Prediction of Surface Quality Based on the Non-Linear Vibrations in Orthogonal Cutting Process: Time Domain Modeling

Abstract

:1. Introduction

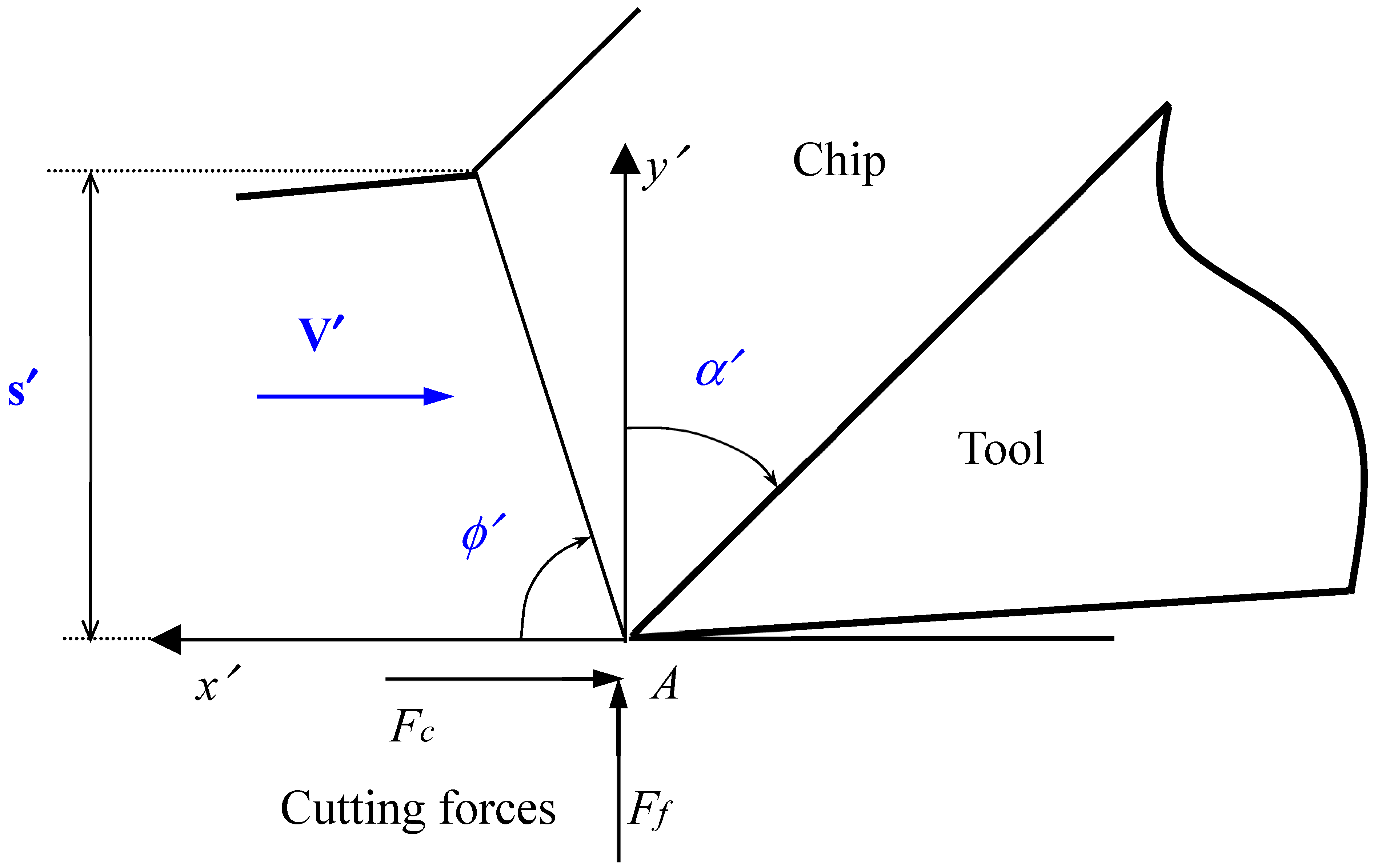

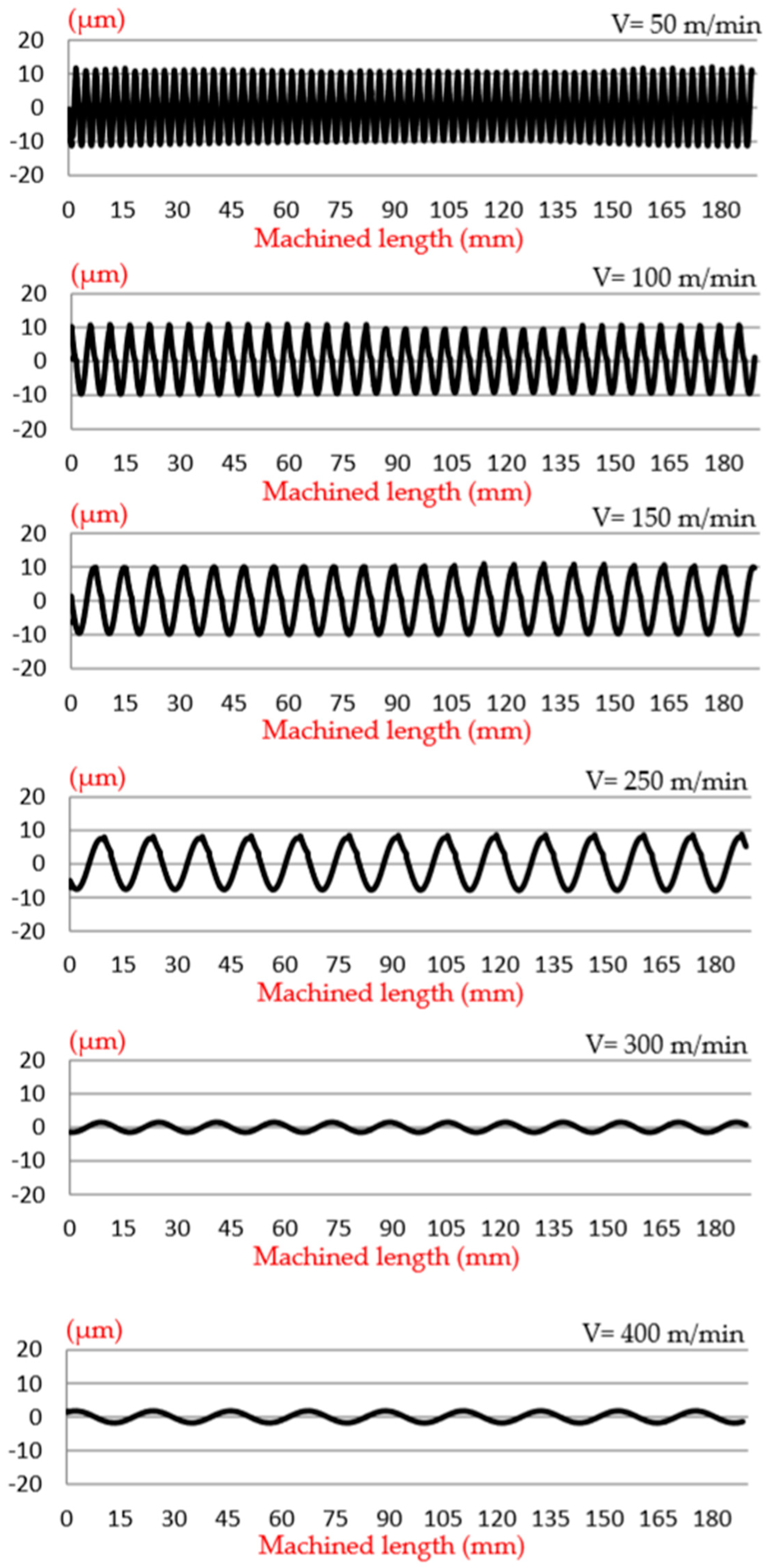

2. Analytical Modeling

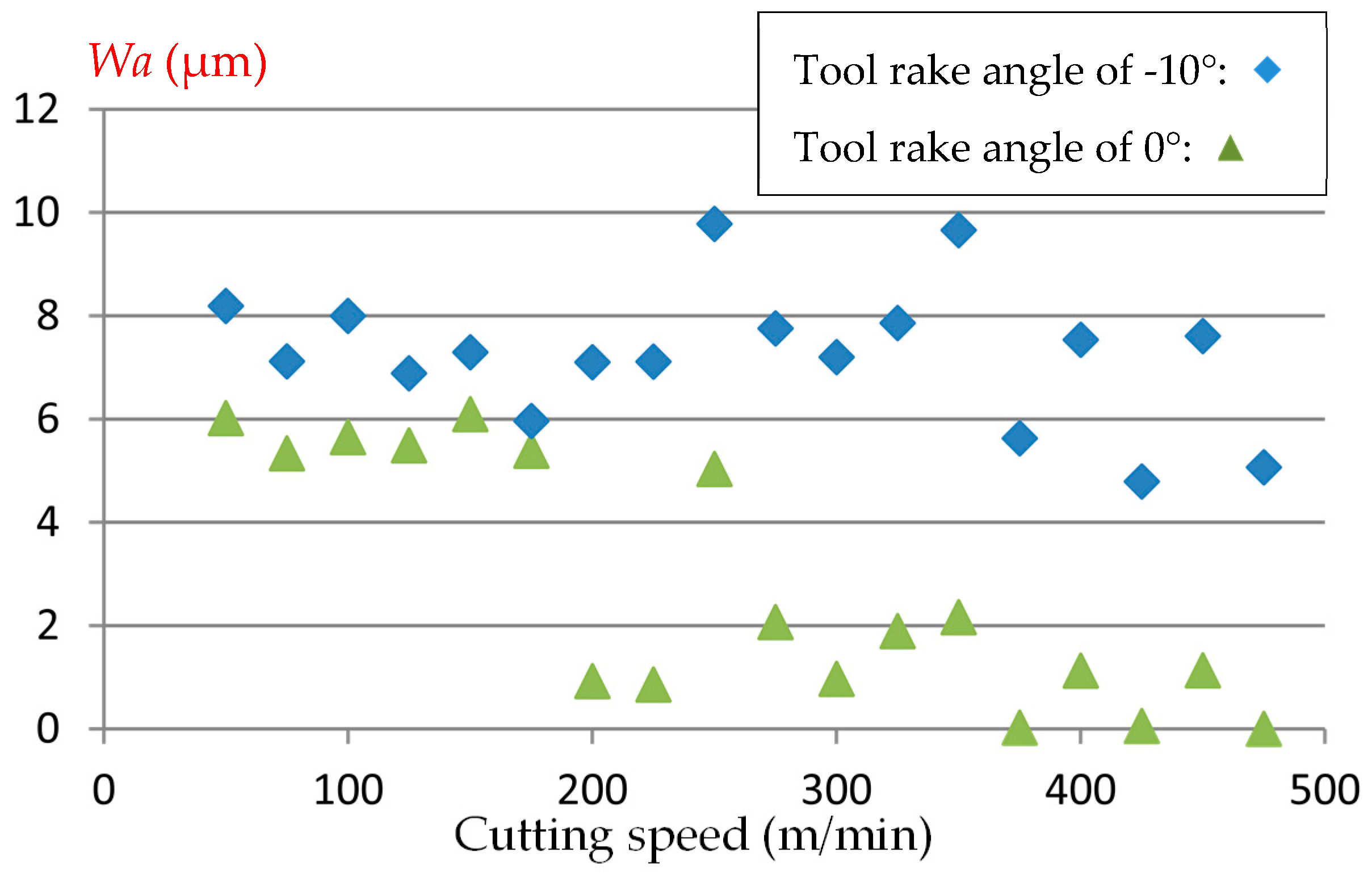

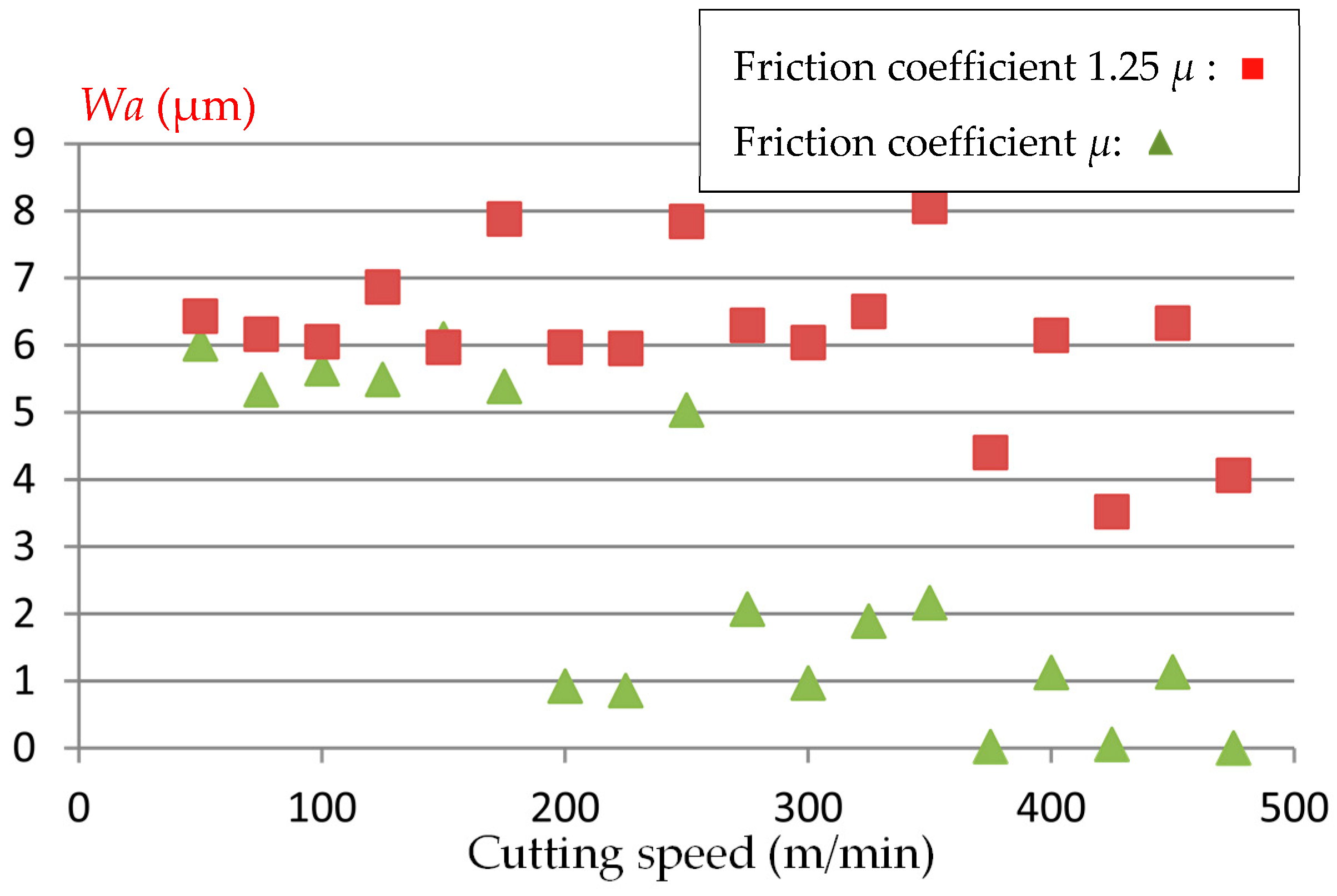

3. Results and Discussion

4. Conclusions

- The used predictive model, including the thermoviscoplastic behavior of the work material, represents an alternative to the classical mechanistic approach which requires many experimental tests to determine the specific cutting coefficients.

- The model takes into account the fact that the regenerative effect results in a variation over time of the cutting conditions (cutting speed, uncut chip thickness, tool rake angle) and the tribological behavior at the tool–chip interface.

- A new computational strategy reducing the computational times in the non-linear approach was developed.

- The arithmetic mean deviation of the waviness profile Wa is highly non-linear with respect to the cutting conditions.

- The friction conditions at the tool–chip interface significantly affect the parameter Wa.

Author Contributions

Funding

Conflicts of Interest

References

- Rakit, A.K.; Osman, M.O.M.; Sankar, T.S. Machine tool vibrations: Its effect on manufactured surface. In Proceedings of the 4th Canadian Congress of Applied Mechanics, Montreal, QC, Canada, 28 May–1 June 1973; pp. 463–464. [Google Scholar]

- Lasota, A.; Rusek, P. Influence of random vibrations on the roughness of turned surfaces. J. Mech. Work. Technol. 1983, 7, 277–284. [Google Scholar] [CrossRef]

- Sata, T.; Li, M.; Takata, S.; Hiraoka, H.; Xing, X.; Xiao, X. Analysis of surface roughness generation in turning operation and its application. Ann. CIRP 1985, 34, 473–476. [Google Scholar] [CrossRef]

- Mital, A.; Mehta, M. Surface finish prediction models for the fine turning. Int. J. Prod. Res. 1988, 26, 1861–1876. [Google Scholar] [CrossRef]

- Zhang, G.M.; KapoorDynamic, S.G. Generation of machined surfaces, Parts 1 and 2. ASME J. Eng. Ind. 1991, 113, 137–152. [Google Scholar] [CrossRef]

- Mer, B.; Diniz, A.E. Correlating tool wear, tool life, surface-roughness and tool vibration in finish turning with coated carbide tools. Wear 1994, 173, 137–144. [Google Scholar]

- Jang, D.Y.; Choi, Y.G.; Kim, H.G.; Hsiao, A. Study of the correlation between surface roughness and cutting vibrations to develop an online roughness measuring technique in hard turning. Int. J. Mach. Tools Manuf. 1996, 36, 453–464. [Google Scholar] [CrossRef]

- Abouelatta, O.B.; Madl, J. Surface roughness prediction based on cutting parameters and tool vibrations in turning operations. J. Mater. Process. Technol. 2001, 118, 269–277. [Google Scholar] [CrossRef]

- Hessainia, Z.; Belbah, A.; Athmane Yallese, M.; Mabrouki, T.; Rigal, J.F. On the prediction of surface roughness in the hard turning based on cutting parameters and tool vibrations. Measurement 2013, 46, 1671–1681. [Google Scholar] [CrossRef]

- Rao, K.V.; Murthy, B.S.N.; Rao, N.M. Cutting tool condition monitoring by analyzing surface roughness, work piece vibration and volume of metal removed for AISI 1040 steel in boring. Measurement 2013, 46, 4075–4084. [Google Scholar]

- Ancio, F.; Gámez, A.J.; Marcos, M. Factors influencing the generation of a machined surface. Application to turned pieces. J. Mater. Process. Technol. 2015, 215, 50–61. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Sanchez, J.A.; Salgado, M.A. Effects of tool deflection in the high-speed milling of inclined surface. Int. J. Adv. Manuf. Technol. 2004, 24, 621–631. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Maruda, R.W.; Krolczyk, G.M.; Niesłony, P. Application of signal to noise ratio and grey relational analysis to minimize forces and vibrations during precise ball end milling. Precis. Eng. 2018, 51, 582–596. [Google Scholar] [CrossRef]

- Tobias, S.A.; Fishwick, W. The chatter of lathe tools under orthogonal cutting conditions. Trans. ASME 1958, 80, 1079–1088. [Google Scholar]

- Tlusty, J.; Polacek, M. The stability of the machine tool against self-exited vibration in machining. Int. Res. Prod. Eng. ASME 1963, 1, 465–474. [Google Scholar]

- Meritt, H.E. Theory of self-excited machine tool chatter contribution to machine-tool chatter: Contribution to machine-tool chatter, research 1. ASME J. Eng. Ind. 1965, 64, 447–454. [Google Scholar] [CrossRef]

- Tobias, S.A. Machine-Tool Vibration; Blackie & Son: London, UK, 1965. [Google Scholar]

- Minis, I.E.; Magrab, E.B.; Pandelidis, I.O. Improved methods for prediction of chatter in turning, Part 1: Determination of structural response parameters. Trans. ASME J. Eng. Ind. 1990, 112, 12–35. [Google Scholar] [CrossRef]

- Shawky, A.M.; Elbestawi, M.A. An enhanced dynamic model in turning including the effect of ploughing forces. Trans. ASME J. Manuf. Sci. Eng. 1997, 119, 10–20. [Google Scholar] [CrossRef]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations and CNC Design; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Lazoglu, I.; Atabey, F.; Altintas, Y. Dynamics of boring processes: Part III-time domain modeling. Int. J. Mach. Tools Manuf. 2002, 42, 1567–1576. [Google Scholar] [CrossRef]

- Kilic, Z.M.; Altintas, Y. Generalized mechanics and dynamics of metal cutting operations for unified simulations. Int. J. Mach. Tools Manuf. 2016, 104, 1–13. [Google Scholar] [CrossRef]

- Wu, D.W.; Liu, C.R. An analytical model of cutting dynamics. Part1: Model building. Trans. ASME J. Eng. Ind. 1985, 107, 107–111. [Google Scholar] [CrossRef]

- Tarng, Y.S.; Young, H.T.; Lee, B.Y. An analytical model of chatter vibration in metal cutting. Int. J. Mach. Tools Manuf. 1994, 34, 183–197. [Google Scholar] [CrossRef]

- Peigne, G.; Paris, H.; Brissaud, D.; Gouskov, A. Impact of the cutting dynamics of small radial immersion milling operations on machined surface roughness. Int. J. Mach. Tools Manuf. 2004, 44, 1133–1142. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Couey, J.; Marsh, E.; Mauntler, N.; Hughes, D. Runout effects in milling: Surface finish, surface location error, and stability. Int. J. Mach. Tools Manuf. 2007, 47, 841–851. [Google Scholar] [CrossRef]

- Afazov, S.M.; Ratchev, S.M.; Segal, J.; Popov, A.A. Chatter modelling in micro-milling by considering process nonlinearities. Int. J. Mach. Tools Manuf. 2012, 56, 28–38. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.; Liu, L.; Liu, Z. Influence of dynamic effects on surface roughness for face milling process. Int. J. Adv. Manuf. Technol. 2015, 80, 1823–1831. [Google Scholar]

- Wojciechowski, S.; Twardowski, P.; Pelic, M.; Maruda, R.W.; Barrans, S.; Krolczyk, G.M. Precision surface characterization for finish cylindrical milling with dynamic tool displacements model. Precis. Eng. 2016, 46, 158–165. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Mrozek, K. Mechanical and technological aspects of micro ball end milling with various tool inclinations. Int. J. Mech. Sci. 2017, 134, 424–435. [Google Scholar] [CrossRef]

- Wojciechowski, S.; Wiackiewicz, M.; Krolczyk, G.M. Study on metrological relations between instant tool displacements and surface roughness during precise ball end milling. Measurement 2018, 129, 686–694. [Google Scholar] [CrossRef]

- Wiercigroch, M.; Budak, E. Sources of nonlinearities, chatter generation and suppression in metal cutting. Philos. Trans. R. Soc. Lond. A 2001, 359, 663–693. [Google Scholar] [CrossRef] [Green Version]

- Karube, S.; Hoshino, W.; Soutome, T.; Sato, K. The non-linear phenomena in vibration cutting system. The establishment of dynamic model. Int. J. Non-Linear Mech. 2002, 37, 541–564. [Google Scholar] [CrossRef]

- Moufki, A.; Devillez, A.; Segreti, M.; Dudzinski, D. A semi-analytical model of non-linear vibrations in orthogonal cutting and experimental validation. Int. J. Mach. Tools Manuf. 2006, 46, 436–449. [Google Scholar] [CrossRef]

- Fu, Z.; Zhang, X.; Wang, X.; Yang, W. Analytical modeling of chatter vibration in orthogonal cutting using a predictive force model. Int. J. Mech. Sci. 2014, 88, 145–153. [Google Scholar] [CrossRef]

- Moufki, A.; Dudzinski, D.; Le Coz, G. Prediction of cutting forces from an analytical model of oblique cutting, application to peripheral milling of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2015, 81, 615–626. [Google Scholar] [CrossRef]

- Huo, M.; Zhao, J.; Xie, H.; Li, Z.; Li, S.; Zhang, H.; Jiang, Z. Analysis of surface roughness alteration in micro flexible rolling. Wear 2019, 426–427, 1286–1295. [Google Scholar] [CrossRef]

- Nguyen, T.T. Prediction and optimization of machining energy, surface roughness, and production rate in SKD61 milling. Measurement 2019, 136, 525–544. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | S | P | Ni | Cr | Mo | Cu | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| × 10−3 (wt.%) | 465 | 224 | 942 | 17 | 15 | 171 | 1070 | 265 | 245 | 22 |

| Hardness (Brinell) | Yield Stress (MPa) | Ultimate Tensile Strength (MPa) | Heat Capacity (J∙Kg−1∙K) | Thermal Conductivity (W∙m−1∙K) |

|---|---|---|---|---|

| 241 | 485 | 814 | 500 | 36 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kibbou, E.M.; Dellagi, S.; Majdouline, I.; Moufki, A. Prediction of Surface Quality Based on the Non-Linear Vibrations in Orthogonal Cutting Process: Time Domain Modeling. J. Manuf. Mater. Process. 2019, 3, 53. https://doi.org/10.3390/jmmp3030053

Kibbou EM, Dellagi S, Majdouline I, Moufki A. Prediction of Surface Quality Based on the Non-Linear Vibrations in Orthogonal Cutting Process: Time Domain Modeling. Journal of Manufacturing and Materials Processing. 2019; 3(3):53. https://doi.org/10.3390/jmmp3030053

Chicago/Turabian StyleKibbou, El Mehdi, Sofiene Dellagi, Ilias Majdouline, and Abdelhadi Moufki. 2019. "Prediction of Surface Quality Based on the Non-Linear Vibrations in Orthogonal Cutting Process: Time Domain Modeling" Journal of Manufacturing and Materials Processing 3, no. 3: 53. https://doi.org/10.3390/jmmp3030053

APA StyleKibbou, E. M., Dellagi, S., Majdouline, I., & Moufki, A. (2019). Prediction of Surface Quality Based on the Non-Linear Vibrations in Orthogonal Cutting Process: Time Domain Modeling. Journal of Manufacturing and Materials Processing, 3(3), 53. https://doi.org/10.3390/jmmp3030053