Adapting the Surface Integrity of High-Speed Steel Tools for Sheet-Bulk Metal Forming

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

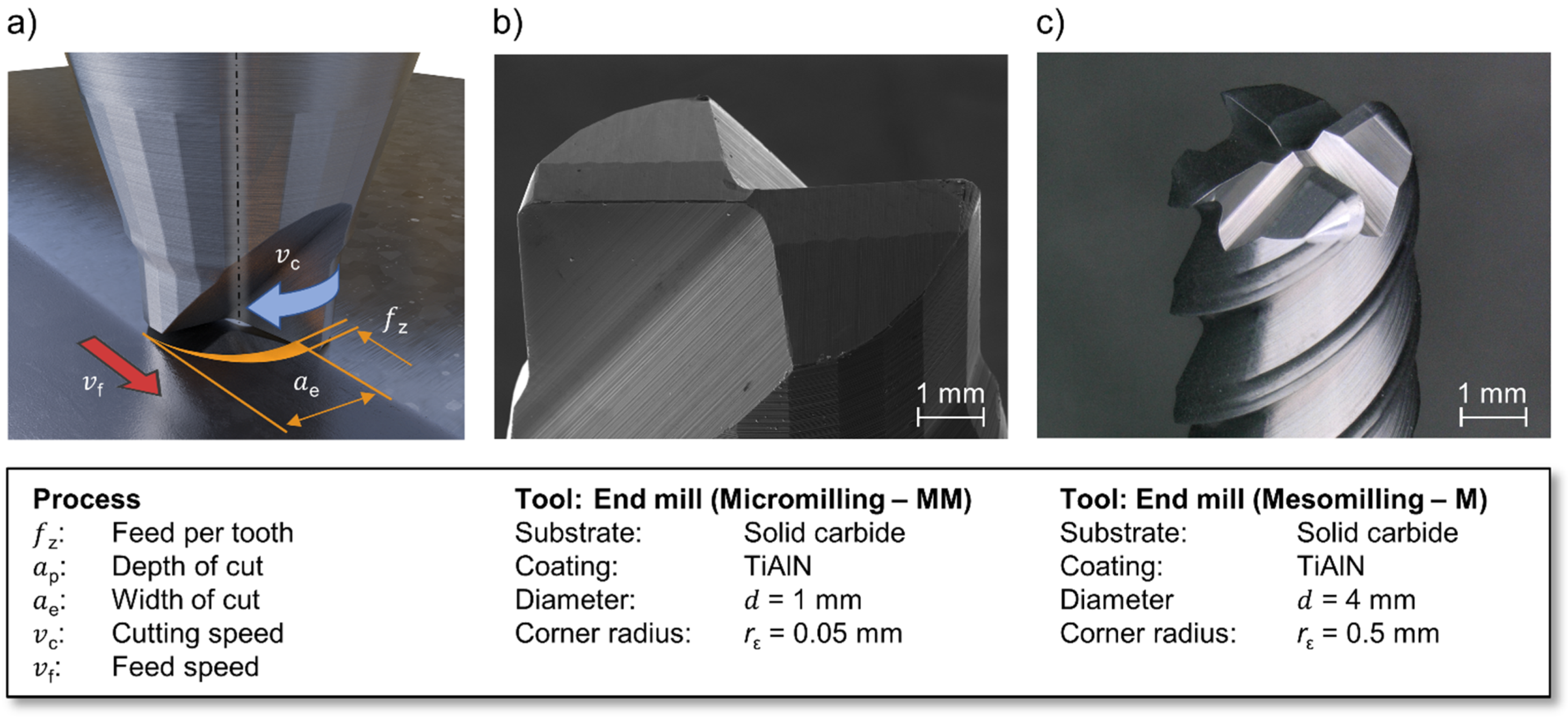

2.2. Mechanical Sample Preparation

2.3. Tribological Investigations of Steel Surfaces

2.4. PVD Coating Process

2.5. Analytical Methods

3. Results

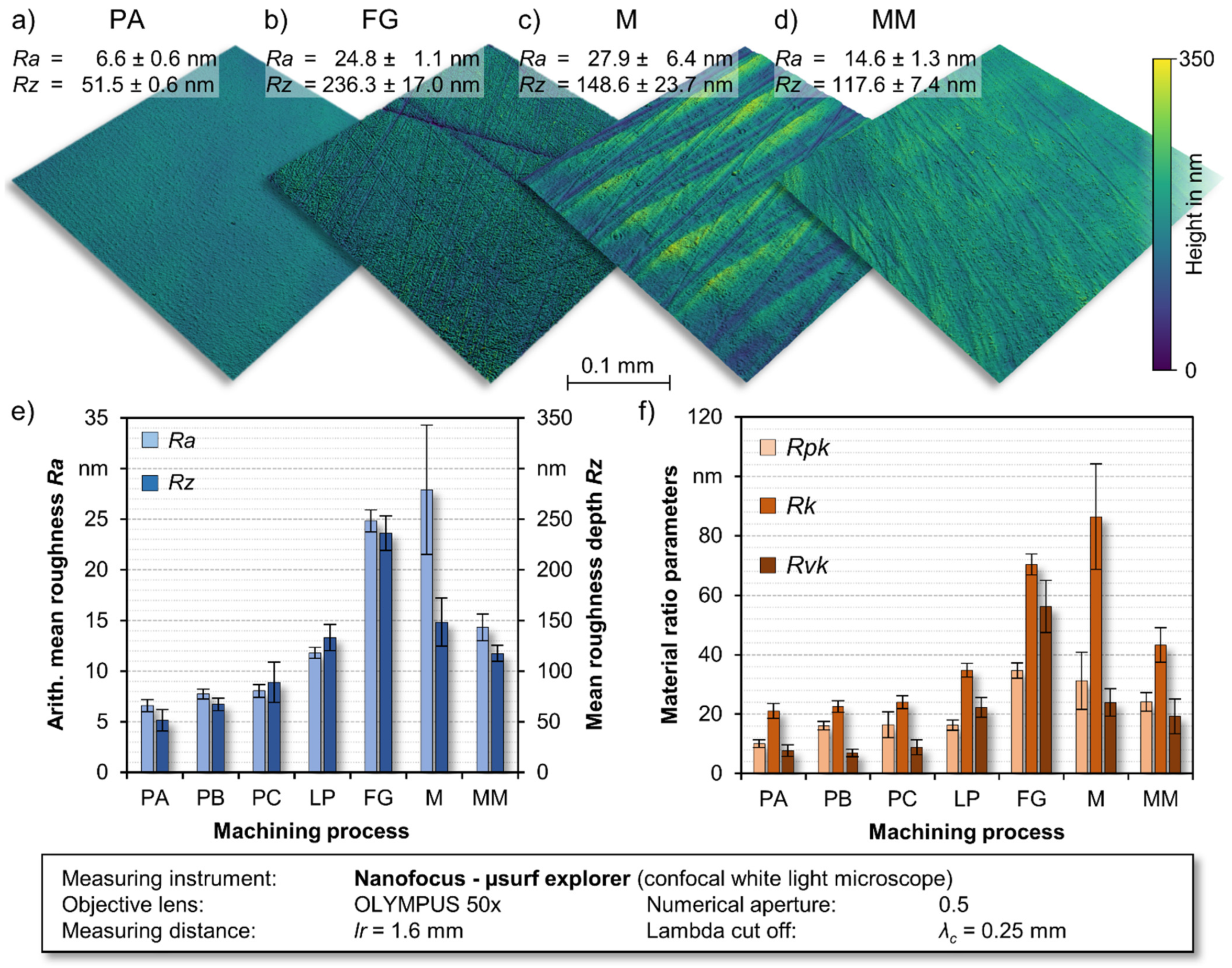

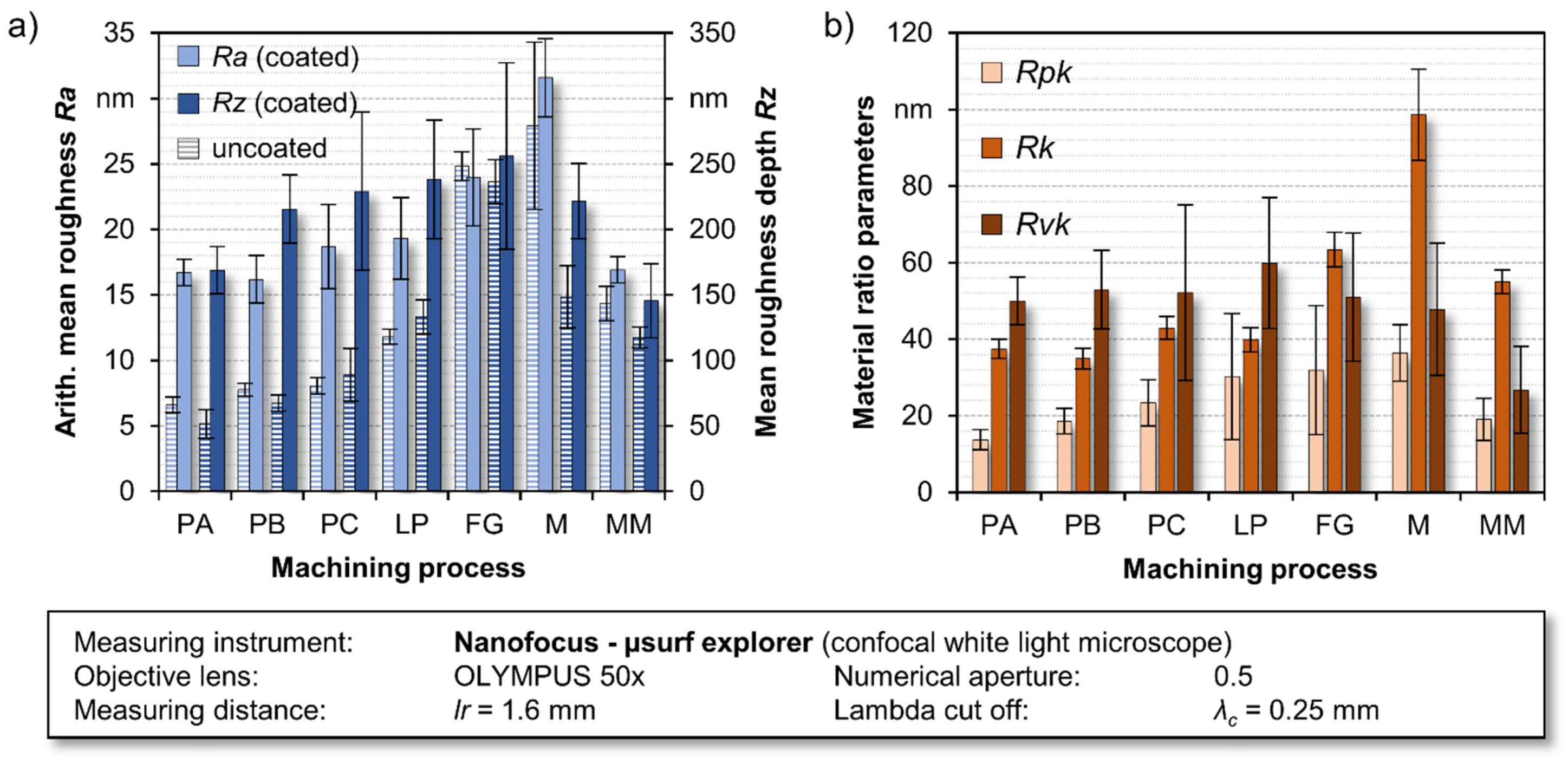

3.1. Influence of the Processing Strategy on the Topography

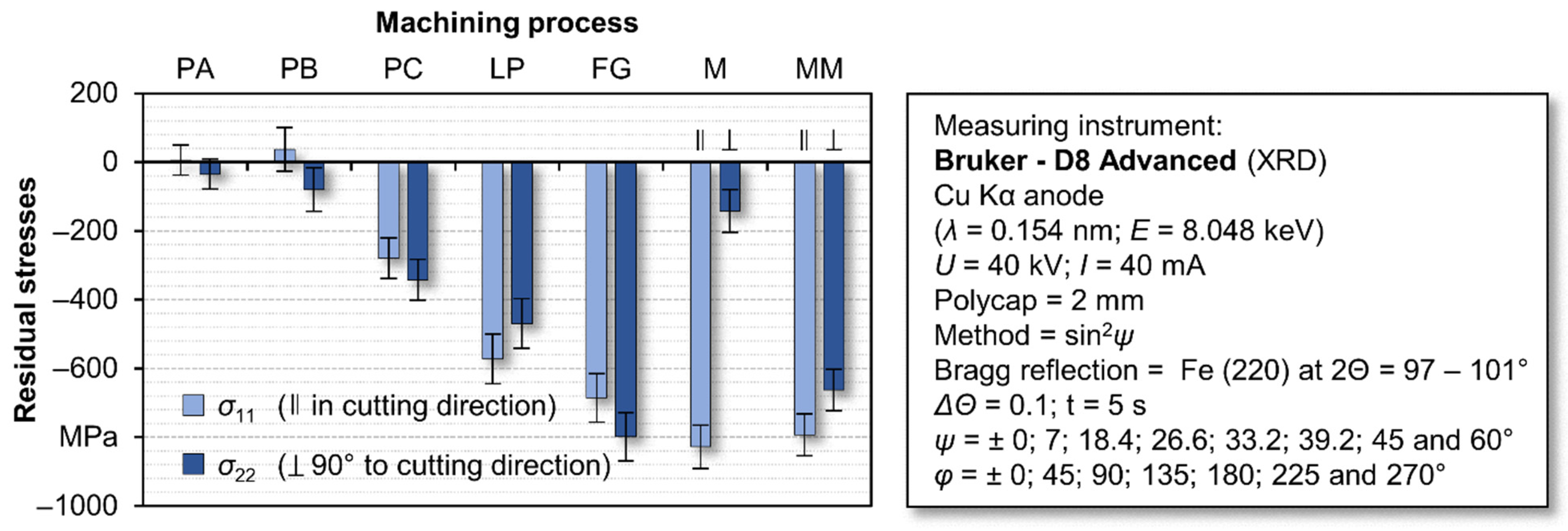

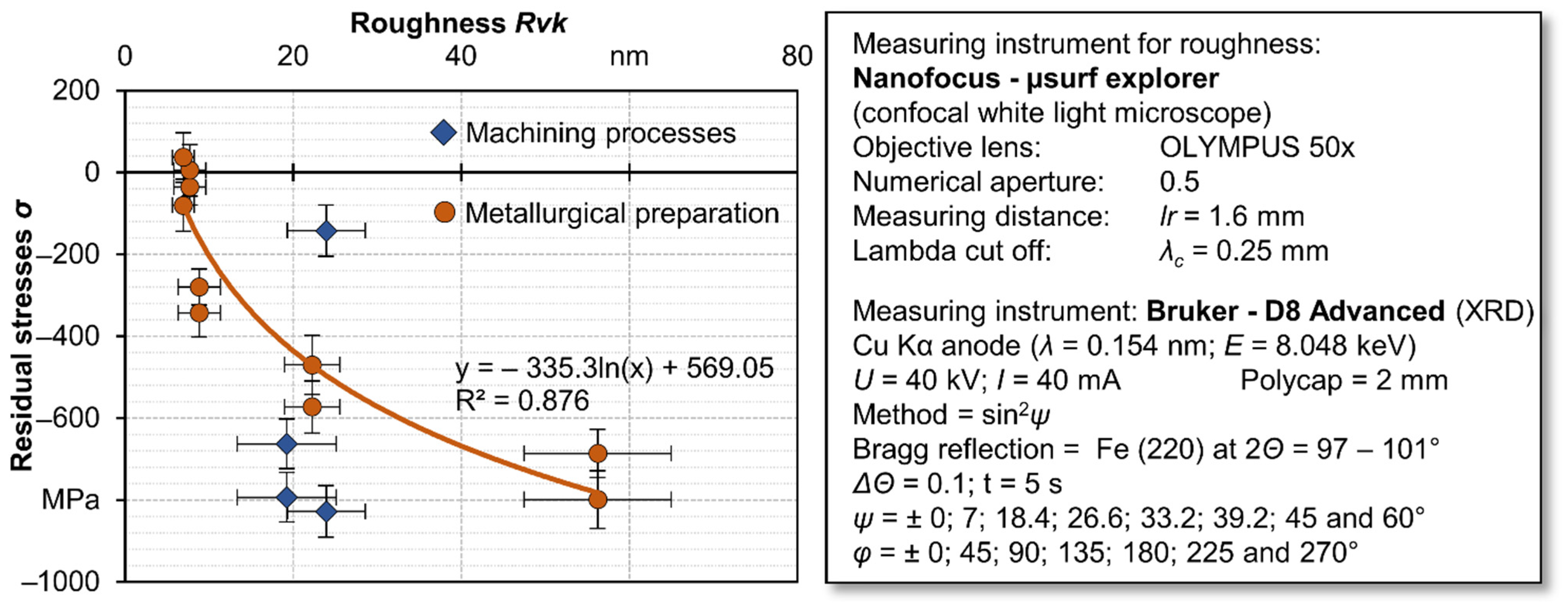

3.2. Residual Stresses in Subsurface Area

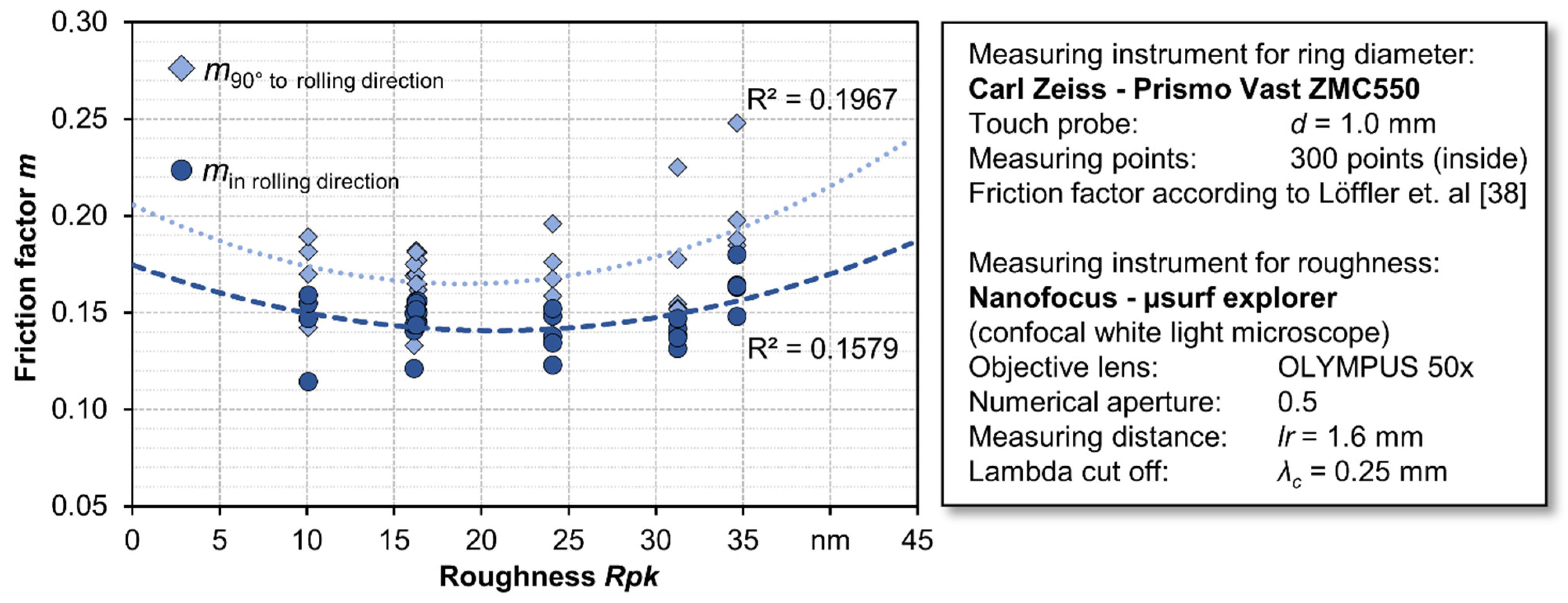

3.3. Tribological Properties of the Surfaces for Sheet Bulk Metal Forming

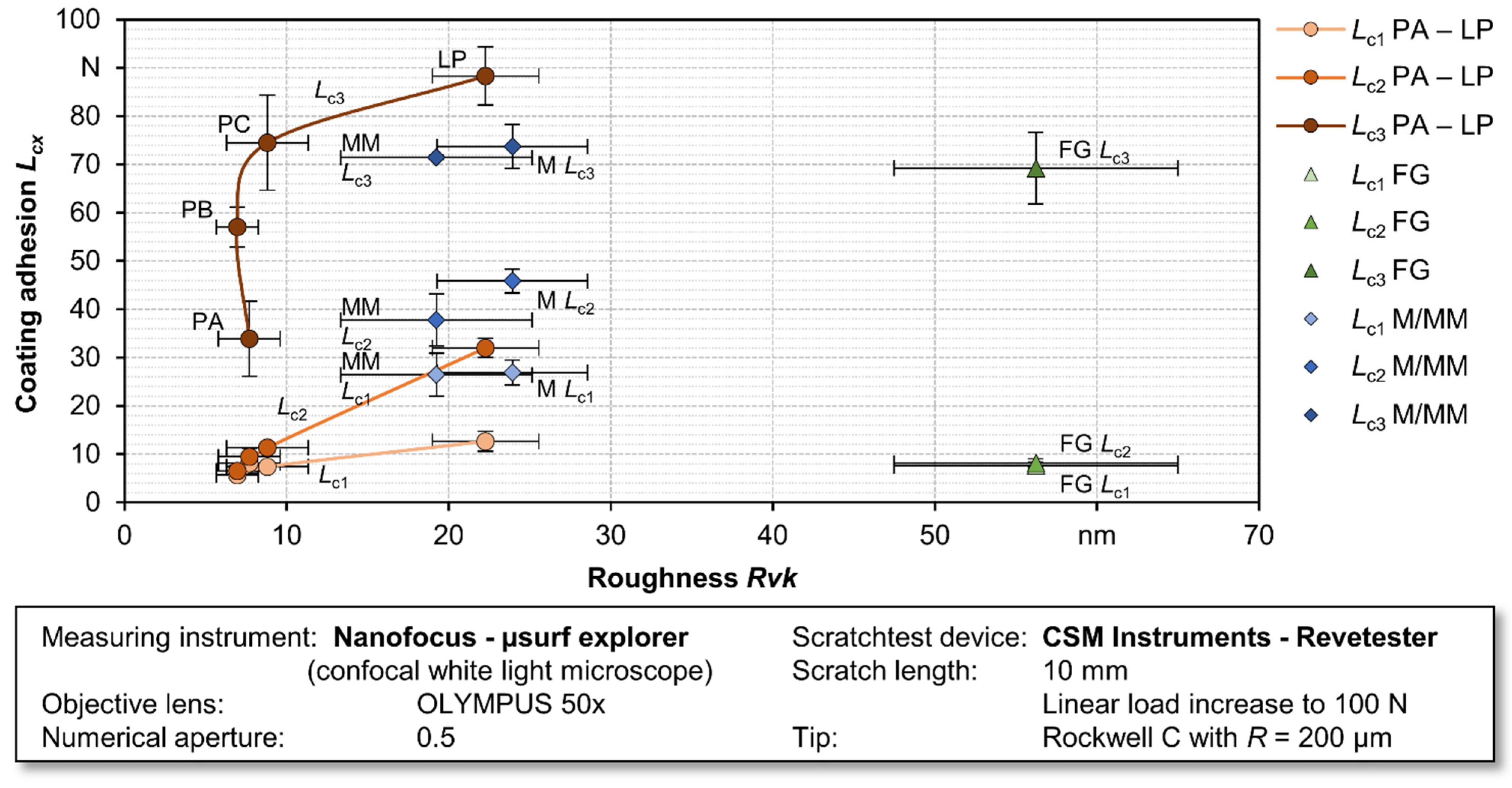

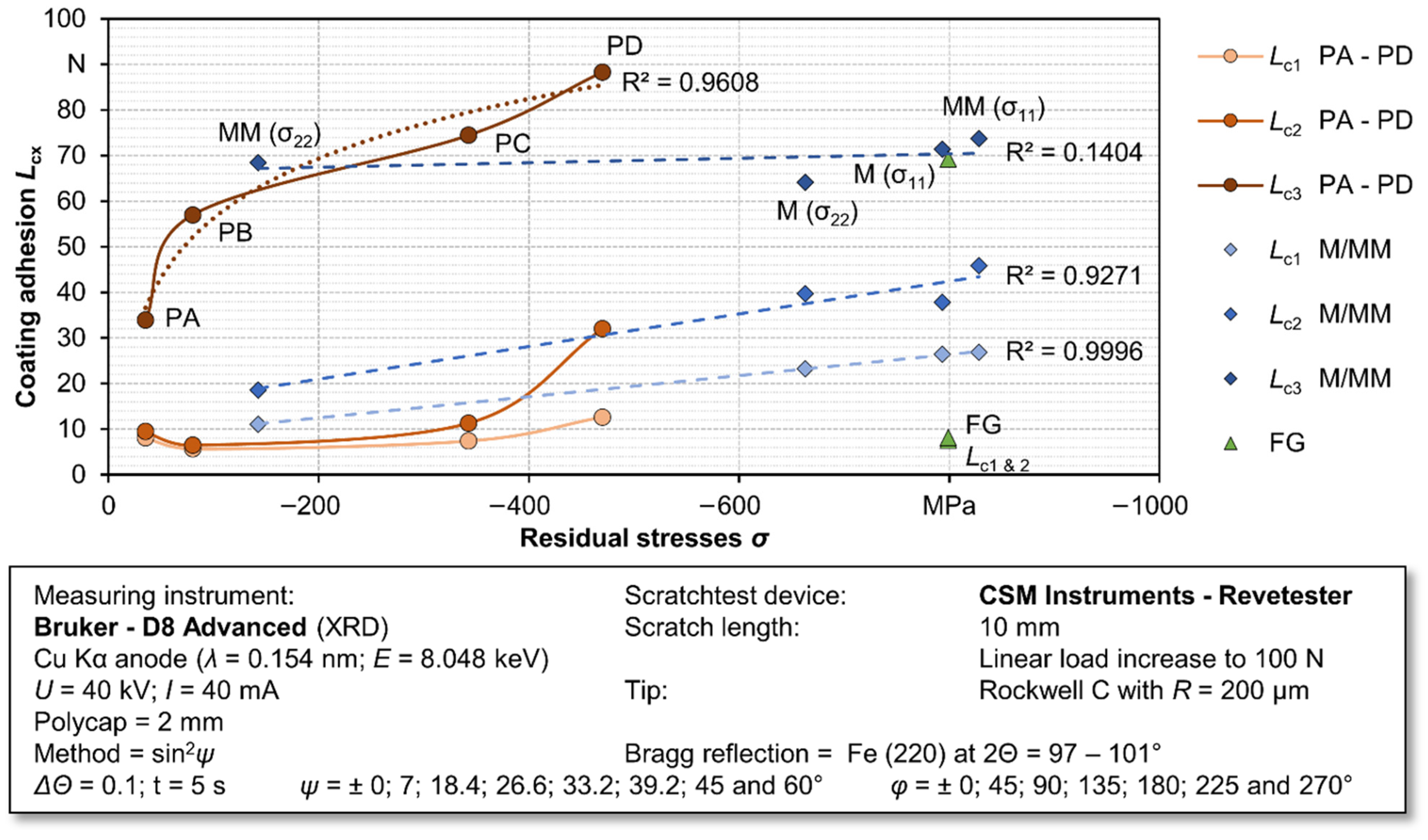

3.4. Influence of Processing Strategy on the Coating Adhesion

4. Conclusions

- The roughness profile of the meso- and micromilling processes configuration achieved nearly the same level of surface finishing as metallographic polishing processes. In contrast to the mesomilling strategy, which showed cutting groves, a defect-free featureless topography can be processed by micromilling with Ra < 15 nm.

- High compressive residual stresses (σ ~ −800 MPa) can be induced by the micromilling processes showing a quasi-isotropic characteristic. The magnitude of residual stresses developed in polished surfaces is directly linked to the grain size of the diamonds.

- In an adapted ring compression test for the sheet material DC04, the micromilled topography shows similar low friction factors in comparison to the polished surfaces, which can be linked to the reduced peak height Rpk.

- The adhesion of the CrAlN coating can be directly correlated to the level of the compressive residual stresses in the subsurface region. Additionally, this correlation is superimposed by the roughness values in terms of the reduced valley height Rvk, which favors a good adhesion for Rvk > 10 nm and especially for the meso- and micromilling process.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cao, J.; Brinksmeier, E.; Fu, M.; Gao, R.X.; Liang, B.; Merklein, M.; Schmidt, M.; Yanagimoto, J. Manufacturing of advanced smart tooling for metal forming. CIRPAnn. Manuf. Technol. 2019, 68, 605–628. [Google Scholar] [CrossRef]

- Gröbel, D.; Schulte, R.; Hildenbrand, P.; Lechner, M.; Engel, U.; Sieczkarek, P.; Wernicke, S.; Gies, S.; Tekkaya, A.E.; Behrens, B.A.; et al. Manufacturing of functional elements by sheet-bulk metal forming processes. Prod. Eng. Res. Dev. 2016, 10, 63–80. [Google Scholar] [CrossRef]

- Merklein, M.; Tekkaya, A.E.; Brosius, A.; Opel, S.; Kwiatkowski, L.; Plugge, B.; Schunck, S. Machines and Tools for Sheet-Bulk Metal Forming. Key Eng. Mater. 2011, 473, 91–98. [Google Scholar] [CrossRef]

- Merklein, M.; Allwood, J.M.; Behrens, B.-A.; Brosius, A.; Hagenah, H.; Kuzman, K.; Mori, K.; Tekkaya, A.E.; Weckenmann, A. Bulk forming of sheet metal. CIRP Ann. Manuf. Technol. 2012, 61, 725–745. [Google Scholar] [CrossRef]

- Merklein, M.; Koch, J.; Opel, S.; Schneider, T. Fundamental investigations on the material flow at combined sheet and bulk metal forming processes. CIRP Ann. Manuf. Technol. 2011, 60, 283–286. [Google Scholar] [CrossRef]

- Hetzner, H.; Koch, J.; Tremmel, S.; Wartzack, S.; Merklein, M. Improved Sheet Bulk Metal Forming Processes by Local Adjustment of Tribological Properties. J. Manuf. Sci. Eng. 2011, 133, 061011. [Google Scholar] [CrossRef]

- Löffler, M.; Andreas, K.; Engel, U.; Schulte, R.; Groebel, D.; Krebs, E.; Freiburg, D.; Biermann, D.; Stangier, D.; Tillmann, W.; et al. Tribological measures for controlling material flow in sheet-bulk metal forming. Prod. Eng. Res. Dev. 2016, 10, 459–470. [Google Scholar] [CrossRef]

- Merklein, M.; Lechner, M.; Gröbel, D.; Löffler, M.; Schneider, T.; Schulte, R.; Hildenbrand, P. Innovative approaches for controlling the material flow in sheet-bulk metal forming processes. Manuf. Rev. 2016, 3, 2. [Google Scholar] [CrossRef][Green Version]

- Tillmann, W.; Stangier, D. Application of Nanostructured Bionic Thin Layers to Enhance the Wear and Friction Behavior of Tools for Sheet-Bulk Metal Forming. In Sheet Bulk Metal Forming; Merklein, M., Tekkaya, A.E., Behrens, B.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 216–238. [Google Scholar]

- Behrens, B.-A.; Meijer, A.; Stangier, D.; Hübner, S.; Biermann, D.; Tillmann, W.; Rosenbusch, D.; Müller, P. Static and oscillation superimposed ring compression tests with structured and coated tools for Sheet-Bulk Metal Forming. J. Manuf. Processes 2020, 55, 78–86. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Tillmann, W.; Biermann, D.; Hübner, S.; Stangier, D.; Freiburg, D.; Meijer, A.; Koch, S.; Rosenbusch, D.; Müller, P. Influence of Tailored Surfaces and Superimposed-Oscillation on Sheet-Bulk Metal Forming Operations. J. Manuf. Mater. Process. 2020, 4, 41. [Google Scholar] [CrossRef]

- Weikert, T.; Tremmel, S.; Stangier, D.; Tillmann, W.; Krebs, E.; Biermann, D. Tribological studies on multi-coated forming tools. J. Manuf. Processes 2020, 49, 141–152. [Google Scholar] [CrossRef]

- Denkena, B.; Breidenstein, B.; Lucas, H.; Keitel, M.; Tillmann, W.; Stangier, D. Influence of Residual Stresses in heat-treated High-Speed Steels on the Adhesion of CrAlN Coatings. J. Heat Treat. Mater. 2020, 75, 163–176. [Google Scholar] [CrossRef]

- Tillmann, W.; Grisales, D.; Stangier, D. Effects of AISI H11 surface integrity on the residual stresses and adhesion of TiAlN/substrate compounds. Surf. Coat. Technol. 2019, 357, 466–472. [Google Scholar] [CrossRef]

- Lange, K. Umformtechnik—Handbuch für Industrie und Wissenschaft—Band 4: Sonderverfahren, Prozeßsimulation, Werkzeugtechnik, Produktion, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 1993; ISBN 3-540-55939-6. [Google Scholar]

- Denkena, B.; Grove, T.; Lucas, H. Interaction of load and residual stresses in sintered 1.3344 high speed steel. Adv. Mater. Res. 2014, 1018, 145–152. [Google Scholar] [CrossRef]

- Lucas, H.; Denkena, B.; Grove, T.; Krebs, E.; Kersting, P.; Freiburg, D.; Biermann, D. Analysis of Residual Stress States of Structured Surfaces Manufactured by High-Feed and Micromilling. HTM J. Heat Treat. Mater. 2015, 70, 183–189. [Google Scholar] [CrossRef]

- Wild, T.; Platt, T.; Biermann, D.; Merklein, M. Analysis of the Influence of Surface Modifications on the Fatigue Behavior of Hot Work Tool Steel Components. Materials 2021, 14, 7324. [Google Scholar] [CrossRef]

- Lange, K.; Kammerer, X.; Lange, K. Fließpressen—Wirtschaftliche Fertigung Metallischer Präzisionswerkstücke, 1st ed.; Lange, K., Kammerer, M., Pöhlandt, K., Schöck, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-30910-9. [Google Scholar]

- Grove, T.; Lucas, H.; Denkena, B. Residual stresses in grinding of forming tools with toric grinding pins. Procedia CIRP 2018, 71, 354–357. [Google Scholar] [CrossRef]

- Denkena, B.; Grove, T.; Lucas, H. Influences of grinding with Toric CBN grinding tools on surface and subsurface of 1.3344 PM steel. J. Mater. Process. Technol. 2016, 229, 541–548. [Google Scholar] [CrossRef]

- Biermann, D.; Baschin, A.; Krebs, E.; Schlenker, J. Manufacturing of dies from hardened tool steels by 3-axis micromilling. Prod. Eng. Res. Dev. 2011, 5, 209–217. [Google Scholar] [CrossRef]

- Biermann, D.; Krebs, E.; Sacharow, A.; Kersting, P. Using NC-path deformation for compensating tool deflections in micromilling of hardened steel. Procedia CIRP 2012, 1, 132–137. [Google Scholar] [CrossRef][Green Version]

- Krebs, E.; Kersting, P. Improving the cutting conditions in the five-axis micromilling of hardened high-speed steel by applying a suitable tool inclination. Procedia CIRP 2014, 14, 366–370. [Google Scholar] [CrossRef][Green Version]

- Landkammer, P.; Loderer, A.; Krebs, E.; Söhngen, B.; Steinmann, P.; Hausotte, T.; Kersting, P.; Biermann, D.; Willner, K. Experimental verification of a benchmark forming simulation. Key Eng. Mater. 2015, 639, 251–258. [Google Scholar] [CrossRef]

- Dambon, O.; Demmer, A.; Peters, J. Surface Interactions in Steel Polishing for the Precision Tool Making. CIRP Ann. 2006, 55, 609–612. [Google Scholar] [CrossRef]

- Wagner, K.; Völkl, R.; Engel, U. Tool life enhancement in cold forging by locally optimized surfaces. J. Mater. Process. Technol. 2008, 201, 2–8. [Google Scholar] [CrossRef]

- Lange, K.; Cser, L.; Geiger, M.; Kals, J.A.G. Tool Life and Tool Quality in Bulk Metal Forming. CIRP Ann. 1992, 41, 667–675. [Google Scholar] [CrossRef]

- Meijer, A.; Biermann, D. Machining of Molds with Filigree Structures for Sheet-Bulk Metal Forming. In Sheet Bulk Metal Forming; Merklein, M., Tekkaya, A.E., Behrens, B.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2021; pp. 147–171. [Google Scholar]

- Twardy, S.M. Funktionsgerechte Fertigung von Mikroumformwerkzeugen Durch Mikrofräsen; Shaker: Aachen, Germany, 2014; ISBN 9783844031294. [Google Scholar]

- Krebs, E. Simulationsgestütze Mikrofräsbearbeitung Gehärteter Werkzeugstähle zur Herstellung Filigraner Formelemente und Funktionaler Oberflächenstrukturen; Vulkan-Verlag GmbH: Essen, Germany, 2018. [Google Scholar]

- Hoffmann, H.; Neugebauer, R.; Spur, G. (Eds.) Handbuch Umformen; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2012; ISBN 3446430040. [Google Scholar]

- Vierzigmann, U.; Schneider, T.; Koch, J.; Groebel, D.; Merklein, M.; Engel, U.; Hense, R.; Biermann, D.; Krebs, E.; Kersting, P.; et al. Untersuchung von Tailored Surfaces für die Blechmassivumformung mittels angepasstem Ringstauchversuch. In Tagungsband zum 2. Erlanger Workshop Blechmassivumformung; Merklein, M., Behrens, B.-A., Tekkaya, A.E., Eds.; Meisenbach: Bamberg, Germany, 2013; pp. 137–162. [Google Scholar]

- Male, A.T.; Cockcroft, M.G. A Method for the Determination of the Coefficient of Friction of Metals under Conditions of Bulk Plastic Deformation. J. Inst. Met. 1964, 93, 38–47. [Google Scholar]

- Löffler, M.; Schulte, R.; Freiburg, D.; Biermann, D.; Stangier, D.; Tillmann, W.; Merklein, M. Control of the material flow in sheet-bulk metal forming using modifications of the tool surface. Int. J. Mater. Form. 2019, 12, 17–26. [Google Scholar] [CrossRef]

- Tillmann, W.; Grisales, D.; Stangier, D.; Ben Jebara, I.; Kang, H. Influence of the etching processes on the adhesion of TiAlN coatings deposited by DCMS, HiPIMS and hybrid techniques on heat treated AISI H11. Surf. Coat. Technol. 2019, 378, 125075. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Tillmann, W.; Stangier, D.; Hagen, L.; Schröder, P.; Krabiell, M. Influence of the WC grain size on the properties of PVD/HVOF duplex coatings. Surf. Coat. Technol. 2017, 328, 326–334. [Google Scholar] [CrossRef]

- Tillmann, W.; Hagen, L.; Stangier, D.; Krabiell, M.; Schröder, P.; Tiller, J.; Krumm, C.; Sternemann, C.; Paulus, M.; Elbers, M. Influence of etching-pretreatment on nano-grained WC-Co surfaces and properties of PVD/HVOF duplex coatings. Surf. Coat. Technol. 2019, 374, 32–43. [Google Scholar] [CrossRef]

- Noyan, I.C.; Cohen, J.B. Residual Stress—Measurement by Diffraction and Interpretation; Springer: New York, NY, USA, 1987. [Google Scholar]

- Eigenmann, B.; Macherauch, E. Röntgenographische Untersuchung von Spannungszuständen in Werkstoffen. Teil III. Fortsetzung von Matwiss. und Werkstofftechn. Heft 3/1995, S. 148–160 und Heft 4/1995, S. 199–216. Mater. Werkst. 1996, 27, 426–437. [Google Scholar] [CrossRef]

- DIN—Deutsches Institut für Normung e.V. DIN EN ISO 20502:2016—Hochleistungskeramik—Bestimmung der Haftung von Keramischen Schichten mit dem Ritztest; Beuth Verlag GmbH: Berlin, Germany, 2016. [Google Scholar]

- Evans, C.J.; Paul, E.; Dornfeld, D.; Lucca, D.A.; Byrne, G.; Tricard, M.; Klocke, F.; Dambon, O.; Mullany, B.A. Material Removal Mechanisms in Lapping and Polishing. CIRP Ann. 2003, 52, 611–633. [Google Scholar] [CrossRef]

- Komanduri, R.; Lucca, D.A.; Tani, Y. Technological Advances in Fine Abrasive Processes. CIRP Ann. 1997, 46, 545–596. [Google Scholar] [CrossRef]

- Klocke, F.; Dambon, O.; Filho, G.C. Influence of the polishing process on the near-surface zone of hardened and unhardened steel. Wear 2005, 258, 1794–1803. [Google Scholar] [CrossRef]

- Meijer, A.; Bergmann, J.A.; Krebs, E.; Biermann, D.; Wiederkehr, P. Analytical and Simulation-Based Prediction of Surface Roughness for Micromilling Hardened HSS. J. Manuf. Mater. Process. 2019, 3, 70. [Google Scholar] [CrossRef]

- Kersting, P.; Gröbel, D.; Merklein, M.; Sieczkarek, P.; Wernicke, S.; Tekkaya, A.E.; Krebs, E.; Freiburg, D.; Biermann, D.; Weikert, T.; et al. Experimental and numerical analysis of tribological effective surfaces for forming tools in Sheet-Bulk Metal Forming. Prod. Eng. Res. Dev. 2016, 10, 37–50. [Google Scholar] [CrossRef]

- Sieczkarek, P.; Wernicke, S.; Gies, S.; Tekkaya, A.E.; Krebs, E.; Wiederkehr, P.; Biermann, D.; Tillmann, W.; Stangier, D. Improvement strategies for the formfilling in incremental gear forming processes. Prod. Eng. Res. Dev. 2017, 11, 623–631. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Riemer, O.; Twardy, S. Tribological behavior of micro structured surfaces for micro forming tools. Int. J. Mach. Tools Manuf. 2010, 50, 425–430. [Google Scholar] [CrossRef]

- Jawahir, I.S.; Brinksmeier, E.; M’Saoubi, R.; Aspinwall, D.K.; Outeiro, J.C.; Meyer, D.; Umbrello, D.; Jayal, A.D. Surface integrity in material removal processes: Recent advances. CIRP Ann. 2011, 60, 603–626. [Google Scholar] [CrossRef]

- Löffler, M.; Andreas, K.; Engel, U.; Weikert, T.; Tremmel, S.; Wartzack, S.; Stangier, D.; Tillmann, W.; Merklein, M. Surface modifications for adaption of tribological conditions in sheet-bulk metal forming processes. In Proceedings of the 12th International Conference the “A” Coatings, Hannover, Germany, 31 March–1 April 2016; Bobzin, K., Bouzakis, K.-D., Denkena, B., Maier, H.J., Merklein, M., Eds.; PZH: Hannover, Germany, 2016; pp. 13–20. [Google Scholar]

- Tillmann, W.; Stangier, D.; Schröder, P. Investigation and optimization of the tribo-mechanical properties of CrAlCN coatings using Design of Experiments. Surf. Coat. Technol. 2016, 308, 147–157. [Google Scholar] [CrossRef]

- Bromark, M.; Larsson, M.; Hedenqvist, P.; Olsson, M.; Hogmark, S. Influence of substrate surface topography on the critical normal force in scratch adhesion of TiN-coated steels. Surf. Coat. Technol. 1992, 52, 195–203. [Google Scholar] [CrossRef]

- Harlin, P.; Carlsson, P.; Bexell, U.; Olsson, M. Influence of surface roughness of PVD coatings on tribological performance in sliding contacts. Surf. Coat. Technol. 2006, 201, 4253–4259. [Google Scholar] [CrossRef]

- Huang, R.; Qi, Z.; Sun, P.; Wang, Z.; Wu, C. Influence of substrate roughness on structure and mechanical property of TiAlN coating fabricated by cathodic arc evaporation. Phys. Procedia 2011, 18, 160–167. [Google Scholar] [CrossRef]

- Holmberg, K.; Laukkanen, A.; Ronkainen, H.; Wallin, K.; Varjus, S. A model for stresses, crack generation and fracture toughness calculation in scratched TiN-coated steel surfaces. Wear 2003, 254, 278–291. [Google Scholar] [CrossRef]

- Denkena, B.; Grove, T.; Lucas, H.; Tillmann, W.; Stangier, D. Influence of PVD-coating manufacturing steps on the subsurface integrity of hardened and soft AISI M3:2 high speed steel. In Proceedings of the 12th International Conference the “A” Coatings, Hannover, Germany, 31 March–1 April 2016; Bobzin, K., Bouzakis, K.-D., Denkena, B., Maier, H.J., Merklein, M., Eds.; PZH-Verlag: Hannover, Germany, 2016; pp. 23–30. [Google Scholar]

- Tillmann, W.; Stangier, D.; Denkena, B.; Grove, T.; Lucas, H. Influence of PVD-coating technology and pretreatments on residual stresses for sheet-bulk metal forming tools. Prod. Eng. Res. Dev. 2016, 10, 17–24. [Google Scholar] [CrossRef]

| C | Cr | Mo | W | Co | V | Fe | |

|---|---|---|---|---|---|---|---|

| AISI M3:2 | 1.27 | 4.17 | 5.67 | 6.44 | - | 3.33 | balanced |

| Process Step | Declaration | Abrasive | Grain Size (µm) | Force (N) | Rotation (min−1) | Medium |

|---|---|---|---|---|---|---|

| Fine Grinding | FG | SiC | 15 | 45 | 300 | water |

| Lapping 9 µm | LP | PCD | 9 | 45 | 150 | water |

| Polishing 6 µm | PC | PCD | 6 | 30 | 150 | lubricant |

| Polishing 3 µm | PB | PCD | 3 | 30 | 150 | lubricant |

| Polishing 1 µm | PA | PCD | 1 | 30 | 150 | lubricant |

| Bragg Reflection | 2Θ (°) | Young’s Modulus E (MPa) | Poisson’s Ratio υ (-) | XEC s1 (10−6 MPa−1) | XEC ½s2 (10−6 MPa−1) |

|---|---|---|---|---|---|

| α-Fe (220) | 98.94 | 220,264 | 0.28 | −1.27 | 5.81 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tillmann, W.; Stangier, D.; Meijer, A.; Krebs, E.; Ott, A.; Platt, T.; Lopes Dias, N.F.; Hagen, L.; Biermann, D. Adapting the Surface Integrity of High-Speed Steel Tools for Sheet-Bulk Metal Forming. J. Manuf. Mater. Process. 2022, 6, 37. https://doi.org/10.3390/jmmp6020037

Tillmann W, Stangier D, Meijer A, Krebs E, Ott A, Platt T, Lopes Dias NF, Hagen L, Biermann D. Adapting the Surface Integrity of High-Speed Steel Tools for Sheet-Bulk Metal Forming. Journal of Manufacturing and Materials Processing. 2022; 6(2):37. https://doi.org/10.3390/jmmp6020037

Chicago/Turabian StyleTillmann, Wolfgang, Dominic Stangier, Alexander Meijer, Eugen Krebs, Alexander Ott, Timo Platt, Nelson Filipe Lopes Dias, Leif Hagen, and Dirk Biermann. 2022. "Adapting the Surface Integrity of High-Speed Steel Tools for Sheet-Bulk Metal Forming" Journal of Manufacturing and Materials Processing 6, no. 2: 37. https://doi.org/10.3390/jmmp6020037

APA StyleTillmann, W., Stangier, D., Meijer, A., Krebs, E., Ott, A., Platt, T., Lopes Dias, N. F., Hagen, L., & Biermann, D. (2022). Adapting the Surface Integrity of High-Speed Steel Tools for Sheet-Bulk Metal Forming. Journal of Manufacturing and Materials Processing, 6(2), 37. https://doi.org/10.3390/jmmp6020037