1. Introduction

Metal additive-manufacturing technologies enable the production of complex geometries. However, high manufacturing costs hinder these technologies being employed in some industries. A cost-effective hybrid strategy can be a good solution to achieve the best of additive and subtractive technologies, i.e., complex geometries at a lower cost, with satisfactory properties. Therefore, the concept of hybrid manufacturing consists of building a complex portion of a part by additive manufacturing on a simple pre-machined simple base substrate. Behind this, this approach can also be favourable in the restoration of damaged parts.

Hybrid manufacturing was proposed by Boivie et al. [

1] for application in steel injection-moulding inserts with conformal cooling channels and replicated by a vast number of other authors [

2,

3,

4]. The results showed that the production cost using hybrid manufacturing technology was reduced by up to 20% with respect to tool inserts made entirely with additive manufacturing [

2,

4]. According to the authors, the best cost–benefit is achieved when 65% of the part is produced by subtractive manufacturing and the remaining 35% by additive manufacturing [

3]. Hybrid manufacturing can also benefit component repair, offering significant economic advantages [

5].

The interface analysis between both technologies considering steel substrates and powders have been successfully investigated, mainly employing uniaxial tensile tests combined with microstructure observation. Even with a strong fusion bonding at the interface boundary between the additive powder and machined substrate, there is a small compromise in tensile strength. Mostly, fractures occurred in the interface, although sometimes it can occur in the side of the weaker material away from the interface, depending on the substrate material and the heat treatment applied [

4,

6,

7,

8,

9].

However, studies of hybrid-built reactive materials such as aluminium are more limited, which, together with the indoor availability of this material, were the reasons that led to the completion of this work. Chan et al. [

10] evaluated the interface bonding integrity, in terms of microstructure and mechanical properties, of AlSi10Mg powder and three types of substrate aluminium alloys: AW-5083, AW-6061 and Alumec 89 [

11,

12,

13,

14]. Microstructure analysis revealed excellent powder substrate fusion and tensile specimens ruptured at the side where the material was of a lower strength. Optical microscopic examinations revealed good adhesion of deposited powder onto the substrate, mainly with Alumec 89. Although this was not the aluminium alloy with the most similar chemical composition to the additive manufacturing alloy, the higher amount of zinc lead to higher solubility and provided a solderable surface [

15].

Later, the same authors fabricated injection-moulding inserts using the hybrid additive–subtractive strategy. 5083-H116 wrought aluminium alloy was selected as the substrate material and a time saving close to 27% was achieved (compared with fully additively manufactured moulding inserts) [

16].

This paper intends to answer the question “How much hybrid manufacturing, that is, combining subtractive and additive technologies, contributes to the production of sustainable aluminium parts and without significant loss of properties?” To this, specimens produced by additive manufacturing with AlSi10Mg by conventional machining with AW-6082 aluminium alloy and by hybrid manufacturing are tested. In AlSi10Mg samples, the influence of the stress relief heat treatment, recommended by the supplier, is reported. In each case, physical, mechanical and thermal properties are evaluated to corroborate the eventual loss of properties caused by hybrid manufacturing. In addition, a flexural test is done on a functional part, previously made in AW-6082 and rebuilt by additive manufacturing, demonstrating that metallic powder bed fusion additive-manufacturing technologies [

17] could have a significant role in the building of a circular economy. This paper is also especially relevant as, to date, there is no knowledge regarding thermal properties on hybrid-manufactured parts.

2. Materials and Methods

2.1. Materials

Considering the powder material used for additive manufacturing—AlSi10Mg, we selected a widely used aluminium alloy with similar chemical composition available: AW-6082. This alloy has excellent mechanical characteristics and good corrosion resistance and it is widely used in the construction of structural elements, machine elements, home appliances, high precision parts and shipbuilding applications [

18]. Chemical composition of both alloys is recorded in

Table 1.

2.2. Methodology

According to the manufacturer, after the production of AlSi10Mg aluminium alloy components in the Concept Laser M2 Cusing equipment, a stress relief heat treatment must be carried out. For this reason, the properties of this alloy with and without heat treatment are analysed. AW-6082 aluminium alloy is already supplied with T6 heat treatment [

14,

18]. So, for physical, mechanical and thermal characterization, specimens are produced in each of the following stages:

AlSi10Mg as-built;

AlSi10Mg with heat treatment;

AW-6082;

AlSi10Mg + AW-6082 as-built;

AlSi10Mg + AW-6082 with heat treatment.

2.3. Production of Specimens

2.3.1. AlSi10Mg Additively Manufactured Specimens

AlSi10Mg additively manufactured specimens were produced in Concept Laser M2 Cusing equipment, vertically oriented to facilitate the subsequent hybrid manufacturing. They were produced in a single batch with layer thickness of 25 µm, as it is known that a smaller layer thickness will improve the tensile strength and strain [

19]. The remaining parameters were a laser power of 200 W with a spot diameter of 50 µm, in an atmosphere inert with nitrogen with a maximum oxygen content of 0.2%. In each production layer, the sintering area was divided into several islands measuring 5 mm. For each consecutive layer, the pattern was shifted 1 mm and rotated 90° to reduce discontinuities between the perimeters of the islands.

After producing the specimens and removing supports, the stress relief heat treatment recommended by the manufacturer was carried out (i) heating the specimens up to 240 °C (in one hour), (ii) maintaining the temperature for six hours, (iii) cooling, in the oven, to 100 °C and (iv) cooling completely in the ambient atmosphere [

14].

2.3.2. AlSi10Mg Subtractive Manufactured Specimens

The production of the AW-6082 aluminium specimens was carried out in the DMG Mori DMU 50 machine (DMG Mori, Bielefeld, Germany), using the appropriate tools and coolant. Each typology was produced according to different batches and programs, using milling cutters with 12 mm of diameter, at 6000 rpm and feed rate of 2000 mm/min, cooled with an emulsion with cutting oil and water.

2.3.3. AlSi10Mg Hybrid Manufactured Specimens

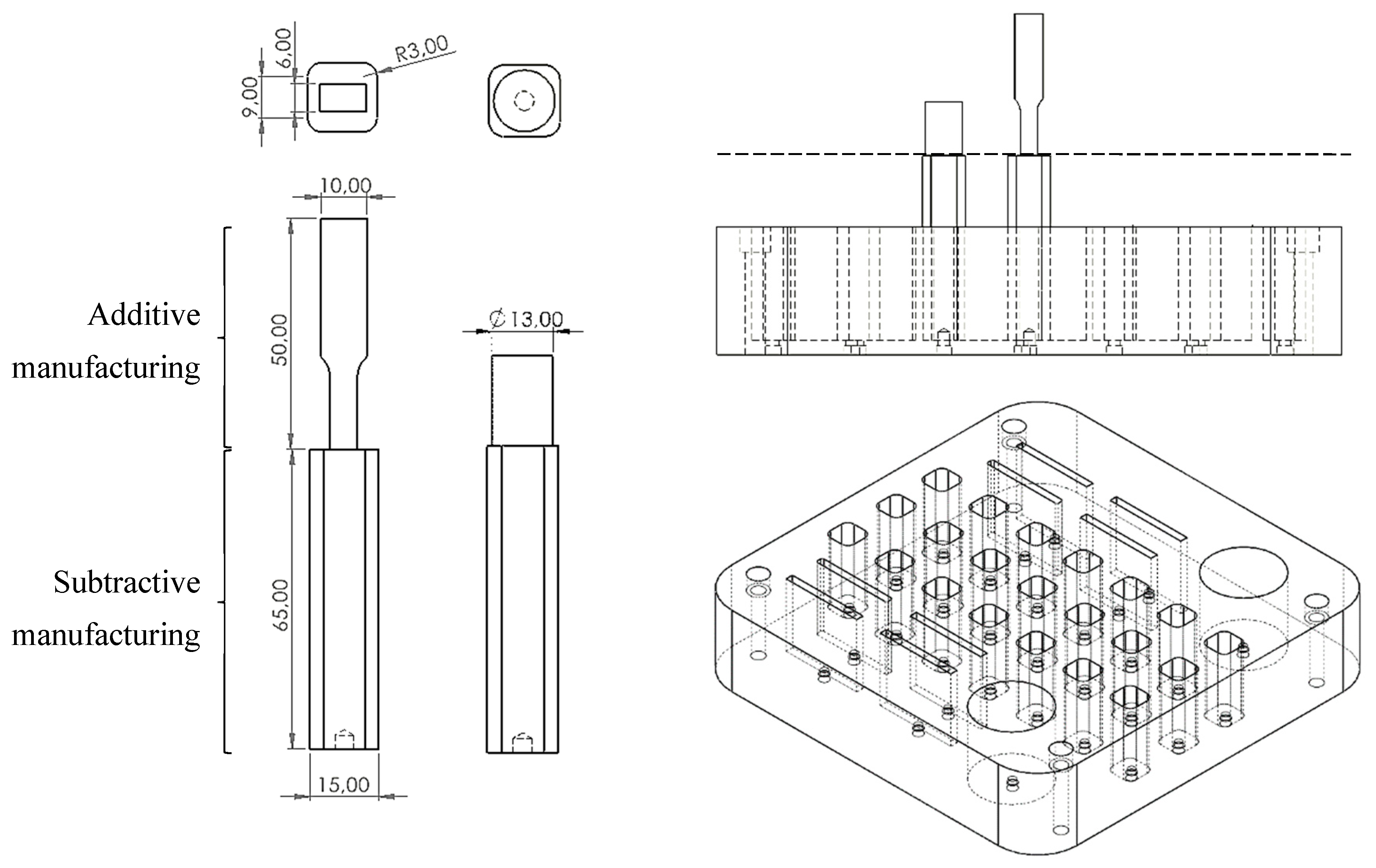

To produce hybrid specimens, solid substrate blocks were designed and manufactured through CNC machining in AW-6082 aluminium alloy for tensile and compressive tests. All substrate blocks were mounted to the pre-machined building platform for the equipment Concept Laser M2 Cusing and fixed with M3 screws (

Figure 1). Before starting the production of the additively manufactured part, it was ensured that the surfaces of the machined substrates were perfectly aligned to guarantee proper calibration of the additive manufacturing process [

4]. After a detailed positioning in Magics software, the remaining half specimens were produced by additive manufacturing. Then, all specimens were obtained from the hybrid-built parts by milling.

3. Experimental Characterization

Even hybrid manufacturing is pertinent for a reduction in manufacturing costs; the characterization of the parts produced by this strategy must be done to ensure the best performance of the component to be applied. In this work, some physical, mechanical and thermal properties are evaluated.

3.1. Physical Properties

Powder bed fusion technologies show potential for fabricating a vast number of components requiring good mechanical and thermal properties, such as heat sinks and injection-moulding inserts, as they can process parts of high relative density. Understanding porosity formation aids in improving parts’ quality and decreasing the limiting effect these defects can have when parts are applied in industry [

20,

21,

22]. The application of heat treatment on AlSi10Mg samples can reduce density due to the exposure to high temperatures. According to some authors, the higher the treatment duration and/or temperature, the lower the density [

23,

24].

In this work, Archimedes principle was used. According to this principle, the volume of an immersed solid is equal to the volume of the displaced volume. Thus, a solid immersed in a liquid is exposed to the buoyancy force which, in turn, is equal to the weight of the liquid displaced by the volume of the solid. The specific density of the solid is calculated using the ratio

where

represents the buoyancy force.

The procedure for determination of density was performed on an analytical balance AS 220.R2 from Radwag (Radom, Poland) with density kit. Based on five samples, the average density obtained for the different aluminium alloys are resumed in

Table 2.

Regardless of the heat treatment, the density of components produced by additive manufacturing is about 96% of the density of components produced by subtractive manufacturing. With the hybrid approach, as expected, the density gets close to that of the AW-6082 aluminium alloy. In hybrid samples, the application of heat treatment decreases the density. However, this effect is not the same on the additively manufactured ones, where density is independent of the heat treatment applied.

3.2. Thermal Properties

Although thermal properties of an equivalent aluminium bulk material may be known, the use of additive manufacturing as a processing technique can result in different values. Uncertainties in the thermal properties may induce under- or overvalued results in thermal management applications such as injection-moulding inserts or additively manufactured heat sinks [

25,

26]. For this reason, a better understanding of these properties is an important step.

3.2.1. Specific Heat Capacity

Specific heat capacity is the quantification of energy required to increment a material’s temperature. Literature values of specific heat capacity for AlSi10Mg additively manufactured alloy vary from about 0.73 J/kg°C to 1.1 J/kg°C, depending on the temperature [

27,

28,

29,

30].

In this work, specific heat capacity under constant pressure was measured using a differential scanning calorimeter (DSC) Netzsch 200 F3 (Netzsch, Selb, Germany) at the 25–200 °C temperature range, with a heating rate of 10 °C/min and in isothermal period of two minutes at the beginning and at the end of the test. Heat flow signals for the sample and the sapphire (a calibration standard of known specific heat capacity) are compared for three samples in each case. According to ASTM E1269 [

31] specific heat capacity is given by

where

Cp,sample and

Cp,sapphire represent the specific heat capacity of the sample and the sapphire,

msample and

msapphire represent the masses and

φsample,

φsapphire and

φ0 represent the signal obtained by DSC for the sample, sapphire and baseline, respectively.

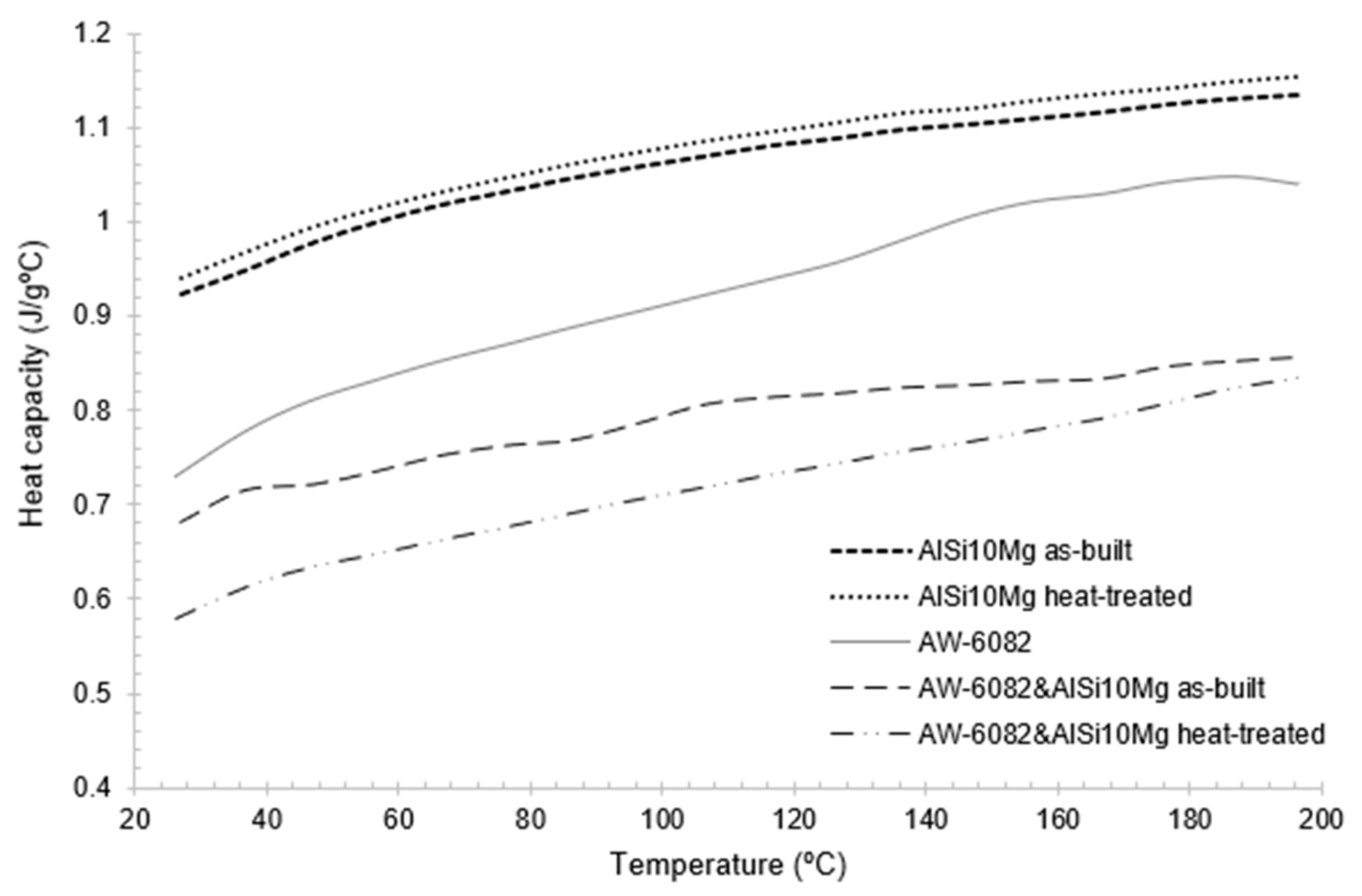

Specific heat capacity evolution along temperature is shown in

Figure 2. As expected, specific heat capacity increases with temperature for all cases. AlSi10Mg aluminium alloys have a higher specific heat capacity, mainly in heat-treated samples. Specific heat capacity of AW-6082 is lower. However, the lower specific heat capacity is achieved in heat-treated hybrid samples; a reduction of 38%, compared to additively manufactured AlSi10Mg.

3.2.2. Coefficient of Thermal Expansion

The thermal expansion describes how the size of an object changes with a change in temperature. Engine parts and heat sinks, e.g., used in cars are often produced from Al–Si alloys due to their low coefficient of thermal expansion (CTE), high wear resistance and the high strength-to-weight ratio [

32,

33].

Gumbleton et al. [

33] evaluated the coefficient of thermal expansion of additively manufactured AlSi10Mg aluminium alloy using microwaves techniques over a temperature range between −267 °C and 177 °C and showed that the material under testing exhibits lower thermal expansion when compared with an equivalent bulk aluminium alloy (~21 × 10

−6 °C

−1). For higher temperatures, Strumza et al. [

34] demonstrated that, above 400 °C, the samples showed anomalous thermal expansion attributed to thermally induced porosity, i.e., a process by which the material swells during heating when pores expand under increasing internal pressure. Based on other studies [

24,

28,

35], CTE increases as the temperature increases and there is no dependence on the polar angle up to approximately 120 °C. For higher temperatures, CTE of parts oriented vertically (90°) shows slight upward deviation when compared to the other orientations.

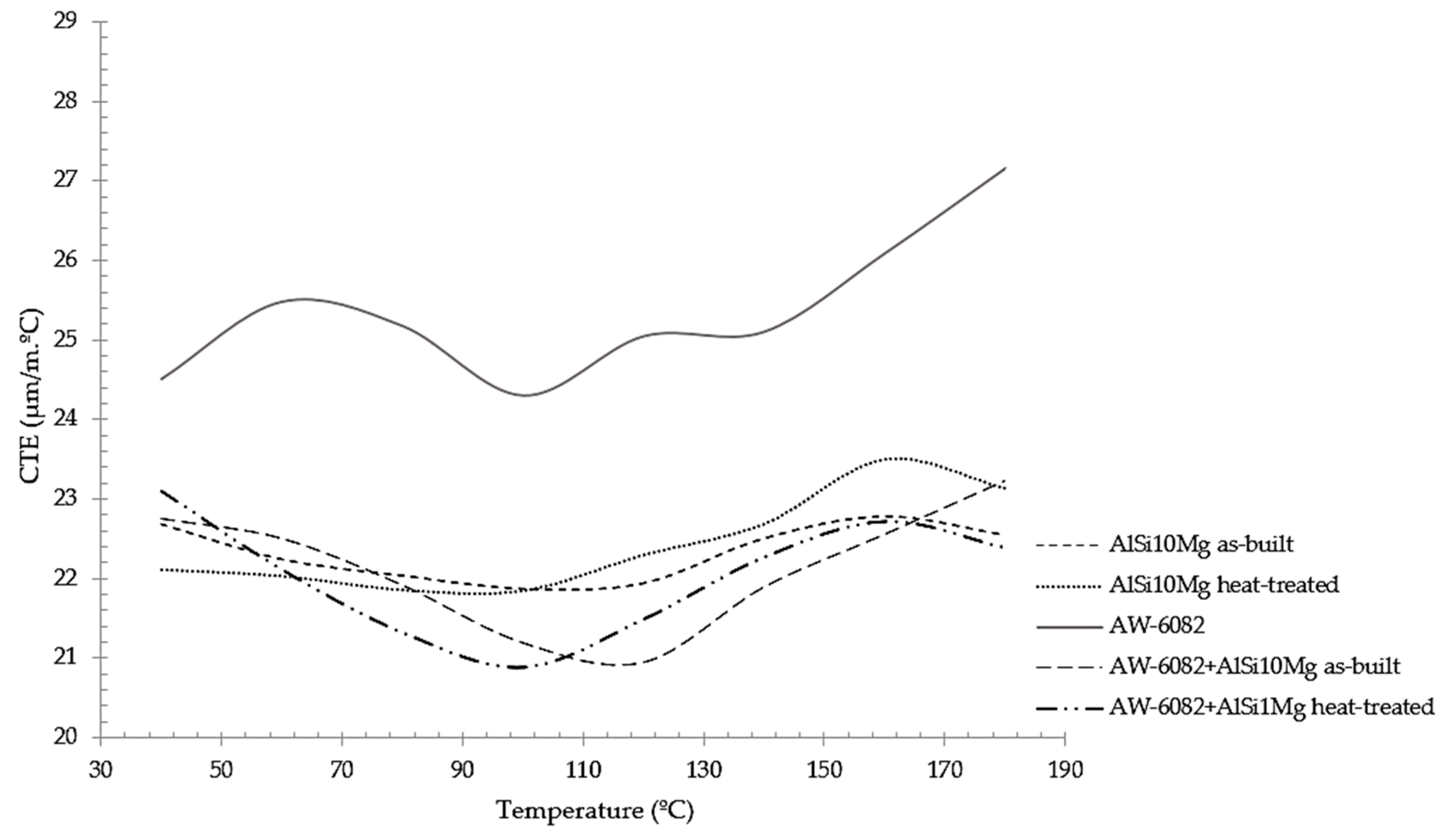

In this work, the coefficient of thermal expansion was determined through Dynamic Mechanical Analysis (DMA) using the equipment Q800 from TA Instruments. Tests were performed between 30 °C and 200 °C at a frequency of 1 Hz for three samples in each case. The change in the specimen length was electronically recorded as a function of temperature (

Figure 3) and the calculated coefficient of thermal expansion is resumed in

Table 3.

According to

Figure 3 and

Table 3, AlSi10Mg and hybrid parts exhibit less of a thermal expansion coefficient when compared to AW-6082 aluminium alloy. Stress relief heat treatment reduces this coefficient by up to 3%, mainly in hybrid-manufactured samples.

3.3. Mechanical Properties

AlSi10Mg additively manufactured parts can have mechanical properties comparable to or even exceeding those of conventionally manufactured AlSi10Mg because of the very fine microstructure and fine distribution of the Si phase [

36,

37,

38,

39,

40,

41,

42,

43,

44,

45]. In general, mechanical properties are worse when the largest dimension of the specimens coincides with the building direction (90°). This is related to the periodical re-melting directions and tiny non-fused defect detections, and the separation between weakly bonded layers along the largest dimension of the specimens [

39,

46]. To facilitate the subsequent hybrid manufacturing, this was the orientation considered in this study.

3.3.1. Tensile Properties

There is a vast number of studies regarding the tensile properties of AlSi10Mg alloy for additive manufacturing. The influence of building orientation and of the heat treatment applied, as well as comparison with conventionally cast AlSi10Mg parts, are the main topics reported in the literature. The application of some post treatment causes a decrease in the strength and an increase in elongation at break, and the higher the time and the temperature of the heat treatment applied, the more significant these variations are [

47,

48,

49,

50,

51].

Terrazas-Najera et al. [

52] reported the effect that PBF process interruptions have on the thermal history during the fabrication of simple geometries made of AlSi10Mg. Systematic experiments were carried out with programmed process interruptions lasting one hour and simulating a stop to refill the system with powder, or an unexpected power outage. Even with these interruptions and a welding on the parts, mechanical and microstructural properties remained essentially unchanged.

Chan et al. [

10,

16] studied the interface bonding integrity in terms of the mechanical properties of AlSi10Mg additively manufactured specimens. Stress–strain curves showed that there was no necking or further elongation of the specimen after the maximum tensile stress was reached. Fracture happened instantaneously straight after, at a position well away from the bonded interface. A comparison of the mechanical strength of different materials and combinations of materials is shown in

Table 4.

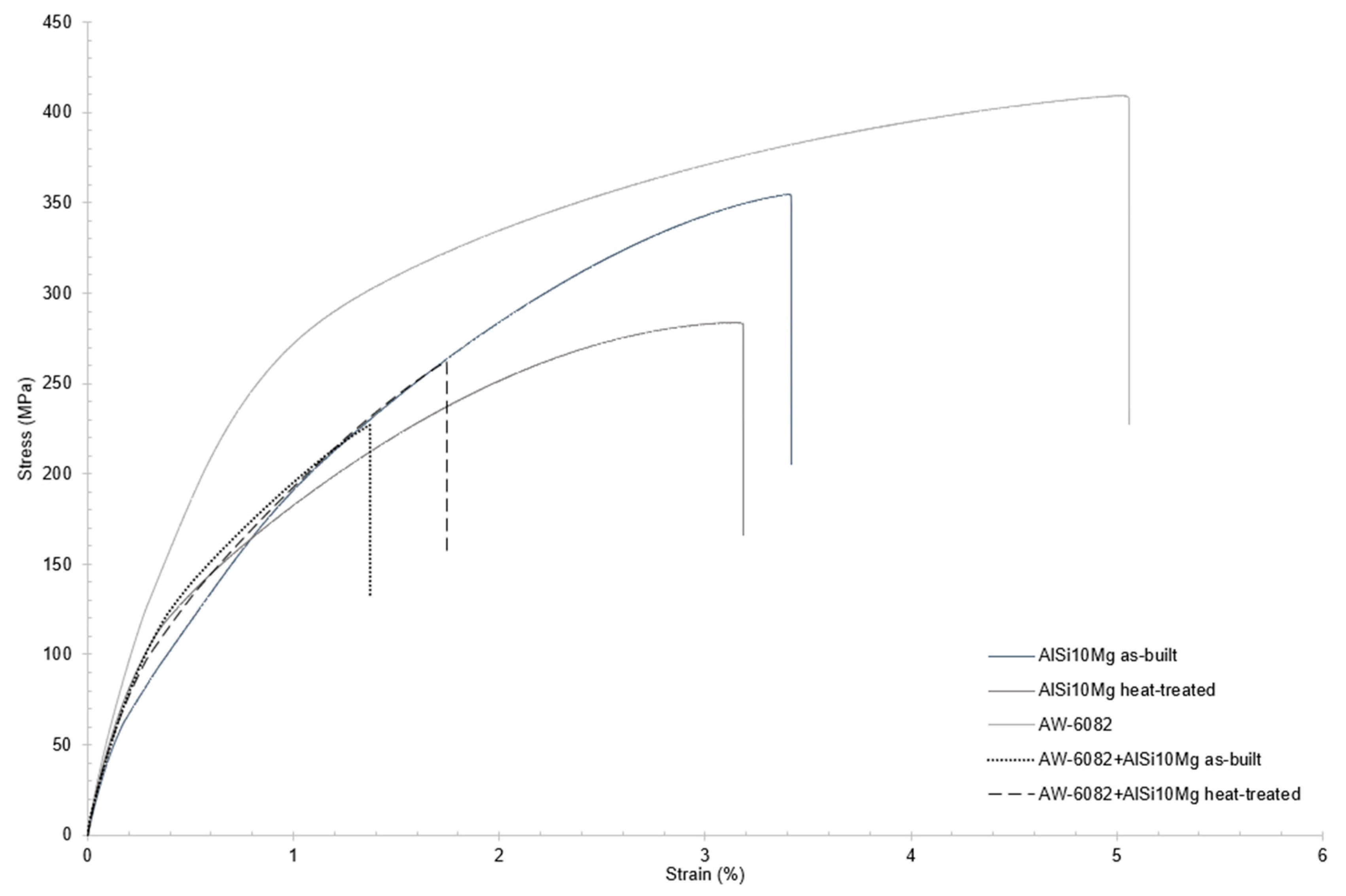

In this work, tensile properties of AlSi10Mg as-built and heat-treated, AW-6082 and hybrid specimens as-built and heat treated were determined through uniaxial tests carried out in the Instron 5969 Universal Testing System (Massachusetts, EUA) using a strain extensometer. In each case, five specimens were tested at 1 mm/min with a 50 kN load cell at room temperature. ASTM E8 standard [

53] was followed and the results are compiled in

Figure 4 and

Table 5.

By analysing the data, the tensile properties of specimens produced by additive manufacturing are improved when heat treatment is applied. Young’s modulus and yield strength increase by approximately 17% and 30%, respectively. Contrarily, the properties at break suffer a slight decrease of 4% in ultimate tensile stress and 7% in the respective strain.

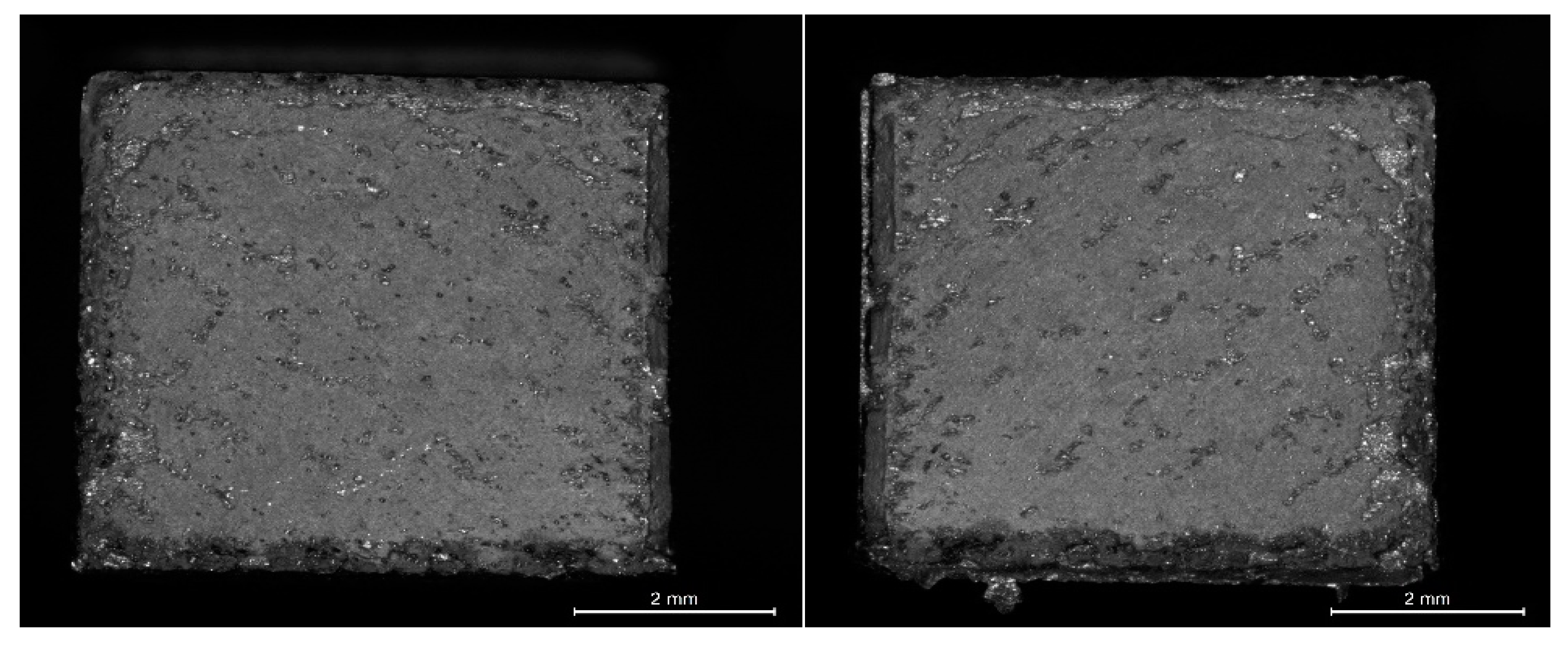

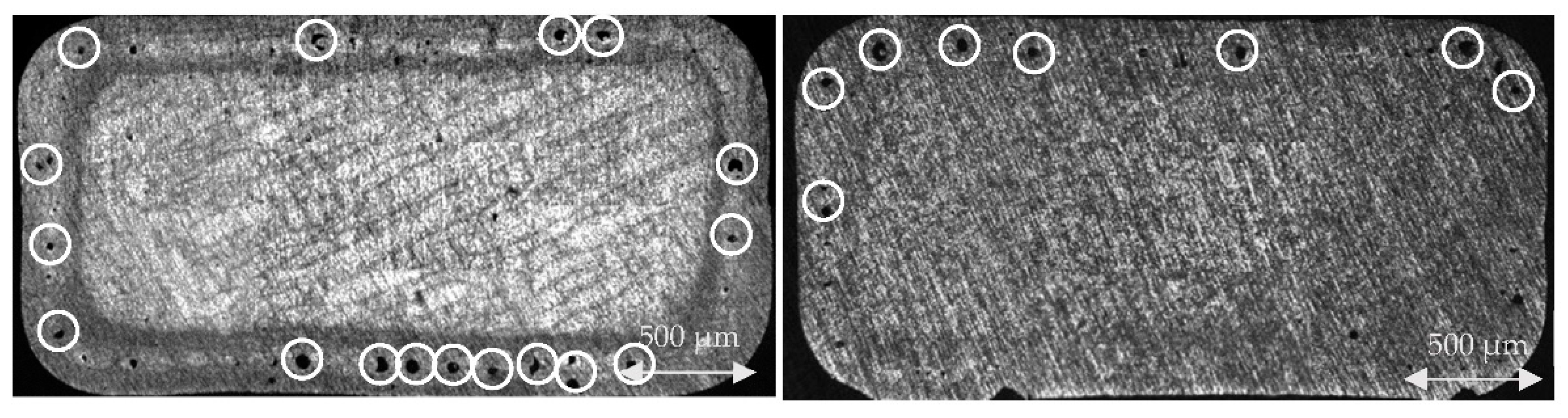

With the bare eye, the rupture of the hybrid specimens occurred, in all cases, in the interface between the two manufacturing methods. However, by images acquired with Leica DMS1000 low-magnification microscope after rupture, it is concluded that in the conventional half, some characteristic details of the additive manufacturing process are visible, which indicates that the rupture occurred in the interface area after the first additive manufacturing layers (

Figure 5).

3.3.2. Compressive Properties

Most of the compressive studies considering AlSi10Mg aluminium alloy have been directed for cellular lattice structures [

54,

55,

56,

57,

58,

59] or other similar and lightweight structures that exhibit a relatively high impact energy absorption [

60,

61]. One of the first compression studies using solid blocks was done by Hitzler et al. [

44]. The obtained compressive modulus exceeded not only the equivalent tensile modulus but also the compressive modulus of the conventionally fabricated bulk material. The results were similar for yield and fracture strengths.

Aboulkhair et al. [

62] recorded a significantly higher compressive yield strength for the as-built material, when compared with heat treated (T6) samples. Nevertheless, both as-built and heat-treated materials demonstrated the ability to withstand high compressive strains as they barrelled and buckled during compression with no evidence of fracture. They also verified that porosity was not critical because the nature of loading tends to close the pores, consolidating the defected regions.

In this work, the compressive properties of AlSi10Mg as-built and heat-treated, AW-6082 and hybrid specimens as-built and heat-treated were determined through uniaxial tests carried out in Instron 5969 Universal Testing System. In each case, five specimens were tested at 1 mm/min with a 50 kN load cell at room temperature, up to the limit of the load cell. ASTM E9 standard [

63] was followed and the results are compiled in

Figure 6 and

Table 6.

Regarding compressive properties, heat treatment increased the compressive modulus by about 7% as well as the yield strength and ductility of the specimen (≈5%). In the case of the hybrid specimens, heat treatment caused a decrease in both. Even so, the compressive properties of the as-built hybrid specimens are up to 27% higher than those of AlSi10Mg.

In none of the cases did the specimen fracture after the end of the test; that is, both materials showed a high capacity to resist compressive stresses, when compared to tensile stimuli. The loading direction tends to close the pores, consolidating the specimen before failure. However, the compression modulus fell short of the tensile modulus.

3.3.3. Case Study

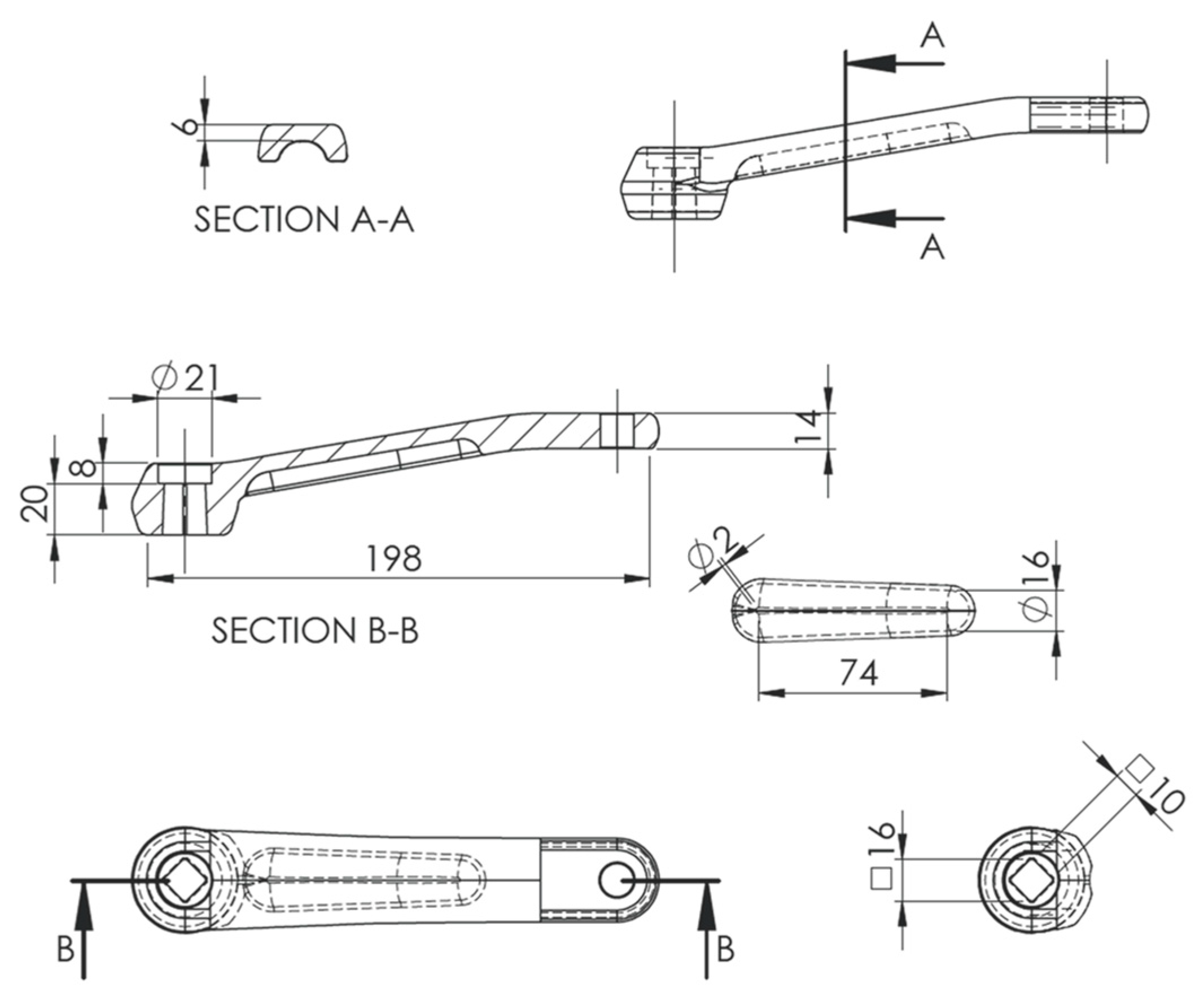

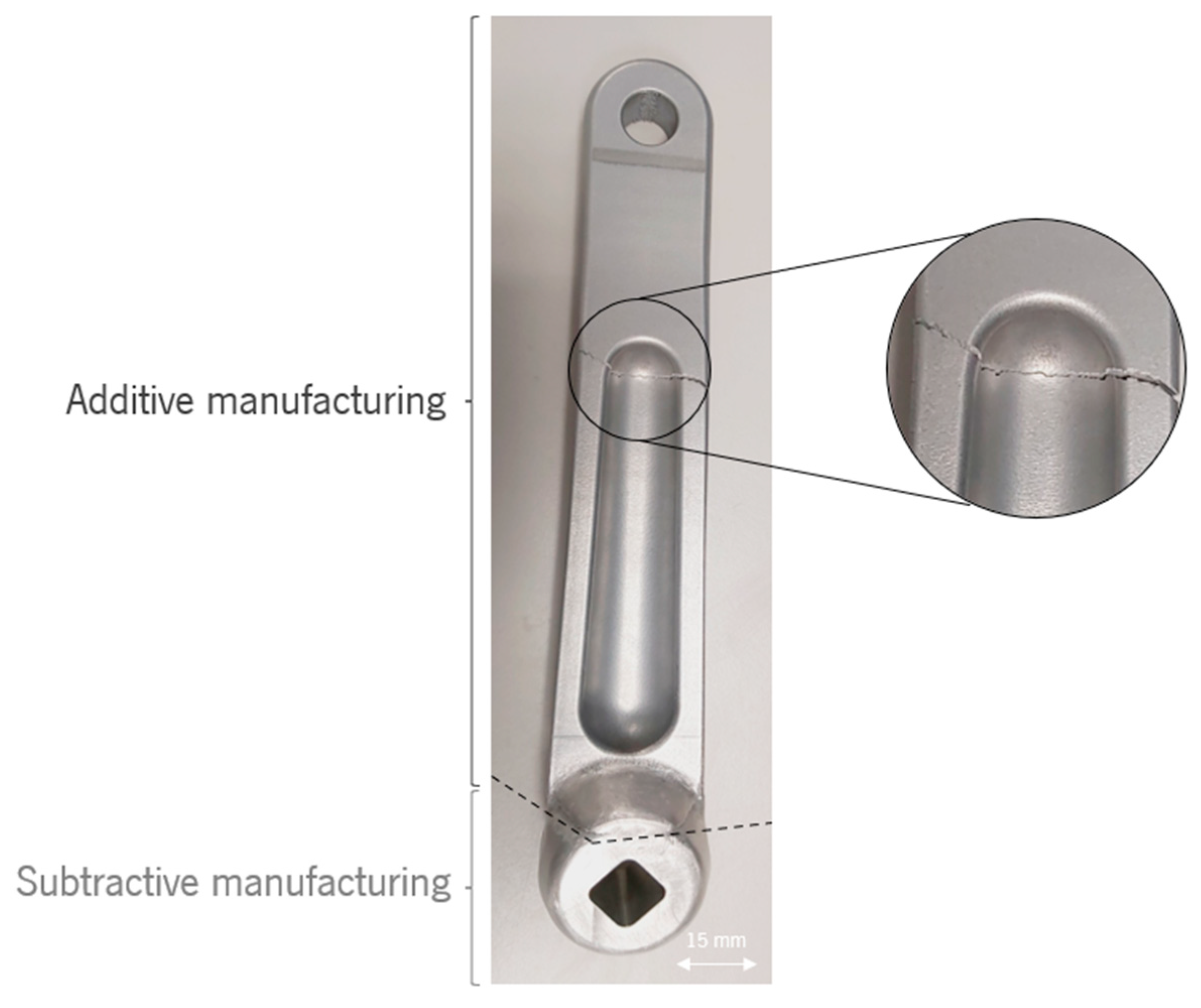

Considering these mechanical results, an aluminium crankset (

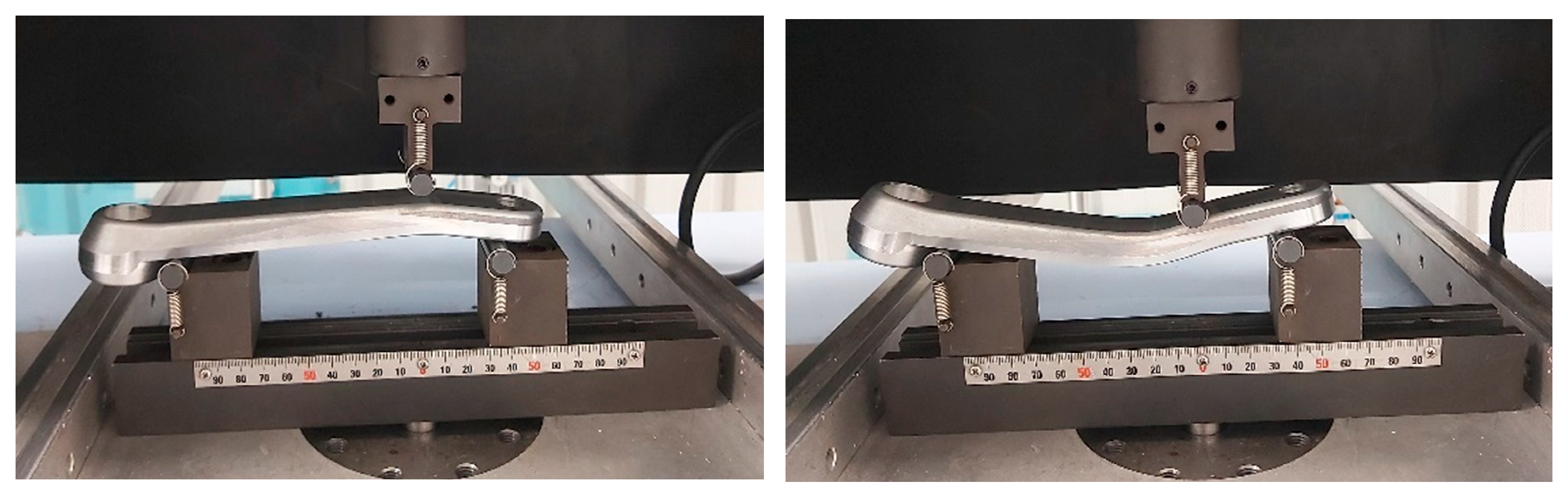

Figure 7), which is a complex and functional part, was developed and produced by conventional subtractive manufacturing and by hybrid manufacturing to validate the application of additive-manufacturing technologies for the restoration of parts.

The main mechanical loading applied to the crankset is bending. Therefore, a three-point flexural test, combining tensile and compressive loads, was done on the original AW-6082 aluminium crankset. Tests were conducted on a Shimadzu AGS-X universal testing machine with a load cell of 50 kN, at a constant crosshead rate of 1 mm/min. The fixed supports were located 110 mm to the left and 35 mm to the right of the load application point and the test stopped when the displacement was maximum, as shown in

Figure 8.

At the end of the test, the part did not break. However, the applied force permanently deformed the crankset in such a way that only a tiny part with a length of 40 mm was considered undamaged and could be used for the reconstruction. The deformed part was sawn and grinded and the remaining 40 mm of the crankset (in light grey on

Figure 9), in good condition, was fixed with an M8 screw on the Concept Laser M2 Cusing building platform. The damaged crankset was rebuilt by additive manufacturing with the silicon aluminium alloy (

Figure 9). At the end of the additive manufacturing process, the hybrid crankset was not subjected to the stress relief heat treatment due to the results mentioned before.

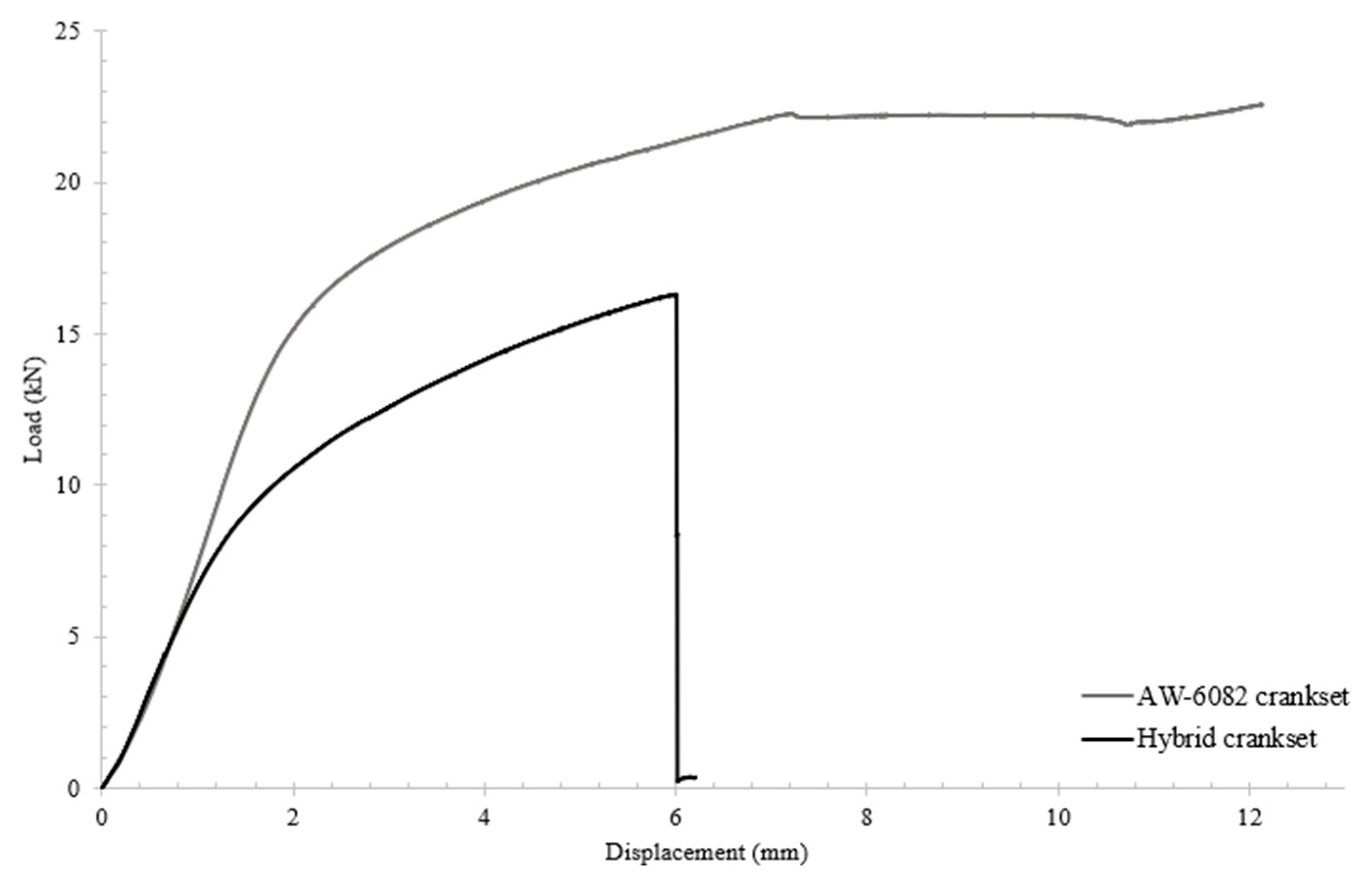

After the restoration of the part, a new three-point flexural test was done on the hybrid crankset, under the same test conditions. According to load–displacement curves (

Figure 10), the original (AW-6082) crankset presented a higher ultimate resistance to bending and a higher ductility. Nevertheless, stiffness was similar in both cases. One important observation to highlight is that, on the hybrid crankset, rupture occurred in the additive manufacturing area, near the load application point and not in the join between the original part and the repaired one (

Figure 11).

4. Discussion of Results

This study demonstrated a hybrid strategy to achieve the best of additive and subtractive technologies, considering the effect of heat treatment application in additively and hybrid-manufactured samples.

Regarding thermal properties, to the authors’ knowledge, this is the first article that reports the analysis of these properties in hybrid-manufactured parts. A reduction of 38% on specific heat capacity was recorded in the hybrid samples when compared to the additively manufactured ones. This reduction in specific heat capacity, to values equivalent to those reported in [

27] for AlSi10Mg, means that the joint between the two aluminium alloys had a good effect on this property once less energy was necessary to increase the temperature by one degree. Results were also good considering the coefficient of thermal expansion, where the high amount of silicon present in AlSi10Mg caused a reduction in this coefficient for the additive and hybrid samples, compared to AW-6082 aluminium alloy [

32]. In thermal properties, there was no visible effect of the heat treatment on both the additive and hybrid samples.

By the images acquired with the Leica DM500 reflection microscope after rupture in the tensile tests, differences are visible in the specimen shell (

Figure 12) which, after heat treatment, appears to have fewer voids (white circles in

Figure 12). This result, similarly reported by Tradowsky et al. [

64], caused an improvement in mechanical properties when heat treatment was applied, as reported in

Section 3.3.

These microstructural differences were also manifested in a slight increase in the density of the heat-treated parts, in relation to the as-built ones. However, the effect of heat treatment was not the same for the hybrid manufactured parts in these tests. The probable cause is to the presence of the AW-6082 aluminium alloy in hybrid samples, which is already supplied with a T6-heat treatment. To the authors’ knowledge, the study of this effect was still not considered in peer works.

As the mechanical properties of the hybrid specimens were especially good in compressive stimuli, this knowledge was applied on a case study, imposing tensile and compressive loads without heat treatment. The bonding between the two alloys in the interface zone of the repaired part was strong enough to withstand the designed loads and the failure occurred outside it.

5. Conclusions

In this work, hybrid aluminium parts were successfully additively fabricated by depositing AlSi10Mg on AW-6082 pre-machined alloys. These parts were physically, mechanically and thermally characterised, considering the influence of a stress relief heat treatment on the parts with AlSi10Mg, as recommended by the supplier, and the main conclusions are as follows:

The density of the components produced by additive manufacturing was about 96% of the density of the components produced by subtractive manufacturing. With the hybrid approach, as expected, the density got close to that of the AW-6082 aluminium alloy. Stress relief heat treatment had no relevant effect.

In both thermal properties evaluated (specific heat capacity and coefficient of thermal expansion), the hybrid manufacturing samples provided positive results, i.e., lower specific heat capacity and lower coefficient of thermal expansion, when compared with the simple additive or conventional samples. Stress relief heat treatment had a good effect on these properties.

Regarding mechanical properties, tensile specimens fractured near the interface, after the initial layers of the additive manufacturing process, as reported in previous studies [

10,

16]. When compressive loads were applied, it was advantageous to apply hybrid manufacturing techniques once compressive properties of as-built hybrid specimens were up to 27% higher than those of AlSi10Mg.

Applying this knowledge to a case study, the AW-6082 crankset presented a higher resistance to bending and higher ductility. When the hybrid crankset was tested, rupture occurred in the additive manufacturing area and not in the interface between the original part and the repaired one. Nevertheless, stiffness was similar in the two cases.

In this sense, the hybrid manufacturing concept can be successfully applied with affirmative results, mainly in parts for thermal management applications or subjected to compressive stimuli. In addition, metallic powder bed fusion additive-manufacturing technologies could have a significant role in the building of a circular economy once the bonding between the two alloys in the interface zone of the repaired crankset is strong enough to withstand the designed loads and the failure occurs outside it.

Author Contributions

Conceptualization, E.C.S.; methodology, E.C.S.; validation, Á.M.S. and A.J.P.; formal analysis, Á.M.S. and A.J.P.; investigation, E.C.S., J.A.C. and S.J.R.; data curation, E.C.S.; writing—original draft preparation, E.C.S.; writing—review and editing, Á.M.S. and A.J.P.; supervision, Á.M.S. and A.J.P.; project administration, Á.M.S. and A.J.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Portuguese Fundação para a Ciência e a Tecnologia (FCT), for financial support under the Ph.D. scholarship SFRH/BD/144590/2019 and by the European Regional Development Fund (ERDF) through the Operational Competitiveness and Internationalization Programme (COMPETE 2020) of the Portugal 2020 Program [Project No. 47108, “SIFA”; Funding Reference: POCI-01-0247-FEDER-047108].

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Boivie, K.; Karlsen, R.; Ystgaard, P. The concept of hybrid manufacturing for high performance parts. S. Afr. J. Ind. Eng. 2012, 23, 106–115. [Google Scholar] [CrossRef]

- Homar, D.; Čerče, L.; Kopač, J. Cooling simulation of conformal cooling injection mould insert produced by hybrid manufacturing. Teh. Vjesn.-Tech. Gaz. 2017, 24, 981–986. [Google Scholar]

- Homar, D.; Pušavec, F. The development of a recognition geometry algorithm for hybrid-Subtractive and additive manufacturing. Stroj. Vestn. J. Mech. Eng. 2017, 63, 151–160. [Google Scholar] [CrossRef]

- Marin, F.; de Souza, A.F.; Ahrens, C.H.; de Lacalle, L.N.L. A new hybrid process combining machining and selective laser melting to manufacture an advanced concept of conformal cooling channels for plastic injection molds. Int. J. Adv. Manuf. Technol. 2021, 113, 1561–1576. [Google Scholar] [CrossRef]

- Schroepfer, D.; Treutler, K.; Boerner, A.; Gustus, R.; Kannengiesser, T.; Wesling, V.; Maus-Friedrichs, W. Surface finishing of hard-to-machine cladding alloys for highly stressed components. Int. J. Adv. Manuf. Technol. 2021, 114, 1427–1442. [Google Scholar] [CrossRef]

- Azizi, H.; Ghiaasiaan, R.; Prager, R.; Ghoncheh, M.H.; Samk, K.A.; Lausic, A.; Phillion, A.B. Metallurgical and mechanical assessment of hybrid additively-manufactured maraging tool steels via selective laser melting. Addit. Manuf. 2019, 27, 389–397. [Google Scholar] [CrossRef]

- Cyr, E.; Asgari, H.; Shamsdini, S.; Purdy, M.; Hosseinkhani, K.; Mohammadi, M. Fracture behaviour of additively manufactured MS1-H13 hybrid hard steels. Mater. Lett. 2018, 212, 174–177. [Google Scholar] [CrossRef]

- Santos, L.M.S.; De Jesus, J.; Ferreira, J.M.; Costa, J.; Capela, C. Fracture toughness of hybrid components with Selective Laser Melting 18Ni300 steel parts. Appl. Sci. 2018, 8, 1879. [Google Scholar] [CrossRef]

- Kučerová, L.; Zetkova, I.; Jenicek, S.; Burdová, K. Hybrid parts produced by deposition of 18Ni300 maraging steel via selective laser melting on forged and heat treated advanced high strength steel. Addit. Manuf. 2020, 32, 101108. [Google Scholar] [CrossRef]

- Chan, Y.L.; Diegel, O.; Xu, X. Evaluation of bonding integrity of hybrid-built AlSi10Mg-aluminium alloys parts using the powder bed fusion process. Mater. Today Proc. 2021, 46, 1277–1282. [Google Scholar] [CrossRef]

- Alloy Data Sheet EN AW-6061; Nedal Aluminium: Utrecht, The Netherlands, 2005; Available online: https://www.nedal.com/wp-content/uploads/2016/11/Nedal-alloy-Datasheet-EN-AW-6061.pdf (accessed on 25 February 2022).

- Universal Afir. Especificações–ALU 5083. 2016, 5083. Available online: https://www.universalafir.pt/item/403 (accessed on 25 February 2022).

- Durbin Metal Industries Ltd. Aluminium Alloy ALUMEC 89. Available online: https://www.durbinmetals.co.uk/resources/data-sheets/view/Aluminium-Alloy-ALUMEC-89-Hot-Rolled-PLATE-Plate_413 (accessed on 25 February 2022).

- Concept Laser. CL 30AL/CL 31AL Aluminium Alloys. Available online: https://www.ge.com/additive/sites/default/files/2018-12/CLMAT_30_31AL_DS_EN_US_2_v1.pdf (accessed on 25 February 2022).

- Totten, G.E.; MacKenzie, D.S. Handbook of Aluminium: Volume 2: Alloy Production and Materials Manufacturing, 1st ed.; CRC Press: New York, NY, USA, 2003. [Google Scholar]

- Chan, Y.L.; Diegel, O.; Xu, X. A machined substrate hybrid additive manufacturing strategy for injection moulding inserts. Int. J. Adv. Manuf. Technol. 2021, 112, 577–588. [Google Scholar] [CrossRef]

- ISO/ASTM 52900. Standard Terminology for Additive Manufacturing–General Principles–Terminology. Available online: https://www.iso.org/standard/69669.html (accessed on 25 February 2022).

- Universal Afir. Especificações—ALU 6082. Available online: https://universalafir.pt/item/410 (accessed on 25 February 2022).

- Paul, M.J.; Liu, Q.; Best, J.P.; Li, X.; Kruzic, J.J.; Ramamurty, U.; Gludovatz, B. Fracture resistance of AlSi10Mg fabricated by laser powder bed fusion. Acta Mater. 2021, 211, 116869. [Google Scholar] [CrossRef]

- Wong, K.K.; Ho, J.Y.; Leong, K.C.; Wong, T.N. Fabrication of heat sinks by Selective Laser Melting for convective heat transfer applications. Virtual Phys. Prototyp. 2016, 11, 159–165. [Google Scholar] [CrossRef]

- Wits, W.W.; Jafari, D.; Jeggels, Y.; van de Velde, S.; Jeggels, D.; Engelberts, N. Freeform-Optimized Shapes for Natural-Convection Cooling. In Proceedings of the 2018 24th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Stockholm, Sweden, 26–28 September 2018. [Google Scholar]

- Taute, C.; Möller, H.; Du Plessis, A.; Tshibalanganda, M.; Leary, M. Characterization of additively manufactured AlSi10Mg cubes with different porosities. J. S. Afr. Inst. Min. Metall. 2021, 121, 143–150. [Google Scholar] [CrossRef]

- Girelli, L.; Giovagnoli, M.; Tocci, M.; Pola, A.; Fortini, A.; Merlin, M.; La Vecchia, G.M. Evaluation of the impact behaviour of AlSi10Mg alloy produced using laser additive manufacturing. Mater. Sci. Eng. A 2019, 748, 38–51. [Google Scholar] [CrossRef]

- Yang, P.; Deibler, L.A.; Bradley, D.R.; Stefan, D.K.; Carroll, J.D. Microstructure evolution and thermal properties of an additively manufactured, solution treatable AlSi10Mg part. J. Mater. Res. 2018, 33, 4040–4052. [Google Scholar] [CrossRef]

- Collins, I.L.; Weibel, J.A.; Pan, L.; Garimella, S.V. Evaluation of additively manufactured microchannel heat sinks. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 446–457. [Google Scholar] [CrossRef]

- Collins, I.L.; Weibel, J.A.; Pan, L.; Garimella, S.V. Evaluation of active heat sinks design under forced convection—Effect of geometric and boundary parameters. Materials 2021, 14, 2041. [Google Scholar] [CrossRef]

- Jiang, X.; Xiong, W.; Wang, L.; Guo, M.; Ding, Z. Heat treatment effects on microstructure-residual stress for selective laser melting AlSi10Mg. Mater. Sci. Technol. 2020, 36, 168–180. [Google Scholar] [CrossRef]

- Kim, M.-S. Effects of processing parameters of selective laser melting process on thermal conductivity of alsi10mg alloy. Materials 2021, 14, 2410. [Google Scholar] [CrossRef]

- Wei, P.; Wei, Z.; Chen, Z.; He, Y.; Du, J. Thermal behavior in single track during selective laser melting of AlSi10Mg powder. Appl. Phys. A 2017, 123, 604. [Google Scholar] [CrossRef]

- Estrada-Díaz, J.; Elías-Zúñiga, A.; Martínez-Romero, O.; Olvera-Trejo, D. Enhanced mathematical model for producing highly dense metallic components through selective laser melting. Materials 2021, 14, 1571. [Google Scholar] [CrossRef]

- ASTM International-E1269-01; Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- Wang, Z.; Ummethala, R.; Singh, N.; Tang, S.; Suryanarayana, C.; Eckert, J.; Prashanth, K.G. Selective laser melting of aluminum and its alloys. Materials 2020, 13, 4564. [Google Scholar] [CrossRef] [PubMed]

- Gumbleton, R.; Cuenca, J.A.; Klemencic, G.M.; Jones, N.; Porch, A. Evaluating the coefficient of thermal expansion of additive manufactured AlSi10Mg using microwave techniques. Addit. Manuf. 2019, 30, 100841. [Google Scholar] [CrossRef]

- Strumza, E.; Hayun, S.; Barzilai, S.; Finkelstein, Y.; Ben David, R.; Yeheskel, O. In situ detection of thermally induced porosity in additively manufactured and sintered objects. J. Mater. Sci. 2019, 54, 8665–8674. [Google Scholar] [CrossRef]

- Strumza, E.; Yeheskel, O.; Hayun, S. The effect of texture on the anisotropy of thermophysical properties of additively manufactured AlSi10Mg. Addit. Manuf. 2019, 29, 100762. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue 2017, 94, 192–201. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M. Characterisation of structural properties for AlSi10Mg alloys fabricated by selective laser melting. Mater. Sci. Technol. 2017, 33, 2274–2282. [Google Scholar]

- Chen, B.; Yao, Y.; Song, X.; Tan, C.; Cao, L.; Feng, J. Microstructure and mechanical properties of additive manufacturing AlSi10Mg alloy using direct metal deposition. Ferroelectrics 2018, 523, 153–166. [Google Scholar] [CrossRef]

- Rakesh, C.S.; Priyanka, N.; Jayaganthan, R.; Vasa, N.J. Effect of build atmosphere on the mechanical properties of AlSi10Mg produced by selective laser melting. Mater. Today Proc. 2018, 5, 17231–17238. [Google Scholar] [CrossRef]

- Raus, A.A.; Wahab, M.S.; Ibrahim, M.; Kamarudin, K.; Ahmed, A.; Shamsudin, S. Mechanical and Physical Properties of AlSi10Mg Processed through Selective Laser Melting. Int. J. Eng. Technol. 2016, 8, 2612–2618. [Google Scholar]

- Li, X.; Ni, J.; Zhu, Q.; Su, H.; Cui, J.; Zhang, Y.; Li, J. Structure and Mechanical Properties of the AlSi10Mg Alloy Samples Manufactured by Selective Laser Melting. IOP Conf. Ser. Mater. Sci. Eng. 2017, 269, 012081. [Google Scholar] [CrossRef]

- Hitzler, L.; Schoch, N.; Heine, B.; Merkel, M.; Hall, W.; Öchsner, A. Compressive behaviour of additively manufactured AlSi10Mg. Mater. Und Werkst. 2018, 49, 683–688. [Google Scholar] [CrossRef]

- Yan, Q.; Song, B.; Shi, Y. Comparative study of performance comparison of AlSi10Mg alloy prepared by selective laser melting and casting. J. Mater. Sci. Technol. 2020, 41, 199–208. [Google Scholar] [CrossRef]

- Rosenthal, I.; Shneck, R.; Stern, A. AlSi10Mg alloy fabricated by selective laser melting: Impact properties and fractography. Ann. “Dunarea De Jos” Univ. Galati Fascicle XII Weld. Equip. Technol. 2018, 29, 5–10. [Google Scholar] [CrossRef][Green Version]

- Takata, N.; Kodaira, H.; Sekizawa, K.; Suzuki, A.; Kobashi, M. Change in microstructure of selectively laser melted AlSi10Mg alloy with heat treatments. Mater. Sci. Eng. A 2017, 704, 218–228. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On the fatigue strength enhancement of additive manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M.; Bandini, M.; Guagliano, M. On laser powder-bed fusion of additively manufactured alsi10mg alloy: Tensile properties and structure characterization. Ann. “Dunarea De Jos” Univ. Galati Fascicle XII Weld. Equip. Technol. 2019, 30, 5–12. [Google Scholar]

- Patakham, U.; Palasay, A.; Wila, P.; Tongsri, R. MPB characteristics and Si morphologies on mechanical properties and fracture behavior of SLM AlSi10Mg. Mater. Sci. Eng. A 2021, 821, 141602. [Google Scholar] [CrossRef]

- AlRedha, S.; Shterenlikht, A.; Mostafavi, M.; Van Gelderen, D.; Lopez-Botello, O.E.; Reyes, L.A.; Zambrano, P.; Garza, C. Effect of build orientation on fracture behaviour of AlSi10Mg produced by selective laser melting. Rapid Prototyp. J. 2021, 27, 112–119. [Google Scholar] [CrossRef]

- Terrazas-Najera, C.A.; Mayoral, F.L.; Garcia, O.F.; Hossain, M.S.; Espalin, D.; Fernandez, A.; Murr, L.E.; Wicker, R.B. Effects of process interruptions on microstructure and mechanical properties of three face centered cubic alloys processed by laser powder bed fusion. J. Manuf. Processes 2021, 66, 397–406. [Google Scholar] [CrossRef]

- ASTM E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2010.

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Processing Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Qiu, C.; Yue, S.; Adkins, N.J.; Ward, M.; Hassanin, H.; Lee, P.D.; Withers, P.J.; Attallah, M.M. Influence of processing conditions on strut structure and compressive properties of cellular lattice structures fabricated by selective laser melting. Mater. Sci. Eng. A 2015, 628, 188–197. [Google Scholar] [CrossRef]

- Amani, Y.; Dancette, S.; Delroisse, P.; Simar, A.; Maire, E. Compression behavior of lattice structures produced by selective laser melting: X-ray tomography based experimental and finite element approaches. Acta Mater. 2018, 159, 395–407. [Google Scholar] [CrossRef]

- Liu, M.; Takata, N.; Suzuki, A.; Kobashi, M. Development of gradient microstructure in the lattice structure of AlSi10Mg alloy fabricated by selective laser melting. J. Mater. Sci. Technol. 2020, 36, 106–117. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Liu, Y.; Zhang, X.; Xiong, J.; Zhou, H.; Fang, D. Crushing behavior of multi-layer metal lattice panel fabricated by selective laser melting. Int. J. Mech. Sci. 2018, 145, 389–399. [Google Scholar] [CrossRef]

- Suzuki, A.; Sekizawa, K.; Liu, M.; Takata, N.; Kobashi, M. Effects of Heat Treatments on Compressive Deformation Behaviors of Lattice-Structured AlSi10Mg Alloy Fabricated by Selective Laser Melting. Adv. Eng. Mater. 2019, 21, 1900571. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, T.; Ren, H.; Maskery, I.; Ashcroft, I. Dynamic compressive response of additively manufactured AlSi10Mg alloy hierarchical honeycomb structures. Compos. Struct. 2018, 195, 45–59. [Google Scholar] [CrossRef]

- Ma, C.; Lei, H.; Hua, J.; Bai, Y.; Liang, J.; Fang, D. Experimental and simulation investigation of the reversible bi-directional twisting response of tetra-chiral cylindrical shells. Compos. Struct. 2018, 203, 142–152. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- ASTM E9-89a; Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM International: West Conshohocken, PA, USA, 1989. [CrossRef]

- Tradowsky, U.; White, J.; Ward, R.M.; Read, N.; Reimers, W.; Attallah, M.M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

Figure 1.

Schematic of the strategy used in the production of components by hybrid manufacturing.

Figure 1.

Schematic of the strategy used in the production of components by hybrid manufacturing.

Figure 2.

Representative curves of specific heat capacity vs. temperature recorded for conventionally, additively and hybrid-manufactured specimens.

Figure 2.

Representative curves of specific heat capacity vs. temperature recorded for conventionally, additively and hybrid-manufactured specimens.

Figure 3.

Representative curves of thermal expansion along temperature evolution for conventionally, additively and hybrid-manufactured specimens.

Figure 3.

Representative curves of thermal expansion along temperature evolution for conventionally, additively and hybrid-manufactured specimens.

Figure 4.

Representative tensile stress–strain curves recorded for conventionally, additively and hybrid-manufactured specimens.

Figure 4.

Representative tensile stress–strain curves recorded for conventionally, additively and hybrid-manufactured specimens.

Figure 5.

Low-magnification microscopic observation of additive (left) and conventional (right) parts of an as-built AW-6082 + AlSi10Mg specimen, after the tensile test.

Figure 5.

Low-magnification microscopic observation of additive (left) and conventional (right) parts of an as-built AW-6082 + AlSi10Mg specimen, after the tensile test.

Figure 6.

Representative compressive stress-strain curves recorded for conventionally, additively and hybrid-manufactured specimens.

Figure 6.

Representative compressive stress-strain curves recorded for conventionally, additively and hybrid-manufactured specimens.

Figure 7.

Technical drawing of the crankset.

Figure 7.

Technical drawing of the crankset.

Figure 8.

Crankset before (left) and after (right) the three-point flexural test.

Figure 8.

Crankset before (left) and after (right) the three-point flexural test.

Figure 9.

Scheme of the strategy used to fix the crankset on the building platform for restoration by additive manufacturing using powder bed fusion [

17].

Figure 9.

Scheme of the strategy used to fix the crankset on the building platform for restoration by additive manufacturing using powder bed fusion [

17].

Figure 10.

Load–displacement curves for AW-6082 and hybrid cranksets.

Figure 10.

Load–displacement curves for AW-6082 and hybrid cranksets.

Figure 11.

Hybrid crankset after the three-point flexural test.

Figure 11.

Hybrid crankset after the three-point flexural test.

Figure 12.

Reflection microscope images of AlSi10Mg specimens before (left) and after (right) heat treatment.

Figure 12.

Reflection microscope images of AlSi10Mg specimens before (left) and after (right) heat treatment.

Table 1.

Chemical composition of AlSi10Mg and AW-6082 aluminium alloys [

14,

18].

Table 1.

Chemical composition of AlSi10Mg and AW-6082 aluminium alloys [

14,

18].

| | AlSi10Mg | AW-6082 |

|---|

| Aluminium | Balance | Balance |

| Silicon | 9–11% | 0.7–1.3% |

| Manganese | <0.45% | 0.4–1.0% |

| Iron | <0.55% | <0.50% |

| Magnesium | 0.20–0.45% | 0.60–1.20% |

Table 2.

Density measurements for conventionally, additively and hybrid-manufactured specimens.

Table 2.

Density measurements for conventionally, additively and hybrid-manufactured specimens.

| | AW-6082 | AlSi10Mg AB | AlSi10Mg HT | AW-6082/

AlSi10Mg AB | AW-6082/

AlSi10Mg HT |

|---|

| Density (g/cm3) | 2.757 ± 0.081 | 2.641 ± 0.007 | 2.645 ± 0.005 | 2.727 ± 0.004 | 2.717 ± 0.002 |

Table 3.

Averaged coefficient of thermal expansion (between 20 °C and 200 °C) for conventionally, additively and hybrid-manufactured specimens.

Table 3.

Averaged coefficient of thermal expansion (between 20 °C and 200 °C) for conventionally, additively and hybrid-manufactured specimens.

| | AW-6082 | AlSi10Mg AB | AlSi10Mg HT | AW-6082/

AlSi10Mg AB | AW-6082/

AlSi10Mg HT |

|---|

| CTE (µm/m°C) | 22.09 ± 0.27 | 21.92 ± 0.65 | 25.85 ± 0.53 | 22.46 ± 0.53 | 21.69 ± 0.77 |

Table 4.

Tensile properties of hybrid specimens [

10,

16].

Table 4.

Tensile properties of hybrid specimens [

10,

16].

| Materials | Yield Strength 0.2% (MPa) | UTS (MPa) | Elongation at Break (%) |

|---|

| AlSi10Mg as-built | - | 470 ± 2 | 6 |

| AlSi10Mg heat-treated | 230 | 350 | 11 |

| AW-5083 | 239 | 312 | 14 |

| AW-6061 | - | 311 | 11 |

| Alumec 89 | - | 590 | - |

| AlSi10Mg/AW-5083 | 200 | 319 | 7.4 |

| AlSi10Mg/AW-6061 | - | 319 | 7.8 |

| AlSi10Mg/Alumec89 | - | 481 | 8.2 |

Table 5.

Tensile properties for conventionally, additively and hybrid-manufactured specimens.

Table 5.

Tensile properties for conventionally, additively and hybrid-manufactured specimens.

| Materials | Young’s Modulus (GPa) | Yield Strength 0.2% (MPa) | Elongation at Yield (%) | UTS (MPa) | Elongation at Break (%) |

|---|

| AlSi10Mg as-built | 55.6 ± 1.1 | 85.6 ± 4.4 | 0.27 ± 0.02 | 336.0 ± 12.2 | 3.56 ± 0.37 |

| AlSi10Mg HT | 64.9 ± 0.3 | 111.5 ± 9.4 | 0.30 ± 0.06 | 322.3 ± 26.3 | 3.29 ± 0.40 |

| Datasheet references | ≈75 | 205 ± 3 | - | 344 ± 2 | 6 ± 1 |

| AW-6082 | 83.7 ± 1.3 | 182.7 ± 10.7 | 0.62 ± 0.06 | 422.0 ± 7.9 | 4.99 ± 0.79 |

| Datasheet references | ≈70 | 110–260 | - | 205–310 | 8–12 |

| AW-6082/AlSi10Mg AB | 59.4 ± 0.5 | 102.5 ± 9.7 | 0.29 ± 0.07 | 227.0 ± 19.3 | 1.32 ± 0.63 |

| AW-6082/AlSi10Mg HT | 59.7 ± 1.1 | 88.4 ± 8.9 | 0.27 ± 0.05 | 268.2 ± 12.3 | 1.76 ± 0.38 |

Table 6.

Compressive properties for conventionally, additively and hybrid-manufactured specimens.

Table 6.

Compressive properties for conventionally, additively and hybrid-manufactured specimens.

| Materials | Compressive Modulus (GPa) | Yield Strength 0.2% (MPa) | Elongation at Yield (%) |

|---|

| AlSi10Mg as-built | 13.3 ± 1.3 | 241.2 ± 14.7 | 2.31 ± 0.25 |

| AlSi10Mg HT | 14.3 ± 0.4 | 252.2 ± 9.2 | 2.43 ± 0.11 |

| AW-6082 | 19.1 ± 0.6 | 328.5 ± 7.8 | 2.06 ± 0.07 |

| AW-6082/AlSi10Mg AB | 16.9 ± 0.5 | 303.5 ± 10.3 | 2.37 ± 0.14 |

| AW-6082/AlSi10Mg HT | 12.9 ± 3.1 | 298.8 ± 7.0 | 2.90 ± 0.27 |

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).