Fabrication of Highly Compacted Green Body Using Multi-Sized Al Powder under a Centrifugal Force

Abstract

:1. Introduction

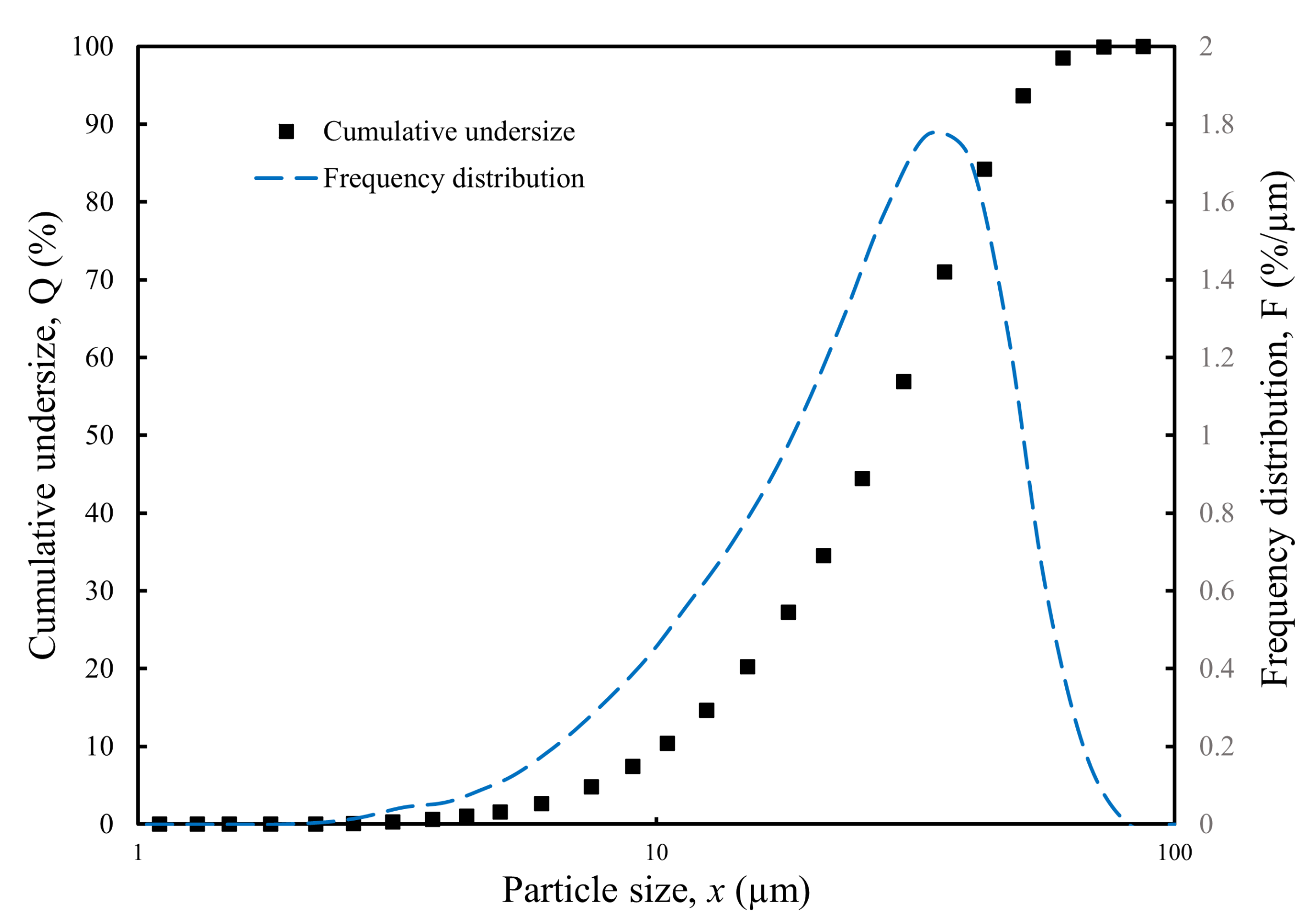

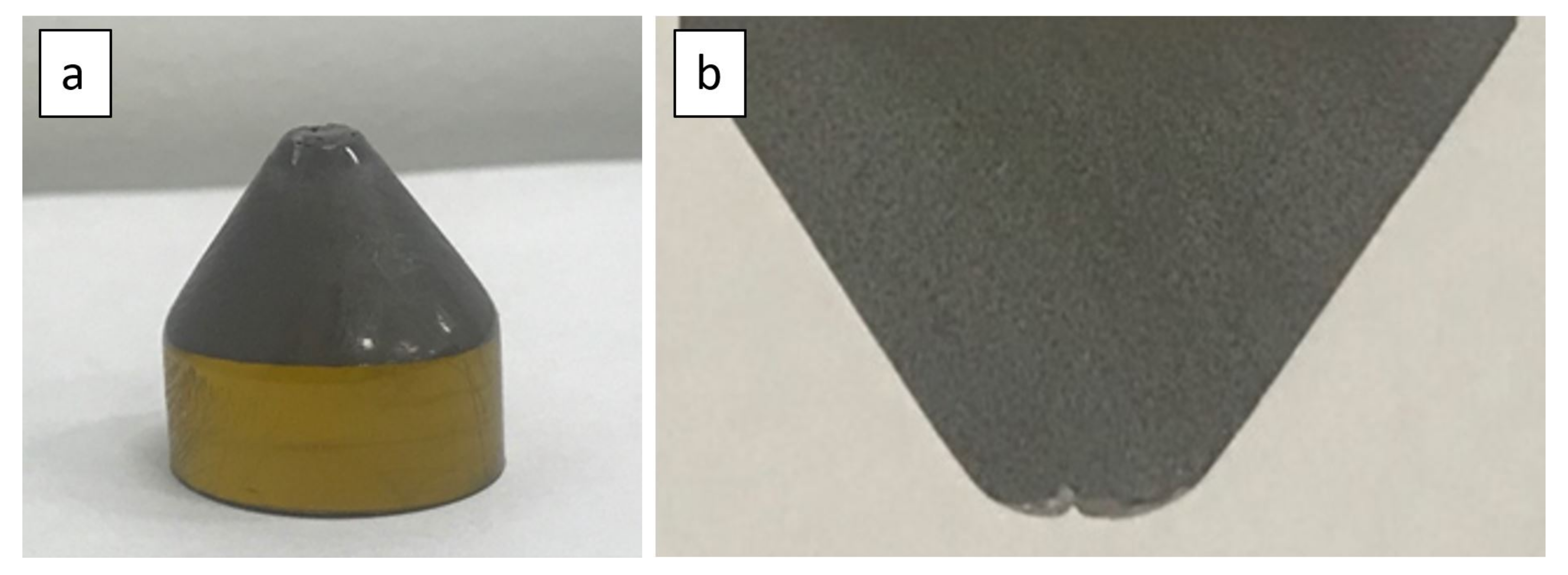

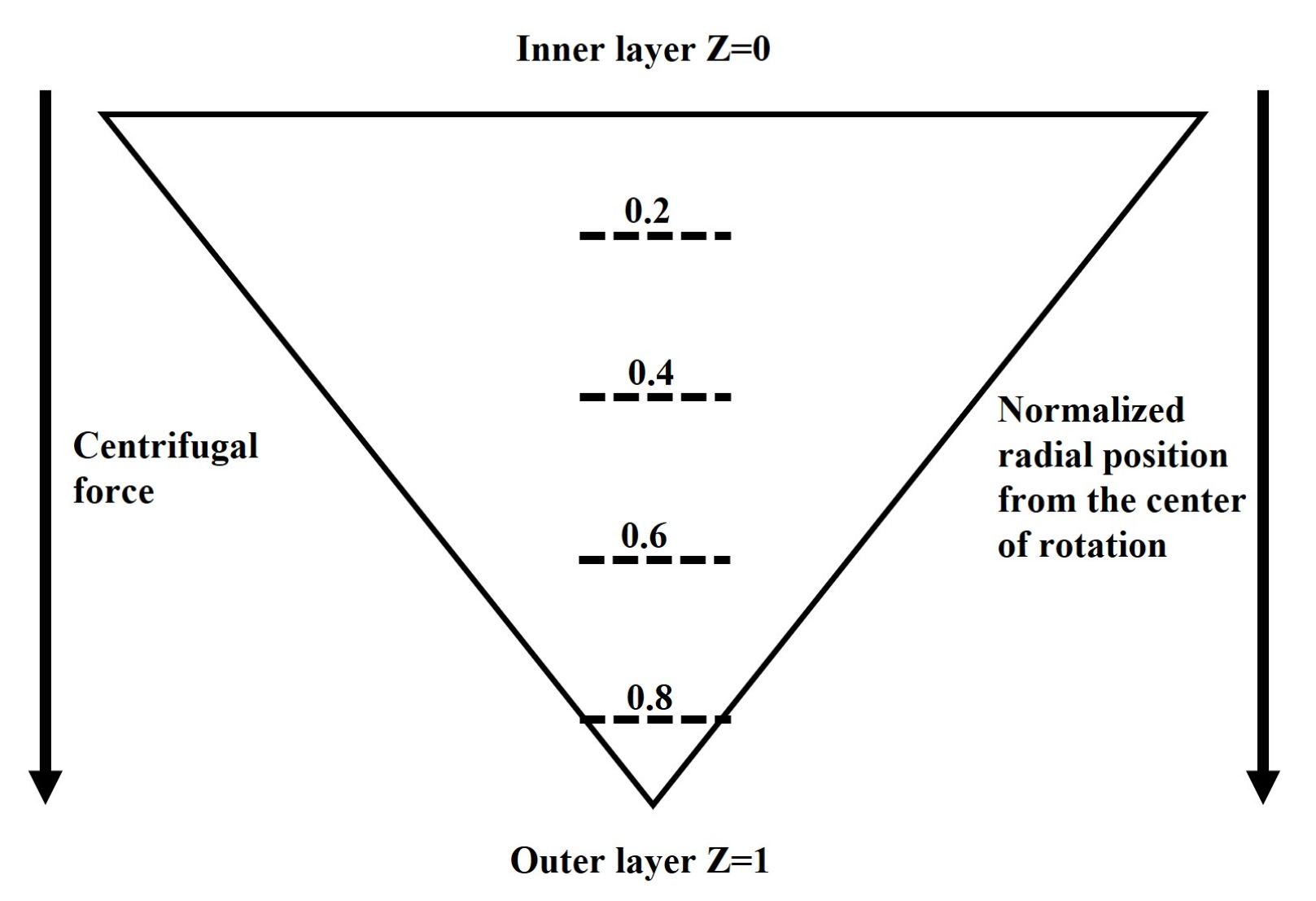

2. Materials and Methods

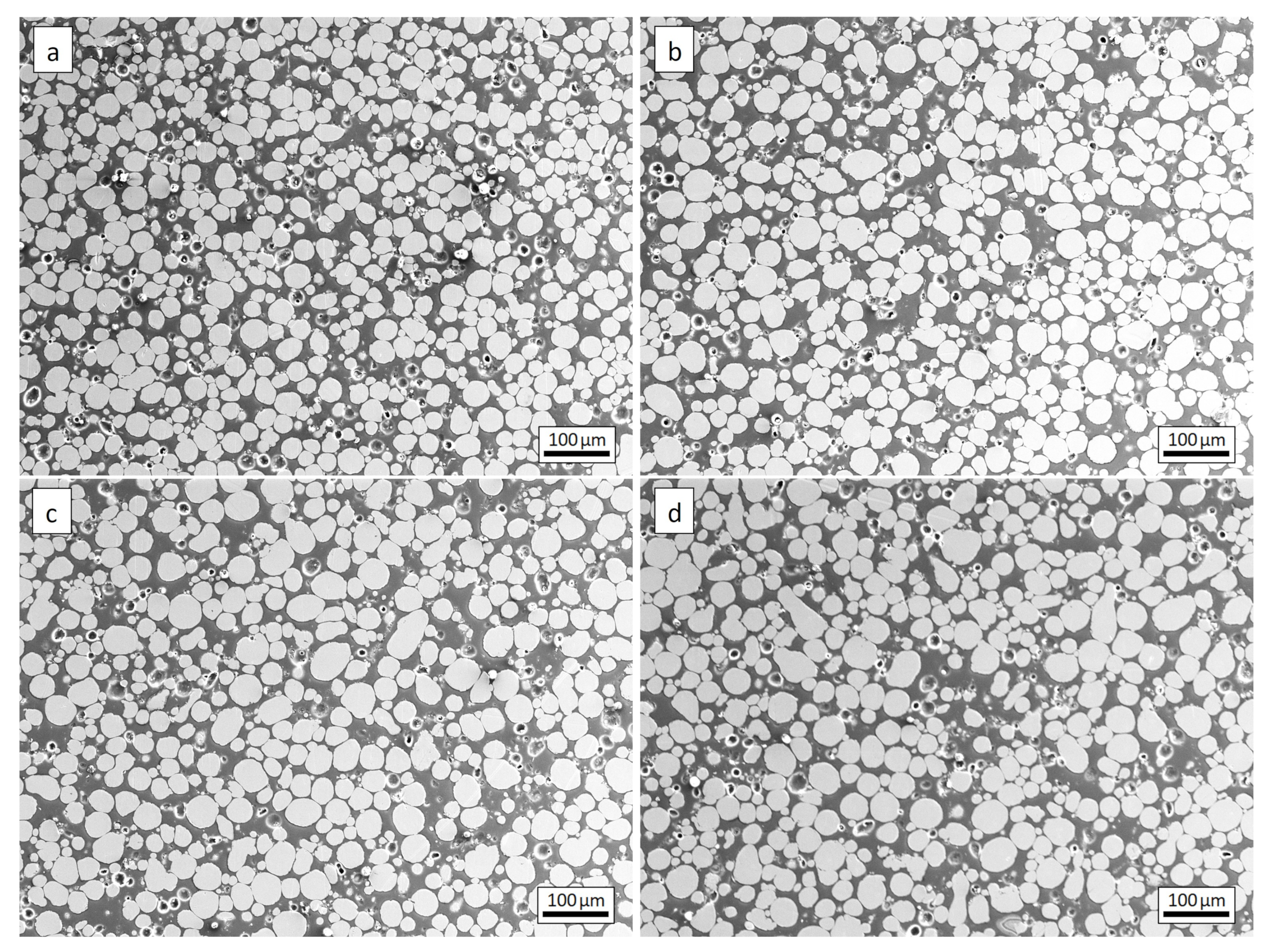

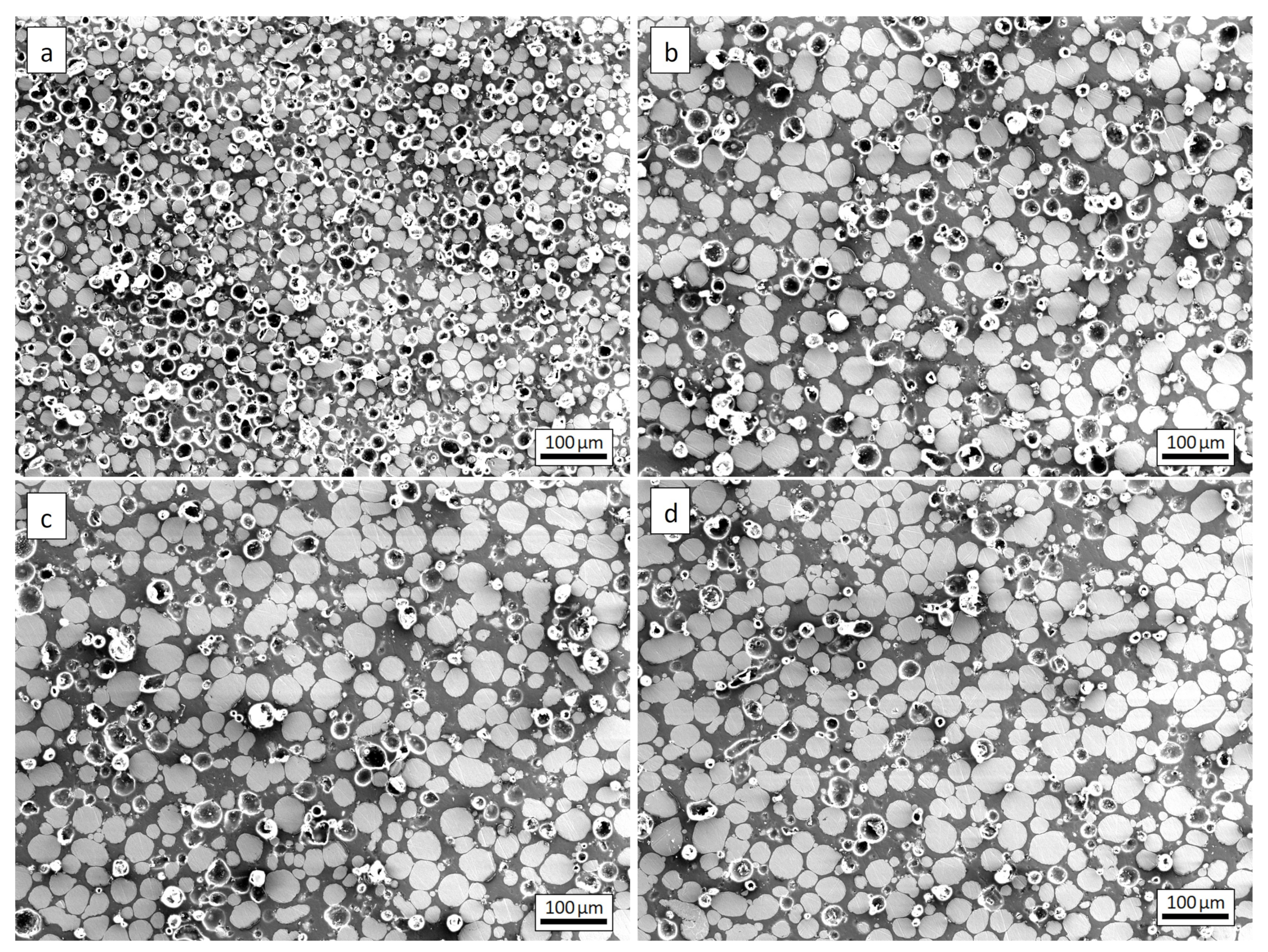

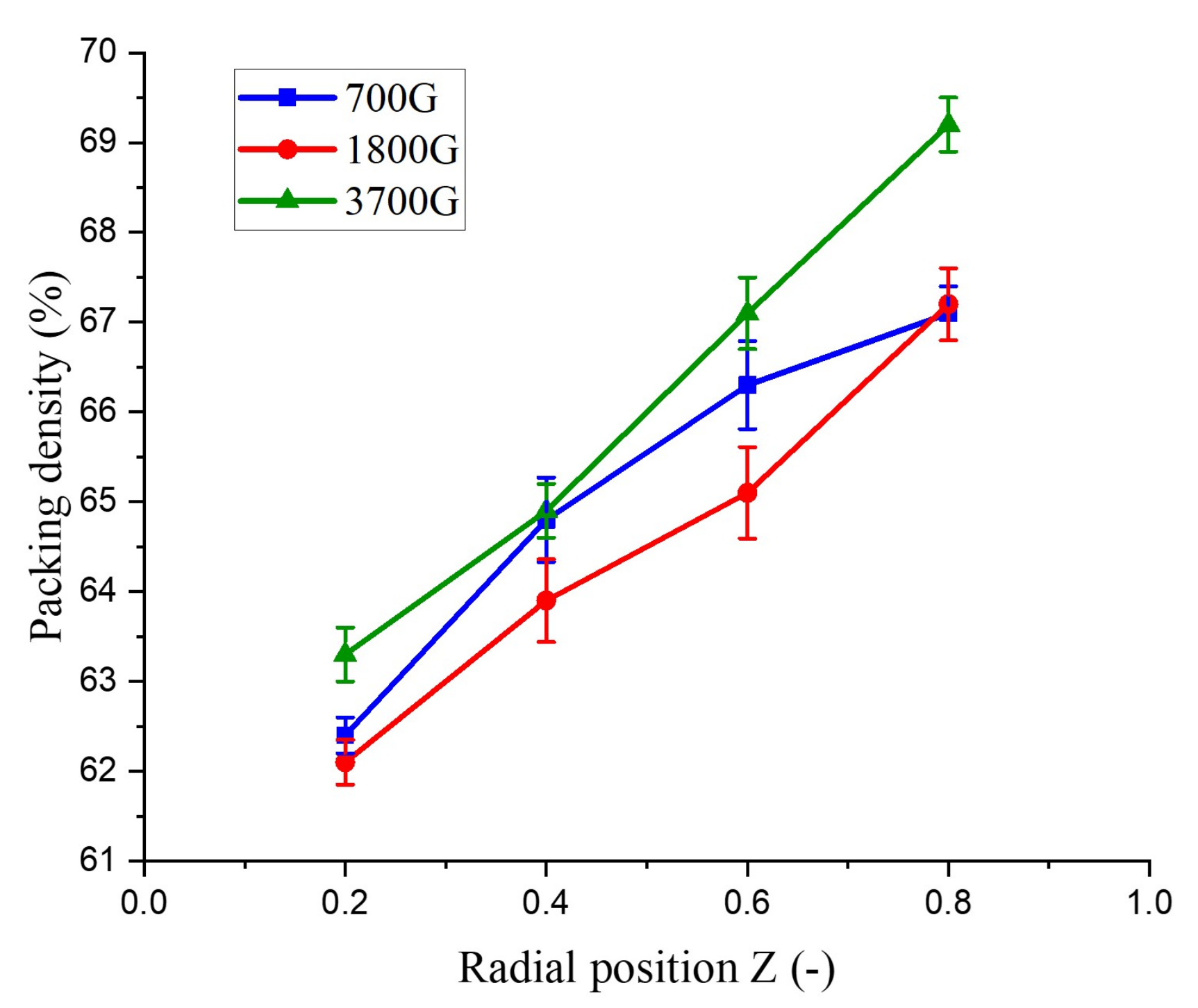

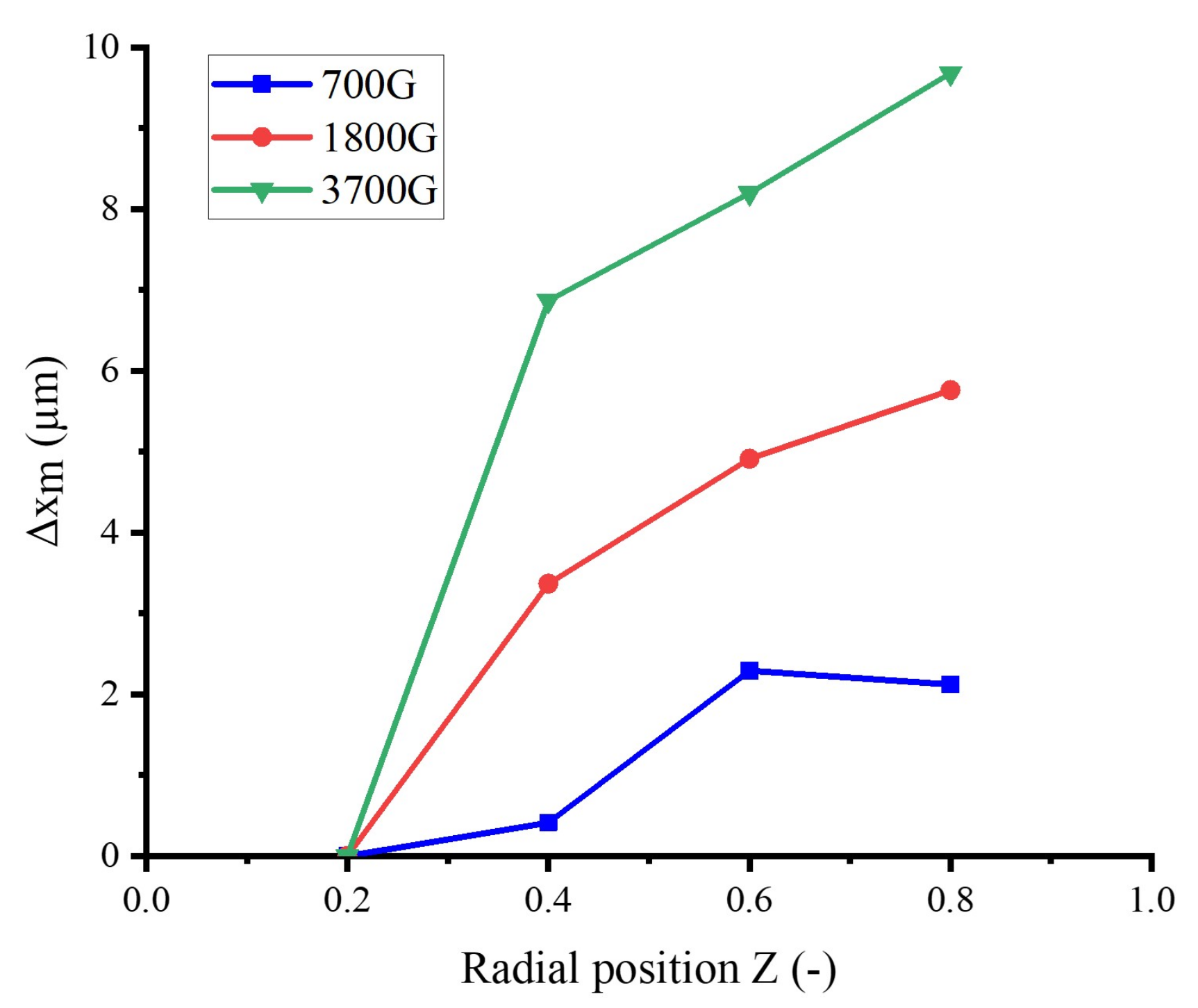

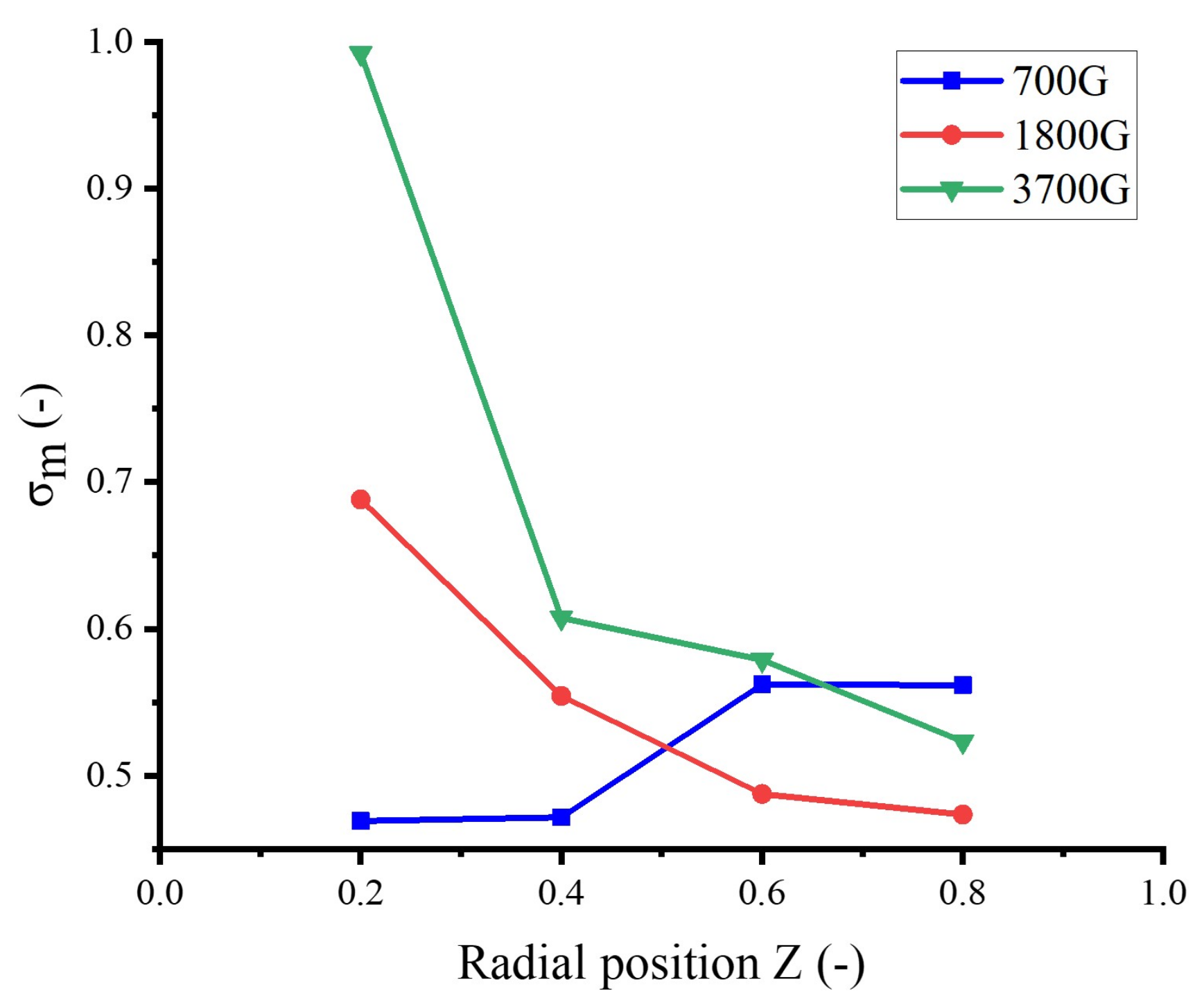

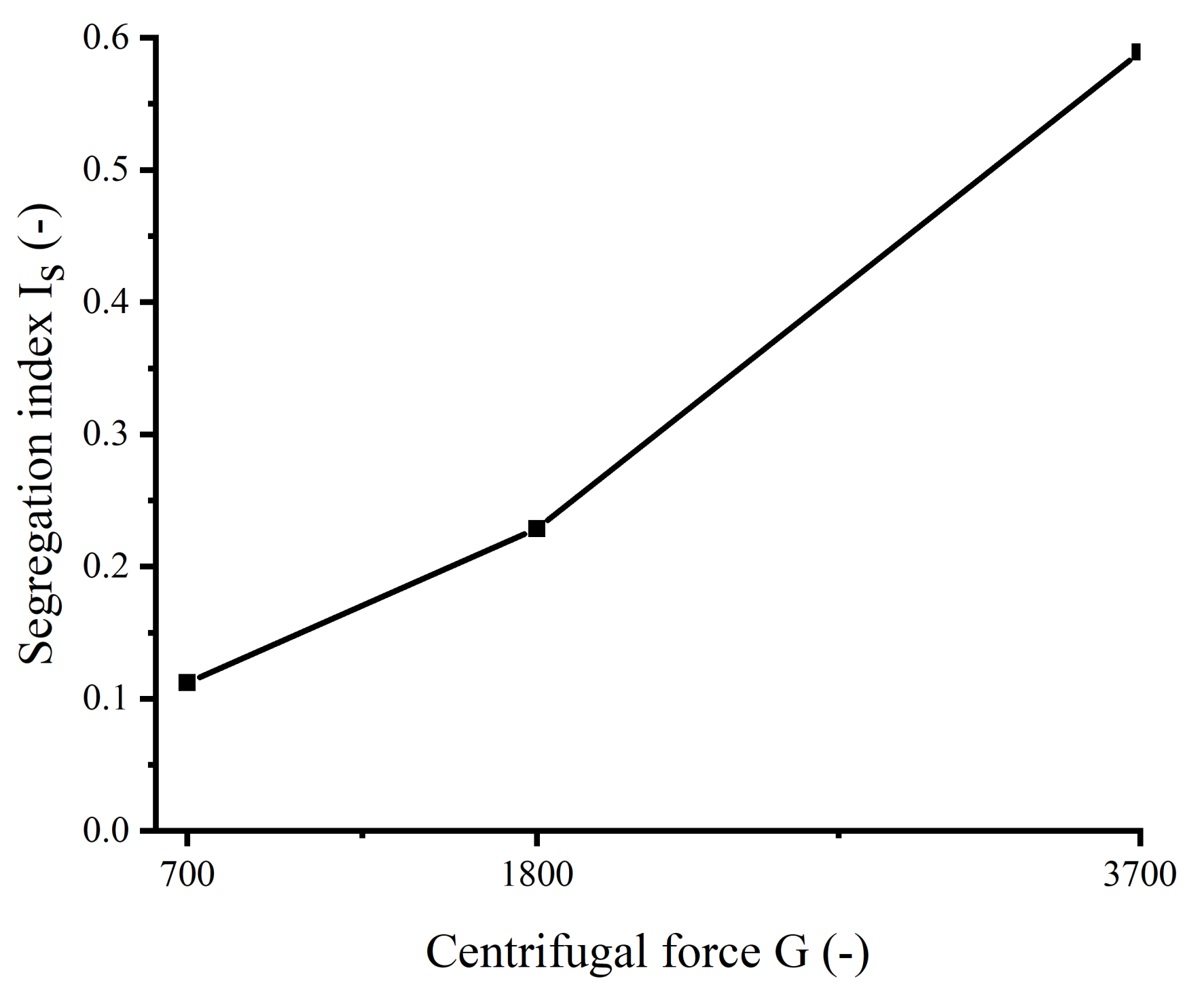

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Torralba Castelló, J.M.; Campos Gómez, M. Toward high performance in Powder Metallurgy. Rev. Metal. 2014, 50, e017. [Google Scholar] [CrossRef] [Green Version]

- Dondi, M. Powder Granulation and Compaction. In Encyclopedia of Materials: Technical Ceramics and Glasses; Pomeroy, M., Ed.; Elsevier: Oxford, UK, 2021; pp. 136–145. [Google Scholar] [CrossRef]

- Bai, Y.; Li, L.; Fu, L.; Wang, Q. A review on high velocity compaction mechanism of powder metallurgy. Sci. Prog. 2021, 104, 00368504211016945. [Google Scholar] [CrossRef] [PubMed]

- Verhaeghe, B.; Courtois, C.; Petit, F.; Cambier, F.; Guérin, J.D.; Leriche, A.; Hampshire, S. Lighter tableware ceramic by controlling porosity: Effect of porosity on mechanical properties. Ceram. Int. 2014, 40, 763–770. [Google Scholar] [CrossRef]

- Law, M.; Hulme-Smith, C.N.; Matsushita, T.; Jönsson, P.G. Assessment of mechanisms for particle migration in semi-solid high pressure die cast aluminium-silicon alloys. J. Manuf. Mater. Process. 2020, 4, 51. [Google Scholar] [CrossRef]

- Gain, A.K.; Song, H.Y.; Lee, B.T. Microstructure and mechanical properties of porous yttria stabilized zirconia ceramic using poly methyl methacrylate powder. Scr. Mater. 2006, 54, 2081–2085. [Google Scholar] [CrossRef]

- Suzuki, M.; Oshima, T. Verification of a model for estimating the void fraction in a three-component randomly packed bed. Powder Technol. 1985, 43, 147–153. [Google Scholar] [CrossRef]

- Thirupathi, N.; Kumar, R.; Kore, S.D. Experimental and numerical investigations on electromagnetic powder compaction of Aluminium 6061 alloy powder. Powder Technol. 2022, 406, 117579. [Google Scholar] [CrossRef]

- Abdizadeh, H.; Ebrahimifard, R.; Baghchesara, M.A. Investigation of microstructure and mechanical properties of nano MgO reinforced Al composites manufactured by stir casting and powder metallurgy methods: A comparative study. Compos. Part B Eng. 2014, 56, 217–221. [Google Scholar] [CrossRef]

- Westman, A.R.; Hugill, H. The packing of particles 1. J. Am. Ceram. Soc. 1930, 13, 767–779. [Google Scholar] [CrossRef]

- McGeary, R. Mechanical packing of spherical particles. J. Am. Ceram. Soc. 1961, 44, 513–522. [Google Scholar] [CrossRef]

- Taskiran, M.; Demirkol, N.; Capoglu, A. Influence of mixing/milling on sintering and technological properties of anorthite based porcelainised stoneware. Ceram. Int. 2006, 32, 325–330. [Google Scholar] [CrossRef]

- Lieberman, M.A.; Lichtenberg, A.J. Principles of Plasma Discharges and Materials Processing; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Suzuki, H.Y.; Kuroki, H. Development of High-Speed Centrifugal Compaction Process of Alumina. Adv. Sci. Technol. Trans. Technol. Publ. 2006, 45, 421–426. [Google Scholar]

- Huisman, W.; Graule, T.; Gauckler, L. Alumina of high reliability by centrifugal casting. J. Eur. Ceram. Soc. 1995, 15, 811–821. [Google Scholar] [CrossRef]

- Porter, Q.; Li, X.; Ma, C. Pressing and Infiltration of Metal Matrix Nanocomposites. J. Manuf. Mater. Process. 2021, 5, 54. [Google Scholar] [CrossRef]

- Gao, J.; Wang, C. Modeling the solidification of functionally graded materials by centrifugal casting. Mater. Sci. Eng. A 2000, 292, 207–215. [Google Scholar] [CrossRef]

- Watanabe, Y.; Yamanaka, N.; Fukui, Y. Control of composition gradient in a metal-ceramic functionally graded material manufactured by the centrifugal method. Compos. Part A Appl. Sci. Manuf. 1998, 29, 595–601. [Google Scholar] [CrossRef]

- Liu, D.M.; Lin, J.T. Influence of ceramic powders of different characteristics on particle packing structure and sintering behaviour. J. Mater. Sci. 1999, 34, 1959–1972. [Google Scholar] [CrossRef]

- Chang, J.C.; Velamakanni, B.V.; Lange, F.F.; Pearson, D.S. Centrifugal consolidation of Al2O3 and AI2O3/ZrO2 composite slurries vs interparticle potentials: Particle packing and mass segregation. J. Am. Ceram. Soc. 1991, 74, 2201–2204. [Google Scholar] [CrossRef]

- Janković Ilić, D.; Fiscina, J.; Oliver, C.G.; Ilić, N.; Mücklich, F. Self Formed Cu-W Functionally Graded Material Produced Via Powder Segregation. Adv. Eng. Mater. 2007, 9, 542–546. [Google Scholar] [CrossRef]

- Chmielewski, M.; Pietrzak, K. Metal-ceramic functionally graded materials–manufacturing, characterization, application. Bull. Pol. Acad. Sci. Tech. Sci. 2016, 64, 151–160. [Google Scholar] [CrossRef] [Green Version]

- Cannillo, V.; Lusvarghi, L.; Manfredini, T.; Montorsi, M.; Siligardi, C.; Sola, A. Glass–ceramic functionally graded materials produced with different methods. J. Eur. Ceram. Soc. 2007, 27, 1293–1298. [Google Scholar] [CrossRef]

- Besisa, D.H.; Ewais, E.M. Advances in functionally graded ceramics—Processing, sintering properties and applications. In Advances in Functionally Graded Materials and Structures; IntechOpen: London, UK, 2016; pp. 1–32. [Google Scholar] [CrossRef] [Green Version]

- Hasanov, S.; Alkunte, S.; Rajeshirke, M.; Gupta, A.; Huseynov, O.; Fidan, I.; Alifui-Segbaya, F.; Rennie, A. Review on additive manufacturing of multi-material parts: Progress and challenges. J. Manuf. Mater. Process. 2021, 6, 4. [Google Scholar] [CrossRef]

- Tripathy, A.; Sarangi, S.K.; Panda, R. Fabrication of functionally graded composite material using powder metallurgy route: An overview. Int. J. Mech. Prod. Eng. Res. Dev. 2017, 7, 135–146. [Google Scholar]

- Fukui, Y. Fundamental investigation of functionally gradient material manufacturing system using centrifugal force. JSME Int. J. Ser. 3 Vib. Control. Eng. Eng. Ind. 1991, 34, 144–148. [Google Scholar] [CrossRef] [Green Version]

- Chirita, G.; Soares, D.; Silva, F. Advantages of the centrifugal casting technique for the production of structural components with Al–Si alloys. Mater. Des. 2008, 29, 20–27. [Google Scholar] [CrossRef]

- Jamian, S.; Watanabe, Y.; Sato, H. Formation of compositional gradient in Al/SiC FGMs fabricated under huge centrifugal forces using solid-particle and mixed-powder methods. Ceram. Int. 2019, 45, 9444–9453. [Google Scholar] [CrossRef]

- Watanabe, Y.; Inaguma, Y.; Sato, H.; Miura-Fujiwara, E. A novel fabrication method for functionally graded materials under centrifugal force: The centrifugal mixed-powder method. Materials 2009, 2, 2510–2525. [Google Scholar] [CrossRef] [Green Version]

- Sato, H.; Maeda, J.; Yamada, M.; Watanabe, Y. Effects of Particle Size on Fabrication of Al-TiO2 Functionally Graded Materials by Centrifugal Mixed-Powder Method. Mater. Sci. Forum. Trans. Technol. Publ. 2017, 879, 1691–1697. [Google Scholar] [CrossRef]

- Sato, H.; Inaguma, Y.; Watanabe, Y. Fabrication of Cu-based functionally graded materials dispersing fine SiC particles by a centrifugal mixed-powder method. Mater. Sci. Forum. Trans. Technol. Publ. 2010, 638, 2160–2165. [Google Scholar] [CrossRef]

- Watanabe, Y.; Miura-Fujiwara, E.; Sato, H.; Takekoshi, K.; Tsuge, H.; Kaga, T.; Bando, N.; Yamagami, S.; Kurachi, K.; Yokoyama, H. Fabrication of functionally graded grinding wheel by a centrifugal mixed-powder method for CFRP-drilling applications. Int. J. Mater. Prod. Technol. 2011, 42, 29–45. [Google Scholar] [CrossRef]

- Shinohara, K.; Golman, B. Segregation indices of multi-sized particle mixtures during the filling of a two-dimensional hopper. Adv. Powder Technol. 2002, 13, 93–107. [Google Scholar] [CrossRef]

- Chung, Y.C.; Liao, C.C.; Zhuang, Z.H. Experimental investigations for the effect of fine powders on size-induced segregation in binary granular mixtures. Powder Technol. 2021, 387, 270–276. [Google Scholar] [CrossRef]

- Kondoh, K.; Watanabe, R.; Hashimoto, H. Analysis of compaction behaviour of wet granulated aluminium alloy powder. Powder Metall. 2000, 43, 359–363. [Google Scholar] [CrossRef]

- Sohn, H.Y.; Moreland, C. The effect of particle size distribution on packing density. Can. J. Chem. Eng. 1968, 46, 162–167. [Google Scholar] [CrossRef]

- Desmond, K.W.; Weeks, E. R Influence of particle size distribution on random close packing of spheres. Phys. Rev. E 2014, 90, 022204. [Google Scholar] [CrossRef] [Green Version]

- Young, Z.; Qu, M.; Coday, M.M.; Guo, Q.; Hojjatzadeh, S.M.H.; Escano, L.I.; Fezzaa, K.; Chen, L. Effects of Particle Size Distribution with Efficient Packing on Powder Flowability and Selective Laser Melting Process. Materials 2022, 15, 705. [Google Scholar] [CrossRef]

- Watanabe, Y.; Kawamoto, A.; Matsuda, K. Particle size distributions in functionally graded materials fabricated by the centrifugal solid-particle method. Compos. Sci. Technol. 2002, 62, 881–888. [Google Scholar] [CrossRef]

- Rasband, W.S. Imagej, Us National Institutes of Health, Bethesda, Maryland, USA. 2011. Available online: http://imagej.nih.gov/ij/ (accessed on 12 June 2022).

- Fan, L.; Too, J.; Rubison, R.; Lai, F. Studies on multicomponent solids mixing and mixtures Part III. Mixing indices. Powder Technol. 1979, 24, 73–89. [Google Scholar] [CrossRef]

- Shinohara, K.; Golman, B.; Nakata, T. Size segregation of multicomponent particles during the filling of a hopper. Adv. Powder Technol. 2001, 12, 33–43. [Google Scholar] [CrossRef]

- Ogawa, T.; Watanabe, Y.; Sato, H.; Kim, I.S.; Fukui, Y. Theoretical study on fabrication of functionally graded material with density gradient by a centrifugal solidparticle method. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2194–2200. [Google Scholar] [CrossRef]

- Lin, X.; Liu, C.; Xiao, H. Fabrication of Al–Si–Mg functionally graded materials tube reinforced with in situ Si/Mg2Si particles by centrifugal casting. Compos. Part B Eng. 2013, 45, 8–21. [Google Scholar] [CrossRef]

- Brenner, M.P. Screening mechanisms in sedimentation. Phys. Fluids 1999, 11, 754–772. [Google Scholar] [CrossRef] [Green Version]

- Ladd, A. Effects of container walls on the velocity fluctuations of sedimenting spheres. Phys. Rev. Lett. 2002, 88, 048301. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nicolai, H.; Peysson, Y.; Guazzelli, É. Velocity fluctuations of a heavy sphere falling through a sedimenting suspension. Phys. Fluids 1996, 8, 855–862. [Google Scholar] [CrossRef]

- Guazzelli, E. Evolution of particle-velocity correlations in sedimentation. Phys. Fluids 2001, 13, 1537–1540. [Google Scholar] [CrossRef]

- Ekiel-Jeżewska, M.; Metzger, B.; Guazzelli, E. Spherical cloud of point particles falling in a viscous fluid. Phys. Fluids 2006, 18, 038104. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Zhou, P.; Yan, Y.; Luo, X.; He, T.; Wang, X. Influence of inelastic collision on the dynamic behavior of particle sedimentation in high-viscosity fluids. Adv. Powder Technol. 2022, 33, 103673. [Google Scholar] [CrossRef]

- Sun, H.; Jiao, R.; Xu, H.; An, G.; Wang, D. The influence of particle size and concentration combined with pH on coagulation mechanisms. J. Environ. Sci. 2019, 82, 39–46. [Google Scholar] [CrossRef]

- Jones, R.; Kutteh, R. Sedimentation of colloidal particles near a wall: Stokesian dynamics simulations. Phys. Chem. Chem. Phys. 1999, 1, 2131–2139. [Google Scholar] [CrossRef]

- Mityushev, V.; Jaworska, L.; Rozmus, M.; Królicka, B. Compaction of the diamond–Ti3SiC2 graded material by the high–speed centrifugal compaction process. Arch. Mater. Sci. Eng. 2007, 28, 677–682. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sariyev, B.; Aldabergen, A.; Akzhigitov, D.; Golman, B.; Spitas, C. Fabrication of Highly Compacted Green Body Using Multi-Sized Al Powder under a Centrifugal Force. J. Manuf. Mater. Process. 2022, 6, 79. https://doi.org/10.3390/jmmp6040079

Sariyev B, Aldabergen A, Akzhigitov D, Golman B, Spitas C. Fabrication of Highly Compacted Green Body Using Multi-Sized Al Powder under a Centrifugal Force. Journal of Manufacturing and Materials Processing. 2022; 6(4):79. https://doi.org/10.3390/jmmp6040079

Chicago/Turabian StyleSariyev, Bakytzhan, Abilkhairkhan Aldabergen, Dulat Akzhigitov, Boris Golman, and Christos Spitas. 2022. "Fabrication of Highly Compacted Green Body Using Multi-Sized Al Powder under a Centrifugal Force" Journal of Manufacturing and Materials Processing 6, no. 4: 79. https://doi.org/10.3390/jmmp6040079

APA StyleSariyev, B., Aldabergen, A., Akzhigitov, D., Golman, B., & Spitas, C. (2022). Fabrication of Highly Compacted Green Body Using Multi-Sized Al Powder under a Centrifugal Force. Journal of Manufacturing and Materials Processing, 6(4), 79. https://doi.org/10.3390/jmmp6040079