A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing

Abstract

:1. Background

2. Experimental Method

2.1. Nanolubricant Preparation

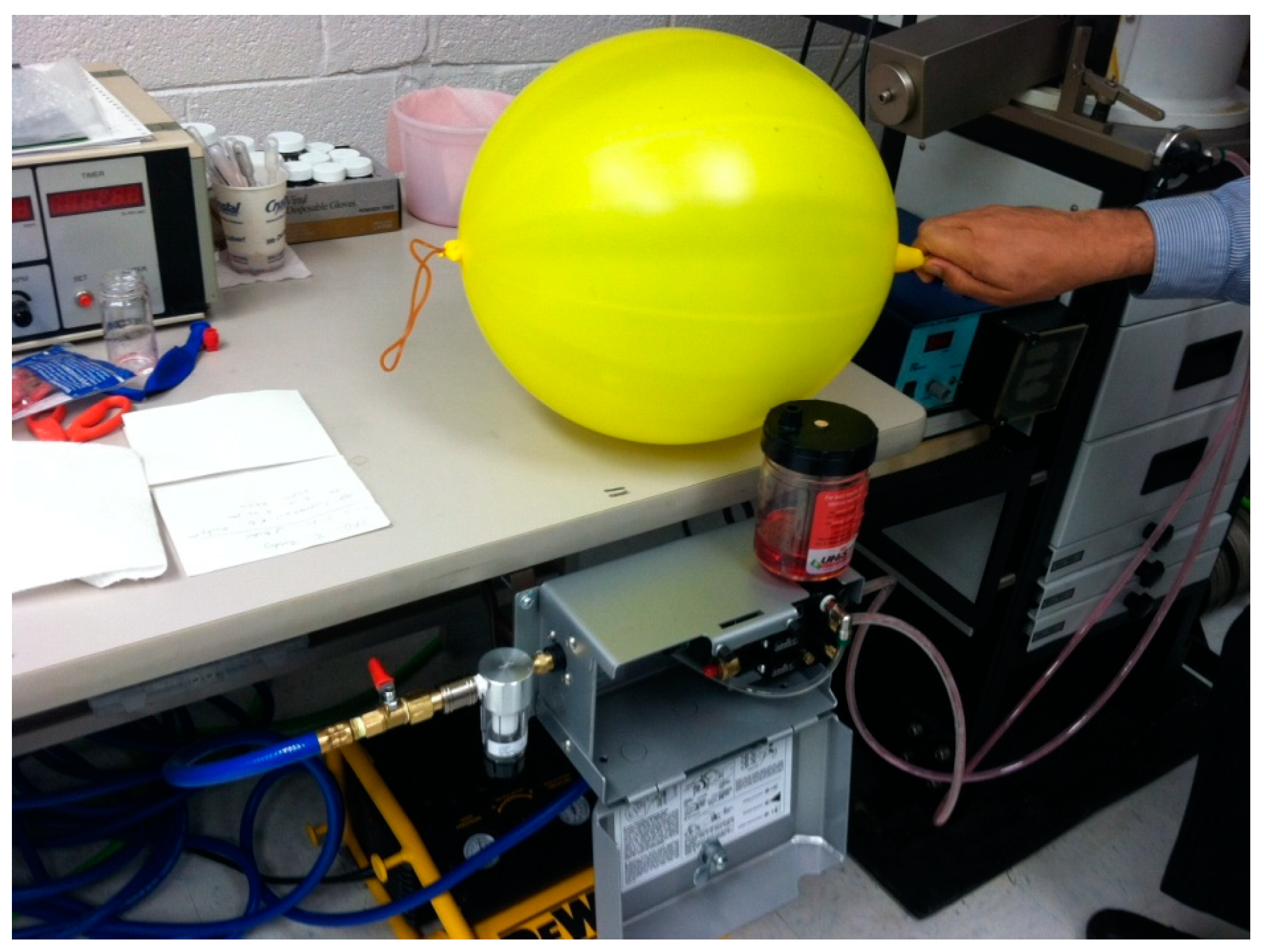

2.2. Mist Pump

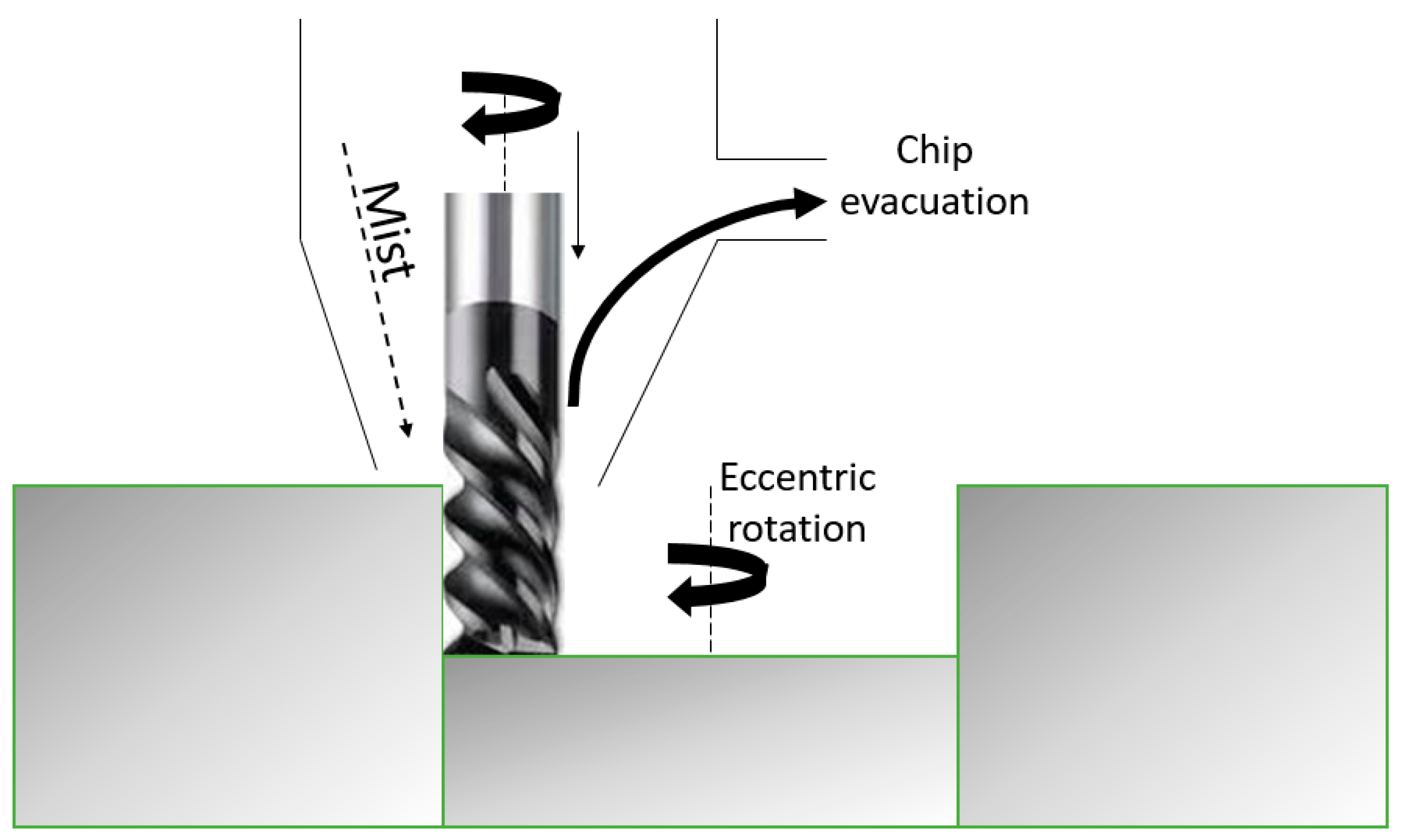

2.3. Orbital Drilling

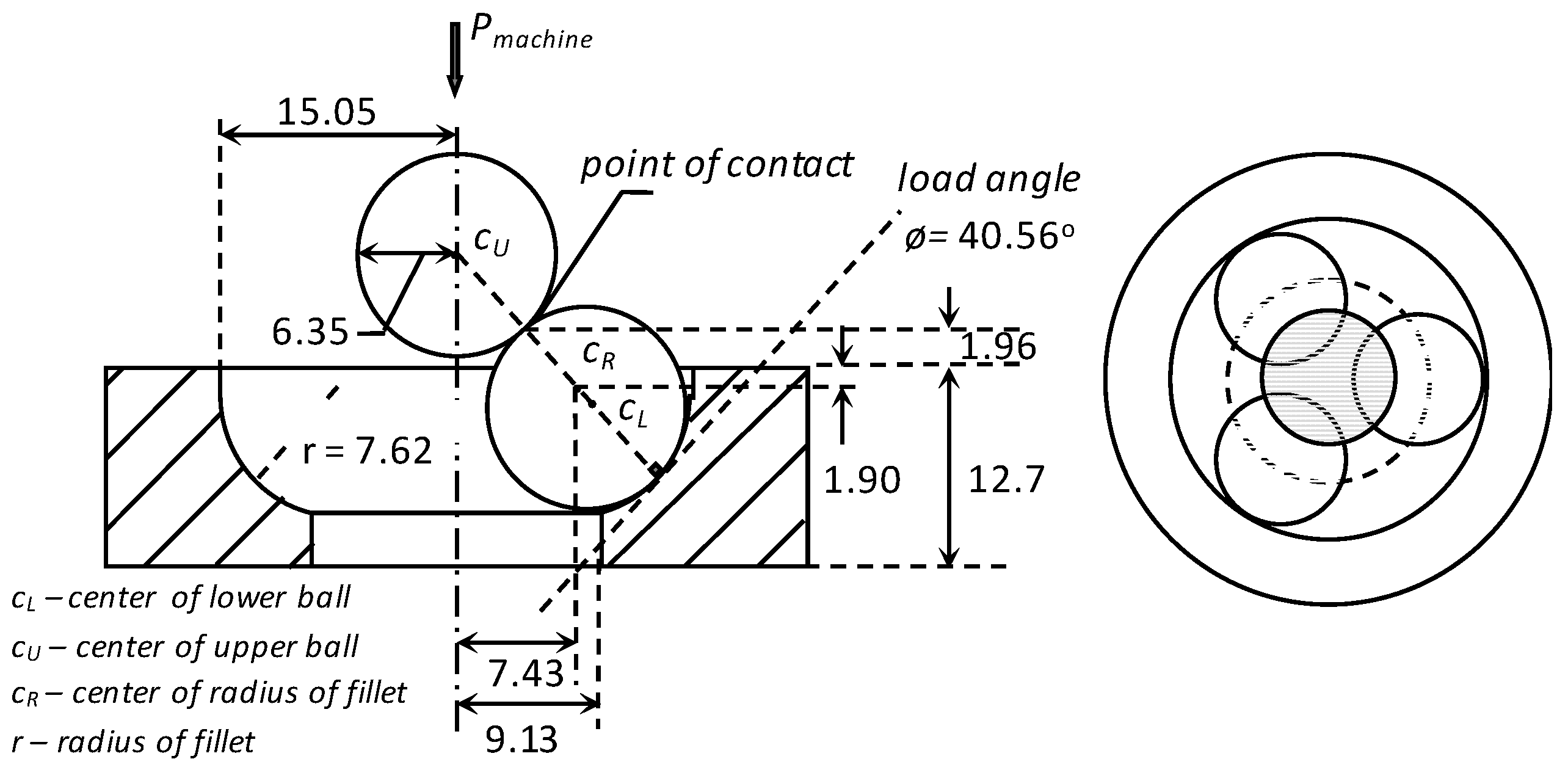

2.4. Four-Ball Testing

3. Experimental Results and Discussion

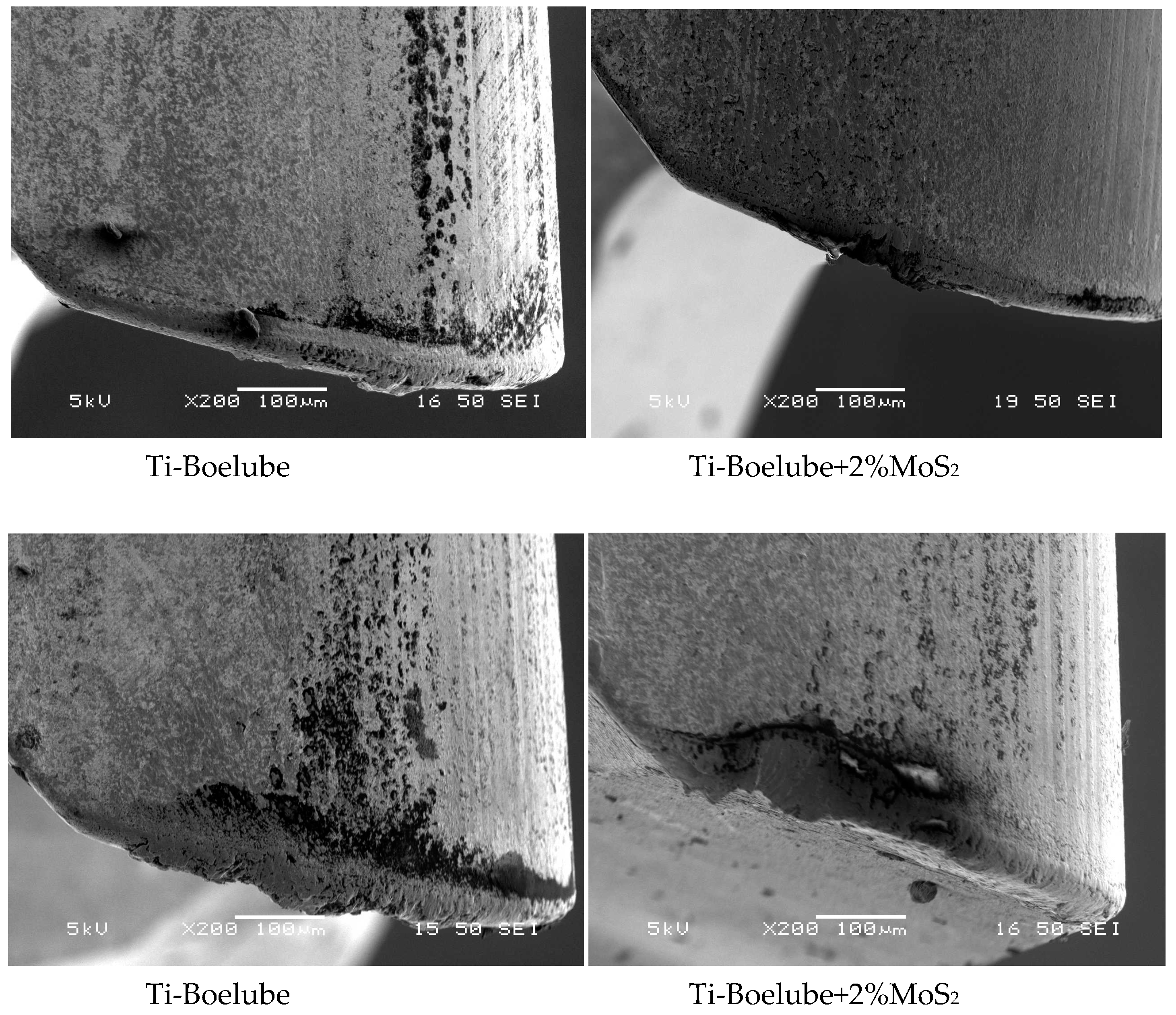

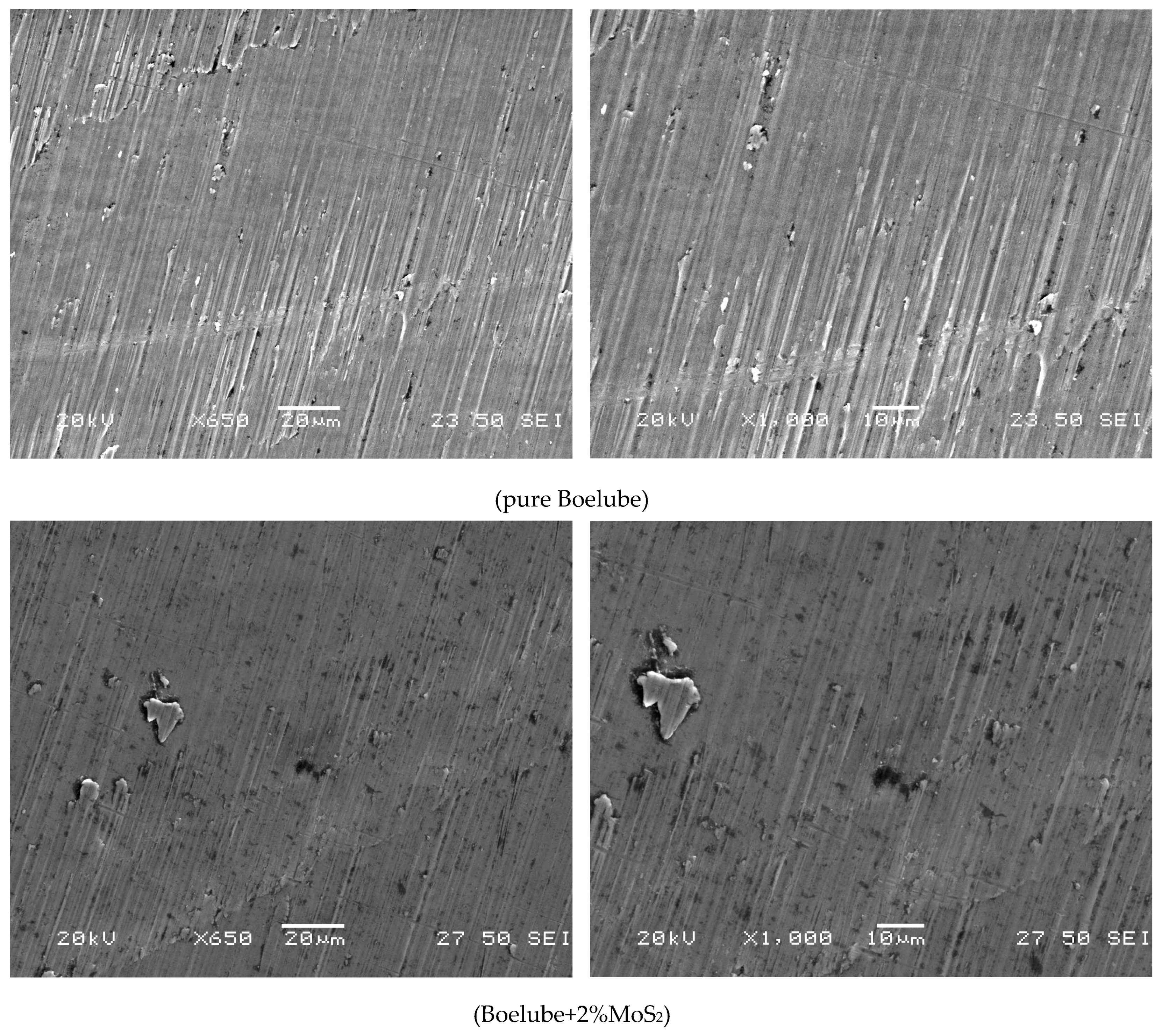

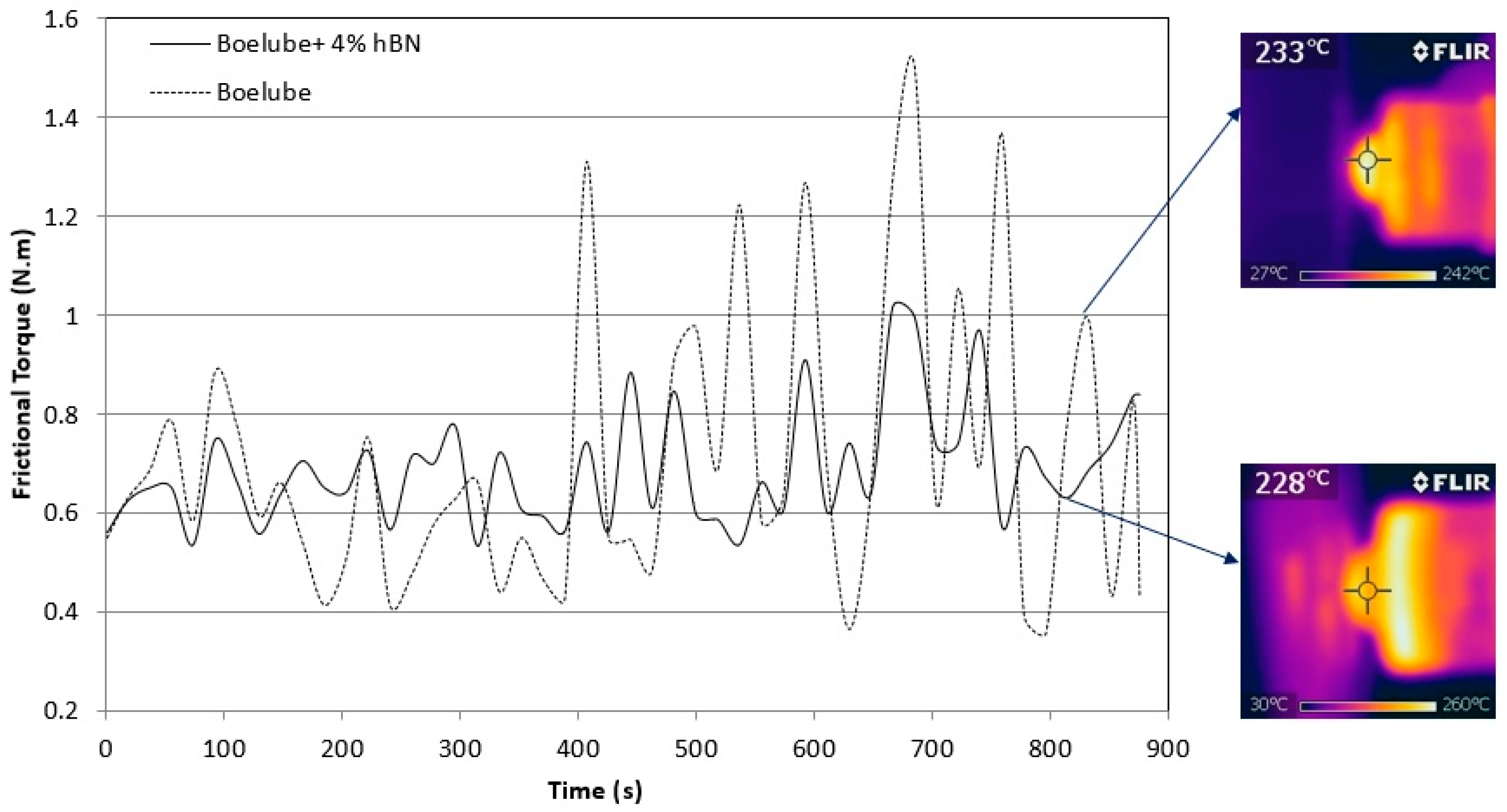

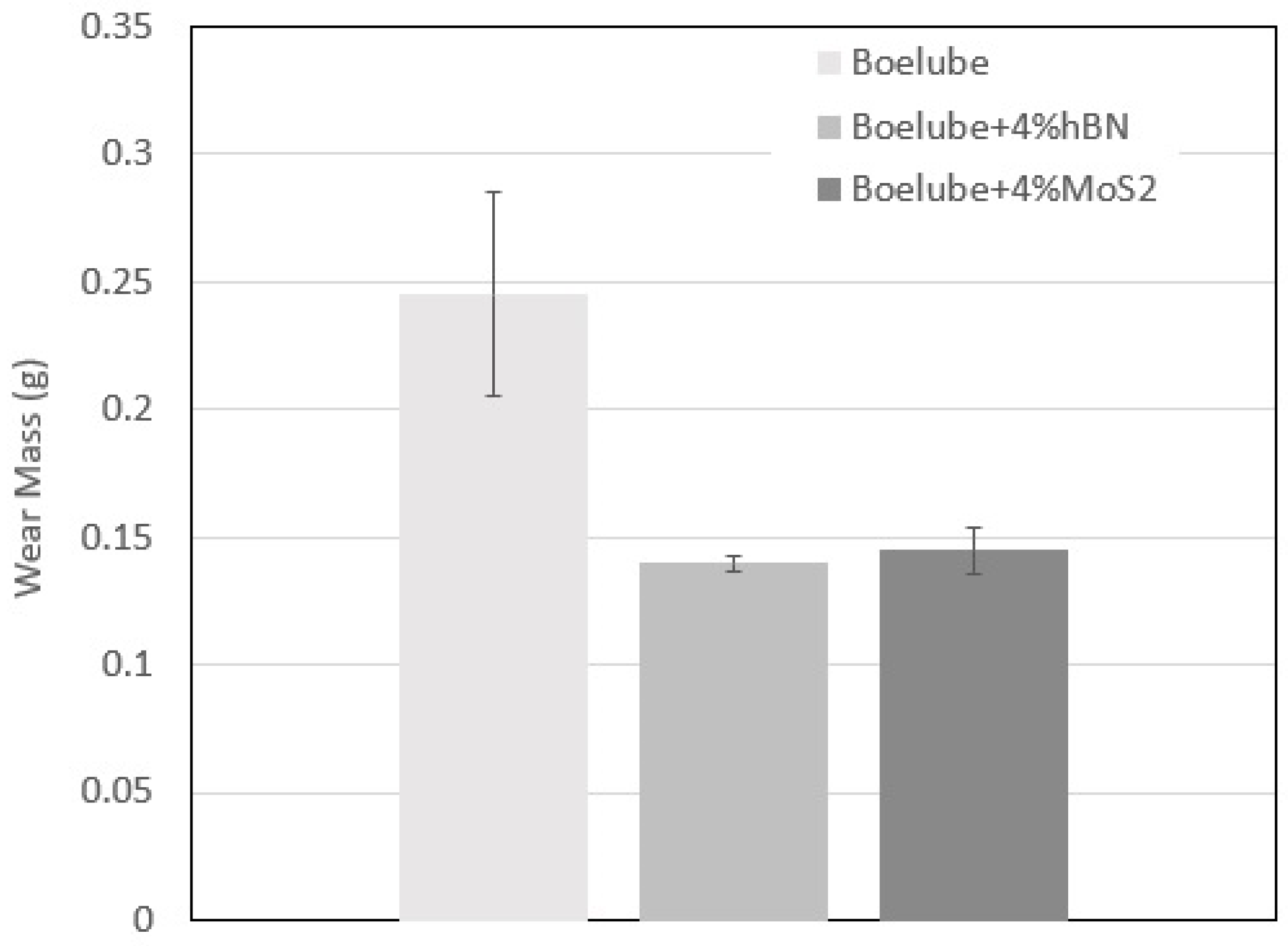

3.1. Results from Orbital Drilling

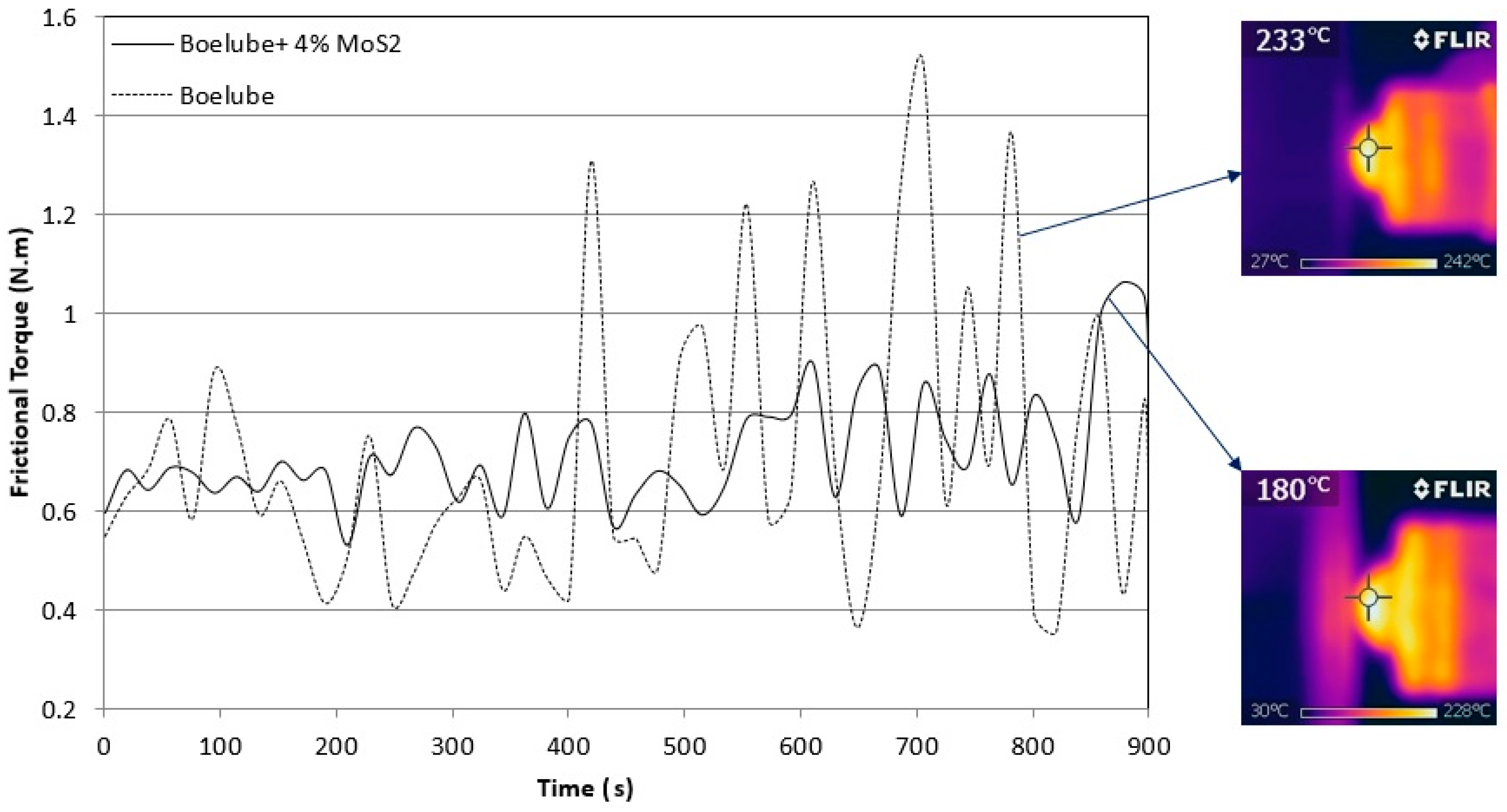

3.2. Results from Four-Ball Testing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ezugwu, E.O. Key improvements in the machining of difficult-to-cut aerospace superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Heisel, U.; Lutz, M.; Spath, D.; Wassmer, R.A.; Walter, U. Application of minimum quantity cooling lubrication technology in cutting processes. Prod. Eng. 1994, 2, 49–54. [Google Scholar]

- Filipovic, A.; Stephenson, D.A. Minimum quantity lubrication (MQL) applications in automotive power-train machining. Mach. Sci. Technol. 2006, 10, 3–22. [Google Scholar] [CrossRef]

- Aronson, R.B. Why Dry Machining. Manuf. Eng. 1995, 114, 33–36. [Google Scholar]

- Bennett, E.O.; Bennett, D.L. Occupational airway diseases in the metalworking industry Part 1: Respiratory infections, pneumonia, chronic bronchitis and emphysema. Tribol. Int. 1985, 18, 169–176. [Google Scholar] [CrossRef]

- Brockhoff, T.; Walter, A. Fluid minimization in cutting and grinding. Abrasives 1998, 10, 38–42. [Google Scholar]

- Jamadar, A.A.; Awale, V.S.; Kale, M.S. Minimum Quantity Lubrication. Int. J. Adv. Res. Sci. Eng. Technol. 2017, 4, 3150–3156. [Google Scholar]

- Heinemann, R.; Hinduja, S.; Barrow, G.; Petuelli, G. Effect of MQL on the tool life of small twist drills in deep-hole drilling. Int. J. Mach. Tools Manuf. 2006, 46, 1–6. [Google Scholar] [CrossRef]

- Attanasio, A.; Gelfi, M.; Giardini, C.; Remino, C. Minimal quantity lubrication in turning: Effect on tool wear. Wear 2006, 260, 333–338. [Google Scholar] [CrossRef]

- Boubekri, N.; Shaikh, V. Machining using minimum quantity lubrication: A technology for sustainability. Int. J. Appl. Sci. Technol. 2012, 2, 111–115. [Google Scholar]

- Yan, L.T.; Yuan, S.M.; Liu, Q. Effect of cutting parameters on minimum quantity lubrication machining of high strength steel. Mater. Sci. Forum 2009, 626, 387–392. [Google Scholar] [CrossRef]

- Sharif, S.; Kurniawan, D.; Mohd, H.; Orady, E. Performance evaluation of vegetable oil as an alternative cutting lubricant when end milling stainless steel using TiAlN coated carbide tools. Trans. N. Am. Manuf. Res. Inst. SME 2009, 37, 9–14. [Google Scholar]

- Mosleh, M.; Atnafu, N.D.; Belk, J.H.; Nobles, O.M. Modification of sheet metal forming fluids with dispersed nanoparticles for improved lubrication. Wear 2009, 267, 1220–1225. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Improved machining performance with nanoparticle enriched cutting fluids under minimum quantity lubrication (MQL) technique: A review. Mater. Today 2015, 2, 3545–3551. [Google Scholar] [CrossRef]

- Krishna, P.V.; Srikant, R.R.; Rao, D.N. Experimental investigation on the performance of nanoboric acid suspensions in SAE-40 and coconut oil during turning of AISI 1040 steel. Int. J. Mach. Tools Manuf. 2010, 50, 911–916. [Google Scholar] [CrossRef]

- Vasu, V.; Kumar, K.M. Analysis of nanofluids as cutting fluid in grinding EN-31 steel. Nano-Micro Lett. 2011, 3, 209–214. [Google Scholar] [CrossRef]

- Mosleh, M.; Ghaderi, M.; Shirvani, K.A.; Belk, J.; Grzina, D.J. Performance of cutting nanofluids in tribological testing and conventional drilling. J. Manuf. Process. 2017, 25, 70–76. [Google Scholar] [CrossRef]

- Rahmati, B.; Sarhan, A.A.; Sayuti, M. Investigating the optimum molybdenum disulfide (MoS2) nanolubrication parameters in CNC milling of AL6061-T6 alloy. Int. J. Adv. Manuf. Technol. 2014, 70, 1143–1155. [Google Scholar] [CrossRef]

- Moura, R.R.; da Silva, M.B.; Machado, Á.R.; Sales, W.F. The effect of application of cutting fluid with solid lubricant in suspension during cutting of Ti-6Al-4V alloy. Wear 2015, 332, 762–771. [Google Scholar] [CrossRef]

- Xie, H.; Jiang, B.; Liu, B.; Wang, Q.; Xu, J.; Pan, F. An investigation on the tribological performances of the SiO2/MoS2 hybrid nanofluids for magnesium alloy-steel contacts. Nanoscale Res. Lett. 2016, 11, 329. [Google Scholar] [CrossRef]

- Hait, S.K.; Chen, Y. Study on the Influence of Li-Grease EP and AW Performance by Exfoliated MoS2 Nanosheet Additive. Adv. Sci. Lett. 2014, 20, 1387–1395. [Google Scholar]

- Mosleh, M.; Ghaderi, M. Deagglomeration of transfer film in metal contacts using nanolubricants. Tribol. Trans. 2012, 55, 52–58. [Google Scholar] [CrossRef]

- Wojtewicz, M.; Nadolny, K.; Kapłonek, W.; Rokosz, K.; Matysek, D.; Ungureanu, M. Experimental studies using minimum quantity cooling (MQC) with molybdenum disulfide and graphite-based microfluids in grinding of Inconel® alloy 718. Int. J. Adv. Manuf. Technol. 2018. [Google Scholar] [CrossRef]

- Marques, A.; Suarez, M.; Sales, W.F.; Machado, A.R. Turning of Inconel 718 with whisker-reinforced ceramic tools applying vegetable-based cutting fluid mixed with solid lubricants by MQL. J. Mater. Process. Technol. 2019, 266, 530–543. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhang, Y.; Wang, Y.; Jia, D.; Yang, M.; Zhang, N.; Wu, Q.; Han, Z.; Sun, K. Heat transfer performance of MQL grinding with different nanofluids for Ni-based alloys using vegetable oil. J. Clean. Prod. 2017, 154, 1–11. [Google Scholar] [CrossRef]

- Paul, S.; Ghosh, A. Grinding of WC-Co cermets using hexagonal boron nitride nano-aerosol. Int. J. Refract. Met. Hard Mater. 2019, 78, 264–272. [Google Scholar] [CrossRef]

- Le Coz, G.; Marinescu, M.; Devillez, A.; Dudzinski, D.; Velnom, L. Measuring temperature of rotating cutting tools: Application to MQL drilling and dry milling of aerospace alloys. Appl. Therm. Eng. 2012, 36, 434–441. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Janssen, R. Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann-Manuf. Technol. 2002, 51, 87–90. [Google Scholar] [CrossRef]

- Whinnem, E.; Lipczynski, G.; Eriksson, I. Development of orbital drilling for the Boeing 787. SAE Int. J. Aerosp. 2008, 1, 811–816. [Google Scholar] [CrossRef]

- Ni, W. Orbital Drilling of Aerospace Materials. No. 2007-01-3814. SAE Tech. Pap. 2007. [Google Scholar] [CrossRef]

- Atarsia, A. Axial and Orbital Drilling of Thick Stacks for New Aircraft Assembly Process. SAE Int. J. Aerosp. Eng. 2013, 6, 540–544. [Google Scholar] [CrossRef]

- Chang, C.H. Boelube R Dissolving Alkaline Cleaning Solution. U.S. Patent 6,240,935, 5 June 2001. [Google Scholar]

- Gansheimer, J.; Holinsky, R. A study of solid lubricant in oils and greases under boundary conditions. Wear 1972, 19, 439–449. [Google Scholar] [CrossRef]

- Hisakado, T.; Tsukizoe, T.; Yoshikawa, H. Lubrication mechanism of solid lubricants in oils. J. Lubr. Technol. 1983, 105, 245–253. [Google Scholar] [CrossRef]

- Cizaire, L.; Vacher, B.; Le Mogne, T.; Martina, J.M.; Rapoport, L.; Margolinc, A.; Tennec, R. Mechanisms of ultra-low friction by hollow inorganic fullerene-like MoS2 nanoparticles. Surf. Coat. Technol. 2002, 160, 282–287. [Google Scholar] [CrossRef]

- Mosleh, M.; Belk, J.H. Methods and Compositions for Reducing Wear of Surfaces in Contact with One Another. U.S. Patent No. 9,605,228, 28 March 2017. [Google Scholar]

- Gulzar, M.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Mufti, R.A.; Zulkifli, N.W.M.; Zahid, R. Improving the AW/EP ability of chemically modified palm oil by adding CuO and MoS2 nanoparticles. Tribol. Int. 2015, 88, 271–279. [Google Scholar] [CrossRef]

- Zhou, X.; Fu, X.; Shi, H.; Hu, Z. Lubricating properties of Cyanex 302-modified MoS2 microspheres in base oil 500SN. Lubr. Sci. 2007, 19, 71–79. [Google Scholar]

- Pawlak, Z.; Kaldonski, T.; Pai, R.; Bayraktar, E.; Oloyede, A. A comparative study on the tribological behaviour of hexagonal boron nitride (h-BN) as lubricating micro-particles—An additive in porous sliding bearings for a car clutch. Wear 2009, 267, 1198–1202. [Google Scholar] [CrossRef]

| Materials | Average Size (nm) as Powder | Average Size (nm) in Boelube after Shaking | Average Size (nm) in Boelube after Sonication |

|---|---|---|---|

| MoS2 nanoparticles | 70–100 | 800 | 550 |

| hBN nanoparticles | 70 | 750–850 | 550 |

| Ball | Diameter (mm) | Grade | Arithmetical Mean Roughness Ra (nm) (ISO 4287:1997) |

|---|---|---|---|

| Tungsten Carbide (WC) | 12.7 | 25 | 50 |

| Titanium 6Al4V (Ti) | 12.7 | 200 | 200 |

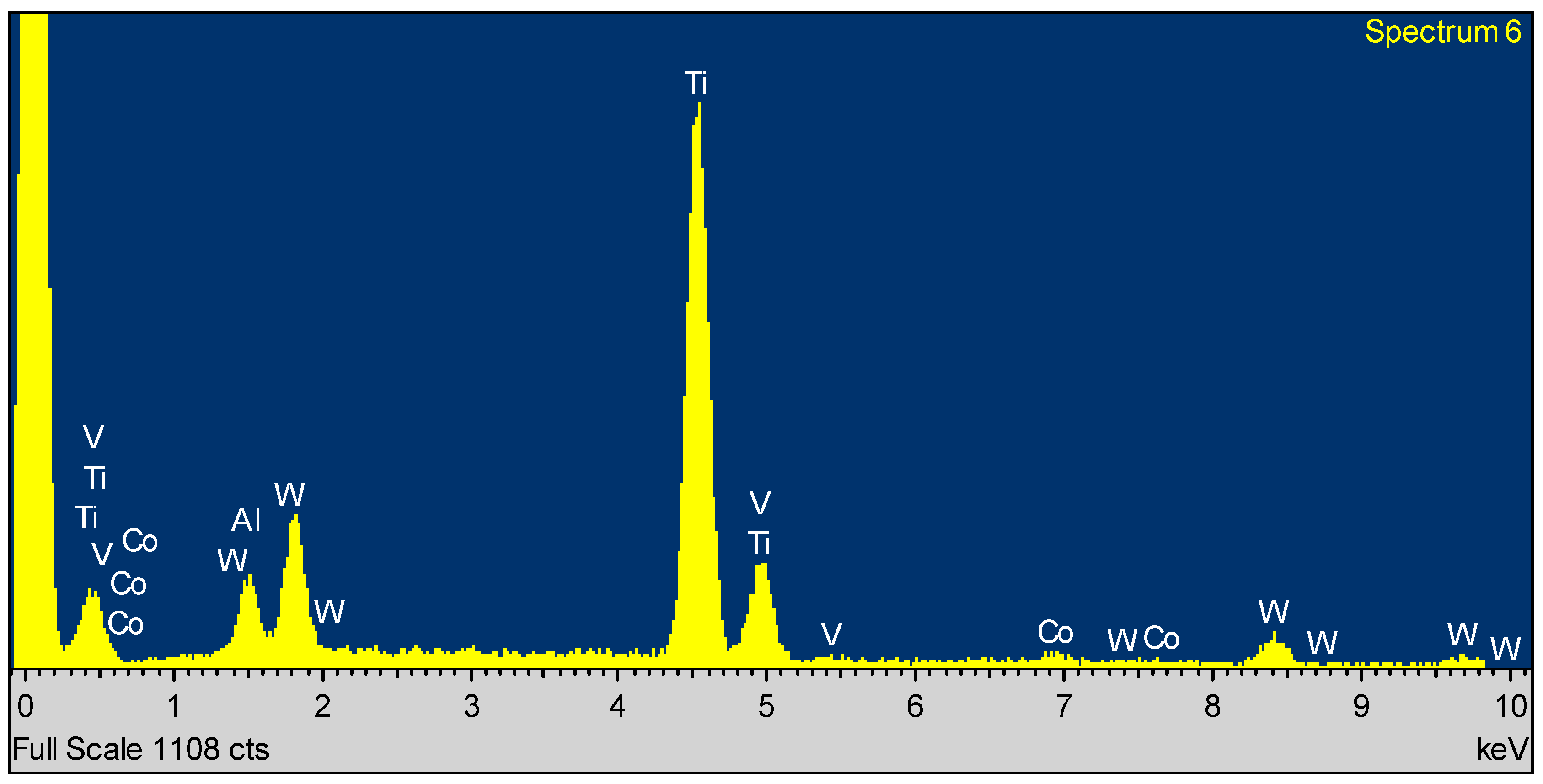

| WC Tool (with Pure Boelube) (all Results in Weight%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Spectrum | In stats. | Al | Ca | Ti | V | Co | W | Total |

| Spectrum 2 | Yes | - | - | 1.12 | - | - | - | 1.12 |

| Spectrum 3 | Yes | 4.59 | - | 71.66 | 3.65 | 1.19 | 7.04 | 88.13 |

| Spectrum 4 | Yes | 2.41 | - | 34.89 | - | 5.13 | 36.65 | 79.08 |

| Spectrum 5 | Yes | 5.04 | - | 61.73 | 2.54 | - | 6.05 | 75.35 |

| Spectrum 6 | Yes | 4.08 | - | 53.33 | 2.83 | 1.76 | 19.1 | 81.1 |

| Spectrum 7 | Yes | 9.11 | - | 90.44 | 2.6 | - | - | 102.16 |

| Spectrum 8 | Yes | 3.36 | 0.79 | 38.58 | 1.44 | 5.62 | 59.02 | 108.8 |

| Spectrum 9 | Yes | 6.11 | - | 72.4 | 3.68 | 3.7 | 32 | 117.88 |

| Spectrum 10 | Yes | 5.58 | - | 68.49 | 3.61 | 2.21 | 32.28 | 112.17 |

| Max. | - | 9.11 | 0.79 | 90.44 | 3.68 | 5.62 | 59.02 | - |

| Min. | - | 2.41 | 0.79 | 1.12 | 1.44 | 1.19 | 6.05 | - |

| - | Average | 5.0 | - | 54.7 | 2.9 | - | 27.4 | - |

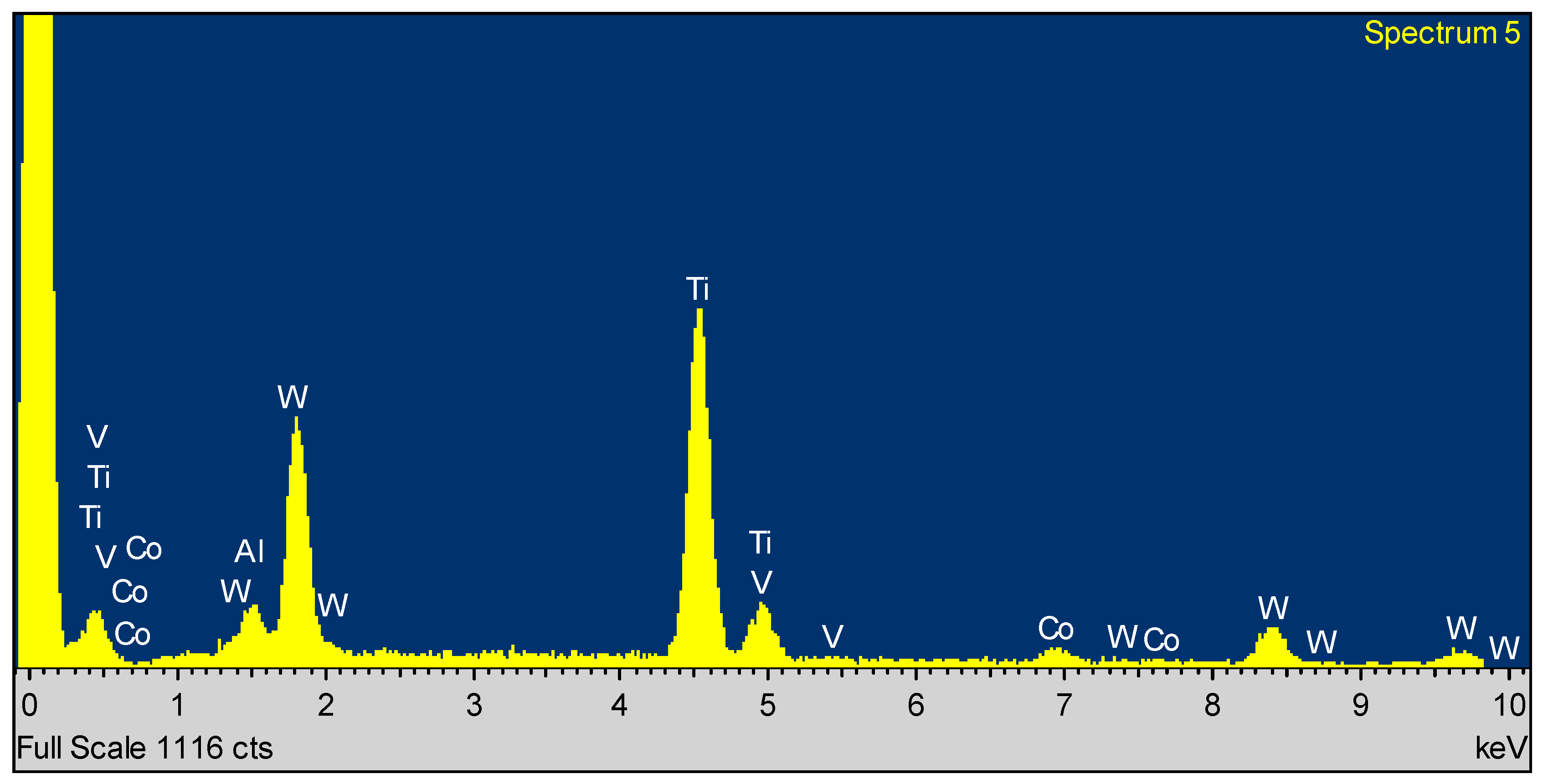

| WC Tool (with Boelube+2%MoS2) (all Results in Weight %) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Spectrum | In stats. | O | Al | Ti | V | Co | W | Total |

| Spectrum 1 | Yes | - | 0.57 | 5 | - | 6.99 | 59.89 | 72.44 |

| Spectrum 2 | Yes | - | 0.79 | 6.99 | - | 6.25 | 59.77 | 73.81 |

| Spectrum 3 | Yes | - | 0.84 | 19.56 | 0.9 | 2.11 | 15.72 | 87.91 |

| Spectrum 4 | Yes | - | - | 11.19 | - | 1.06 | 2.27 | 14.51 |

| Spectrum 5 | Yes | - | 2.19 | 33.72 | 1.09 | 2.53 | 30.02 | 69.55 |

| Spectrum 6 | Yes | - | 2.3 | 53.42 | 2.64 | 0.84 | 4.96 | 64.15 |

| Spectrum 7 | Yes | 6.07 | 1.06 | 8.6 | 0.87 | 3.48 | 71.5 | 91.57 |

| Spectrum 8 | Yes | - | 5.86 | 73.98 | 2.83 | - | 6.68 | 89.34 |

| Spectrum 9 | Yes | - | 4.78 | 59.41 | 2.56 | 2.72 | 24.69 | 94.15 |

| Spectrum 10 | Yes | - | 3.69 | 44.08 | 2.7 | 3.89 | 45.94 | 100.3 |

| Max. | - | 6.07 | 5.86 | 73.98 | 2.83 | 6.99 | 71.5 | - |

| Min. | - | 6.07 | 0.57 | 5 | 0.87 | 0.84 | 2.27 | - |

| - | Average | 2.5 | 31.6 | 1.9 | - | 32.1 | - | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mosleh, M.; Shirvani, K.A.; Smith, S.T.; Belk, J.H.; Lipczynski, G. A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing. J. Manuf. Mater. Process. 2019, 3, 5. https://doi.org/10.3390/jmmp3010005

Mosleh M, Shirvani KA, Smith ST, Belk JH, Lipczynski G. A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing. Journal of Manufacturing and Materials Processing. 2019; 3(1):5. https://doi.org/10.3390/jmmp3010005

Chicago/Turabian StyleMosleh, Mohsen, Khosro A. Shirvani, Sonya T. Smith, John H. Belk, and Gary Lipczynski. 2019. "A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing" Journal of Manufacturing and Materials Processing 3, no. 1: 5. https://doi.org/10.3390/jmmp3010005

APA StyleMosleh, M., Shirvani, K. A., Smith, S. T., Belk, J. H., & Lipczynski, G. (2019). A Study of Minimum Quantity Lubrication (MQL) by Nanofluids in Orbital Drilling and Tribological Testing. Journal of Manufacturing and Materials Processing, 3(1), 5. https://doi.org/10.3390/jmmp3010005