Deformation Heating and Temperature Changes in a Near-β Titanium Alloy during β-Processed Forging

Abstract

:1. Introduction

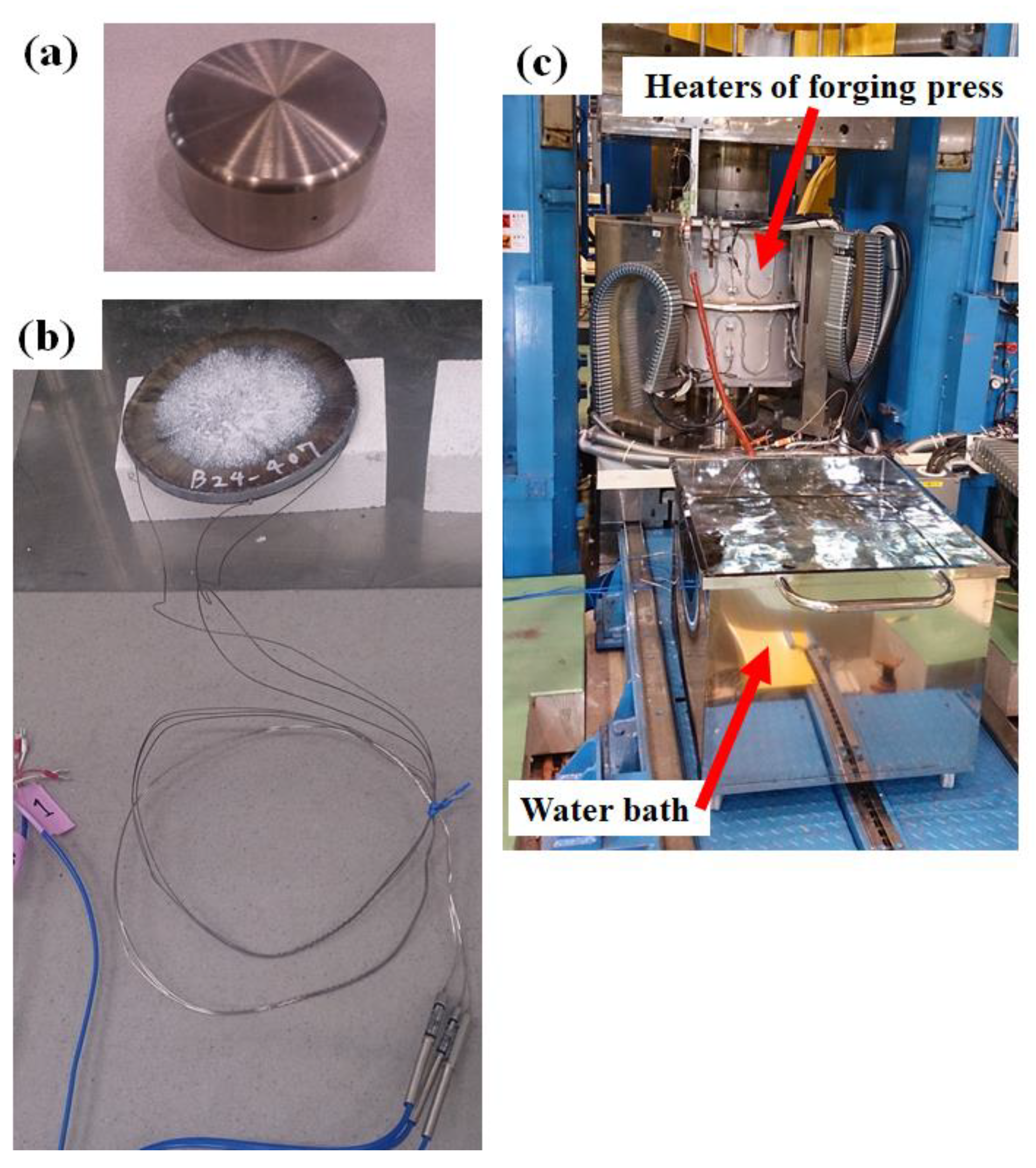

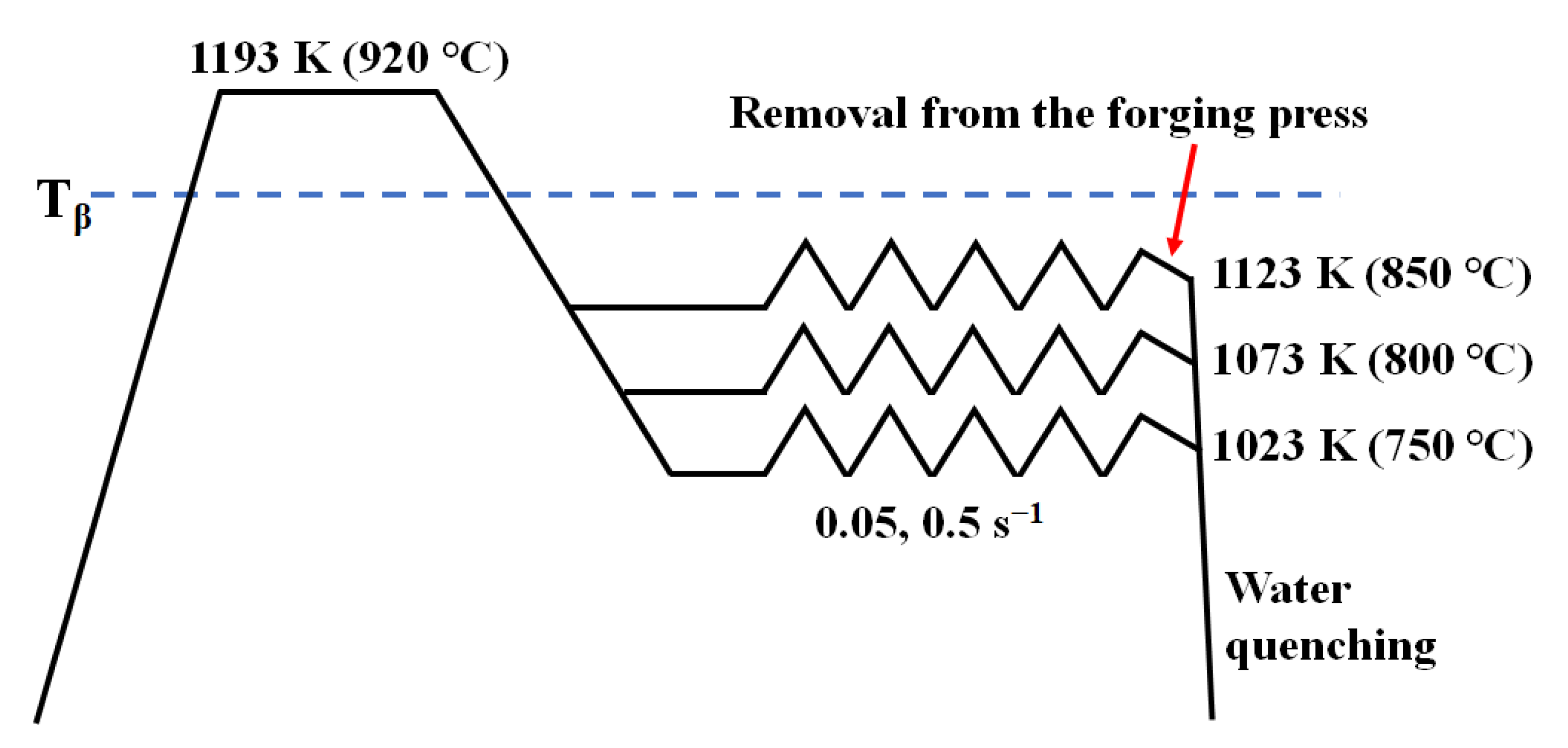

2. Materials and Methods

3. Results and Discussion

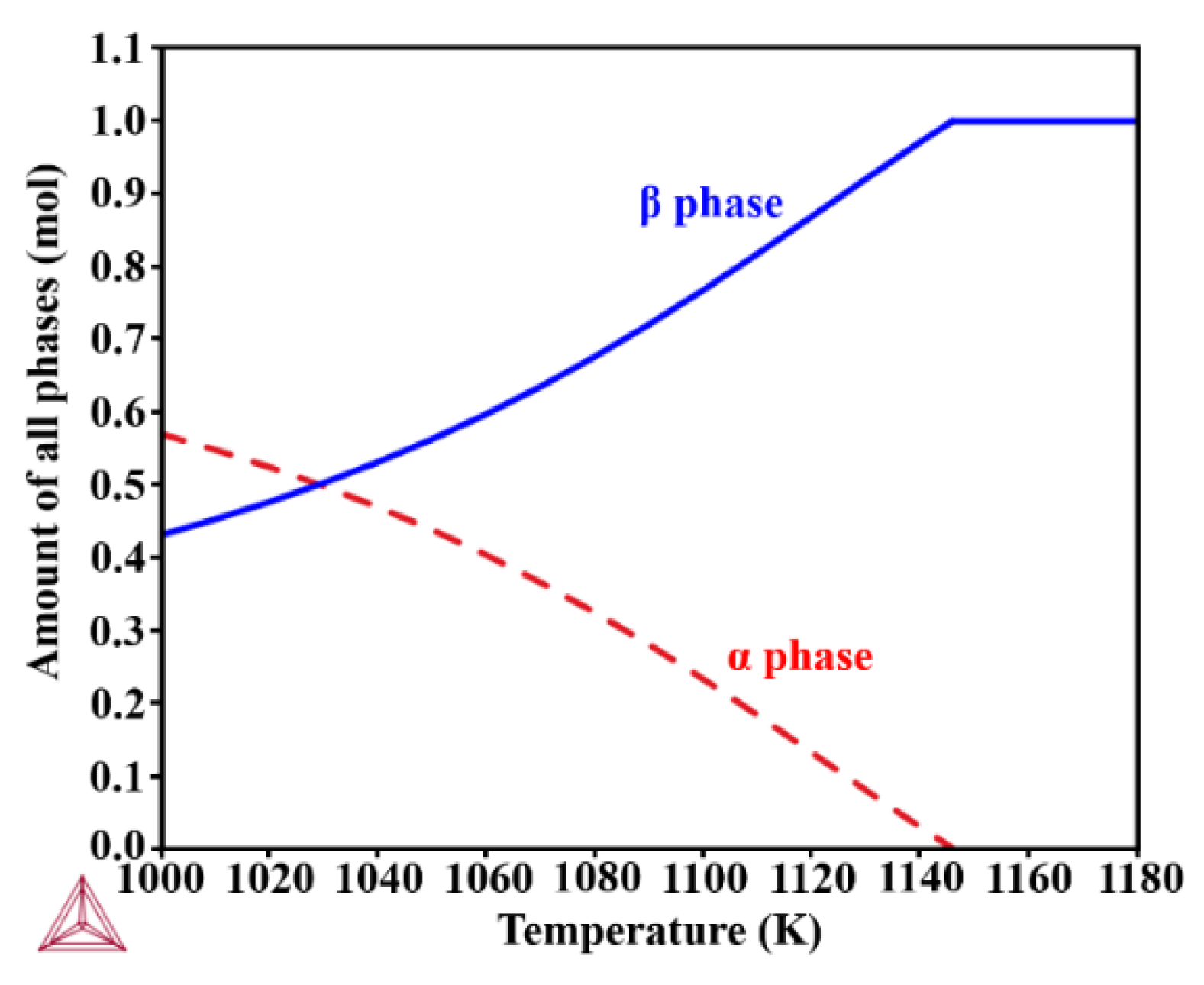

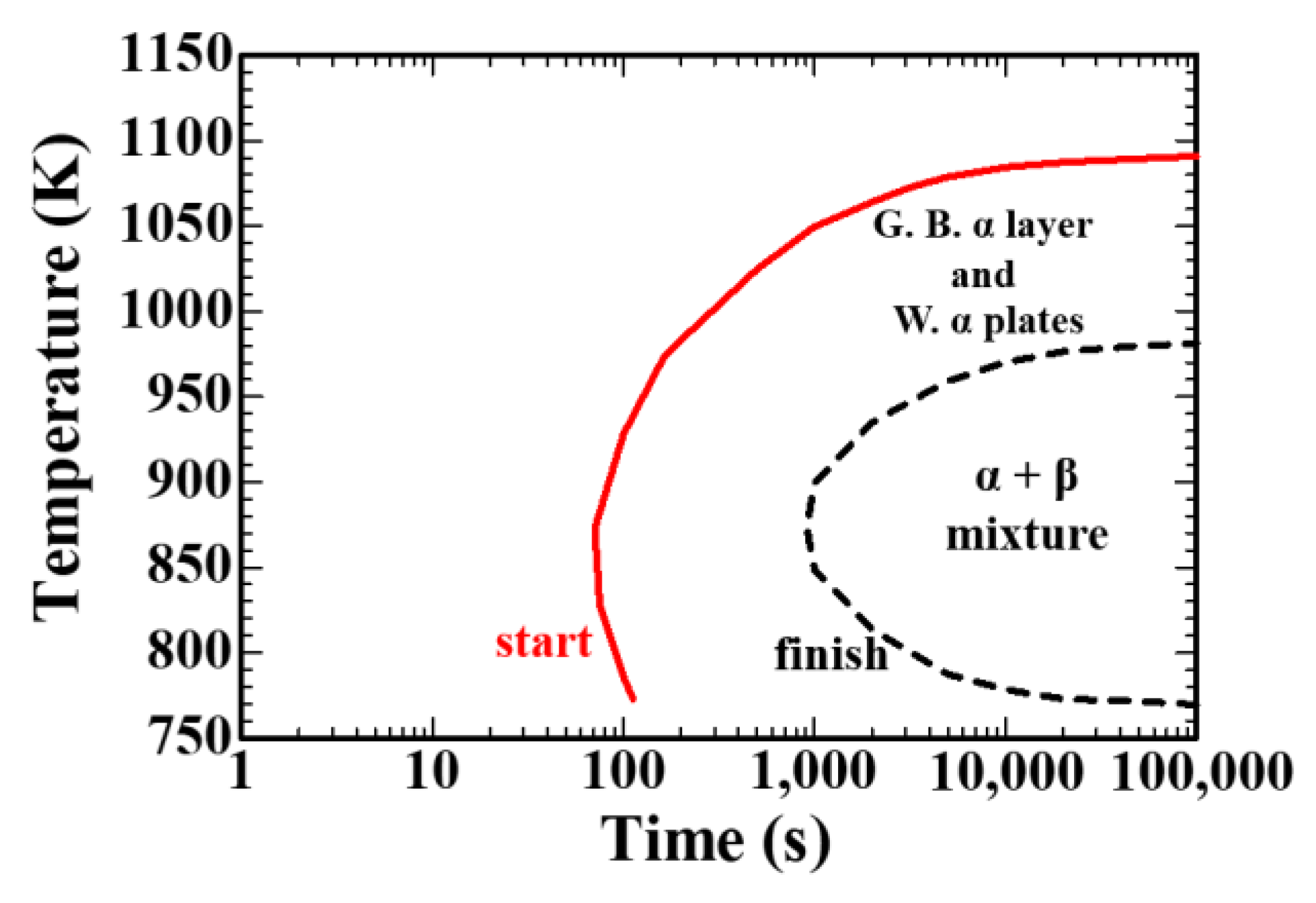

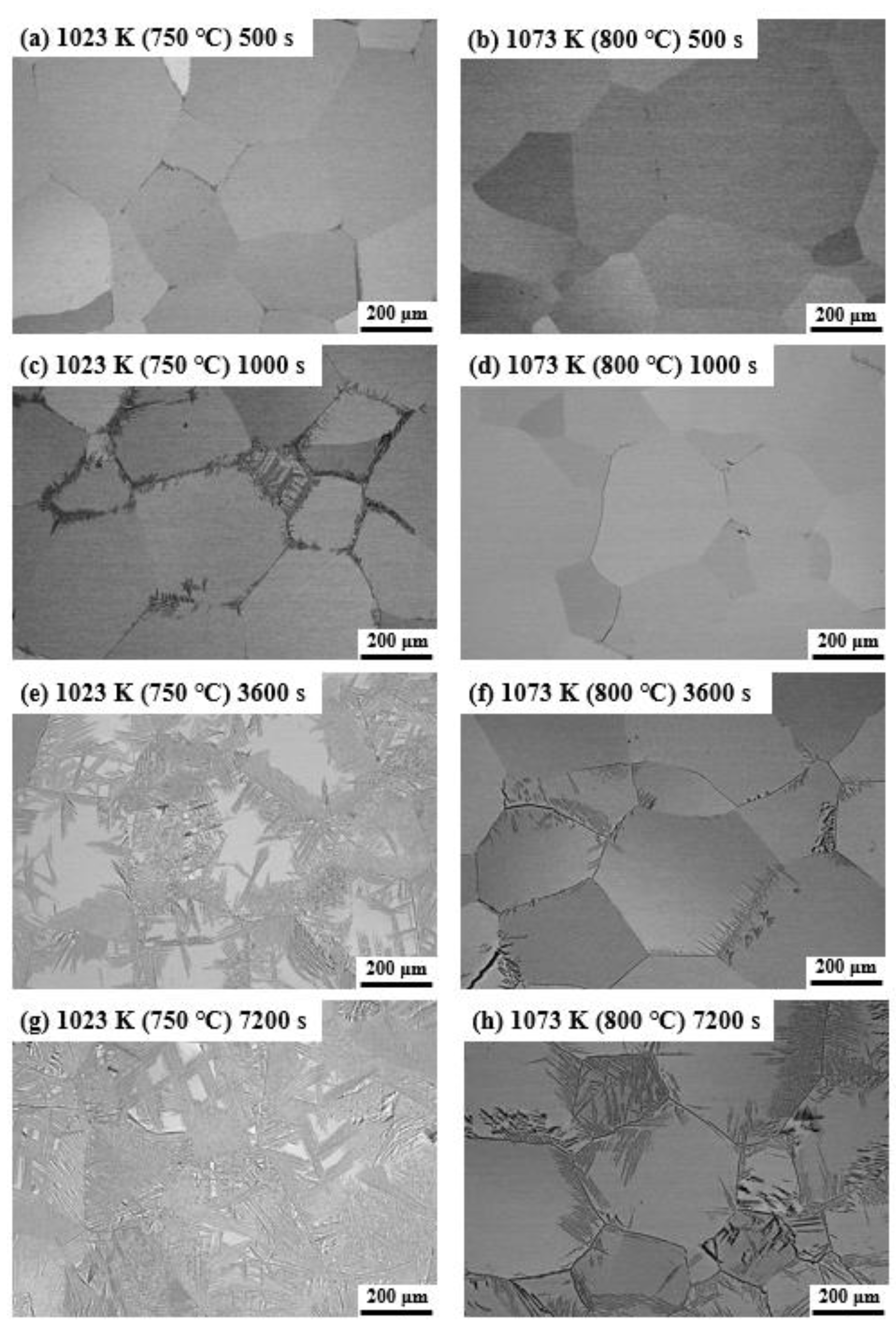

3.1. α Precipitation in the (α + β) Region after Cooling from the β Region

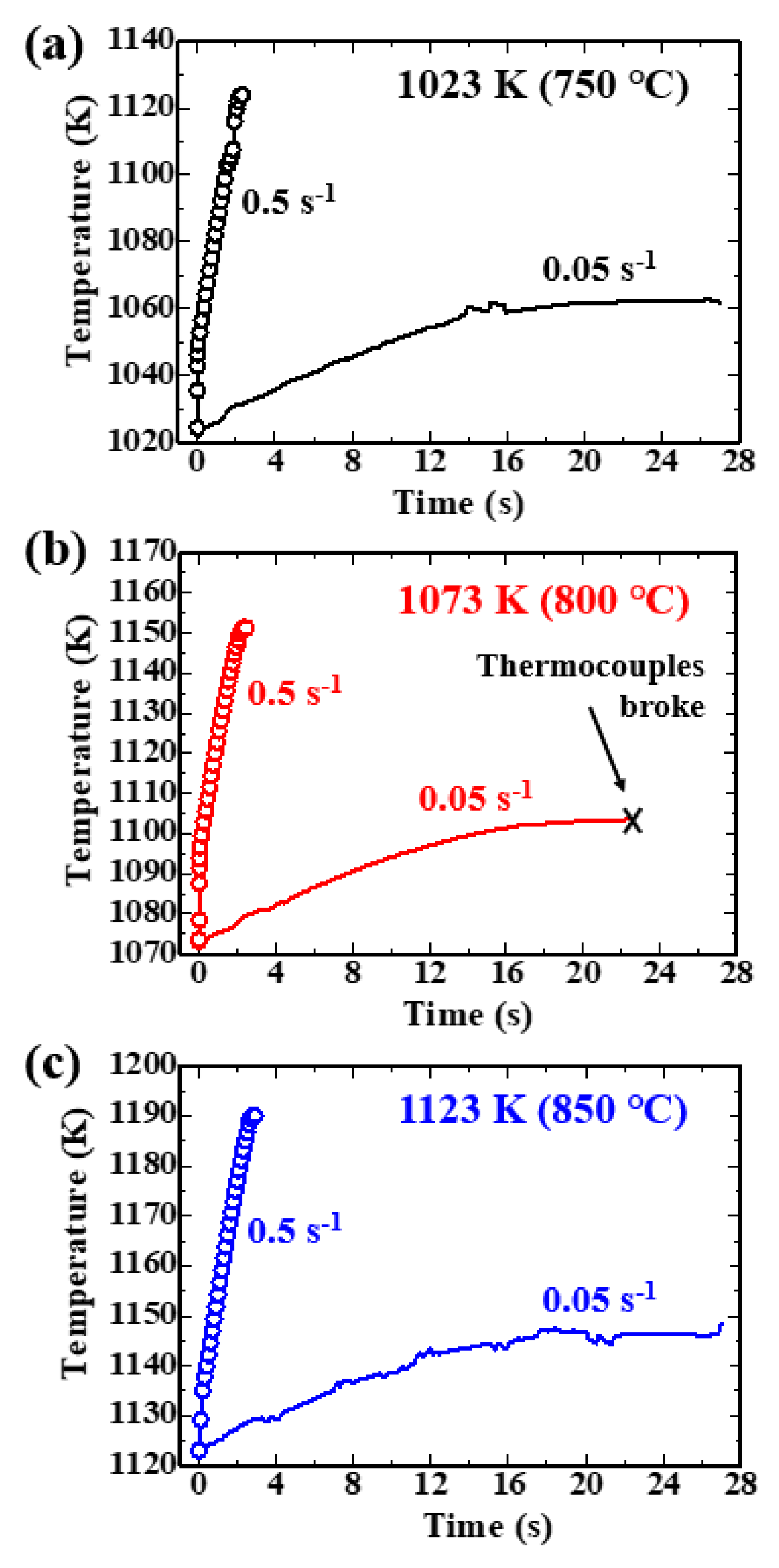

3.2. Temperature Increase during Forging

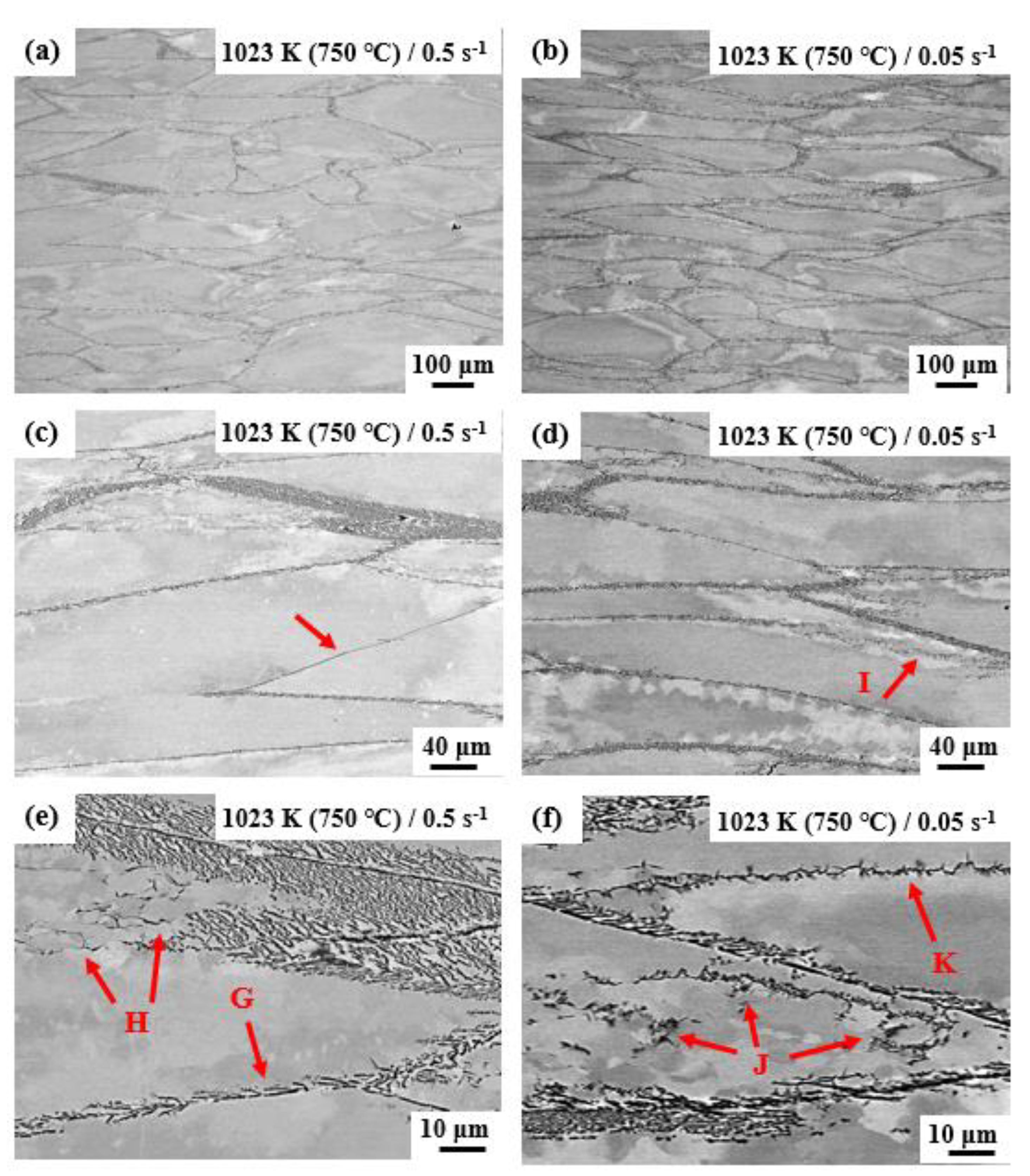

3.3. Microstructure Formation during Forging and Cooling

4. Conclusions

- The lower the forging temperature, the higher the strain rate, and the larger the temperature increase because of deformation heating. At 0.5 s−1, the difference in the temperature increase between 1023 and 1073 K grew small as the forging proceeded, that is, being 27 K at the last stage of forging. In contrast, at 0.05 s−1, the difference in the temperature increase between those temperatures was 41 K, which was closer to the temperature difference before forging (50 K).

- The material temperature instantly exceeded and reached close to β-transus temperature during forgings at 0.5 s−1. At 0.05 s−1, the temperature increase was not significant.

- These results would affect underlying microstructure and texture changes during the β-processed forging.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lütjering, G.; Williams, J.C. Titanium, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2007; ISBN 978-3-540-71397-5. [Google Scholar]

- Sauer, C.; Luetjering, G. Thermo-mechanical processing of high strength β-titanium alloys and effects on microstructure and properties. J. Mater. Process. Technol. 2001, 117, 311–317. [Google Scholar] [CrossRef]

- Lütjering, G. Influence of processing on microstructure and mechanical properties of (α + β) titanium alloys. Mater. Sci. Eng. A 1998, 243, 32–45. [Google Scholar] [CrossRef]

- Weiss, I.; Semiatin, S.L. Thermomechanical processing of alpha titanium alloys—An overview. Mater. Sci. Eng. A 1999, 263, 243–256. [Google Scholar] [CrossRef]

- Le Corre, S.; Forestier, R.; Brisset, F.; Mathon, M.; Solas, D. Influence of Beta-Forging on Texture Development In Ti 6246 Alloy. In Proceedings of the 13th World Conference on Titanium, San Diego, CA, USA, 16–20 August 2015; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 757–764. [Google Scholar] [CrossRef]

- Kitashima, T.; Meng, L.; Watanabe, M. Deformation-Induced Grain-Interior α Precipitation and β Texture Evolution during the β-Processed Forging of a Near-β Titanium Alloy. Metals 2021, 11, 1405. [Google Scholar] [CrossRef]

- Meng, L.; Kitashima, T.; Tsuchiyama, T.; Watanabe, M. β-Texture Evolution During α Precipitation in the Two-Step Forging Process of a Near-β Titanium Alloy. Metall. Mater. Trans. A 2020, 51A, 5912. [Google Scholar] [CrossRef]

- Meng, L.; Kitashima, T.; Tsuchiyama, T.; Watanabe, M. Effect of α precipitation on β texture evolution during β-processed forging in a near-β titanium alloy. Mater. Sci. Eng. A 2020, 771, 138640. [Google Scholar] [CrossRef]

- Hua, K.; Xue, X.; Kou, H.; Fan, J.; Tang, B.; Li, J. Characterization of hot deformation microstructure of a near beta titanium alloy Ti-5553. J. Alloys Compd. 2014, 615, 531–537. [Google Scholar] [CrossRef]

- Dehghan-Manshadi, A.; Dippenaar, R.J. Strain-induced phase transformation during thermo-mechanical processing of titanium alloys. Mater. Sci. Eng. A 2012, 552, 451–456. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Di, H. Deformation heating and flow localization in Ti-15-3 metastable β titanium alloy subjected to high Z deformation. Mater. Sci. Eng. A 2016, 676, 506–509. [Google Scholar] [CrossRef]

- Charpentier, P.L.; Stone, B.C.; Ernst, S.C.; Thomas, J.F., Jr. Characterization and modeling of the high temperature flow behavior of aluminum alloy 2024. Metall. Trans. A 1986, 17A, 2227–2237. [Google Scholar] [CrossRef]

- Mataya, M.C.; Sackschewsky, V.E. Effect of internal heating during hot compression on the stress–strain behavior of alloy 304L. Metall. Mater. Trans. A 1994, 25A, 2737–2752. [Google Scholar] [CrossRef]

- Li, L.; Li, M.Q.; Luo, J. Flow softening mechanism of Ti-5Al-2Sn-2Zr-4Mo-4Cr with different initial microstructures at elevated temperature deformation. Mater. Sci. Eng. A 2015, 628, 11–20. [Google Scholar] [CrossRef]

- Knysh, P.; Korkolis, Y.P. Determination of the fraction of plastic work converted into heat in metals. Mech. Mater. 2015, 86, 71–80. [Google Scholar] [CrossRef]

- Rittel, D.; Zhang, L.H.; Osovski, S. The dependence of the Taylor-Quinney coefficient on the dynamic loading mode. J. Mech. Phys. Solids 2017, 107, 96–114. [Google Scholar] [CrossRef]

- Kitashima, T.; Matsumoto, R.; Yoshida, Y.; Matsumoto, H.; Nishihara, T.; Kuroda, S.; Motohashi, N.; Hagiwara, M.; Emura, S. Measurement and prediction of temperature increase during isothermal forging of Titanium-6Aluminium-4Vanadium. Mater. Perform. Charact. 2019, 8, 389–401. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of steel flow stresses at high temperatures and strain rates. Metall. Trans. A 1991, 22A, 1545–1558. [Google Scholar] [CrossRef]

- Elagina, L.A.; Brun, M.Y.; Brailovskaya, B.F. Isothermal forging of titanium alloys. Met. Sci. Heat Treat. 1980, 22, 447–450. [Google Scholar] [CrossRef]

- Niinomi, M.; Akahori, T.; Nakai, M.; Koizumi, Y.; Chiba, A.; Nakano, T.; Kakeshita, T.; Yamabe-Mitarai, Y.; Kuroda, S.; Motohashi, N.; et al. Quantitative and Qualitative Relationship between Microstructural Factors and Fatigue Lives under Load- and Strain-Controlled Conditions of Ti-5Al-2Sn-2Zr-4Cr-4Mo (Ti-17) Fabricated Using a 1500-ton Forging Simulator. Mater. Trans. 2019, 60, 1740–1748. [Google Scholar] [CrossRef] [Green Version]

- Bèchet, J.; Hocheid, B. Decomposition of the Beta-Phase in Titanium Alloy Ti-17. In Titanium, Science and Technology; Lutjering, G., Zqicker, U., Bunk, W., Eds.; Deutsche Gesellschaft für Metallkunde: Oberursel, Germany, 1985; pp. 1613–1619. [Google Scholar]

- Le, K.C.; Tran, T.M. Thermodynamic dislocation theory of high temperature deformation in aluminum and steel. Phys. Rev. E 2017, 96, 013004. [Google Scholar] [CrossRef] [Green Version]

- Longère, P.; Dragon, A. Evaluation of the inelastic heat fraction in the context of microstructure-supported dynamic plasticity modelling. Int. J. Impact Eng. 2008, 35, 992–999. [Google Scholar] [CrossRef]

- Nieto-Fuentes, J.C.; Rittel, D.; Osovski, S. On a dislocation-based constitutive model and dynamic thermomechanical considerations. Int. J. Plast. 2018, 108, 55–69. [Google Scholar] [CrossRef]

- Zubelewicz, A. Century-long Taylor-Quinney interpretation of plasticity-induced heating reexamined. Sci. Rep. 2019, 9, 9088. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meng, L.; Kitashima, T.; Tsuchiyama, T.; Watanabe, M. β-Texture Evolution of a Near-β Titanium Alloy During Cooling After Forging in the β Single-Phase and (α + β) Dual-Phase Regions. Metall. Mater. Trans. A 2021, 52A, 303. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Dutta, B. Influence of prior deformation rate on the mechanism of β to α + β transformation in Ti–6Al–4V. Scripta Mater. 2002, 46, 673–678. [Google Scholar] [CrossRef]

- Guo, B.; Liu, Y.; Jonas, J.J. Dynamic transformation of two-phase titanium alloys in stable and unstable alloys. Metall. Mater. Trans. A 2019, 50A, 4502–4505. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kitashima, T.; Meng, L. Deformation Heating and Temperature Changes in a Near-β Titanium Alloy during β-Processed Forging. J. Manuf. Mater. Process. 2022, 6, 47. https://doi.org/10.3390/jmmp6020047

Kitashima T, Meng L. Deformation Heating and Temperature Changes in a Near-β Titanium Alloy during β-Processed Forging. Journal of Manufacturing and Materials Processing. 2022; 6(2):47. https://doi.org/10.3390/jmmp6020047

Chicago/Turabian StyleKitashima, Tomonori, and Lingjian Meng. 2022. "Deformation Heating and Temperature Changes in a Near-β Titanium Alloy during β-Processed Forging" Journal of Manufacturing and Materials Processing 6, no. 2: 47. https://doi.org/10.3390/jmmp6020047

APA StyleKitashima, T., & Meng, L. (2022). Deformation Heating and Temperature Changes in a Near-β Titanium Alloy during β-Processed Forging. Journal of Manufacturing and Materials Processing, 6(2), 47. https://doi.org/10.3390/jmmp6020047