A Rapid Throughput System for Shock and Impact Characterization: Design and Examples in Compaction, Spallation, and Impact Welding

Abstract

:1. Introduction

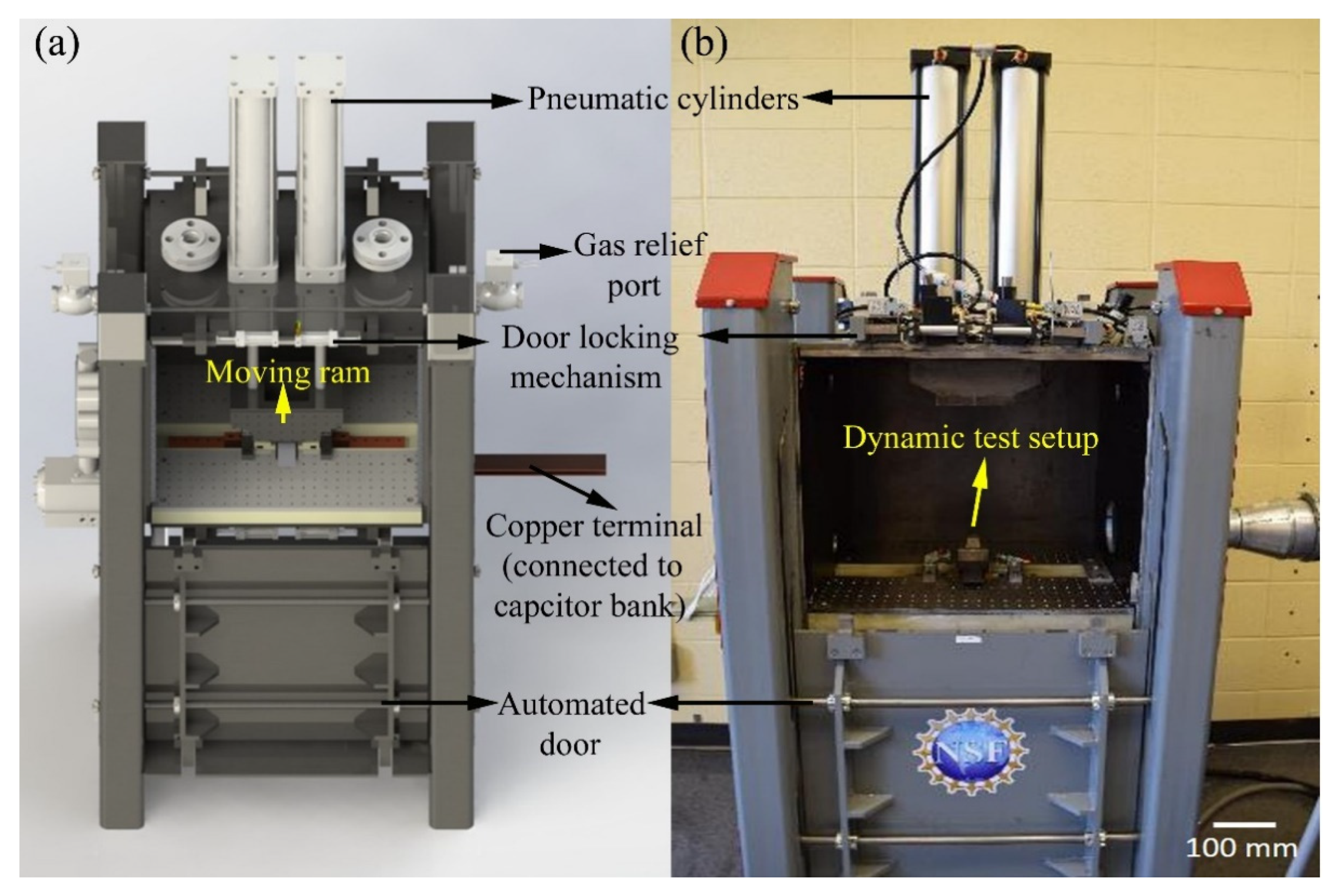

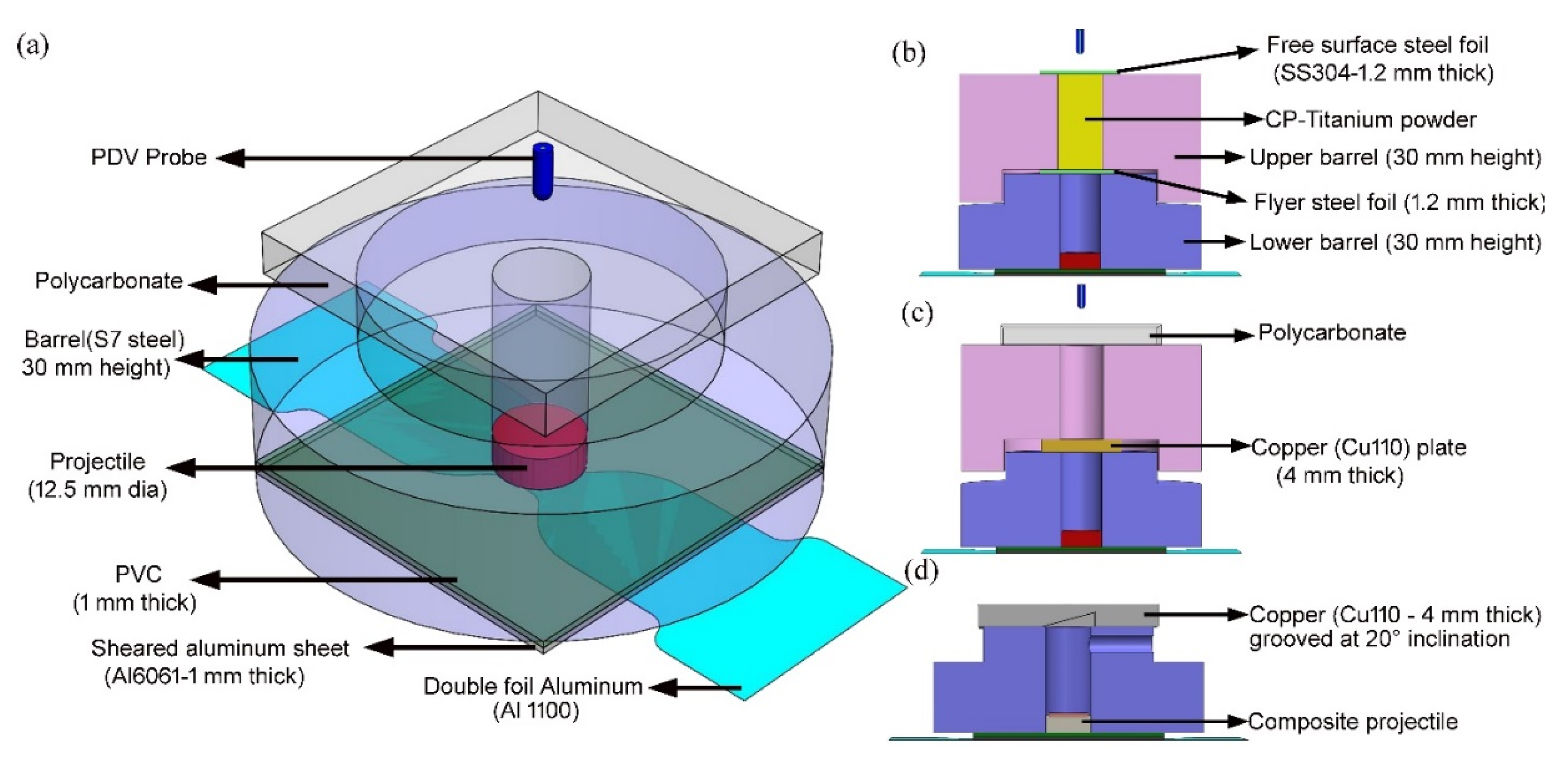

2. Materials and Methods

3. Result and Discussion

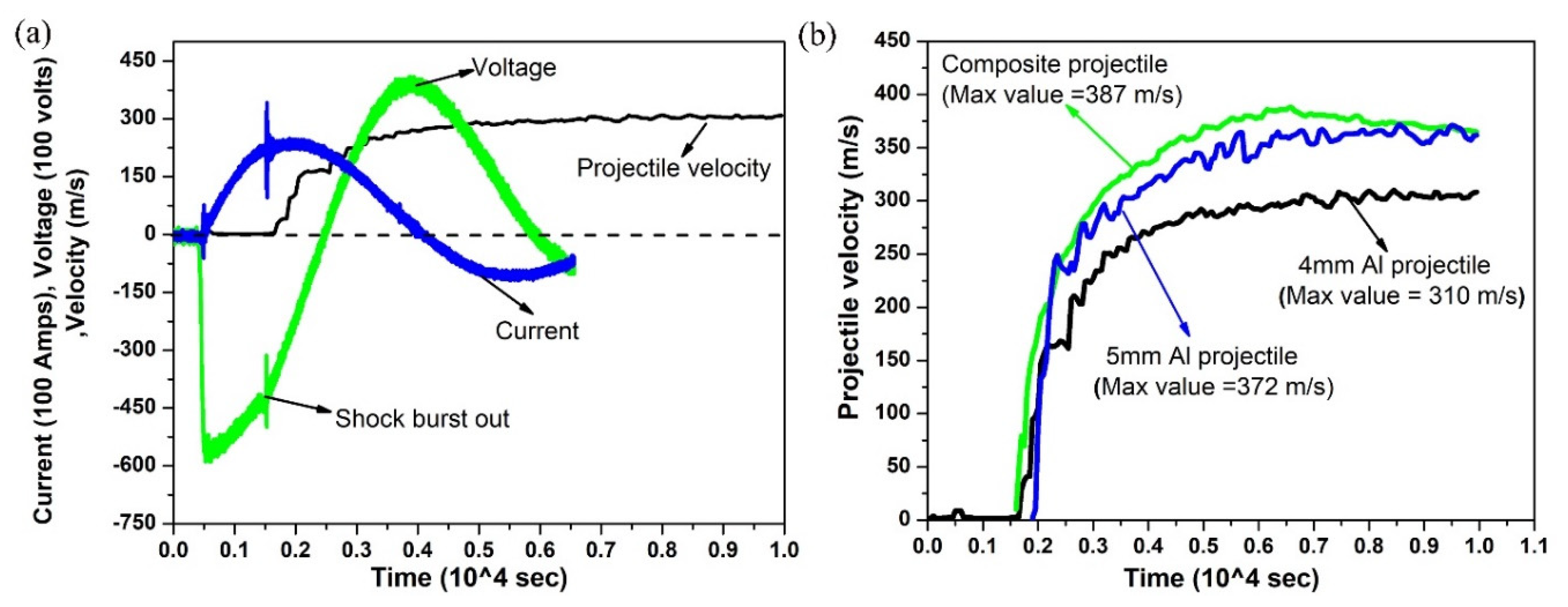

3.1. Effect of Projectile Configuration on Impact Velocity

3.2. Effect of Lubrication on Projectile Velocity

3.3. Case Studies

3.3.1. Powder Compaction of CP-Ti

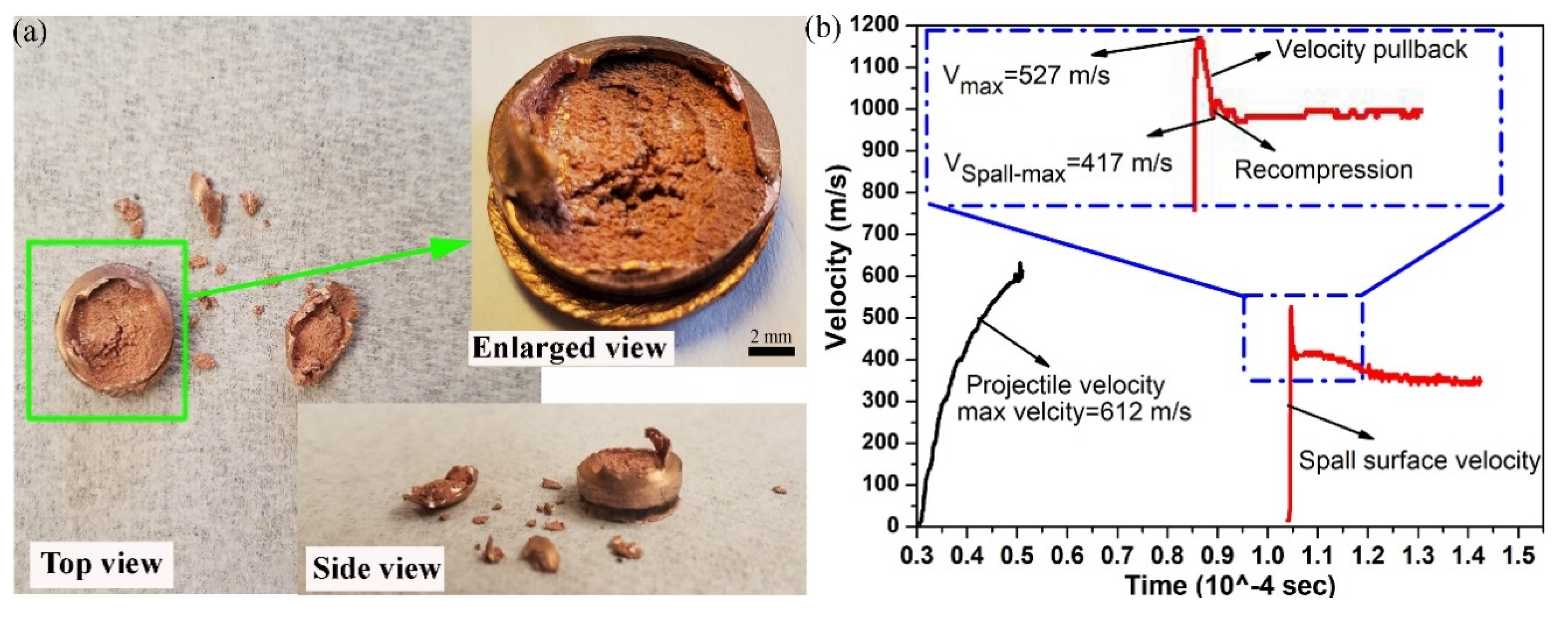

3.3.2. Spallation in Copper

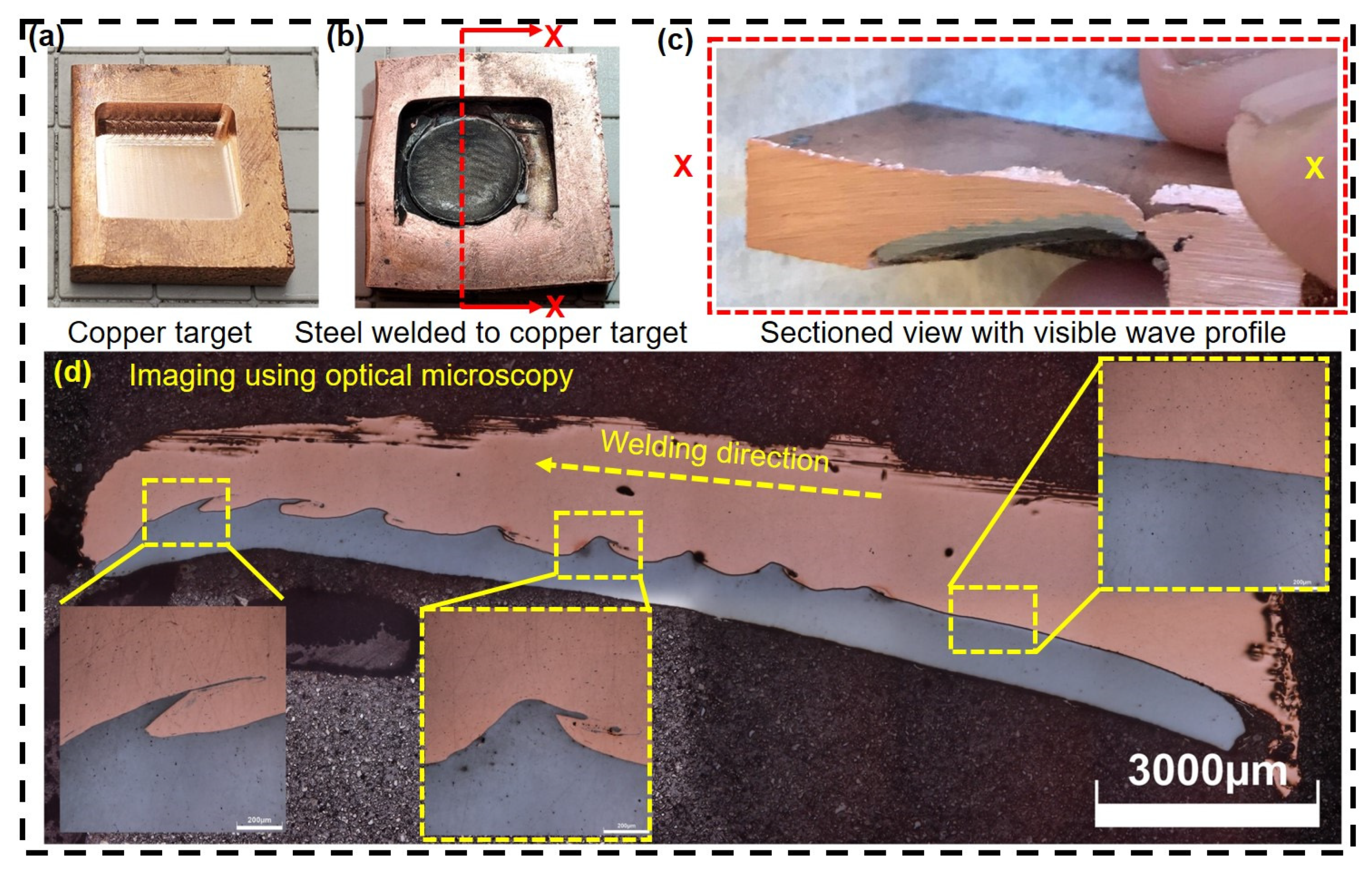

3.3.3. Collision Welding of Inclined Target

4. Summary

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Davison, L.; Graham, R.A. Shock compression of solids. Phys. Rep. 1979, 55, 255–379. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, W.; Wan, Y.; Chu, G.; Chen, D. Study on equation of state and spall strength of sintered Nd-Fe-B magnets. J. Magn. Magn. Mater. 2020, 497, 166014. [Google Scholar] [CrossRef]

- Mao, H.; Hemley, R.J. Ultrahigh-pressure transitions in solid hydrogen. Rev. Mod. Phys. 1994, 66, 671. [Google Scholar] [CrossRef]

- Kimura, T.; Ozaki, N.; Okuchi, T.; Mashimo, T.; Miyanishi, K.; Endo, T.; Jitsui, T.; Hirose, A.; Ikoma, M.; Kakeshita, T.; et al. Static compression experiments for advanced coupling techniques of laser-driven dynamic compression and precompression target. J. Phys. Conf. Ser. 2010, 215, 12152. [Google Scholar] [CrossRef]

- Banishev, A.A.; Shaw, W.L.; Bassett, W.P.; Dlott, D.D. High-Speed Laser-Launched Flyer Impacts Studied with Ultrafast Photography and Velocimetry. J. Dyn. Behav. Mater. 2016, 2, 194–206. [Google Scholar] [CrossRef] [Green Version]

- Curtis, A.D.; Banishev, A.A.; Shaw, W.L.; Dlott, D.D. Laser-driven flyer plates for shock compression science: Launch and target impact probed by photon Doppler velocimetry. Rev. Sci. Instrum. 2014, 85, 043908. [Google Scholar] [CrossRef]

- Moshe, E.; Eliezer, S.; Henis, Z.; Werdiger, M.; Dekel, E.; Horovitz, Y.; Maman, S.; Goldberg, I.B. Experimental measurements of the strength of metals approaching the theoretical limit predicted by the equation of state. Appl. Phys. Lett. 2000, 76, 1555–1557. [Google Scholar] [CrossRef]

- Okada, A.; Aso, Y.; Hamada, K.; Yasunaga, K.; Kiritani, M. Ultra-high-speed deformation by impact of a projectile flying at speeds on the order of km s−1. Mater. Sci. Eng. A 2003, 350, 86–91. [Google Scholar] [CrossRef]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Han, R.; Zhou, H.; Liu, Q.; Wu, J.; Jing, Y.; Chao, Y.; Zhang, Y.; Qiu, A. Generation of Electrohydraulic Shock Waves by Plasma-Ignited Energetic Materials: I. Fundamental Mechanisms and Processes. IEEE Trans. Plasma Sci. 2015, 43, 3999–4008. [Google Scholar] [CrossRef]

- Vivek, A.; Hansen, S.; Liu, B.C.; Daehn, G.S. Vaporizing foil actuator: A tool for collision welding. J. Mater. Process. Technol. 2013, 213, 2304–2311. [Google Scholar] [CrossRef]

- Kapil, A.; Lee, T.; Vivek, A.; Bockbrader, J.; Abke, T.; Daehn, G. Benchmarking strength and fatigue properties of spot impact welds. J. Mater. Process. Technol. 2018, 255, 219–233. [Google Scholar] [CrossRef]

- Lee, T.; Mao, Y.; Gerth, R.; Vivek, A.; Daehn, G. Civilized explosive welding: Impact welding of thick aluminum to steel plates without explosives. J. Manuf. Process. 2018, 36, 550–556. [Google Scholar] [CrossRef]

- Vivek, A.; Brune, R.; Hansen, S.R.; Daehn, G. Vaporizing foil actuator used for impulse forming and embossing of titanium and aluminum alloys. J. Mater. Process. Technol. 2014, 214, 865–875. [Google Scholar] [CrossRef]

- Vivek, A.; DeFouw, J.D.; Daehn, G. Dynamic compaction of titanium powder by vaporizing foil actuator assisted shearing. Powder Technol. 2014, 254, 181–186. [Google Scholar] [CrossRef]

- Vivek, A.; Daehn, G. Vaporizing Foil Actuator: A Versatile Tool for High Energy-rate Metal Working. Procedia Eng. 2014, 81, 2129–2134. [Google Scholar] [CrossRef] [Green Version]

- Johnson, J.R.; Taber, G.; Vivek, A.; Zhang, Y.; Golowin, S.; Banik, K.; Fenton, G.K.; Daehn, G.S. Coupling Experiment and Simulation in Electromagnetic Forming Using Photon Doppler Velocimetry. Steel Res. Int. 2009, 80, 359–365. [Google Scholar] [CrossRef]

- Vogler, T.; Lee, M.; Grady, D. Static and dynamic compaction of ceramic powders. Int. J. Solids Struct. 2007, 44, 636–658. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, Y.; Kiggans, J.; Clark, M.B.; Nunn, S.D.; Sabau, A.S.; Peter, W.H. Consolidation Process in Near Net Shape Manufacturing of Armstrong CP-Ti/Ti-6Al-4V Powders. Key Eng. Mater. 2010, 436, 103–111. [Google Scholar] [CrossRef]

- Nagarathnam, K.; Renner, A.; Trostle, D.; Kruczynski, D.; Massey, D. Development of 1000-Ton combustion-driven compaction press for materials development and processing. Adv. Powder Metall. Part. Mater. 2007, 1, 3. [Google Scholar]

- Skoglund, P.; Kejzelman, M.; Hauer, I. High density P/M components by high velocity compaction. Adv. Powder Metall. Part. Mater. 2002, 4–85. Available online: https://www.hoganas.com/globalassets/download-media/technical-papers/pm/highdensitypmcomponentsbyhighvelocitycompaction.pdf (accessed on 9 December 2020).

- Sethi, G.; Hauck, E.; German, R. High velocity compaction compared with conventional compaction. Mater. Sci. Technol. 2006, 22, 955–959. [Google Scholar] [CrossRef]

- Wang, J.; Qu, X.; Yin, H.; Yi, M.; Yuan, X. High velocity compaction of ferrous powder. Powder Technol. 2009, 192, 131–136. [Google Scholar] [CrossRef]

- Yi, M.-J.; Yin, H.-Q.; Wang, J.-Z.; Yuan, X.-J.; Qu, X.-H. Comparative research on high-velocity compaction and conventional rigid die compaction. Front. Mater. Sci. China 2009, 3, 447–451. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Dmitriev, A.M.; Dmitriev, A.M.; Fedorov, S.V. A Cold-Pressing Method Combining Axial and Shear Flow of Powder Compaction to Produce High-Density Iron Parts. Technologies 2019, 7, 70. [Google Scholar] [CrossRef] [Green Version]

- Raming, T.P.; Van Zyl, W.E.; Carton, E.P.; Verweij, H. Sintering, sinterforging and explosive compaction to densify the dual phase nanocomposite system Y2O3-doped ZrO2 and RuO2. Ceram. Int. 2004, 30, 629–634. [Google Scholar] [CrossRef]

- Johnson, K.; Murr, L.E.; Staudhammer, K. Comparison of residual microstructures for 304 stainless steel shock loaded in plane and cylindrical geometries: Implications for dynamic compaction and forming. Acta Met. 1985, 33, 677–684. [Google Scholar] [CrossRef]

- Lenihan, D.; Ronan, W.; O’Donoghue, P.E.; Leen, S.B. A review of the integrity of metallic vehicle armour to projectile attack. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2018, 233, 73–94. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Yao, X. The spallation of single crystal SiC: The effects of shock pulse duration. Comput. Mater. Sci. 2016, 124, 151–159. [Google Scholar] [CrossRef]

- Montgomery, J.S.; Wells, M.G.H.; Roopchand, B.; Ogilvy, J.W. Low-cost titanium armors for combat vehicles. JOM 1997, 49, 45–47. [Google Scholar] [CrossRef]

- Forbes, J.W. Shock Wave Compression of Condensed Matter: A Primer; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Vignjevic, R.; Bourne, N.K.; Millett, J.C.F.; Devuyst, T. Effects of orientation on the strength of the aluminum alloy 7010-T6 during shock loading: Experiment and simulation. J. Appl. Phys. 2002, 92, 4342–4348. [Google Scholar] [CrossRef]

- Turley, W.D.; Fensin, S.J.; Hixson, R.S.; Jones, D.R.; La Lone, B.M.; Stevens, G.D.; Thomas, S.A.; Veeser, L.R. Spall response of single-crystal copper. J. Appl. Phys. 2018, 123, 055102. [Google Scholar] [CrossRef] [Green Version]

- Millett, J.C.F.; Whiteman, G.; Bourne, N.K. Lateral stress and shear strength behind the shock front in three face centered cubic metals. J. Appl. Phys. 2009, 105, 033515. [Google Scholar] [CrossRef]

- Xie, P.; Wang, Y.; Shi, T.; Wang, X.; Hu, C.; Hu, J.; Zhang, F. Damage evolution and spall failure in copper under complex shockwave loading conditions. J. Appl. Phys. 2020, 128, 055111. [Google Scholar] [CrossRef]

- Khomskaya, I.V.; Razorenov, S.V.; Garkushin, G.V.; Shorokhov, E.V.; Abdullina, D.N. Dynamic Strength of Submicrocrystalline and Nanocrystalline Copper Obtained by High-Strain-Rate Deformation. Phys. Met. Met. 2020, 121, 391–397. [Google Scholar] [CrossRef]

- Lee, T.; Nassiri, A.; Dittrich, T.; Vivek, A.; Daehn, G. Microstructure Development in Impact Welding of a Model System. SSRN Electron. J. 2019, 178, 203–206. [Google Scholar] [CrossRef]

- Kuzmin, S.V.; Lysak, V.I. Main regularities of transfer to waveless modes of joint formation in explosive welding. In Explosive Welding and Properties of Welded Joints; Inter-Departmental TransactionVolgograd Polytechnic Institute: Volgograd, Russia, 1991; pp. 29–38. [Google Scholar]

- Zhang, Y.; Babu, S.S.; Prothe, C.; Blakely, M.; Kwasegroch, J.; Laha, M.; Daehn, G.S. Application of high velocity impact welding at varied different length scales. J. Mater. Process. Technol. 2011, 211, 944–952. [Google Scholar] [CrossRef]

- Malakhov, A.Y.; Saikov, I.V.; Denisov, I.V.; Niyezbekov, N.N. AlMg6 to Titanium and AlMg6 to Stainless Steel Weld Interface Properties after Explosive Welding. Metals 2020, 10, 1500. [Google Scholar] [CrossRef]

- Carvalho, G.; Galvão, I.; Mendes, R.; Leal, R.; Loureiro, A. Aluminum-to-Steel Cladding by Explosive Welding. Metals 2020, 10, 1062. [Google Scholar] [CrossRef]

- Kapil, A.; Sharma, A. Magnetic pulse welding: An efficient and environmentally friendly multi-material joining technique. J. Clean. Prod. 2015, 100, 35–58. [Google Scholar] [CrossRef]

- Manikandan, P.; Lee, J.O.; Mizumachi, K.; Mori, A.R.; Raghukandan, K.; Hokamoto, K. Underwater explosive welding of thin tungsten foils and copper. J. Nucl. Mater. 2011, 418, 281–285. [Google Scholar] [CrossRef]

- Wang, K.; Wang, H.; Zhou, H.; Zheng, W.; Xu, A. Research Status and Prospect of Laser Impact Welding. Metals 2020, 10, 1444. [Google Scholar] [CrossRef]

- Ngaile, G.; Löhr, P.; Lowrie, J.; Modlin, R. Development of chemically produced hydrogen energy-based impact bonding process for dissimilar metals. J. Manuf. Process. 2014, 16, 518–526. [Google Scholar] [CrossRef]

- Vivek, A.; Hansen, S.R.; Benzing, J.; He, M.; Daehn, G. Impact Welding of Aluminum to Copper and Stainless Steel by Vaporizing Foil Actuator: Effect of Heat Treatment Cycles on Mechanical Properties and Microstructure. Met. Mater. Trans. A 2014, 46, 4548–4558. [Google Scholar] [CrossRef]

- Liu, B.; Palazotto, A.; Vivek, A.; Daehn, G.S. Impact welding of ultra-high-strength stainless steel in wrought vs. additively manufactured forms. Int. J. Adv. Manuf. Technol. 2019, 104, 4593–4604. [Google Scholar] [CrossRef]

- Nassiri, A.; Vivek, A.; Abke, T.; Liu, B.; Lee, T.; Daehn, G. Depiction of interfacial morphology in impact welded Ti/Cu bimetallic systems using smoothed particle hydrodynamics. Appl. Phys. Lett. 2017, 110, 231601. [Google Scholar] [CrossRef]

- Vivek, A.; Liu, B.; Hansen, S.R.; Daehn, G. Accessing collision welding process window for titanium/copper welds with vaporizing foil actuators and grooved targets. J. Mater. Process. Technol. 2014, 214, 1583–1589. [Google Scholar] [CrossRef]

- Gupta, V.; Lee, T.; Vivek, A.; Choi, K.S.; Mao, Y.; Sun, X.; Daehn, G. A robust process-structure model for predicting the joint interface structure in impact welding. J. Mater. Process. Technol. 2019, 264, 107–118. [Google Scholar] [CrossRef]

- Osher, J.E.; Barnes, G.; Chau, H.H.; Lee, R.S.; Lee, C.; Speer, R.; Weingart, R.S. Operating characteristics and modeling of the LLNL 100-kV electric gun. IEEE Trans. Plasma Sci. 1989, 17, 392–402. [Google Scholar] [CrossRef]

- Chau, H.H.; Dittbenner, G.; Hofer, W.W.; Honodel, C.A.; Steinberg, D.J.; Stroud, J.R.; Weingart, R.C.; Lee, R.S. Electric gun: A versatile tool for high-pressure shock-wave research. Rev. Sci. Instrum. 1980, 51, 1676–1681. [Google Scholar] [CrossRef]

- Hahn, M.; Tekkaya, A.E. Experimental and Numerical Analysis of the Influence of Burst Pressure Distribution on Rapid Free Sheet Forming by Vaporizing Foil Actuators. Metals 2020, 10, 845. [Google Scholar] [CrossRef]

- Sethi, G.; Myers, N.S.; German, R. An overview of dynamic compaction in powder metallurgy. Int. Mater. Rev. 2008, 53, 219–234. [Google Scholar] [CrossRef]

- Borg, J.P.; Vogler, T.J. Aspects of simulating the dynamic compaction of a granular ceramic. Model. Simul. Mater. Sci. Eng. 2009, 17, 45003. [Google Scholar] [CrossRef]

- Gluth, J.W.; Hall, C.A.; Vogler, T.J.; Grady, D.E. Dynamic Compaction of Tungsten Carbide Powder; No SAND2005-1510; Sandia National Laboratories: Albuquerque, NM, USA, 2005. [Google Scholar]

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons: Hoboken, NJ, USA, 1994. [Google Scholar]

- Kerley, G.I. The linear us-up relation in shock-wave physics. arXiv 2013, arXiv:1306.6916. [Google Scholar]

- Tarver, C.M.; Forbes, J.W.; Garcia, F.; Urtiew, P.A. Manganin Gauge and Reactive Flow Modeling Study of the Shock Initiation of PBX 9501. AIP Conf. Proc. 2002, 620, 1043–1046. [Google Scholar]

- Watson, R.W. Gauge for Determining Shock Pressures. Rev. Sci. Instrum. 1967, 38, 978–980. [Google Scholar] [CrossRef]

- Turley, W.D.; Stevens, G.D.; Hixson, R.S.; Cerreta, E.K.; Daykin, E.P.; Graeve, O.A.; La Lone, B.M.; Novitskaya, E.; Perez, C.; Rigg, P.A.; et al. Explosive-induced shock damage in copper and recompression of the damaged region. J. Appl. Phys. 2016, 120, 085904. [Google Scholar] [CrossRef] [Green Version]

- Remington, T.; Hahn, E.N.; Zhao, S.; Flanagan, R.; Mertens, J.; Sabbaghianrad, S.; Langdon, T.G.; Wehrenberg, C.; Maddox, B.; Swift, D.; et al. Spall strength dependence on grain size and strain rate in tantalum. Acta Mater. 2018, 158, 313–329. [Google Scholar] [CrossRef] [Green Version]

- Turley, W.L.; Daykin, E.P.; Hixson, R.S.; LaLone, B.M.; Perez, C., Jr.; Stevens, G.D.; Veeser, L.; Ceretta, E.; Gray, G.T.; Rigg, P.; et al. Copper Spall Experiments with Recompression Using HE (Copper Spall Soft Recovery Experiments); Rep No DOE/NV/25946-2108; Nevada Test Site/National: Nye County, NV, USA, 2014. [Google Scholar]

- Li, J.; Panton, B.; Mao, Y.; Vivek, A.; Daehn, G. High strength impact welding of NiTi and stainless steel wires. Smart Mater. Struct. 2020, 29, 105023. [Google Scholar] [CrossRef]

- Benzing, J.; He, M.; Vivek, A.; Taber, G.A.; Mills, M.; Daehn, G.S. A Microsample Tensile Test Application: Local Strength of Impact Welds between Sheet Metals. J. Mater. Eng. Perform. 2017, 26, 1229–1235. [Google Scholar] [CrossRef]

- Szecket, A.; Mayseless, M. The triggering and controlling of stable interfacial conditions in explosive welding. Mater. Sci. Eng. 1983, 57, 149–154. [Google Scholar] [CrossRef]

- Szecket, A.; Inal, O.T.; Vigueras, D.J.; Rocco, J. A wavy versus straight interface in the explosive welding of aluminum to steel. J. Vac. Sci. Technol. A 1985, 3, 2588–2593. [Google Scholar] [CrossRef]

| Projectile Configuration | Initial Tap Density (g/cm3) | Plunger Impact Speed (m/s) | Plunger Kinetic Energy (J) | Final Density (g/cm3) |

|---|---|---|---|---|

| 5 mm Al projectile | 1.32 | 953 | 777 | 3.33 |

| 5 mm composite projectile | 1.32 | 612 | 442 | 3.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prasad, K.S.; Mao, Y.; Vivek, A.; Niezgoda, S.R.; Daehn, G.S. A Rapid Throughput System for Shock and Impact Characterization: Design and Examples in Compaction, Spallation, and Impact Welding. J. Manuf. Mater. Process. 2020, 4, 116. https://doi.org/10.3390/jmmp4040116

Prasad KS, Mao Y, Vivek A, Niezgoda SR, Daehn GS. A Rapid Throughput System for Shock and Impact Characterization: Design and Examples in Compaction, Spallation, and Impact Welding. Journal of Manufacturing and Materials Processing. 2020; 4(4):116. https://doi.org/10.3390/jmmp4040116

Chicago/Turabian StylePrasad, K. Sajun, Yu Mao, Anupam Vivek, Stephen R. Niezgoda, and Glenn S. Daehn. 2020. "A Rapid Throughput System for Shock and Impact Characterization: Design and Examples in Compaction, Spallation, and Impact Welding" Journal of Manufacturing and Materials Processing 4, no. 4: 116. https://doi.org/10.3390/jmmp4040116