Additive Surface Graining in Prototype Tooling for Injection Molding

Abstract

:1. Introduction

2. State-of-the-Art

2.1. Structured Surfaces in Additive Tooling

2.2. Micro Structuring of Conventional Injection Molds

3. Materials and Methods

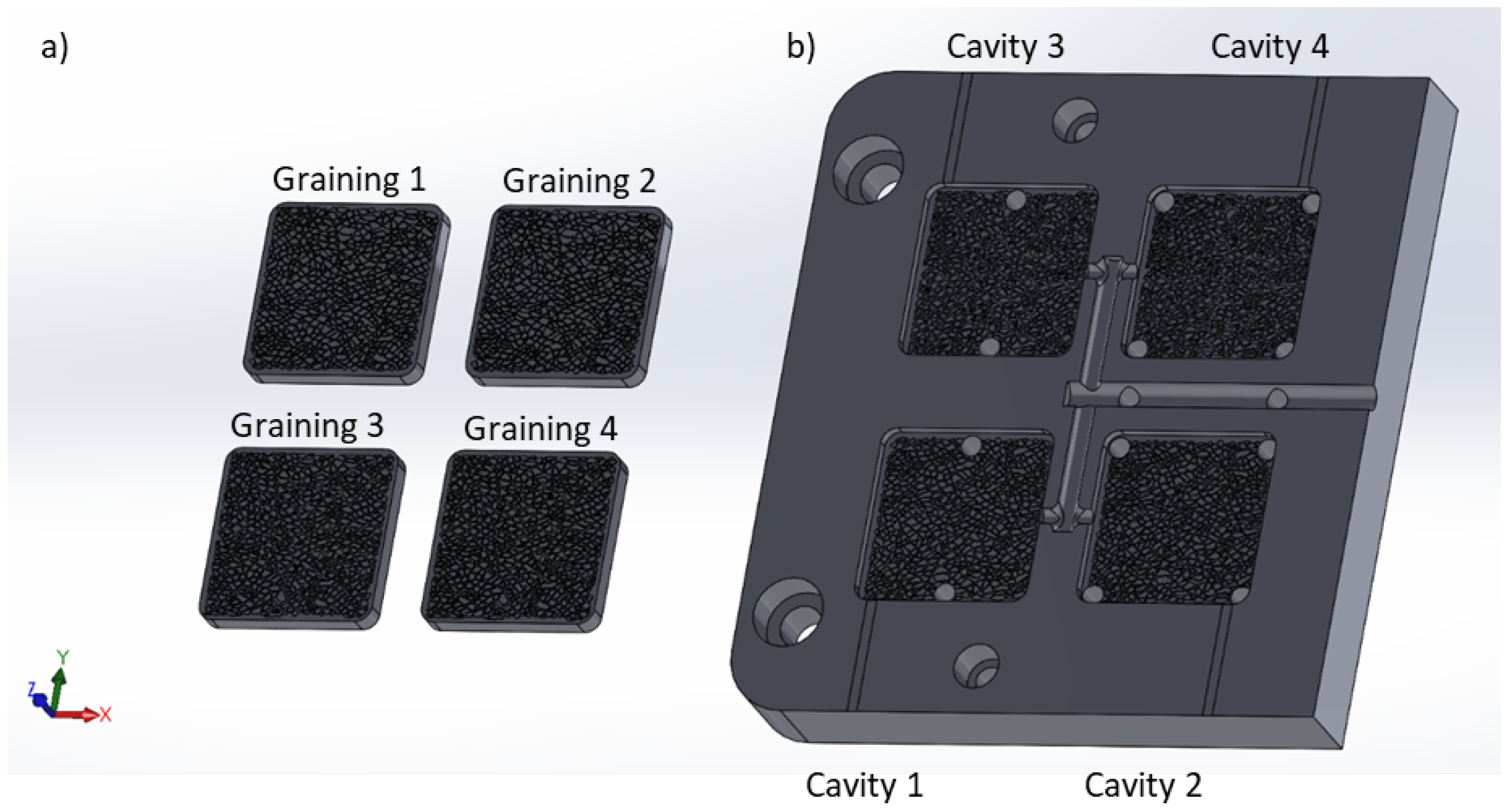

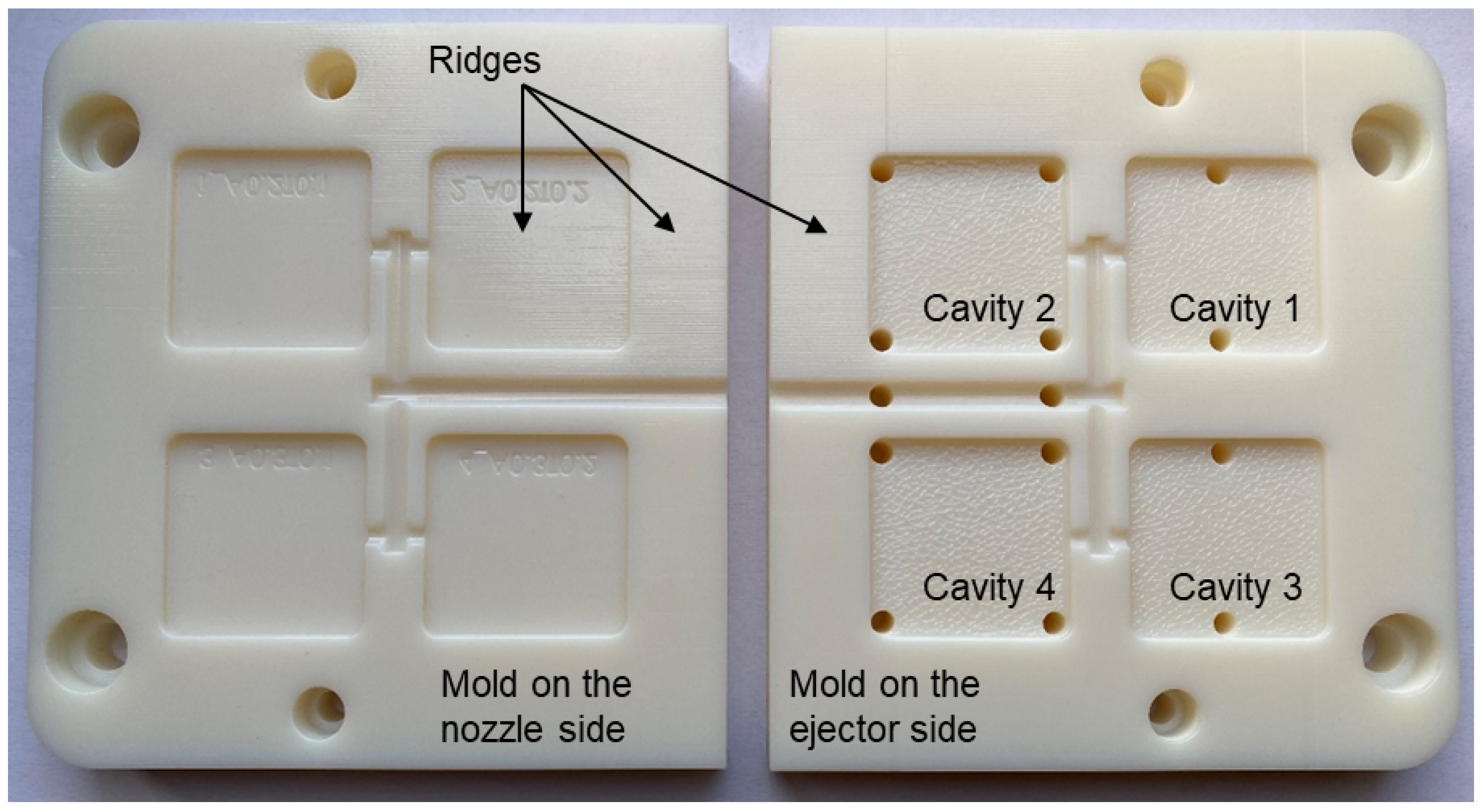

3.1. Mold Design

3.2. Realization and Try-Outs

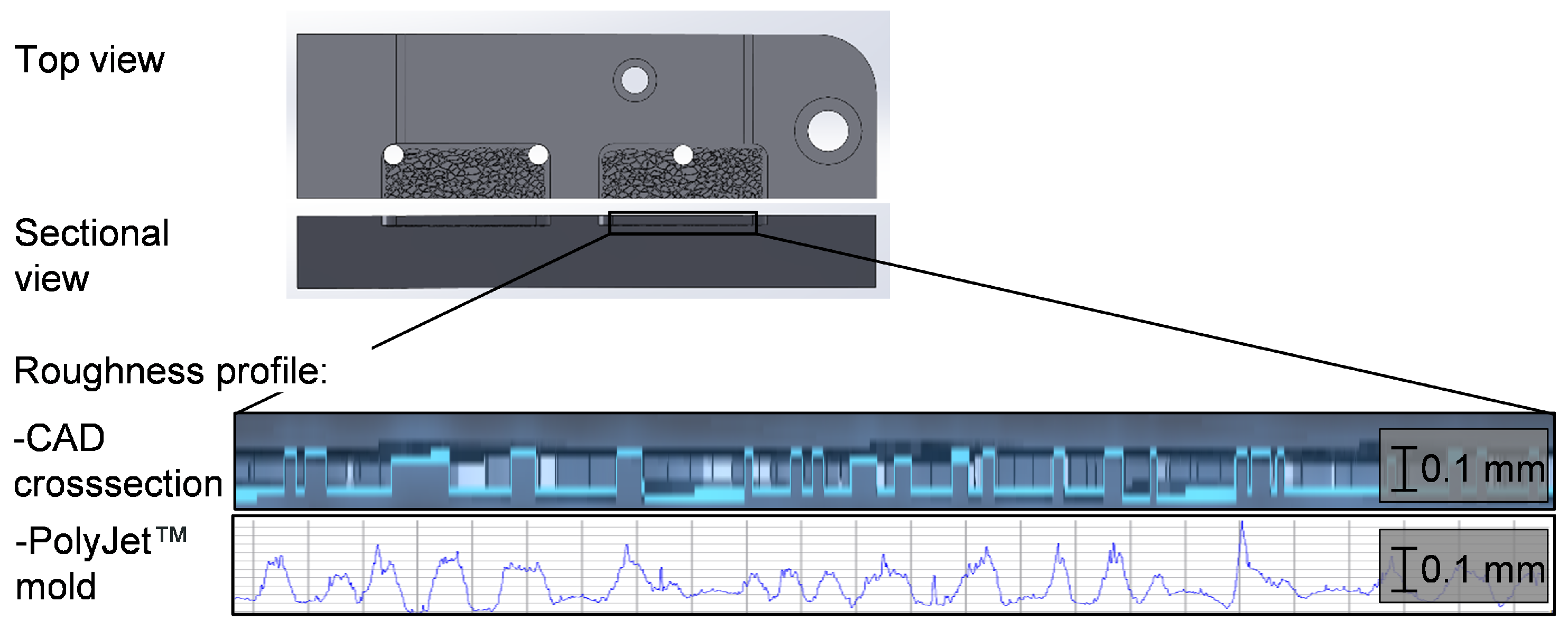

3.3. Assessment of Surface Quality

4. Results

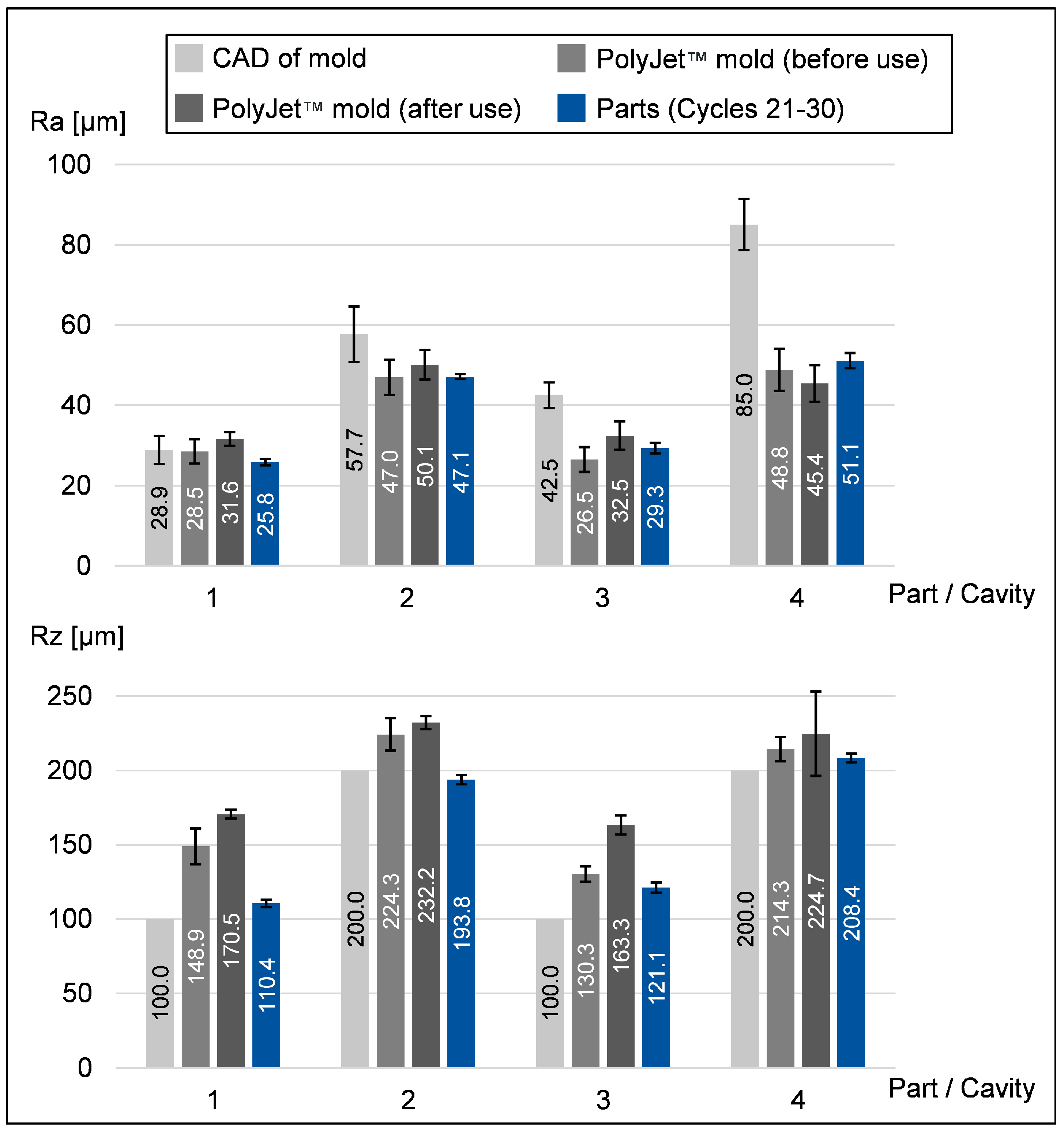

4.1. Assessment of the Additively Manufactured Mold

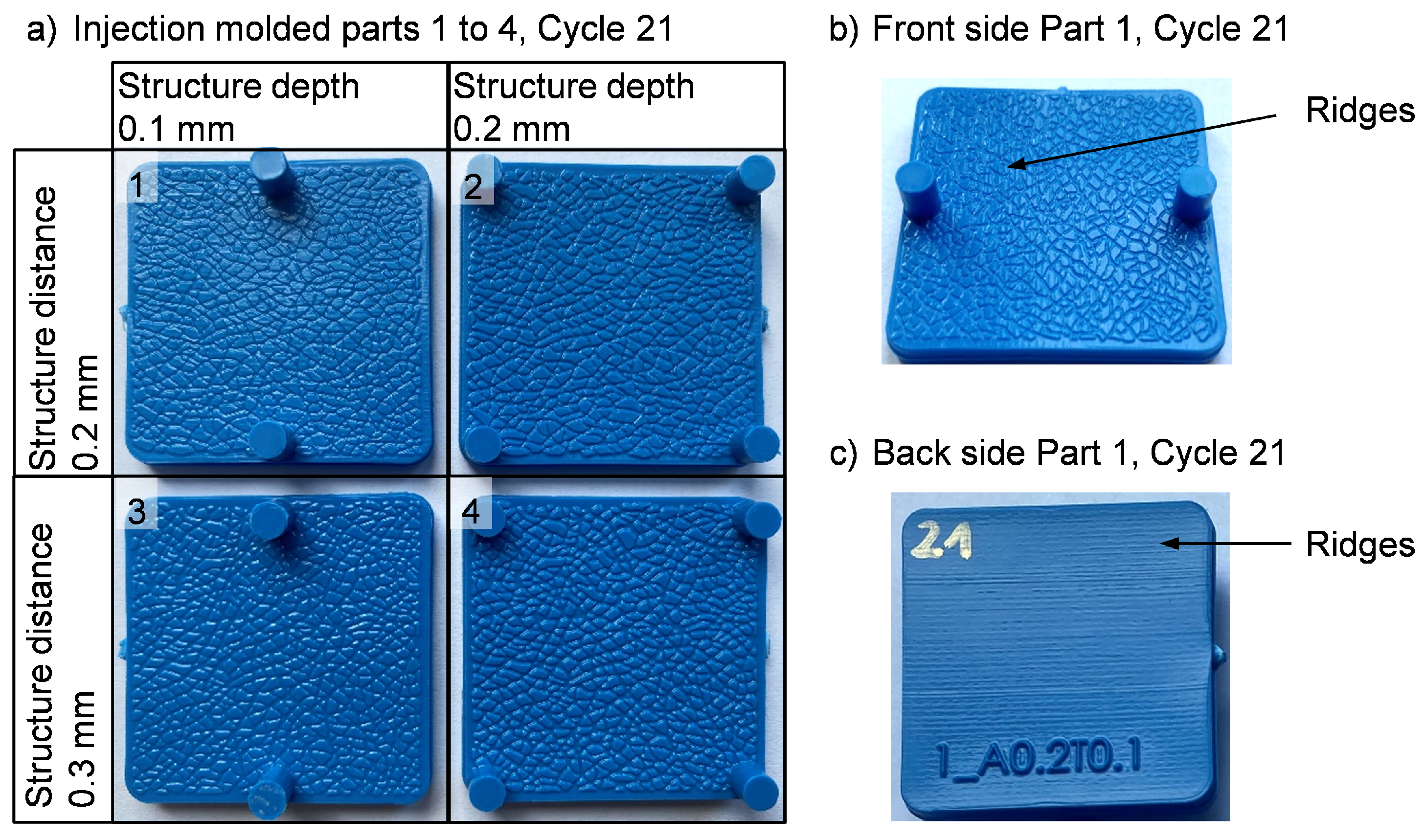

4.2. Assessment of the Injection Molded Parts

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Glokowo, K.; Mugele, P.; Zimmer, D. Neue Möglichkeiten Der Innenraumgestaltung. ATZ Extra. 2017. Available online: https://www.bertrandt.com/fileadmin/files/files/00_Unternehmen/03_Presse/Fachartikel/2017/2017-08-16_Fachartikel_ATZextra_Automatisiertes_Fahren_Innenraumgestaltung_Bertrandt.pdf (accessed on 19 April 2022).

- Blomeyer, D.; Schulte-Gehrmann, A.L. Oberflächeninnovation für das Interieur künftiger Fahrzeuge. ATZ. 2019. Available online: https://www.springerprofessional.de/oberflaecheninnovationen-fuer-das-interieur-kuenftiger-fahrzeuge/16750348 (accessed on 19 April 2022).

- Lachmayer, R.; Lippert, R.B. Entwicklungsmethodik für die Additive Fertigung; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Lake, M. Oberflächentechnik in der Kunststoffverarbeitung, 2nd ed.; Hanser-eLibrary: Munich, Germany, 2016. [Google Scholar]

- Günther, S.; Georg, B.; Gerret, L.; Josef, A.A. Feasibility and Process capability of polymer additive injection molds with slide technology. Procedia CIRP 2020, 93, 102–107. [Google Scholar] [CrossRef]

- Kuo, C.C.; You, Z.Y.; Wu, J.Y.; Huang, J.L. Development and application of a conformal cooling channel with easy removal and smooth surfaces. Int. J. Adv. Manuf. Technol. 2019, 102, 2029–2039. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. 3D Printed Injection Molds Using Various 3D Printing Technologies. Mater. Sci. Forum 2020, 1005, 150–156. [Google Scholar] [CrossRef]

- Zhang, Y.; Pedersen, D.B.; Mischkot, M.; Calaon, M.; Baruffi, F.; Tosello, G. A Soft Tooling Process Chain for Injection Molding of a 3D Component with Micro Pillars. J. Vis. Exp. JoVE 2018. [Google Scholar] [CrossRef]

- Dempsey, D.; McDonald, S.; Masato, D.; Barry, C. Characterization of Stereolithography Printed Soft Tooling for Micro Injection Molding. Micromachines 2020, 11, 819. [Google Scholar] [CrossRef]

- Dangel, R. Spritzgießwerkzeuge für Einsteiger, 2nd ed.; Hanser: Munich, Germany, 2017. [Google Scholar]

- Deutsches Institut für Normung. Leder- Terminologie- Hauptdefinitionen für den Lederhandel. 2015. Available online: https://www.beuth.de/de/norm/din-en-15987/224357219 (accessed on 19 April 2022). [CrossRef]

- StandexEngravingMoldTech. Texturkatalog. 2021. Available online: https://upmold.com/wp-content/uploads/Data-center/Mold-Tech-texture.pdf (accessed on 19 April 2022).

- Upmold. Yick Sang Texture Technology Datasheet. 2021. Available online: https://upmold.com/wp-content/uploads/Data-center/Yicksang-Texture-fold.pdf (accessed on 19 April 2022).

- Verein Deutscher Ingenieure. Elektroerosive Bearbeitung: Begriffe, Verfahren, Anwendung. 1975. Available online: https://www.beuth.de/de/technische-regel/vdi-3400/542958 (accessed on 19 April 2022).

- Grote, K.H.; Bender, B.; Göhlich, D.; Dubbel, H. Taschenbuch für den Maschinenbau, 25th ed.; Springer Vieweg: Berlin, Germany, 2018. [Google Scholar] [CrossRef]

- Pruner, H.; Nesch, W. Spritzgießwerkzeuge Kompakt: Ein Praxisbuch für Einsteiger, 2nd ed.; Hanser: Munich, Germany, 2020. [Google Scholar] [CrossRef]

- Klocke, F.; König, W. Fertigungsverfahren 3: Abtragen, Generieren Lasermaterialbearbeitung, 4th ed.; Fertigungsverfahren; Springer: Berlin/Heidelberg, Germany, 2007; Volume 3. [Google Scholar] [CrossRef] [Green Version]

- Biermann, D.; Kahnis, P.; Kuttkatt, B. Mikrofräsen filigraner Strukturen in Formeinsätzen. MM MaschinenMarkt 2010, 5, 36–40. [Google Scholar]

- Kordt, J.M. Konturnahes Laserstrukturieren für Kunststoffspritzgießwerkzeuge. 2007. Available online: https://publications.rwth-aachen.de/record/51988/files/Kordt_Johannes.pdf (accessed on 19 April 2022).

- Ho, K.; Newman, S. State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300. [Google Scholar] [CrossRef]

- Mappes, T.; Worgull, M.; Heckele, M.; Mohr, J. Submicron polymer structures with X-ray lithography and hot embossing. Microsyst. Technol. 2008, 14, 1721–1725. [Google Scholar] [CrossRef]

- Schlussbericht zu BMBF-Projekt “Holo-Impact: Nanostrukturieren von Metalloberflächen Mittels Holografischer Prägevorlagen”. 2010. Available online: https://www.tib.eu/en/suchen/id/TIBKAT:667760091/ (accessed on 19 April 2022).

- Zhang, J.; Cui, T.; Ge, C.; Sui, Y.; Yang, H. Review of micro/nano machining by utilizing elliptical vibration cutting. Int. J. Mach. Tools Manuf. 2016, 106, 109–126. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung. Benennungen, Definitionen und Kenngrößen der Oberflächenbeschaffenheit. 2010. Available online: https://www.beuth.de/de/norm/din-en-iso-4287/129356592 (accessed on 19 April 2022).

- Deutsches Institut für Normung. Ermittlung der Rauheitskenngrößen Ra, Rz, Rmax Mit Elektrischen Tastschnittgeräten: Begriffe Messbedingungen. 1990. Available online: https://www.beuth.de/de/norm/din-4768/1552484 (accessed on 19 April 2022).

| Structuring Method | Structure Size | Advantages | Disadvantages |

|---|---|---|---|

| Photoetching | ∼1 µm [19] | - low process costs - uniform roughness and mattness | - many complex manual process steps - not achievable for all materials - no exact reproducibility of structures |

| EDM | ∼5 µm [20] | - high dimensional and shape accuracy - production of sharp edges | - high costs due to complex manufacturing of electrodes - only for conductive materials |

| Laser structruing | ∼1 µm [21] | - easy transfer of any structural pattern | - for complex shapes laser focusing is more complicated |

| Explosive embossing | ∼1 µm [22] | - very fine structures can be realized - few working steps necessary | - structure cannot be transferred to complex shapes - structural template necessary |

| Micromilling | ∼ 5 µm [23] | - high geometrical freedom - high removal rate | - increase in complexity due to miniaturization - high costs and machine running times |

| Structure Distance [mm] | Structure Depth [mm] | |

|---|---|---|

| Graining 1 | 0.2 | 0.1 |

| Graining 2 | 0.2 | 0.2 |

| Graining 3 | 0.3 | 0.1 |

| Graining 4 | 0.3 | 0.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burggräf, P.; Bergweiler, G.; Abrams, J.A.; Dunst, A. Additive Surface Graining in Prototype Tooling for Injection Molding. J. Manuf. Mater. Process. 2022, 6, 54. https://doi.org/10.3390/jmmp6030054

Burggräf P, Bergweiler G, Abrams JA, Dunst A. Additive Surface Graining in Prototype Tooling for Injection Molding. Journal of Manufacturing and Materials Processing. 2022; 6(3):54. https://doi.org/10.3390/jmmp6030054

Chicago/Turabian StyleBurggräf, Peter, Georg Bergweiler, Josef Andrew Abrams, and Anna Dunst. 2022. "Additive Surface Graining in Prototype Tooling for Injection Molding" Journal of Manufacturing and Materials Processing 6, no. 3: 54. https://doi.org/10.3390/jmmp6030054

APA StyleBurggräf, P., Bergweiler, G., Abrams, J. A., & Dunst, A. (2022). Additive Surface Graining in Prototype Tooling for Injection Molding. Journal of Manufacturing and Materials Processing, 6(3), 54. https://doi.org/10.3390/jmmp6030054