Crystallization and Aging Behavior of Polyetheretherketone PEEK within Rapid Tooling and Rubber Molding

Abstract

:1. Introduction

2. State-of-Art

3. Materials and Methods

3.1. Test Setup

- Raw material–Source filament;

- PEEK after processing by FFF (nozzle temperature 420 °C, build platform temperature 150 °C)

- Build chamber temperature below Tg—90 °C

- Build chamber temperature above Tg—150 °C;

- Material after annealing—Holding time 2 h; 5 h; and 10 h;

- Mold material after 100 loaded cycles at 200 °C (corresponds to 24 h at continuous thermal load);

- Artificially aged material 10–30 days at 200 °C.

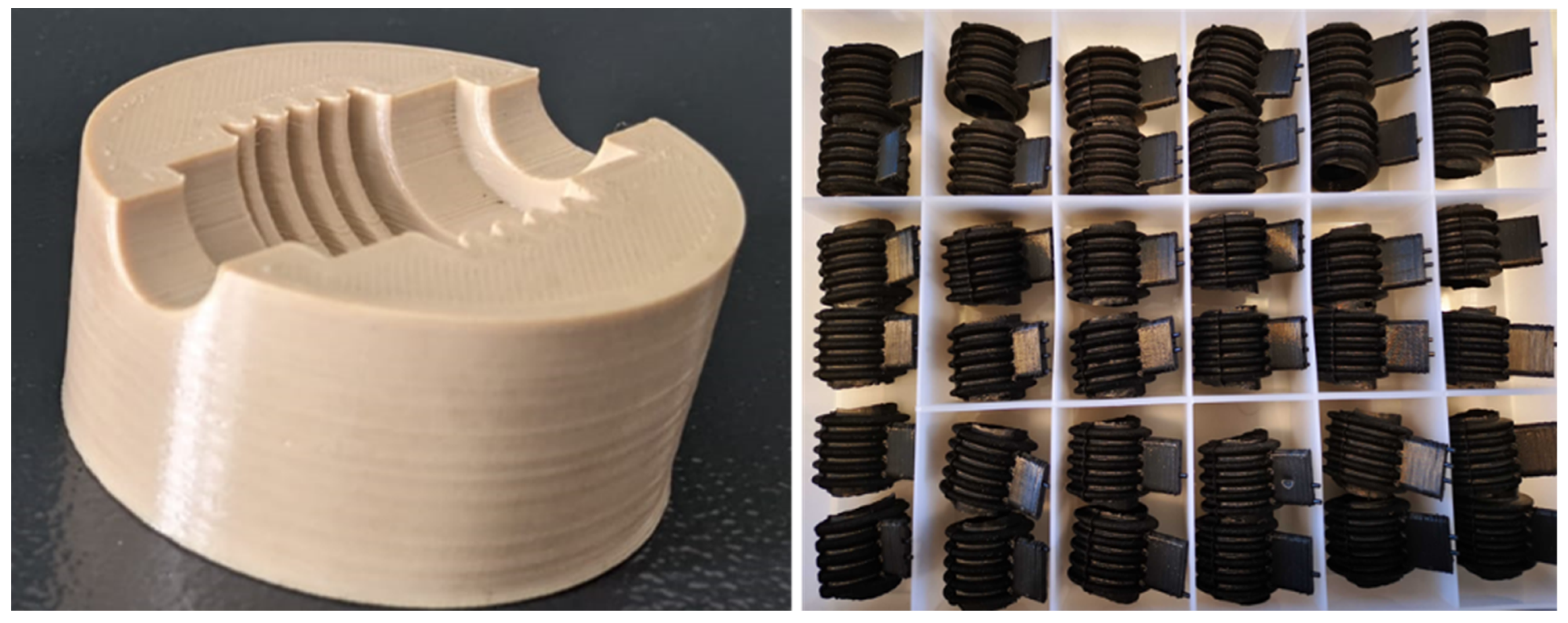

3.2. Laboratory Plant and Manufacturing

3.3. Samples

3.4. Thermal Post-Treatment

3.5. DSC Analysis

3.6. Tensile Test

4. Results

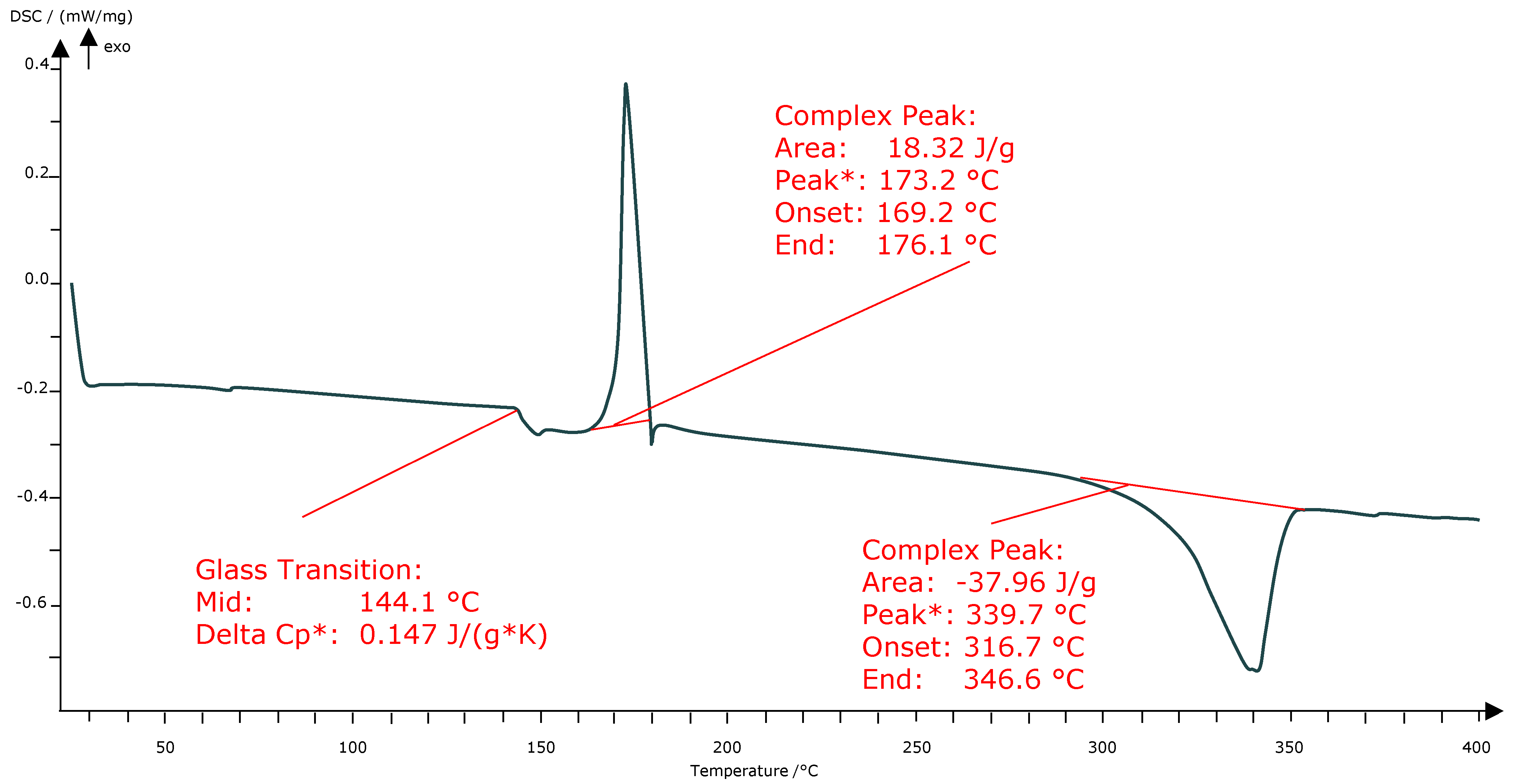

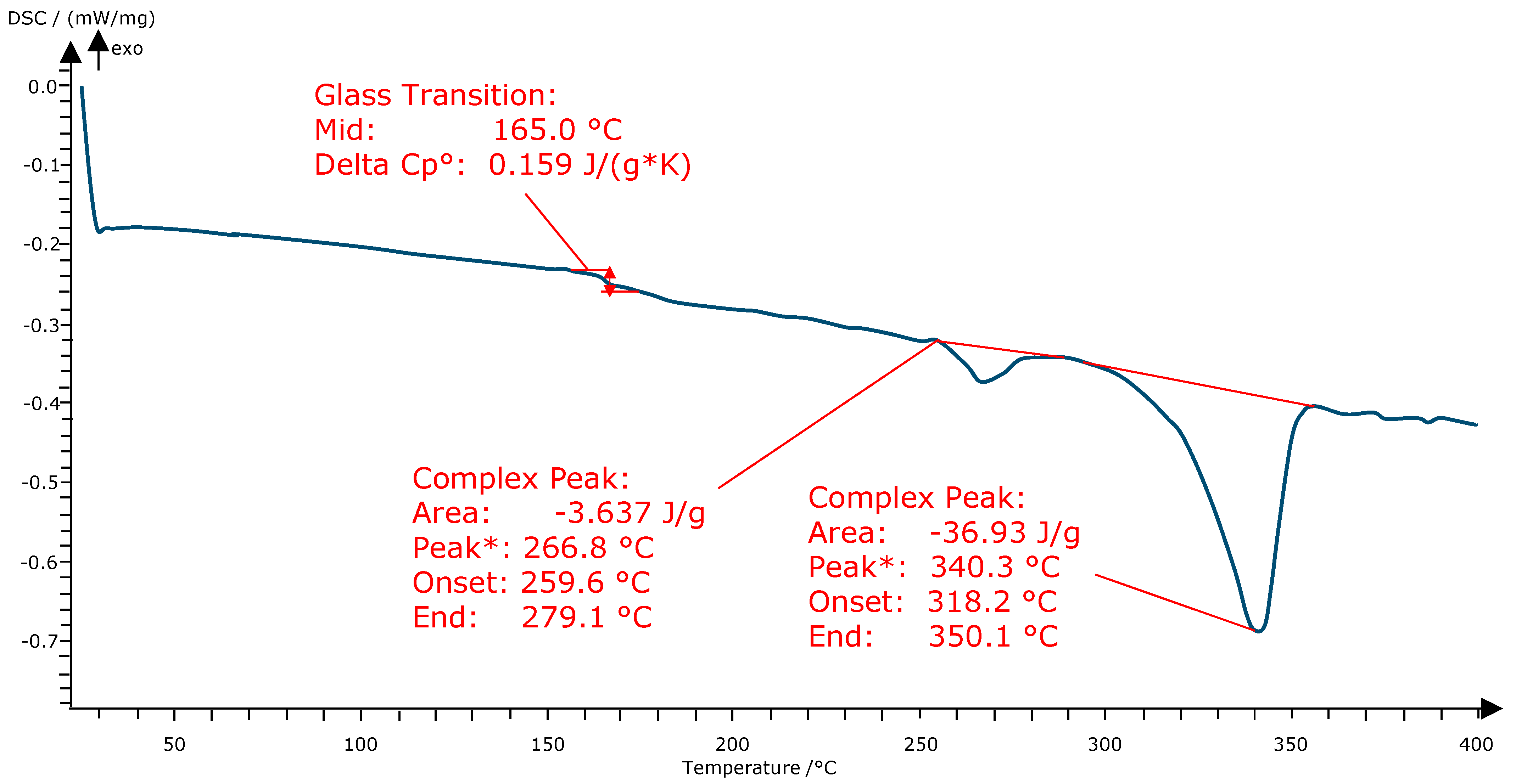

4.1. Source Material

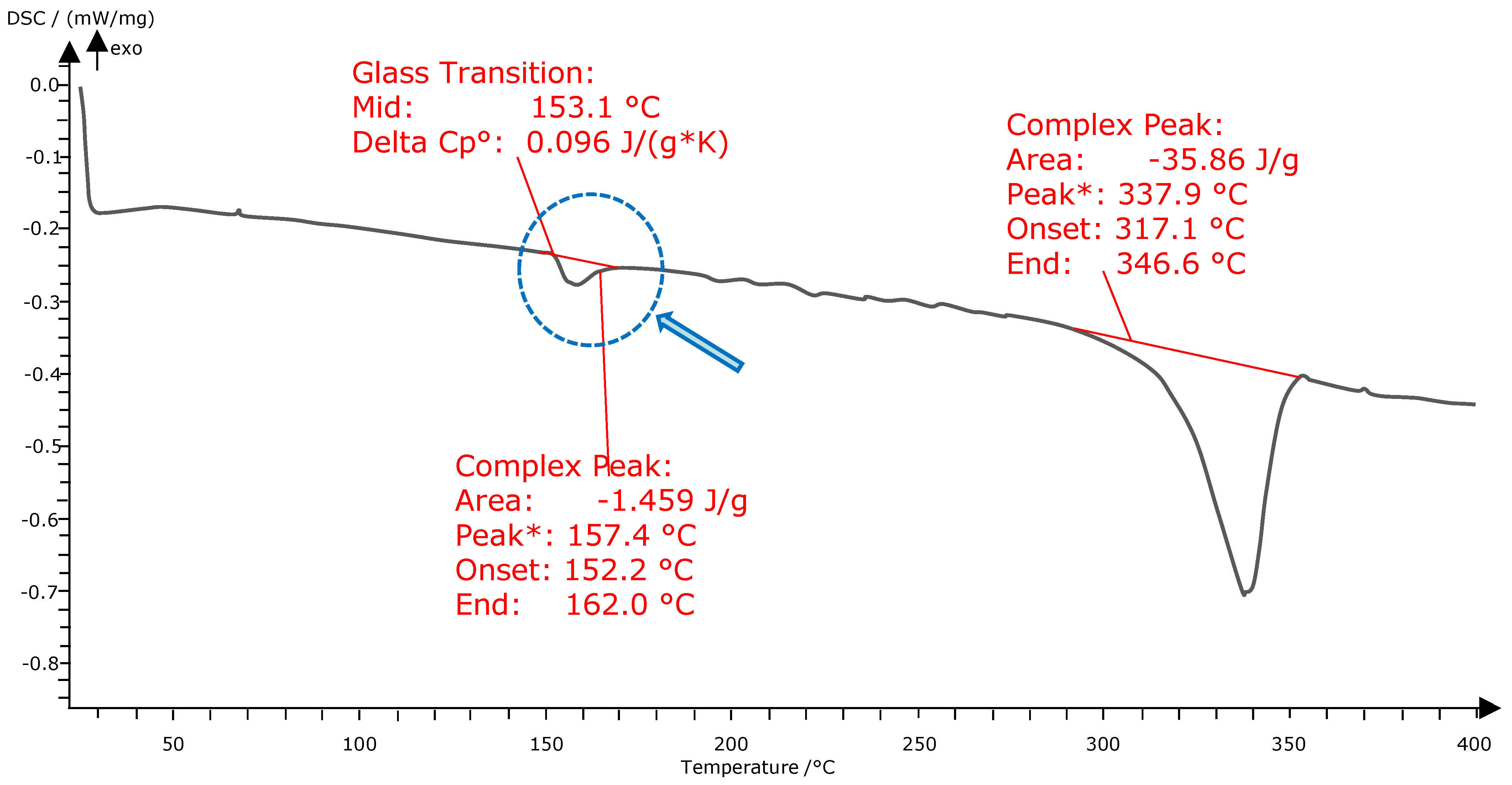

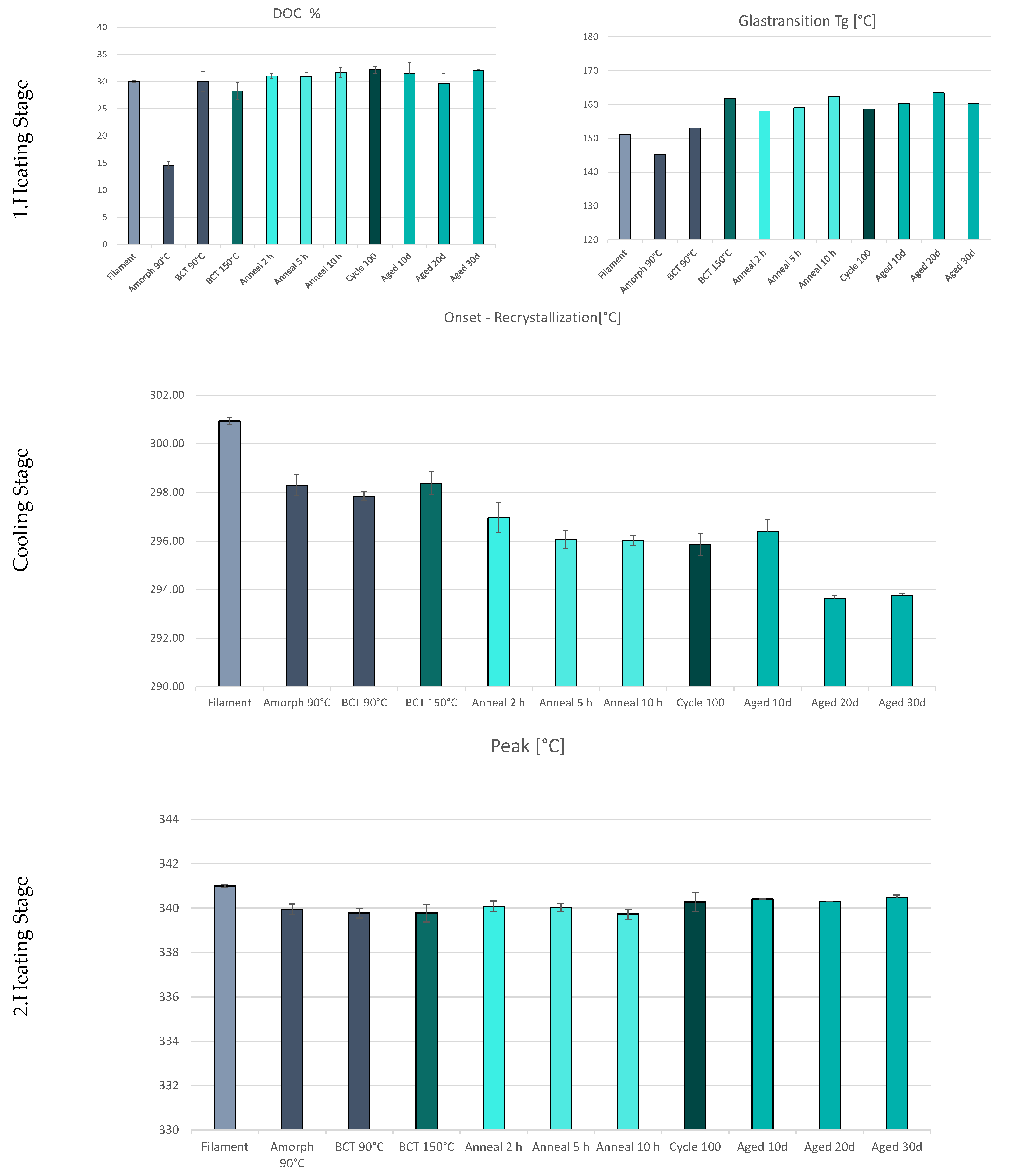

4.2. FFF Process—Build Chamber Temperature

4.3. Annealed Samples

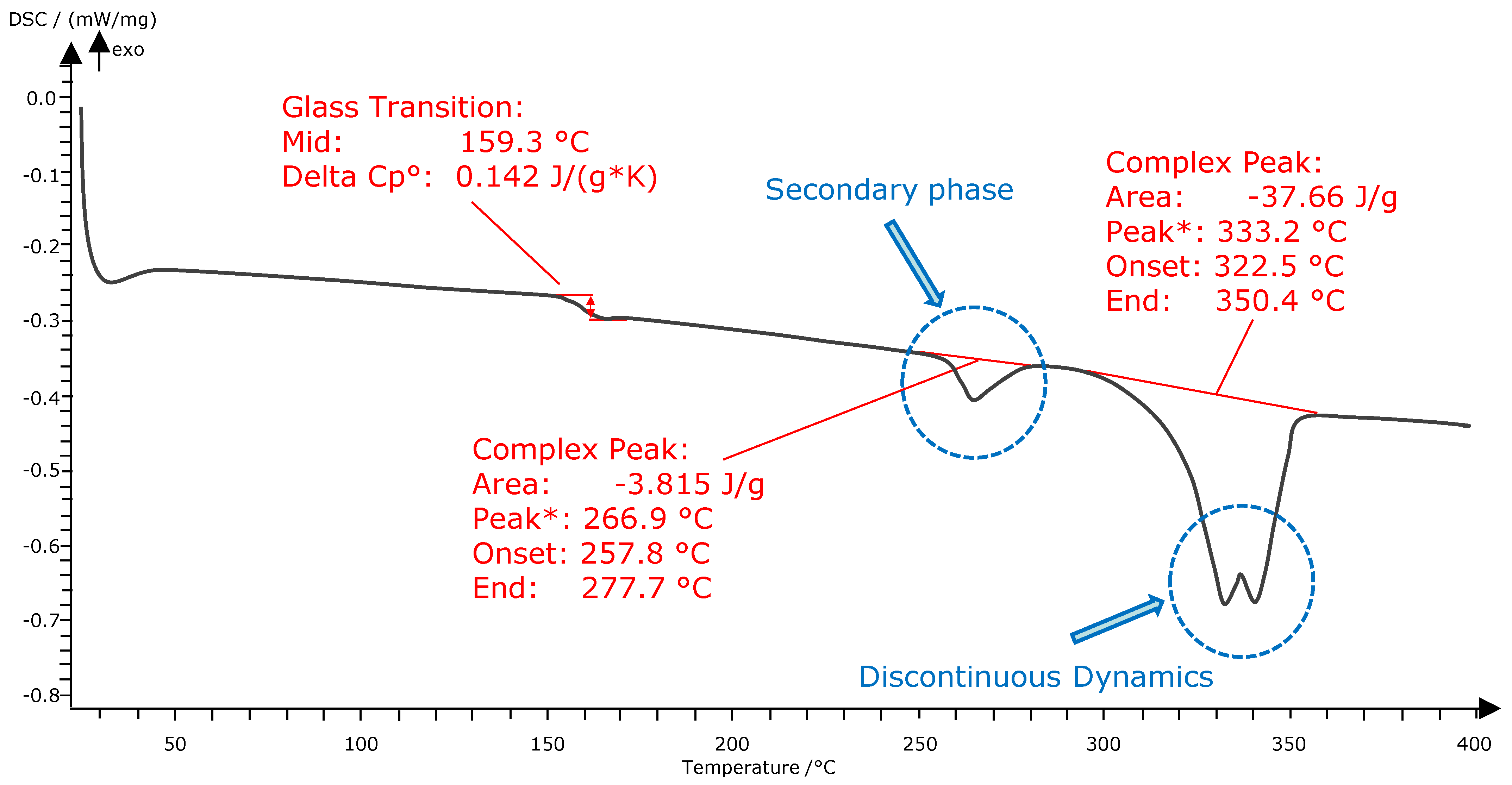

4.4. Cyclus100 and Artificially Aged Material

5. Conclusions and Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gebhardt, A.; Hötter, J.-S. Additive Manufacturing: 3D Printing for Prototyping and Manufacturing; Hanser Publishers: Munich, Germany; Cincinnati, OH, USA, 2016. [Google Scholar]

- Kovács, J.G.; Szabó, F.; Kovács, N.K.; Suplicz, A.; Zink, B.; Tábi, T.; Hargitai, H. Thermal simulations and measurements for rapid tool inserts in injection molding applications. Appl. Therm. Eng. 2015, 85, 44–51. [Google Scholar] [CrossRef]

- Dizon, J.R.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. 3D Printed Injection Molds Using Various 3D Printing Technologies. In Materials Science Forum; Trans Tech Publications Ltd.: Bäch, Switzerland, 2020; Volume 1005, pp. 150–156. [Google Scholar]

- Hopkinson, N.; Dickens, P. A comparison between stereolithography and aluminium injection moulding tooling. Rapid Prototyp. J. 2000, 6, 253–258. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vaxevanidis, N.; Kechagias, J. Surface Roughness Investigation of Poly-Jet 3D Printing. Mathematics 2020, 8, 1758. [Google Scholar] [CrossRef]

- Fortify, Injection Molded Materials with Fortify’s Tools—Fortify. 2020. Available online: https://3dfortify.com/molded-materials-fortify-mold-tools/ (accessed on 5 March 2022).

- Formlabs, Novus Applications setzt für Spritzguss von Prototypenformen auf Rigid 10K Resin. 2022. Available online: https://formlabs.com/de/blog/novus-applications-rigid-10k-resin/ (accessed on 26 August 2022).

- Kaiser, W. Kunststoffchemie für Ingenieure; Hanser: München, Germany; Wien, Austria, 2006. [Google Scholar]

- Eyerer, P.; Hirth, T.; Elsner, P. Polymer Engineering; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Vassallo, M.; Rochman, A. Rapid prototyping solution for the production of vulcanized rubber components. In AIP Conference Proceedings; AIP Publishing LLC.: Melville, NY, USA, 2019; Volume 2113, p. 150014. [Google Scholar]

- Zanjanijam, A.R.; Major, I.; Lyons, J.G.; Lafont, U.; Devine, D.M. Fused Filament Fabrication of PEEK: A Review of Process-Structure-Property Relationships. Polymers 2020, 12, 1665. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Leiner, M.; Ghita, O.; McKay, R.; Kurtz, S.M. Additive Manufacturing of Polyaryletherketones. In PEEK Biomaterials Handbook; Elsevier: Philadelphia, PA, USA, 2019; pp. 89–103. [Google Scholar]

- Ehrenstein, G.W.; Pongratz, S. Beständigkeit von Kunststoffen; Edition Kunststoffe; Hanser: München, Germany, 2007. [Google Scholar]

- Elsner, P.; Domininghaus, H. (Eds.) Kunststoffe: Eigenschaften und Anwendungen. In Mit 240 Tabellen. VDI-Buch, 7th ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Schönhoff, L.M.; Mayinger, F.; Eichberger, M.; Reznikova, E.; Stawarczyk, B. 3D printing of dental restorations: Mechanical properties of thermoplastic polymer materials. J. Mech. Behav. Biomed. Mater. 2021, 119, 104544. [Google Scholar] [CrossRef] [PubMed]

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- Abdullah, F.; Okuyama, K.; Morimitsu, A.; Yamagata, N. Effects of Thermal Cycle and Ultraviolet Radiation on 3D Printed Carbon Fiber/Polyether Ether Ketone Ablator. Aerospace 2020, 7, 95. [Google Scholar] [CrossRef]

- Mylläri, V.; Ruoko, T.-P.; Vuorinen, J.; Lemmetyinen, H. Characterization of thermally aged polyetheretherketone fibres—Mechanical, thermal, rheological and chemical property changes. Polym. Degrad. Stab. 2015, 120, 419–426. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, H.; Li, J. Thermal aging study of PEEK for nuclear power plant containment dome. J. Polym. Res. 2022, 29, 5. [Google Scholar] [CrossRef]

- Tardif, X.; Pignon, B.; Boyard, N.; Schmelzer, J.W.; Sobotka, V.; Delaunay, D.; Schick, C. Experimental study of crystallization of PolyEtherEtherKetone (PEEK) over a large temperature range using a nano-calorimeter. Polym. Test. 2014, 36, 10–19. [Google Scholar] [CrossRef]

- Day, M.; Suprunchuk, T.; Cooney, J.D.; Wiles, D.M. Thermal degradation of poly(aryl-ether–ether-ketone) (PEEK): A differential scanning calorimetry study. J. Appl. Polym. Sci. 1988, 36, 1097–1106. [Google Scholar] [CrossRef]

- Lee, A.; Wynn, M.; Quigley, L.; Salviato, M.; Zobeiry, N. Effect of Temperature History During Additive Manufacturing on Crystalline Morphology of Polyether Ether Ketone. arXiv 2021, arXiv:2109.04506. [Google Scholar]

- Wang, Y.; Beard, J.D.; Evans, K.E.; Ghita, O. Unusual crystalline morphology of Poly Aryl Ether Ketones (PAEKs). RSC Adv. 2016, 6, 3198–3209. [Google Scholar] [CrossRef] [Green Version]

| Leiyer Height 0.1 mm | Tensile Strength [MPa] |

|---|---|

| Post Treatment | |

| None | 63.4 |

| Annealing 250 °C | 73.8 |

| 10 days 200 °C | 80.6 |

| 20 days 200 °C | 75.2 |

| 30 days 200 °C | 70.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, K.; Balc, N.; Bremen, S.; Skupin, M. Crystallization and Aging Behavior of Polyetheretherketone PEEK within Rapid Tooling and Rubber Molding. J. Manuf. Mater. Process. 2022, 6, 93. https://doi.org/10.3390/jmmp6050093

Abbas K, Balc N, Bremen S, Skupin M. Crystallization and Aging Behavior of Polyetheretherketone PEEK within Rapid Tooling and Rubber Molding. Journal of Manufacturing and Materials Processing. 2022; 6(5):93. https://doi.org/10.3390/jmmp6050093

Chicago/Turabian StyleAbbas, Karim, Nicolae Balc, Sebastian Bremen, and Marco Skupin. 2022. "Crystallization and Aging Behavior of Polyetheretherketone PEEK within Rapid Tooling and Rubber Molding" Journal of Manufacturing and Materials Processing 6, no. 5: 93. https://doi.org/10.3390/jmmp6050093

APA StyleAbbas, K., Balc, N., Bremen, S., & Skupin, M. (2022). Crystallization and Aging Behavior of Polyetheretherketone PEEK within Rapid Tooling and Rubber Molding. Journal of Manufacturing and Materials Processing, 6(5), 93. https://doi.org/10.3390/jmmp6050093