Influence of Powder Particle Morphology on the Static and Fatigue Properties of Laser Powder Bed-Fused Ti-6Al-4V Components

Abstract

:1. Introductions

2. Materials and Methods

2.1. Selection of Powder Lots

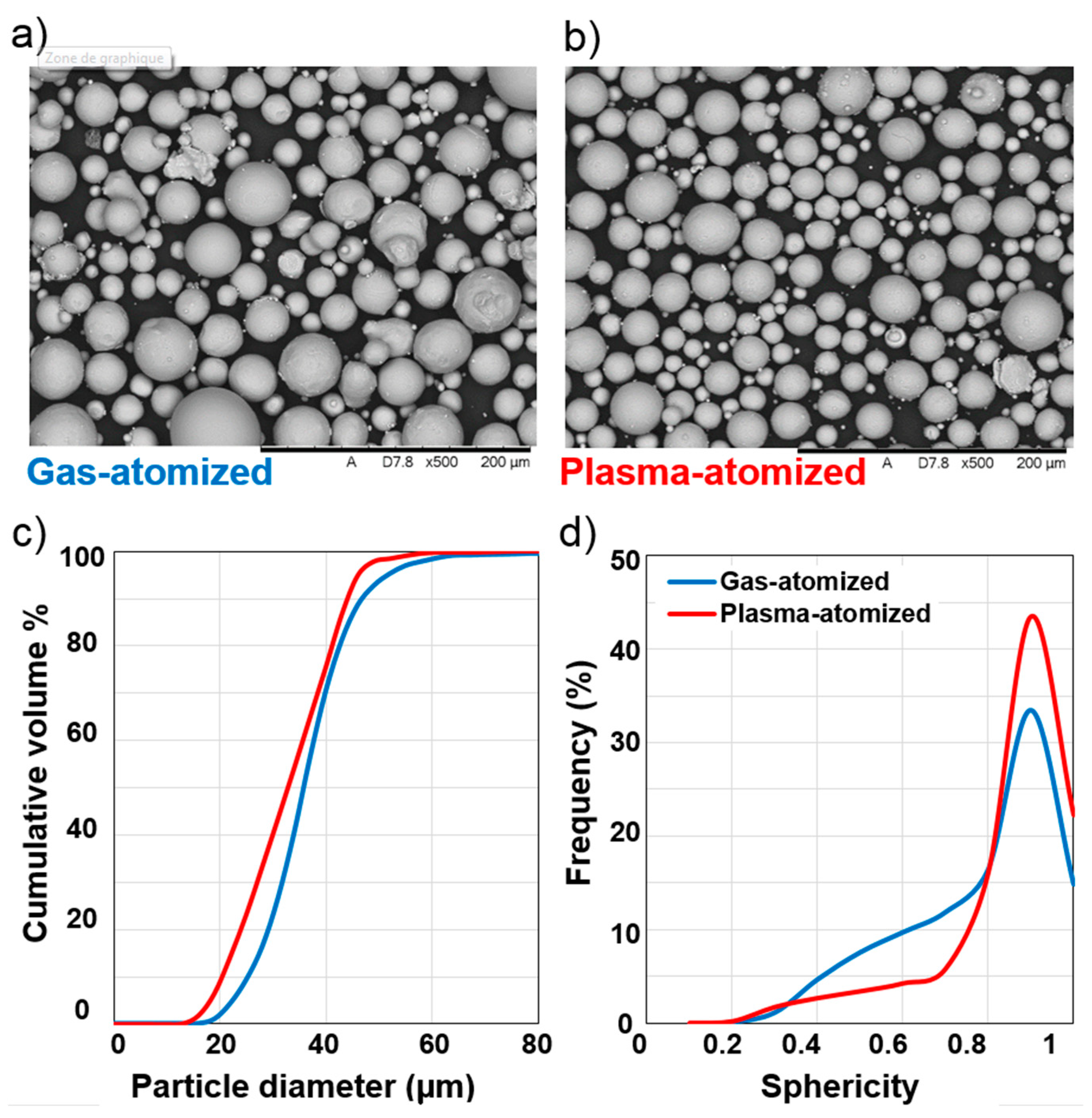

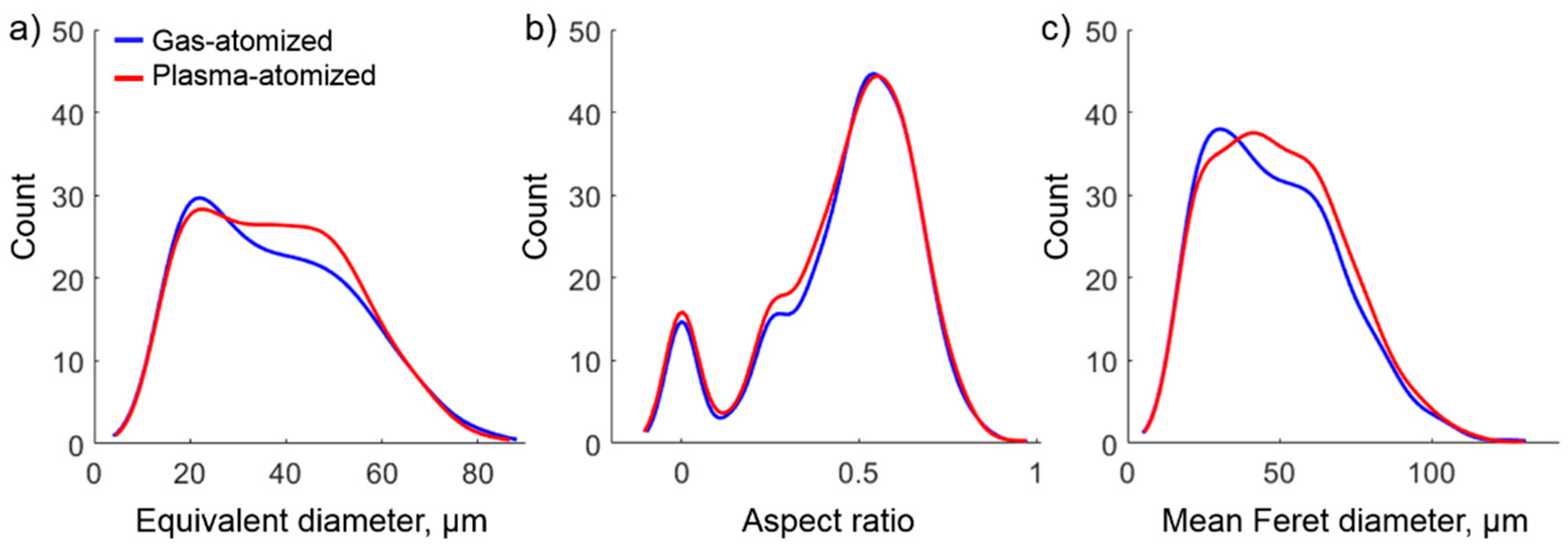

2.2. Powder Lot Characterization

2.3. Manufacture of LPBF Specimens

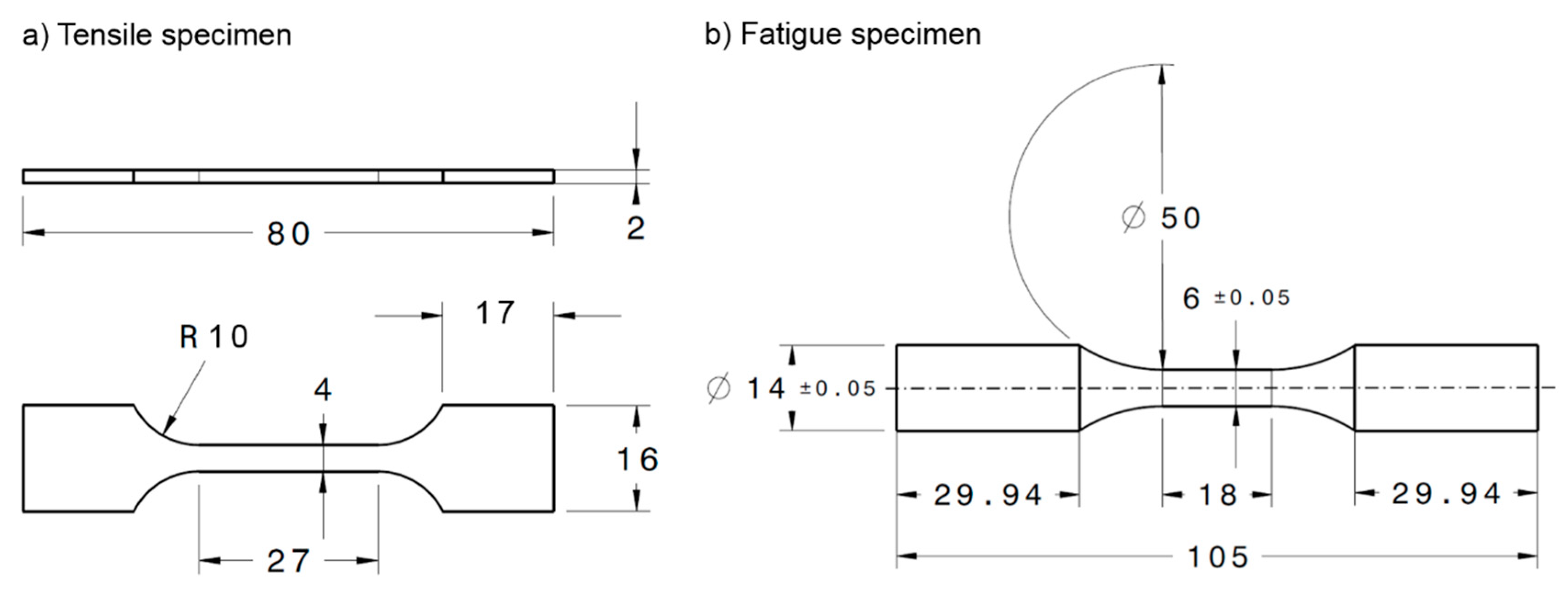

2.4. Characterization of Printed Specimens

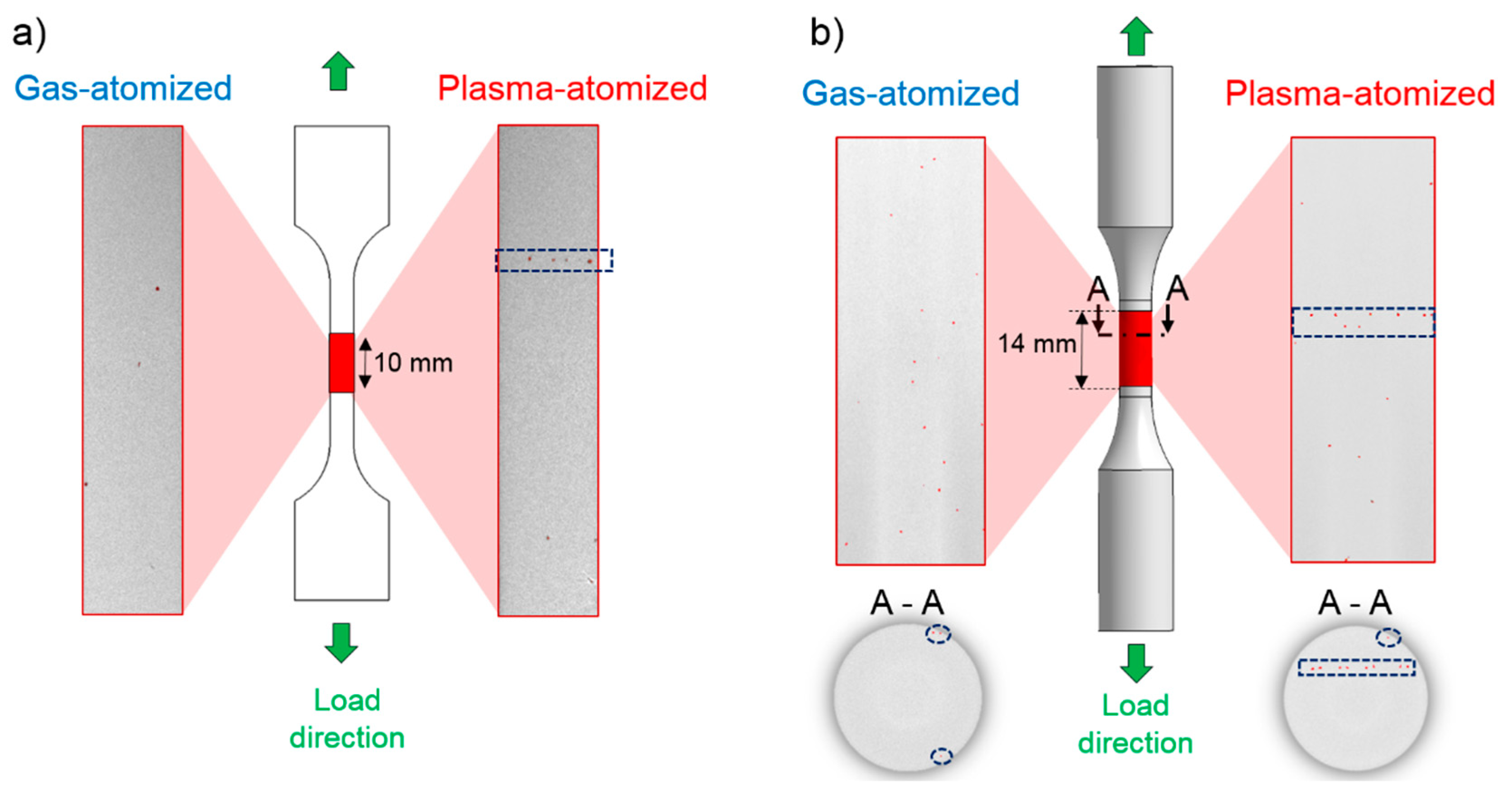

2.4.1. Processing-Induced Porosity

2.4.2. Tensile Properties

2.4.3. Fatigue Properties

2.4.4. Failure Analysis

2.4.5. Microstructure Analysis

3. Results

3.1. Particle Size Distribution and Morphology

3.2. Characterization of Printed Specimens

3.2.1. Internal Defects

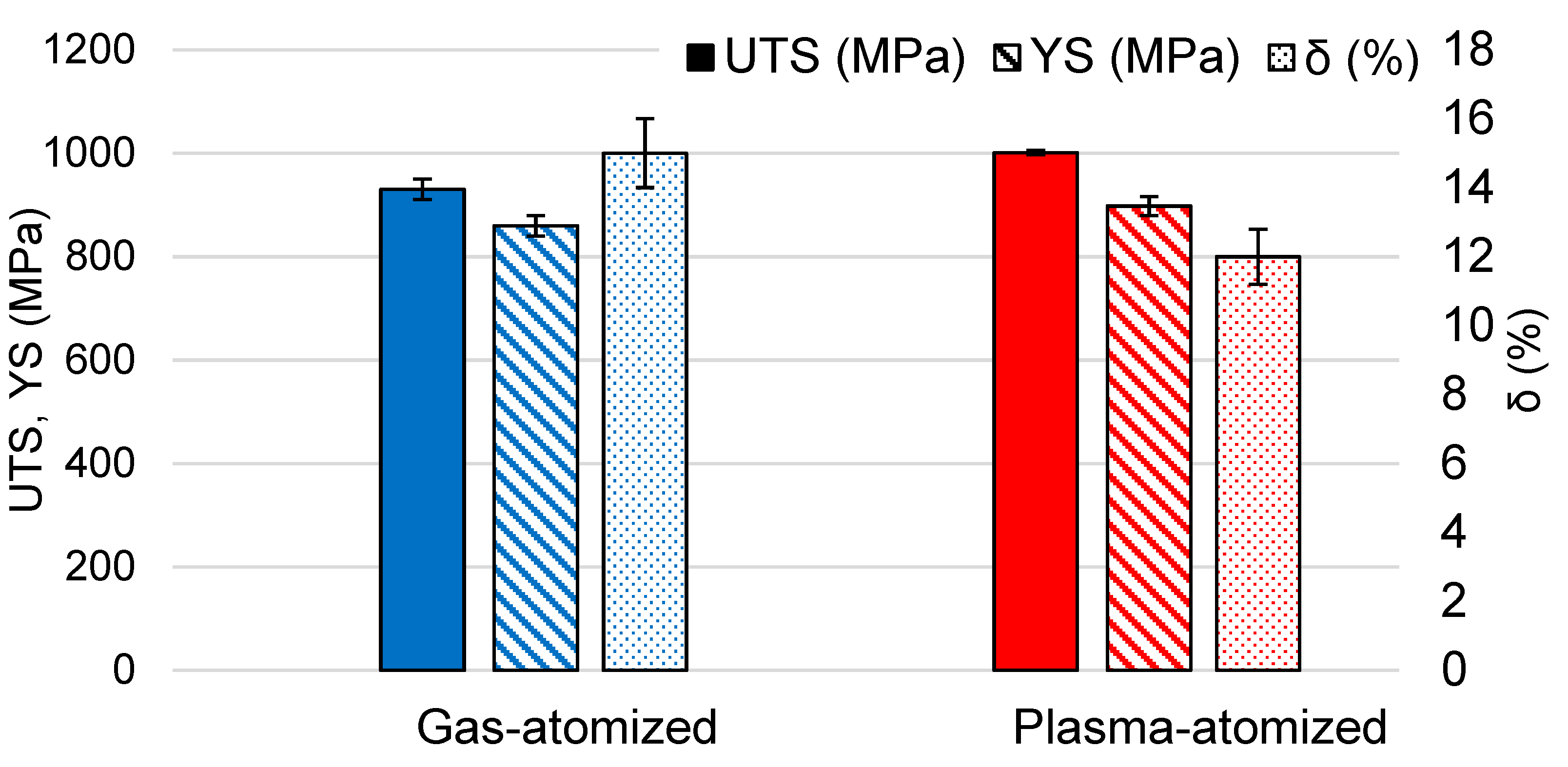

3.2.2. Tensile Properties

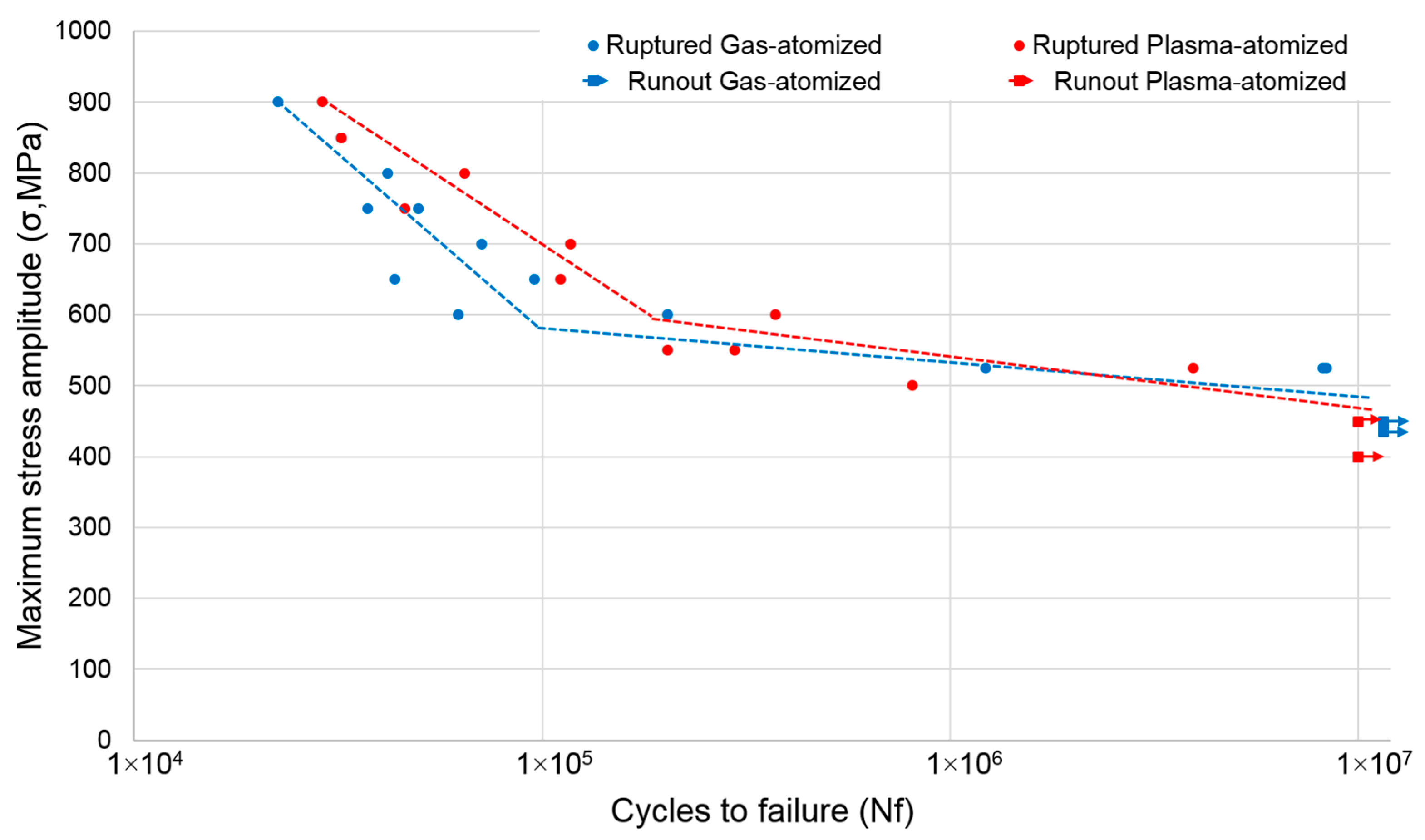

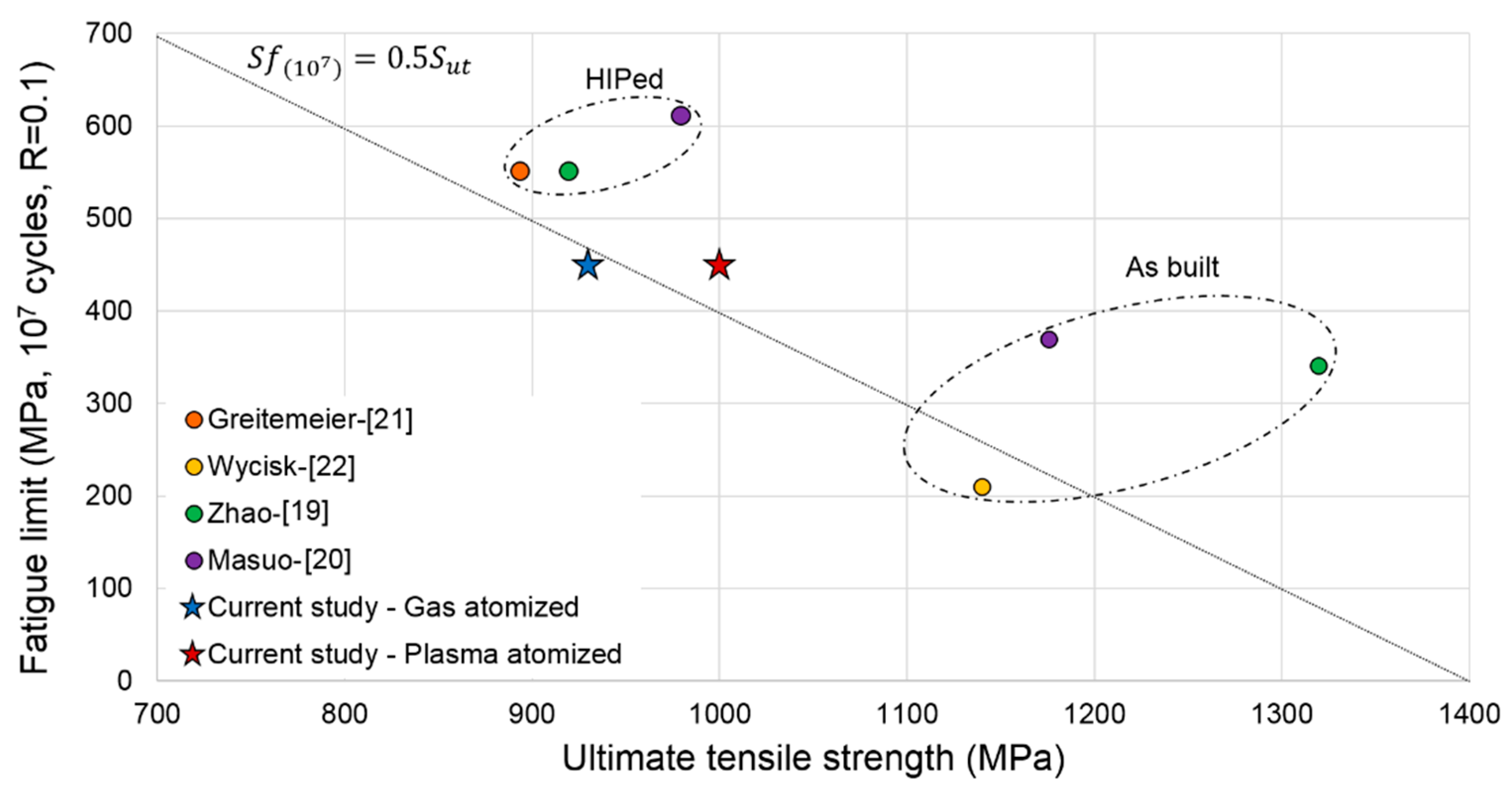

3.2.3. Fatigue Properties

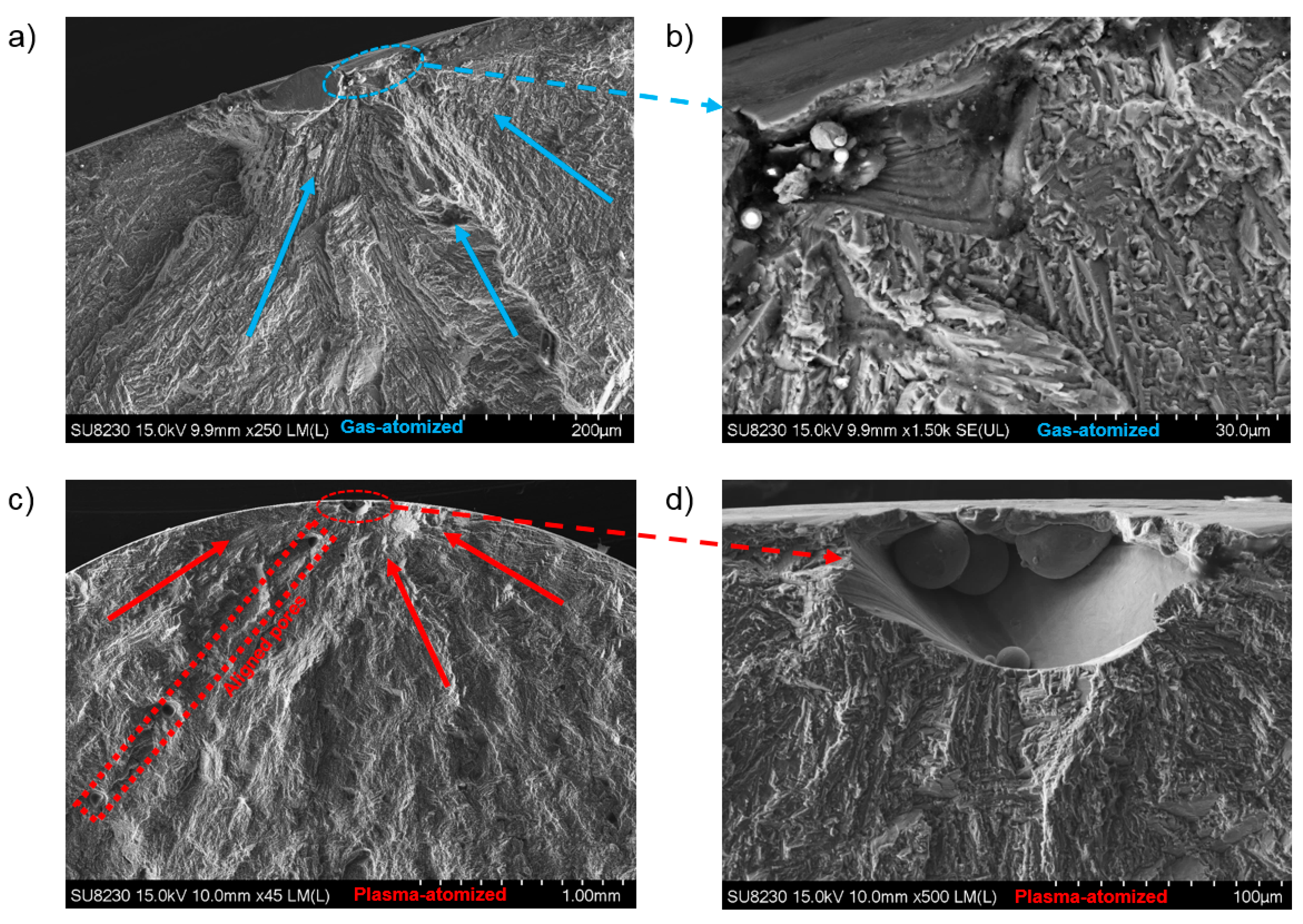

3.2.4. Fractographic Examination

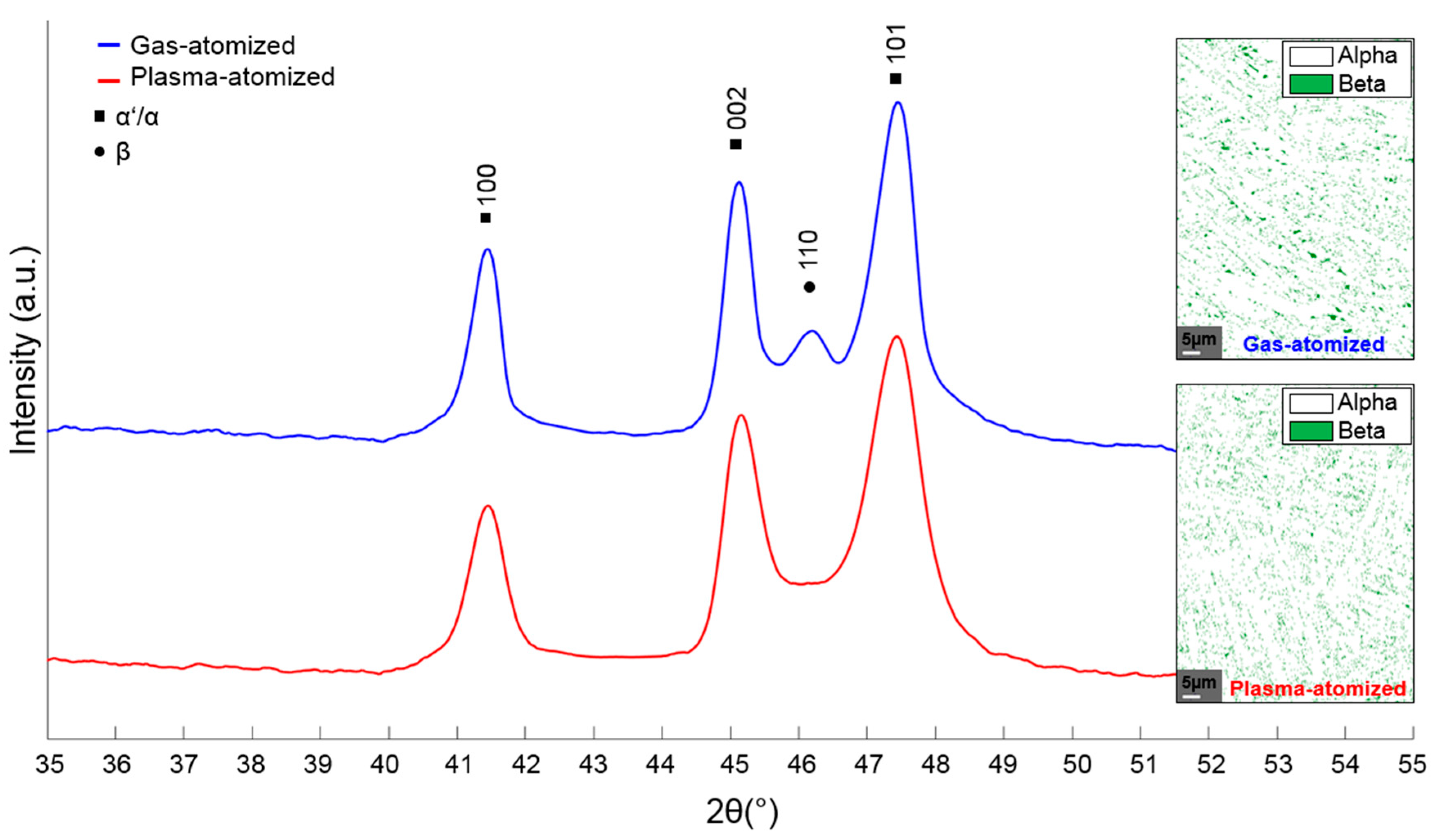

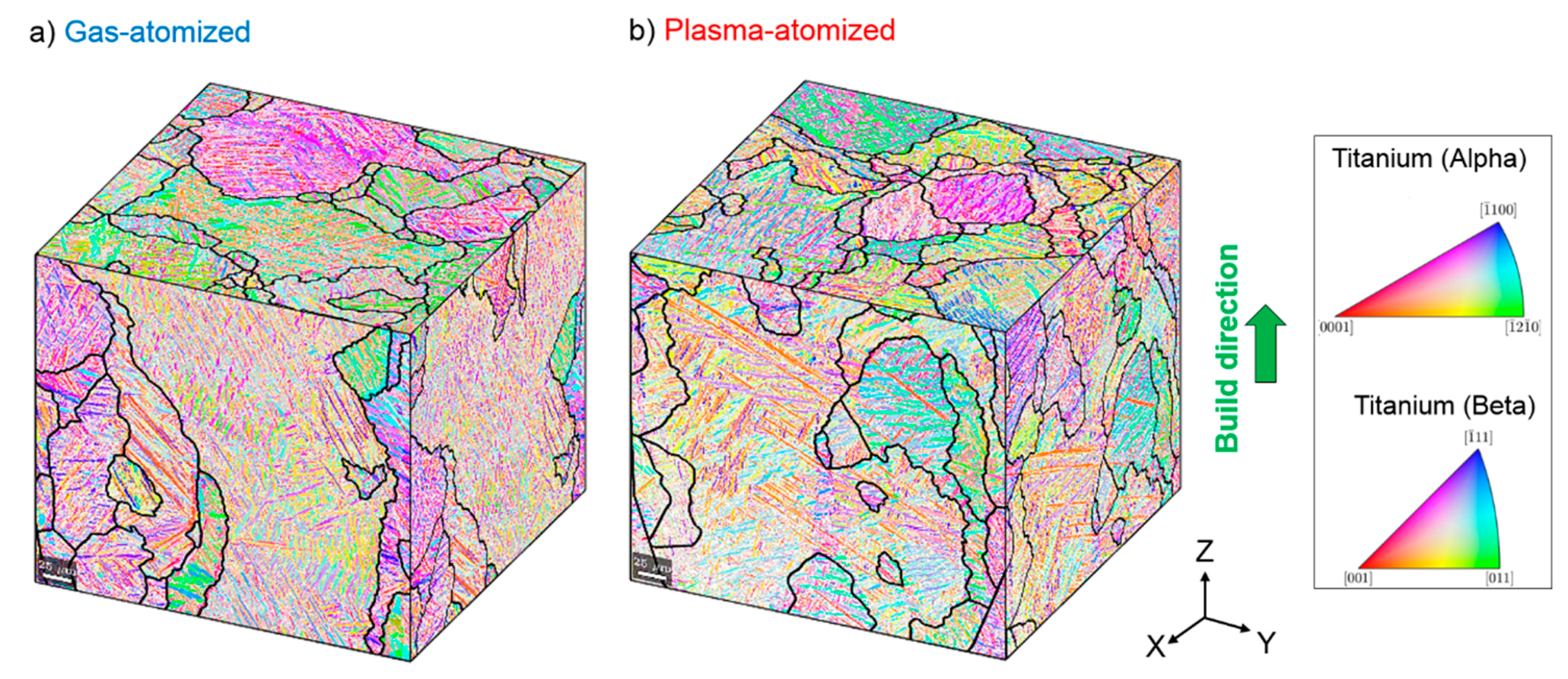

3.2.5. Microstructure Analysis

4. General Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Campbell, I.; Diegel, O.; Kowen, J.; Wohlers, T. Wohlers Report 2017 3D Printing and Additive Manufacturing State of the Industry: Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2017. [Google Scholar]

- Sun, S.; Brandt, M.; Easton, M. Powder bed fusion processes: An overview. In Laser Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2017; pp. 55–77. [Google Scholar]

- Seyda, V.; Herzog, D.; Emmelmann, C. Relationship between powder characteristics and part properties in laser beam melting of Ti–6Al–4V, and implications on quality. J. Laser Appl. 2017, 29, 22311. [Google Scholar]

- Chen, G.; Zhao, S.Y.; Tan, P.; Wang, J.; Xiang, C.S.; Tang, H.P. A comparative study of Ti-6Al-4V powders for additive manufacturing by gas atomization, plasma rotating electrode process and plasma atomization. Powder Technol. 2018, 333, 38–46. [Google Scholar] [CrossRef]

- Brika, S.E.; Letenneur, M.; Dion, C.A.; Brailovski, V. Influence of particle morphology and size distribution on the powder flowability and laser powder bed fusion manufacturability of Ti-6Al-4V alloy. Addit. Manuf. 2020, 31, 100929. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and control of powder properties for additive manufacturing. JOM 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Karapatis, N.P.; Egger, G.; Gygax, P.E.; Glardon, R. Optimization of powder layer density in selective laser sintering. In Proceedings of the 1999 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9–11 August 1999; pp. 255–263. [Google Scholar]

- Spierings, A.B.; Levy, G. Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades. In Proceedings of the Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 3–5 August 2009; pp. 342–353. [Google Scholar]

- Spierings, A.B.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 195–202. [Google Scholar]

- Bourell, D.; Leu, M.; Rosen, D. Roadmap for additive manufacturing-Identifying the future of freeform processing. The University of Texas at Austin, Laboratory for Freeform Fabrication. Adv. Manuf. Cent. 2009, 32, 11–15. [Google Scholar]

- Abd-Elghany, K.; Bourell, D.L. Property evaluation of 304L stainless steel fabricated by selective laser melting. Rapid Prototyp. J. 2012, 18, 420–428. [Google Scholar]

- Badrossamay, M.; Yasa, E.; van Vaerenbergh, J.; Kruth, J.-P. Improving productivity rate in SLM of commercial steel powders. Technol. Pap. Manuf. Eng. 2009, TP09PUB17, 1–13. [Google Scholar]

- Liu, B.; Wildman, R.; Tuck, C.; Ashcroft, I.; Hague, R. Investigation the Effect of Particle Size Distribution on Processing Parameters Optimisation in Selective Laser Melting Process. Available online: https://www.researchgate.net/publication/268365007_Investigaztion_the_effect_of_particle_size_distribution_on_processing_parameters_optimisation_in_selective_laser_melting_process (accessed on 8 November 2020).

- Seifi, M.; Gorelik, M.; Waller, J.; Hrabe, N.; Shamsaei, N.; Daniewicz, S.; Lewandowski, J.J. Progress towards metal additive manufacturing standardization to support qualification and certification. JOM 2017, 69, 439–455. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of materials qualification needs for metal additive manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef] [Green Version]

- Carrion, P.E.; Soltani-Tehrani, A.; Phan, N.; Shamsaei, N. Powder recycling effects on the tensile and fatigue behavior of additively manufactured Ti-6Al-4V parts. JOM 2019, 71, 963–973. [Google Scholar] [CrossRef] [Green Version]

- Gong, H.; Dilip, J.J.S.; Yang, L.; Teng, C.; Stucker, B. Influence of small particles inclusion on selective laser melting of Ti-6Al-4V powder. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Prague, Czech Republic, 21–22 September 2017; Volume 272, p. 12024. [Google Scholar]

- Pabst, W.; Gregorova, E. Characterization of particles and particle systems. ICT Prague 2007, 122, 122. [Google Scholar]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti--6Al--4V fabricated by selective laser melting and electron beam melting. Mater. Design 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue 2018, 117, 163–179. [Google Scholar] [CrossRef]

- Greitemeier, D.; Palm, F.; Syassen, F.; Melz, T. Fatigue performance of additive manufactured TiAl6V4 using electron and laser beam melting. Int. J. Fatigue 2017, 94, 211–217. [Google Scholar] [CrossRef]

- Wycisk, E.; Solbach, A.; Siddique, S.; Herzog, D.; Walther, F.; Emmelmann, C. Effects of defects in laser additive manufactured Ti-6Al-4V on fatigue properties. Phys. Procedia 2014, 56, 371–378. [Google Scholar] [CrossRef] [Green Version]

- He, J.; Li, D.; Jiang, W.; Ke, L.; Qin, G.; Ye, Y.; Qin, Q.; Qiu, D. The martensitic transformation and mechanical properties of Ti6Al4V prepared via selective laser melting. Materials 2019, 12, 321. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boley, C.D.; Mitchell, S.C.; Rubenchik, A.M.; Wu, S.S.Q. Metal powder absorptivity: Modeling and experiment. Appl. Opt. 2016, 55, 6496–6500. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Gusarov, A.V.; Belyaev, V.V. Morphology of random packing of micro-particles and its effect on the absorption of laser radiation during selective melting of powders. Int. J. Eng. Sci. 2020, 157, 103378. [Google Scholar] [CrossRef]

- Letenneur, M.; Brailovski, V.; Kreitcberg, A.; Paserin, V.; Bailon-Poujol, I. Laser powder bed fusion of water-atomized iron-based powders: Process optimization. J. Manuf. Mater. 2017, 1, 23. [Google Scholar] [CrossRef] [Green Version]

- Molaei, R.; Fatemi, A.; Phan, N. Significance of hot isostatic pressing (HIP) on multiaxial deformation and fatigue behaviors of additive manufactured Ti-6Al-4V including build orientation and surface roughness effects. Int. J. Fatigue 2018, 117, 352–370. [Google Scholar] [CrossRef]

- Letenneur, M.; Kreitcberg, A.; Brailovski, V. Optimization of Laser Powder Bed Fusion Processing Using a Combination of Melt Pool Modeling and Design of Experiment Approaches: Density Control. J. Manuf. Mater. Process. 2019, 3, 21. [Google Scholar] [CrossRef] [Green Version]

| Element | Gas-Atomized | Plasma-Atomized | ASTM B348 | Test Method |

|---|---|---|---|---|

| C | 0.01 | 0.02 | 0.08 (max) | ASTM E1941 |

| O | 0.11 | 0.11 | 0.13 (max) | ASTM E1409 |

| N | 0.020 | 0.020 | 0.030 (max) | ASTM E1409 |

| H | 0.0030 | 0.0080 | 0.01250 (max) | ASTM E1447 |

| Fe | 0.190 | 0.180 | 0.250 (max) | ASTM E2371 |

| Al | 6.30 | 6.26 | 5.50–6.50 (range) | ASTM E2371 |

| V | 4.10 | 3.85 | 3.50–4.50 (range) | ASTM E2371 |

| Ti | Balance | Balance | Balance | ASTM E2371 |

| Powder Characteristics | Gas-Atomized | Plasma-Atomized | |

|---|---|---|---|

| Particle size distribution | D10 (μm) | 25.3 | 20.3 |

| D50 (μm) | 35.8 | 32.7 | |

| D90 (μm) | 46.4 | 43.9 | |

| Span (3) | 0.59 | 0.72 | |

| Sphericity | D10 | 0.46 | 0.55 |

| D50 | 0.79 | 0.84 | |

| D90 | 0.91 | 0.93 | |

| Mean | 0.73 | 0.79 | |

| Std deviation | 0.18 | 0.16 | |

| Span (3) | 0.57 | 0.45 |

| Gas-Atomized | Plasma-Atomized | Diff (%) | p-Value | |||||

|---|---|---|---|---|---|---|---|---|

| UTS (MPa) | 930 | ± | 20 | 1001 | ± | 4 | 7.1 | 0.0038 |

| YS (MPa) | 860 | ± | 20 | 898 | ± | 18 | 4.2 | 0.0706 |

| δ (%) | 15 | ± | 1 | 12 | ± | 0.8 | 3 | 0.01 |

| E (GPa) | 114 | ± | 9 | 113 | ± | 1 | 0.9 | 0.85762 |

| Gas Atomized (µm) | Plasma Atomized (µm) | p-Value | |||||

|---|---|---|---|---|---|---|---|

| Average | Min | Max | Average | Min | Max | ||

| Parallel to build direction (XZ) | 111.3 | 21.3 | 502.4 | 116.9 | 29.2 | 467.7 | 0.85 |

| Perpendicular to build direction (XY) | 79.8 | 19.4 | 272.6 | 75.6 | 19.6 | 252.9 | 0.74 |

| p-value | 0.02 | 0.03 | |||||

| Gas-Atomized | Plasma-Atomized | Diff (%) | |

|---|---|---|---|

| Rheological properties | |||

| Specific energy (mJ/g) | 2.85 ±0.03 | 1.73 ± 0.06 | 39.3 |

| Cohesion coeff. (kPa) | 0.39 ± 0.08 | 0.28 ± 0.01 | 28.2 |

| Powder bed density (g/cm3) | 2.602 ± 0.03 | 2.743 ± 0.004 | 5.1 |

| Normalized average Ra | 0.99 ± 0.01 | 0.92 ± 0.01 | 7.1 |

| Average difference in % between the printed and nominal dimension | |||

| Walls | −13.4 | −12.2 | 8.9 |

| Sinks | −11.5 | −10.1 | 12.1 |

| Gaps | +16.8 | +14.9 | 11.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brika, S.E.; Brailovski, V. Influence of Powder Particle Morphology on the Static and Fatigue Properties of Laser Powder Bed-Fused Ti-6Al-4V Components. J. Manuf. Mater. Process. 2020, 4, 107. https://doi.org/10.3390/jmmp4040107

Brika SE, Brailovski V. Influence of Powder Particle Morphology on the Static and Fatigue Properties of Laser Powder Bed-Fused Ti-6Al-4V Components. Journal of Manufacturing and Materials Processing. 2020; 4(4):107. https://doi.org/10.3390/jmmp4040107

Chicago/Turabian StyleBrika, Salah Eddine, and Vladimir Brailovski. 2020. "Influence of Powder Particle Morphology on the Static and Fatigue Properties of Laser Powder Bed-Fused Ti-6Al-4V Components" Journal of Manufacturing and Materials Processing 4, no. 4: 107. https://doi.org/10.3390/jmmp4040107

APA StyleBrika, S. E., & Brailovski, V. (2020). Influence of Powder Particle Morphology on the Static and Fatigue Properties of Laser Powder Bed-Fused Ti-6Al-4V Components. Journal of Manufacturing and Materials Processing, 4(4), 107. https://doi.org/10.3390/jmmp4040107