 ± 0.05 |

| HT Al2O3 5% | 92.58 ± 12.00 | 5.56% | 2.69 ± 0.12 |

| HT SiO2 1% | 96.27 ± 13.58 | 5.47% | 2.81 ± 0.16 |

| HT SiO2 5% | 67.62 ± 20.68 | 4.24% | 2.81 ± 0.23 |

| Coupon | Specimens No. | Separation Pressure (MPa) | Separation Force (N) |

|---|---|---|---|

| As-printed | 1 | 0.255 | 8.01 |

| 2 | 0.262 | 8.23 | |

| Sanded | 1 | 0.131 | 4.11 |

| 2 | 0.131 | 4.11 | |

| Sanded + Dip-coated | 1 | 0.131 | 4.11 |

| 2 | 0.145 | 4.55 | |

| As-printed with PTFE spray | 1 | 0 | 0 |

| 2 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karatza, A.; Zouboulis, P.; Gavalas, I.; Semitekolos, D.; Kontiza, A.; Karamitrou, M.; Koumoulos, E.P.; Charitidis, C. SLA Resins Modification by Liquid Mixing with Ceramic Powders Aiming at Mechanical Property and Thermal Stability Enhancement for Rapid Tooling Applications. J. Manuf. Mater. Process. 2022, 6, 129. https://doi.org/10.3390/jmmp6060129

Karatza A, Zouboulis P, Gavalas I, Semitekolos D, Kontiza A, Karamitrou M, Koumoulos EP, Charitidis C. SLA Resins Modification by Liquid Mixing with Ceramic Powders Aiming at Mechanical Property and Thermal Stability Enhancement for Rapid Tooling Applications. Journal of Manufacturing and Materials Processing. 2022; 6(6):129. https://doi.org/10.3390/jmmp6060129

Chicago/Turabian StyleKaratza, Anna, Panagiotis Zouboulis, Iakovos Gavalas, Dionisis Semitekolos, Artemis Kontiza, Melpo Karamitrou, Elias P. Koumoulos, and Costas Charitidis. 2022. "SLA Resins Modification by Liquid Mixing with Ceramic Powders Aiming at Mechanical Property and Thermal Stability Enhancement for Rapid Tooling Applications" Journal of Manufacturing and Materials Processing 6, no. 6: 129. https://doi.org/10.3390/jmmp6060129

APA StyleKaratza, A., Zouboulis, P., Gavalas, I., Semitekolos, D., Kontiza, A., Karamitrou, M., Koumoulos, E. P., & Charitidis, C. (2022). SLA Resins Modification by Liquid Mixing with Ceramic Powders Aiming at Mechanical Property and Thermal Stability Enhancement for Rapid Tooling Applications. Journal of Manufacturing and Materials Processing, 6(6), 129. https://doi.org/10.3390/jmmp6060129