Development and Characterization of Stable Polymer Formulations for Manufacturing Magnetic Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Scanning Electron Microscopy

2.2. Preparation of Magnetic Paste Formulations

2.3. Rheological Characterization

2.4. Particle Settling Evaluation in Uncured and Cured Magnetic Polymer Composites

2.5. Additive Manufacturing of Magnetic Polymer Composites

2.6. Magnetic Characterization

3. Results

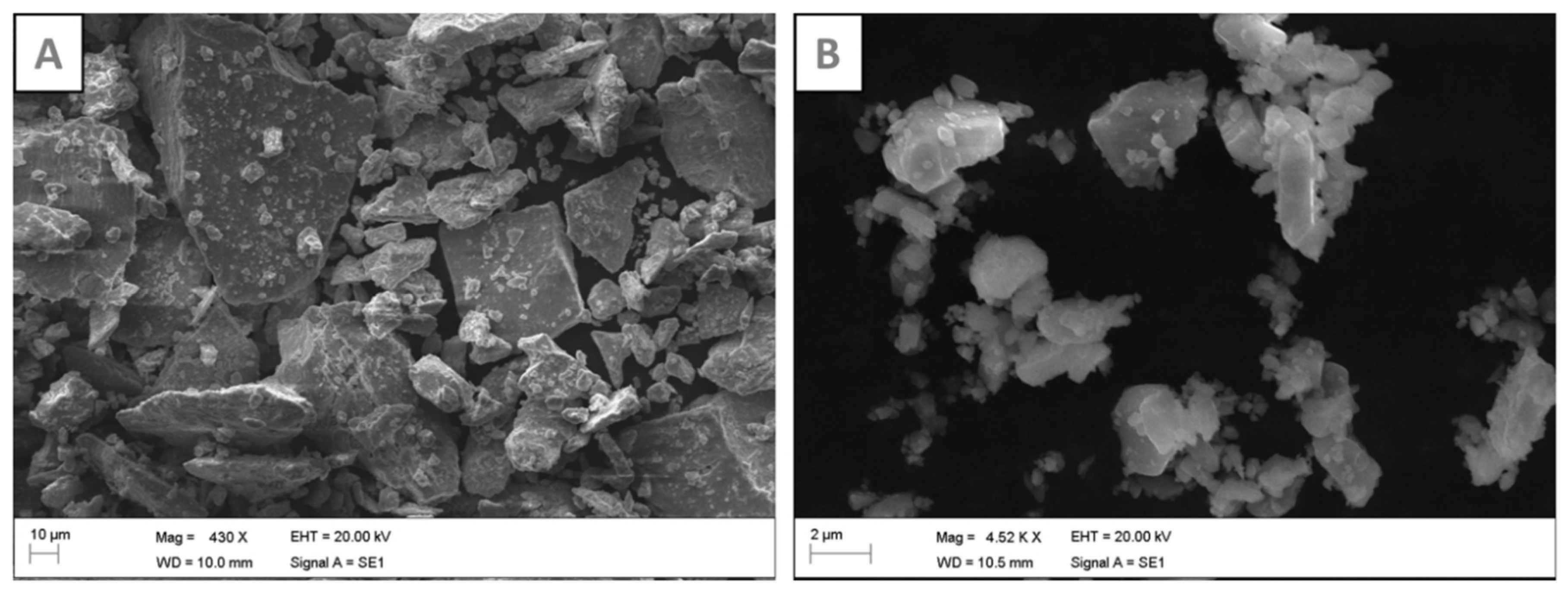

3.1. SEM Characterization of Magnetic Fillers

3.2. Rheological Analysis of Magnetic Pastes

3.2.1. Viscosity and Flow Curve Analysis

3.2.2. Influence of Temperature on Viscosity

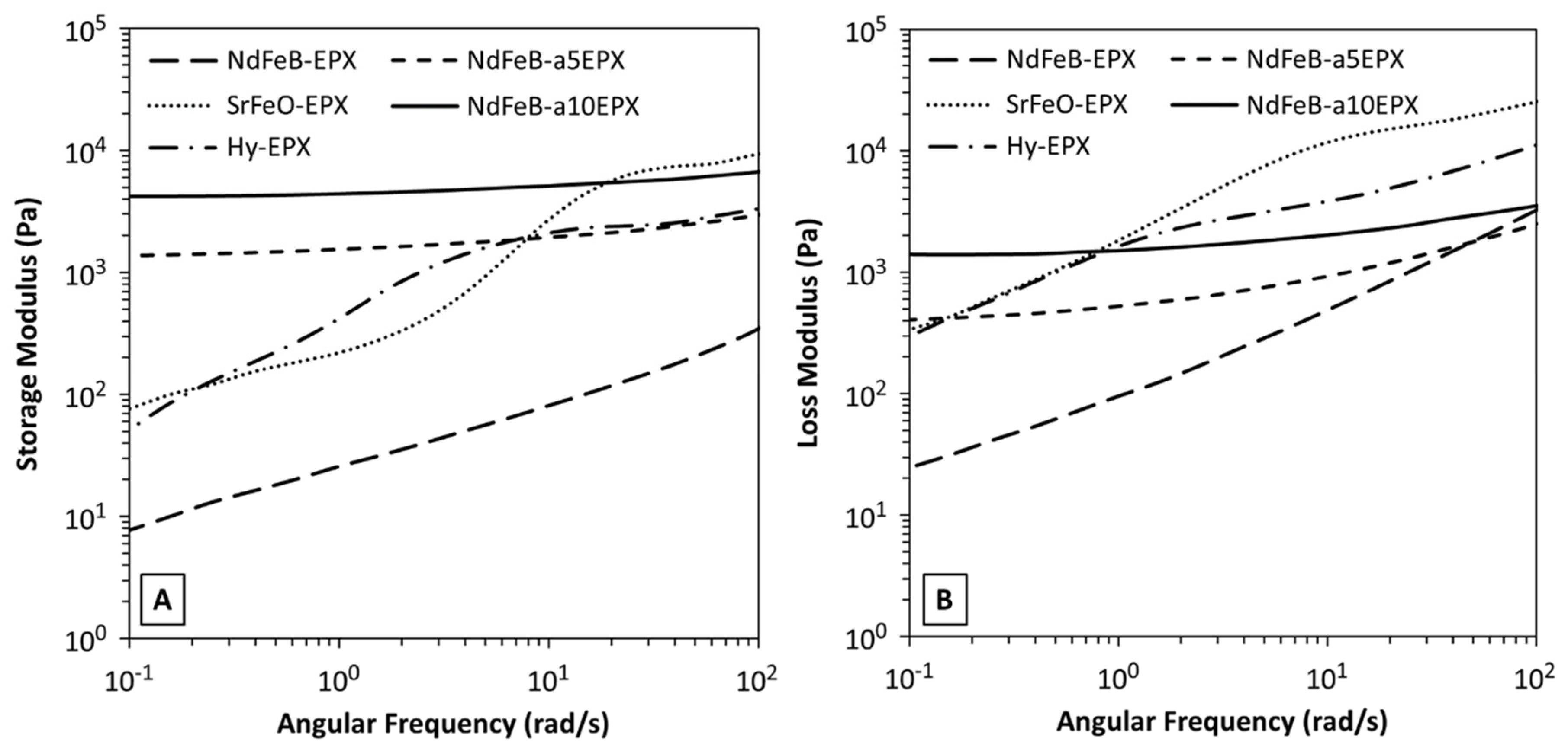

3.2.3. Oscillatory Rheology Analysis of Magnetic Paste Formulations

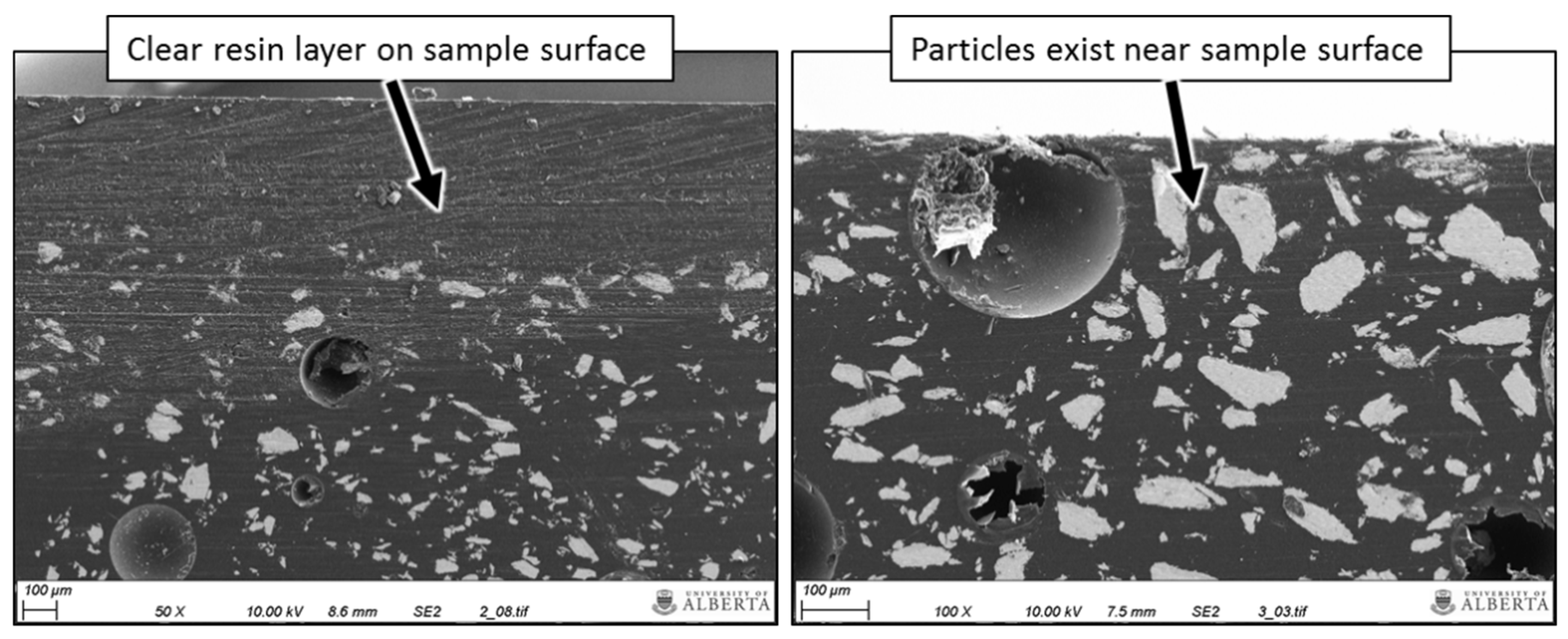

3.3. Analysis of Magnetic Particle Settling in Uncured Resin and Cured Polymer Composites

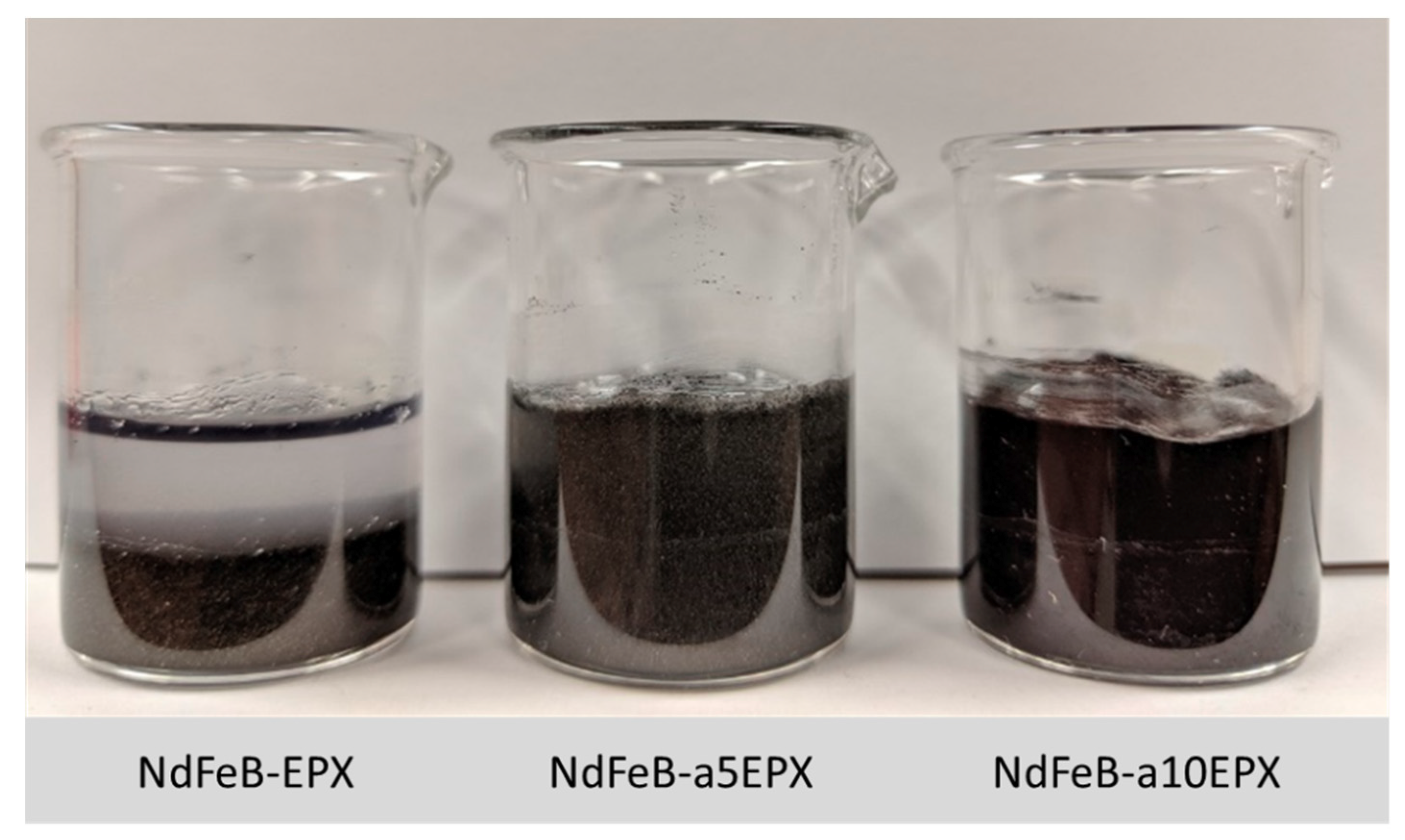

3.3.1. Particle Settling at Stationary Conditions

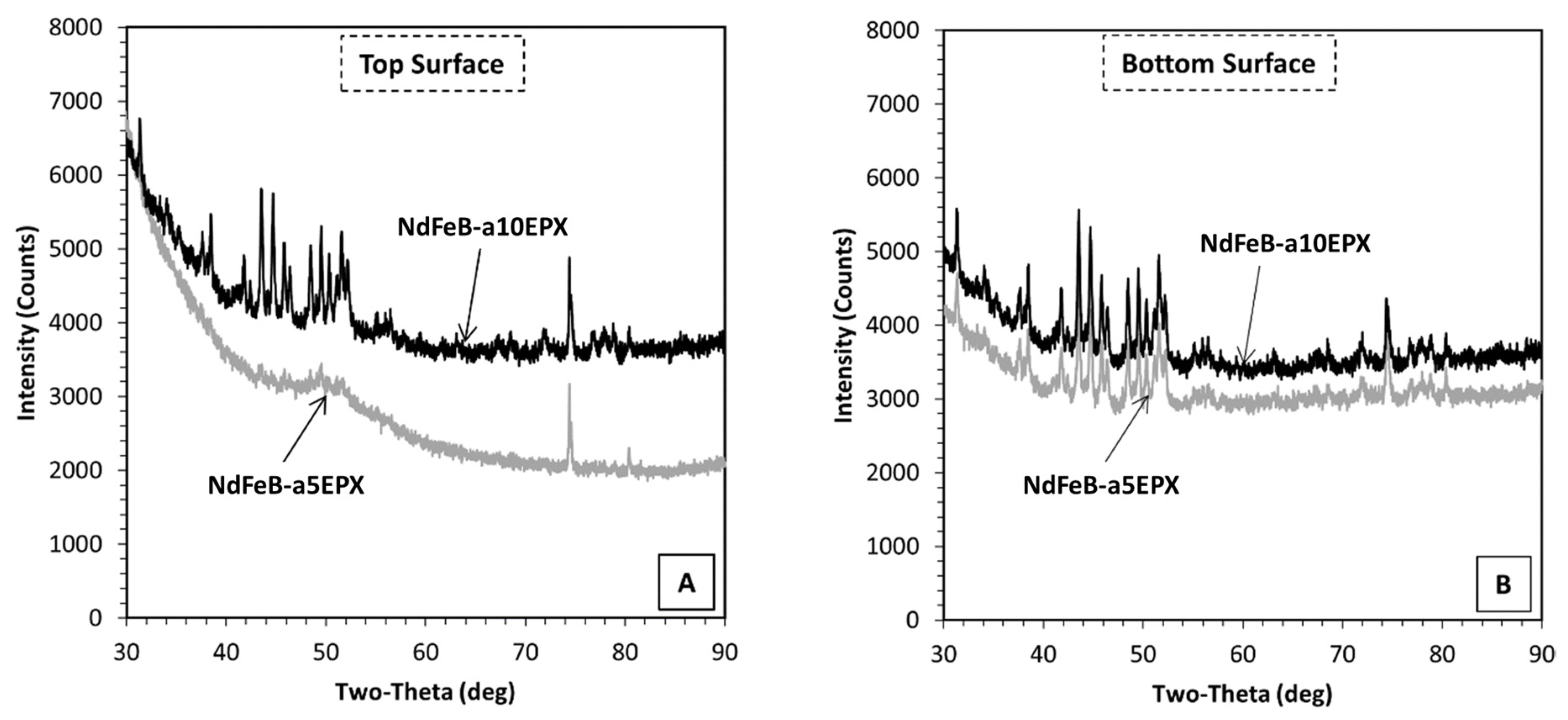

3.3.2. Particle Settling in Cured Magnetic Polymer Composites—In-Situ Polymerization

3.4. Additive Manufacturing and Characterization of Magnetic Composites

3.4.1. Geometric Stability Observations in 3D Printed Magnetic Composites

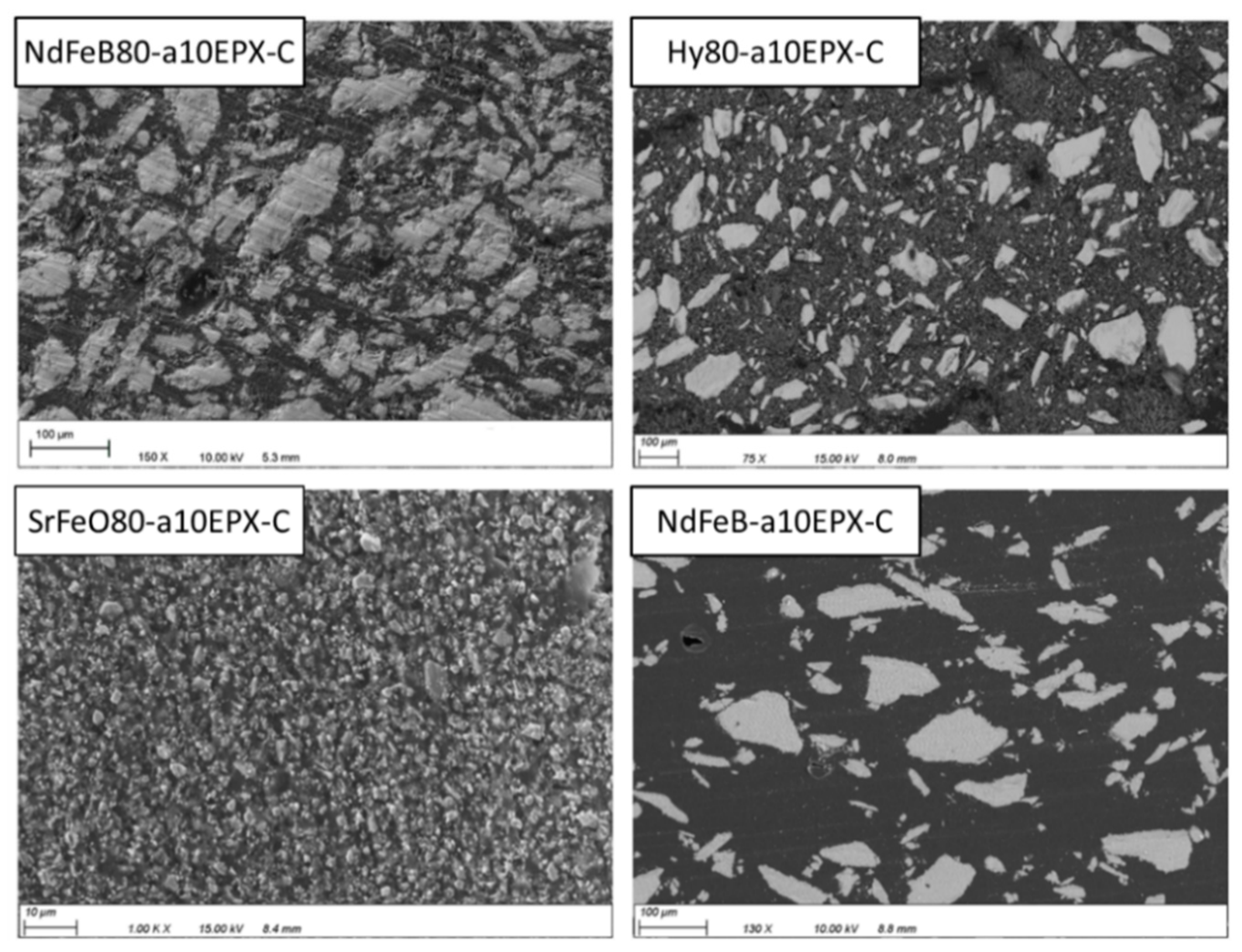

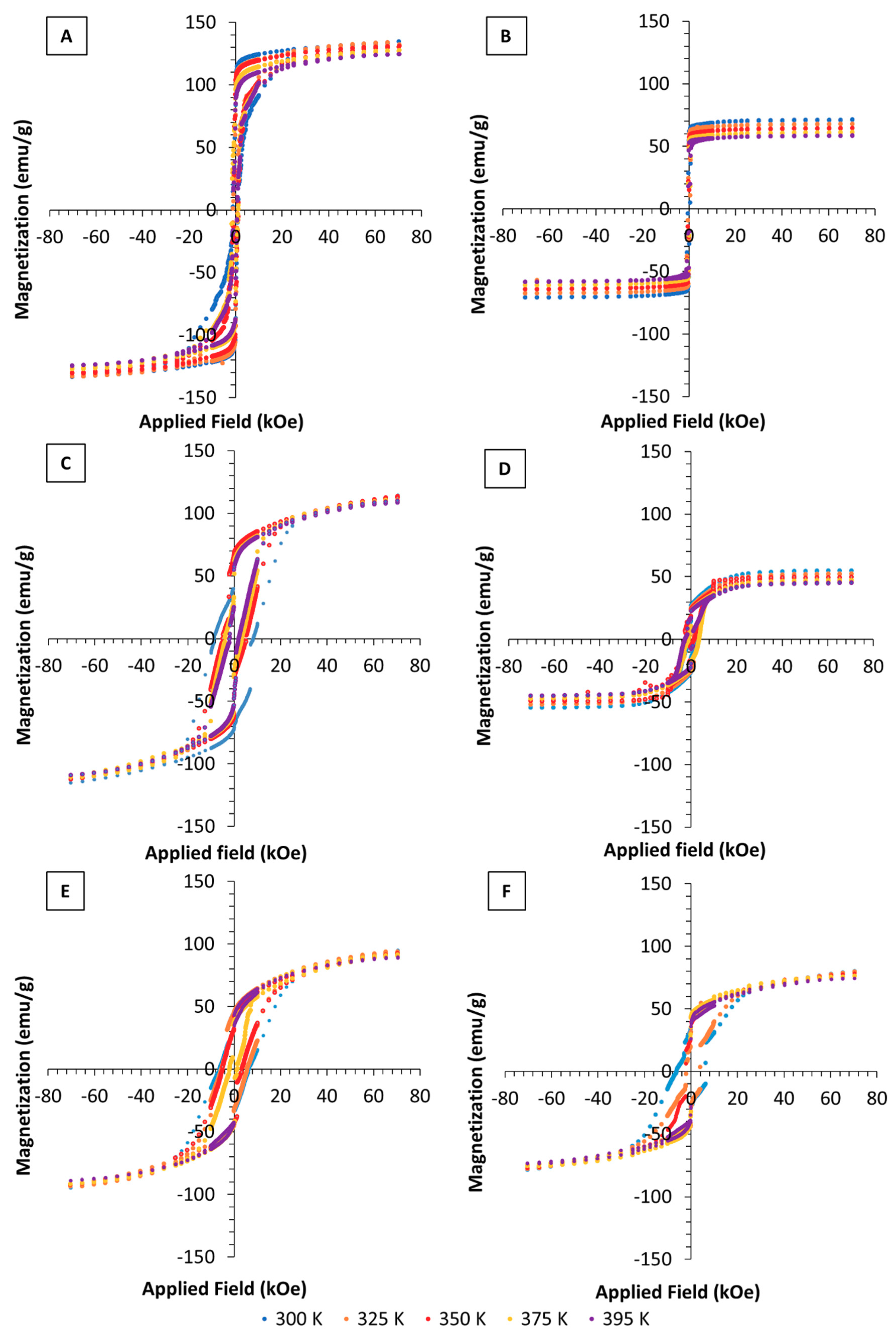

3.4.2. SEM and Magnetic Characterization of 3D Printed Composite Magnets

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Coey, J.M.D. Permanent magnets: Plugging the gap. Scr. Mater. 2012, 67, 524–529. [Google Scholar] [CrossRef]

- Brown, D.; Ma, B.-M.; Chen, Z. Developments in the processing and properties of NdFeb-type permanent magnets. J. Magn. Magn. Mater. 2002, 248, 432–440. [Google Scholar] [CrossRef]

- Ormerod, J.; Constantinides, S. Bonded permanent magnets: Current status and future opportunities (invited). J. Appl. Phys. 1997, 81, 4816. [Google Scholar] [CrossRef] [Green Version]

- Xiao, J.; Otaigbe, J.U. Polymer-bonded magnets: Part I. Analytic thermogravimetry to determine the effect of surface modification on dispersion of Nd–Fe–B fillers. J. Mater. Res. 1999, 14, 2893–2896. [Google Scholar] [CrossRef]

- Najgebauer, M.; Szczygłowski, J.; Ślusarek, B.; Przybylski, M.; Kapłon, A.; Rolek, J. Magnetic Composites in Electric Motors. In Analysis and Simulation of Electrical and Computer Systems Cham; Mazur, D., Gołkebiowski, M., Korkosz, M., Eds.; Springer International Publishing: New York, NY, USA, 2018; pp. 15–28. [Google Scholar]

- Ertz, G.; Hrynik, T.; Lafleur, D.; Mertiny, P.; Secanell, M.; Wagner, N. Design of Low-Cost Fly Wheel Energy Storage Systems. SAMPE J. 2017, 53, 18–26. [Google Scholar]

- Edwards, L.; Yon, J.; Bond, I.; Mellor, P. Structural Magnetic Composites for Use in Electro-Mechanical Applications. In Proceedings of the ICCM 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015; pp. 1–8. [Google Scholar]

- Martin, J.E.; Rohwer, L.E.S.; Stupak, J. Elastic magnetic composites for energy storage flywheels. Compos. Part B Eng. 2016, 97, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Martin, J.; Venturini, E.; Odinek, J.; Anderson, R. Anisotropic magnetism in field-structured composites. Phys. Rev. E 2000, 61, 2818–2830. [Google Scholar] [CrossRef] [Green Version]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 2nd ed.; Springer: New York, NY, USA, 2015; 498p. [Google Scholar]

- Mikler, C.V.; Chaudhary, V.; Borkar, T.; Soni, V.; Jaeger, D.; Chen, X.; Contieri, R.; Ramanujan, R.V.; Banerjee, R. Laser Additive Manufacturing of Magnetic Materials. JOM 2017, 69, 532–543. [Google Scholar] [CrossRef] [Green Version]

- Nilsén, F.; Ituarte, I.F.; Salmi, M.; Partanen, J.; Hannula, S.-P. Effect of process parameters on non-modulated Ni-Mn-Ga alloy manufactured using powder bed fusion. Addit. Manuf. 2019, 28, 464–474. [Google Scholar] [CrossRef] [Green Version]

- Yan, Y.; Liu, L.; Ding, C.; Nguyen, L.; Moss, J.; Mei, Y.; Lu, G. Additive manufacturing of magnetic components for heterogeneous integration. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 324–330. [Google Scholar]

- Yan, Y.; Moss, J.; Ngo, K.D.T.; Mei, Y.; Lu, G.-Q. Additive Manufacturing of Toroid Inductor for Power Electronics Applications. IEEE Trans. Ind. Appl. 2017, 53, 5709–5714. [Google Scholar] [CrossRef]

- Compton, B.G.; Kemp, J.W.; Novikov, T.V.; Pack, R.C.; Nlebedim, C.I.; Duty, C.E.; Rios, O.; Paranthaman, M.P. Direct-write 3D printing of NdFeB bonded magnets. Mater. Manuf. Process. 2016, 1–5. [Google Scholar] [CrossRef]

- Li, L.; Tirado, A.; Nlebedim, I.C.; Rios, O.; Post, B.; Kunc, V.; Lowden, R.R.; Lara-Curzio, E.; Fredette, R.; Ormerod, J.; et al. Big Area Additive Manufacturing of High Performance Bonded NdFeB Magnets. Sci. Rep. 2016, 6, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Gandha, K.; Li, L.; Nlebedim, I.C.; Post, B.K.; Kunc, V.; Sales, B.C.; Bell, J.; Paranthaman, M.P. Additive manufacturing of anisotropic hybrid NdFeB-SmFeN nylon composite bonded magnets. J. Magn. Magn. Mater. 2018, 467, 8–13. [Google Scholar] [CrossRef]

- Nagarajan, B.; Eufracio Aguilera, A.F.; Wiechmann, M.; Qureshi, A.J.; Mertiny, P. Characterization of magnetic particle alignment in photosensitive polymer resin: A preliminary study for additive manufacturing processes. Addit. Manuf. 2018, 22, 528–536. [Google Scholar] [CrossRef]

- Palmero, E.M.; Casaleiz, D.; Jimenez, N.A.; Rial, J.; de Vicente, J.; Nieto, A.; Altimira, R.; Bollero, A. Magnetic-Polymer Composites for Bonding and 3D Printing of Permanent Magnets. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Noetzel, D.; Pursche, K.; Hanemann, T. A 3D-Printable Polymer-Metal Soft-Magnetic Functional Composite—Development and Characterization. Materials 2018, 11, 189. [Google Scholar] [CrossRef] [Green Version]

- von Petersdorff-Campen, K.; Hauswirth, Y.; Carpenter, J.; Hagmann, A.; Boës, S.; Schmid Daners, M.; Penner, D.; Meboldt, M. 3D Printing of Functional Assemblies with Integrated Polymer-Bonded Magnets Demonstrated with a Prototype of a Rotary Blood Pump. Appl. Sci. 2018, 8, 1275. [Google Scholar] [CrossRef] [Green Version]

- Mezger, T.G. The Rheology Handbook. Pigment Resin Technol. 2009, 38. [Google Scholar] [CrossRef]

- ASTM E3070-18 Standard Test Method for Shear Thinning Index of Non-Newtonian Liquids Using a Rotational Viscometer; ASTM International: West Conshohocken, PA, USA, 2018; Available online: http://www.astm.org/cgi-bin/resolver.cgi?E3070-18 (accessed on 9 January 2020).

- Elbadawi, M.; Rivera-Armenta, J.L.; Cruz, B.A.S. Polymeric Additive Manufacturing: The Necessity and Utility of Rheology. In Polymer Rheology; IntechOpen: Rijeka, Croatia, 2018; pp. 43–63. [Google Scholar]

- Burlawar, S.; Klingenberg, D.J.; Root, T.W.; Schlafmann, K.; Tim Scott, C. Effect of temperature on the rheology of concentrated fiber suspensions. J. Rheol. 2019, 63, 677–691. [Google Scholar] [CrossRef]

- Sotomayor, M.E.; Várez, A.; Levenfeld, B. Influence of powder particle size distribution on rheological properties of 316L powder injection moulding feedstocks. Powder Technol 2010, 200, 30–36. [Google Scholar] [CrossRef]

- Eufracio Aguilera, A.F.; Nagarajan, B.; Fleck, B.A.; Qureshi, A.J. Ferromagnetic particle structuring in material jetting—Manufacturing control system and software development. Procedia Manuf. 2019, 34, 545–551. [Google Scholar] [CrossRef]

- Ranellucci, A. Slic3r. Available online: https://slic3r.org/ (accessed on 27 September 2019).

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671. [Google Scholar] [CrossRef] [PubMed]

- Kamkar, M.; Aliabadian, E.; Shayesteh Zeraati, A.; Sundararaj, U. Application of nonlinear rheology to assess the effect of secondary nanofiller on network structure of hybrid polymer nanocomposites. Phys. Fluids 2018, 30, 023102. [Google Scholar] [CrossRef]

- Manning, K.B.; Wyatt, N.; Hughes, L.; Cook, A.; Giron, N.H.; Martinez, E.; Campbell, C.G.; Celina, M.C. Self Assembly–Assisted Additive Manufacturing: Direct Ink Write 3D Printing of Epoxy–Amine Thermosets. Macromol. Mater. Eng. 2019, 304, 1800511. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; Scarpas, T. Rheological Behavior and Its Chemical Interpretation of Crumb Rubber Modified Asphalt Containing Warm-Mix Additives. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 337–348. [Google Scholar] [CrossRef]

- Berndlmaier, R. Rheology additives for coatings. In Handbook of Coating Additives; John, J., Florio, D.J.M., Eds.; Marcel Dekker Inc.: New York, NY, USA, 2008; pp. 363–403. [Google Scholar]

- Kamkar, M.; Sadeghi, S.; Arjmand, M.; Sundararaj, U. Structural Characterization of CVD Custom-Synthesized Carbon Nanotube/Polymer Nanocomposites in Large-Amplitude Oscillatory Shear (LAOS) Mode: Effect of Dispersion Characteristics in Confined Geometries. Macromolecules 2019, 52, 1489–1504. [Google Scholar] [CrossRef]

- Aliabadian, E.; Sadeghi, S.; Kamkar, M.; Chen, Z.; Sundararaj, U. Rheology of fumed silica nanoparticles/partially hydrolyzed polyacrylamide aqueous solutions under small and large amplitude oscillatory shear deformations. J. Rheol. 2018, 62, 1197–1216. [Google Scholar] [CrossRef]

- Rezvani Moghaddam, A.; Kamkar, M.; Ranjbar, Z.; Sundararaj, U.; Jannesari, A.; Ranjbar, B. Tuning the Network Structure of Graphene/epoxy nanocomposites by Controlling Edge/Basal Localization of Functional Groups. Ind. Eng. Chem. Res. 2019, 58, 21431–21440. [Google Scholar] [CrossRef]

- Nlebedim, I.C.; Ucar, H.; Hatter, C.B.; McCallum, R.W.; McCall, S.K.; Kramer, M.J. Studies on in situ magnetic alignment of bonded anisotropic Nd-Fe-B alloy powders. J. Magn. Magn. Mater. 2017, 422, 168–173. [Google Scholar] [CrossRef] [Green Version]

- Su, K.P.; Liu, Z.W.; Zeng, D.C.; Huo, D.X.; Li, L.W.; Zhang, G.Q. Structure and size-dependent properties of NdFeB nanoparticles and textured nano-flakes prepared from nanocrystalline ribbons. J. Phys. D Appl. Phys. 2013, 46, 245003. [Google Scholar] [CrossRef]

- Wang, X.F.; Lee, D.; Jiang, Z.L. Magnetic properties of hybrid polymer bonded Nd–Fe–B/ferrite magnets. J. Appl. Phys. 2006, 99, 08B513. [Google Scholar] [CrossRef]

| Material Type | Average Particle Size | Density [g/cm3] |

|---|---|---|

| MQA-38-14 (NdFeB) | 90 μm | 7.51 |

| SF-500 (SrFeO) | 1.41 μm | 3.41 |

| EPON 826 | - | 1.16 |

| Sample Name | Material Type | Magnetic Filler Loading |

|---|---|---|

| EPX | Pure epoxy | - |

| NdFeB-EPX | NdFeB + epoxy | 50 wt% |

| SrFeO-EPX | SrFeO + epoxy | 50 wt% |

| Hy-EPX | NdFeB + SrFeO + epoxy | 50 wt% |

| NdFeB-a5EPX | NdFeB + epoxy modified with 5 wt% additive | 50 wt% |

| NdFeB-a10EPX | NdFeB + epoxy modified with 10 wt% additive | 50 wt% |

| Material Number | Material Type | Magnetic Filler Loading |

|---|---|---|

| NdFeB80-a10EPX-C | NdFeB + epoxy modified with 10 wt% additive | 80.2 wt% |

| SrFeO80-a10EPX-C | SrFeO + epoxy modified with 10 wt% additive | 80.1 wt% |

| Hy80-a10EPX-C | NdFeB + SrFeO + epoxy modified with 10 wt% additive | 80.8 wt% |

| NdFeB-a10EPX-C | NdFeB + epoxy modified with 10 wt% additive | 50.1 wt% |

| Material Number | Yield Strength [Pa] | Flow Index-n | Consistency Index-C | STI |

|---|---|---|---|---|

| EPX | - | - | - | 1 |

| NdFeB-EPX | 7.87 | 0.96 | 17.02 | 3 |

| SrFeO-EPX | 235.16 | 0.82 | 43.48 | 30 |

| Hy-EPX | 67.77 | 0.84 | 36.92 | 10 |

| NdFeB-a5EPX | 159.40 | 0.49 | 63.24 | 26 |

| NdFeB-a10EPX | 232.66 | 0.19 | 302.37 | 46 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagarajan, B.; Kamkar, M.; Schoen, M.A.W.; Sundararaj, U.; Trudel, S.; Qureshi, A.J.; Mertiny, P. Development and Characterization of Stable Polymer Formulations for Manufacturing Magnetic Composites. J. Manuf. Mater. Process. 2020, 4, 4. https://doi.org/10.3390/jmmp4010004

Nagarajan B, Kamkar M, Schoen MAW, Sundararaj U, Trudel S, Qureshi AJ, Mertiny P. Development and Characterization of Stable Polymer Formulations for Manufacturing Magnetic Composites. Journal of Manufacturing and Materials Processing. 2020; 4(1):4. https://doi.org/10.3390/jmmp4010004

Chicago/Turabian StyleNagarajan, Balakrishnan, Milad Kamkar, Martin A.W. Schoen, Uttandaraman Sundararaj, Simon Trudel, Ahmed Jawad Qureshi, and Pierre Mertiny. 2020. "Development and Characterization of Stable Polymer Formulations for Manufacturing Magnetic Composites" Journal of Manufacturing and Materials Processing 4, no. 1: 4. https://doi.org/10.3390/jmmp4010004

APA StyleNagarajan, B., Kamkar, M., Schoen, M. A. W., Sundararaj, U., Trudel, S., Qureshi, A. J., & Mertiny, P. (2020). Development and Characterization of Stable Polymer Formulations for Manufacturing Magnetic Composites. Journal of Manufacturing and Materials Processing, 4(1), 4. https://doi.org/10.3390/jmmp4010004