Reduction of Ejection Forces in Injection Molding by Applying Mechanically Post-Treated CrN and CrAlN PVD Films

Abstract

1. Introduction

2. Materials and Methods

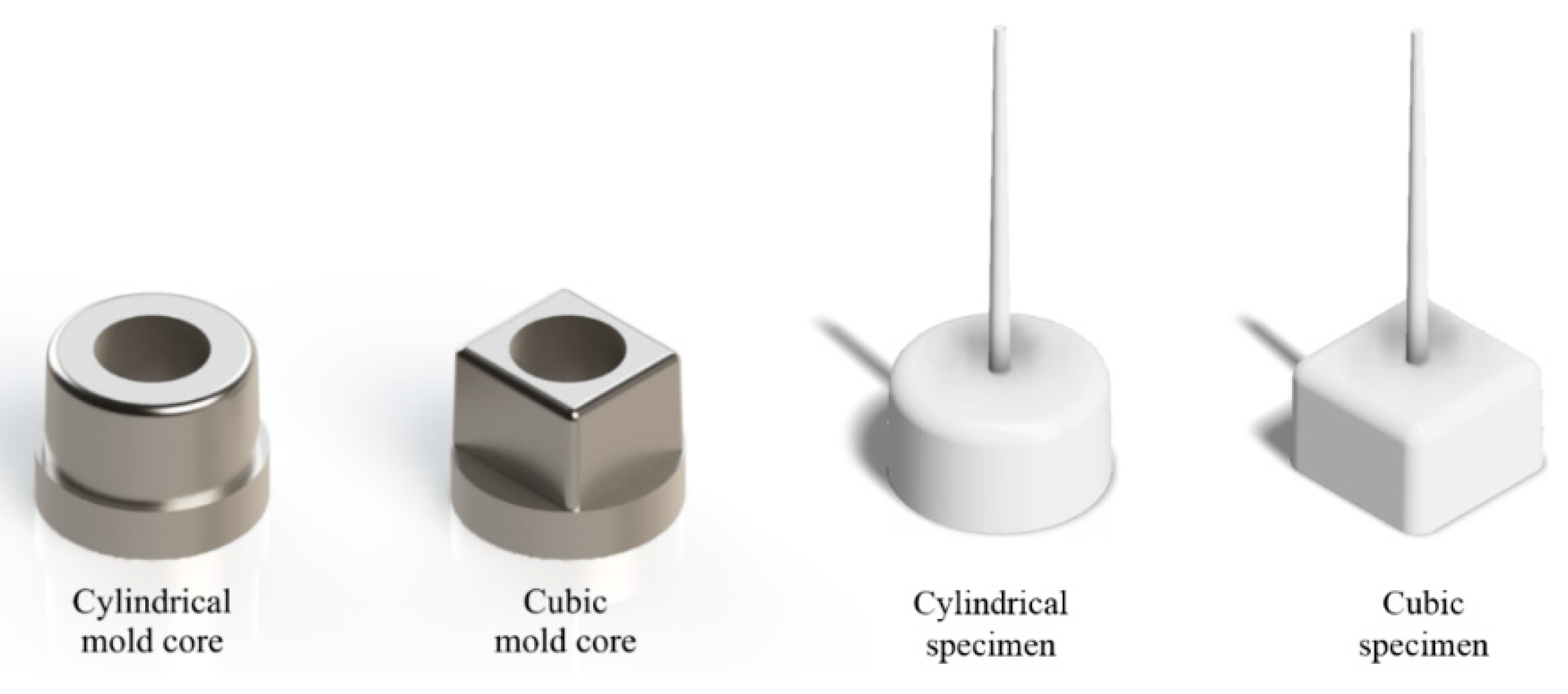

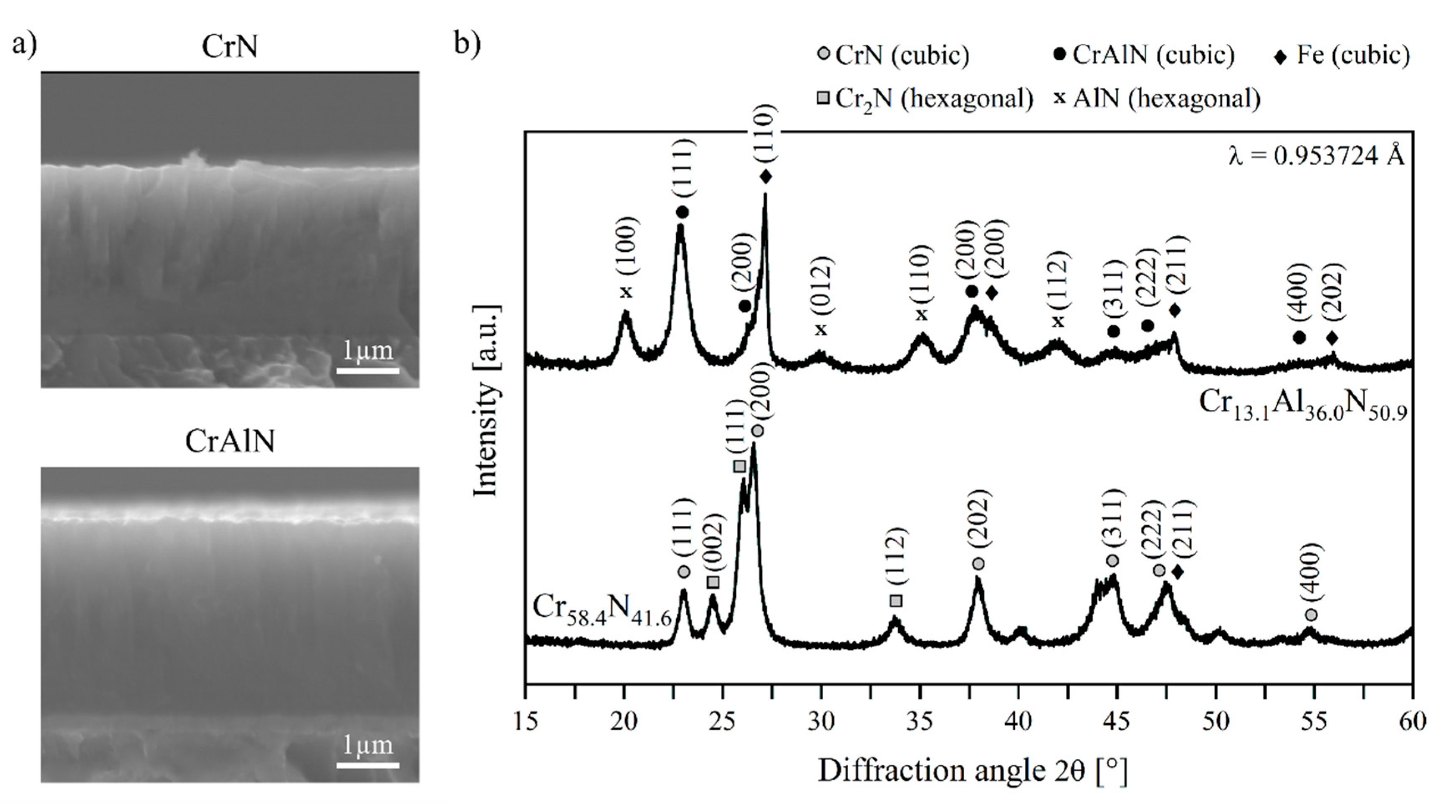

2.1. Mold Core Geometries and Deposition of CrN and CrAlN Films

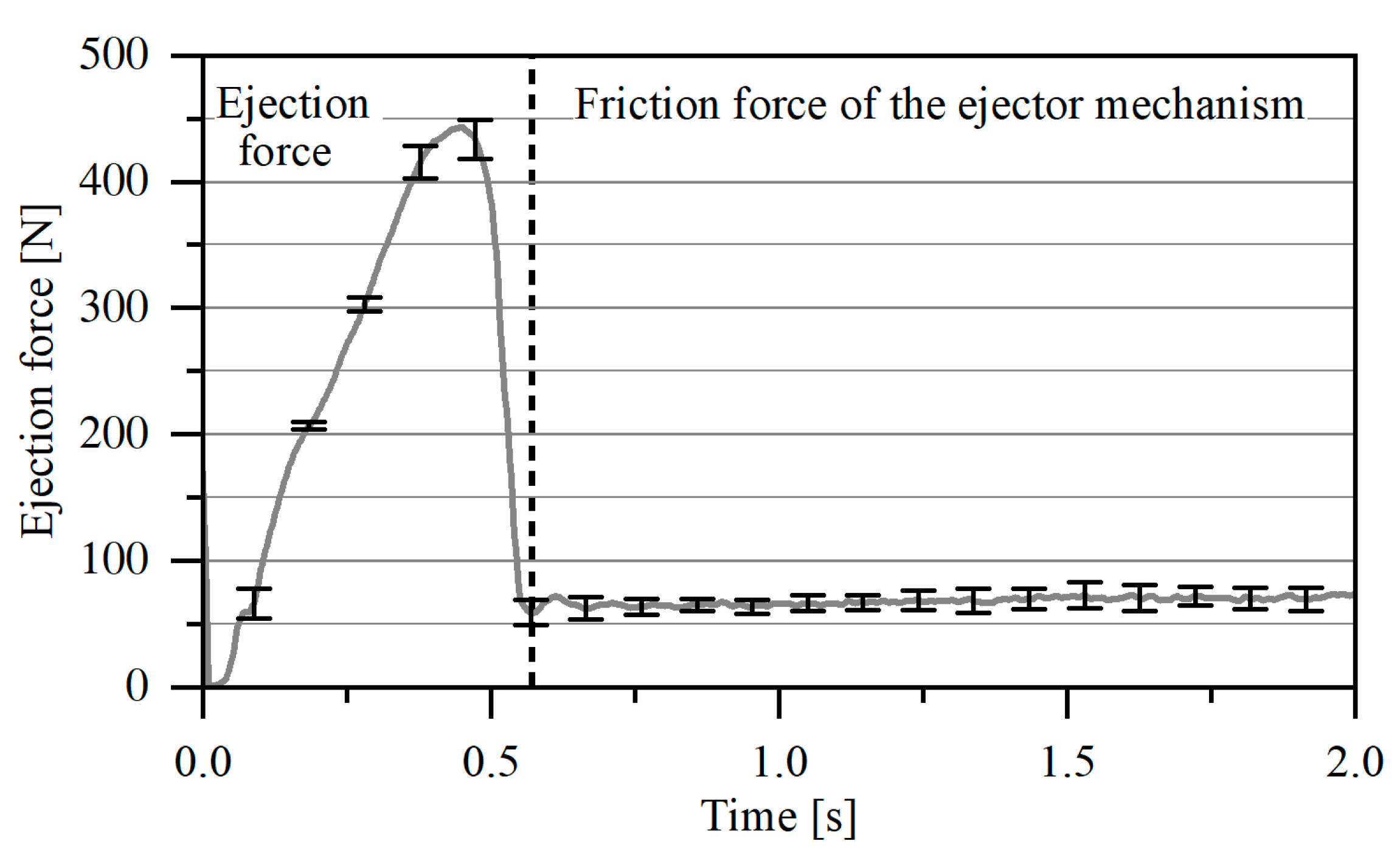

2.2. Surface Characterization of Coated Cores and Injection Molding Experiments

3. Results and Discussion

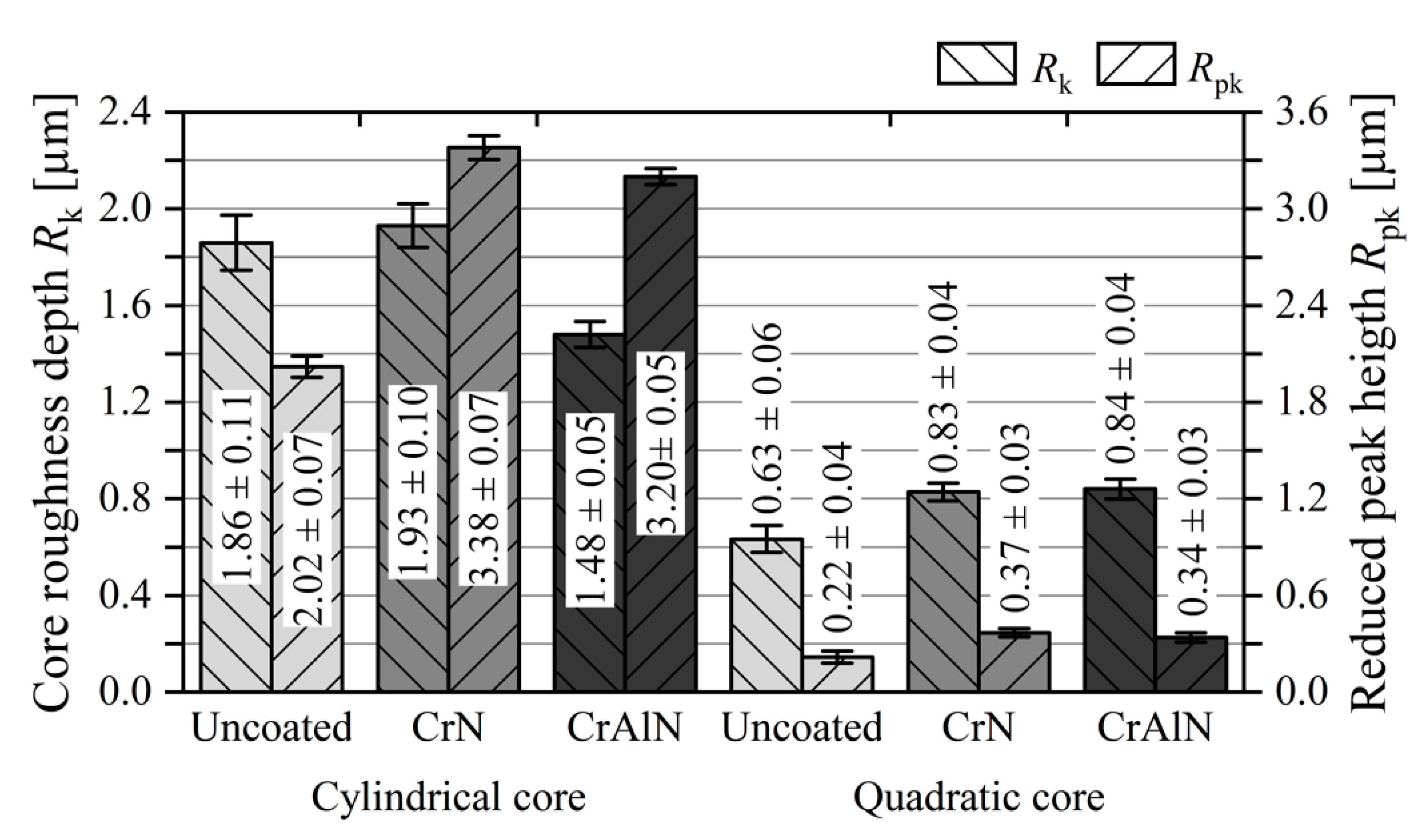

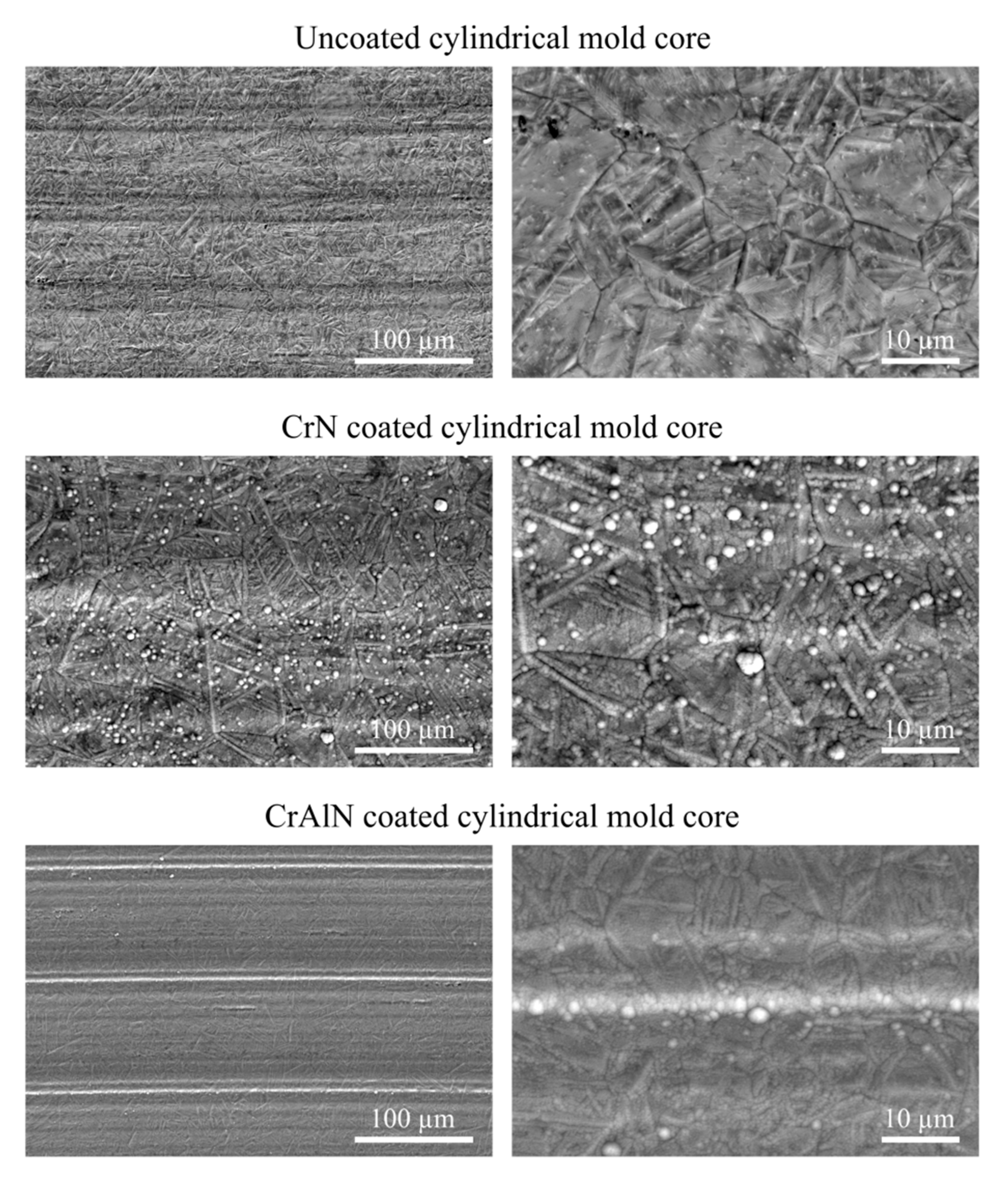

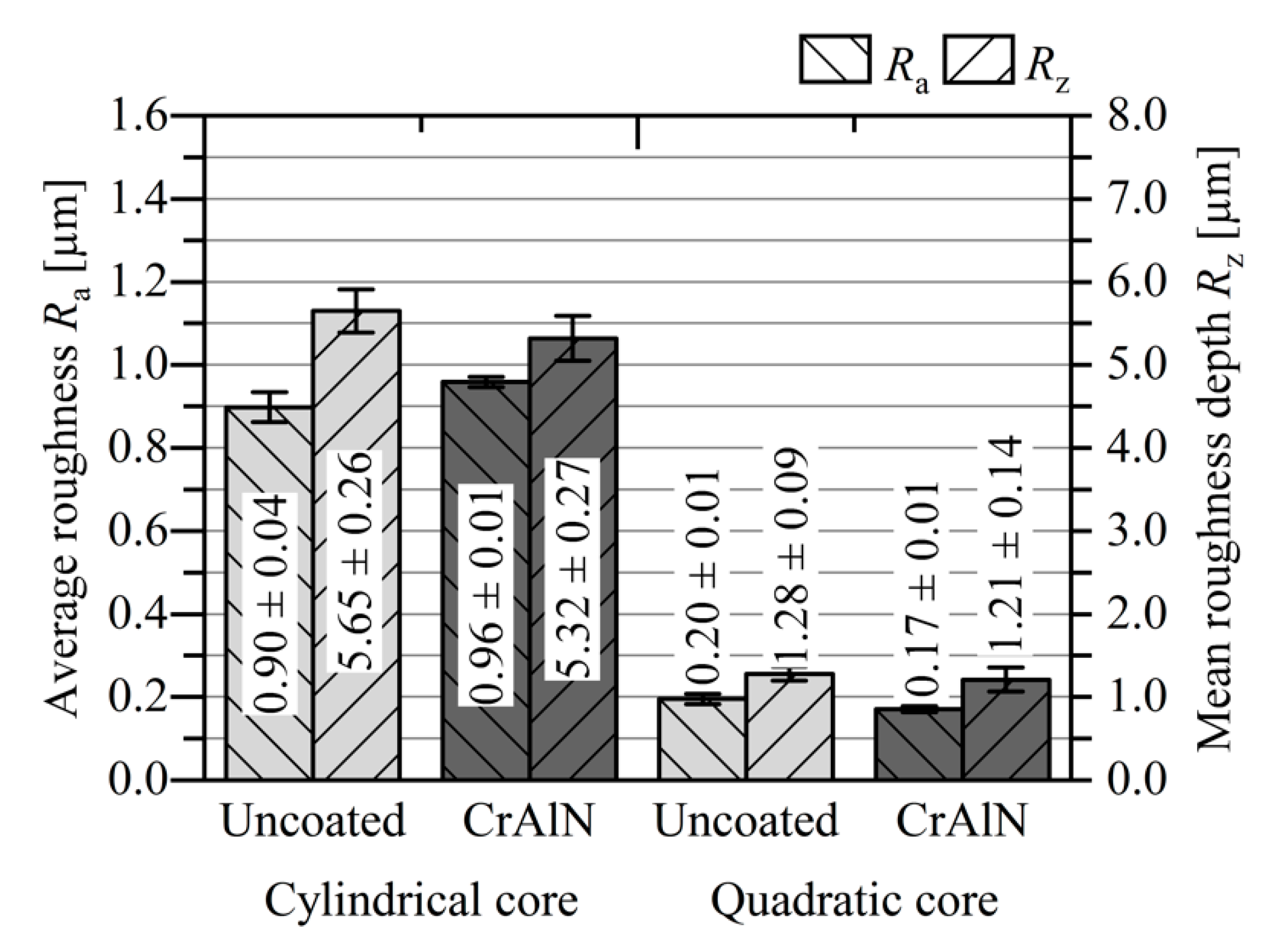

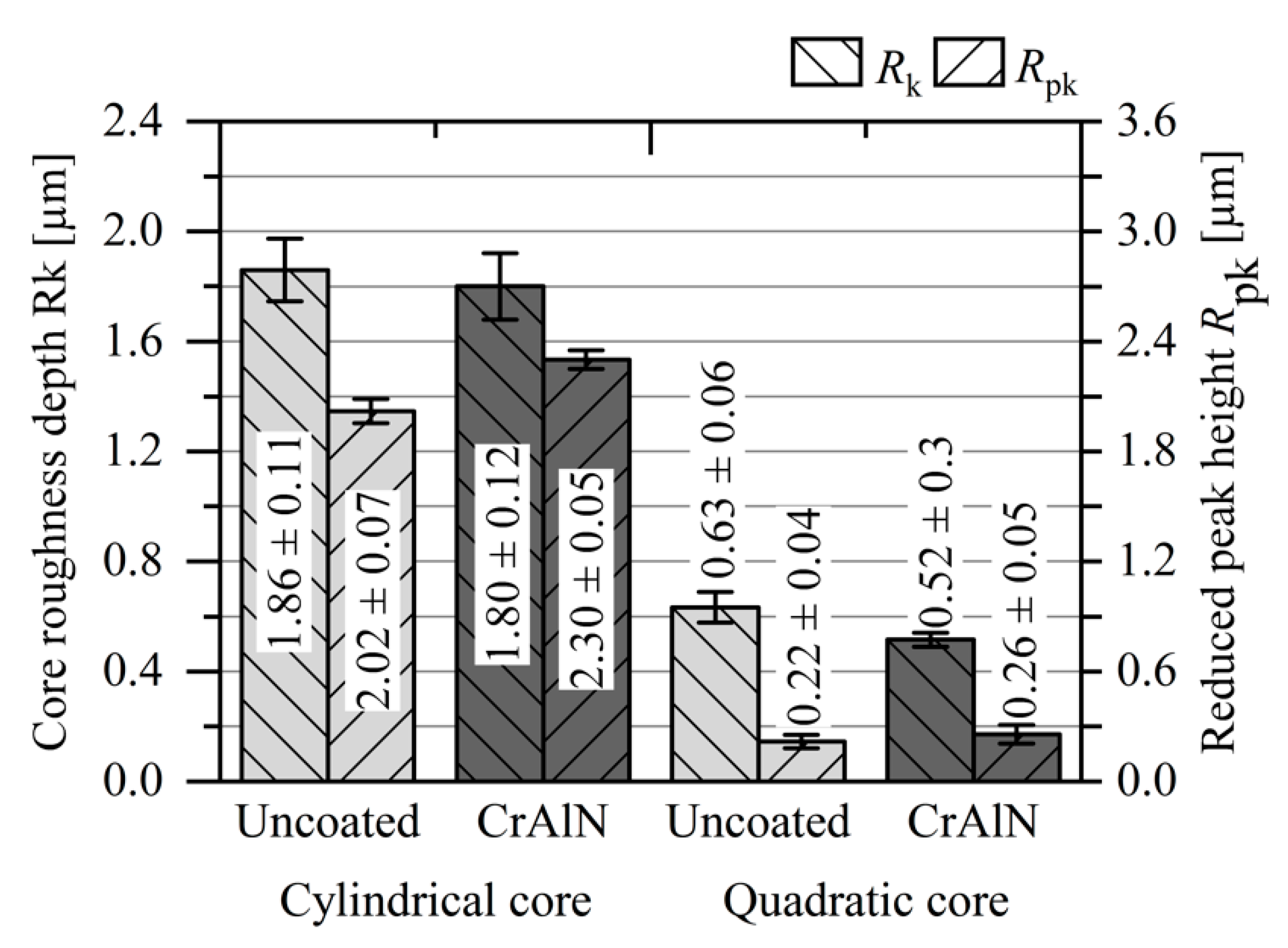

3.1. Surface Roughness of the Coated Cores without a Mechanical Post-Treatment

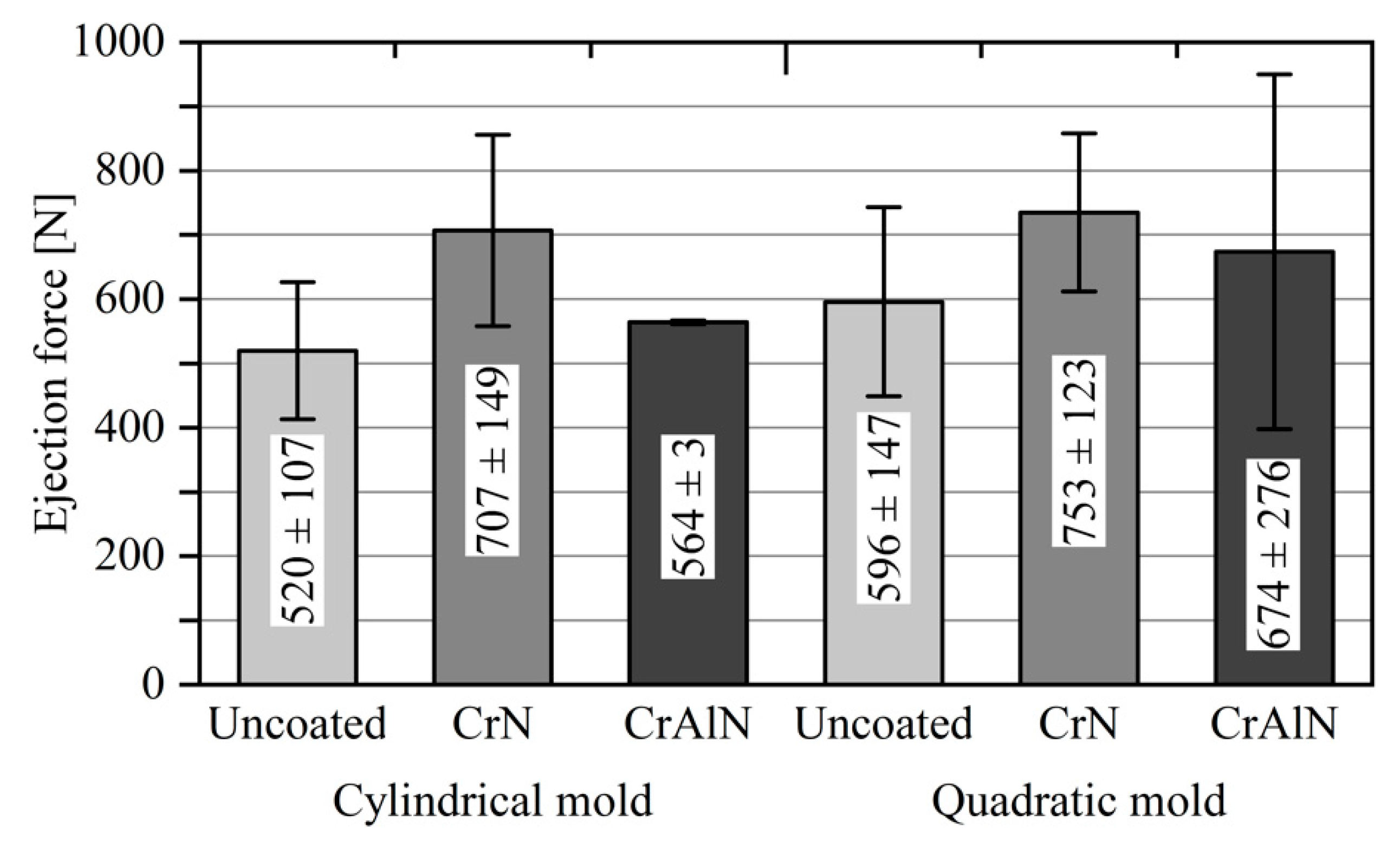

3.2. Ejection Forces of Coated Cores without a Mechanical Post-Treatment

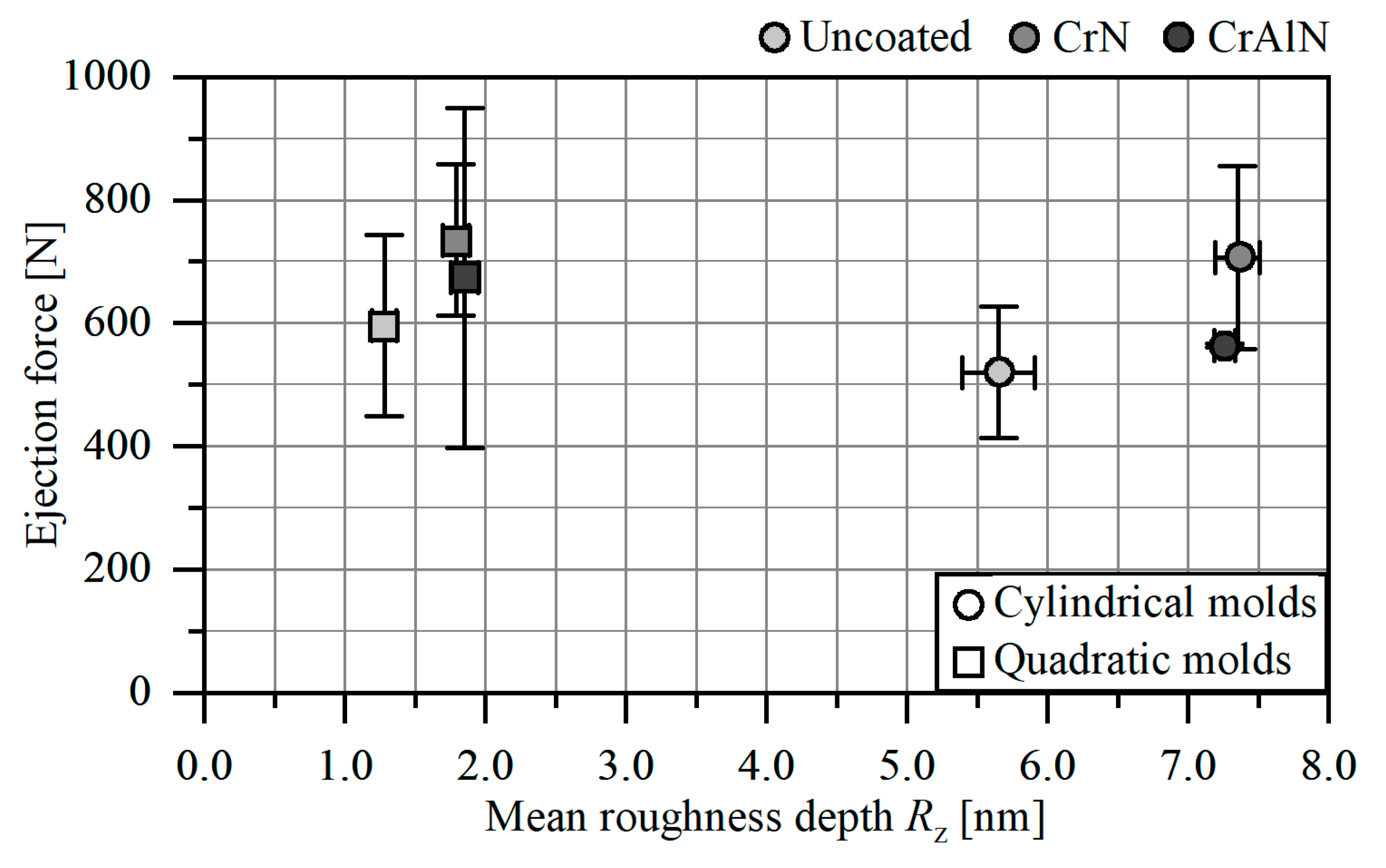

3.3. Influence of the Surface Roughness on the Ejection Forces

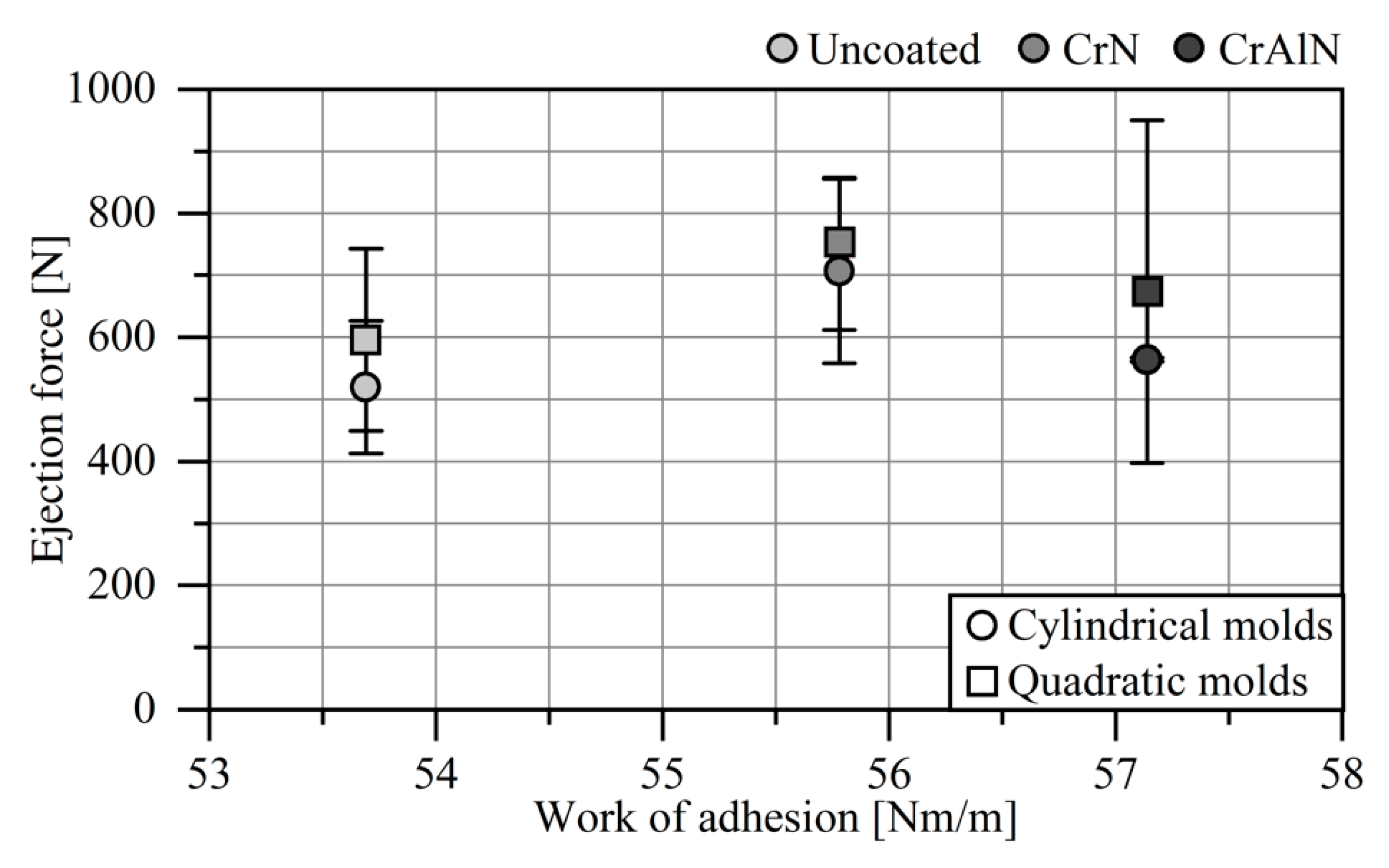

3.4. Influence of the Adhesion Behavior on the Ejection Forces

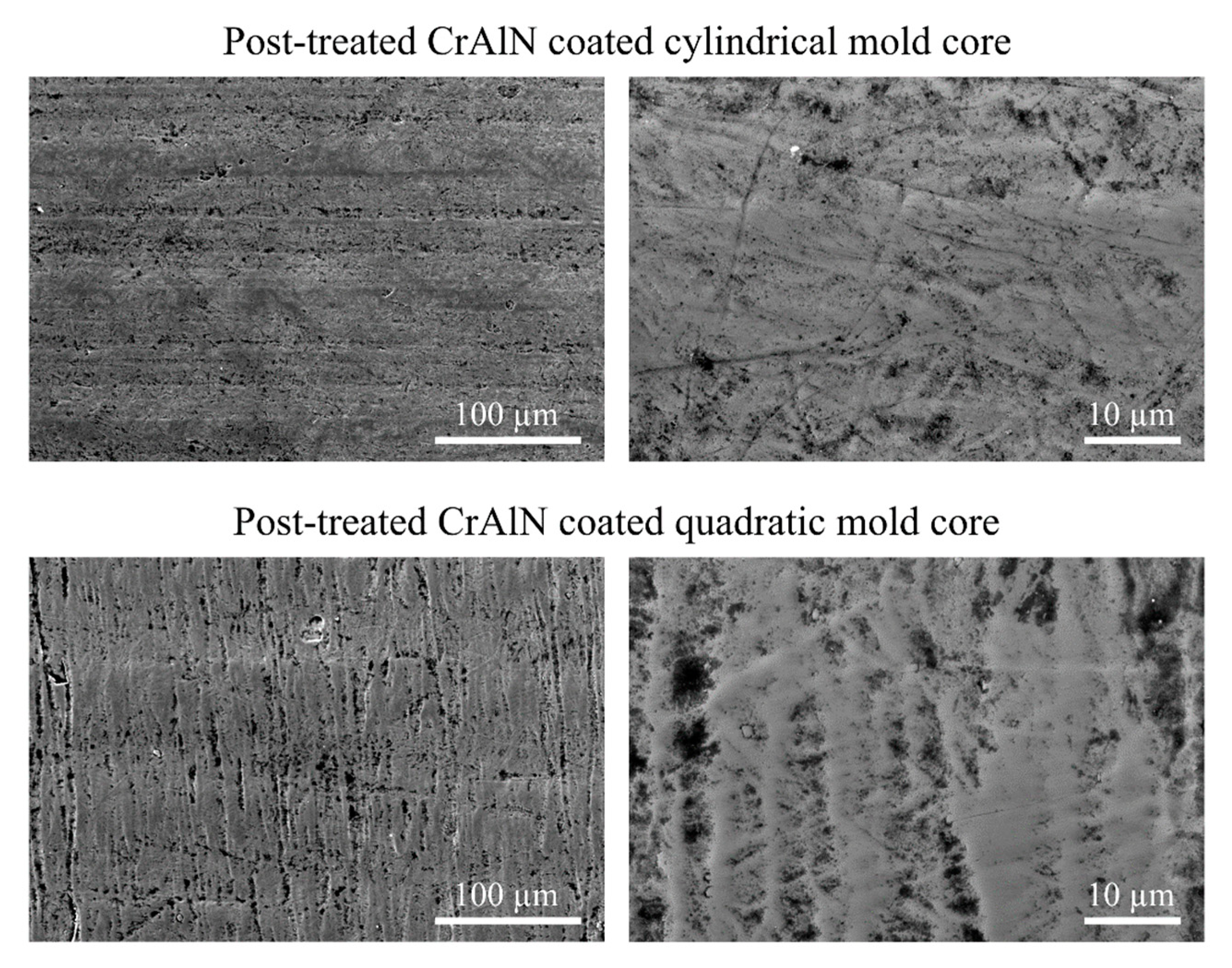

3.5. Ejection Forces of Mechanically Post-Treated CrAlN Coated Cores

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zheng, R.; Tanner, R.I.; Fan, X.-J. Injection Molding: Integration of Theory and Modeling Methods; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-21262-8. [Google Scholar]

- Gramann, P.J.; Osswald, T.A. Introduction. In Injection Molding Handbook, 2nd ed.; Osswald, T.A., Turng, L.-S., Gramann, P.J., Eds.; Hanser: Munich, Germany; Cincinnati, OH, USA, 2008; pp. 1–18. ISBN 978-3-446-40781-7. [Google Scholar]

- Sakai, T.; Kikugawa, K. Injection Molding Machinery and Systems. In Injection Molding: Technology and Fundamentals; Kamal, M.R., Agassant, J.-F., Eds.; Hanser: Munich, Germany, 2009; pp. 73–131. ISBN 978-3-446-41685-7. [Google Scholar]

- Kazmer, D. Injection Mold Design Engineering, 2nd ed.; Hanser Publications: Munich, Germany; Cincinnati, OH, USA, 2016; ISBN 978-1-56990-570-8. [Google Scholar]

- Osswald, T.A. Processing Fundamentals. In Injection Molding Handbook, 2nd ed.; Osswald, T.A., Turng, L.-S., Gramann, P.J., Beaumont, J., Eds.; Hanser: Munich, Germany; Cincinnati, OH, USA, 2008; pp. 63–124. ISBN 978-3-446-40781-7. [Google Scholar]

- Pouzada, A.S.; Ferreira, E.C.; Pontes, A.J. Friction properties of moulding thermoplastics. Polym. Test. 2006, 25, 1017–1023. [Google Scholar] [CrossRef]

- Delaney, K.D.; Bissacco, G.; Kennedy, D. A Structured Review and Classification of Demolding Issues and Proven Solutions. IPP 2012, 27, 77–90. [Google Scholar] [CrossRef]

- Štěpek, J.; Daoust, H. Lubricants and Mold-Release Agents. In Additives for Plastics; Štěpek, J., Daoust, H., Eds.; Springer: New York, NY, USA, 1983; pp. 34–49. ISBN 978-1-4612-6417-0. [Google Scholar]

- Percell, K.S.; Tomlinson, H.H.; Walp, L.E. Nonmetallic Fatty Chemicals as Internal Mold Release Agents in Polymers. In Coatings Technology Handbook, 3rd ed.; Tracton, A.A., Ed.; CRC Taylor & Francis: Boca Raton, FL, USA, 2006; pp. 573–580. ISBN 9781574446494. [Google Scholar]

- Tölke, T.; Keil, D.; Marschner, C.; Homuth, M.; Pfuch, A.; Matthes, G.; Hering, W.; Grünler, B. Sol-Gel-coatings—Versatile possibilities for surface functionalization. Galvanotechnik 2015, 9, 1848–1854. [Google Scholar]

- Yamamoto, H.; Ohkubo, Y.; Ogawa, K.; Utsumi, K. Application of a chemically adsorbed fluorocarbon film to improve demolding. Precis. Eng. 2009, 33, 229–234. [Google Scholar] [CrossRef]

- Yamamoto, H.; Ohkubo, Y.; Ogawa, K.; Utsumi, K. Physical performance of the metal surface covered with the highly durable and chemically adsorbed fluorocarbon film. Precis. Eng. 2010, 34, 440–445. [Google Scholar] [CrossRef]

- Hopmann, C.; Pauling, A.; Holz, C.; Vissing, K. Investigations on a plasma polymeric mould coating for the release agent-free demoulding of PU-parts. J. Plast. Technol. 2014, 5, 166–187. [Google Scholar]

- Mori, K.; Sasaki, Y.; Hirahara, H.; Oishi, Y. Development of polymer-molding-releasing metal mold surfaces with perfluorinated-group-containing polymer plating. J. Appl. Polym. Sci. 2003, 90, 2549–2556. [Google Scholar] [CrossRef]

- Crisan, N.; Descartes, S.; Berthier, Y.; Cavoret, J.; Baud, D.; Montalbano, F. Tribological assessment of the interface injection mold/plastic part. Tribol. Int. 2016, 100, 388–399. [Google Scholar] [CrossRef]

- Silva, F.; Martinho, R.; Andrade, M.; Baptista, A.; Alexandre, R. Improving the Wear Resistance of Moulds for the Injection of Glass Fibre–Reinforced Plastics Using PVD Coatings: A Comparative Study. Coatings 2017, 7, 28. [Google Scholar] [CrossRef]

- Silva, F.J.G.; Martinho, R.P.; Baptista, A.P.M. Characterization of laboratory and industrial CrN/CrCN/diamond-like carbon coatings. Thin Solid Film. 2014, 550, 278–284. [Google Scholar] [CrossRef]

- D’Avico, L.; Beltrami, R.; Lecis, N.; Trasatti, S. Corrosion Behavior and Surface Properties of PVD Coatings for Mold Technology Applications. Coatings 2019, 9, 7. [Google Scholar] [CrossRef]

- Sasaki, T.; Koga, N.; Shirai, K.; Kobayashi, Y.; Toyoshima, A. An experimental study on ejection forces of injection molding. Precis. Eng. 2000, 24, 270–273. [Google Scholar] [CrossRef]

- Burkard, E.; Walther, T.; Schinköthe, W. Influence of Mold Wall Coatings While Demoulding in the Injection Molding Process; Stuttgarter Kunststoff-Kolloquium: Stuttgart, Germany, 1999. [Google Scholar]

- Martins, L.C.; Ferreira, S.C.; Martins, C.I.; Pontes, A.J. Study of ejection forces in injection moulding of thin-walled tubular mouldings. In Proceedings of the PMI 2014 International Conference on Polymers and Moulds Innovations, Guimarães, Portugal, 10–12 September 2014; pp. 281–286. [Google Scholar]

- Sorgato, M.; Masato, D.; Lucchetta, G. Tribological effects of mold surface coatings during ejection in micro injection molding. J. Manuf. Process. 2018, 36, 51–59. [Google Scholar] [CrossRef]

- Lucchetta, G.; Masato, D.; Sorgato, M.; Crema, L.; Savio, E. Effects of different mould coatings on polymer filling flow in thin-wall injection moulding. Cirp Ann. 2016, 65, 537–540. [Google Scholar] [CrossRef]

- Tillmann, W.; Lopes Dias, N.F.; Stangier, D.; Gelinski, N. Tribological Performance of PVD Film Systems against Plastic Counterparts for Adhesion-Reducing Application in Injection Molds. Coatings 2019, 9, 588. [Google Scholar] [CrossRef]

- Mitschang, P.; Schledjewski, R.; Schlarb, A.K. Molds for Continuos Fibre Reinforced Polymer Composites. In Mold-Making Handbook, 3rd ed.; Mennig, G., Stoeckhert, K., Eds.; Hanser: München, Germany, 2013; pp. 200–238. ISBN 978-1-56990-446-6. [Google Scholar]

- Pruner, H.; Nesch, W. Understanding Injection Molds; Hanser: München, Germany, 2013; ISBN 978-1-56990-527-2. [Google Scholar]

- Krywka, C.; Paulus, M.; Sternemann, C.; Volmer, M.; Remhof, A.; Nowak, G.; Nefedov, A.; Pöter, B.; Spiegel, M.; Tolan, M. The new diffractometer for surface X-ray diffraction at beamline BL9 of DELTA. J. Synchrotron Radiat. 2006, 13, 8–13. [Google Scholar] [CrossRef]

- Panjan, P.; Čekada, M.; Panjan, M.; Kek-Merl, D. Growth defects in PVD hard coatings. Vacuum 2009, 84, 209–214. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition (PVD) Processing; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Löffler, M.; Schulte, R.; Freiburg, D.; Biermann, D.; Stangier, D.; Tillmann, W.; Merklein, M. Control of the material flow in sheet-bulk metal forming using modifications of the tool surface. Int. J. Mater. Form. 2019, 12, 17–26. [Google Scholar] [CrossRef]

- Lee, S.-C.; Ho, W.-Y.; Lai, F.D. Effect of substrate surface roughness on the characteristics of CrN hard film. Mater. Chem. Phys. 1996, 43, 266–273. [Google Scholar] [CrossRef]

- Bobzin, K.; Bagcivan, N.; Goebbels, N.; Yilmaz, K.; Hoehn, B.-R.; Michaelis, K.; Hochmann, M. Lubricated PVD CrAlN and WC/C coatings for automotive applications. Surf. Coat. Technol. 2009, 204, 1097–1101. [Google Scholar] [CrossRef]

- Pontes, A.J.; Pinho, A.M.; Miranda, A.S.; Pouzada, A.S. Effect of Processing Conditions on Ejection Forces of Injection Moulds. O Molde 1997, 10, 24–33. [Google Scholar]

- Chen, J.-Y.; Hwang, S.-J. Application of surface treatments on releasing adhesion force during thermoplastic polyurethane injection molding process. Polym. Eng. Sci. 2017, 57, 299–305. [Google Scholar] [CrossRef]

- Bobzin, K.; Hopmann, C.H.; Gillner, A.; Brögelmann, T.; Kruppe, N.C.; Orth, M.; Steger, M.; Naderi, M. Enhanced replication ratio of injection molded plastic parts by using an innovative combination of laser-structuring and PVD coating. Surf. Coat. Technol. 2017, 332, 474–483. [Google Scholar] [CrossRef]

- Krebs, E. Simulationsgestützte Mikrofräsbearbeitung Gehärteter Werkzeugstähle zur Herstellung Filigraner Formelemente und Funktionaler Oberflächenstrukturen; Vulkan: Essen, Germany, 2018. [Google Scholar]

- Tillmann, W.; Stangier, D.; Lopes Dias, N.F.; Biermann, D.; Krebs, E. Adjustment of friction by duplex-treated, bionic structures for Sheet-Bulk Metal Forming. Tribol. Int. 2017, 111, 9–17. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Mold wall temperature | °C | 60 |

| Melt temperature | °C | 220 |

| Injection speed | cm3/s | 40 |

| Packing pressure | MPa | 35 |

| Packing time | s | 10 |

| Cooling time | s | 60 |

| Ejector speed | mm/s | 10 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tillmann, W.; Stangier, D.; Lopes Dias, N.F.; Gelinski, N.; Stanko, M.; Stommel, M.; Krebs, E.; Biermann, D. Reduction of Ejection Forces in Injection Molding by Applying Mechanically Post-Treated CrN and CrAlN PVD Films. J. Manuf. Mater. Process. 2019, 3, 88. https://doi.org/10.3390/jmmp3040088

Tillmann W, Stangier D, Lopes Dias NF, Gelinski N, Stanko M, Stommel M, Krebs E, Biermann D. Reduction of Ejection Forces in Injection Molding by Applying Mechanically Post-Treated CrN and CrAlN PVD Films. Journal of Manufacturing and Materials Processing. 2019; 3(4):88. https://doi.org/10.3390/jmmp3040088

Chicago/Turabian StyleTillmann, Wolfgang, Dominic Stangier, Nelson Filipe Lopes Dias, Nikolai Gelinski, Michael Stanko, Markus Stommel, Eugen Krebs, and Dirk Biermann. 2019. "Reduction of Ejection Forces in Injection Molding by Applying Mechanically Post-Treated CrN and CrAlN PVD Films" Journal of Manufacturing and Materials Processing 3, no. 4: 88. https://doi.org/10.3390/jmmp3040088

APA StyleTillmann, W., Stangier, D., Lopes Dias, N. F., Gelinski, N., Stanko, M., Stommel, M., Krebs, E., & Biermann, D. (2019). Reduction of Ejection Forces in Injection Molding by Applying Mechanically Post-Treated CrN and CrAlN PVD Films. Journal of Manufacturing and Materials Processing, 3(4), 88. https://doi.org/10.3390/jmmp3040088