Post-Weld Heat Treatment Effects on Mechanical Properties and Microstructure of AA6061-T6 Butt Joints Made by Friction Stir Welding at Right Angle (RAFSW)

Abstract

1. Introduction

2. Materials and Methods

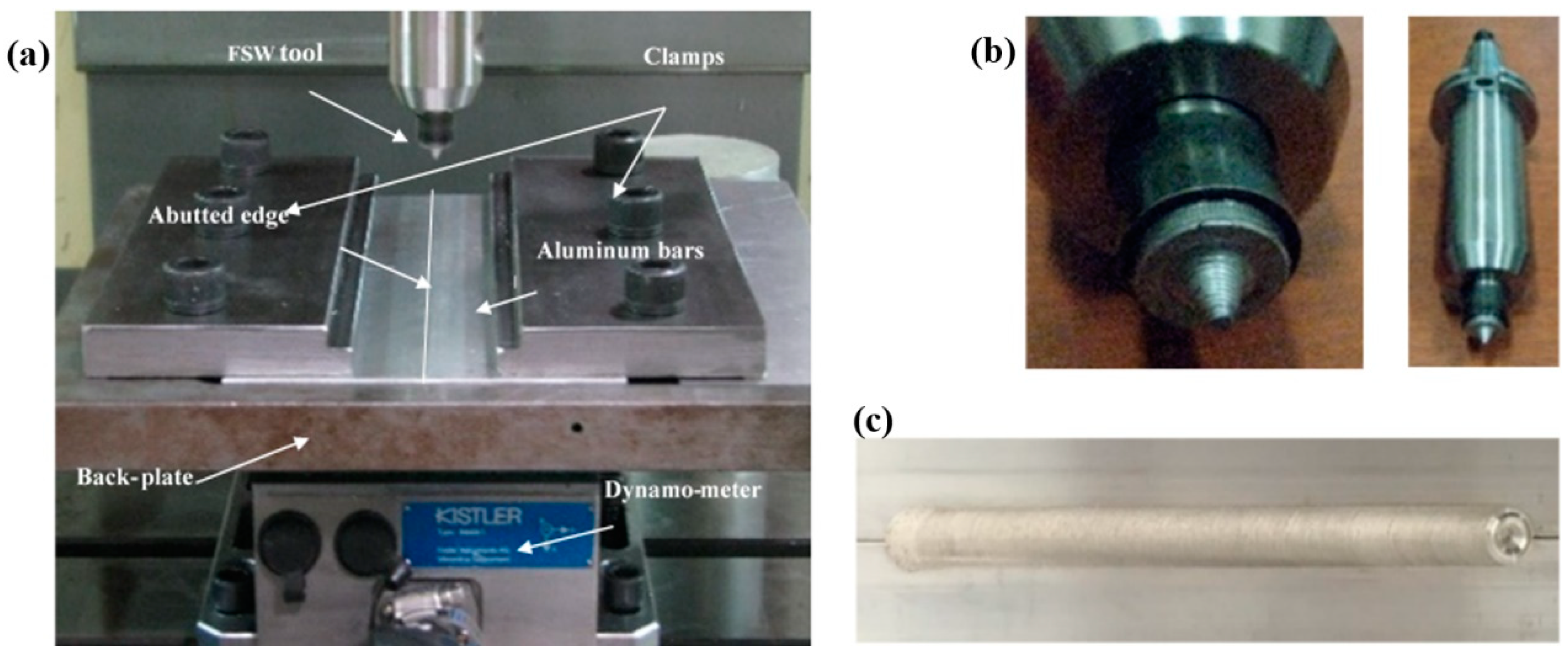

2.1. Preparation of the Joints

2.2. Post-Weld Heat Treatment

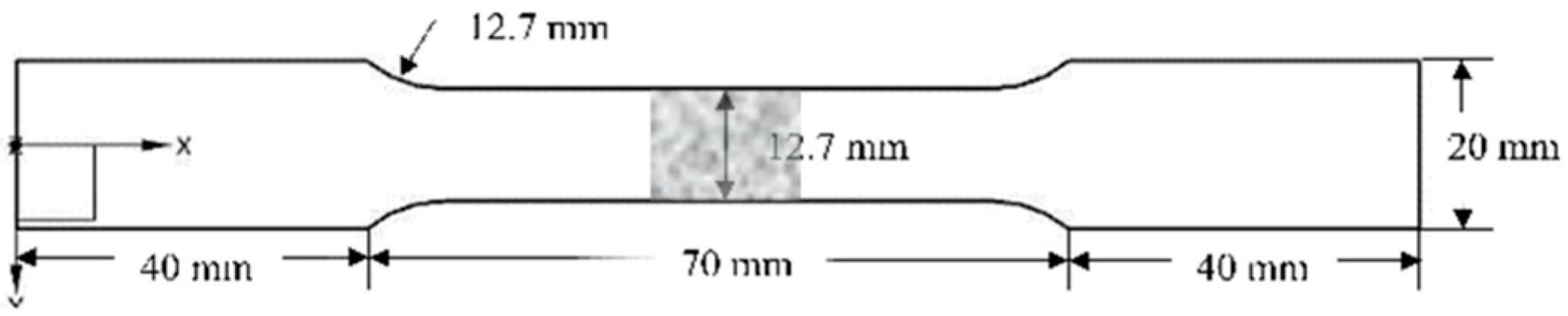

2.3. Characterization

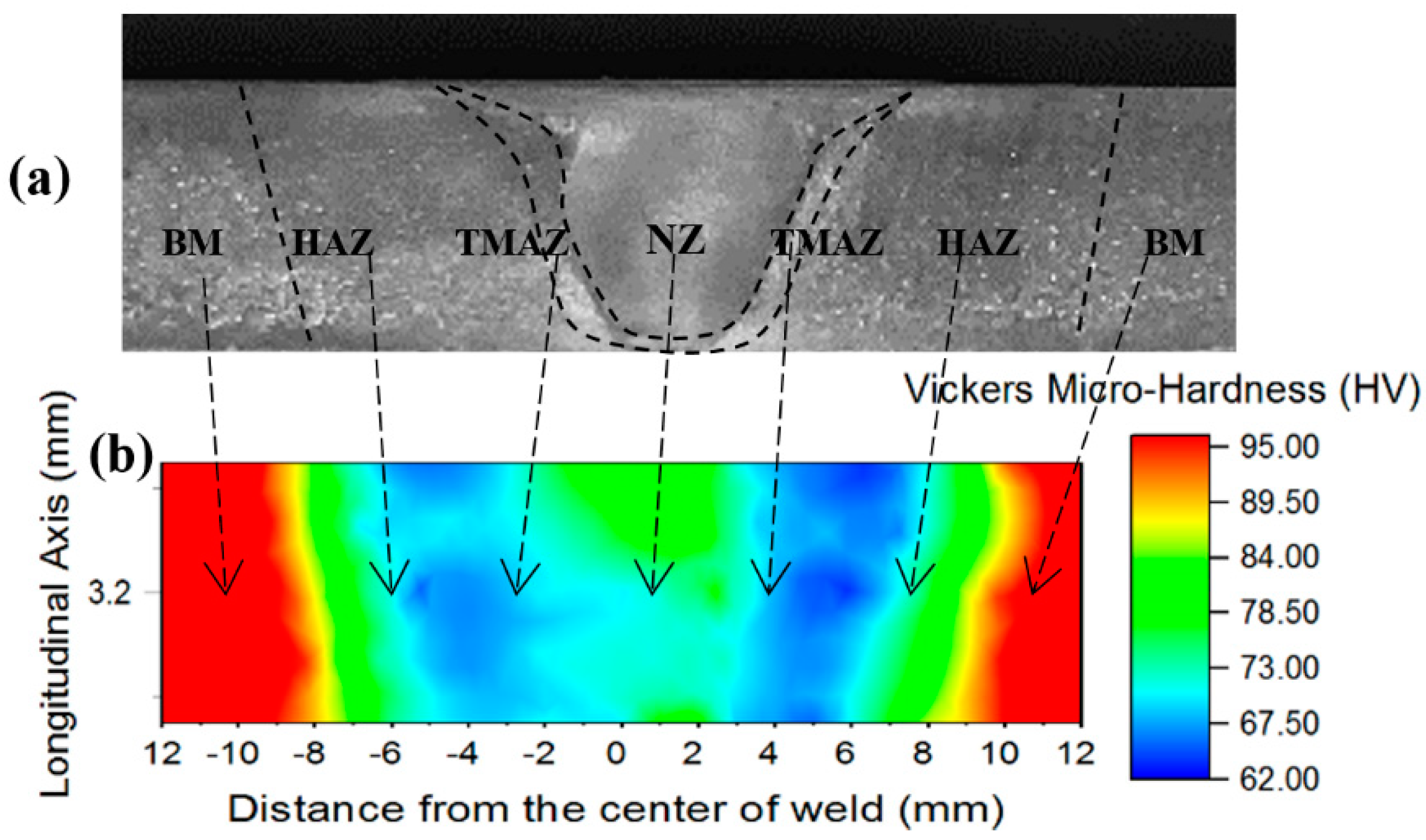

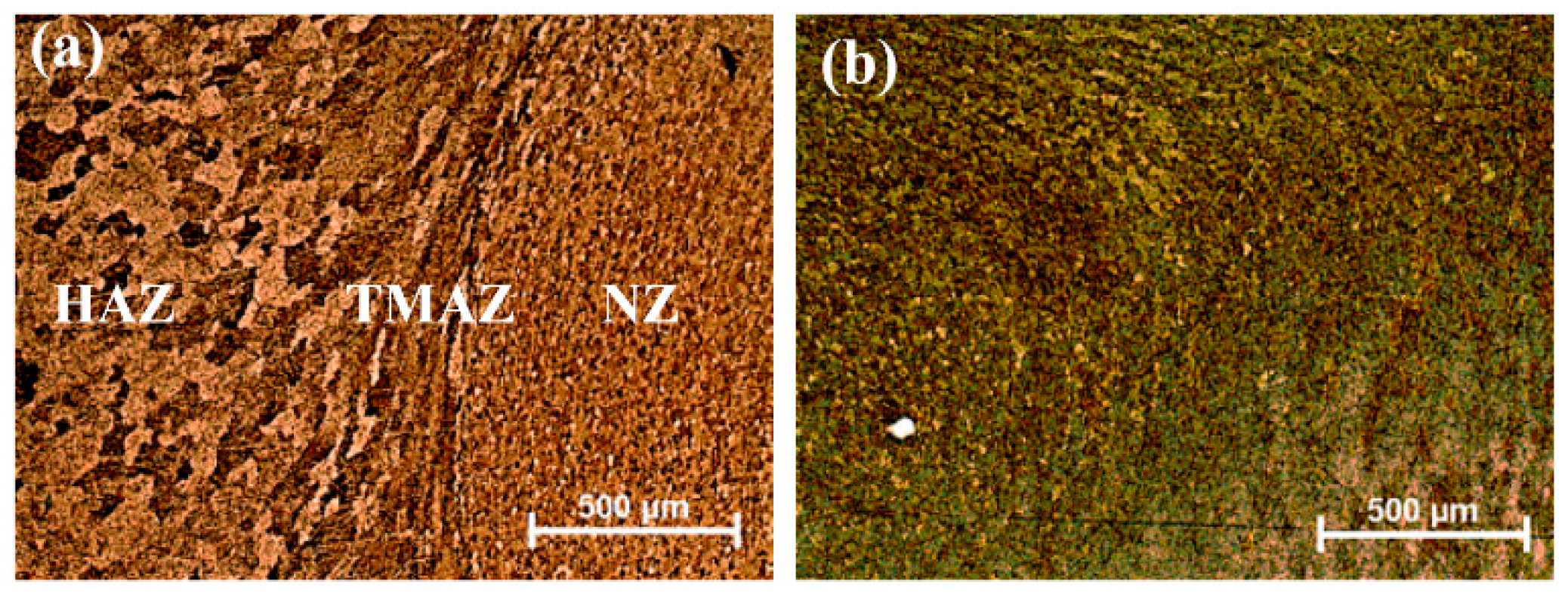

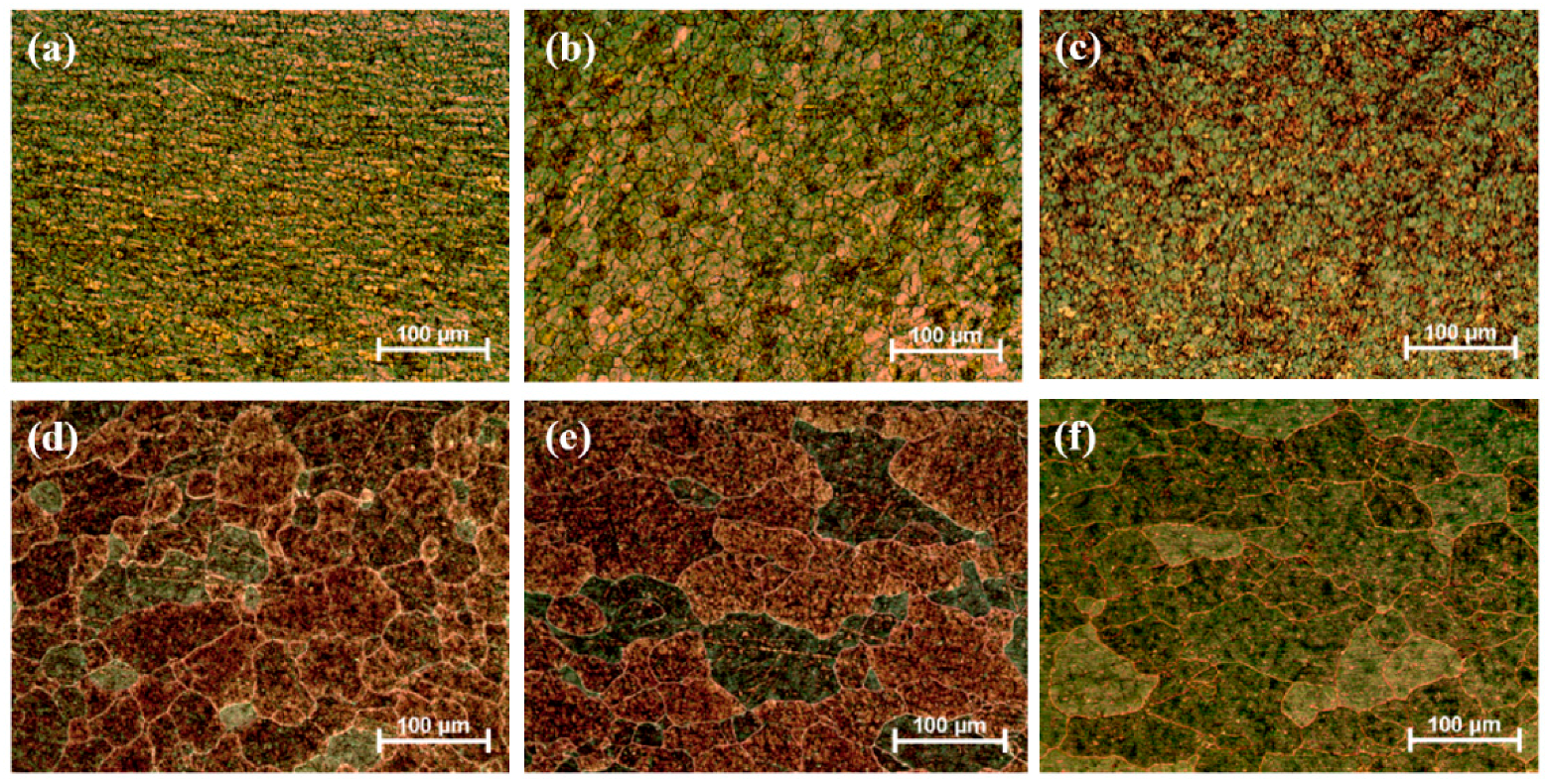

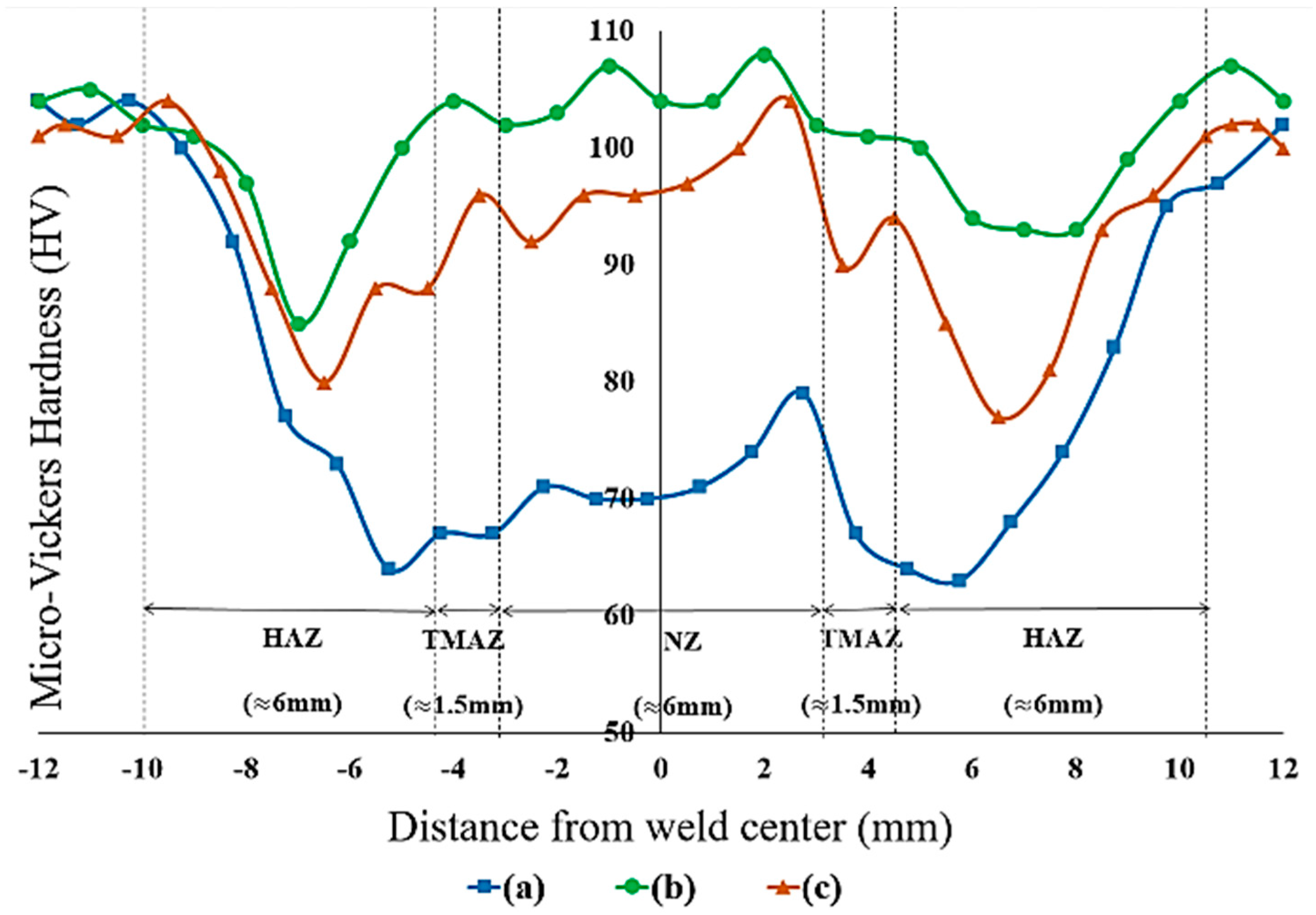

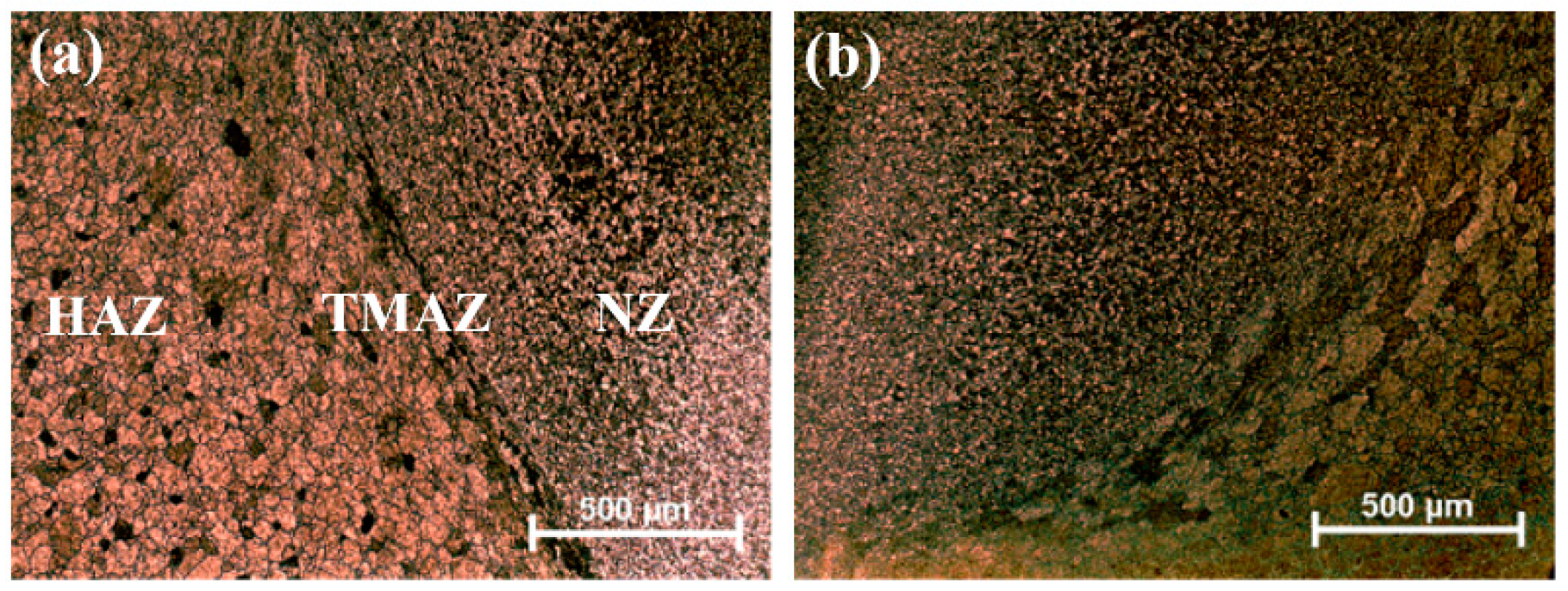

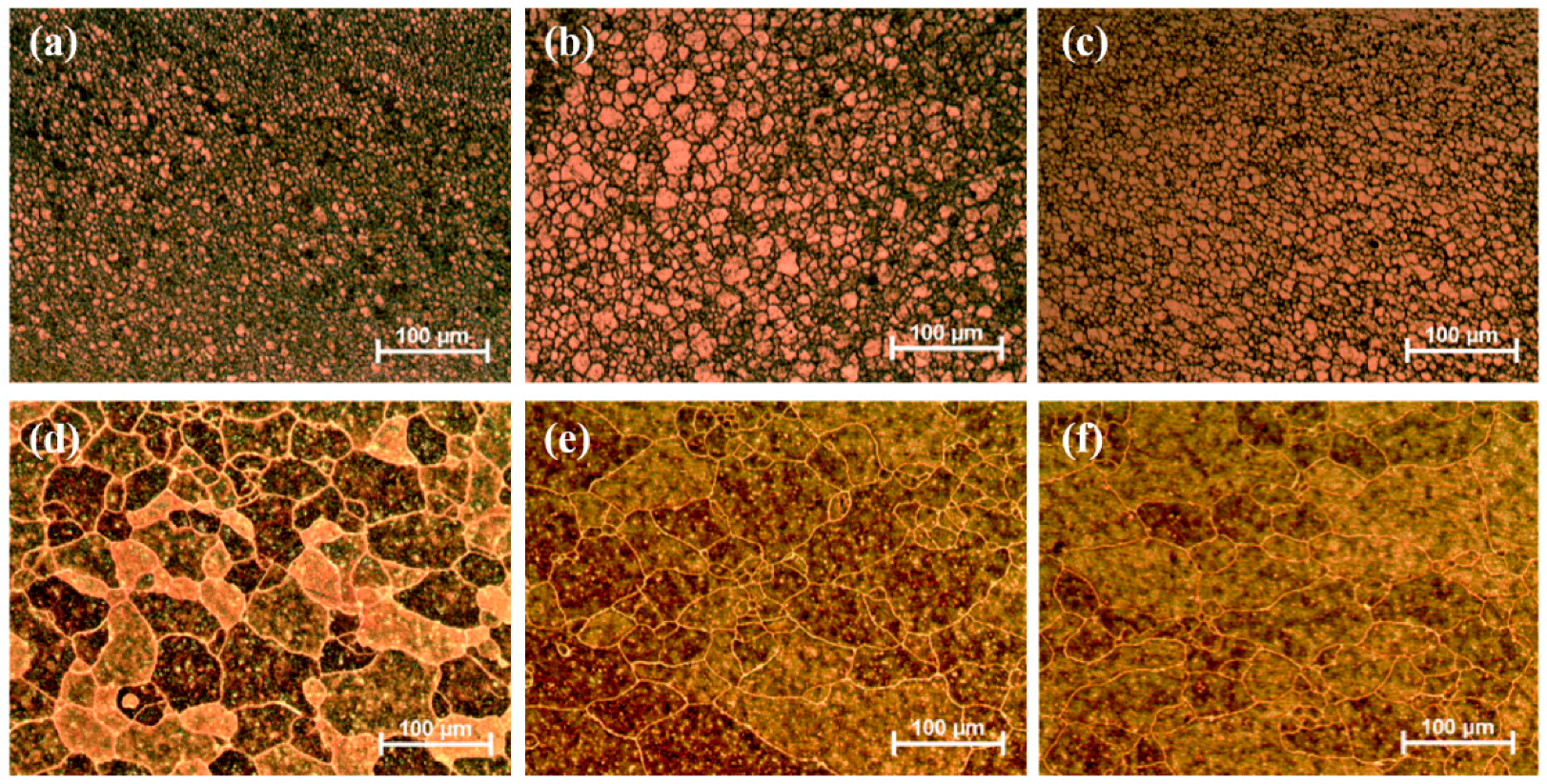

3. Results and Discussion

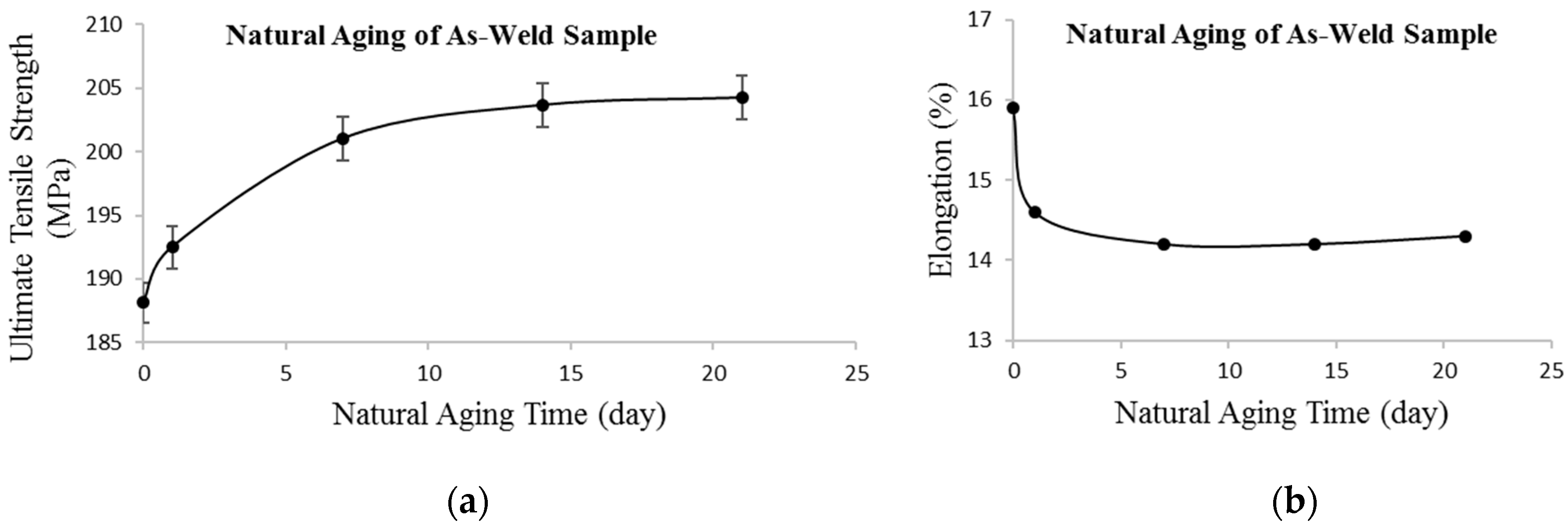

3.1. Natural Aging

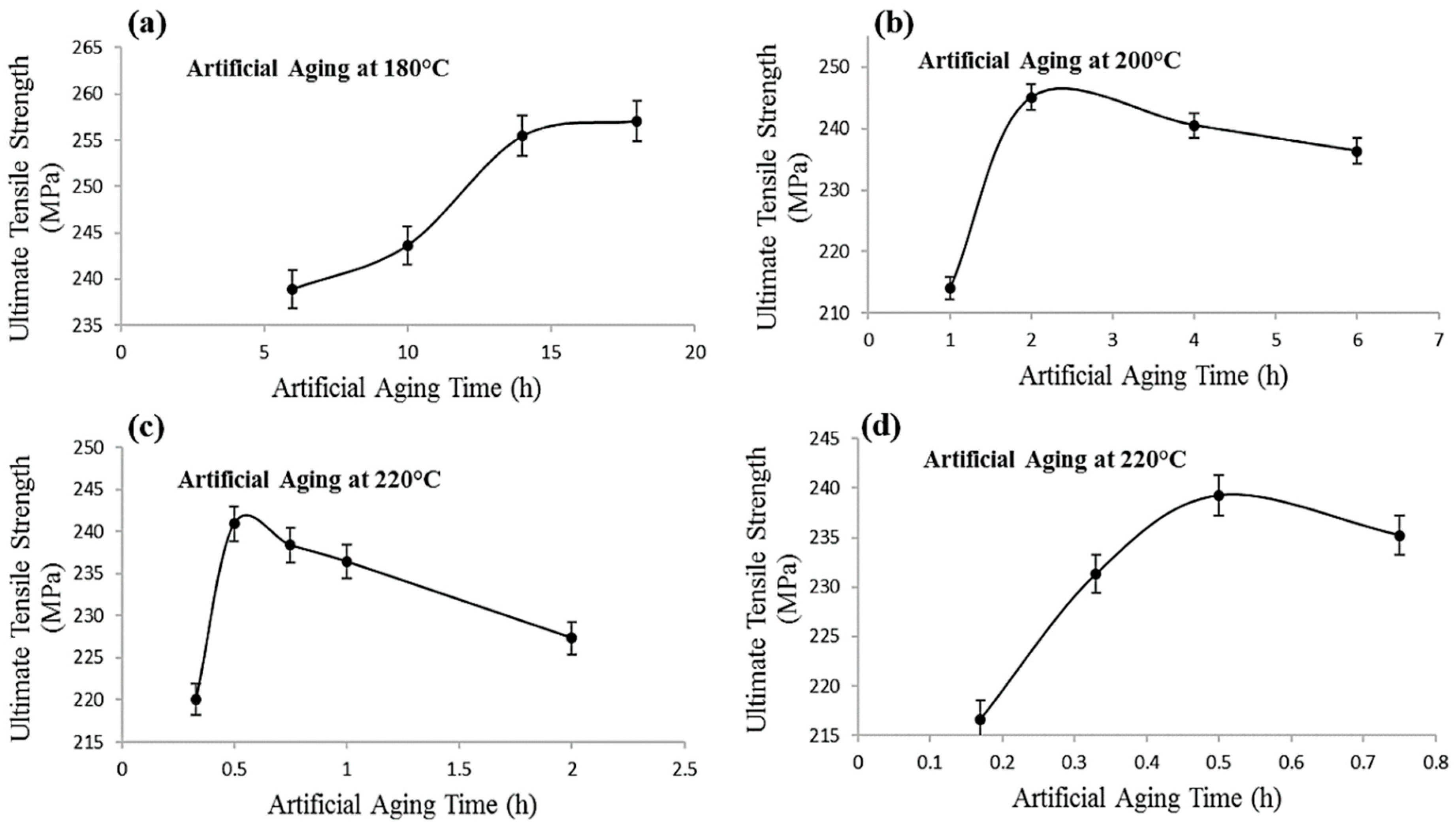

3.2. Artificial Aging

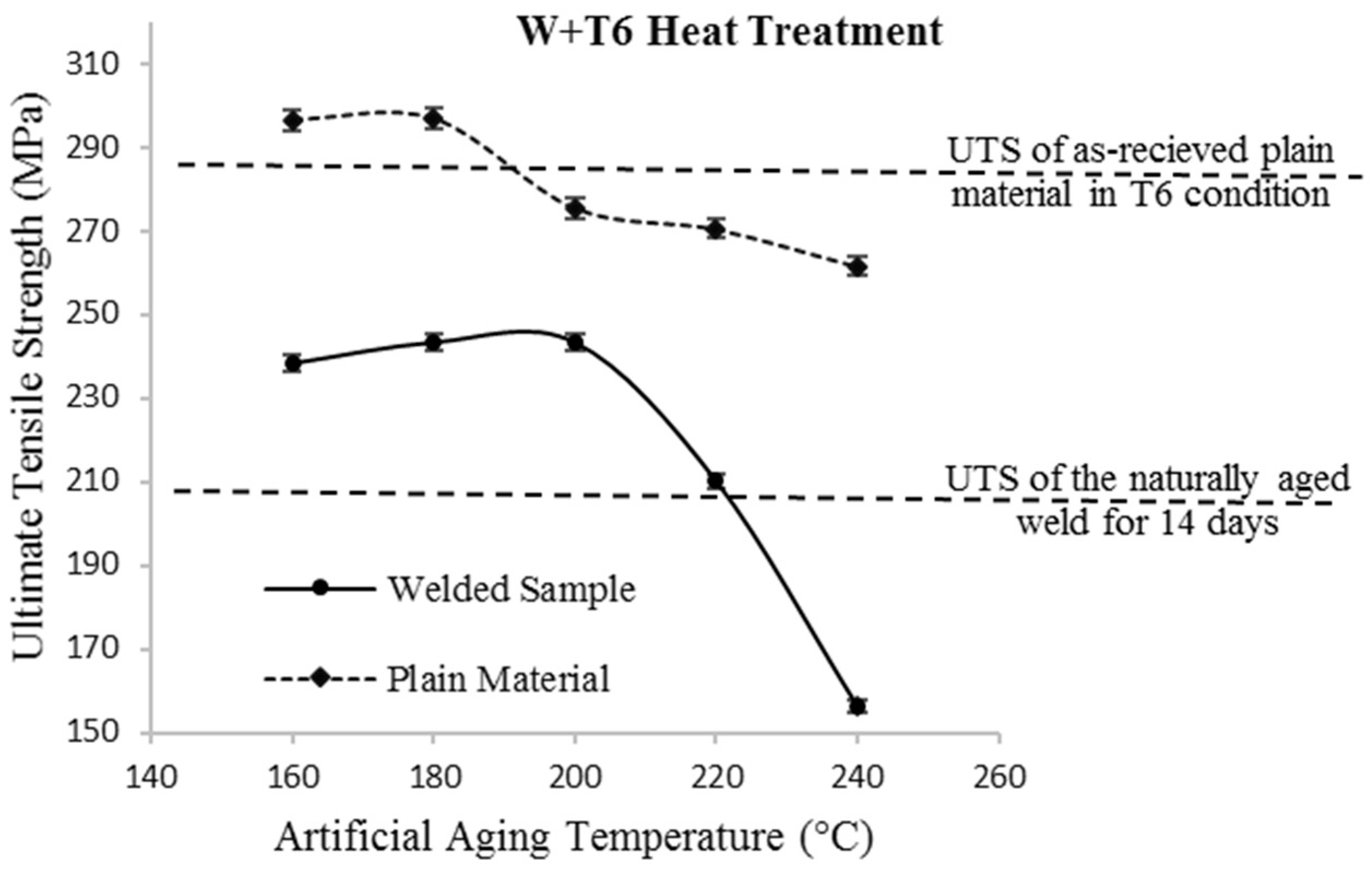

3.3. Solubilizing Followed by Artificial Aging (W + T6)

4. Conclusions

- A comprehensive study was done on the effect of natural aging, artificial aging, and T6 heat treatments on the mechanical and physical properties of the butt-welded bars of AA6061-T6 by a recently developed RAFSW technique using low-cost 3-axis machine tools.

- The joint efficiency of a naturally aged weld reaches 72% after 14 days.

- The optimized conditions for artificial aging were obtained as presented in Table 1. It was found that the joint efficiency of RAFSW samples reaches 90% by artificial aging at 180 °C for 18 h.

- Moreover, it was found that industrial users could take advantage of a fast artificial aging process at 220 °C for 30 min to obtain a RAFSW joint with 85% of joint efficiency and 241 MPa of tensile strength.

- In the industry, a delay is likely to happen between welding and PWHT. In this regard, the repeatability of the optimized artificial aging processes was validated for the time gaps up to 21 days between the welding and PWHT processes.

- A solubilizing heat treatment prior to artificial aging, called W + T6, at 200 °C for 2 h results in an improvement of the tensile strength of RAFSW samples up to 243 MPa. However, the welds have low ductility compared to the samples just aged artificially.

- It was shown that the artificial aging process on RAFSW samples is not only more time and cost-effective than the solubilizing followed by artificial aging process but also yields higher mechanical properties, even when it is done at a high pace.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W. Future Outlook for Friction Stir Welding and Processing. In Friction Stir Welding and Processing; Mishra, R.S., Mahoney, M.W., Eds.; ASM International: Materials Park, OH, USA, 2007; pp. 351–352. [Google Scholar]

- Arbegast, W.J. Application of Friction Stir Welding and Related Technologies. In Friction Stir Welding and Processing; Mishra, R.S., Mahoney, M.W., Eds.; ASM International: Materials Park, OH, USA, 2007; pp. 273–308. [Google Scholar]

- Nandan, R.; Debroy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lammlein, D.H.; Prater, T.J.; Longhurst, W.R.; Cox, C.D.; Ballun, M.C.; Dharmaraj, K.J.; Cook, G.E.; Strauss, A.M. Friction stir welding: Process, automation, and control. J. Manuf. Process. 2014, 16, 56–73. [Google Scholar] [CrossRef]

- Fadaeifard, F.; Matori, K.; Abd Aziz, S.; Zolkarnain, L.; Rahim, M. Effect of the Welding Speed on the Macrostructure, Microstructure and Mechanical Properties of AA6061-T6 Friction Stir Butt Welds. Metals 2017, 7, 16. [Google Scholar] [CrossRef]

- Patel, V.; Li, W.; Wang, G.; Wang, F.; Vairis, A.; Niu, P. Friction Stir Welding of Dissimilar Aluminum Alloy Combinations: State-of-the-Art. Metals 2019, 9, 19. [Google Scholar] [CrossRef]

- Smith, C.B. Robots and Machines for Friction Stir Welding/Processing. In Friction Stir Welding and Processing; Mishra, R.S., Mahoney, M.W., Eds.; ASM International: Materials Park, OH, USA, 2007; pp. 219–233. [Google Scholar]

- Imani, Y.; Guillot, M. Axial Force Reduction in Friction Stir Welding of AA6061-T6 at Right Angle. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Imani, Y. Development of Friction Stir Welding Techniques for Multi-Axis Machines. Ph.D. Thesis, Laval University, Quebec City, QC, Canada, 2015. [Google Scholar]

- Imani, Y.; Guillot, M.; Tremblay, A. Optimization of FSW Tool Design and Operating Parameters for Butt Welding of AA6061-T6 at Right angle. In Proceedings of the CSME Proceedings of the Canadian Society for Mechanical Engineering International Congress, Toronto, ON, Canada, 1–4 June 2014. [Google Scholar]

- Imani, Y.; Guillot, M.; Tremblay, A. Study and Application of Complex 3D Friction Stir Welding of Butt and Lap Joints Using a 5-axis CNC Mashine Tool. In Proceedings of the CSME Proceedings of the Canadian Society for Mechanical Engineering International Congress, Toronto, ON, Canada, 1–4 June 2014. [Google Scholar]

- Imani, Y.; Guillot, M. Tolerating for joint fit-up issues using welding parameters in friction stir welding of AA6061-T6 at right angle. In Proceedings of the CSME Canadian Society for Mechanical Engineering International Congress, Toronto, ON, Canada, 1–4 June 2014. [Google Scholar]

- Momeni, M.; Guillot, M. Development of friction stir welding technique at right angle (RAFSW) applied on butt joint of AA6061-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 99, 3077–3089. [Google Scholar] [CrossRef]

- Zhang, Z.; Xiao, B.L.; Ma, Z.Y. Enhancing mechanical properties of friction stir welded 2219Al-T6 joints at high welding speed through water cooling and post-welding artificial ageing. Mater. Charact. 2015, 106, 255–265. [Google Scholar] [CrossRef]

- Ipekoglu, G.; Erim, S.; Cam, G. Investigation into the Influence of Post-Weld Heat Treatment on the Friction Stir Welded AA6061 Al-Alloy Plates with Different Temper Conditions. Metall. Mater. Trans. B 2014, 45A, 864–877. [Google Scholar] [CrossRef]

- El-Danaf, E.A.; El-Rayes, M.M. Microstructure and mechanical properties of friction stir welded 6082 AA in as welded and post weld heat treated conditions. Mater. Des. 2013, 46, 561–572. [Google Scholar] [CrossRef]

- Peng, G.; Ma, Y.; Hu, J.; Jiang, W.; Huan, Y.; Chen, Z.; Zhang, T. Nanoindentation Hardness Distribution and Strain Field and Fracture Evolution in Dissimilar Friction Stir-Welded AA 6061-AA 5A06 Aluminum Alloy Joints. Adv. Mater. Sci. Eng. 2018, 2018, 4873571. [Google Scholar] [CrossRef]

- Peng, G.; Yan, Q.; Hu, J.; Chen, P.; Chen, Z.; Zhang, T. Effect of Forced Air Cooling on the Microstructures, Tensile Strength, and Hardness Distribution of Dissimilar Friction Stir Welded AA5A06-AA6061 Joints. Metals 2019, 9, 304. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, S.J.; Wang, J.; Wang, P.; Xia, J. Influences of Pin Shape on a High Rotation Speed Friction Stir Welding Joint of a 6061-T6 Aluminum Alloy Sheet. Metals 2018, 8, 13. [Google Scholar] [CrossRef]

- Gao, L.; Harada, Y.; Kumai, S. Microstructural characterization of aluminum alloys using Weck’s reagent, part I: Applications. Mater. Charact. 2015, 107, 426–433. [Google Scholar] [CrossRef]

- Jamshidi Aval, H.; Serajzadeh, S. A study on natural aging behavior and mechanical properties of friction stir-welded AA6061-T6 plates. Int. J. Adv. Manuf. Technol. 2014, 71, 933–941. [Google Scholar] [CrossRef]

- Kang, S.; Han, H.; Oh, K.; Cho, J.-H.; Lee, C.; Kim, S.-J. Investigation of the material flow and texture evolution in friction-stir welded aluminum alloy. Met. Mater. Int. 2009, 15, 1027–1031. [Google Scholar] [CrossRef]

- Tao, W.; Yong, Z.; Xuemei, L.; Matsuda, K. Special grain boundaries in the nugget zone of friction stir welded AA6061-T6 under various welding parameters. Mater. Sci. Eng. A 2016, 671, 7–16. [Google Scholar] [CrossRef]

- Chen, Y.; Ding, H.; Li, J.-Z.; Zhao, J.-W.; Fu, M.-J.; Li, X.-H. Effect of welding heat input and post-welded heat treatment on hardness of stir zone for friction stir-welded 2024-T3 aluminum alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 2524–2532. [Google Scholar] [CrossRef]

- Polat, A.; Avsar, M.; Ozturk, F. Effects of the artificial-aging temperature and time on the mechanical properties and springback behavior of AA6061. Mater. Technol. 2015, 49, 487–493. [Google Scholar]

- Malard, B.; De Geuser, F.; Deschamps, A. Microstructure distribution in an AA2050 T34 friction stir weld and its evolution during post-welding heat treatment. Acta Mater. 2015, 101, 90–100. [Google Scholar] [CrossRef]

- Elangovan, K.; Balasubramanian, V. Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Mater. Charact. 2008, 59, 1168–1177. [Google Scholar] [CrossRef]

- Malopheyev, S.; Vysotskiy, I.; Kulitskiy, V.; Mironov, S.; Kaibyshev, R. Optimization of processing-microstructure-properties relationship in friction-stir welded 6061-T6 aluminum alloy. Mater. Sci. Eng. A 2016, 662, 136–143. [Google Scholar] [CrossRef]

- Chang, C.; Xiao, G.; Liu, E.; Lin, J.; Zhang, X.; Long, X.; Zhang, L.L. Revisiting the procedure for characterising mechanical properties in welded joints through nanoindentation. Mater. Sci. Technol. 2019, 35, 986–992. [Google Scholar] [CrossRef]

- Boonma, J.; Khammuangsa, S.; Uttarasak, K.; Dutchaneephet, J.; Boonruang, C.; Sirikulrat, N. Post weld heat treatment effects on hardness and impact strength of aluminum alloy 6061 friction stir butt weld. Mater. Trans. 2015, 56, 1072–1076. [Google Scholar] [CrossRef]

- Madhusudhan Reddy, G.; Mastanaiah, P.; Sata Prasad, K.; Mohandas, T. Microstructure and mechanical property correlations in AA 6061 aluminium alloy friction stir welds. Trans. Indian Inst. Met. 2009, 62, 49–58. [Google Scholar] [CrossRef]

- Krishnan, K. The effect of post weld heat treatment on the properties of 6061 friction stir welded joints. J. Mater. Sci. 2002, 37, 473–480. [Google Scholar] [CrossRef]

- Aydın, H.; Bayram, A.; Durgun, İ. The effect of post-weld heat treatment on the mechanical properties of 2024-T4 friction stir-welded joints. Mater. Des. 2010, 31, 2568–2577. [Google Scholar] [CrossRef]

| Samples Condition | UTS (MPa) | El (%) | Joint Efficiency 2 |

|---|---|---|---|

| Plain Material (as received) | 285 | 16.4 | |

| As-weld | 188 | 15.9 | 66% |

| NA 1 for 14 days | 204 | 14.2 | 72% |

| AA 1 at 160 °C for 18 h | 254 | 4.1 | 89% |

| AA at 180 °C for 18 h | 257 | 4.2 | 90% |

| AA at 200 °C for 2 h | 245 | 6 | 86% |

| AA at 220 °C for 30 min | 241 | 6.1 | 85% |

| AA at 240 °C for 30 min | 230 | 6.6 | 81% |

| UTS (MPa) after Artificial Aging at Different Conditions | ||||||

|---|---|---|---|---|---|---|

| At 160 (°C) for 18 h | At 180 (°C) for 18 h | At 200 (°C) for 2 h | At 220 (°C) for 30 min | At 240 (°C) for 30 min | ||

| Natural aging time (days) prior to artificial aging | 1≤ | 254 | 257 | 245 | 241 | 230 |

| 7 | 251 | 257 | 249 | 243 | 225 | |

| 14 | 249 | 255 | 251 | 238 | 229 | |

| 21 | 250 | 252 | 246 | 238 | 230 | |

| Average UTS and standard deviation | 251.0 ± 1.9 | 255.2 ± 2.0 | 247.7 ± 2.4 | 240.0 ± 2.1 | 228.5 ± 2.1 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Momeni, M.; Guillot, M. Post-Weld Heat Treatment Effects on Mechanical Properties and Microstructure of AA6061-T6 Butt Joints Made by Friction Stir Welding at Right Angle (RAFSW). J. Manuf. Mater. Process. 2019, 3, 42. https://doi.org/10.3390/jmmp3020042

Momeni M, Guillot M. Post-Weld Heat Treatment Effects on Mechanical Properties and Microstructure of AA6061-T6 Butt Joints Made by Friction Stir Welding at Right Angle (RAFSW). Journal of Manufacturing and Materials Processing. 2019; 3(2):42. https://doi.org/10.3390/jmmp3020042

Chicago/Turabian StyleMomeni, Mahboubeh, and Michel Guillot. 2019. "Post-Weld Heat Treatment Effects on Mechanical Properties and Microstructure of AA6061-T6 Butt Joints Made by Friction Stir Welding at Right Angle (RAFSW)" Journal of Manufacturing and Materials Processing 3, no. 2: 42. https://doi.org/10.3390/jmmp3020042

APA StyleMomeni, M., & Guillot, M. (2019). Post-Weld Heat Treatment Effects on Mechanical Properties and Microstructure of AA6061-T6 Butt Joints Made by Friction Stir Welding at Right Angle (RAFSW). Journal of Manufacturing and Materials Processing, 3(2), 42. https://doi.org/10.3390/jmmp3020042