Abstract

Cloud Manufacturing (CM) is the concept of using manufacturing resources in a service-oriented way over the Internet. Recent developments in Additive Manufacturing (AM) are making it possible to utilise resources ad-hoc as replacements for traditional manufacturing resources in case of spontaneous problems in the established manufacturing processes. In order to be of use in these scenarios, the AM resources must adhere to a strict principle of transparency and service composition in adherence to the Cloud Computing (CC) paradigm. With this review, we provide an overview of CM, AM and relevant domains as well as presenting the historical development of scientific research in these fields, from 2002 to 2016. Part of this work is also a meta-review on the domain to further detail its development and structure.

1. Introduction

Cloud Manufacturing (here CM, in other works also CMfg) as a concept is not new and has been executed in enterprises for many years [1], under different terms, e.g., Grid Manufacturing [2] or Agile Manufacturing [3].

The decision to have a globally distributed production process with many contractors or partners interconnected and related supply chains is a luxurious one. Large global corporations and competition makes “expensive” local production nearly impossible.

CM is based on the strict service orientation of its constituent production resources and capabilities.

Manufacturing resources become compartmentalised and connected; they are worked with as service entities, that can be rented, swapped, expanded, dismantled or scaled up or down just by the use of software. This almost instantaneous and flexible model of resource usage is what made the Cloud Computing (CC) paradigm very successful for a number of companies. Here, computing resources and data storage are all virtual, living in large data-centres around the globe, with the user only interfacing these resources through well-defined APIs (application programming interfaces) and paying for only the resources utilised—apart from the costs incurred by the cloud service providers due to their business model and the surcharged or otherwise calculated requirement for profit.

With this work, we contribute to the dissemination of knowledge in the domain of Additive Manufacturing (AM) and the concept of CM. Cloud Manufacturing can be seen as having two aspects and applications, where the first application is within an industrial environment for which CM provides a concept to embed, connect and utilise existing manufacturing resources, e.g., 3D printers, drilling-, milling- and other machines, i.e., cloud manufacturing is not limited to AM but AM can be utilised within a CM concept. The second application is for end-users that use AM/3D printing resources over the Internet instead of acquiring their own 3D printer. The usage in this second application is highly service-oriented and has mainly end-users or consumers as target clients. The consumers can profit from online-based services without the requirement of having to own either hard- or software resources for 3D printing.

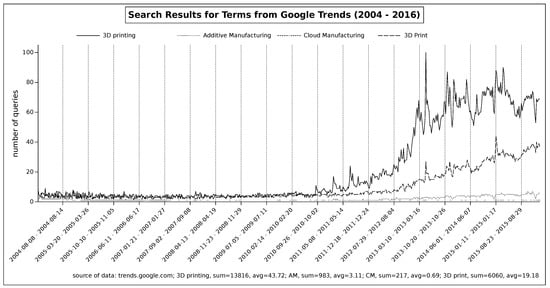

This work aims to provide an overview of the historical development of scientific research in these domains starting from 2002. With this, we show that the scientific output within these fields has increased by an average of 41.3 percent annually to about 20,000 publications per year (see Section 1.2). The latest considered research is from 2016. See Figure 1 for a historical trend analysis of the relevant keywords as presented in Google trends. This Figure shows the public interest of this domain.

Figure 1.

Queries for 3D Printing, AM, CM and 3D Print on google.com for 2004–2016 from trends.google.com.

To develop a better understanding of the topic at hand, we discuss various terminological definitions found in literature and standards. We give a critique on the common definitions of AM and propose a simpler, yet more accurate definition.

Cloud Manufacturing relies on a service-oriented concept of production services or capabilities. We extend an existing study on cloud printing services as we see such services as integral components for future CM systems.

Cloud manufacturing has two aspects which are detailed in this work. First, CM is a methodology that is used within industrial settings for the connection of existing resources to form either a virtual assembly line or to acquire access to a manufacturing resources in a service oriented manner. Due to the globalisation of the industry, manufacturers face increased challenges with shorter time-to-markets, requirements for mass customisation (MC) and increased involvement of customers within the product development process. In order to stay or become competitive, companies must utilise their resources more efficiently and where not available, they must acquire those resources in an efficient and transparent way. These resources must then be integrated into the existing process environment and released when no longer required. The concepts of Cloud Computing, where resources are available as services from providers that can be leased, rented, acquired or utilised in other ways, are proposed to be applied to the domain of manufacturing.

Resources like machines and software, as well as capabilities/abilities, become transparently available as services that customers or end-users can use through the respective providers and pay for only the services they require momentarily. Most often, no contractual obligations exist between the provider and the consumer (but they can exist, especially for high-value or high-volume usage) which gives the consumer great flexibility at the expense of possible unavailability of resources by the provider.

In the end-user segment, or the consumer aspect of CM, the user is interested in using AM resources like 3D printers through a Web-based interface in order to be able to have objects produced, that are designed to be 3D printed, without the necessity to purchase and own a 3D printer themselves. The user commonly uses such services in a similar fashion that they would use a (online) photography lab/printing service. The users’ experience and knowledge of AM and 3D printing can vary significantly.

Although these two aspects seem to be far apart, the commonality between them is that the service operator must provide AM resources in a transparent and usable manner, in both cases. Resources must be provided with clear definitions of the interface to the service, i.e., the data consumed by the service and data rendered by the service. The description and provisioning of the service must be hardware agnostic as the consumer must be able to select the resources required, e.g., have an object manufactured either on a FDM (Fused Deposition Modeling, also Fused Filament Fabrication FFF) machine or an SLA (Stereolithography) machine without the necessity to alter the underlying data and models, but by selection.

This work is structured as follows: Section 1.1 provides information on the objective we accomplish with this review. Section 1.1.1 presents the research methodology applied for this work. In Section 1.1.2, we disseminate the sources that were used to gather information for this work. Section 1.2 provides a dissemination of the scientific research in these fields with a discussion on its historical development. Section 2 contains sections on key terminology and their definition throughout literature and standards. We present these terms as well as synonyms and provide an alternative definition as a proposal. Section 3 provides a meta-review on the subject for the reader to enhance his/her understanding of the subject and its relevant components.

In Section 4, we discuss the audience or target group for CM- and 3D printing-related cloud services. Section 5 extends the study by Rayna and Striukova [4] due to the importance of 3D printing-related cloud services for the topic at hand. Section 6 provides information on the concepts, terminology, and methods relevant to the subject as they are disseminated in literature. We conclude this work with a summary in Section 7.

1.1. Research Objective

This review is performed to establish an overview on the concept and implementation of CM and the utilisation of Additive Manufacturing (AM) therein. For better understanding, it is required to become familiar with the various definitions available and the problems arising from inconsistent usage of terminology. For this, we compile differing definitions on key terminology.

With this work, we aim to present an overview of the topic of CM, and its current research findings. We, furthermore, present a summary overview of existing online and cloud-based 3D printing services that can either be regarded as implementations of CM or be utilised in CM scenarios. This part is to extend the knowledge on relevant online services and their orientation towards numerous services. The review work of this article has the objective to identify relevant literature and summarise the key and essential findings thereof. The review is also intended to provide a high-level overview on identified research needs that are considered essential for the evolution of AM and CM.

1.1.1. Methodology

The first part of this review is the analysis of other reviews in order to establish a foundation of the existing works and to have a baseline for the analysis of the literature in this area.

This review identified its sources by a web search for each of the identified topics depicted in the concept map (see Section 6.1), where the first 30 results from the search engines (see Section 1.1.2) are each scanned first by title, then by their abstract. For the creation of the topological map, an iterative process is applied. The process starts with the analysis of the following works [1,5,6,7,8], which we had prior knowledge of, due to previous engagements in this research area. After the analysis, a backward and forward search is performed.

The searches for the content of the review are sorted by relevance, according to the search engine operator. The articles are then analysed and their core concepts are presented in this work. For the review, first the titles were checked for applicability to the area of interest. Research that could clearly be identified as out of scope by the title was discarded. The remaining works were divided amongst the authors for analysis of their abstracts. A classification into the topics was performed and discussed amongst the authors. Works that were identified as out of scope based on the analysis of the abstract were also discarded. The remaining literature was consecutively analysed by the authors. Consensus on the abstraction was achieved via discussion.

The reviews for the meta-review are identified by a web search and data gathered during our review.

To compile the definitions, an extraction process is employed where the identified literature for the review is the basis for information extraction and dissemination. The compilation is expanded by literature and Internet research for the appropriate keywords and concepts.

The study by Rayna and Striukova [4] is extended following the research methodology applied in the original work.

1.1.2. Sources

This review is based on scientific literature acquired through the respective publishers and searched for using the following search engines:

- Google Scholar (https://scholar.google.com).

- SemanticScholar (https://semanticscholar.org).

- dblp (https://dblp.uni-trier.de).

- Web of Science (https://webofknowledge.com).

- ProQuest (https://proquest.com).

Microsoft Academic Search (http://academic.research.microsoft.com) is not used for the search as the quality and number of results is unsatisfactory. Scopus (https://www.scopus.com) is not used for the research, as we have no subscription for it.

The search engines differ in the handling of grouping and selection operators (e.g., OR, +). For each search engine, the appropriate operators were selected when not explicitly stated otherwise. As a search engine for scientific literature, Google Scholar yields the most results, but with a high degree of unrelated or otherwise unusable sources, similar to the Google search engine (https://google.com) itself. Furthermore, the search engine enforces strict usage rules, thus hindering automated querying and usage. Results from patents and citations are excluded from the result set for Google Scholar.

SemanticScholar offers a responsive interface, that allows for automated querying through JSON (JavaScript Object Notation), to “millions” of articles (https://www.semanticscholar.org/faq#index-size) from computer science—a statement that we cannot verify, as we have seen articles from other domains too. The dblp project indexes over 3,333,333 (news from 3 May 2016: “Today, dblp reached the wonderful “Schnapszahl” of 3,333,333 publications”) from computer science in a very high quality. Its interface allows for automated and scripted usage. Web of Science provides an index of a large number (over 56 (a search for publications with its publication date between 1700 and 2100 yields 56,998,216 results) million) of scientific works. The entries in the index are of high quality but the interface is rather restrictive. ProQuest also has a very restrictive and non-scriptable interface and contains over 54 million (a search for publications with its publication date after 1700 yields 54,266,680 results) entries in its corpus, among which are historical news articles and dissertations. The quality of the results is high. ProQuest and Web of Science are subscription-based services.

Most of the reviewed literature pertains to FDM technology, to limit the scope of this work. This limitation is arbitrary but warranted as this technology is widespread. Other technologies are considered where appropriate and common concepts are discussed as such.

1.2. Development in Scientific Publications

The significance and maturity of a research area is reflected in the number of publications available. We perform a keyword-based analysis utilising the sources described in Section 1.1.2. The searches are performed with a number of relevant keywords (including various technologies and methods for AM) and a restricted time period of between 2002 and 2016. The queries are also restricted by the type of results, with an exclusion of citations and patents, where applicable. For a study on the patents and the development of patent registrations for this domain, we refer readers to Park et al. [9].

Caveat: Searching using search engines for specific keywords such as clip and lens in their abbreviated form will lead to a number of skewed results from works that are not significant for this body of work. For example, the search for “Additive Manufacturing” and LENS yields articles in the results that are either about fabricating (optical) lenses using AM or are about lenses in lasers that are used in AM. In the case of result sets that are as large as ours, it is not feasible to remove those erroneous results and adjust the result set accordingly. We encourage the reader to only take the given numbers as an indication.

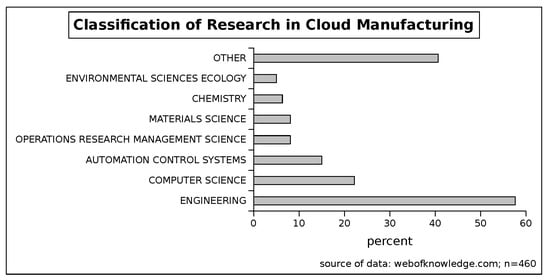

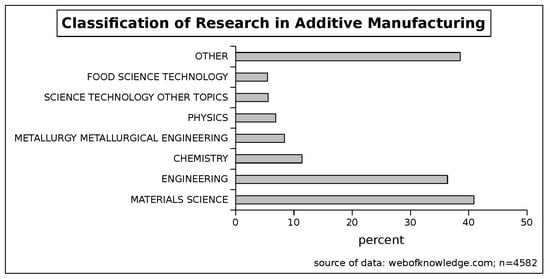

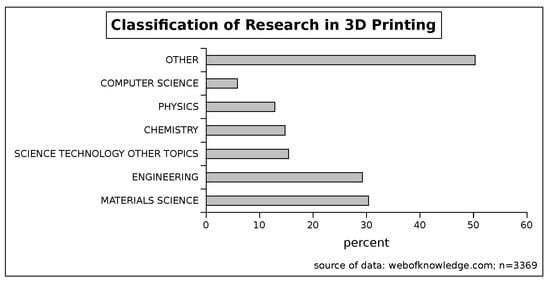

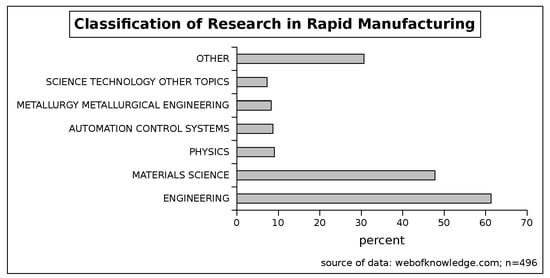

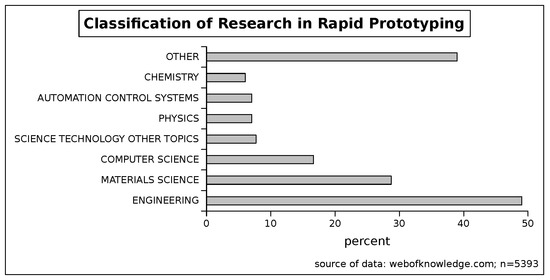

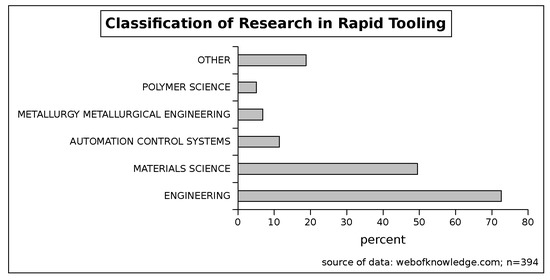

In Figure 2, Figure 3, Figure 4, Figure 5, Figure 6 and Figure 7, the classification of scientific articles according to Web of Science is shown. The classifications do not add up to 100 percent, as the respective articles can be classified in more than one field. In the figures, the number of results per search term is also listed. Domains with less than five percent aggregated classification are grouped together as “OTHER”. Other categories include, for example, food processing, computer science or legal sciences.

Figure 2.

Classification of articles for Cloud Manufacturing; source of data: webofknowledge.com.

Figure 3.

Classification of articles for Additive Manufacturing; source of data: webofknowledge.com.

Figure 4.

Classification of articles for 3D Printing; source of data: webofknowledge.com.

Figure 5.

Classification of articles for Rapid Manufacturing; source of data: webofknowledge.com.

Figure 6.

Classification of articles for Rapid Prototyping; source of data: webofknowledge.com.

Figure 7.

Classification of articles for Rapid Tooling; source of data: webofknowledge.com.

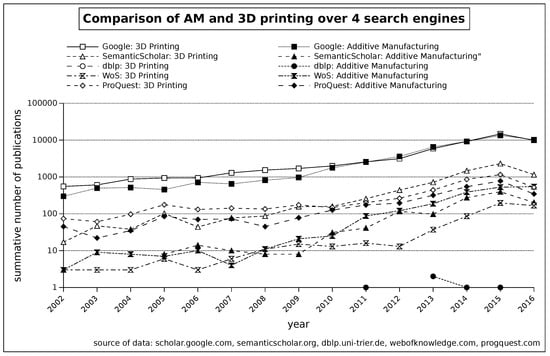

In Figure 8, the accumulated prevalence of the terms 3D printing versus Additive Manufacturing (AM) is displayed. For these numbers, queries are made for a combination of search terms and restrictions on the time period. The scale of the Y-Axis is logarithmic due to the large differences in the number of results per search engine. The dblp database returned the lowest number of results, with results consistently less than 10. Google Scholar yielded the largest number of results, with the accumulated number of results for the term AM gaining on the term 3D printing since 2009.

Figure 8.

Comparison of AM and 3D Printing using selected search engines (2002–2016).

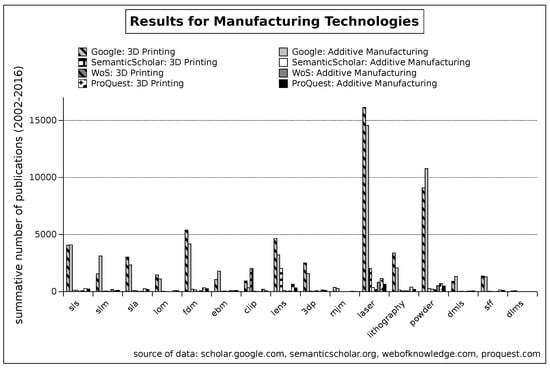

In Figure 9, the prevalence of certain AM or 3D Printing technologies is studied by the number of articles from four different search engines for the respective combination of search terms. The largest number of results are from Google Scholar for search term combinations with “3D Printing”. Furthermore, a generalised search is performed for the terminology “Laser, Lithography and Powder”, e.g., summarising technologies such as SLM (Selective Laser Melting), SLS (Selective Laser Sintering), SLA, LOM (Laminated Object Manufacturing), LENS (Laser Engineered Net Shaping) with the term “Laser”. The search for technologies such as CLIP and LENS is problematic due to the non-specificity of the terminology as described before (see Section 1.2).

Figure 9.

Comparison of 3D printing technologies using selected search engines (2002–2016).

2. Definition and Terminology

In general, the usage of the terminology within this field is very inconsistent. Commonly and colloquially, the terms 3D printing and AM are used as synonyms. Analysing the prevalence of either of these terms, we find that 3D printing is slightly more prevalent for results of scientific literature with 68,164 results for the sources described in Section 1.1.2 during the period of 2002–2016. In the same period, there are over 59,506 results for the term Additive Manufacturing. SemanticScholar provided significantly more results (7072 over 1211) for 3D printing and Web of Science yielded almost four times the number of results for Additive Manufacturing over 3D Printing (1956 results to 578). There is also no clear trend in the usage of either term. With this section, we exemplify this situation and present common definitions throughout literature and standards. We, furthermore, add our point of view in the form of a critique at the end of the section.

2.1. Additive Manufacturing and 3D Printing

In this section, we present established definitions for AM and related terminology as presented in literature and standards.

2.1.1. Definitions of Additive Manufacturing

AM is most often regarded as an umbrella term for technology and methods for the creation of objects from digital models from scratch. It is usually in contrast to subtractive and formative methods of manufacturing, as defined in the standard [10]. It is also commonly a synonym for 3D printing.

Gibson et al. [11] define AM as: “Additive manufacturing is the formalised term for what used to be called rapid prototyping and what is popularly called 3D Printing. [...] Referred to, in short, as AM, the basic principle of this technology is that a model, initially generated using a three-dimensional Computer-Aided Design (3D CAD) system, can be fabricated directly without the need for process planning. [...]”.

Gebhardt [12] defines AM as: “Als Generative Fertigungsverfahren werden alle Fertigungsverfahren bezeichnet, die Bauteile durch Auf- oder Aneinanderfügen von Volumenelementen (Voxel’n), vorzugsweise schichtweise, automatisiert herstellen”, which we translate to “As generative/additive manufacturing processes, all production processes are referred that produce components automatically by depositioning of volume elements (Voxels), preferably layer-wise”.

The VDI directives VDI 3404 (Version 2009 [13] and 2014 [14]) define additive fabrication as: “Additive fabrication refers to manufacturing processes which employ an additive technique whereby successive layers or units are built up to form a model”.

The 2009 directive “VDI-Richtlinie: VDI 3404 Generative Fertigungsverfahren—Rapid-Technologien (Rapid Prototyping)—Grundlagen, Begriffe, Qualitätskenngrößen, Liefervereinbarungen” and the 2014 directive “VDI-Richtlinie: VDI 3404 Additive Fertigung—Grundlagen, Begriffe, Verfahrensbeschreibungen” are both currently in retracted states.

The also retracted ASTM standard F2792-12a “Standard terminology for additive manufacturing technologies” defines AM as “A process of joining materials to make objects from 3D model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies”, with the following synonyms listed “additive fabrication, additive processes, additive techniques, additive layer manufacturing, layer manufacturing, and freeform fabrication”. This standard is replaced by ISO/ASTM Standard 52900:2015(E) [15] through a joint agreement of both organisations.

Bechthold et al. [16] define AM as: “The terms additive manufacturing (AM) and 3D printing describe production processes in which a solid 3D structure is produced layer by layer by the deposition of suitable materials via an additive manufacturing machine”.

Thomas and Gilbert [17] define AM as: “Additive manufacturing is the process of joining materials to make objects from three-dimensional (3D) models layer by layer as opposed to subtractive methods that remove material. The terms additive manufacturing and 3D printing tend to be used interchangeably to describe the same approach to fabricating parts. This technology is used to produce models, prototypes, patterns, components, and parts using a variety of materials including plastic, metal, ceramics, glass, and composites”.

Klocke [18] defines AM as: “Generative Verfahren: Diese Verfahrensgruppe umfasst alle Technologien, mit denen eine aufbauende, schichtweise Fertigung von Bauteilen realisiert wird. Sie werden auch als Additive Manufacturing Technologies oder als Layer-based Manufacturing Technologies bezeichnet. Zum Herstellen der Schichten wird häufig Laserstrahlung verwendet. [...]”.

Translation “Generative Processes: This process group contains all technologies, with which an additive, layer-wise generation of parts is realised. They are also referred to as additive manufacturing technologies or layer-based manufacturing technologies. For the creation of the layers, often laser emission is used. [...]”.

Gao et al. [19] use the term AM and 3D printing synonymously: “Additive manufacturing (AM), also referred to as 3D printing, [...]”.

Sames et al. [20] also use the term AM and 3D printing synonymously: “Additive manufacturing (AM), also known as three-dimensional (3D) printing, [...]”.

Lachmayer and Lippert [21] define AM as: “Das Additive Manufacturing (AM), als Überbegriff für das Rapid Prototyping (RP), das Rapid Tooling (RT), das Direct Manufacturing (DM) und das Rapid Repair (RR) basiert auf dem Prinzip des additiven Schichtaufbaus in x-, y- und z-Richtung zur maschinellen Herstellung einer (Near-) Net-Shape Geometrie”, which translates to: “Additive manufacturing as an umbrella term for Rapid Prototyping (RP), Rapid Tooling (RT), Direct Manufacturing (DM) and Rapid Repair (RR) is based on the principle of the additive layer fabrication in x-, y- and z-direction for the fabrication of a (near-) net-shape geometry by machines”.

The ISO/ASTM Standard 52900:2015(E) [15] defines AM as: “process of joining materials to make parts (2.6.1) from 3D model data, usually layer (2.3.10) upon layer, as opposed to subtractive manufacturing and formative manufacturing methodologies”.

2.1.2. Definitions of 3D Printing

According to Gebhardt [12], 3D Printing is a generic term that is synonymous to AM and will replace the term AM in the future due to its simplicity. Bechtholdt et al. [16] use the terms 3D Printing and AM synonymously, as umbrella terms for technologies and applications. In the VDI directive [22], the term 3D printing is used for a certain additive process, but it is acknowledged that it is generally used as a synonym for AM.

The ASTM standard F2792-12a (retracted) defines 3D printing as “The fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology”, but also acknowledges the common synonymous use of this term for AM, mostly of low-end quality and price machines.

Gibson [11] uses the term 3D Printing for the technology invented by researches at MIT [23], but also acknowledges that it is used synonymously for AM and will eventually replace the term AM due to media coverage.

The ISO/ASTM Standard 52900:2015(E) [15] defines 3D Printing as: “fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology”.

It is also noted in this standard that the term 3D printing is often used as a synonym for AM, mostly in a non-technical context. Furthermore, it is noted that 3D printing is associated with low-price and -capability machines.

2.1.3. Definitions of Rapid Prototyping

In Hopkinson and Dickens [24], Rapid Prototyping (RP) is defined as: “RP refers to a group of commercially available processes which are used to create solid 3D parts from CAD, from this point onwards these processes will be referred to as layer manufacturing techniques (LMTs)”.

The VDI directive 3405 defines RP as: “Additive fabrication of parts with limited functionality, but with sufficiently well-defined specific characteristics”.

Weber et al. [25] define RP as: “Early AM parts were created for the rapid prototyping market and were first employed as visual aids and presentation models. Many lower cost AM systems are still used in this way”.

2.1.4. Definitions of Rapid Manufacturing

Hopkinson et al. [26] define Rapid Manufacturing (RM) as: “the use of a computer aided design (CAD)-based automated additive manufacturing process to construct that are used directly as finished products or components”. Previously, Hopkinson and Dickens [24] defined RM as: “Rapid manufacturing uses LMTs for the direct manufacture of solid 3D products to be used by the end user either as parts of assemblies or as stand-alone products”.

The VDI directive 3404 Version 2009 [13] defines RM as: “Additive fabrication of end products (often also described as production parts). Characteristics: Has all the characteristics of the end product or is accepted by the customer for “series production readiness”. Material is identical to that of the end product. Construction corresponds to that of the end product”.

The VDI directive 3405 [22] defines RM as a synonym for direct manufacturing, which is defined as: “Additive fabrication of end products”.

2.1.5. Definitions of Rapid Tooling

King and Tansey [27] define Rapid Tooling (RT) as an extension of RP as such: “Rapid tooling is a progression from rapid prototyping. It is the ability to build prototype tools directly as opposed to prototype products directly from the CAD model resulting in compressed time to market solutions”.

The VDI directive 3405 [22] defines RT as: “The use of additive technologies and processes to fabricate end products which are used as tools, moulds and mould inserts”.

Weber et al. [25] define RT as: “Another class of applications for AM parts is patterns for tooling or tooling directly made by AM. AM processes can be used to significantly shorten tooling time and are especially useful for low-run production of products”.

2.1.6. Definitions of Cloud Manufacturing

The work by Li et al. [28] appears to be the first to introduce the concept and definition of Cloud Manufacturing (CM), but unfortunately this article is only available in Chinese and could therefore not be verified. The article is cited by more than 450 publications according to Google Scholar.

Wu and Yang [29] define CM as such: “Cloud manufacturing is an integrated supporting environment both for the share and integration of resources in enterprise. It provides virtual manufacturing resources pools, which shields the heterogeneousness and the regional distribution of resources by the way of virtualisation. cloud manufacturing provides a cooperative work environment for manufacturing enterprises and individuals and enables the cooperation of enterprise”.

Tao et al. [30] define CM indirectly by the following description: “Cloud manufacturing is a computing and service-oriented manufacturing model developed from existing advanced manufacturing models (e.g., ASP, AM, NM, MGrid) and enterprise information technologies under the support of cloud computing, IoT, virtualisation and service-oriented technologies, and advanced computing technologies”.

Xu [31] defines CM similar to the NIST definition of CC as: “a model for enabling ubiquitous, convenient, on-demand network access to a shared pool of configurable manufacturing resources (e.g., manufacturing software tools, manufacturing equipment, and manufacturing capabilities) that can be rapidly provisioned and released with minimal management effort or service provider interaction”. This definition is also used in the work by Wang and Xu [6].

Zhang et al. [32] describe CM as: “Cloud manufacturing (CMfg) is a new manufacturing paradigm based on networks. It uses the network, cloud computing, service computing and manufacturing enabling technologies to transform manufacturing resources and manufacturing capabilities into manufacturing services, which can be managed and operated in an intelligent and unified way to enable the full sharing and circulating of manufacturing resources and manufacturing capabilities. CMfg can provide safe, reliable, high-quality, cheap and on-demand manufacturing services for the whole life cycle of manufacturing.”

2.1.7. Synonyms for AM

As with the previous definitions for AM, RP, RT, RM, and 3D printing, there is no consensus in the terminology for synonyms of AM in general. The following synonyms can be found in literature and are used in existing works.

- direct layer manufacturing or layer manufacturing or additive layer manufacturing

- direct digital manufacturing is a synonym for rapid manufacturing [11]

- solid freeform fabrication (SFF), three dimensional printing [25]

- 3D printing, Additive Techniques, Layer Manufacturing, and Freeform fabrication [33]

- additive fabrication, additive processes, additive techniques, additive layer manufacturing, layer manufacturing, and freeform fabrication [34] (also https://wohlersassociates.com/additive-manufacturing.html)

- “The technical name for 3D printing is additive manufacturing [...]” [35]

2.1.8. Critique

Through a systematic decomposition of the existing definitions of AM, we conclude that the basic commonality of AM is described as the creation of a physical object from a digital model by a machine.

Furthermore, we propose the term AM as an umbrella term that signifies industrial, commercial or professional application and usage whereas 3D printing can be colloquially used for technologies and methods for the creation of physical objects from 3D (CAD) models in other situations.

For the actual building machines of additively manufactured parts, we recommend the synonymous use of an AM fabricator or 3D printer. The first as it describes the functionality in a precise way and the second as it is commonly used and understood by a broad audience.

The existing definitions fall short on their focus on the layer-wise creation of objects. As a counter-example, technologies such as LENS and multi-axis (n > 3) are not bound and defined by a layer structure, but can be regarded as a form of AM as they create objects based on 3D (CAD) models from scratch, without any of the characteristics of traditional subtractive or formative fabrication methods.

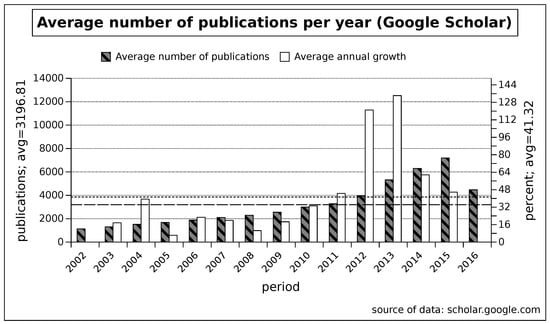

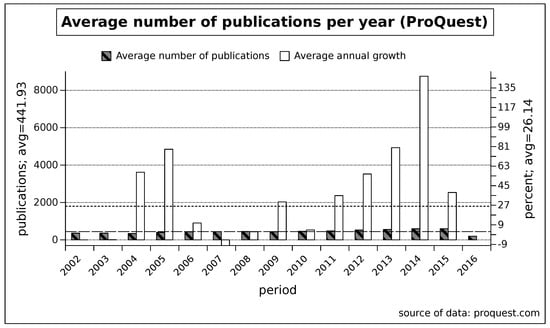

3. Reviews on the Subject

The topic of AM in general and its special applications, technologies and directions is extensively researched and results are published in literature. The growth of the number of publications as found by Google Scholar and Proquest is illustrated in the following figures (see Figure 10 and Figure 11).

Figure 10.

Average number of publications and annual average growth for the combined results from scholar.google.com for 2002–2016.

Figure 11.

Average number of publications and annual average growth for the combined results from proquest.com for 2002–2016.

An analysis of literature within this domain from sources (see Section 1.1.2) of scientific literature shows an increase in the number of published works from 2002 to 2016 of 41.3% on average (see Figure 10)—26.1% for the search engine Proquest. This number is from the average growth of results found for keywords related to specific AM topics and AM related literature in general from http://scholar.google.com.

In this section, we will present the findings of the analysis of available data on the scientific publications.

Specific aspects of AM, 3D printing and associated areas are the topic of a number of reviews listed below. The list of reviews is compiled by searching using the previously mentioned search engines (see Section 1.1.2) using a keyword search. The keywords are “3D Printing” +Review/Survey/“State of the Art”, “Additive Manufacturing” +Review/Survey“State of the Art”, “Rapid Manufacturing” +Review/Survey“State of the Art”.

The time range for the search for reviews is restricted to the period 2005–2016. Following this literature search, a backward search on the results is performed. From the 70 reviews identified, we calculate the average number of authors per review to be 3.3 with an average length of 15.2 pages. The list is sorted chronologically with the general theme or domain of the review provided.

- Dimitar Dimitrov, Kristiaan Schreve and N. de Beer [36]; General Introduction, Applications, Research Issues

- Vladimir Mironov, Nuno Reis and Brian Derby [37]; Bioprinting, Technology

- Ben Utela et al. [38]; New Material Development (Mainly Powders)

- Abbas Azari and Sakineh Nikzad [39]; Dentistry, Applications in Dentistry

- Hongbo Lan [40]; Rapid Prototyping, Manufacturing Systems

- Daniel Eyers and Krassimir Dotchev [41]; Rapid Manufacturing, Mass Customisation

- Ferry P. W. Melchels, Jan Feijen and Dirk W. Grijpma [42]; Stereolithography, Biomedical Engineering

- Fabian Rengier et al. [43]; Medicine, Data Acquisition (Reverse-Engineering) using Image Data

- R. Sreenivasan, A. Goel and D. L. Bourell [44]; Energy Consumption, Sustainability

- Rupinder Singh [45]; Rapid Prototyping, Casting

- R. Ian Campbell, Deon J. de Beer and Eujin Pei [46]; Application and Development of AM in South Africa

- Benjamin Vayre, Frédéric Vignat and François Villeneuve [47]; Metal Components, Technology

- Dongdong Gu et al. [48]; Metal Components, Technology, Terminology

- Ferry P. W. Melchels et al. [49]; Medicine, Tissue and Organ Engineering

- Kaufui V. Wong and Aldo Hernandez [50]; General, Technology

- Lawrence E. Murr et al. [51]; Metal Components, EBM, Laser Melting

- Shawn Moylan et al. [52]; Quality, Test Artifacts

- Timothy J. Horn and Ola L. A. Harrysson [53]; General, Applications, Technology

- Xibing Gong, Ted Anderson and Kevin Chou [54]; EBM, Powder Based AM

- Flavio S. Fogliatto, Giovani J.C. da Silveira and Denis Borenstein [55]; Mass-Customization

- K. P. Karunakaran et al. [56]; Rapid Manufacturing, Metal Object Manufacturing

- Carl Schubert, Mark C. van Langeveld and Larry A. Donoso [57]; General

- Irene J. Petrick and Timothy W. Simpson [58]; Economics, Business

- Iulia D. Ursan, Ligia Chiu and Andrea Pierce [59]; Pharmaceutical Drug Printing

- Jasper Cerneels et al. [60]; Thermoplastics

- Mohammad Vaezi, Hermann Seitz and Shoufeng Yang [61]; Micro-Structure AM

- Nannan Guo and Ming C. Leu [62]; General, Technology, Materials, Applications

- Olga Ivanova, Christopher Williams and Thomas Campbell [63]; Nano-Structure AM

- Robert Bogue [64]; General

- Samuel H. Huang et al. [65]; Socio-Ecological and Economy

- Zicheng Zhu et al. [66]; Hybrid Manufacturing

- Dazhong Wu et al. [67]; Cloud Manufacturing

- Bethany C. Gross et al. [68]; Biotech, Chemistry

- Brett P. Conner et al. [69]; Classification, Object Complexity

- Brian N. Turner, Robert Strong and Scott A. Gold [70]; Thermoplastics, Physical Properties

- David W. Rosen [71]; Design for Additive Manufacturing

- Dimitris Mourtzis, Michael Doukas and Dimitra Bernidaki [72]; Simulation

- Douglas S. Thomas and Stanley W. Gilbert [17]; Economy, Cost

- Gustavo Tapia and Alaa Elwany [73]; Process Monitoring, Quality

- Hae-Sung Yoon et al. [74]; Energy Consumption

- Jan Deckers, Jef Vleugels and Jean-Pierre Kruth [75]; Ceramics AM

- Rouhollah Dermanaki Farahani, Kambiz Chizari and Daniel Therriault [76]; Micro-Structure AM

- Siavash H. Khajavi, Jouni Partanen and Jan Holmström [77]; Supply Chain, Application

- William E. Frazier [78]; Metal Components

- Wu He and Lida Xu [8]; Cloud Manufacturing

- Syed Hasan Massod [79]; Fused Deposition Modeling (FDM)

- Brian N. Turner and Scott A Gold [80]; Thermoplastic AM, Material Properties

- Carlos Mota et al. [81]; Medicine, Tissue Engineering

- C. Y. Yap et al. [82]; SLM

- Donghong Ding et al. [83]; Metal Components, Wire Fed Processes

- Adamson et al. [84]; Cloud Manufacturing, Terminology

- Jie Sun et al. [85]; Food Printing, Technology

- Jin Choi et al. [86]; 4D Printing

- K. A. Lorenz et al. [87]; Hybrid Manufacturing

- Merissa Piazza and Serena Alexander [88]; General, Terminology, Academic

- Omar A. Mohamed, Syed H. Masood and Jahar L. Bhowmik [89]; Process Parameter Optimization (FDM)

- Seyed Farid Seyed Shirazi et al. [90]; Tissue Engineering, Powder Based AM

- Sheng Yang and Yaoyao Fiona Zhao [91]; Design for AM, Complexity

- Sofiane Guessasma et al. [92]; Design for AM, Process Parameter Optimization

- Wei Gao et al. [19]; General, Technology, Engineering

- Yong Huang et al. [93]; General, Technology, Research Needs

- Zhong Xun Khoo et al. [94]; Smart Materials, 4D Printing

- Hammad H. Malik et al. [95]; Medicine, Surgery

- Jie Sun et al. [96]; Food Printing

- Behzad Esmaeilian, Sara Behdad and Ben Wang [97]; Manufacturing

- H. Bikas, P. Stavropoulos and G. Chryssolouris [98]; General, Technology

- Julien Gardan [99]; Technology, Engineering, Manufacturing

- Swee Leong Sing et al. [100]; Metal Components, Medicine, Implants, Materials

- William J. Sames et al. [20]; Metal Components, Materials

- Andrew J. Pinkerton [101]; Laser-technology

4. Stakeholder Distinction

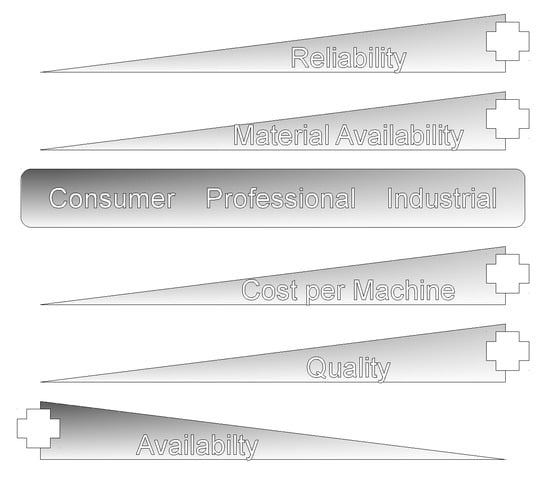

Different 3D printing technologies, machines and manufacturers, as well as services, target different clients, for which we propose the following classification. Generally, the discerning factors are

- cost per machine

- quality of print (e.g., surface quality, physical properties of object)

- reliability of machine and

- materials available.

From literature, three classes of audience are apparent:

- consumer/end user

- professional user

- industrial application.

For the consumer, a very important factor is the cost of the printer itself, with 45% of consumers not willing to pay more than $US299 for a 3D printer [102].

In recent years, the price of entry level consumer 3D printers, especially for build-kits, decreased to about $US300 (XYZPrinting da Vinci Jr. 1.0, $US297.97, https://www.amazon.com/XYZprinting-Vinci-Jr-1-0-Printer). Open-source projects, such as RepRap have contributed to the decline of costs for these machines [103].

In Figure 12, we differentiate between the user groups of end-users/consumer, professional users and industrial users. Industrial users rely on high quality available with a large selection of processable materials. Machines for these users are expensive and out of reach for most end-users and professional users. The quality these machines produce is very high and the objects can be used for integration in a product or be a product themselves. Due to these restrictions, the availability of such machines is not very widespread but limited to highly specialised enterprises.

Figure 12.

Audience classification and expectations.

At the other end of the spectrum, the end-user/consumer has a large choice of 3D printers to select from: they are relatively inexpensive, produce objects of acceptable quality, work on a much lower number of materials (typically thermoplastics) and have a reliability that is lower than the reliability of professional equipment. In the middle of the spectrum, we see professional users, e.g., from design bureaus or architects, that use such machines in a professional manner and draw benefits from the usage of such technology; however, in general, it is not their main area of business. As an example, an architect makes use of a 3D printer for the creation of a high-quality model of a building he designed, which is faster and easier than making such a model by hand.

5. 3D Printing Services

There are numerous dedicated 3D printing services available to end-users, professionals and industrial users. They differ with regards to the clients they address, the services they offer, the quality they can provide and their cost. In this section, we give an overview of a selection of available 3D printing services. The list is not conclusive as a number of enterprises do offer 3D printing services in their portfolio but they are not necessarily to be considered 3D printing services due to either their local mode of operation or the number of 3D printers the user can chose from. This overview is closely based on the work of [4] and extends its findings.

We use the following list of properties to distinguish the services:

- The target group (end-users, industrial users or professional users).

- The geographic reach (local or global).

- Availability of an API.

- Services rendered (design, 3D printing, marketplace, other).

Rayna and Striukova [4] based their exploratory study on the following list of services they have identified. For the original list of services, we add the following information.

- 3D Burrito (http://3dburrito.com)—Pre-Launch Phase

- 3D Creation Lab (http://www.3dcreationlab.co.uk)

- 3DLT (http://3dlt.com)—Shut down on 31 December 2015

- 3DPrintUK (https://www.3dprint-uk.co.uk)

- Additer.com (http://additer.com)—Unreachable

- Cubify Cloud (http://cubify.com)—Acquired by 3D Systems, Service no longer available

- i.Materialise (https://i.materialise.com/)

- iMakr (http://imakr.co.uk)

- Kraftwürx.com (http://www.kraftwurx.com)

- MakerBot/Thingiverse (http://thingiverse.com)

- MakeXYZ (https://www.makexyz.com)

- Ponoko (https://www.ponoko.com/)

- Sculpteo (https://www.sculpteo.com)

- Shapeways (http://www.shapeways.com/)

For this study, we extend the selection with the additional services listed in Table 1 and Table 2. Services omitted in these two tables are described in the original study.

Table 1.

3D printing platforms and services included in this study—Part 1.

Table 2.

3D printing platforms and services included in this study—Part 2.

In contrast to the authors of the original work, we think that an exhaustive list of such services is impossible to compile as a large number of local businesses do offer 3D printing services over the Internet and would therefore qualify to be included in such a list. These (local) businesses are hard to identify due to their limited size and reach. Also, an exhaustive list would need to contain 3D printing services and repositories of which many similar and derivative services exist.

Further, we extend the classification and study to the provisioning of an API (Application Programming Interface) by the respective service. An API should provide methods to use the service programmatically. With an API, such printing services can be used as a flexible production means in CM settings. The range of functionality of such APIs can vary significantly and range from the possibility of having a widget displayed on a website with a 3D model viewer, to uploading and storing digital models in a repository, requesting quotes for manufacturing or digital fabrication. A commonality for these APIs is the requirement for the third-party user to have an account with the service, which is indicated in Table 3 and Table 4 by Implementer in the column Required for registration. The indication User in this column indicates that the user must be registered with this service too.

Table 3.

3D printing platforms and services and their APIs—Part 1.

Table 4.

3D printing platforms and services and their APIs—Part 2.

The implementer registration is intended for scenarios where the API is embedded in a service or website that a third party user then uses. The findings of this study are presented in Table 3 and Table 4, where we state whether the service provides an API and if it is publicly available or only accessible for business partners; who needs to be registered for the usage of the API; and what capabilities the API provides (See Table 5).

Table 5.

Categorising 3D printing online platforms.

This explorative extension study is performed as described by the original authors.

As analysed in Table 5, the services surveyed offer a different range of services each. No provider could be identified that offers a complete set of services for 3D printing and related tasks. In the table, the indication of p marks companies that do not themselves offer printers through this service but their parental companies do. The o character in the column for printing service for Tinkercad and YouMagine, indicates that the service itself does not provide printing services, but cooperates with a third party for the provision of this service. In this table, the plus sign + indicates that a service is regarded in the specific category. With the exception of La Poste, UPS and iMakr, all the services carry out their business completely on the Internet without the requirement for physical interaction. La Poste and UPS offer an Internet interface with the physical delivery of the objects in some of their shops. Services that offer a design market place can offer designs and other files free-of-charge or for a fee—no distinction is made for this study. Yeggi and stlfinder are search engines for 3D model data that work on the data from other sources. Although it is a search engine, Yeggi provides the integration of printing services and cloud printing services for models available from third party services, thus Yeggi can be classified as a service of services. The service rendered by Trinpy is subscription-based with various membership options. Grabcab provides 3D printing planning and control services, and integration with an online editor.

6. Review

Cloud Manufacturing is mainly an overlapping manufacturing or engineering concept, with application and grounding in the development of parts or objects in “traditional” manufacturing. With traditional manufacturing, we denote all technologies and methods to create or fabricate objects or parts, other than AM. For a distinction between manufacturing methods, see Klocke [18], Nee [104], and the DIN Standard 8580 [10]. In this sense, all subtractive or formative manufacturing methods are summarised as “traditional manufacturing” methods. As AM offers a large degree of flexibility due to short lead times, as well as other beneficial properties, we see that AM is the ideal technology to be considered within CM scenarios. Taking the properties of AM into account, we do not predict that AM will replace other manufacturing methods, not even within CM scenarios. Rather, AM will fill niches for special applications such as mass-customisation, rapid replacement production capabilities or RT, especially within CM scenarios. With this work, we aim to contribute to the development of AM methodology and technology in the CM paradigm.

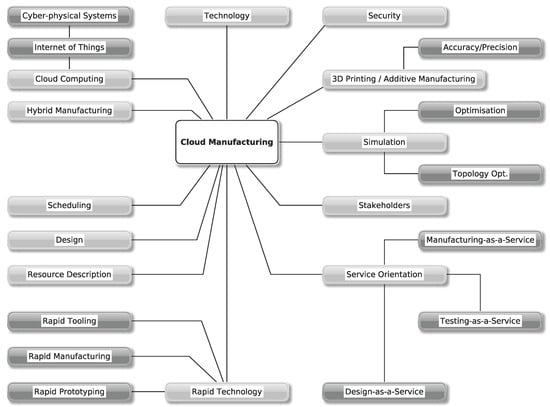

6.1. Topological Map

In Figure 13, the relationship and connection of various concepts relevant to CM is depicted. This map forms the basis of the following review; the nodes from the map represent sections for the review in which we present the current state of research and elaborate on open research questions. The topics are extracted from literature.

Figure 13.

Topological Map for Cloud Manufacturing.

This topological map displays the relationship of CM with a variety of connected and enabling technologies, and concepts. Additive Manufacturing/3D printing (see Section 6.4) enables CM to be more modular, flexible and offers new capabilities, and business opportunities. The Rapid Technology (see Section 6.5) and its composition Rapid Prototyping (RP, see Section 6.5.3), Rapid Manufacturing (RM, see Section 6.5.2) and Rapid Tooling (RT, see Section 6.5.1) are areas in which CM can be applied. The topic of Service Orientation (see Section 6.9) and its composition “as-a-Service”, of which Design-as-a-Service (DaaS, see Section 6.9.2), Testing-as-a-Service (TaaS, see Section 6.9.3) and Manufacturing-as-a-Service (MaaS, see Section 6.9.1) are explored as examples; these are concepts that enable the efficient application of CM. For a broader understanding, it is required to research the stakeholders involved in this technology; this is done in Section 6.8. The topics of Scheduling, (see Section 6.12) and Resource Description (see Section 6.13) are to be discussed for the universal and efficient application of CM. The domain of Simulation (see Section 6.7), with its composition of Optimisation (see Section 6.7.2) and Topological Optimisation (see Section 6.7.1), enable a more rapid, more flexible and more robust usage of the technology. For AM technology, the application of Topology Optimisation enables the benefits of this technology. The topic of 3D printing or AM is described in Section 6.4, with its subtopic of Accuracy and Precision (see Section 6.4.1). The topic of Hybrid Manufacturing (see Section 6.6) is gaining importance in flexible and agile manufacturing systems which warrants and requires its research. On the topic of Technology (see Section 6.2), the general principles and technologies of CM and AM are discussed, as these are basic principles for the efficient implementation of these systems. The topic of Cloud Computing (CC, see Section 6.11) with its sub-components Internet of Things (IoT, see Section 6.11.1) and Cyber-physical Systems (CPS, see Section 6.11.2) is the conceptual progenitor of CM and, therefore, requires careful studying. IoT and CPS are key enabling technologies for CM. The topic of Security (see Section 6.3) is of increasing importance, with the spreading application of AM and CM, as cyber attacks become more frequent and potential damage increases.

6.2. Technology

A large number of technologies and technological advances have made it possible for AM to evolve from its origin as a RP method to its current state, where it is used for end-part manufacturing (RM) and is available to consumers [12,105]. All 3D printed objects are based on a digital model. This model can either be created using CAD software, 3D sculpting software, or acquired using reverse-engineering methods (e.g., object scanning or photo reconstruction) [11].

Although direct slicing from a CAD model was proposed by Jamieson [106] in 1995, it is still rarely performed. Direct slicing requires implementation in the CAD software for each printer type and printer manufacturer, which is not feasible. Further shortcomings of the de-facto standard file format for AM, i.e., STL, namely the possibility of containing mis-aligned facets, holes or being non-watertight, as well as being too large in file size, are reported by [107].

Besides a Steiner-patch-based [108] file format to replace the STL file format, the ASTM Committee F42 has published an ISO Standard [109] for the AMF (Additive Manufacturing File Format), with the same intention. Both file formats are created to increase the accuracy for the models described and, therefore, increase the quality of the resulting printed objects. STL seems to be the prevalent file format for AM with 25,700 results on Google Scholar compared to 8230 results for AMF. Further investigation into the file support for different hard- and software vendors is warranted but out of the scope of this work.

The review by Dimitrov et al. [36] presents further information on the technology that AM is based on with an overview of applications for it.

In the review by Esmaeilian et al. [97], the authors present the relationship of AM and Manufacturing in general, as well its benefits. With the emergence of Internet- or cloud-based CAD Modelling software, the creation of models for AM becomes easier, as direct integration of 3D printing providers is possible.

Furthermore, the collaborative aspect of 3D modelling is enhanced as studied by Jou and Wang [110]. This study used a group of college students as a test group and investigated the adoption of an online CAD modelling (Autodesk AutoCAD (http://autodesk.com/products/autocad)) software in the curriculum.

The authors, Andreadis et al. [111], present a case study on the adoption of an unnamed cloud-based CAD system in comparison to traditional software, as well as an exhaustive list of benefits of cloud-based software.

Wu et al. [112] present an economic analysis of cloud-based services for design and manufacturing. This work also explores a number of cloud-based services along with their pricing.

Communities are of great importance to enterprises, as shown in West and Kuk [105]. One form of community is a repository for 3D printable digital models that collects and curates models supplied by users for collaboration, exchange, co-creation, and sale. In this work, the authors conduct a study to research the profit of catering for such a community/repository (Thingiverse) by a former open-source company (Makerbot).

Wittbrodt et al. [113] performed experiments to determine the ROI (Return on Investment) of 3D printers for common households and their feasibility in application in end-user scenarios. With their experiment, they concluded that an average household can achieve between 40 and 200 percent ROI, based on average usage of such machines.

6.3. Security

Security for 3D Printing, AM or CM can be discussed from at least three perspectives. The first perspective would be the legal security of data and models processed within such a scenario. Discussions can range from whether it is legal to manufacture an existing object (replication) which might be protected by intellectual copyright laws to questions regarding product liability in the case of company-supplied model data. The second perspective is closely related to intellectual property (IP) as it is the technological discussion about the safeguarding of digital model files and data. The third perspective is about the data and process security itself, in scenarios with malicious third-parties (e.g., Hackers, Cyber-criminals). This third perspective is not limited to AM but shares many problems with CC and computing in general.

Dolinksy [114] analysed the concept of copyright and its application to 3D Printing for the jurisdiction of the USA. Because legal systems are different to each other, such an analysis cannot be exhaustive.

Grimmelmann [115] further exemplified the legal status of 3D printing and model creation in the USA with fictitious characters from literature and cinema. He stated that the creation of an object, regardless of the source of the model for such a creation, is infringing on copyright if the object that is replicated is protected by copyright.

In [116], the author discussed the current situation of 3D printing in regard to gun laws. This discussion was started by the media in 2013, as models for a functional plastic gun were distributed and the gun consequently manufactured. The author stated that current gun control laws are adequate to control 3D printed weapons and that this is currently not a big issue.

On a broader scope, the authors McNulty et al. [117] researched the implications of AM for the national security of the USA, where the authors presented the benefits of bio or tissue 3D printing for the treatment of battlefield wounds as well as the implications of AM technologies for criminal misconduct.

For the analysis of data security, the authors Wu et al. [118] presented the importance of such technologies within a CM environment. They proposed the development of trust models for cyber-physical systems, as well as discussing the actors within such systems.

The authors Yampolskiy et al. [119] provided a full risk analysis of a scenario for outsourcing AM under consideration of IP. The risk assessment did not include malicious behaviour other than IP infringement.

To secure printed objects against counterfeiting, the authors of [120] studied and recommended the use of chemical components for authentication. Possible attacks on the 3D printing process by third parties is researched in [121], where one scenario is about wilfully integrating material differences in an object in order to weaken the object under load. If the printing process itself is secured, the question remains if a printed object is the original, a genuine replicate or a faked replicate. For the identification of genuine objects, the authors of [122] researched the applicability of physical signatures to 3D printed objects.

In [123], the authors presented a watermarking technique for 3D printed objects that is resilient against repeated digital scanning of the manufactured object.

For a generalised discussion on security of cloud services and Cloud Computing, we refer readers to [124], where the authors presented issues ranging from data integrity to confidentiality. The concepts and terminology of CC security are also discussed in [125], of which the concepts of confidentiality, trust and privacy are most relevant to scenarios of cloud-based AM where users have physical objects created from digital models by third parties.

Sturm et al. [126] presented attack scenarios and mitigation strategies for attacks on AM system. The authors saw rising CPS implementations in AM as potential intrusion vectors for attacks. The authors discussed various attacks for each of the manufacturing process phases. Furthermore, the authors identified the STL file format as a potential risk for tampering and attacking. Among the recommendations for mitigation is file hashing and improved process monitoring.

Bridges et al. [127] briefly explored possible attacks on the CPS, that are used for AM. Among the attack scenarios, the authors identified theft and tampering.

Baumann and Roller [128] provided a surface altering watermarking schema to be utilised in FDM 3D printing. This watermarking method was based on selective seam placement, i.e., entry points for each layer. This work is to be utilised in conjunction with the model distribution architecture, described in Baumann et al. [129]. In their proposed architecture, model files are not distributed to the end user but pre-processed GCode files are distributed to printer-attached adaptors. With this approach, the authors also claim the benefit of optimal process parameter selection to the clients’ 3D printer, thus avoiding misconfiguration and misprinting.

6.4. 3D Printing

Following the distinction between AM and 3D printing, given in the definition of 3D printing (see Section 2.1.2) by some authors, into high-quality professional or industrial usage and lower-quality end-user or semi-professional usage, 3D printing could not be part of CM. As we relax the definition of AM and 3D printing and use the terms as synonyms, we survey technological developments within this chapter. Technological progress and development are essential to the widespread use and application of 3D Printing or AM in the CM paradigm.

We see AM as an integral component in CM and Industry 4.0 settings, due to the benefits it provides. Among those benefits are flexibility, resource efficiency and design freedom. In this section, we survey scientific literature regarding AM, especially works that provide an overview (e.g., reviews, surveys), present important aspects or exhibit common characteristics of this domain.

In the short article by Hansen et al. [130], the authors proposed a measurement method for the correction or calibration of FDM printers. For this purpose, the authors developed a measurement plate, that is printed with specified parameters. In their experiment, the authors recorded roundness errors of up to 100 μm. The calibration could not be applied due to the printer control software being closed-source.

Anitha et al. [131] analysed the process variables’ layer thickness, bead width and deposition speed for their influence on the quality of objects manufactured using FDM. The authors found that the layer thickness is contributing approximately 50% to the surface roughness of the manufactured objects.

Balogun et al. [132] described and experimented on the energy consumption and carbon footprint of models printed using FDM technology. They defined three specimens of 9000 mm and 18,000 mm in volume, which were printed on a Stratasys dimension SST FDM. Their experiment also captured the energy consumption of the post processing with an ultrawave precision cleaning machine. The energy consumed for the print was approximately 1 kWh. Over 60% of the energy was consumed in non-productive states, e.g., pre-heating. This energy consumption profile warrants high utilisation of 3D printers when aiming for a low ecological impact and penalises frequent and long idle times of the 3D printer.

Brajlih et al. [133] proposed a comparison method for the speed and accuracy of 3D printers. As a basis, the authors introduced properties and capabilities of 3D printers. A test-object designed by the authors is used to evaluate the average manufacturing speed of an Objet EDEN330 Polyjet and 3D Systems SLA3500 SLA manufacturing machine in an experiment. Furthermore, the experiment included an EOS EOSINT P385 SLS and Stratasys Prodigy Plus FDM machine. The experiment concluded that the SLS machine is capable of achieving the highest manufacturing speed (approximately 140 cm/h). In the experiment, the angular and dimensional deviations are significant (up to 2.5° for a 90° nominal, and 0.8 mm for a 10 mm nominal).

Roberson et al. [134] developed a ranking model for the selection of 3D printers, based on the accuracy, surface roughness, and printing time. This decision making model was intended to enable consumers and buyers of such hardware to select the most appropriate device.

Utela et al. [38] provided a review on the literature related to the development of new materials for powder bed-based 3D printing systems. They decomposed the development into five steps, for which they provided information on the relevant literature.

Brooks et al. [135] performed a review on the history and business implications of 3D printing. They argued that the most promising approach for companies to benefit from 3D printing technology is to invest in and adapt current business models to support supplementary printing for the users. They also presented the importance of the DMCA (Digital Millennium Copyright Act) in the USA from the perspective of 3D printing, for current and upcoming businesses and services in the USA.

Bogue [64] aimed to provide an introduction to 3D printing with this review. The historical development of the various printing technologies is presented and furthermore, applications with examples were explored.

Petrick and Simpson [58] compared traditional manufacturing, which they classify as “economy of scale”, with AM. AM is classified by the authors as “economy of one”. They based their future hypotheses on the traditional design–build–deliver model and current patterns in supply chains, from which they drew the logical conclusion for future developments. These hypotheses are sparsely supported by literature. They predicted that, in the future, the boundaries between the design–build–deliver paradigm will be less clear and that design and production will be closely coupled with experiments. One obvious prediction is that the supply chains will get shorter and the production will be more localised both geographically and in regard to time planning.

Matias and Rao [102] conducted an exploratory study on the business and consumer markets of 3D printing. This study consisted of a survey-based part for consumers, within the area of 3D printing, with a sample size of 66 participants conducted in 2014. One of their findings for the consumers is the willingness of 45% of the participants to spend only $US299 on this technology. They also found out that a large number of consumers is not proficient with the technology and the required software. This finding was backed by five interviews conducted with business persons from five different companies. Their interviewees also expressed concerns that there will not be a mass market for 3D printing within the next five to ten years.

Le Bourhis et al. [136] developed the design concept of sustainable AM (DFSAM) to minimise the yet unknown environmental impact of AM. According to the authors, about 41% of the total energy consumption globally is attributed to industry. Furthermore, the authors provided a division for the French industry in 2010, showing that about 12% of the total energy consumption is attributed to manufacturing.The authors claimed that AM can reduce the energy required as it limits waste material. The authors experimented on the energy and resource consumption of the Additive Laser Manufacturing (ALM) process and presented a method to calculate electricity, powder and gas consumption for an object based on the respective GCode.

In their work, Kim et al. [137] presented a federated information systems architecture for AM. This architecture was intended to facilitate an end-to-end digital implementation of AM, i.e., “digital thread”, design-to-product process. The authors analysed, for each phase (part geometry/design, raw/tessellated data, tessellated 3D model, build file, machine data, fabricated part, finished part, validated art), the available and used data formats and supporting software. The focus of their conceptual architecture was interoperability by an open architecture.

Balogun et al. [138] performed an experiment on the electricity consumption of the FDM process. The authors divided the manufacturing process into its components (start-up, warm-up, ready-state, build-state). In an experiment, they analysed three different FDM machines (Stratasys Dimension SST FDM, Dentford Inspire D290 and PP3DP) for their power consumption profile during manufacturing. The machines differ significantly in the energy demand, with the Dentford machine requiring 1418 Wh and the PP3DP only requiring 66 Wh. Furthermore, the authors compared the energy consumption and manufacturing duration of a FDM machine to a milling machine. In the experiment, the AM process consumed 685 Wh and the Mikron HSM 400 milling machine only 114 Wh. The AM cycle time was 3012 s (without 3600 s for support structure removal in an ultrasonic cleaning tank) and the milling machine cycle time was 137 s.

Weller et al. [139] discussed the implications of AM on the company and industry level. Economic characteristics, i.e., opportunities such as acceleration and possible price premiums, lower market entry barriers and limitations such as missing economy of scale, missing quality standards are discussed in this analysis. The authors performed a modelling of various scenarios and propositions for the market under the influence of AM. Their prediction for first adoption is within markets with an overall lower economy of scale.

Efthymiou et al. [140] presented a systematic survey on the complexity in manufacturing systems. Albeit not directly referencing AM, this study is relevant to understanding the implications of AM on manufacturing systems.

Turner et al. [70] surveyed melt extrusion AM processes. This work is part of a two piece series (see also [80]), with this part focusing on the design and process modelling. The authors provided a short market analysis in their introduction. The authors discussed literature relating to various processing steps and problems, e.g., die swelling, with melt extrusion processes. The authors provided a thorough overview on the literature for this topic.

Mitev [141] approached the topic of AM in a very uncommon manner, namely with a philosophical approach. This is the sole publication with this approach found by us. The author discussed AM for the question on what matter is and how 3D printing affects our concept of matter and material.

In contrast to the previous author, Bayley et al. [142] presented a model for the understanding of error generation in FDM. This work consisted of two parts with experiments. The first part analysed actual errors in FDM manufactured parts (e.g., roundness error, geometrical deviation). In the second part, the authors constructed a framework for error characterisation and quantification.

In the review by Kai et al. [143], the authors evaluated the relationship of manufacturing systems and AM briefly. The authors also provided an overview of one possible decomposition of AM and its academic relevance through a number of published works from 1975 to 2015.

Accuracy/Precision

The accuracy, precision and geometrical fidelity of 3D printed objects has been researched in many works for over 20 years [144,145], due to the necessity to produce objects that match their digital models closely. This topic is of general relevance to AM, as only precise objects are usable for the various applications. Increased precision and accuracy enables AM and CM to be a valid manufacturing technology.

Dimitrov et al. [36] conducted a study on the accuracy of the 3DP (3D-Printing) process with a benchmark model. Among the three factors influencing the accuracy is the selected axis and the material involved.

Turner and Gold [80] provided a review on FDM with a discussion on the available process parameters and the resulting accuracy and resolution.

Boschetto and Bottini [146] developed a geometrical model for the prediction of the accuracy in the FDM process. They predicted the accuracy based on process parameters for a case study for 92% of their specimens within 0.1 mm.

Armillotta [147] discussed the surface quality of FDM-printed objects. The author utilised a non-contacting scanner with a resolution of 0.03 mm for the assessment of the surface quality. Furthermore, the work provided a set of guidelines for the FDM process in respect to the achievable surface quality.

Equbal et al. [148] presented a Fuzzy classifier and neural-net implementations for the prediction of the accuracy within the FDM process under varying process parameters. They achieved a mean absolute relative error of 5.5% for the predictor based on Fuzzy logic.

Sahu et al. [149] also predicted the precision of FDM manufactured parts using a Fuzzy prediction, but with different input parameters (signal to noise ratio of the width, length and height).

Katatny et al. [150] presented a study on the dimensional accuracy of FDM manufactured objects for use as medical models. The authors captured the geometrical data with a 3D Laser scanner at a resolution of 0.2 mm in the vertical direction. In this work, a standard deviation of 0.177 mm is calculated for a model of a mandible acquired from Computer Tomography (CT) data.

To counter expected deviations of the object to the model, Tong et al. [151] proposed the adaption of slice files. For this adaption, the authors presented a mathematical error model for the FDM process and compared the adaption of slice files to the adaption of STL (STereoLitography) files. Due to machine restrictions, the corrections in either the slice file or the STL file are comparable, i.e., control accuracy of the AM fabricator is not sufficient to distinguish between the two correction methods.

Boschetto and Bottini [152] discussed the implications of AM methods on the process of design. For this discussion, they utilised digitally acquired images to make a comparison with model files.

Baumann et al. [153] developed a method to assess the quality of FDM printed parts by the utilisation of a normal 2D scanner. The implemented approach aids quality examiners by providing a computer aided measurement system. The authors also published the underlying image data as a dataset that was associated with this research.

Garg et al. [154] presented a study on the comparison of surface roughness of chemically treated and untreated specimens manufactured using FDM. They concluded that for minimal dimensional deviation from the original model, the objects should be manufactured either parallel or perpendicular to the main axis of the part and the AM fabricator axis.

6.5. Rapid Technology

As an umbrella term in accordance with the definition “General term to describe all process chains that manufacture parts using additive fabrication processes”, by [13], we examine the relevance of this technology for CM with this chapter. This technology is integral to the product development, especially with its sub-technology that is RP (see Section 6.5.3). This and the following sections elaborate upon the definitions provided in Section 2 by examples and research findings.

For a brief introduction, we refer readers to the following articles. Li et al. [155] proposed a method for rapid new product ramp-up within large multi-national companies relying on disperse supply chain networks and out-sourcing partners. In this work, the authors considered large-volume product development. For the conceptual framework, the authors identified critical members and defined a ramp-up process as a flowchart.

Mavri [156] described 3D printing itself as a rapid technology and analysed the impact of this technology on the production chain. The author performed an analysis of the influences on the phases of product design, production planning, product manufacturing, as well as the topic’s material utilisation, inventory and retail market. The findings of the author included that AM enables companies to act with more agility, cater for smaller markets, limit potential inventory issues and sustain smaller and slimmer supply chain networks.

Muita et al. [157] discussed the evolution of rapid production technologies and its implications for businesses. The authors investigated business models and processes, transitions as well as materials and logistics. A decomposition of rapid technology into phases or layers (Rapid Prototyping, 3D Printing, Rapid Tooling, Rapid Product Development and Rapid Manufacturing) is provided and discussed. The authors recommended the adoption of AM by all companies.

In the book by Bertsche and Bullinger [158], the authors presented the work of a research project on RP and the various problems addressed within the topic of Rapid Product Development (RPD). One aspect of this research is the development and integration of systems to efficiently store and retrieve information required throughout the process. Information required in the process is knowledge on construction, quality, manufacturing, cost and time.

In Lachmayer et al. [21], the authors presented current topics of AM and its application in the industry. In the chapter by Zghair [159], the concept of rapid repair is discussed. This concept was intended to prolong the life-time of high-investment parts, as well as modification of parts in academic settings. The authors performed an experiment for this approach with three objects and concluded that there is no visible difference between additional object geometry in the case of previously SLM manufactured objects. Differences are visually detectable for cast objects that are repaired.

6.5.1. Rapid Tooling

The use case of RT for AM is that the required tools or moulds for the (mass-) production of other parts or objects is supported by provisioning of said tools or moulds. See the definitions of RT in Section 2.1.5. RT as a concept has been researched and applied for at least 26 years [23]. Conceptually, little has changed since the early publications, but the number of available AM technologies, materials and support by other concepts such as CC has increased. Since its inception, the idea of RT has been to create tools or tooling directly from CAD models, thus, saving time and material. In this section, we present articles from this research to give an overview to the reader and present its relevance and relationship to the concept of CM.

In the review by Boparai et al. [160], the authors thoroughly analysed the development of RT using FDM technology. FDM manufactured objects commonly require post-processing for higher-quality surfaces, which was discussed by the authors in a separate section of their work. The authors presented a variety of applications of RT with FDM, which include casting and injection moulds and scaffolds for tissue engineering. Furthermore, the authors discussed material selection and manufacturing, as well as testing and inspection.

The review by Levy et al. [161] on RT and RM for layer-oriented AM from 2003, already states that AM is no longer just for RP. According to the definition of RT by the authors, tools are supposed to last a few thousand to millions of applications. The authors focused mainly on plastic injection moulds for tooling and surveyed a large number of different technologies and materials.