Mechanical Performance Assessment of Internally-Defected Materials Manufactured Using Additive Manufacturing Technology †

Abstract

1. Introduction

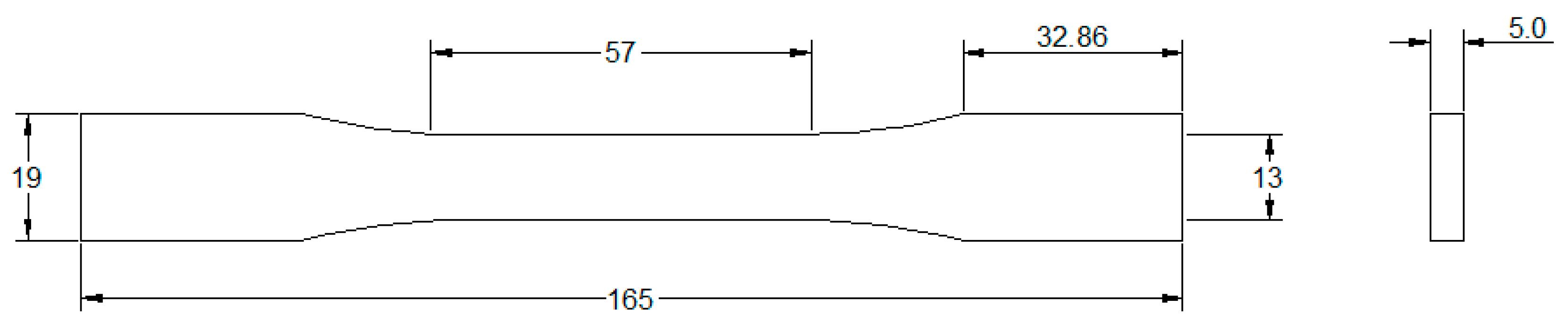

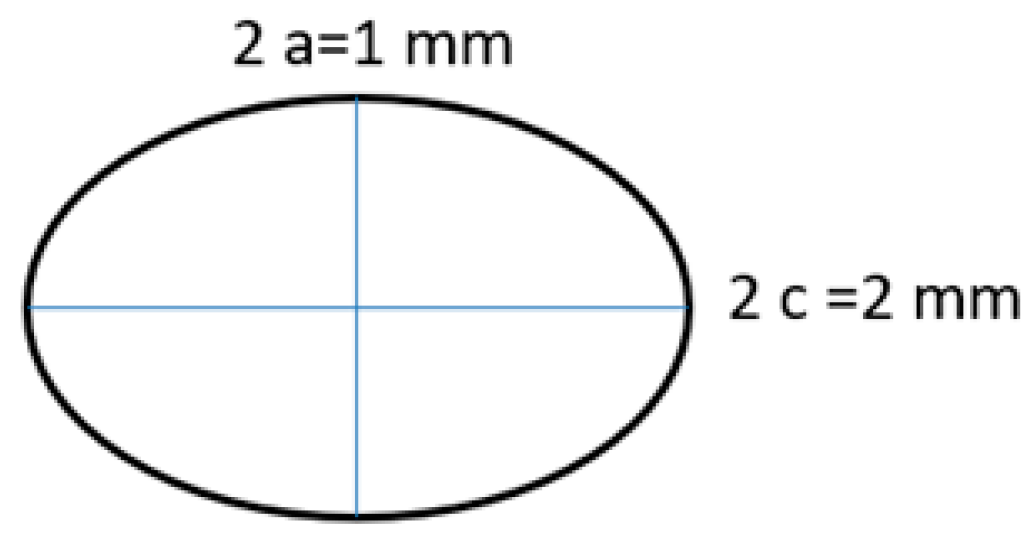

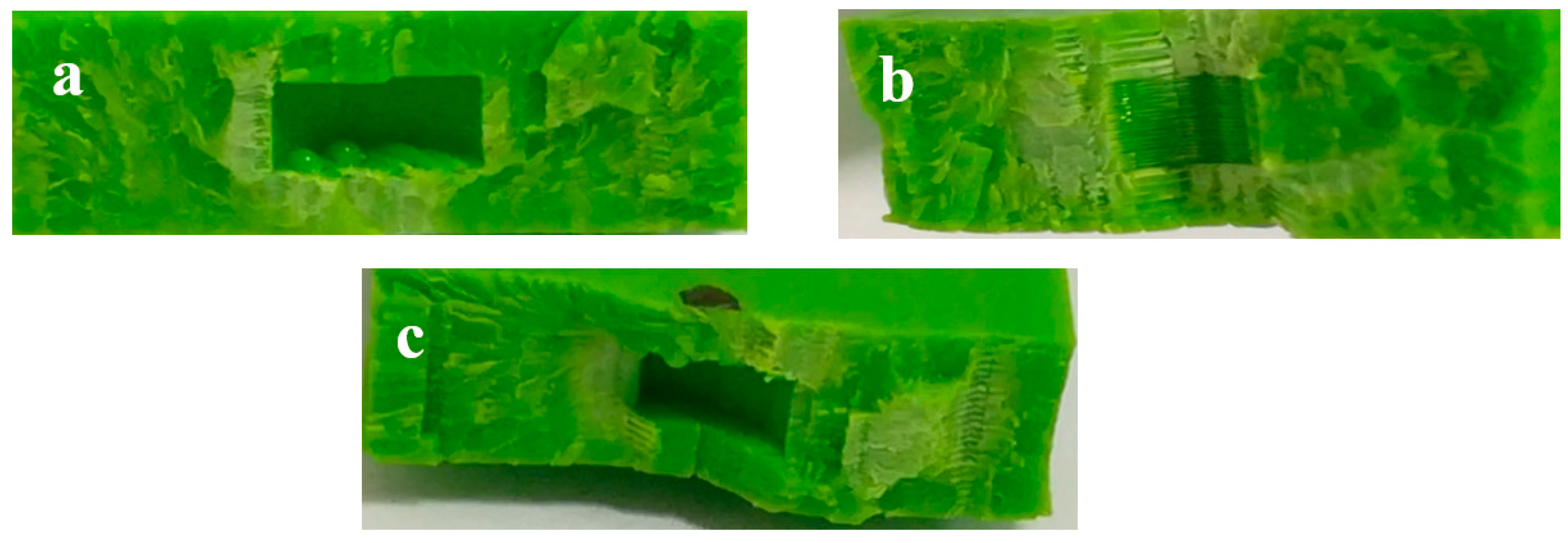

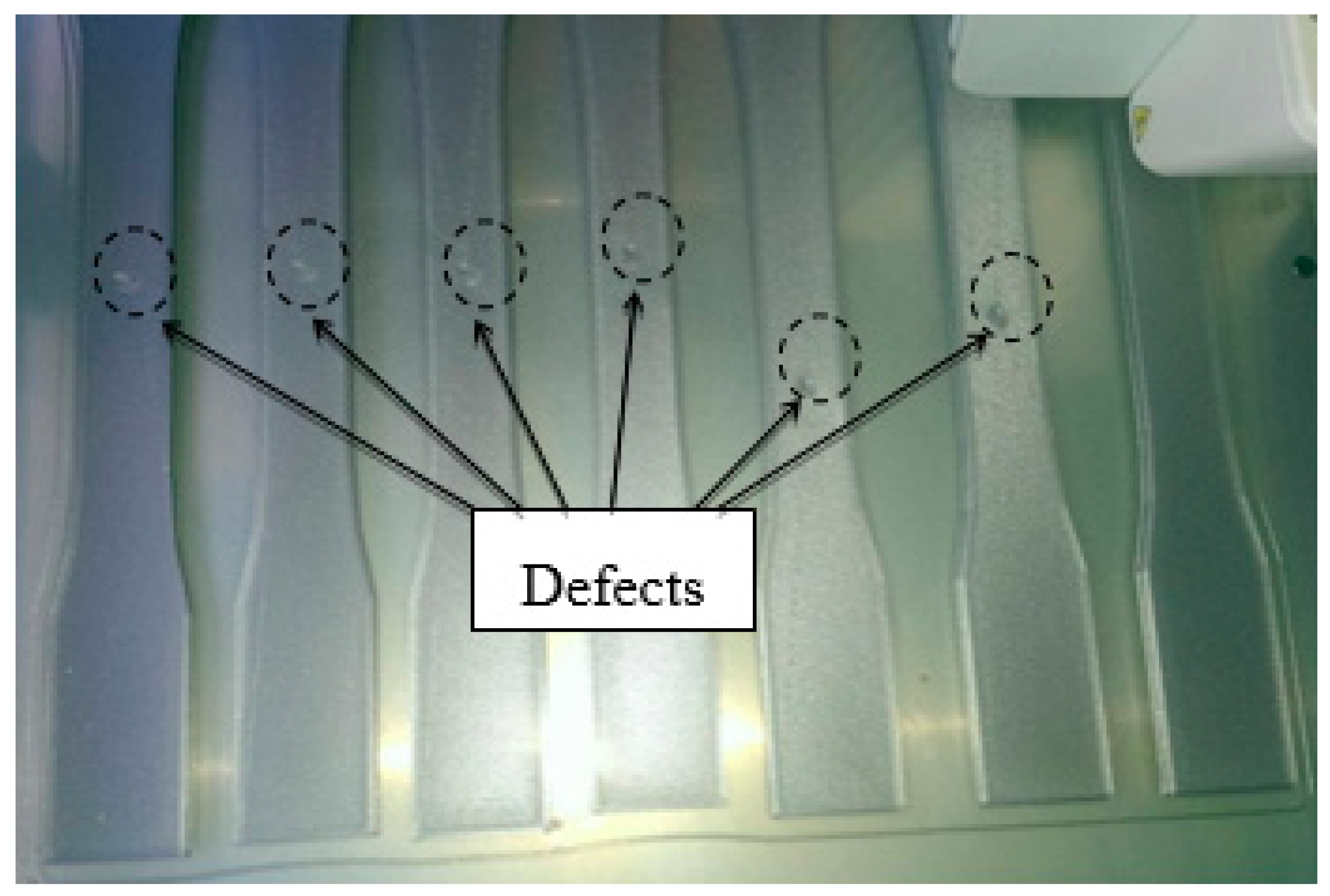

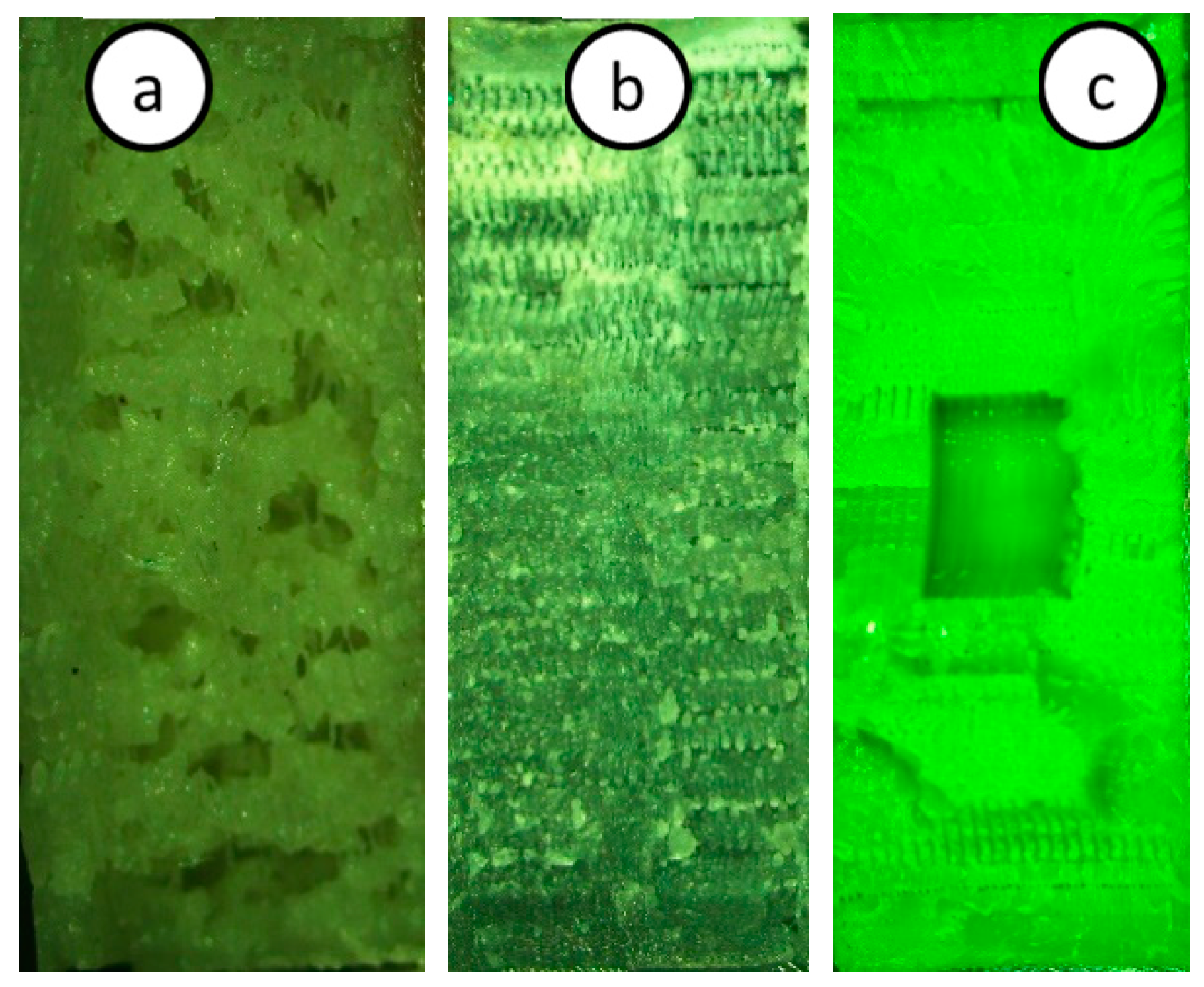

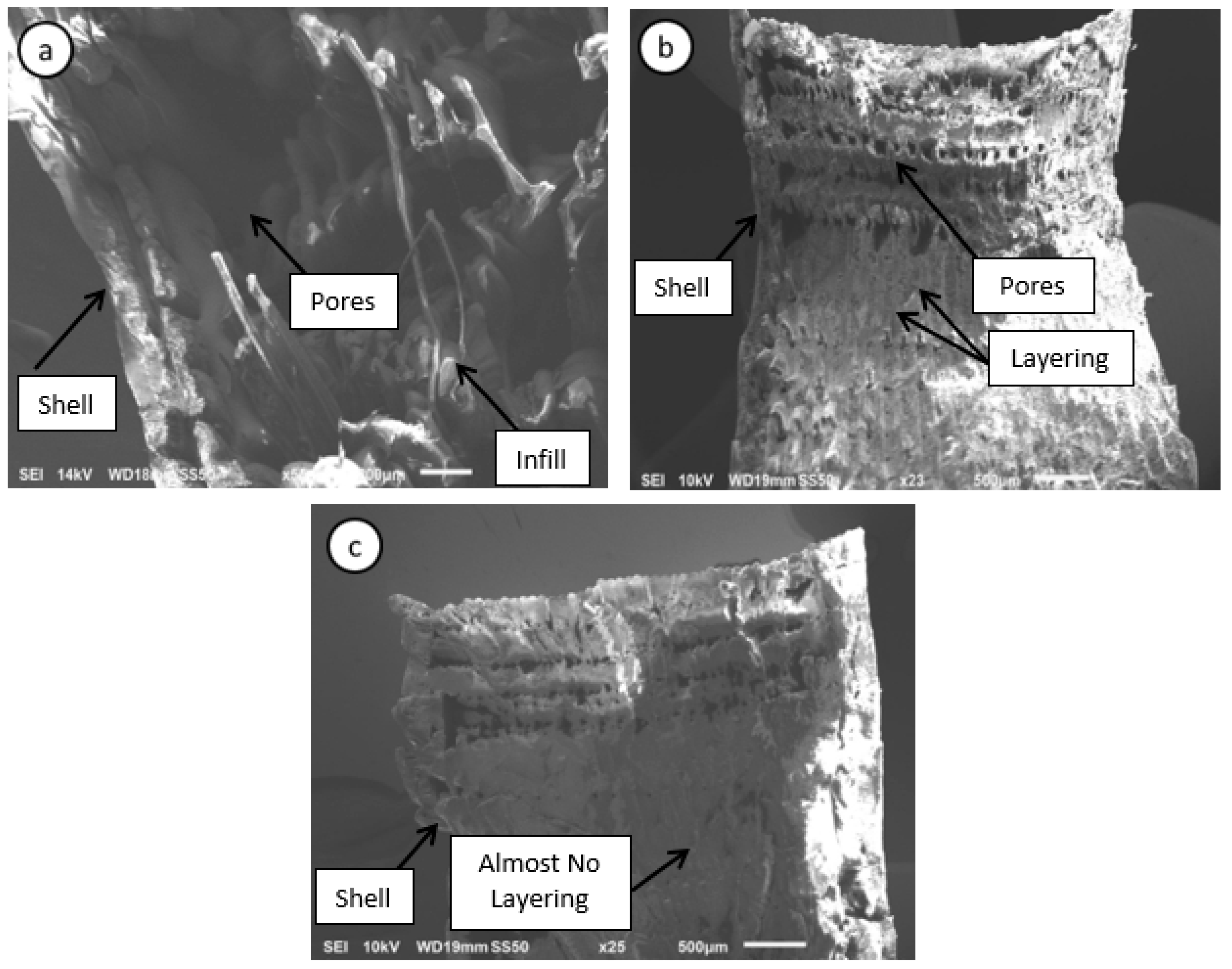

2. Materials and Methods

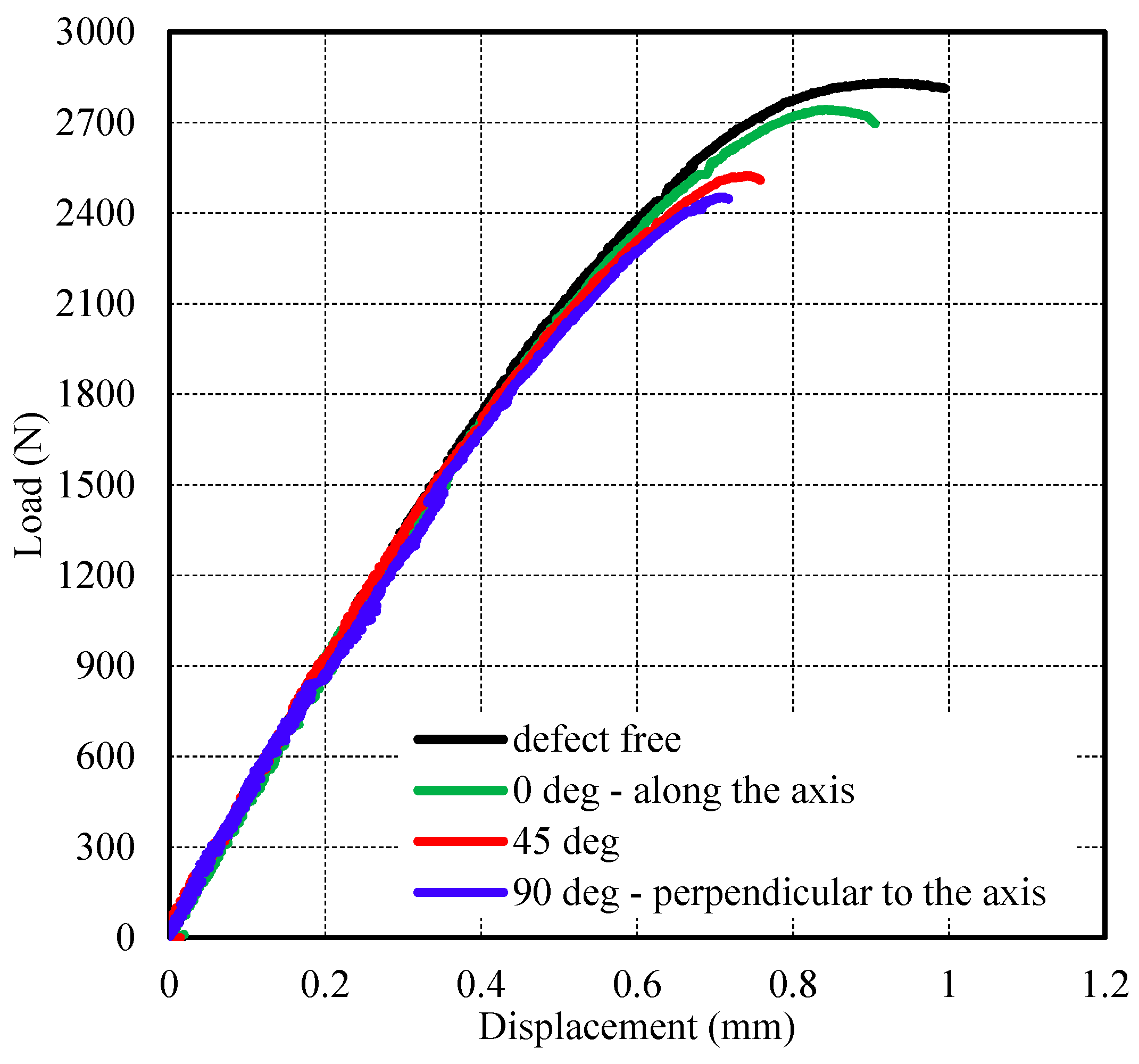

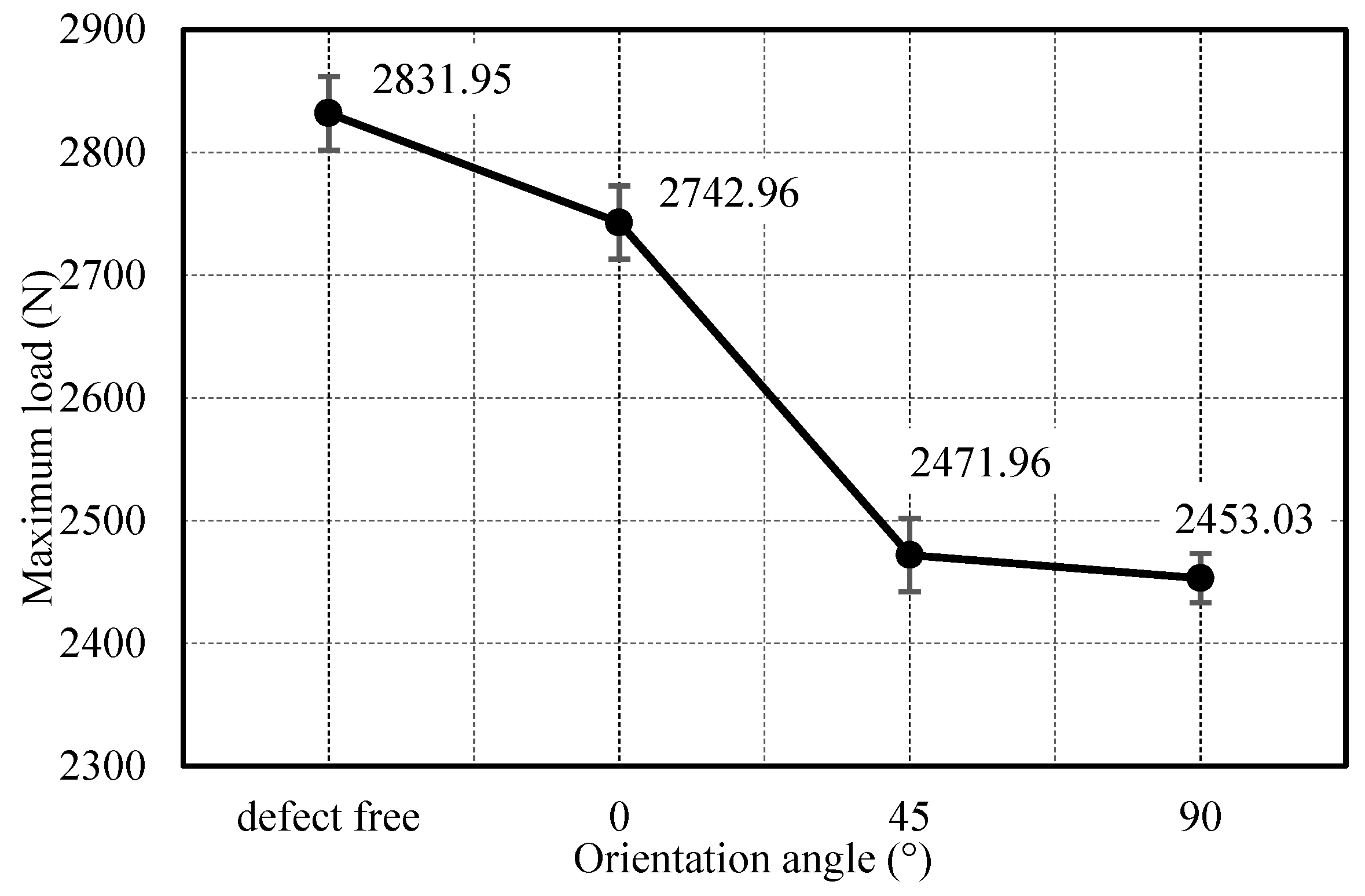

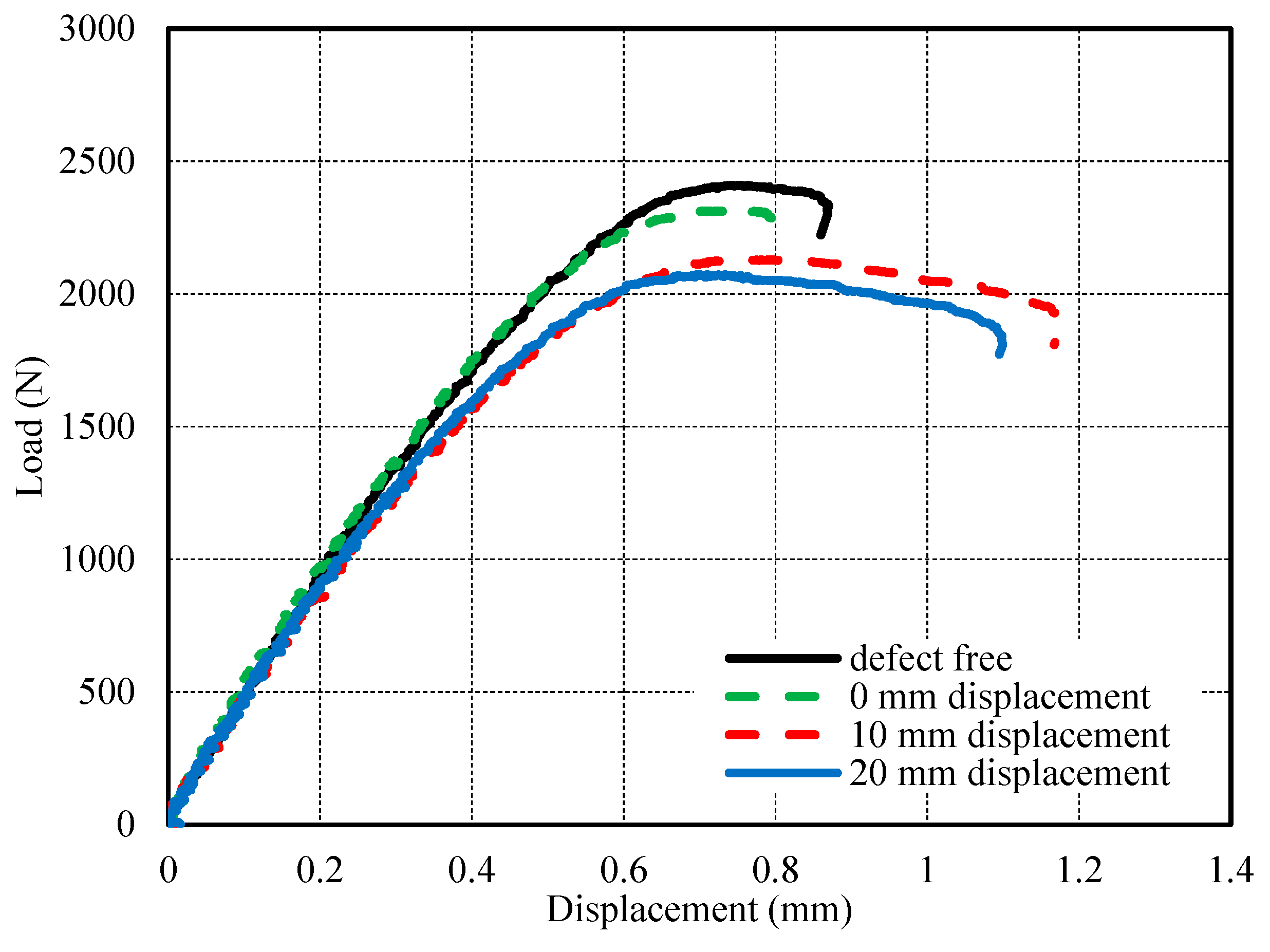

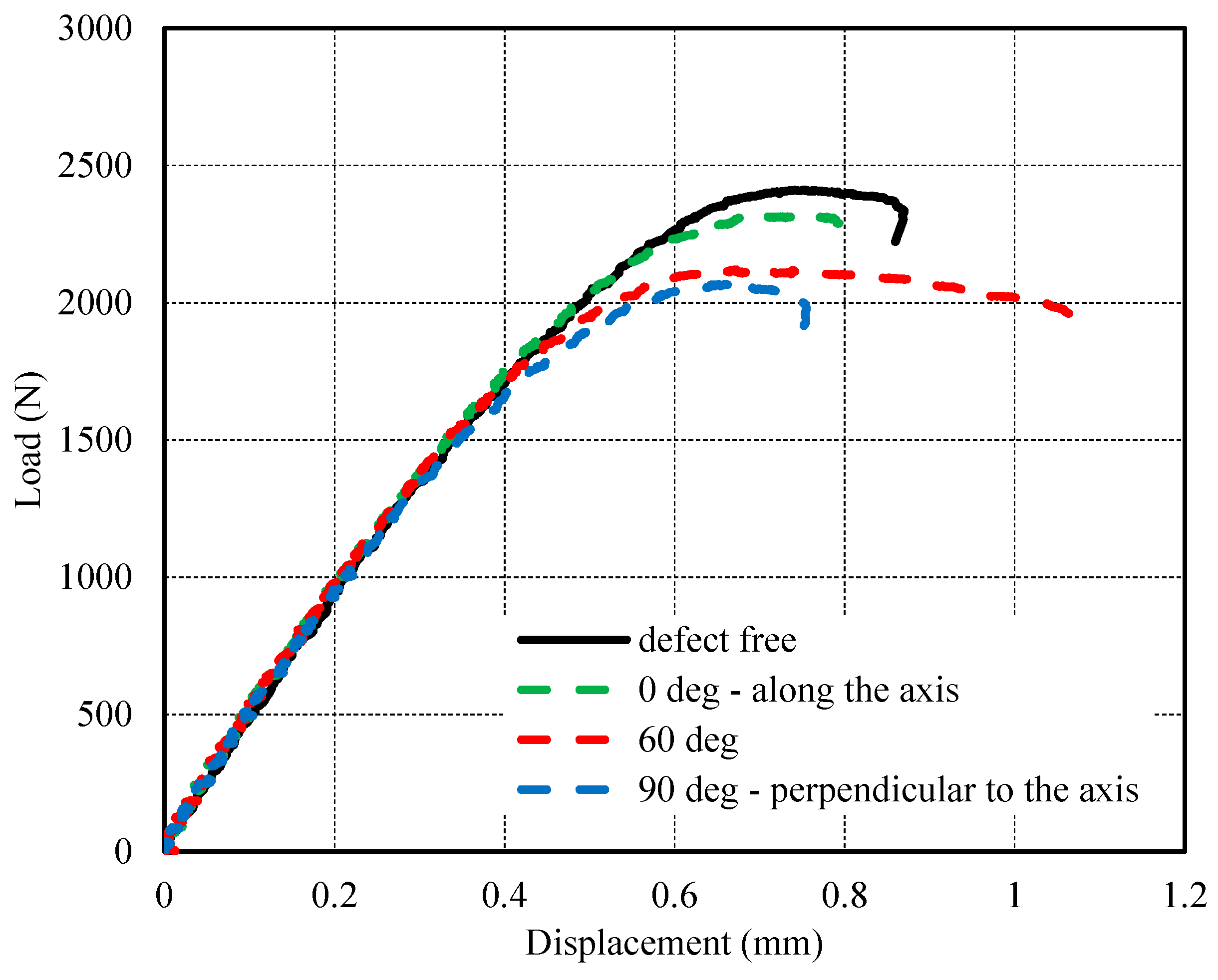

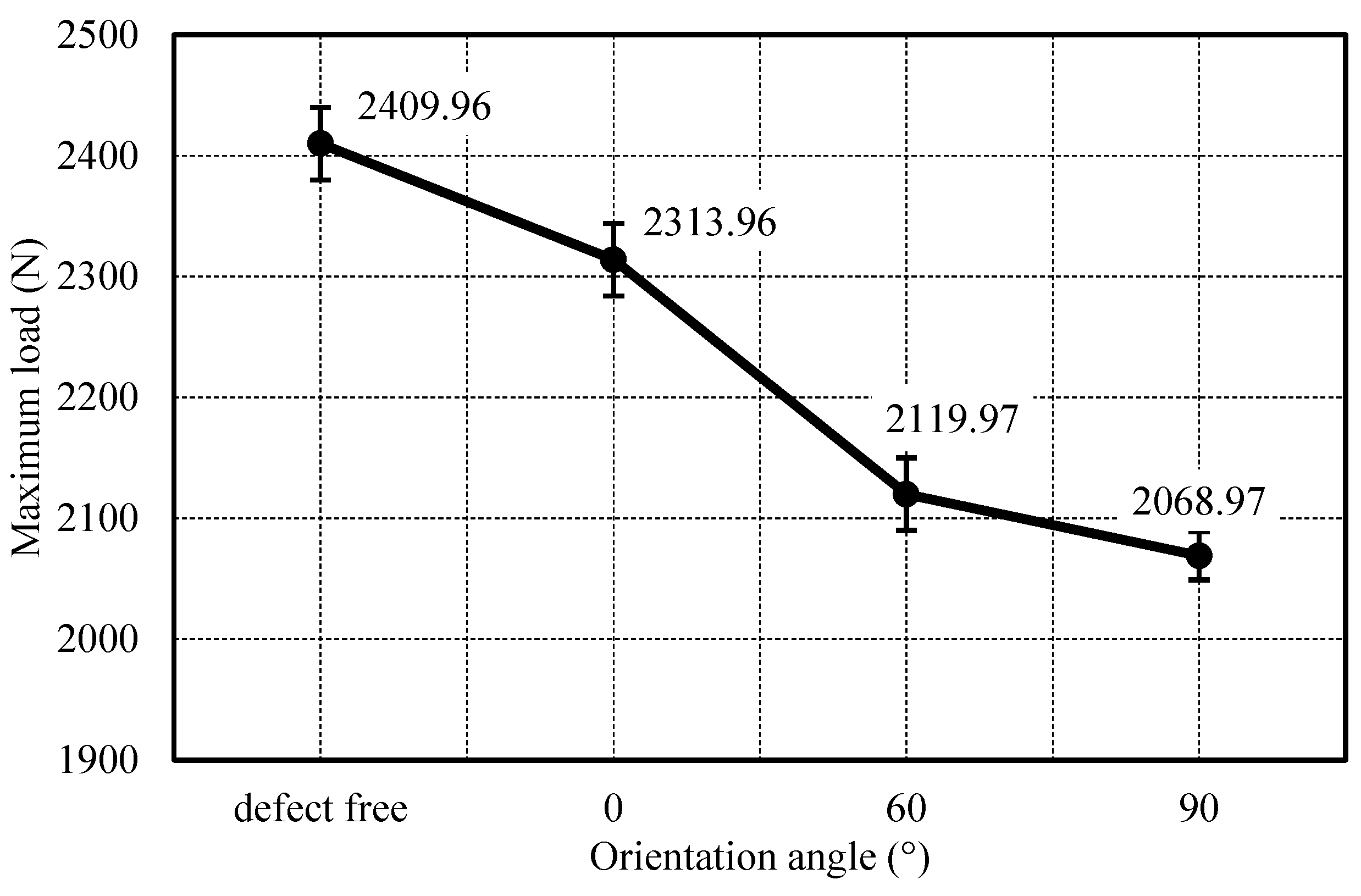

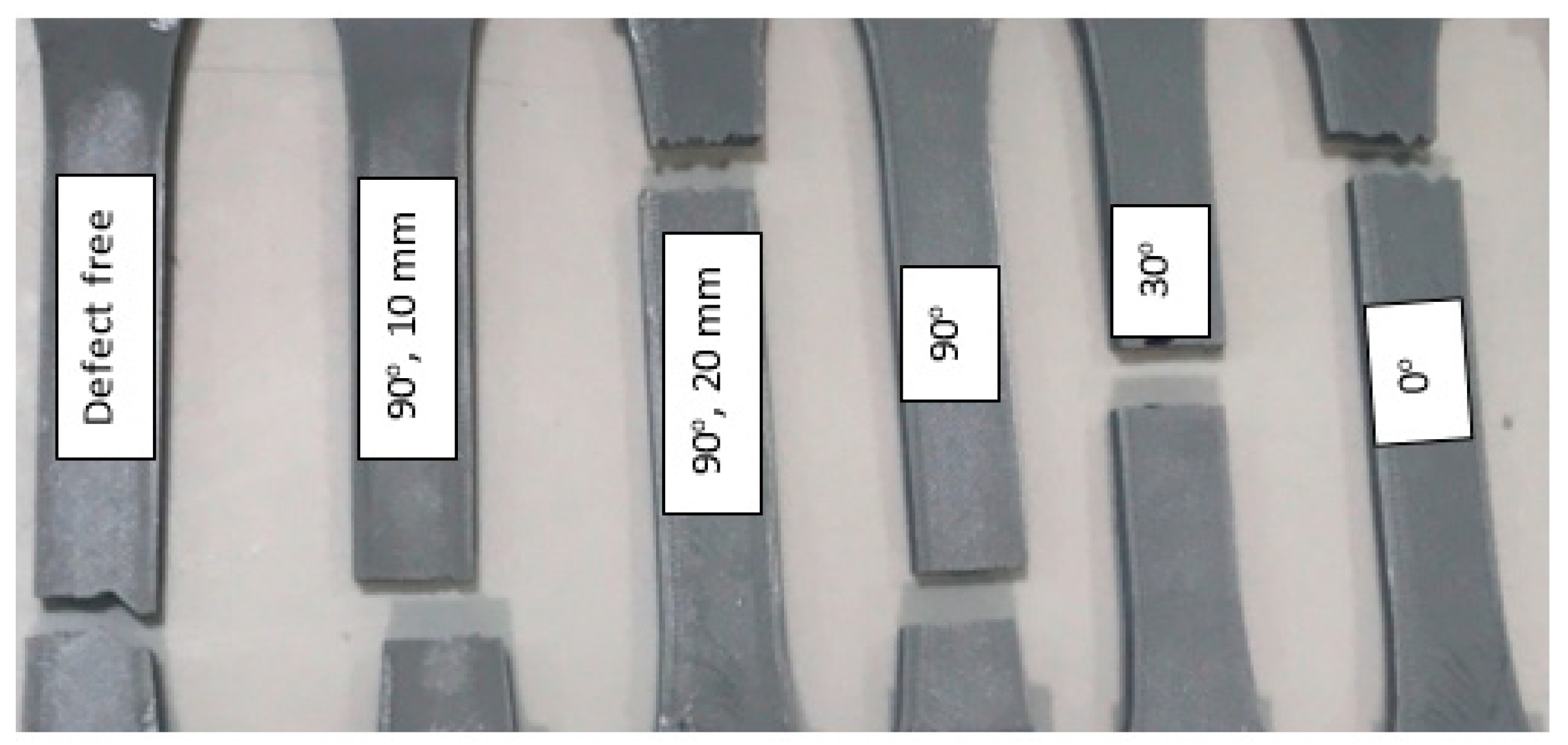

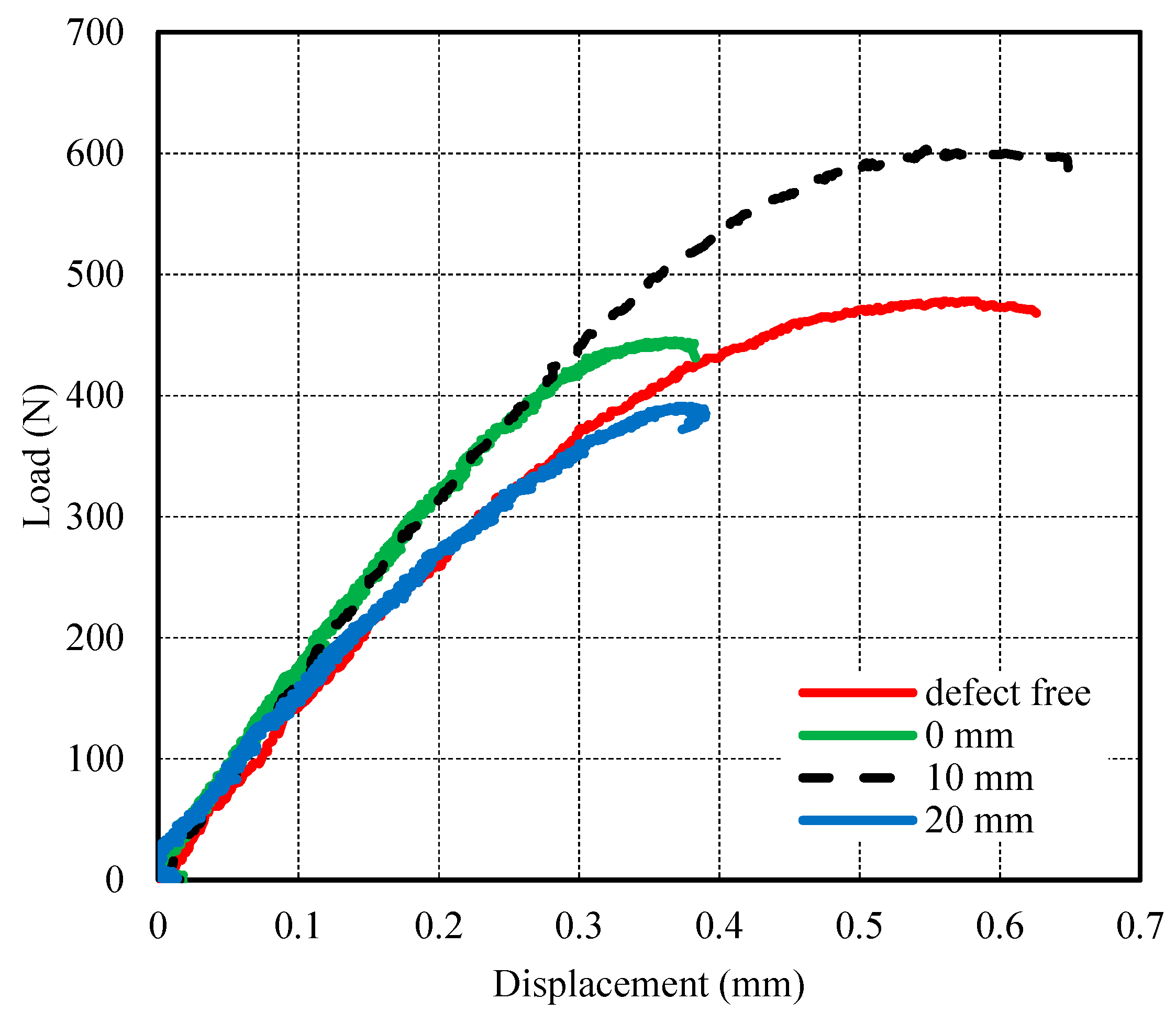

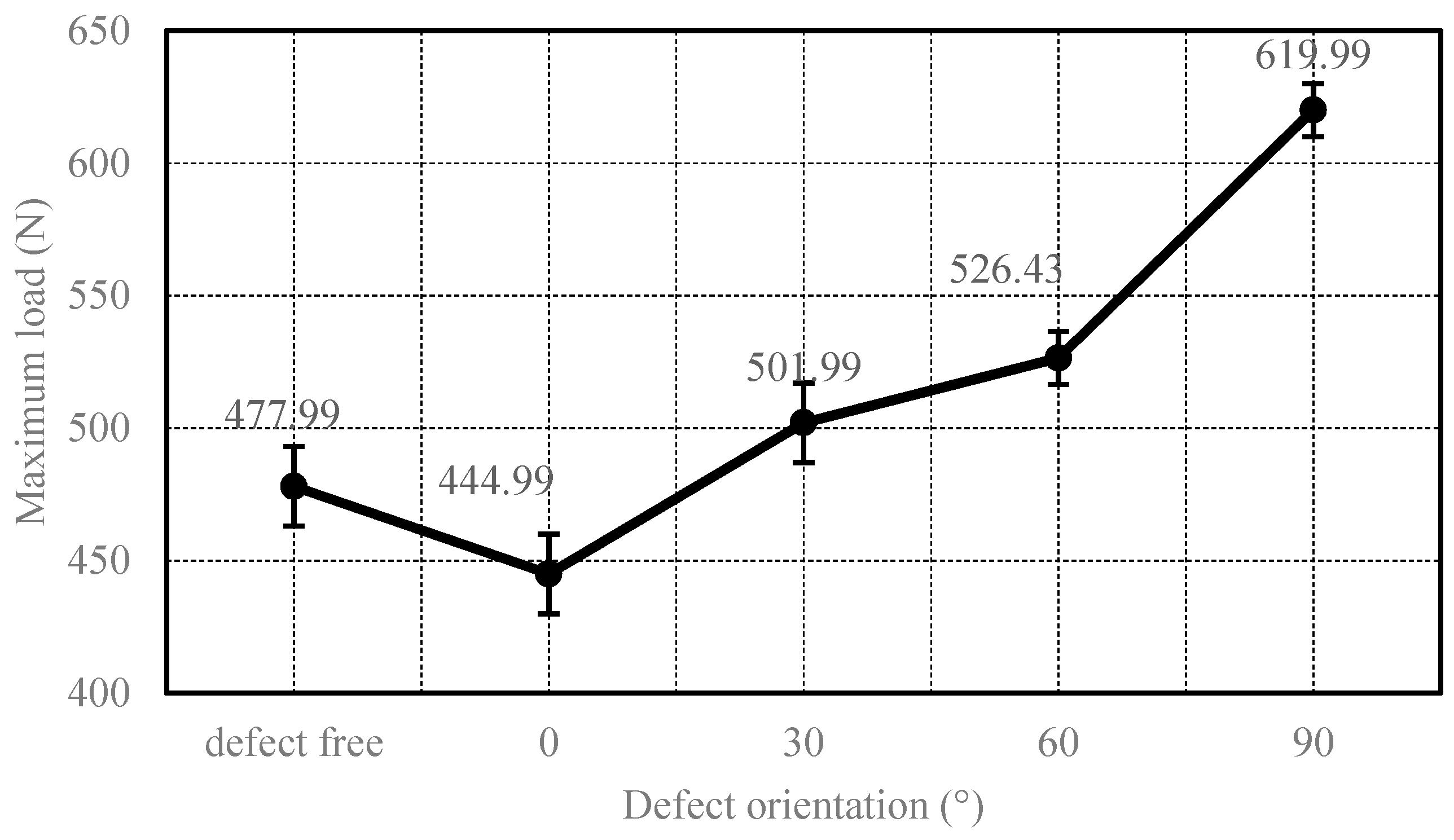

3. Results

3.1. Effect of Internal Defects

3.2. The Effect of Infill Rate and Additive Color

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, D.; Miyoshi, T.; Takaya, Y.; Ha, T. 3D microfabrication of photosensitive resin reinforced with ceramic nanoparticles using LCD microstereolithography. J. Laser Micro/Nanoeng. 2006, 1, 142–148. [Google Scholar]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Horn, T.J.; Harrysson, O.L.A. Overview of current additive manufacturing technologies and selected applications. Sci. Prog. 2012, 95, 255–282. [Google Scholar] [CrossRef] [PubMed]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Wohler, T.T. Additive Manufacturing and 3D Printing State of the Industry: Annual Wourldwide Progress Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2011. [Google Scholar]

- Singh, D.; Singh, R.; Boparai, K.S.; Farina, I.; Feo, L.; Verma, A.K. In-vitro studies of SS 316 L biomedical implants prepared by FDM, vapor smoothing and investment casting. Compos. Part B Eng. 2018, 132, 107–114. [Google Scholar] [CrossRef]

- Singh, R.; Sandhu, G.; Penna, R.; Farina, I. Investigations for thermal and electrical conductivity of ABS-graphene blended prototypes. Materials 2017, 10, 881. [Google Scholar] [CrossRef]

- Kim, H.; Park, E.; Kim, S.; Park, B.; Kim, N.; Lee, S. Experimental study on mechanical properties of single-and dual-material 3D-printed products. Procedia Manuf. 2017, 10, 887–897. [Google Scholar] [CrossRef]

- Raut, S.; Jatti, V.S.; Khedkar, N.K.; Singh, T.P. Investigation of the effect of built orientation on mechanical properties and total cost of FDM parts. Procedia Mater. Sci. 2014, 6, 1625–1630. [Google Scholar] [CrossRef]

- Qattawi, A.; Alrawi, B.; Guzman, A. Experimental optimization of fused deposition modelling processing parameters: A design-for-manufacturing approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar]

- Gardan, J.; Makke, A.; Recho, N. A method to improve the fracture toughness using 3D printing by extrusion deposition. Procedia Struct. Integr. 2016, 2, 144–151. [Google Scholar] [CrossRef]

- Letcher, T.; Waytashek, M. Material property testing of 3d-printed specimen in PLA on an entry-level 3D printer. In ASME 2014 International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers: New York, NY, USA, 2014; p. V02AT02A014. [Google Scholar]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K.M. Effect of Material and Process Specific Factors on the Strength of Printed Parts in Fused Filament Fabrication: A Review of Recent Developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef] [PubMed]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Patterson, A.E. Crack Propagation in 3DPrinted PLA: Finite Element Modeling, Test Bed Design, and Preliminary Experimental Results; Technical Report; IDEALS: University of Illinois at Urbana-Champaign, Champaign County, IL, USA, 2018. [Google Scholar]

- Maiti, S.K.; Mourad, A.-H.I. Criterion for mixed-mode stable crack growth, Part I: Three point bend geometry and Part D Compact tension geometry with and without stiffener. Eng. Fract. Mech. 1995, 52, 321–347. [Google Scholar] [CrossRef]

- Farbman, D.; McCoy, C. Materials Testing of 3D-printed ABS and PLA Samples to Guide Mechanical Design. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, Blacksburg, VA, USA, 27 June–1 July 2016; American Society of Mechanical Engineers: New York, NY, USA, 2016; p. V002T01A015. [Google Scholar]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zeltmann, S.E.; Gupta, N.; Tsoutsos, N.G.; Maniatakos, M.; Rajendran, J.; Karri, R. Manufacturing and security challenges in 3D printing. JOM 2016, 68, 1872–1881. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Maiti, S.K. Mode I and Mixed-Mode Stable Crack Extensions through Stiffened Three-Point Bend Specimens. Fatigue Fract. Eng. Mater. Struct. 1995, 18, 645–652. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Maiti, S.K. Mode II stable crack growth. Fatigue Fract. Eng. Mater. Struct. 1996, 19, 75–84. [Google Scholar] [CrossRef]

- Mourad, A.H.I.; Alghafri, M.J.; Zeid, O.A.A.; Maiti, S.K. Experimental investigation on ductile stable crack growth emanating from wire-cut notch in AISI 4340 steel. Nucl. Eng. Des. 2005, 235, 637–647. [Google Scholar] [CrossRef]

- Mourad, A.-H.I. Effect of stress state on mode II stable crack extension. Key Eng. Mater. 2005, 297, 1604–1610. [Google Scholar] [CrossRef]

- Maiti, S.K.; Kishore, G.K.; Mourad, A.-H.I. Bilinear CTOD/CTOA scheme for characterisation of large range mode I and mixed mode stable crack growth through AISI 4340 steel. Nucl. Eng. Des. 2008, 238, 3175–3185. [Google Scholar] [CrossRef]

- Maiti, S.K.; Namdeo, S.; Mourad, A.-H.I. A scheme for finite element analysis of mode I and mixed mode stable crack growth and a case study with AISI 4340 steel. Nucl. Eng. Des. 2008, 238, 787–800. [Google Scholar] [CrossRef]

- El-Sayed, M.; El Domiaty, A.; Mourad, A.-H.I. Fracture assessment of axial crack in steel pipe under internal pressure. Procedia Eng. 2015, 130, 1273–1287. [Google Scholar] [CrossRef]

- Mourad, A.I. Pure shear stable crack growth through Compact-Tension-Shear specimen in plane state of stress. Strength Fract. Complex. 2004, 2, 111–125. [Google Scholar]

- Mourad, A.-H.I.; Alghafri, M.G.; Abu Zeid, O.A. Stable crack extension through AISI 4340 steel: Experimental investigation. Key Eng. Mater. 2004, 261, 207–212. [Google Scholar] [CrossRef]

- Mourad, A.-H.; Maiti, S.K. Influence of state of stress on mixed mode stable crack growth through D16AT aluminium alloy. Int. J. Fract. 1995, 72, 241–258. [Google Scholar] [CrossRef]

- Maiti, S.K.; Mourad, A.-H.I. Criterion for mixed mode stable crack growth—II. Compact tension geometry with and without stiffener. Eng. Fract. Mech. 1995, 52, 349–378. [Google Scholar] [CrossRef]

- Kerekes, T.W.; Lim, H.; Joe, W.Y.; Yun, G.J. Characterization of process–deformation/damage property relationship of fused deposition modeling (FDM) 3D-printed specimens. Addit. Manuf. 2019, 25, 532–544. [Google Scholar] [CrossRef]

- DeVries, M.; Subhash, G.; Mcghee, A.; Ifju, P.; Jones, T.; Zheng, J.; Halls, V. Quasi-static and dynamic response of 3D-printed alumina. J. Eur. Ceram. Soc. 2018, 38, 3305–3316. [Google Scholar] [CrossRef]

- Tetsworth, K.; Block, S.; Glatt, V. Putting 3D modelling and 3D printing into practice: Virtual surgery and preoperative planning to reconstruct complex post-traumatic skeletal deformities and defects. SICOT-J 2017, 3, 16. [Google Scholar] [CrossRef]

- Kotlinski, J. Mechanical properties of commercial rapid prototyping materials. Rapid Prototyp. J. 2014, 20, 499–510. [Google Scholar] [CrossRef]

- Lanzotti, A.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Standard, A. D638: Standard Test Method for Tensile Properties of Plastics; ASTM Internation: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Mourad, A.-H.I.; Ghazal, A.M.; Syam, M.M.; Al Qadi, O.D.; Al Jassmi, H. Utilization of Additive Manufacturing in Evaluating the Performance of Internally-defected Materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 362, 12026. [Google Scholar] [CrossRef]

- Roberson, D.A.; Espalin, D.; Wicker, R.B. 3D printer selection: A decision-making evaluation and ranking model. Virtual Phys. Prototyp. 2013, 8, 201–212. [Google Scholar] [CrossRef]

- Torrado, A.R.; Roberson, D.A. Failure analysis and anisotropy evaluation of 3D-printed tensile test specimens of different geometries and print raster patterns. J. Fail. Anal. Prev. 2016, 16, 154–164. [Google Scholar] [CrossRef]

- Idrisi, A.H.; Mourad, A.-H.I. Conventional stir casting versus ultrasonic assisted stir casting process: Mechanical and physical characteristics of AMCs. J. Alloys Compd. 2019, 805, 502–508. [Google Scholar] [CrossRef]

- Mourad, A.-H.I.; Idrisi, A.H.; Wrage, M.C.; Abdel-Magid, B.M. Long-term durability of thermoset composites in seawater environment. Compos. Part B Eng. 2019, 168, 243–253. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Polymer density (g/cm3) | 1.21–1.25 |

| Tensile strength (MPa) | 15.5–72.2 (21–60) |

| Tensile modulus (GPa) | 2.020–3.550 (0.35–3.5) |

| Elongation at break (%) | 0.5–9.2 |

| Ultimate strain (%) | 2.5–6 |

| Specific tensile strength (Nm/g) | 16.8–48 |

| Specific tensile modulus (kNm/g) | 0.28–2.80 |

| Glass transition temperature (°C) | 45–60 |

| Melting temperature (°C) | 150–162 |

| Parameters | Value/Specification |

|---|---|

| PLA (colors) | White, Gray, Green |

| Layer thickness (mm) | 0.1 |

| Shell wall thickness (mm) | 1.05 |

| Shell top/bottom thickness (mm) | 0.8 |

| Infill percentage (%) | 50% (White), 100% (Green, Gray and White) |

| Feed rate/printing speed (mm/s) | 50 (Gray), 80 (White and Green) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ismail Mourad, A.-H.; Idrisi, A.H.; Christy, J.V.; Thekkuden, D.T.; Al Jassmi, H.; Ghazal, A.M.; Syam, M.M.; Ali Ahmed Al Qadi, O.D. Mechanical Performance Assessment of Internally-Defected Materials Manufactured Using Additive Manufacturing Technology. J. Manuf. Mater. Process. 2019, 3, 74. https://doi.org/10.3390/jmmp3030074

Ismail Mourad A-H, Idrisi AH, Christy JV, Thekkuden DT, Al Jassmi H, Ghazal AM, Syam MM, Ali Ahmed Al Qadi OD. Mechanical Performance Assessment of Internally-Defected Materials Manufactured Using Additive Manufacturing Technology. Journal of Manufacturing and Materials Processing. 2019; 3(3):74. https://doi.org/10.3390/jmmp3030074

Chicago/Turabian StyleIsmail Mourad, Abdel-Hamid, Amir Hussain Idrisi, John Victor Christy, Dinu Thomas Thekkuden, Hamad Al Jassmi, Abdallah M. Ghazal, Mahmmoud M. Syam, and Omar Darwish Ali Ahmed Al Qadi. 2019. "Mechanical Performance Assessment of Internally-Defected Materials Manufactured Using Additive Manufacturing Technology" Journal of Manufacturing and Materials Processing 3, no. 3: 74. https://doi.org/10.3390/jmmp3030074

APA StyleIsmail Mourad, A.-H., Idrisi, A. H., Christy, J. V., Thekkuden, D. T., Al Jassmi, H., Ghazal, A. M., Syam, M. M., & Ali Ahmed Al Qadi, O. D. (2019). Mechanical Performance Assessment of Internally-Defected Materials Manufactured Using Additive Manufacturing Technology. Journal of Manufacturing and Materials Processing, 3(3), 74. https://doi.org/10.3390/jmmp3030074