Multi-Objective Optimization of Turning Operation of Stainless Steel Using a Hybrid Whale Optimization Algorithm

Abstract

1. Introduction

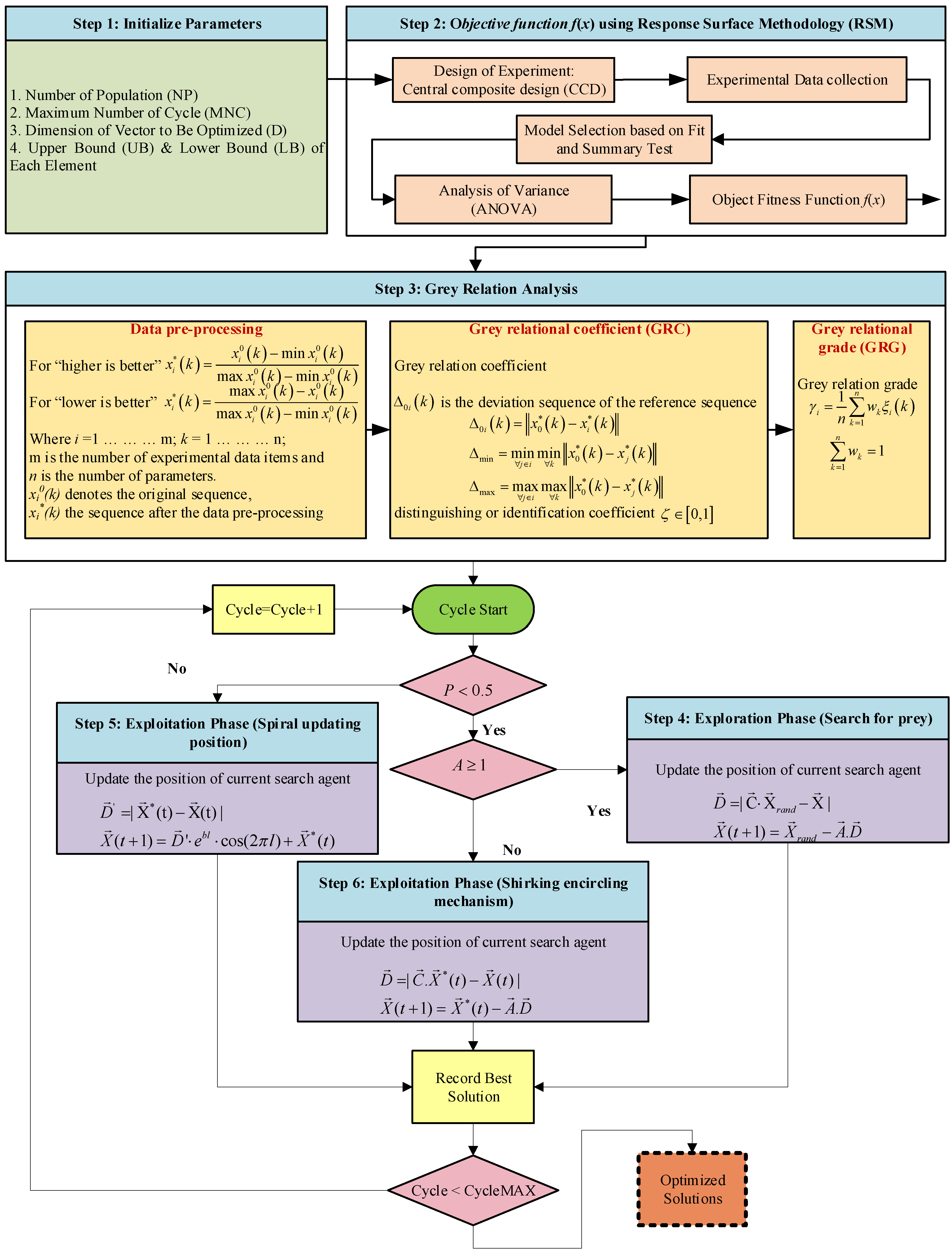

2. Development of the Hybrid Algorithm

3. Methodology

3.1. Design of Experiment

3.2. Workpiece Material and Tool Geometry

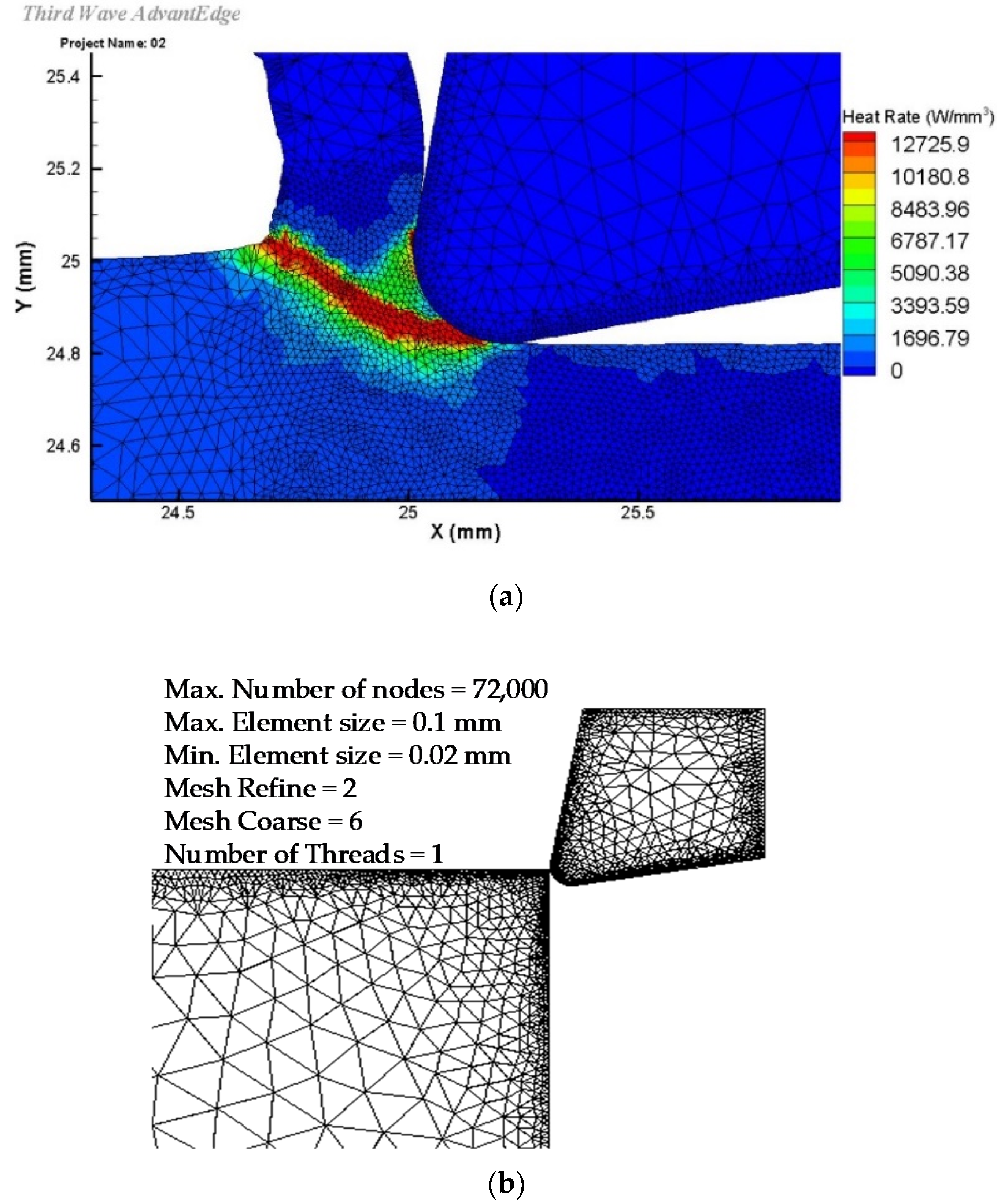

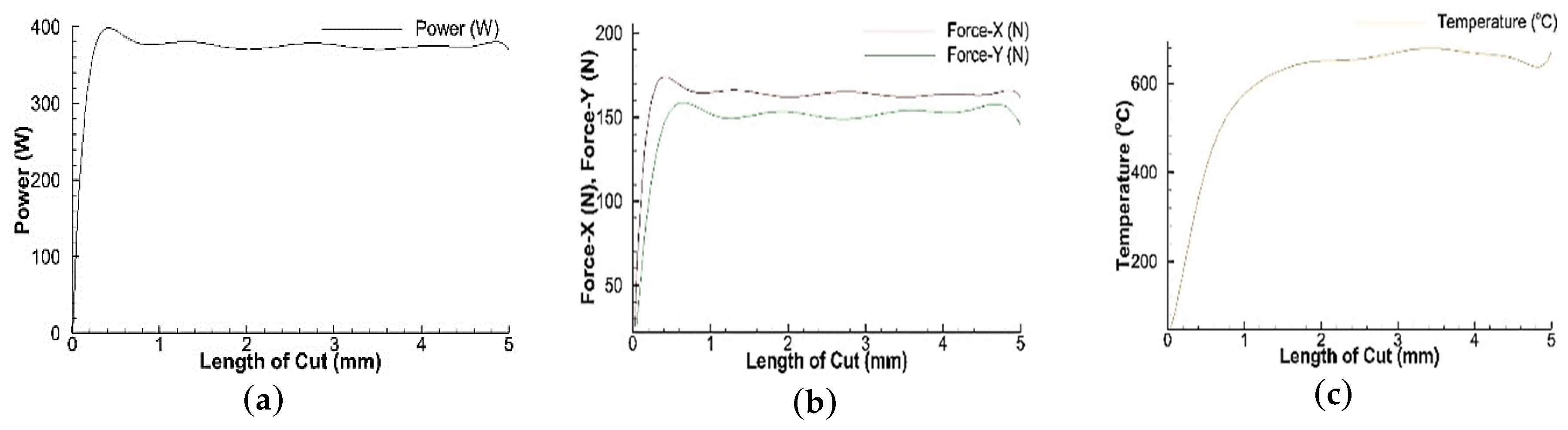

3.3. Output Parameters and Simulation Conditions

4. Results and Discussion

4.1. Results of the Output Parametres

4.2. Generating Objective Functions

4.3. Optimization Process

4.4. Optimization Results

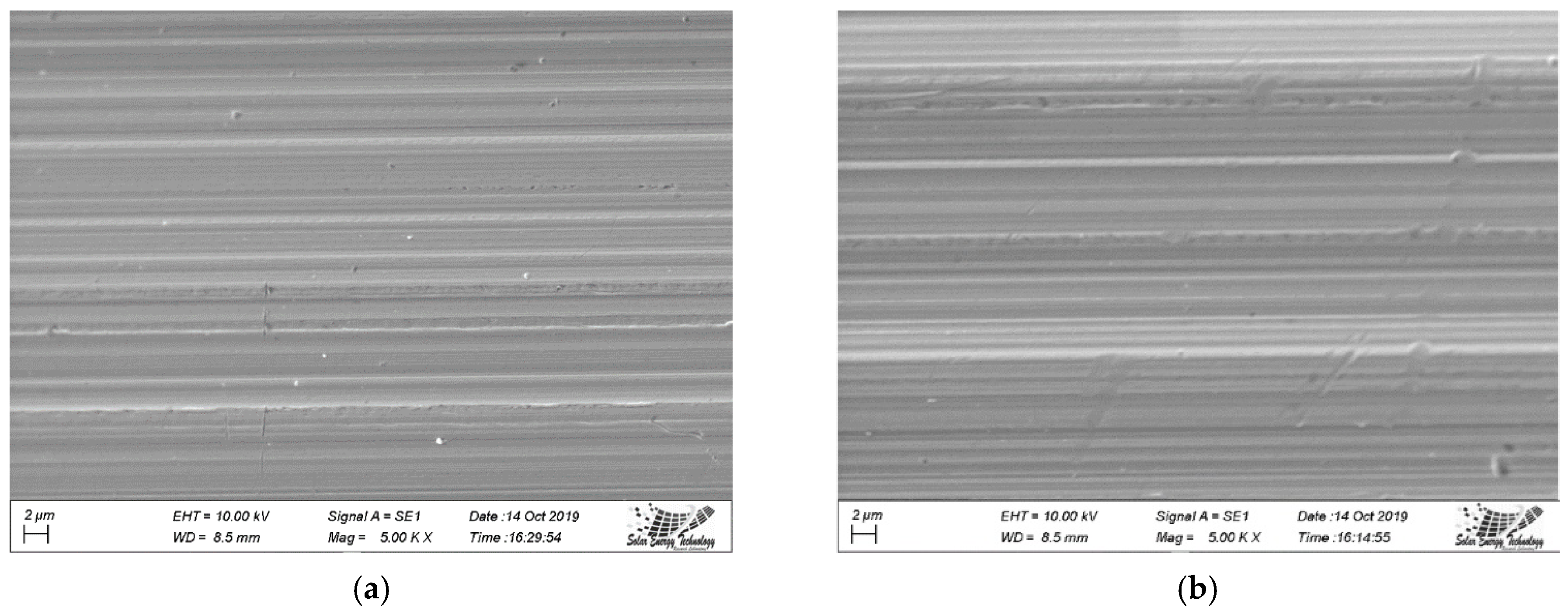

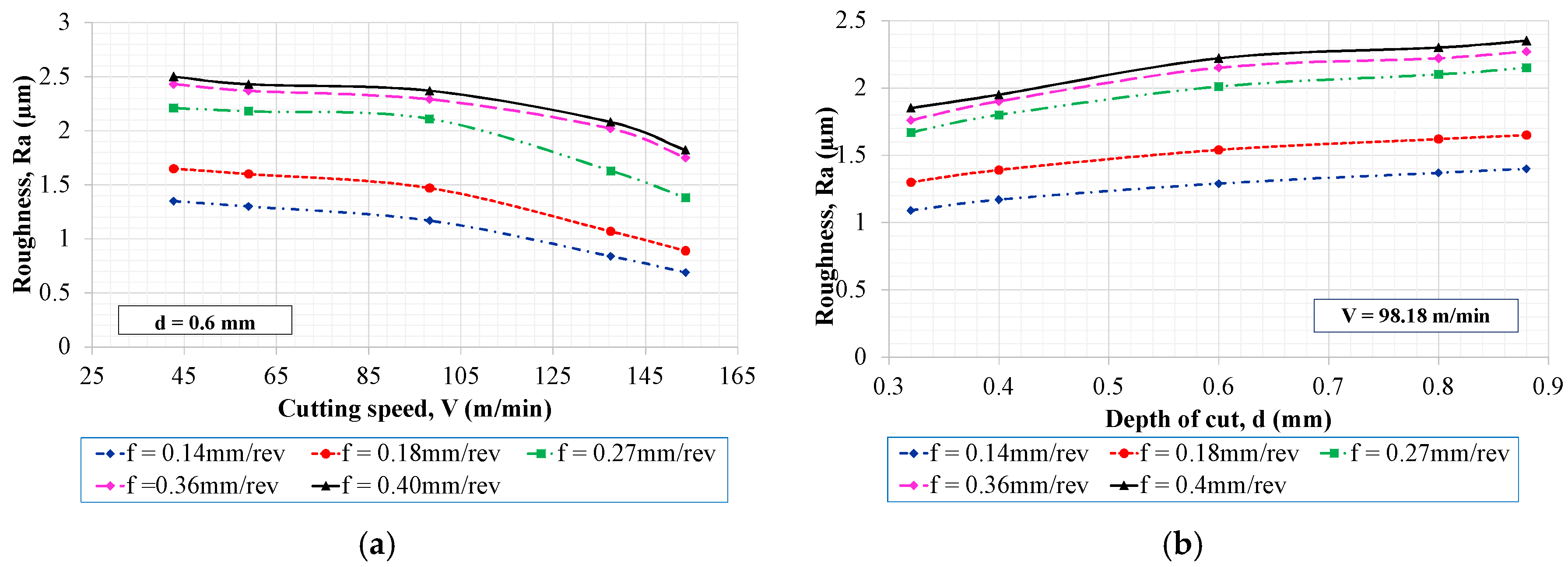

4.5. Effect of Cutting Parameters on Surface Roughness

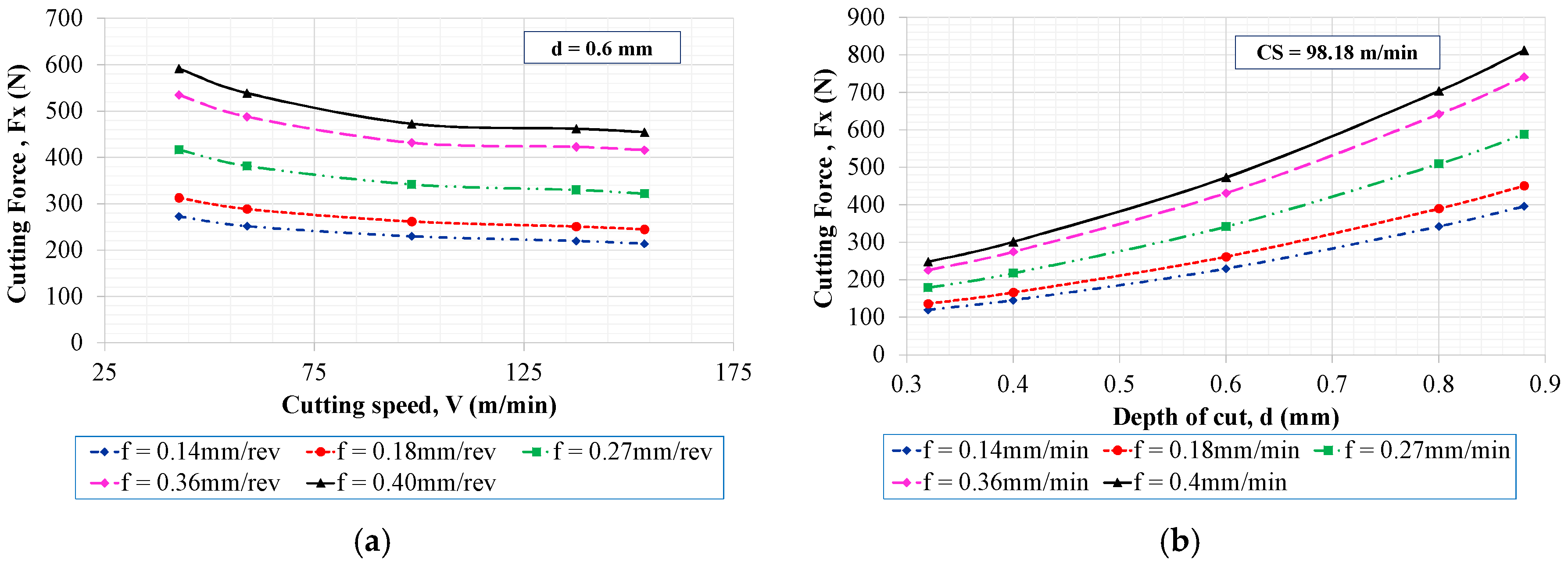

4.6. Effect on Cutting Force (X Direction)

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| MRR | Metal Removal Rate (mm3/min) |

| PTT | Peak Tool Temperature (°C) |

| H | Heat rate () |

| P | Power (W) |

| Fx | Force in x direction (N) |

| Fy | Force in y direction (N) |

| f | Feed rate (mm/rev) |

| V | Cutting Speed () |

| d | Depth of Cut (mm) |

References

- Dikshit, M.K.; Puri, A.B.; Maity, A.; Banerjee, A.J. Analysis of Cutting Forces and Optimization of Cutting Parameters in High Speed Ball-end Milling Using Response Surface Methodology and Genetic Algorithm. Procedia Mater. Sci. 2014, 5, 1623–1632. [Google Scholar] [CrossRef]

- Abhang, L.; Hameedullah, M. Optimization of Machining Parameters in Steel Turning Operation by Taguchi Method. Procedia Eng. 2012, 38, 40–48. [Google Scholar] [CrossRef]

- Mukherjee, I.; Ray, P.K. A review of optimization techniques in metal cutting processes. Comput. Ind. Eng. 2006, 50, 15–34. [Google Scholar] [CrossRef]

- Rao, R.V.; Pawar, P.J. Parameter optimization of a multi-pass milling process using non-traditional optimization algorithms. Appl. Soft. Comput. 2010, 10, 445–456. [Google Scholar] [CrossRef]

- Mirjalili, S. Dragonfly algorithm: A new meta-heuristic optimization technique for solving single-objective, discrete, and multi-objective problems. Neural Comput. Appl. 2015, 27, 1053–1073. [Google Scholar] [CrossRef]

- Habib, M.A.; Patwari, M.A.; Jabed, A.; Bhuiyan, M.N. Optimization of Surface Roughness in Drilling of GFRP Composite Using Harmony Search Algorithm. Int. J. Mech. Eng. Robot. Res. 2016, 5, 311–316. [Google Scholar] [CrossRef]

- Solarte-Pardo, B.; Hidalgo, D.; Yeh, S. Cutting Insert and Parameter Optimization for Turning Based on Artificial Neural Networks and a Genetic Algorithm. Appl. Sci. 2019, 9, 479. [Google Scholar] [CrossRef]

- Petkovic, D.; Radovanovic, M. Using Genetic Algorithms for Optimization of Turning Machining Process. J. Eng. Stud. Res. 2016, 19, 47–55. [Google Scholar] [CrossRef]

- Teti, R.; D’Addona, D. Genetic Algorithm-based Optimization of Cutting Parameters in Turning Processes. Procedia CIRP 2013, 7, 323–328. [Google Scholar] [CrossRef]

- Sangwan, K.S.; Kant, G. Optimization of Machining Parameters for Improving Energy Efficiency using Integrated Response Surface Methodology and Genetic Algorithm Approach. Procedia CIRP 2017, 61, 517–522. [Google Scholar] [CrossRef]

- Prasad, D.V.V.K.; Bharathi, K. Multi-Objective Optimization of Milling Parameters for Machining Cast Iron on Machining Centre. Res. J. Eng. Sci. 2013, 2, 2278–9472. [Google Scholar]

- Yan, J.; Li, L. Multi-objective optimization of milling parameters—The trade-offs between energy, production rate and cutting quality. J. Clean. Prod. 2013, 52, 462–471. [Google Scholar] [CrossRef]

- Dhabale, R.; Jatti, V.S.; Singh, T.P. Multi-objective Optimization of Turning Process During Machining of AlMg1SiCu Using Non-dominated Sorted Genetic Algorithm. Procedia Mater. Sci. 2014, 6, 961–966. [Google Scholar] [CrossRef][Green Version]

- Deng, J. Introduction to grey system. J. Grey Syst. 1989, 1, 1–24. [Google Scholar]

- Gupta, M.; Kumar, S. Multi-objective optimization of cutting parameters in turning using grey relational analysis. Int. J. Ind. Eng. Comput. 2013, 4, 547–558. [Google Scholar] [CrossRef]

- Ramu, I.; Srinivas, P.; Vekatesh, K. Taguchi based grey relational analysis for optimization of machining parameters of CNC turning steel 316. IOP Conf. Ser. Mater. Sci. Eng. 2018, 377, 012078. [Google Scholar] [CrossRef]

- Yang, W.H.; Tarng, Y.S. Design optimization of cutting parameters for turning operations based on the Taguchi method. J. Mater. Process. Technol. 1998, 84, 122–129. [Google Scholar] [CrossRef]

- Mirjalili, S.; Lewis, A. The Whale Optimization Algorithm. Adv. Eng. Softw. 2016, 95, 51–67. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Kundrak, J.; Markopoulos, A.; Manolakos, D.E. On the finite element modelling of high speed hard turning. Int. J. Adv. Manuf. Technol. 2007, 38, 441–446. [Google Scholar] [CrossRef]

- Qian, L.; Hossan, M.R. Effect on cutting force in turning hardened tool steels with cubic boron nitride inserts. J. Mater. Process. Technol. 2007, 191, 274–278. [Google Scholar] [CrossRef]

- Jiang, F.; Li, J.; Sun, J.; Zhang, S.; Wang, Z.; Yan, L. Al7050-T7451 turning simulation based on the modified power-law material model. Int. J. Adv. Manuf. Technol. 2009, 48, 871–880. [Google Scholar] [CrossRef]

- Thakare, A.; Nordgren, A. Experimental Study and Modeling of Steady State Temperature Distributions in Coated Cemented Carbide Tools in Turning. Procedia CIRP 2015, 31, 234–239. [Google Scholar] [CrossRef]

- Yousefi, S.; Zohoor, M. Effect of cutting parameters on the dimensional accuracy and surface finish in the hard turning of MDN250 steel with cubic boron nitride tool, for developing a knowledged base expert system. Int. J. Mech. Mater. Eng. 2019, 14, 1. [Google Scholar] [CrossRef]

- Danieel, C.; Rao, K.V.; Olson, W.W.; Sutherland, J.W. Effect of cutting fluid properties and application variables on heat transfer in turning and boring operations. Proc. Jpn. USA Symp. Flex. Autom. 1966, 7, 1119–1126. [Google Scholar]

- Makadia, A.J.; Nanavati, J.I. Optimisation of machining parameters for turning operations based on response surface methodology. Meas. J. Int. Meas. Confed. 2013, 46, 1521–1529. [Google Scholar] [CrossRef]

- Kumar, N.S.; Shetty, A.; Shetty, A.; Ananth, K.; Shetty, H. Effect of Spindle Speed and Feed Rate on Surface Roughness of Carbon Steels in CNC Turning. Procedia Eng. 2012, 38, 691–697. [Google Scholar] [CrossRef]

- Ndaruhadi, P.Y.M.W.; Sharif, S.; Noordin, M.Y.; Kurniawan, D. Effect of Cutting Parameters on Surface Roughness in Turning of Bone. Adv. Mater. Res. 2014, 845, 708–712. [Google Scholar] [CrossRef]

- Sumardiyanto, D.; Susilowati, S.E.; Cahyo, A. Effect of Cutting Parameter on Surface Roughness Carbon Steel S45C. J. Mech. Eng. Autom. 2018, 8, 1–6. [Google Scholar]

- Lalwani, D.I.; Mehta, N.K.; Jain, P.K. Experimental investigations of cutting parameters influence on cutting forces and surface roughness in finish hard turning of MDN250 steel. J. Mater. Process. Technol. 2008, 206, 167–179. [Google Scholar] [CrossRef]

- Huang, Y.; Liang, S.Y. Modeling of Cutting Forces under Hard Turning Conditions Considering Tool Wear Effect. J. Manuf. Sci. Eng. 2005, 127, 262–270. [Google Scholar] [CrossRef]

- Sivaraman, V.; Sankaran, S.; Vijayaraghavan, L. The Effect of Cutting Parameters on Cutting Force during Turning Multiphase Microalloyed Steel. Procedia CIRP 2012, 4, 157–160. [Google Scholar] [CrossRef]

| Parameters | |||||

|---|---|---|---|---|---|

| V | 42.64 | 58.91 | 98.18 | 137.45 | 153.71 |

| f | 0.14 | 0.18 | 0.27 | 0.36 | 0.4 |

| d | 0.32 | 0.4 | 0.6 | 0.8 | 0.88 |

| C | Cr | Mn | Ni | P | S | Si |

|---|---|---|---|---|---|---|

| 0.03 | 19 | 2 | 10 | 0.045 | 0.03 | 0.75 |

| Hardness, Brinell | Hardness, Rockwell B | Tensile Strength, Ultimate | Tensile Strength, Yield | Elongation at Break | Modulus of Elasticity | Charpy Impact | Shear Modulus |

|---|---|---|---|---|---|---|---|

| 123 | 70 | 505 MPa | 215 MPa | 70% | 193–200 GPa | 325 J | 86 GPa |

| No. | Input Parameters | Output Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| V | f | d | MRR | PTT, | Heat Rate, H | Power, P | Force X, | Force Y, | Roughness, | |

| 1 | 58.90 | 0.18 | 0.40 | 4048.60 | 540 | 5453 | 170 | 175.0 | 150.0 | 1.48 |

| 2 | 137.40 | 0.18 | 0.40 | 9993.08 | 675 | 12,726 | 400 | 178.0 | 160.0 | 0.95 |

| 3 | 58.90 | 0.36 | 0.40 | 8352.32 | 682 | 2727 | 282 | 290.0 | 190.0 | 2.24 |

| 4 | 137.40 | 0.36 | 0.40 | 19,672.08 | 820 | 6363 | 660 | 286.0 | 185.0 | 1.76 |

| 5 | 58.90 | 0.18 | 0.80 | 8386.32 | 720 | 5541 | 440 | 440.0 | 355.0 | 1.65 |

| 6 | 137.40 | 0.18 | 0.80 | 19,722.08 | 860 | 12,930 | 1000 | 440.0 | 355.0 | 1.08 |

| 7 | 58.90 | 0.36 | 0.80 | 16,794.64 | 830 | 2771 | 730 | 740.0 | 430.0 | 2.57 |

| 8 | 137.40 | 0.36 | 0.80 | 39,686.16 | 970 | 6465 | 1510 | 690.0 | 385.0 | 2.07 |

| 9 | 42.60 | 0.27 | 0.60 | 6999.58 | 740 | 2674 | 320 | 445.0 | 300.0 | 2.21 |

| 10 | 153.70 | 0.27 | 0.60 | 24,981.25 | 830 | 9640 | 850 | 330.0 | 235.0 | 1.38 |

| 11 | 98.20 | 0.14 | 0.60 | 8146.70 | 675 | 11,875 | 360 | 220.0 | 210.0 | 1.17 |

| 12 | 98.20 | 0.40 | 0.60 | 23,662.00 | 800 | 4156 | 790 | 470.0 | 279.0 | 2.52 |

| 13 | 98.20 | 0.27 | 0.32 | 8682.32 | 685 | 6010 | 320 | 190.0 | 142.0 | 1.72 |

| 14 | 98.20 | 0.27 | 0.88 | 23,426.38 | 700 | 6157 | 870 | 525.0 | 390.0 | 2.08 |

| 15 | 98.20 | 0.27 | 0.60 | 15,704.35 | 690 | 6062 | 570 | 345.0 | 262.0 | 2.11 |

| 16 | 98.20 | 0.27 | 0.60 | 15,704.35 | 690 | 6062 | 570 | 345.0 | 262.0 | 2.11 |

| 17 | 98.20 | 0.27 | 0.60 | 15,704.35 | 690 | 6062 | 570 | 345.0 | 262.0 | 2.11 |

| 18 | 98.20 | 0.27 | 0.60 | 15,704.35 | 690 | 6062 | 570 | 345.0 | 262.0 | 2.11 |

| 19 | 98.20 | 0.27 | 0.60 | 15,704.35 | 690 | 6062 | 570 | 345.0 | 262.0 | 2.11 |

| 20 | 98.20 | 0.27 | 0.60 | 15,704.35 | 690 | 6062 | 570 | 345.0 | 262.0 | 2.11 |

| No. | Output Parameters | ||||||

|---|---|---|---|---|---|---|---|

| MRR | H | P | |||||

| 1 | 4029.84 | 576.6 | 5435.1 | 173.7 | 181.8 | 152.7 | 1.48 |

| 2 | 9920.53 | 693.2 | 12,938.1 | 401.1 | 175.0 | 155.4 | 0.95 |

| 3 | 8318.46 | 711.6 | 2686.8 | 301.0 | 308.3 | 196.5 | 2.24 |

| 4 | 20,052.02 | 829.9 | 6394.5 | 661.3 | 282.2 | 180.9 | 1.76 |

| 5 | 8259.00 | 714.9 | 5525.2 | 430.7 | 434.4 | 353.6 | 1.65 |

| 6 | 19,878.37 | 828.3 | 13,151.1 | 919.1 | 403.1 | 334.2 | 1.08 |

| 7 | 16,982.40 | 812.2 | 2731.3 | 714.2 | 733.0 | 431.1 | 2.57 |

| 8 | 40,023.97 | 912.9 | 6499.8 | 1449.9 | 646.8 | 368.4 | 2.07 |

| 9 | 7074.88 | 701.1 | 2744.2 | 307.9 | 416.8 | 286.5 | 2.21 |

| 10 | 24,526.73 | 867.5 | 9354.1 | 918.1 | 371.4 | 259.6 | 1.38 |

| 11 | 8269.97 | 654.5 | 11,662.7 | 377.8 | 229.8 | 218.8 | 1.17 |

| 12 | 23,138.70 | 817.3 | 4214.7 | 781.1 | 473.4 | 281.8 | 2.52 |

| 13 | 8676.45 | 618.1 | 6000.9 | 297.5 | 178.9 | 140.5 | 1.72 |

| 14 | 23,259.65 | 768.1 | 6140.1 | 973.3 | 588.3 | 416.2 | 2.08 |

| 15 | 15,724.00 | 691.1 | 6066.1 | 566.4 | 342.0 | 259.7 | 2.11 |

| 16 | 15,724.00 | 691.1 | 6066.1 | 566.4 | 342.0 | 259.7 | 2.11 |

| 17 | 15,724.00 | 691.1 | 6066.1 | 566.4 | 342.0 | 259.7 | 2.11 |

| 18 | 15,724.00 | 691.1 | 6066.1 | 566.4 | 342.0 | 259.7 | 2.11 |

| 19 | 15,724.00 | 691.1 | 6066.1 | 566.4 | 342.0 | 259.7 | 2.11 |

| 20 | 15,724.00 | 691.1 | 6066.1 | 566.4 | 342.0 | 259.7 | 2.11 |

| No. | Data Pre-Processing | ||||||

|---|---|---|---|---|---|---|---|

| MRR | H | P | |||||

| 1 | 0.04 | 0.95 | 0.74 | 0.96 | 0.94 | 0.88 | 0.67 |

| 2 | 0.16 | 0.72 | 0.02 | 0.84 | 0.95 | 0.88 | 1 |

| 3 | 0.13 | 0.68 | 1 | 0.89 | 0.76 | 0.75 | 0.21 |

| 4 | 0.36 | 0.45 | 0.65 | 0.7 | 0.8 | 0.79 | 0.5 |

| 5 | 0.12 | 0.68 | 0.73 | 0.82 | 0.58 | 0.25 | 0.57 |

| 6 | 0.36 | 0.45 | 0 | 0.57 | 0.63 | 0.31 | 0.92 |

| 7 | 0.3 | 0.48 | 1 | 0.68 | 0.16 | 0 | 0 |

| 8 | 0.76 | 0.28 | 0.64 | 0.29 | 0.28 | 0.2 | 0.31 |

| 9 | 0.1 | 0.7 | 0.99 | 0.89 | 0.61 | 0.46 | 0.23 |

| 10 | 0.45 | 0.37 | 0.36 | 0.57 | 0.67 | 0.54 | 0.73 |

| 11 | 0.13 | 0.8 | 0.14 | 0.85 | 0.87 | 0.67 | 0.87 |

| 12 | 0.42 | 0.47 | 0.85 | 0.64 | 0.53 | 0.47 | 0.04 |

| 13 | 0.13 | 0.87 | 0.68 | 0.9 | 0.94 | 0.92 | 0.53 |

| 14 | 0.42 | 0.57 | 0.67 | 0.54 | 0.36 | 0.05 | 0.31 |

| 15 | 0.27 | 0.72 | 0.68 | 0.75 | 0.71 | 0.54 | 0.28 |

| 16 | 0.27 | 0.72 | 0.68 | 0.75 | 0.71 | 0.54 | 0.28 |

| 17 | 0.27 | 0.72 | 0.68 | 0.75 | 0.71 | 0.54 | 0.28 |

| 18 | 0.27 | 0.72 | 0.68 | 0.75 | 0.71 | 0.54 | 0.28 |

| 19 | 0.27 | 0.72 | 0.68 | 0.75 | 0.71 | 0.54 | 0.28 |

| 20 | 0.27 | 0.72 | 0.68 | 0.75 | 0.71 | 0.54 | 0.28 |

| No. | Grey Relational Coefficient (GRC) | Grade (GRG) | ||||||

|---|---|---|---|---|---|---|---|---|

| MRR | H | P | ||||||

| 1 | 0.5 | 1 | 0.66 | 1 | 0.98 | 0.94 | 0.6 | 0.78 |

| 2 | 0.55 | 0.64 | 0.34 | 0.77 | 1 | 0.92 | 1 | 0.74 |

| 3 | 0.53 | 0.61 | 1 | 0.86 | 0.71 | 0.76 | 0.39 | 0.64 |

| 4 | 0.64 | 0.45 | 0.59 | 0.61 | 0.76 | 0.82 | 0.5 | 0.6 |

| 5 | 0.53 | 0.6 | 0.65 | 0.74 | 0.56 | 0.46 | 0.54 | 0.58 |

| 6 | 0.64 | 0.45 | 0.33 | 0.5 | 0.59 | 0.48 | 0.86 | 0.57 |

| 7 | 0.61 | 0.47 | 0.99 | 0.58 | 0.37 | 0.38 | 0.33 | 0.52 |

| 8 | 1 | 0.38 | 0.58 | 0.37 | 0.41 | 0.44 | 0.42 | 0.54 |

| 9 | 0.52 | 0.62 | 0.99 | 0.85 | 0.58 | 0.55 | 0.39 | 0.61 |

| 10 | 0.7 | 0.42 | 0.44 | 0.5 | 0.63 | 0.6 | 0.65 | 0.57 |

| 11 | 0.53 | 0.73 | 0.37 | 0.79 | 0.86 | 0.7 | 0.79 | 0.67 |

| 12 | 0.68 | 0.46 | 0.77 | 0.55 | 0.53 | 0.56 | 0.34 | 0.54 |

| 13 | 0.54 | 0.83 | 0.61 | 0.86 | 0.99 | 1 | 0.51 | 0.72 |

| 14 | 0.68 | 0.52 | 0.6 | 0.48 | 0.45 | 0.4 | 0.42 | 0.52 |

| 15 | 0.6 | 0.64 | 0.61 | 0.66 | 0.67 | 0.6 | 0.41 | 0.58 |

| 16 | 0.6 | 0.64 | 0.61 | 0.66 | 0.67 | 0.6 | 0.41 | 0.58 |

| 17 | 0.6 | 0.64 | 0.61 | 0.66 | 0.67 | 0.6 | 0.41 | 0.58 |

| 18 | 0.6 | 0.64 | 0.61 | 0.66 | 0.67 | 0.6 | 0.41 | 0.58 |

| 19 | 0.6 | 0.64 | 0.61 | 0.66 | 0.67 | 0.6 | 0.41 | 0.58 |

| 20 | 0.6 | 0.64 | 0.61 | 0.66 | 0.67 | 0.6 | 0.41 | 0.58 |

| Trail No. | Weightage of Output Parameters | Optimize Results | Output Parameters Values for Optimum Conditions |

|---|---|---|---|

| 1 | |||

| 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanvir, M.H.; Hussain, A.; Rahman, M.M.T.; Ishraq, S.; Zishan, K.; Rahul, S.T.T.; Habib, M.A. Multi-Objective Optimization of Turning Operation of Stainless Steel Using a Hybrid Whale Optimization Algorithm. J. Manuf. Mater. Process. 2020, 4, 64. https://doi.org/10.3390/jmmp4030064

Tanvir MH, Hussain A, Rahman MMT, Ishraq S, Zishan K, Rahul STT, Habib MA. Multi-Objective Optimization of Turning Operation of Stainless Steel Using a Hybrid Whale Optimization Algorithm. Journal of Manufacturing and Materials Processing. 2020; 4(3):64. https://doi.org/10.3390/jmmp4030064

Chicago/Turabian StyleTanvir, Mahamudul Hasan, Afzal Hussain, M. M. Towfiqur Rahman, Sakib Ishraq, Khandoker Zishan, SK Tashowar Tanzim Rahul, and Mohammad Ahsan Habib. 2020. "Multi-Objective Optimization of Turning Operation of Stainless Steel Using a Hybrid Whale Optimization Algorithm" Journal of Manufacturing and Materials Processing 4, no. 3: 64. https://doi.org/10.3390/jmmp4030064

APA StyleTanvir, M. H., Hussain, A., Rahman, M. M. T., Ishraq, S., Zishan, K., Rahul, S. T. T., & Habib, M. A. (2020). Multi-Objective Optimization of Turning Operation of Stainless Steel Using a Hybrid Whale Optimization Algorithm. Journal of Manufacturing and Materials Processing, 4(3), 64. https://doi.org/10.3390/jmmp4030064