Die Material Selection Criteria for Aluminum Hot Stamping

Abstract

1. Introduction

- Wear resistance is required to ensure the dies hold their shape within admissible tolerance limits during production. Hardness is often used in industrial practice for wear related material selection. Nevertheless, its correlation to wear resistance in hot stamping is not straightforward. Works studying tool wear for steel hot stamping show that tool steels with the same hardness levels being tested under the same setups may lead to significantly different wear rates [2]. This behavior is associated to microstructural and compositional differences between tool steels [3]. Furthermore, the stamping conditions can also significantly affect wear, as for example with the addition of lubricants [4]. Only dry contact is considered for this work, so that the developed material selection criterion cannot be extrapolated to lubricated hot stamping.

- High thermal conductivity is a specific requirement of hot stamping die materials, as this production process combines a hot forming operation and a heat treatment. The cooling rate of this heat treatment determines the mechanical properties of the formed part and has become an issue of interest both in steel [5,6,7,8] and aluminum [9,10] hot stamping. A high thermal conductivity tool material combined with a properly designed internal cooling channel system allows the right stabilization of die temperature [11] for the high production demands of the automotive industry.

- Toughness must also be considered to stand the high stress intensity factors that arise on cooling channels. Unless the die material is tough enough, these stress intensity factors have been known to cause die failures in service.

- Hot testing temperature ranging from room temperature (most works use it as reference) up to 500 °C [15,19,21]. It must be remarked here that hot strip drawing and top hat drawing tests, whose setup resembles most closely the industrial processing conditions, are performed with the aluminum being hot and the die being at a lower temperature. This approach simulates the extraction of the hot blank from the furnace and die refrigeration.

- a single experimental approach applied to the three tool material families and two relevant families of aluminum alloys; this experimental approach is based on tribological methods, more specifically reciprocating friction and wear tests, since thermal conductivity and toughness are less relevant when conventional hot stamping mass production is not concerned (assumptions per family are made in Table 1),

- different supply chain assumptions (cost and lead time assumptions are referred in Table 2),

- and industrial variables different from regular automotive high productivity scenarios (takt time and expected volume of production for the die).

2. Materials and Methods

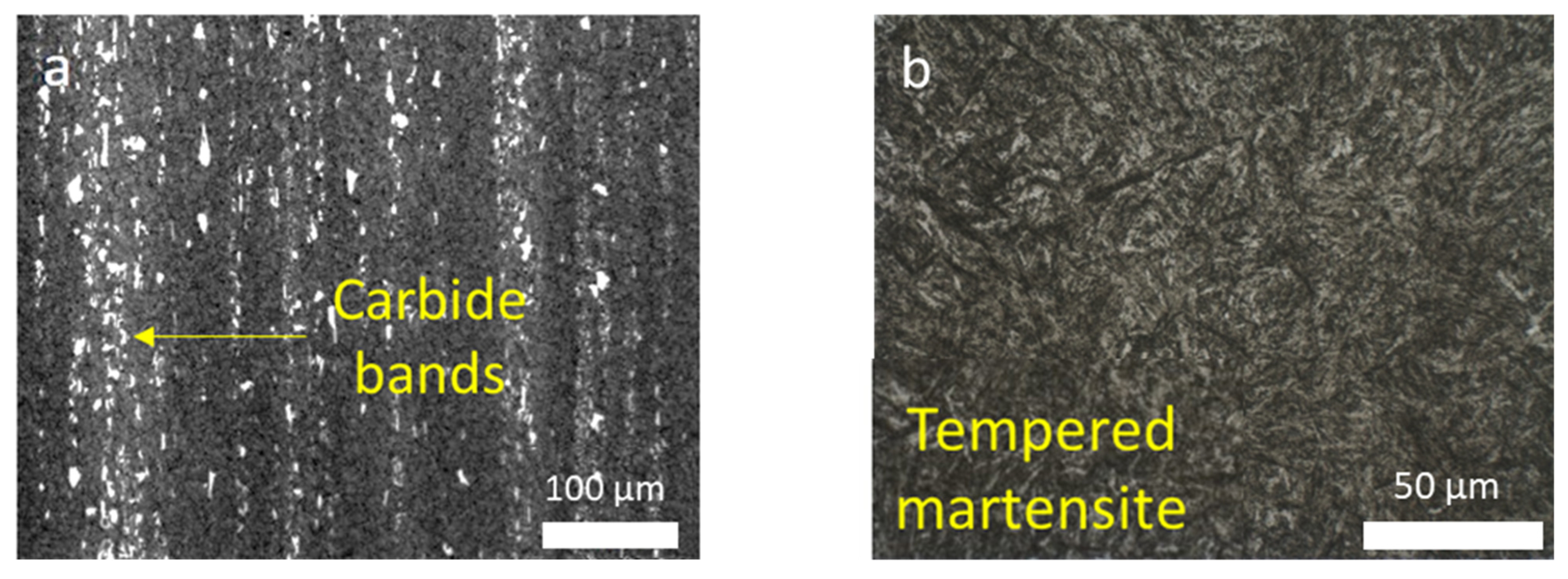

2.1. Die Materials

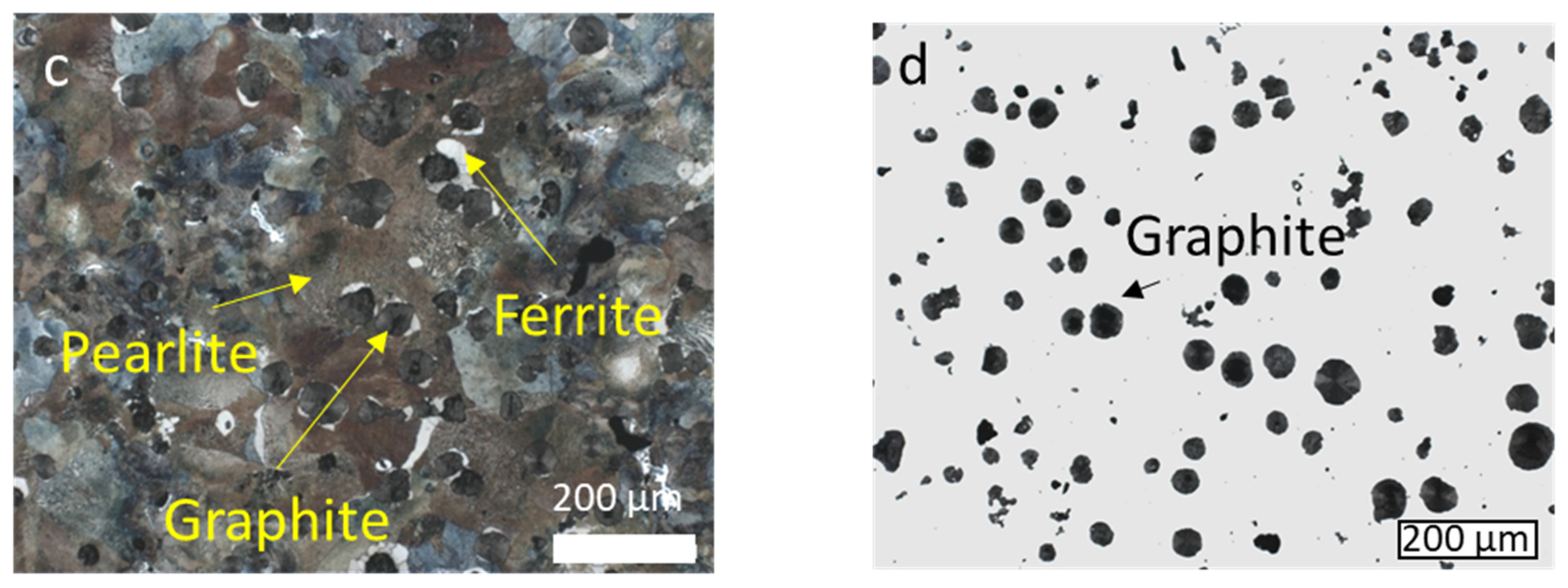

2.2. Pin Materials

2.3. Experimental Method

- The stroke length has been selected so that the total covered length was at least three times the pin diameter (4 mm stroke + 2 mm pin diameter = 6 mm of covered surface).

- The frequency has been chosen to resemble the average sliding speed between a die radius and a hot stamped sheet in a contact radius of an omega profile of a servo-mechanical press 100 mm/s. Although it is several orders of magnitude over the value employed in some references [26,27], this value fits with most works in the checked literature 25–100 mm/s [2,3,15,16,20,21,25].

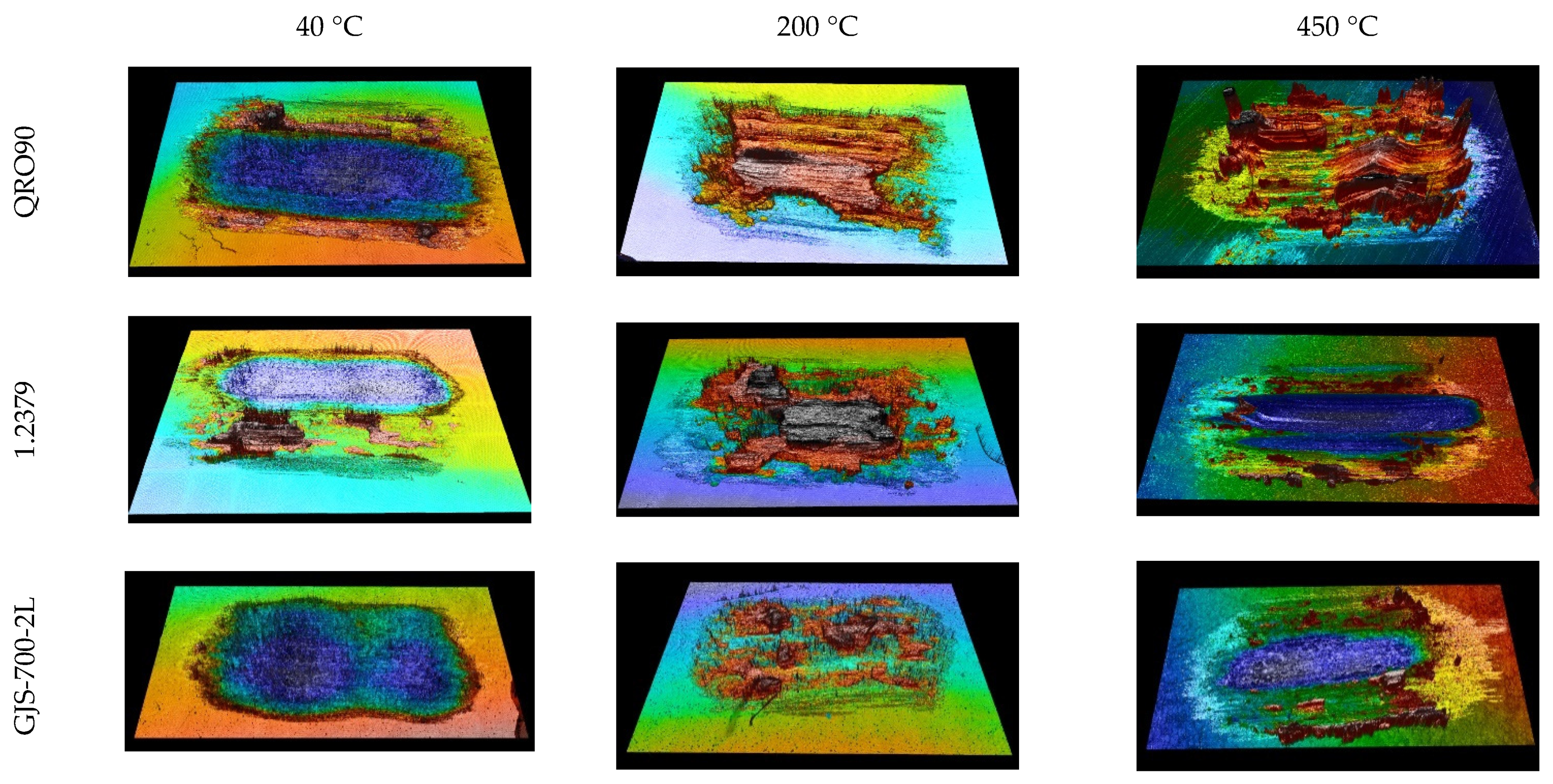

- The temperatures of 40, 200, and 450 °C have been chosen to be representative of the die temperature for a prototyping low productivity scenario, the die temperature for an industrial high productivity scenario, and a condition of high production rate (short takt time) hot stamping without quenching, respectively. Furthermore, it must be considered that the COF is related to microhardness and microstructure in heat treatable aluminum alloys, and three clearly distinct conditions have been forced in the tests: at 40 °C, the materials are in T6 condition, which means that the microstructure is composed by an alpha aluminum matrix and a collection of coherent hardening precipitates. When the tests are set at 200 °C, a progressive over-ageing is provoked in the aluminum. In this process, the CuAl2 (for 2011) and Mg2Si (for 6026) precipitates grow, and the matrix softens not only due to temperature increase, but also due to coarsening of the hardening precipitates. Finally, when the tests are performed at 450 °C a more complex scenario arises: a fraction of the precipitates starts dissolving back in the matrix, while the rest grows coarser, free machining additions melt (Pb and Bi), and the matrix keeps softening because of temperature increase.

3. Results and Discussion

3.1. Coefficient of Friction

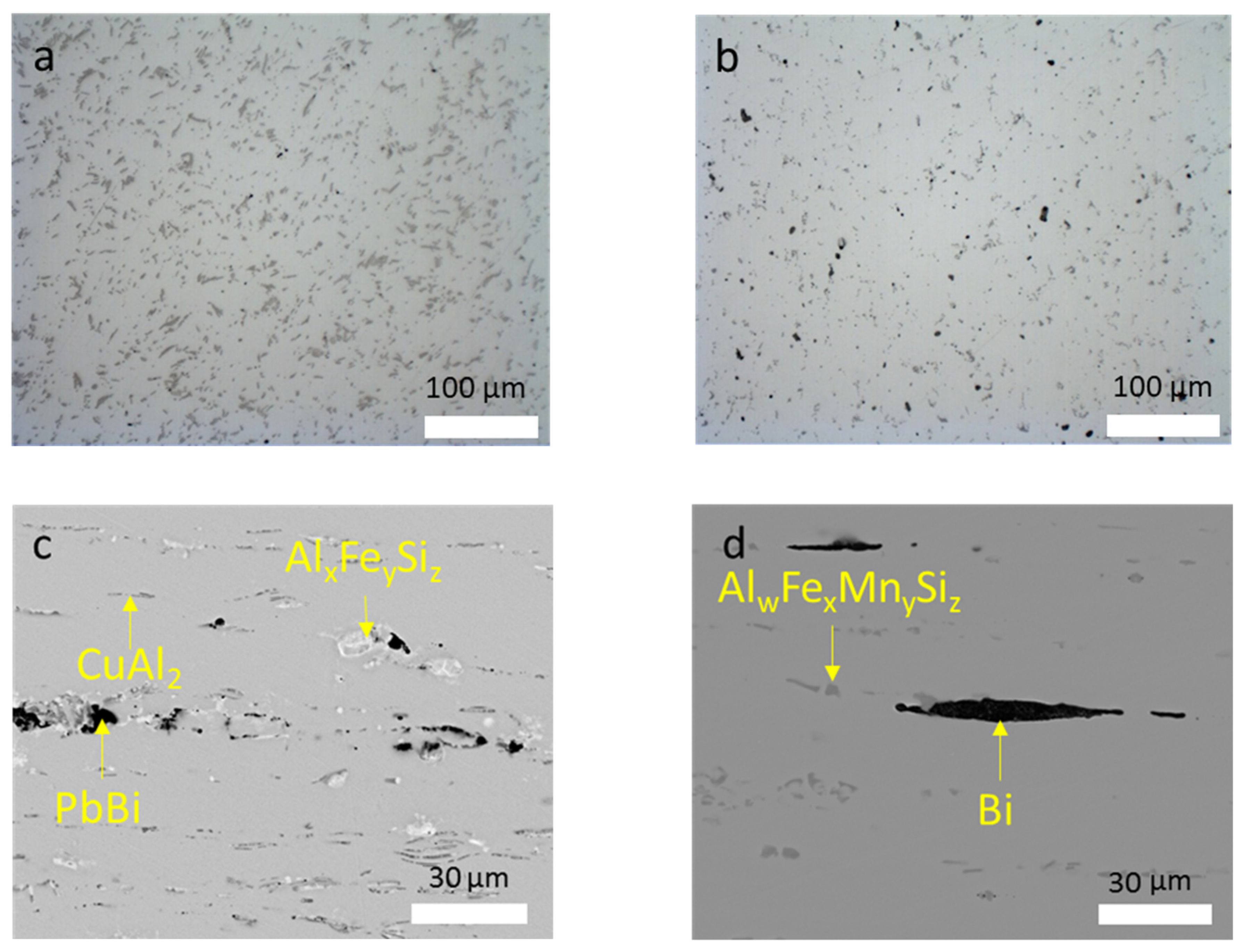

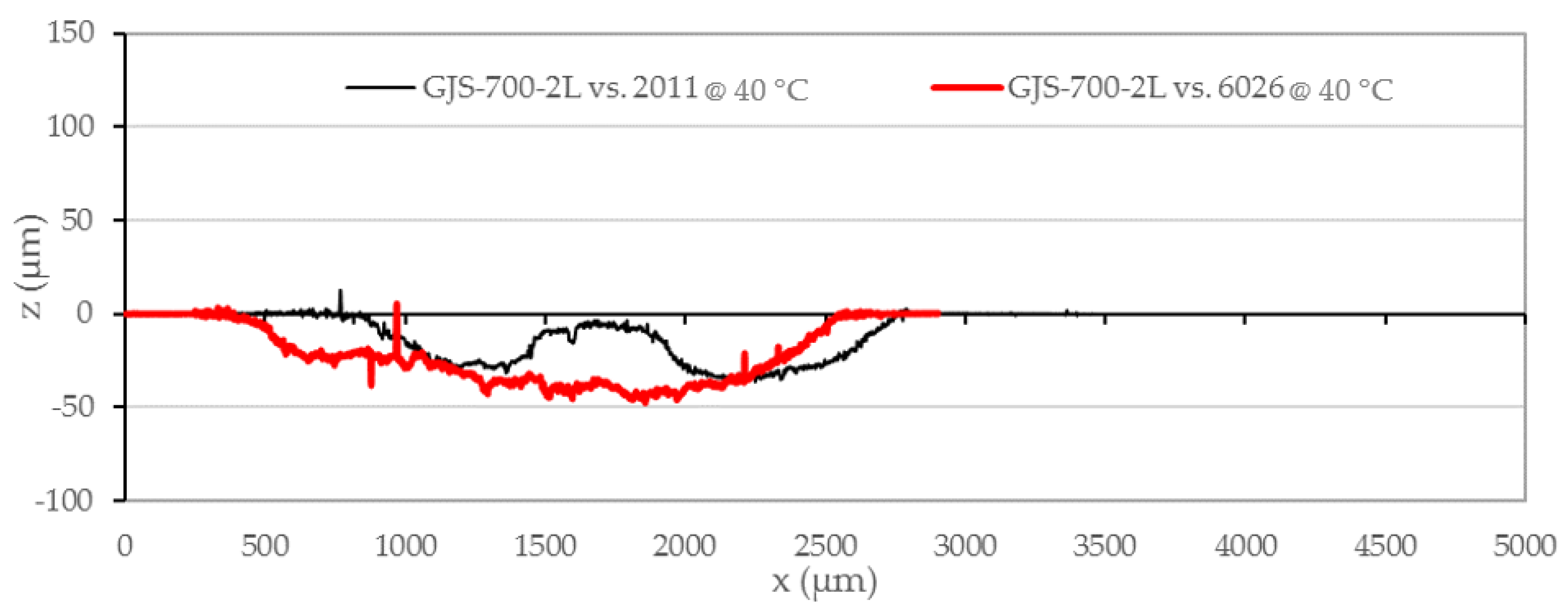

- Results at room temperature: at room temperature, both tool steels showed a more consistent average COF, close to 0.5 for the hot work steel and close to 0.65 for the cold work steel, independently of the aluminum series tested. The cast iron, on the other hand, showed a higher dependence on the aluminum family at room temperature: COFs 0.4 and 0.9 have been found when using 2011 and 6026, respectively. It is worth noting that the GJS-700-2 shows a much steadier COF reading, which is related to an abrasive wear mechanism [34] for both aluminum alloy pins, while cold work tool steel shows this behavior only for the 2011 alloy.

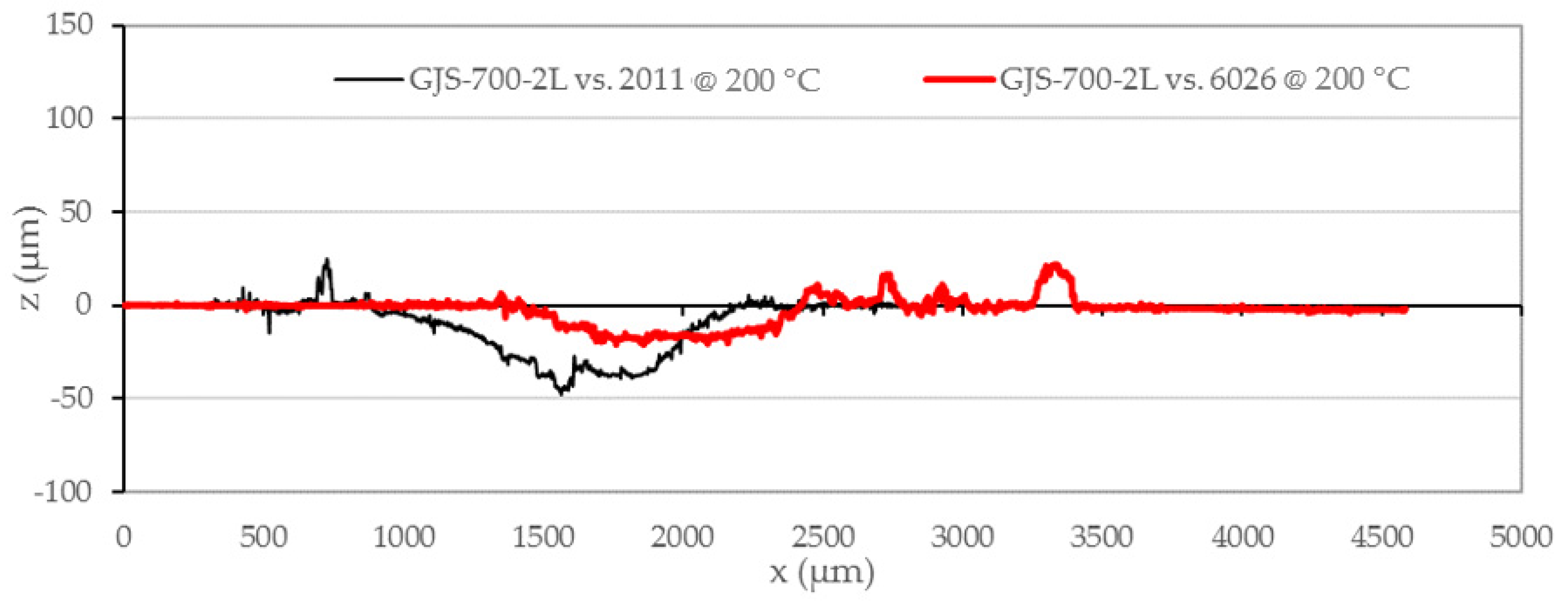

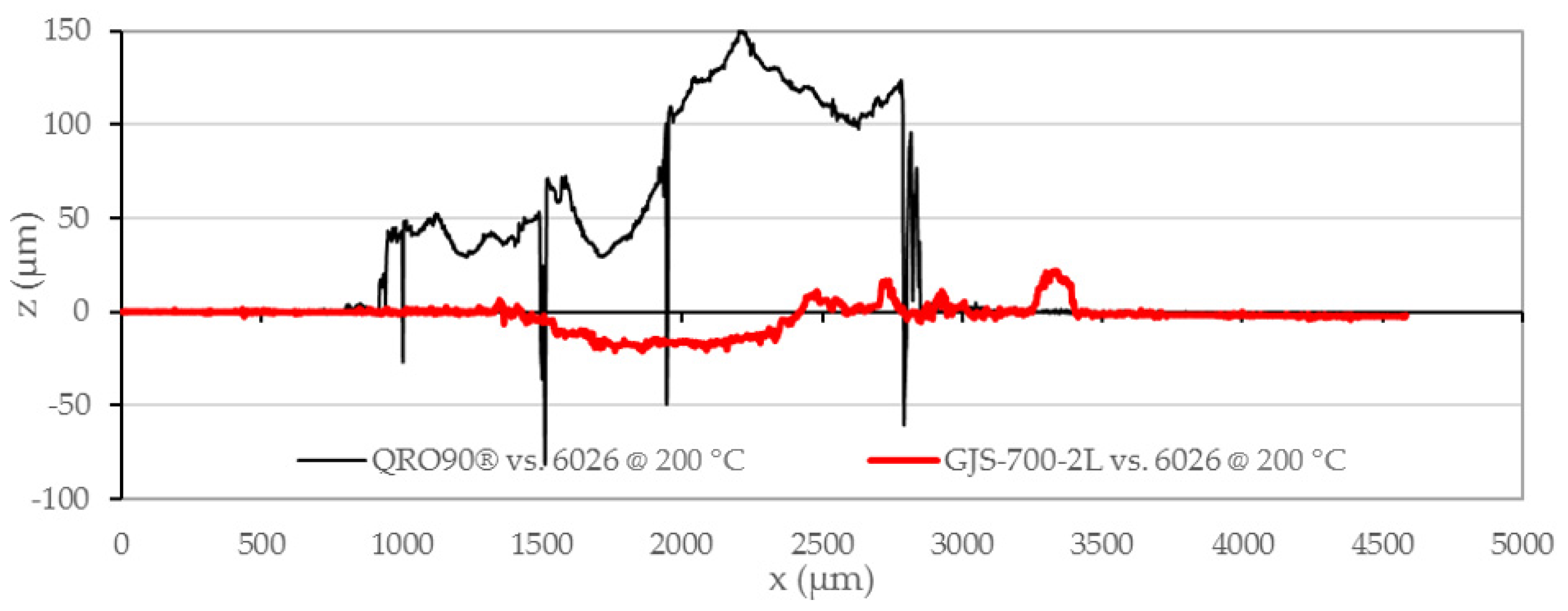

- Results at 200 °C: when comparing room temperature COF with the COF at 200 °C, no major differences have been found when using 2011, with the values converging to the range 0.50–0.70. On the other hand, when 6026 has been employed the COF showed a higher variation, no matter the tool material involved (from 0.40 to 1.40): the average COF increased up to 63% for the hot work tool steel and up to 16% for the cold work tool steel, while the COF against cast iron decreased by 15%. Tests in [16] with a hot work tool steel (H11) and a 7XXX series aluminum (7075) were performed at the same temperature under similar conditions. In this case, COF values ranged from 0.40 to 0.60, which also is observed in Figure 4 for the 2XXX alloy. Other works such as [19] suggest that COFs over 2.0 for higher contact pressures (600 MPa) should be expected for a hot work steel (H13) and 6XXX (6060) tribopair. No information has been found in the literature to assess whether the COF increase in [19] is due to the use of 6XXX in the tribopair, which would fit with the Figure 4, or due to the high pressure. The high variability of the COF reading for the 6026 alloy indicates that stick–slip behavior is governing the contact, thus indicating an abrasive wear mechanism.

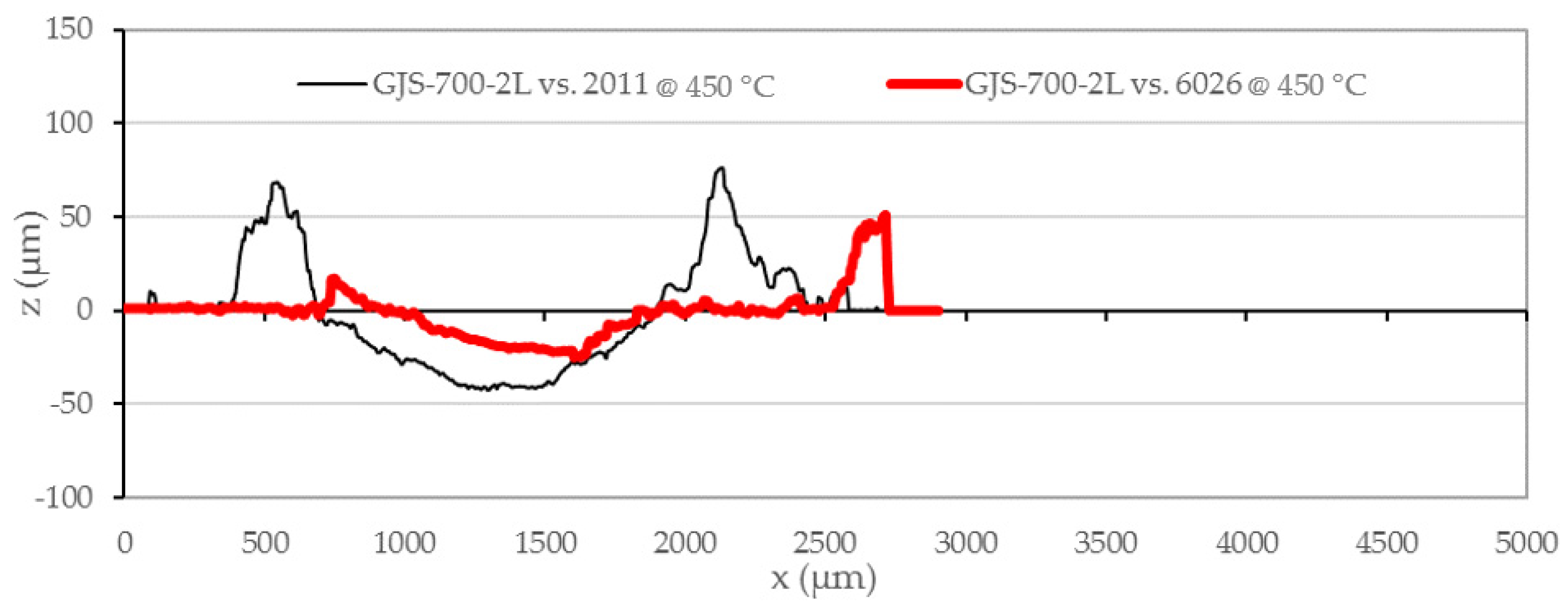

- Results at 450 °C: all the tool materials tend to converge in time to a COF close to 0.55 both when 2011 and 6026 are used. Results from ball-on-disk and hot strip drawing tests performed at the same temperature [14,16], using a hot work tool steel (H11) and 7XXX series aluminums (7475 and 7075) in T6 condition suggest that higher COF values (from 1.2 to 1.75) should be expected. The tests with 7475 were performed at higher pressures (120 MPa), while the tests with 7075 were performed at pressures close to the 10 MPa employed in this work, but with a lubricant. It is noticeable that the exposure time to 450 °C for the specimens giving a COF of 1.2 was rather short (10 s for [16]), meaning that the T6 condition was not degraded during the test. On the other hand, the specimen results in Figure 4 correspond to dwelling plus sliding times up to 20 min, which would lead the aluminum progressively closer to a T4 condition, which was also tested in [16] and for which the COF dropped to 0.4 for [16]. Observing Figure 4, it fits that during the first minutes of the tests at 450 °C the pins worked in the T6 condition giving COFs close to 1.0–1.2 as in the T6 specimens from [16], while as the test progressed, the hardening precipitates of the aluminum progressively dissolved into a T4-like condition, like the T4 specimens from [16]. Thus, no major differences in the result would be expected if 7XXX aluminum series would have been used to build Figure 4.

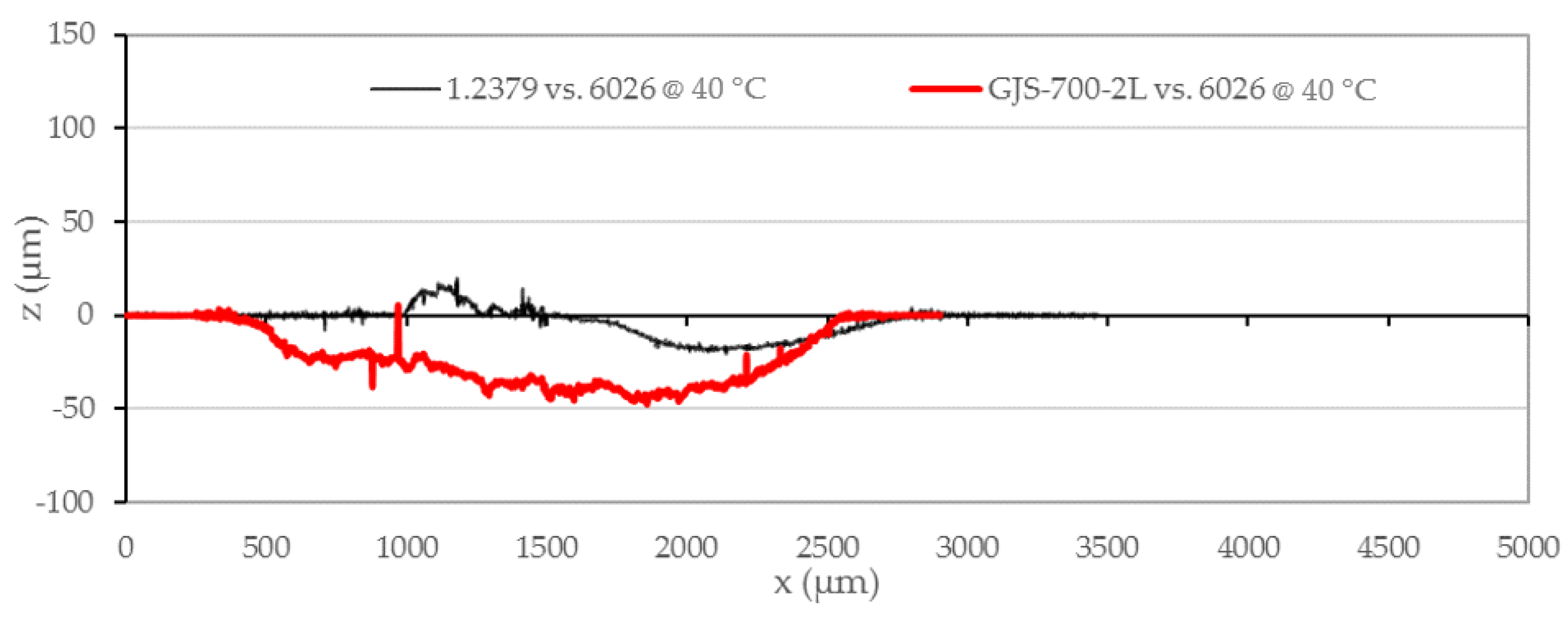

3.2. Tool Material Wear

4. Conclusions

- After the initial 400 s of the test, average friction coefficients are in the range between 0.4 and 0.9 for the three die material options in most cases. Hot work tool steel showed the most acute COF oscillation, what indicates it is more prone to adhesive wear.

- The 6026 alloy is more adhesive than the 2011, especially at 200 °C. This is proposed to be related to the combined effect of Mg2Si coarsening and aluminum matrix softening, which should then be stronger than for CuAl2 precipitates.

- The tested hot work tool steel has shown the worst performance in terms of adhesion not only in the COF graphs but also in confocal microcopy inspection, especially when a 6XXX aluminum has been used.

- Cast iron showed the lowest level of adhesion against both aluminum alloys at the most usual die temperature in press quenching technologies (200 °C).

- Under extreme conditions, such as the test at 450 °C, the three die materials showed a very similar behavior, with the hot work tool steel being more strongly affected by galling with 6026. Thus, cost would be the driving element for material selection leading to cast iron as the choice for very short takt time scenarios where die temperature is the highest.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chantzis, D.; Liu, X.; Politis, D.J.; El Fakir, O.; Chua, T.Y.; Shi, Z.; Wang, L. Review on additive manufacturing of tooling for hot stamping. Int. J. Adv. Manuf. Technol. 2020, 109, 87–107. [Google Scholar] [CrossRef]

- Muro, M.; Artola, G.; Gorriño, A.; Angulo, C. Wear and friction evaluation of different tool steels for hot stamping. Adv. Mater. Sci. Eng. 2018, 2018, 3296398. [Google Scholar] [CrossRef]

- Muro, M.; Artola, G.; Leunda, J.; Soriano, C.; Angulo, C. Compositional modification of tool steel to improve its wear resistance. Met. Mater. Trans. A 2019, 50, 3912–3921. [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S.; Medea, F. Wear onset in hot stamping of aluminium alloy sheets. Wear 2017, 376–377, 484–495. [Google Scholar] [CrossRef]

- Fernández, B.; González, B.; Artola, G.; López de Lacalle, N.; Angulo, C. A quick cycle time sensitivity analysis of boron steel in hot stamping. Metals 2019, 9, 235. [Google Scholar] [CrossRef]

- Muro, M.; Artola, G.; Gorriño, A.; Angulo, C. Effect of the Martensitic Transformation on the Stamping Force and Cycle Time of Hot Stamping Parts. Metals 2018, 8, 385. [Google Scholar] [CrossRef]

- Mendiguren, J.; Ortubay, R.; Saenz de Argandoña, E.; Galdos, L. Experimental characterization of the heat transfer coefficient under different close loop controlled pressures and die temperatures. Appl. Therm. Eng. 2016, 99, 813–824. [Google Scholar] [CrossRef]

- Cortina, M.; Arrizubieta, J.I.; Calleja, A.; Ukar, E.; Alberdi, A. Case study to illustrate the potential of conformal cooling channels for hot stamping dies manufactured using hybrid process of laser metal deposition (LMD) and milling. Metals 2018, 8, 102. [Google Scholar] [CrossRef]

- Lui, X.; El Fakir, O.; Zheng, Y.; Gharbi, M.; Wang, L. Effect of tool coating on the interfacial heat transfer coefficient in hot stamping of aluminium alloys under variable contact pressure conditions. Int. J. Heat Mass Transf. 2019, 137, 74–83. [Google Scholar] [CrossRef]

- Baghbane, A.; Eivani, A.; Hasheminiasari, M.; Park, N.; Jafarian, H. Application of hot forming cold die quenching for facilitating equal channel angular pressing of AA2024 aluminium alloy. J. Alloys Compd. 2019, 791, 265–277. [Google Scholar] [CrossRef]

- Zheng, K.; Lee, J.; Xiao, W.; Wang, B.; Lin, J. Experimental investigation of the in-die quenching efficiency and die surface temperature of stamping aluminium alloys. Metals 2018, 8, 231. [Google Scholar] [CrossRef]

- Lui, Y.; Zhu, Z.; Wang, Z.; Zhu, B.; Wang, Y.; Zhang, Y. Flow and friction behaviour of 6061 aluminium alloy at elevated temperatures and hot stamping of a B-Pillar. Int. J. Adv. Manuf. Technol. 2018, 96, 4063–4083. [Google Scholar] [CrossRef]

- Celik, G.; Polat, S.; Atapek, S. Effect of single and duplex thin hard film coating on the wear resistance of 1.2343 tool steel. Trans. Indian Inst. Met. 2017, 71, 411–419. [Google Scholar] [CrossRef]

- Wang, L.; Cai, J.; Zhou, J.; Duszczyk, J. Characteristics of the friction between aluminium and steel at elvated temperatures during ball-on-disk tests. Tribol. Lett. 2009, 36, 183–190. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Kilpi, L.; Hakala, T.; Metsäjoki, H.; Ronkainen, H. Insights of tool steel-aluminium alloy tribopair at different temperatures. Tribol. Int. 2018, 119, 567–584. [Google Scholar] [CrossRef]

- Ghiotti, A.; Simonetto, E.; Bruschi, S. Influence of process parameters on tribological behavior of 7075 in hot stamping. Wear 2019, 426–427, 348–356. [Google Scholar] [CrossRef]

- Zaba, K.; Kita, P.; Nowosielski, M.; Kwiatkowski, M.; Madej, M. Influence of lubricants on wear resistance of aluminium alloy strips series 2XXX. Arch. Metall. Mater. 2015, 60, 1833–1837. [Google Scholar] [CrossRef]

- Pujante, J.; Vilaseca, M.; Casellas, D.; Riera, M. The role of adhesive forces and mechanical interaction on material transfer in hot forming of aluminium. Tribol. Lett. 2015, 59, 10. [Google Scholar] [CrossRef]

- Jerina, J.; Kalin, M. Initiation and evolution of the aluminium-alloy transfer on hot-work too steel at temperatures from 20 °C to 500 °C. Wear 2014, 319, 234–244. [Google Scholar] [CrossRef]

- Pujante, J.; Pelcastre, L.; Vilaseca, M.; Casellas, D.; Prakash, B. Investigations into wear and galling mechanisms of aluminium alloy-tool steel tribopair at different temperatures. Wear 2013, 308, 193–198. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Heino, V.; Vjoki, A.; Hakala, T.; Ronkainen, H. Wear of additively manufactured tool steel in contact with aluminium alloy. Wear 2019, 432–433, 20294. [Google Scholar] [CrossRef]

- Venema, J.; Hazrati, J.; Matthews, D.; Stegeman, A.; van den Boogrd, A. The effects of temperature on friction and wear mechanisms during direct press hardening of Al-Si coated ultra-high strength steel. Wear 2018, 406–407, 149–155. [Google Scholar] [CrossRef]

- Mozgovoy, S.; Lofti, A.; Hardell, J.; Prakash, B. Material transfer during high temperature sliding of Al-Si coated 22MnB5 steel against PVD coatings with and without aluminium. Wear 2019, 426–427, 401–411. [Google Scholar] [CrossRef]

- Schwingenschlögl, P.; Weldi, M.; Merklein, M. Investigation of the influence of process parameters on adhesive wear under hot stamping conditions. J. Phys. Conf. Ser. 2017, 896, 012048. [Google Scholar] [CrossRef]

- Deng, L.; Pelcastre, L.; Hardell, J.; Prakash, B.; Oldenburg, M. Experimental evaluation of galling under press hardening conditions. Tribol. Lett. 2018, 66, 93. [Google Scholar] [CrossRef]

- Dong, Y.; Formosa, D.; Fernandez, J.; Li, X.; Zoltan, K.; Dong, H. Development of low-friction and wear-resistant for low-cost Al hot stamping tools. In Proceedings of the 4th International Conference on New Forming Technology (ICNFT 2015), Glasgow, UK, 6–9 August 2015; Volume 21, p. 05009. [Google Scholar] [CrossRef]

- Dong, Y.; Zheng, K.; Fernandez, J.; Li, X.; Dong, H.; Lin, J. Experimental investigations on hot forming of AA6082 using advanced plasma nitrocarburised and CAPVD WC:C coated tools. J. Mater. Proc. Technol. 2017, 240, 190–199. [Google Scholar] [CrossRef]

- Alava, L.A.; Artola, G.; Guinea, I.; Muro, M. On the Influence of Cryogenic Steps on Heat Treatment Processes. Mater. Perform. Charact. 2017, 6, 837–849. [Google Scholar] [CrossRef]

- Jesperson, H. Influence of cooling rate during quenching on the toughness at typical working temperatures of die-casting dies. Metall. Ital. 2009, 55–60. [Google Scholar]

- Picas, I.; Casellas, D.; Llanes, L. R-Curve approach to describe the fracture resistance of tool steels. Met. Mater. Trans. A 2016, 47, 2739–2754. [Google Scholar] [CrossRef]

- UNE-EN 1563. Founding-Spheroidal graphite cast irons. In Asociación Española de Normalización; Asociación Española de Normalización: Madrid, Spain, 2019; p. 38. [Google Scholar]

- Doong, J.L.; Hwang, J.R.; Chen, H.S. The influence of pearlite fraction on the fracture toughness and fatigue crack growth in nodular cast iron. J. Mater. Sci. 1986, 21, 871–878. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Metal prices in the United States through 2010: U.S. Geological Survey Scientific Investigations Report 2012–5188. 2013; p. 204. Available online: http://pubs.usgs.gov/sir/2012/5188 (accessed on 15 September 2020).

- Menezes, P.L.; Kishore; Kailas, S.V. Role of surface texture and roughness parameters in friction and transfer layer formation under dry and lubricated sliding conditions. Int. J. Mater. Res. 2008, 99, 795–807. [CrossRef]

- Gromov, V.E.; Ivanov; Yu, F.; Stolboushkina, O.A.; Konovalov, S.V. Dislocation substructure evolution on Al creep under the action of the weak electric potential. Mater. Sci. Eng. A 2017, 527, 858–861. [CrossRef]

- Aryshenskii, E.; Hirsch, J.; Yashin, V.; Konovalov, S.; Kawallla, R. Influence of Local Inhomogeneity of Thermomechanical Treatment Conditions on Microstructure Evolution in Aluminum Alloys. J. Mater. Eng. Perform. 2018, 27, 6780–6799. [Google Scholar] [CrossRef]

| Tool Material | Thermal Conductivity | Toughness | Cost | Lead Time |

|---|---|---|---|---|

| Hot work tool steel | High | High | High | Low |

| Cold work tool steel | Low | Medium | Medium | Medium |

| Cast iron | Medium | Low | Low | High |

| Takt Time | ||||

|---|---|---|---|---|

| Short | Regular | Long | ||

| Production Volume | Low | Hot forming without press quenching | Aerospace | Prototyping |

| Medium | Automotive | Aerospace | ||

| High | N/A | |||

| Material | Description | C | Si | Mn | Cr | Mo | Ni | V | Hardness |

|---|---|---|---|---|---|---|---|---|---|

| [HRC] | |||||||||

| 1.2379 | Specification | 1.45–1.60 | 0.10–0.60 | 0.20–0.60 | 11.0–13.0 | 0.7–1.0 | --- | 0.70–1.00 | 59 |

| Tested batch | 1.53 | 0.25 | 0.31 | 11.46 | 0.78 | --- | 0.92 | 62 ± 1 1 | |

| QRO90 | Specification 2 | 0.38 | 0.3 | 0.8 | 2.6 | 2.3 | -- | -- | 52 |

| Tested batch | 0.38 | 0.3 | 0.74 | 1.6 | 2.27 | -- | 0.9 | 51 ± 1 1 | |

| GJS-700-2L | Specification | 3.40–3.80 | 2.30–3.10 | 0.20–0.80 | -- | <0.60 | <1.50 | -- | 302 |

| Tested batch | 3.5 | 2.12 | 0.71 | --- | 0.53 | 1.06 | -- | 30 ± 2 1,3 |

| Alloy | Description | Si | Fe | Cu | Mn | Mg | Zn | Bi | Pb | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 2011 | Specification | <0.40 | <0.70 | 5.0–6.0 | -- | -- | <0.30 | 0.2–0.6 | 0.2–0.4 | Balance |

| Tested batch | 0.26 | 0.59 | 5.7 | -- | -- | <0.04 | 0.48 | 0.31 | Balance | |

| 6026 | Specification | 0.6–1.4 | <0.7 | 0.2–0.5 | 0.2–1.0 | 0.6–1.2 | <0.3 | 0.5–1.5 | <0.05 | Balance |

| Tested batch | 0.75 | 0.48 | 0.4 | 0.5 | 0.71 | 0.14 | 0.9 | 0.01 | Balance |

| Alloy | Description | Yield Strength Rp0.2 [MPa] | Ultimate Tensile Strength Rm [MPa] | Elongation E [%] |

|---|---|---|---|---|

| 2011 | Specification | >270 | >320 | >10 |

| Tested batch | 327 ± 5 | 397 | 21 | |

| 6026 | Specification | >330 | >360 | >4 |

| Tested batch | 338 ± 5 | 391 | 15 |

| Test Parameter | Value |

|---|---|

| Load [N] | 31 |

| Frequency [Hz] | 15 |

| Stroke [mm] | 4 |

| Temperature [°C] | 40, 200, 450 |

| Test duration [s] | 900 |

| Takt Time | ||||

|---|---|---|---|---|

| Short | Regular | Long | ||

| Production Volume | Low | Cast Iron | Aerospace | Prototyping |

| Medium | Automotive | Aerospace | ||

| High | N/A | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muro, M.; Aseguinolaza, I.; Artola, G. Die Material Selection Criteria for Aluminum Hot Stamping. J. Manuf. Mater. Process. 2021, 5, 15. https://doi.org/10.3390/jmmp5010015

Muro M, Aseguinolaza I, Artola G. Die Material Selection Criteria for Aluminum Hot Stamping. Journal of Manufacturing and Materials Processing. 2021; 5(1):15. https://doi.org/10.3390/jmmp5010015

Chicago/Turabian StyleMuro, Maider, Ines Aseguinolaza, and Garikoitz Artola. 2021. "Die Material Selection Criteria for Aluminum Hot Stamping" Journal of Manufacturing and Materials Processing 5, no. 1: 15. https://doi.org/10.3390/jmmp5010015

APA StyleMuro, M., Aseguinolaza, I., & Artola, G. (2021). Die Material Selection Criteria for Aluminum Hot Stamping. Journal of Manufacturing and Materials Processing, 5(1), 15. https://doi.org/10.3390/jmmp5010015