2.1. The Ultrasonic Spot Welding Configuration

The ultrasonic spot welding was done without energy directors in the interface; the energy focusing was achieved by applying the welds amid a flat-end anvil and a flat-end ultrasonic horn. The anvil and the horn had circular contact to the welded parts, in which the anvil had a smaller contact diameter

with the welded parts than the horn

. A combination of a relative high static weld force [

8] and the geometry of the anvil/horn ends facilitate the focusing of the ultrasonic energy at a spot in the weld interface. The configuration of the ultrasonic welding is given in

Figure 1; a detailed view of the horn/anvil ends and the essential dimensions are illustrated in the detail view.

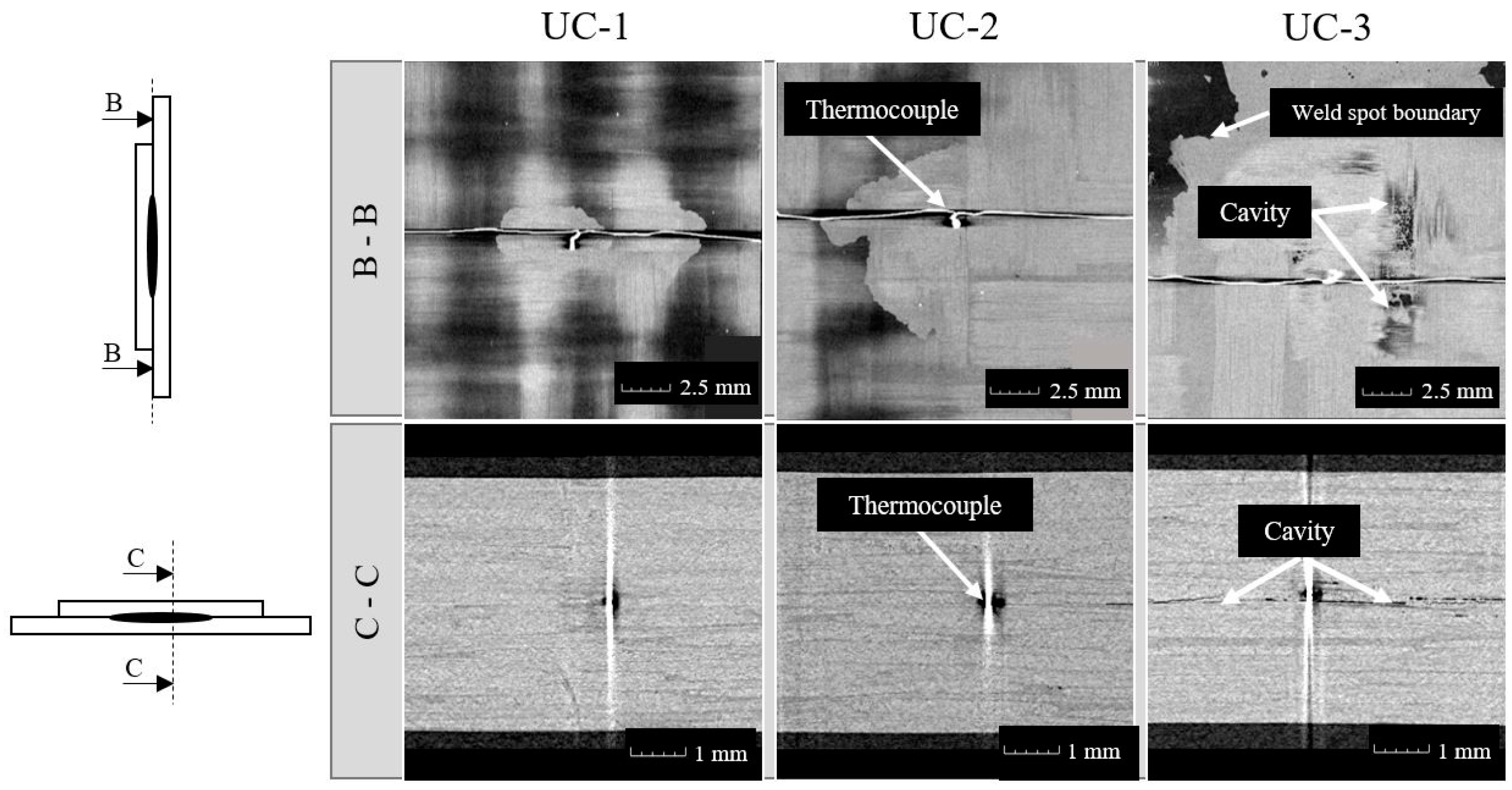

One of the main problems which was observed during the ultrasonic spot welding of fiber-reinforced thermoplastic laminates without energy directors was overheating and thermal decomposition of the thermoplastic matrix in the weld interface. It was observed that, at an unpredictable time, the temperature in the weld spot rose very rapidly and exceeded the thermal decomposition temperature of the matrix. The decomposition of the matrix caused defects in the weld spot in the form of cavities, delamination, and gas entrapments, which in turn reduced the quality and strength of the weld spot. To avoid overheating and create a uniform weld spot, a control method was essential.

2.2. The Process Controlling Hypothesis

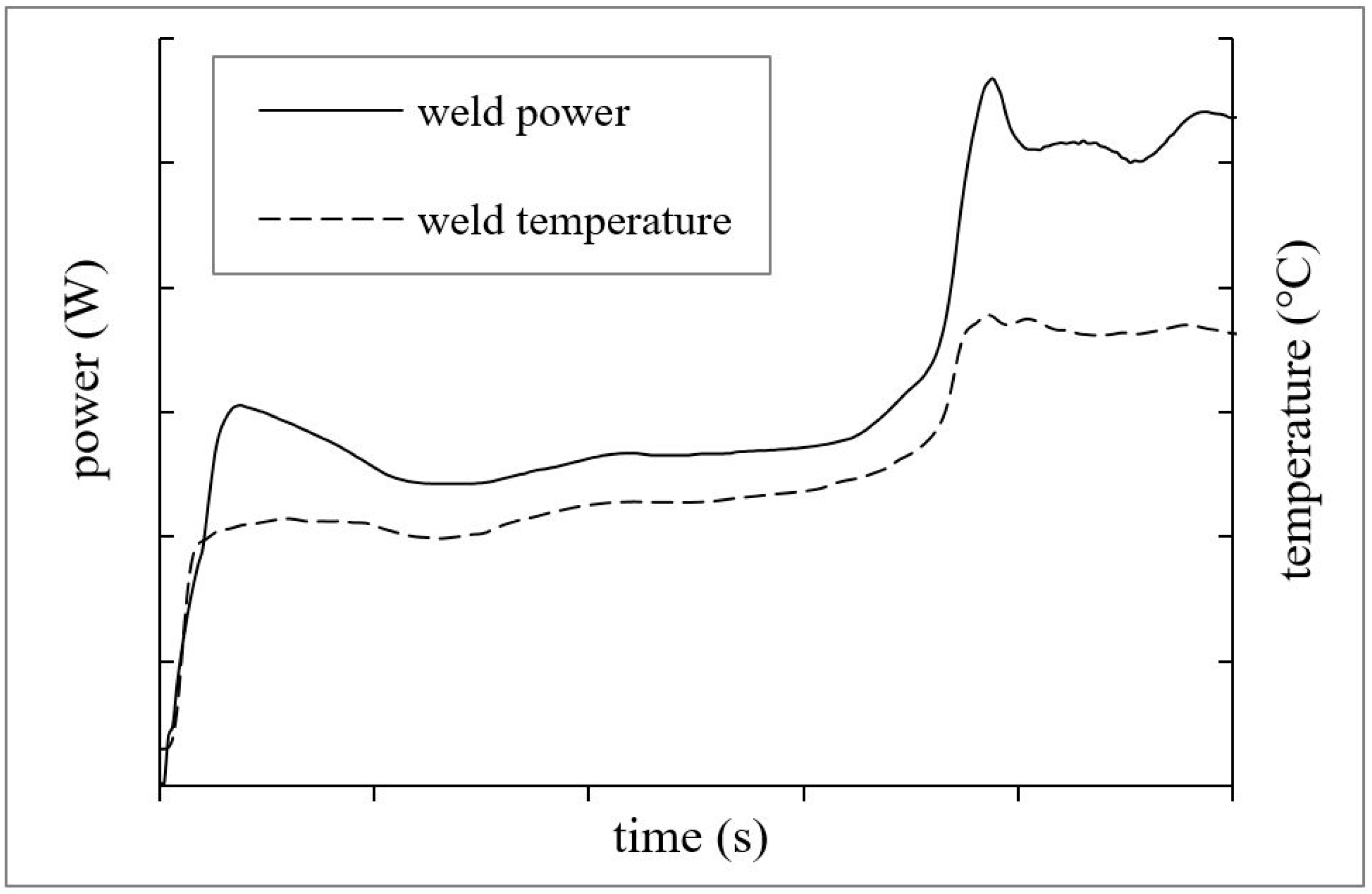

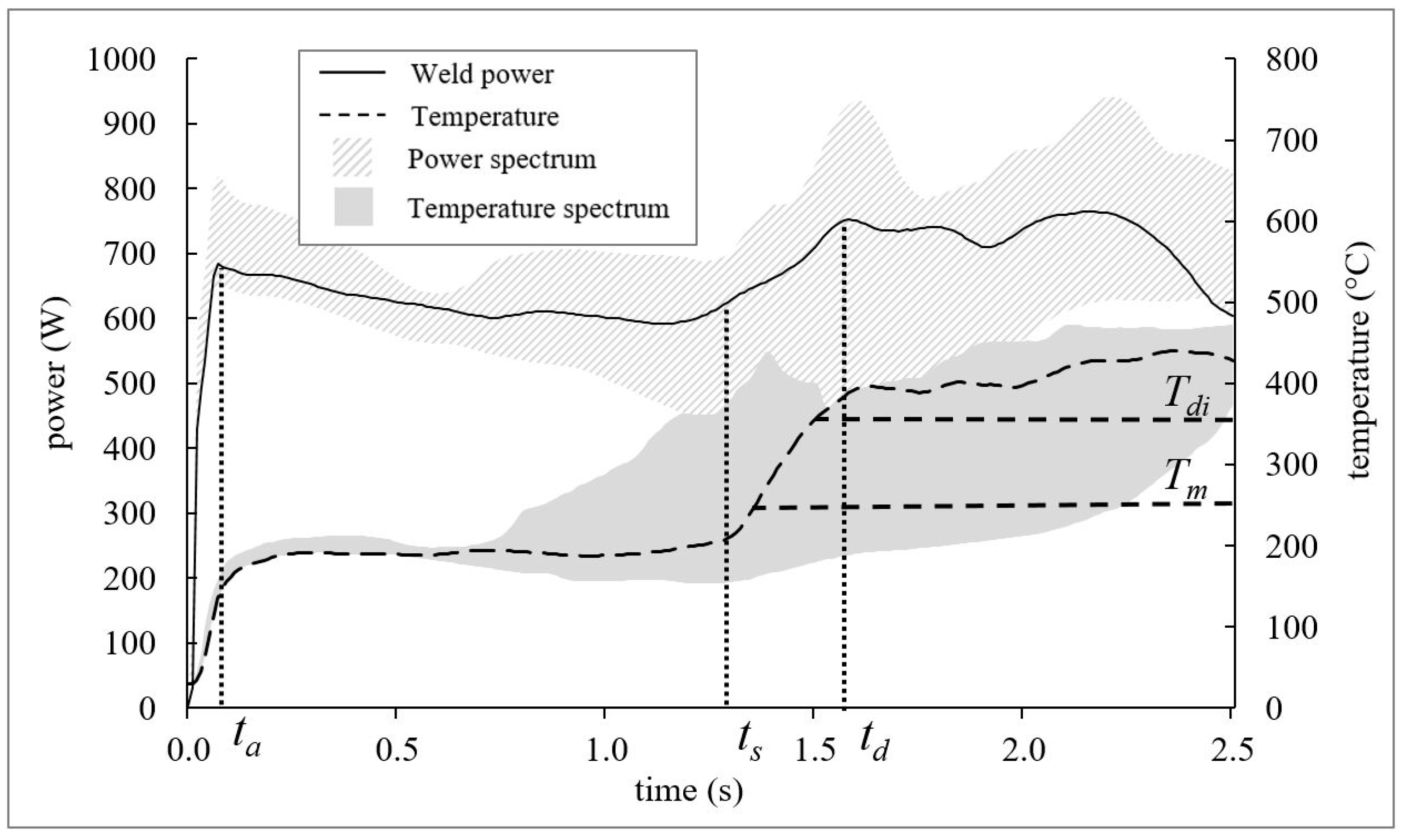

The power consumed by the ultrasonic welder

P(t) during the ultrasonic spot welding follows, in most cases, a typical time-trace pattern, which is plotted as the solid line in

Figure 2. Parallel to it, plotted as the broken line, is the temperature curve measured in the center of the spot weld. The plots illustrated in

Figure 2 are real measurements which belong to a single ultrasonic spot weld.

By observing the temperature and the power curve patterns, one might clearly notice that the weld power

P(t) and the weld center temperature

T(t) have a clear correlation. In the weld initiation phase, the power and the temperature curves rise rapidly; then, at a transition phase, the temperature and the power curves undergo only slight changes. At a certain instance of time, both curves show an abrupt rise before stabilizing again. This second rise of the temperature leads to the decomposition of the matrix at the weld spot. A similar observation was made by Tolunay [

19] while measuring the temperature in the interface of two disc-shaped specimens during ultrasonic welding.

It was assumed in this work that, if the second rise of the power curve is prevented, then this may prevent the sudden increase in temperature up to the decomposition zone. It may lead instead to the stabilization of the temperature and, consequently, the weld spot will have sufficient time in the optimum temperature zone to undergo a uniform diffusion process. The prevention of the second rise of temperature was achieved by means of monitoring the power time derivative in real-time. If the derivative in the expected time period exceeded a certain pre-set value, then the applied vibration displacement amplitude was reduced. The pre-set power derivative value to trigger the amplitude drop and the amount of amplitude drop were determined experimentally.

It was reported that the power

P(t) consumed by the weld is the sum of the total power dissipated in the welded material as heat through friction and viscoelastic mechanisms plus the power lost in the rig and system [

6,

14]. The viscoelastic dissipated power is a function of the square of the strain amplitude (Equation (2)) and, thus, a function of the square of the deformation amplitude [

15]. The friction heating on the other hand is a function of the average slippage amplitude in the weld interface

and both components of the interfacial pressure amplitude

, which are the average static interfacial pressure

and the average dynamic interfacial pressure amplitude

. By a closer observation of the friction dissipation (Equation (1)), both the slippage and the dynamic pressure are functions of the displacement amplitude

A0. Thus, the friction power dissipation becomes a function of the square of the ultrasonic vibration amplitude. The parameters and variables which correlate with

are given in Equation (3) and the parameters which correlate with

are given in Equation (4). The variables which mainly influence the dissipated or consumed power are given in Equation (5).

In this discussion, only the adjustable variables were taken into consideration. The static pressure (the static welding force), in addition to its influence on the friction heating, influences the heating rate through effecting the hammering effect as reported in References [

14,

15]. Therefore, adjusting it might give unpredictable influence on the power dissipation. The frequency is assumed by several researchers to be used as a weld control input because it is in a linear correlation with the weld power; however, this in turn is constant in the given welder and can only be adjusted in a narrow range. Therefore, to control the weld power

P(t), the active adjusting of the vibration amplitude is most applicable to the design of the control system.

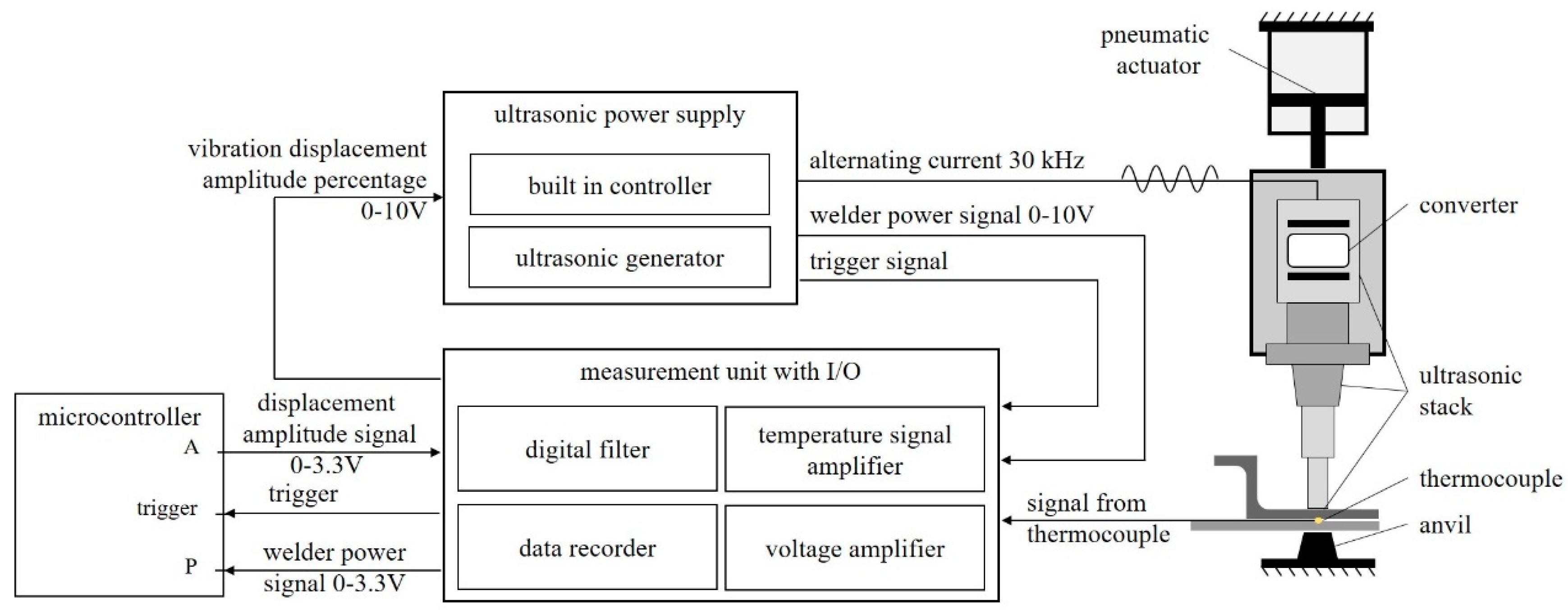

2.3. The Control System and Instruments

The control system used for the experimental study was attained by connecting an external microcontroller through a commercial high-speed digital amplifier/data recorder to the main welder controller. The latter in turn was the standard built-in controller of the ultrasonic generator. The used weld generator was capable of outputting a nominal maximum power of 2400 W with a nominal mean frequency of 30 kHz. The ultrasonic stack consisted of a 30-kHz converter, a 1.5:1 titanium booster and a 4:1 steel stepped flat-end horn. The horn-end had a diameter of Dh = 18 mm and the anvil had a diameter of Da = 10 mm. The anvil was constructed in a way that it had a natural frequency of about 42 kHz to avoid resonance vibrations within the rig.

According to the laser vibrometer measurements, the stack provided a maximum base-to-peak displacement amplitude A100% = 0.028 mm at the horn-end. The displacement amplitude at the end of the horn could be adjusted through the internal controller of the welder in terms of percentage from the maximum available amplitude A = 100 A0/A100%. During welding, it can be varied through an external analog signal; a 10-V analog signal from the external controller sent to the generator corresponds to A = 0% amplitude and 0 V corresponds to A = 100%. The welder generator can provide, in real time, the consumed electrical power value as an analog output signal in the range of 0–10 V, where 0 V corresponds to 0 W and 10 V corresponds to the maximum welder power of 2400 W.

The measurement and amplification unit consisted of a temperature signal amplification module, an amplification module for input signals, an amplification module for the output signals, and a data recorder. The sample rate at which the measurement unit was operated at was 300 Hz. The implemented controlling unit was a commercial programmable microcontroller. The wiring and connections are schematically illustrated in

Figure 3. The algorithm for the controller is illustrated in

Figure 4. The microcontroller read the amount of power consumed by the welder in terms of an analog voltage signal (0–3.3 V); then, it converted the voltage into the power value in terms of watts, where 0 V corresponded to 0 W and 3.3 V corresponded to 2400 W. The discrete time derivative of the measured power value

dP/dt was calculated in the microcontroller in real time by dividing the difference in the power value between two successive controller loops over the duration of the complete loop. In the same internal cycle, the controller checked within three if-loops for certain conditions of the power derivative. In the first if-loop, the controller checked if dP/dt was within the range between

dPset1 and

dPset2; then, the pre-set initial amplitude

A was dropped with a value of

ΔA = a. This means that the new amplitude percentage after the loop would be

A = A − ΔA. In a similar manner, the amplitude was dropped in the second and third if-loops, although with larger step sizes of

b and

c, respectively. At the end of each control loop, the microcontroller output the target vibration displacement amplitude percentage in terms of an analog 0–3.3 V signal at

A, which was further amplified by the digital amplifier to 0–10 V and fed to the welder internal controller. The amplitude drop repeated for each loop of the controller until the if-loop conditions were not true; then, the amplitude remained constant until the pre-set weld time was reached and the trigger signal was set to LOW. Then, the ultrasonic vibrations were stopped and the weld healing took place under static pressure for a duration of 2 s.

This may be expressed as follows: if the slope of the power curve exceeds a critical value, then the amplitude

A is reduced with a constant pre-set

ΔA. With this approach, the amount of heat being generated in the weld zone is actively reduced and controlled within an optimum range. In previous work in the frame of this research, it was reported that only one if-loop is sufficient to control the weld power [

20]. In this current work, the algorithm was expanded to include three parallel if-loops, thus allowing the system to react to small

dP/dt values with smaller-amplitude drop steps and for larger

dP/dt values with higher-amplitude drop steps. The controller started checking for the power derivative only after a delay of

t0 from the weld start trigger point. This delay served to avoid the amplitude drop in the early phase of the welding, i.e., during the weld initiation where

dP/dt becomes very large. The control principle is explained further in the later paragraphs.

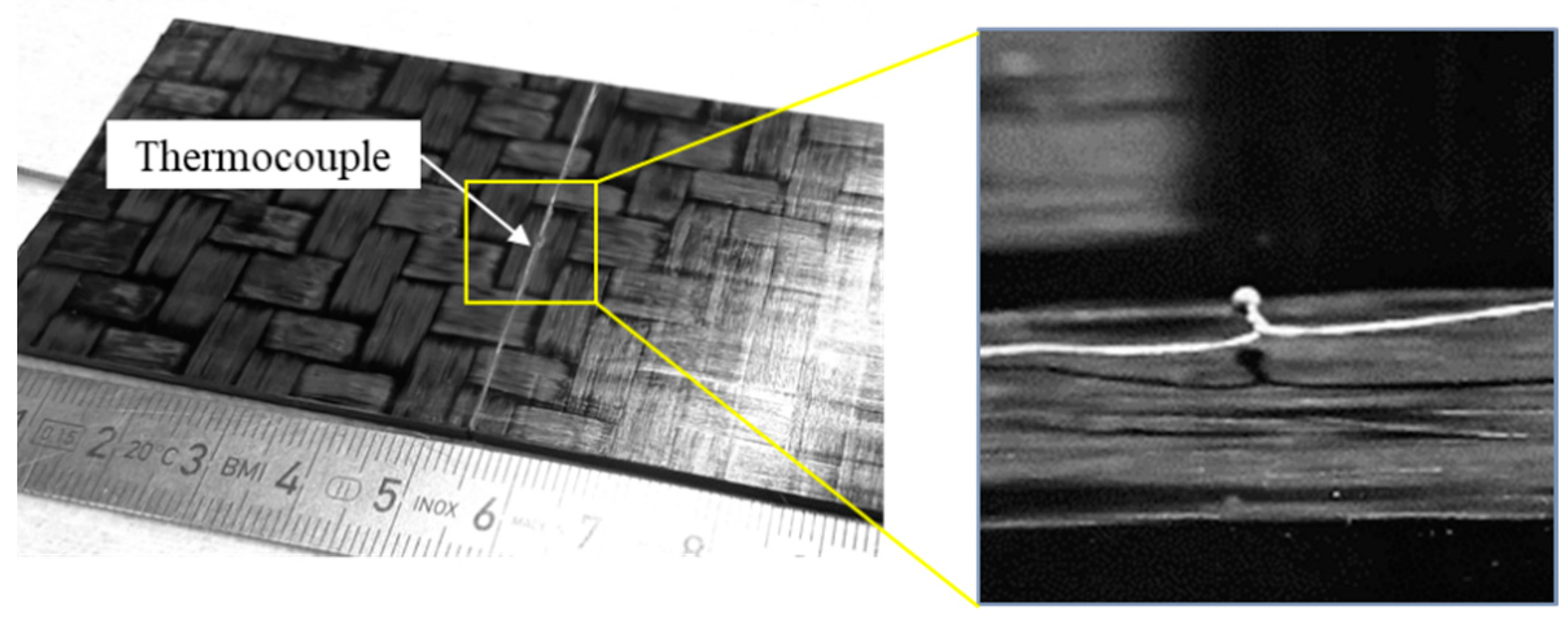

In order to verify the process, the temperature vs. time in the center of the weld spots was measured using a thermocouple (twisted and arc welded K-Type 0.08-mm wire) and the temperature signal value was amplified and stored parallel to the power and amplitude values using the data recorder with a sample rate of 300 Hz. The measured values of the power, for the calculation of dP/dt, were filtered using a low-pass Butterworth filter with a frequency of 5 Hz, because the noise in the power values may result in undesired peaks in its derivative curves, whereas the measured temperature values were filtered using a low-pass Bessel filter with a frequency of 50 Hz.

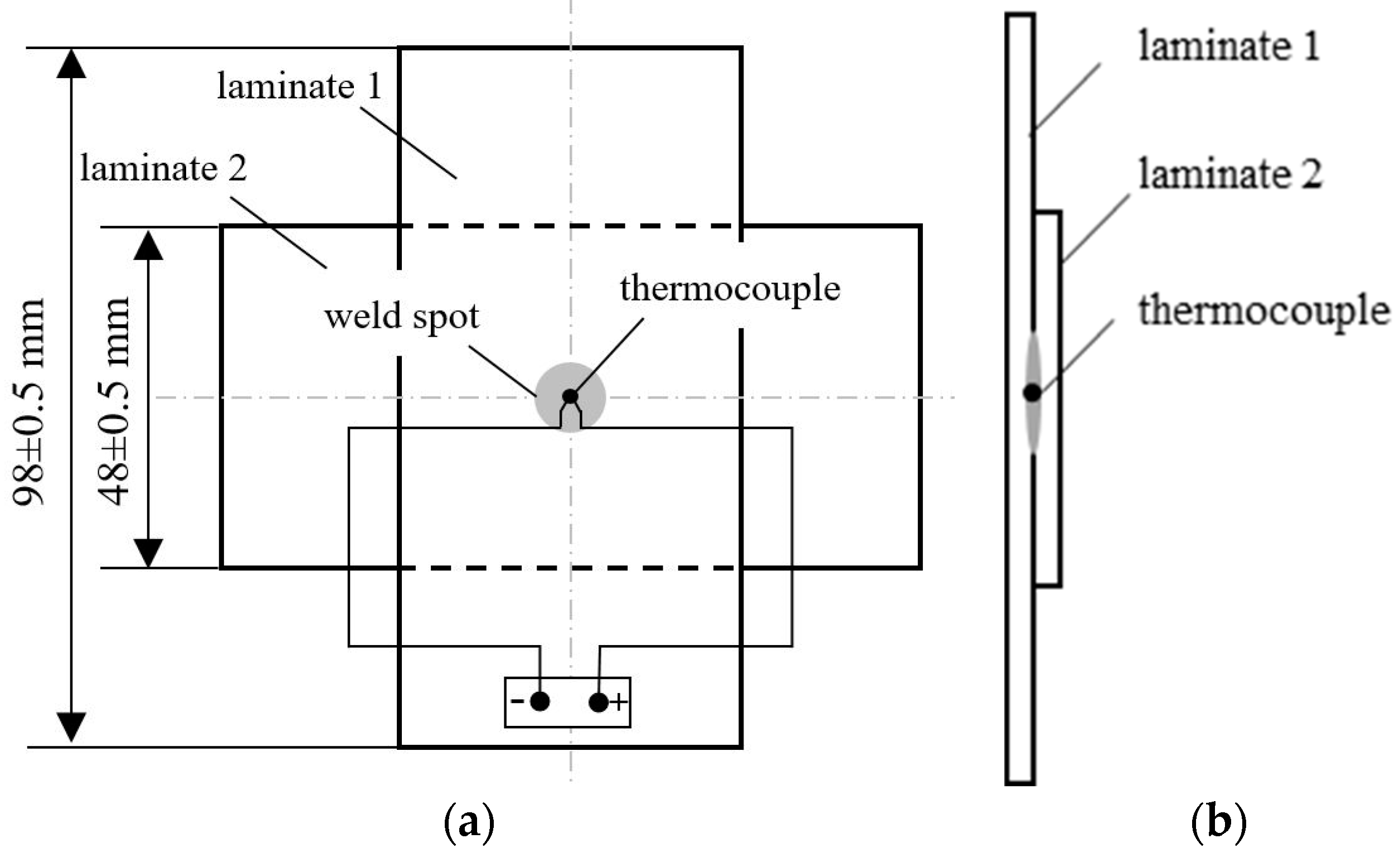

2.4. The Specimen and the Specimen Fixture

The laminates were positioned as illustrated in

Figure 5, and the spot weld was applied on their coinciding center of symmetries.

The fixture of the specimens is illustrated in

Figure 6. It was constructed to allow the precise positioning of the laminates. It was designed to constrain all the relative in-plane movements but, at the same time, ensure the parallelism of the laminate surfaces with the horn and the anvil ends. The anvil end was built to resemble a freely rotating semi-sphere which was cut at one side to form the contact surface. The parallelism of the anvil and the horn-end faces played a crucial role in the uniform distribution of the vibration energy, thus avoiding the melting of the laminate surfaces at their contact with the horn and anvil.

The specimens for the experimental studies were cut from 960 mm × 800 mm × 2.1 mm thermoplastic laminate sheets made form a 12 K 2 × 2 twill carbon woven fabric-reinforced thermoplastic. The matrix was a high-fluidity Polyamide 6.6 (Nylon 6.6). Based on the differential scanning calorimetry test, the recorded glass transition temperature of the composite was

Tg = 69 °C, the melt onset temperature was 243 °C, and the melt point was

Tm = 259 °C. The thermal decomposition initiation temperature was taken from literature as

Tdi = 358 °C according to Reference [

21]. The laminates were consolidated with the hot-plate press approach. The final thickness of

h = 2.1 ± 0.05 mm was resulted by stacking seven prepregs in the cross-ply sequence with a nominal fiber volume fraction of 50%. The specimens were dried in an oven at 75 °C for a minimum duration of 96 h before welding to ensure that the laminates were free from excessive water content.

For the temperature measurement, the thermocouples were prepared by twisting and arc-welding the ends of a fine gauge 40 (

ϕ = 0.08 mm) K-type thermocouple wire pair. The thermocouples were carefully placed in the center of the laminate pairs at the weld interface (see

Figure 5 and

Figure 7); then, they were incorporated into the matrix by applying a short pulse (0.2 s) of ultrasonic vibration with an adequate static force on it. This approach ensured that the sensing end of the thermocouple was fixed in the desired location; later, during welding, the strain concentration at the matrix in the direct vicinity of thermocouple was significantly reduced. It is a well-known challenge to measure the temperature in the weld spot during ultrasonic welding. During the initial phase, the measured temperature might be higher than expected. This might be due to high local strain concentration around the thermocouple sensing end. The K-type thermocouple may also give misleading measurements under static pressure if no appropriate filters are applied. Nevertheless, in literature, the use of thermocouples to analyze and monitor the ultrasonic welding process is often encountered [

9,

10,

19].

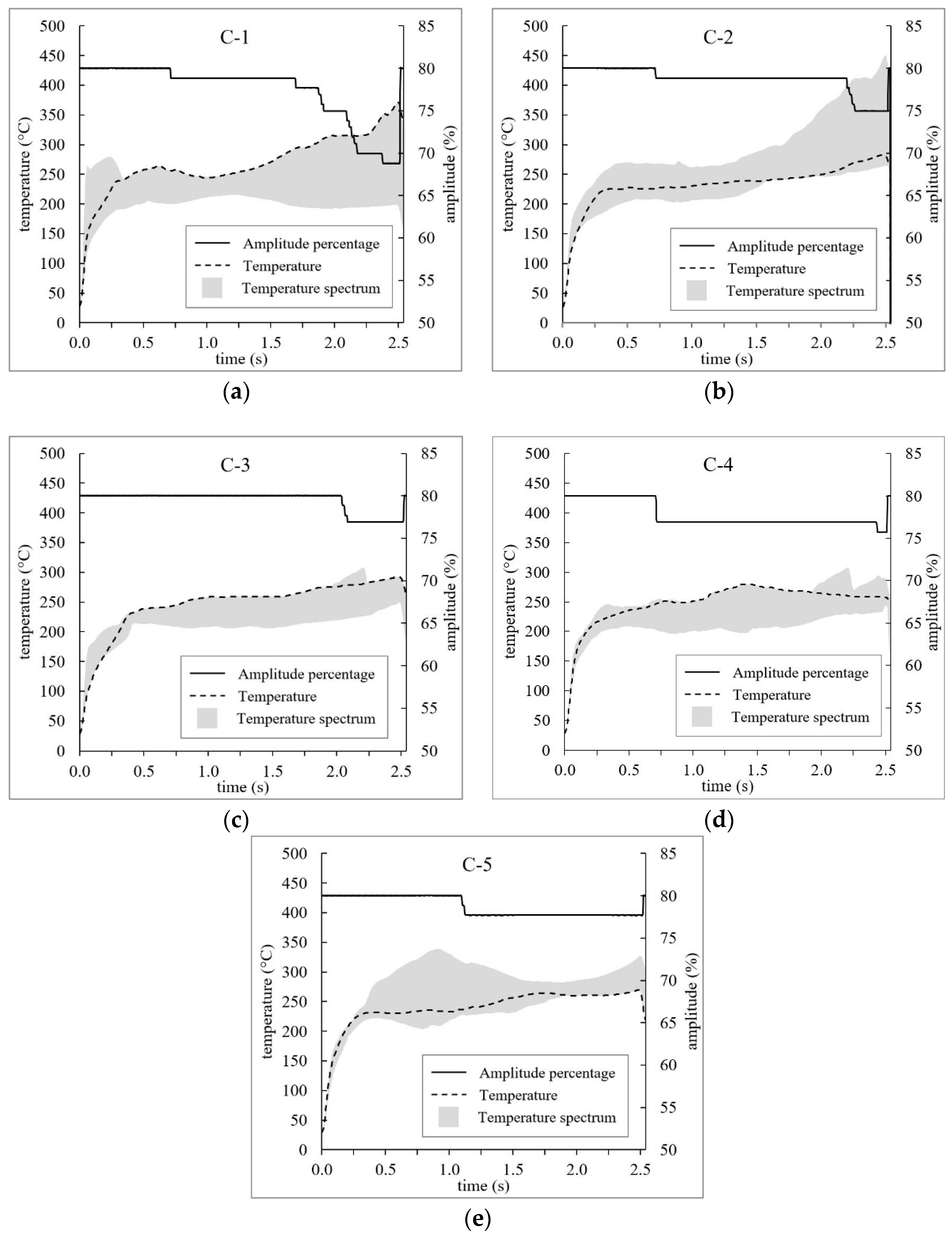

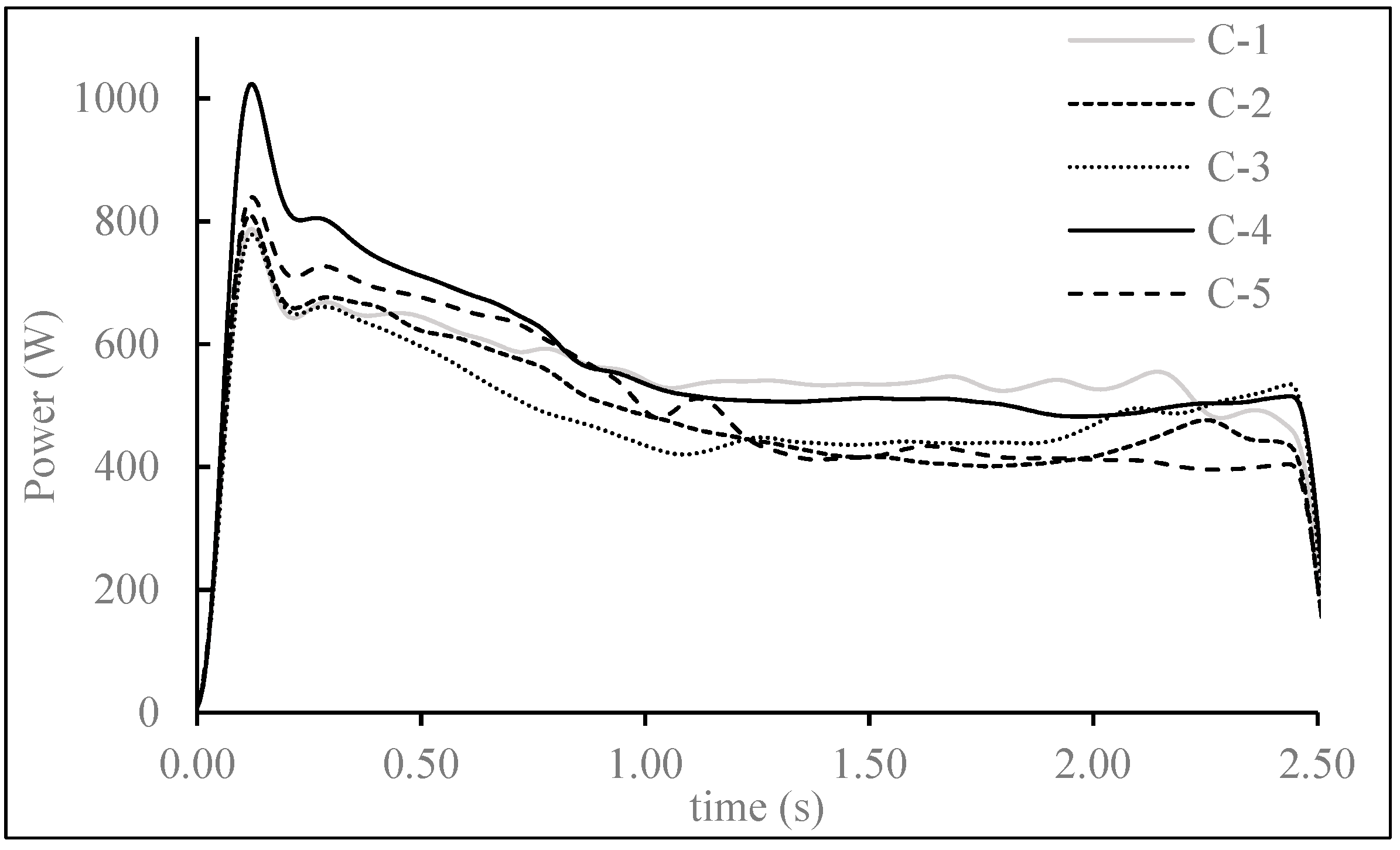

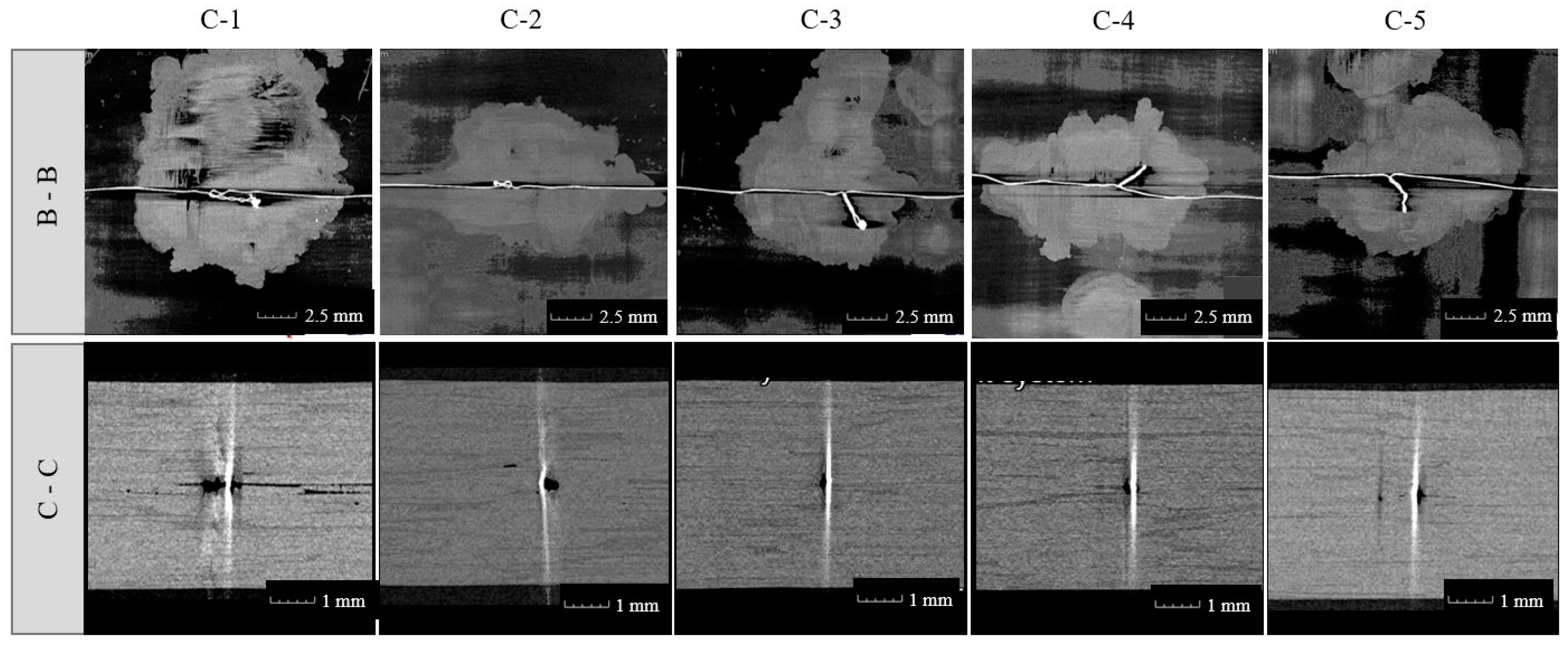

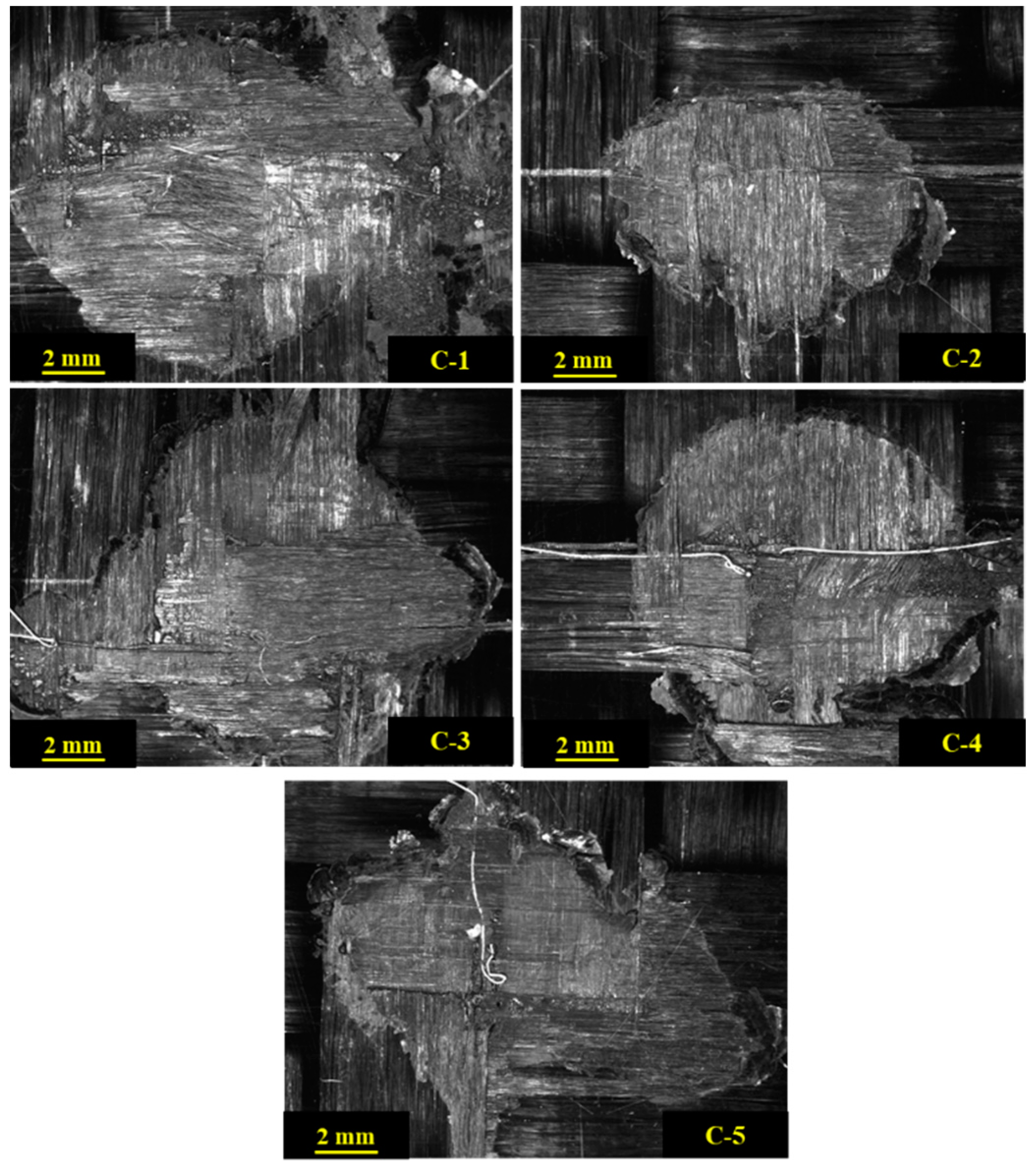

2.5. Experiment Plan

The experiments were divided into two groups. In the first group (UC-x), the influence of the weld duration

tw was monitored under constant parameters and without an active weld control. In the second group (C-x), the weld process control was turned on and the weld duration was set as constant at

tw = 2.5 s. The weld control system was bypassed for the first group by setting the

dPset values very high (considered as inf.). This high value during the welding was not exceeded, and the amplitude remained constant throughout the entire weld duration. In the C-x cases, different values and scenarios for the

dPset were investigated; in the first three cases, the second and third if-loops were ignored by setting the

dPset very high and, for the fourth and the fifth cases, the second and third if-loops were taken into consideration. The relevant process control parameters which were used for the experimental studies are given in

Table 1.

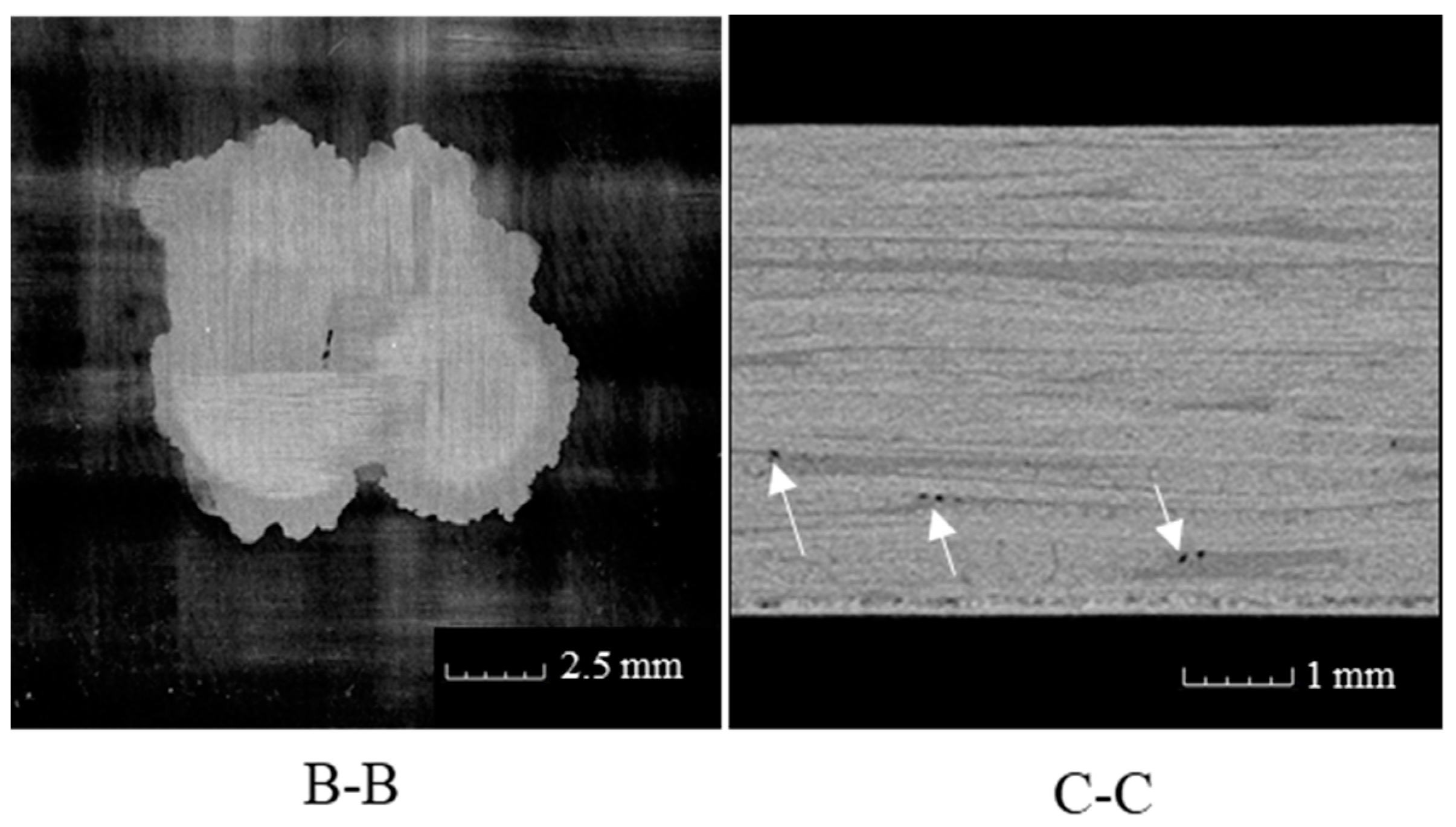

The additional relevant process variables, which were set constant throughout the investigations, were as follows: the weld press average static force, 650 N; the static force at the solidification phase, 600 N; the solidification time, 2 s. Several repetitions for each weld case (7–10 repetitions) were done to gather statistical data. The time traces of the temperature and the power were plotted for the UC-3 case, in order to discuss and illustrate the behavior of the temperature development in relation to the power curve during the DUS weld process. The results of the temperature measurement in the weld spots of the controlled welds were analyzed to identify the influence of the control system on the temperature development vs. time at the center of the weld spot. A reference weld spot was chosen from each case and was scanned through the computed tomography method. The scans were done in the laboratories of the Institute of Lightweight Engineering and Polymer Technology (ILK) at Technische Universität Dresden, using an in situ FICT 160; the X-Ray microfocus was 80 kV at 80 µA. The scans were done with a resolution of 12 µm with a duration of 15 min/scan. The computed tomography (CT) scans delivered insight into the quality of the weld spots. The quality was determined by the presence or the absence of the irregularities caused by the overheating of the matrix.