Abstract

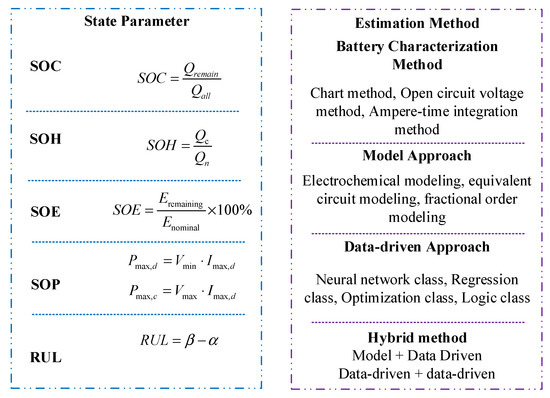

The reliability of unmanned aerial vehicle (UAV) energy storage battery systems is critical for ensuring their safe operation and efficient mission execution, and has the potential to significantly advance applications in logistics, monitoring, and emergency response. This paper reviews theoretical and technical advancements in UAV battery reliability, covering definitions and metrics, modeling approaches, state estimation, fault diagnosis, and battery management system (BMS) technologies. Based on international standards, reliability encompasses performance stability, environmental adaptability, and safety redundancy, encompassing metrics such as the capacity retention rate, mean time between failures (MTBF), and thermal runaway warning time. Modeling methods for reliability include mathematical, data-driven, and hybrid models, which are evaluated for accuracy and efficiency under dynamic conditions. State estimation focuses on five key battery parameters and compares neural network, regression, and optimization algorithms in complex flight scenarios. Fault diagnosis involves feature extraction, time-series modeling, and probabilistic inference, with multimodal fusion strategies being proposed for faults like overcharge and thermal runaway. BMS technologies include state monitoring, protection, and optimization, and balancing strategies and the potential of intelligent algorithms are being explored. Challenges in this field include non-unified standards, limited model generalization, and complexity in diagnosing concurrent faults. Future research should prioritize multi-physics-coupled modeling, AI-driven predictive techniques, and cybersecurity to enhance the reliability and intelligence of battery systems in order to support the sustainable development of unmanned systems.

1. Introduction

Amid the global transition toward low-carbon and intelligent energy systems, unmanned aerial systems (UASs) have emerged as critical enablers for smart cities, logistics, emergency response, and environmental monitoring [1]. The International Civil Aviation Organization (ICAO) forecasts a 10-fold increase in the number of global civilian UAVs by 2030, with electric multirotor drones dominating the market [2]. However, as UAVs are increasingly deployed in complex environments, the reliability of their battery systems has become a critical concern, as it directly impacts flight safety and mission success rates and poses stringent demands on the safety, stability, and consistency of UAVs [3]. Developing a systematic theoretical and engineering framework for assessing UAV battery reliability is essential for ensuring low-altitude airspace safety and enhancing the operational efficiency of unmanned systems.

Diverse application scenarios impose varied and stringent requirements on UAV battery reliability. For instance, logistics drones like the Amazon Prime Air drone require their batteries to retain over 80% capacity after 500 charge–discharge cycles and withstand mechanical shocks from 20 takeoffs and landings per hour [4]. Military drones, such as the MQ-9 Reaper, demand batteries that support 5C high-rate discharge in extreme temperatures ranging from −40 °C to 65 °C to ensure rapid mission response [5]. A 2022 commercial UAV crash highlighted the consequences of reliability failures, where localized overheating in a battery pack under a temperature differential exceeding 15 °C led to state-of-charge (SOC) misestimation, triggering erroneous battery management system (BMS) protection mechanisms and resulting in flight control loss. This incident underscores deficiencies in thermal management, cell consistency, and BMS integration strategies.

International and industry standards provide fundamental guidance for battery reliability. For example, the United Nations Manual of Tests and Criteria (Part III, Sub-Section 38.3) requires lithium batteries to undergo laboratory tests such as high- and low-temperature cycling, vibration, and short circuiting prior to transportation, with a focus on verifying their physical safety during transit. The Airworthiness Standards for Medium Civil Unmanned Aircraft Systems (MH/T 6043-2021) [6] issued by the Civil Aviation Administration of China mandates endurance flight tests under real operational conditions to assess the long-term stability and reliability of batteries. Additionally, the Technical Requirements for Electric Multirotor Unmanned Aircraft Systems for Urban Logistics Scenarios (T/CAAC 002—2022) [7] stipulates that batteries must possess a power redundancy capacity of 25% to ensure emergency capabilities in complex urban environments.

These three standards exhibit significant differences in their testing environments, validation methods, and performance criteria. For instance, UN 38.3 emphasizes individual physical tests conducted under standardized laboratory conditions; MH/T 6043-2021 focuses on a comprehensive evaluation of battery degradation during flight missions; and T/CAAC 002—2022 introduces scenario-specific requirements for performance redundancy. Such disparities necessitate that manufacturers develop and adapt distinct battery system testing and certification processes depending on the target country or application scenario, thereby complicating efforts to meet multi-regional regulatory requirements in a unified manner [8]. Therefore, it is imperative to establish a reliability evaluation framework for battery systems that is applicable across multiple operating conditions, performance metrics, and regions to support the globally consistent deployment and regulatory compliance of unmanned aerial vehicle battery management systems.

Quantifying the reliability of UAV batteries requires a multilevel, multidimensional metric system. At the cell level, the cycle life and capacity retention rate are core indicators. At the system level, the availability (mean time between failures, MTBF) and mission completion rate are more practical, with commercial UAVs often requiring a battery system availability that exceeds 98% annually [9]. Recent advancements in artificial intelligence have driven the development of predictive metrics, such as state-of-health (SOH) and remaining useful life (RUL), with advanced algorithms reducing estimation errors to within 3% and enabling a shift from reactive to proactive maintenance [10]. Nevertheless, most metrics are derived from controlled laboratory conditions, which results in researchers struggling to address complex real-world scenarios that involve high temperatures, high altitudes, and strong electromagnetic interference. A dynamic adaptability evaluation framework remains a critical research gap.

Reliability modeling underpins the state assessment of UAV battery systems. Electrochemical models that couple the Butler–Volmer equation with diffusion theory accurately simulate internal reactions, which makes them suitable for extreme condition analysis. However, their computational intensity, requiring hours for a single simulation, limits real-time applications [11]. Equivalent circuit models (ECMs) offer millisecond-level responses, which supports embedded flight control systems, but their depiction of aging mechanisms is limited [12]. Data-driven models that leverage superior temporal learning capabilities achieve high accuracy in state-of-health and remaining useful life predictions, yet rely heavily on high-quality training data [13]. Multiscale coupled models, which integrate electrochemical mechanisms with data-driven approaches, enhance SOH assessment accuracy [14]. Nonetheless, model generalization across operating conditions and online deployment capabilities require further improvement.

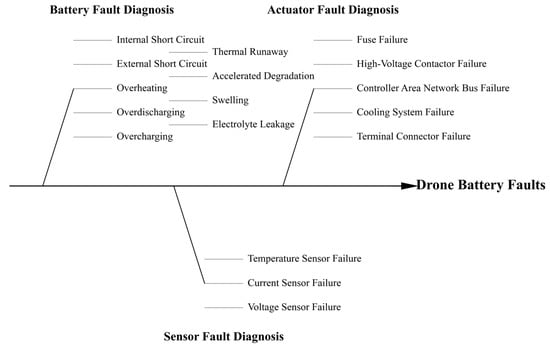

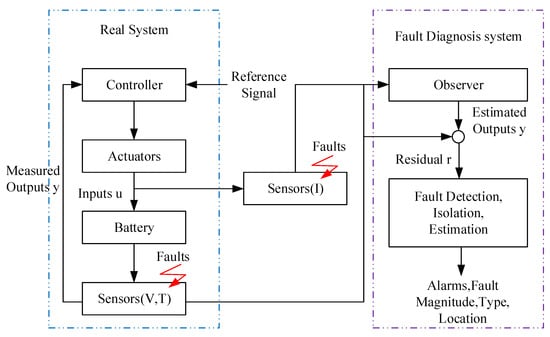

The accurate estimation of battery state parameters is central to UAV battery reliability. The use of traditional ampere-hour integration for state-of-charge estimation yields errors up to 10%, whereas extended Kalman filtering (EKF) significantly reduces the amount of errors when it is adapted to dynamic flight scenarios [15]. In fault diagnosis, acoustic emission sensing can predict lithium plating faults 30 min in advance, with a sensitivity that is five times higher than that of voltage monitoring [16]. Infrared thermography combined with convolutional neural networks (CNNs) detects micron-scale separator defects [17]. However, concurrent fault scenarios, such as overcharge and thermal runaway, result in feature overlap, causing misclassification rates up to 15% and necessitating multimodal fusion algorithms to improve their diagnostic specificity [18].

The battery management system serves as a critical safeguard for UAV battery reliability. Hardware-wise, active balancing circuits enhance pack capacity utilization [19]. Algorithmically, distributed BMSs with machine learning improve the SOH prediction accuracy while preserving data privacy. Cutting-edge digital twin technology, which synchronizes physical and virtual models in real time, significantly reduces fault response times [20]. However, BMS cybersecurity is increasingly critical, with a rising number of network attacks targeting battery systems, which underscores the need for robust intrinsic security mechanisms.

Current research on UAV battery reliability faces multiple challenges:

- Fragmented reliability standards with varying definitions and the lack of a unified framework;

- Disjointed modeling approaches, with electrochemical, ECM, and data-driven models failing to achieve effective integration, which limits their generalization;

- Fault diagnosis being largely confined to single-fault scenarios, and struggling with complex features of concurrent faults like overcharge and thermal runaway as a result;

- Underdeveloped BMS research in edge computing, cybersecurity, and real-time balancing strategies that inadequately addresses highly dynamic flight demands.

This paper systematically elucidates key technologies for UAV battery reliability, with the following contributions:

- A comprehensive review of reliability modeling methods, including mathematical, data-driven, and hybrid models, and an analysis of their applicability and limitations under complex conditions;

- An in-depth exploration of state estimation techniques for five key battery parameters and fault diagnosis methods;

- A systematic analysis of UAV BMS architecture and active balancing strategies, with trends toward intelligent management being envisioned, which provides theoretical guidance and practical references for safe and efficient UAV battery operation.

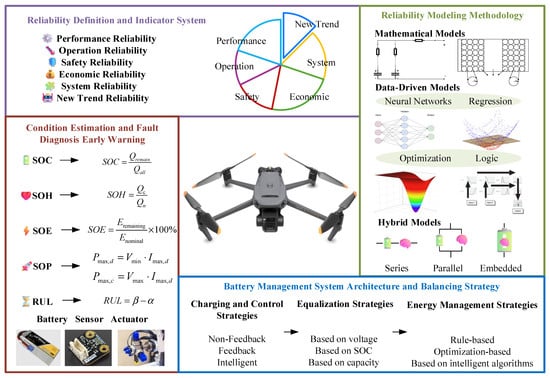

This paper is organized as follows: Section 2 defines UAV battery reliability and metrics. Section 3 reviews the state of reliability modeling. Section 4 discusses state estimation, fault diagnosis, and early warning. Section 5 addresses BMS architecture and balancing strategies. Figure 1 details the UAV battery reliability review in this paper. Finally, Section 6 summarizes the findings and outlines future research directions.

Figure 1.

A review of UAV battery reliability.

2. Definition and Metrics of Unmanned Aerial Vehicle Battery Reliability

2.1. Definition of Drone Battery Reliability by International Organizations

The definition of reliability for unmanned aerial vehicle battery systems has evolved with the diversification of application scenarios. The International Electrotechnical Commission (IEC) standard IEC 62619 [21] indirectly supports battery system reliability through safety requirements, focusing on performance under extreme conditions such as short circuits, overcharging, and thermal abuse to prevent explosions or fires, which aligns with UAV safety and stability needs [22]. The International Civil Aviation Organization (ICAO) [23], in its Technical Specifications for Unmanned Aircraft Systems, emphasizes dynamic reliability in high-altitude and vibrational environments, which requires a stable performance output under complex flight conditions [24]. The Institute of Electrical and Electronics Engineers (IEEE) explores mission reliability, modeling the relationship between battery failure rates and mission success rates to ensure high completion rates. These varied definitions reflect multidimensional evaluations of UAV battery performance across standards.

Differences in safety redundancy requirements significantly influence UAV battery design specifications. IEC 62619 mandates multiple protection mechanisms, such as overcharging and overheating safeguards, to address sudden failures, reflecting a conservative design approach. In contrast, IEEE 1625 [25] favors risk-based, system-level safety designs without mandating specific protection levels, offering greater flexibility. These differences manifest in market applications: European markets typically adopt IEC’s stringent safety standards, while U.S. markets prefer IEEE’s adaptable frameworks. Additionally, China’s GB/T 34131-2023 Technical [26] Requirements for Civil UAV Batteries impose strict criteria for cycle life and fast charging, requiring batteries to maintain a specified capacity after a defined number of cycles and complete rapid charging within set times, and addresses reliability demands for high-frequency mission scenarios.

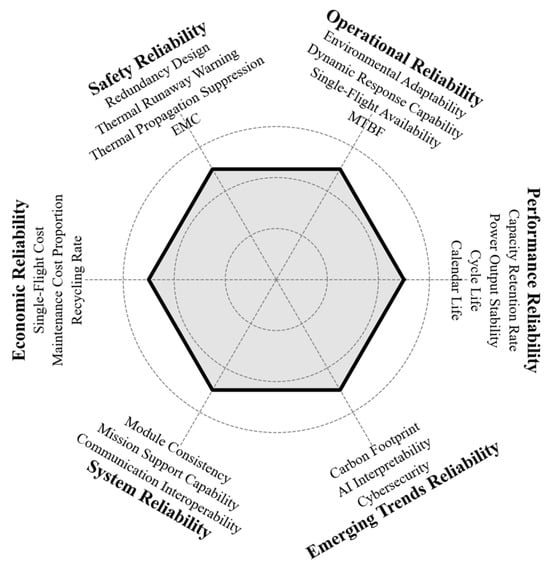

The reliability of unmanned aerial vehicle battery systems is defined as the system’s ability to maintain the expected performance levels throughout its lifecycle under specified environmental conditions and flight scenarios. This comprehensive concept encompasses five core dimensions. Additionally, a six-dimensional radar chart that integrates emerging trends in reliability metrics for evaluating UAV battery reliability is presented in Figure 2.

- Performance reliability: The battery must achieve a cycle life of at least 500 charge–discharge cycles while maintaining the designed capacity, retaining ≥80% of its initial capacity after 500 cycles. Power output fluctuations should be constrained within ±5% under rated conditions, and the calendar life should exceed 5 years;

- Operational reliability: The battery must exhibit environmental adaptability, operating effectively within a temperature range from −20 °C to 50 °C and from 20% to 95% relative humidity (non-condensing). For its dynamic response, it should maintain ≥90% power output during load transitions from 2C to 5C discharge. Continuous operation is reflected by a single-flight availability of ≥95% and a mean time between failures (MTBF) of ≥5000 h;

- Safety reliability: The system must incorporate fault tolerance and ensure that single-cell failures do not compromise the system’s overall operation through an N + 1 redundancy design. For thermal runaway protection, a warning time of ≥5 min and a propagation suppression time of ≥15 min are required. Electromagnetic interference resistance must ensure no performance degradation under a 10 kV/m field strength;

- Economic reliability: The lifecycle cost per flight should be ≤0.05 USD/Wh, and the maintenance costs should not exceed 10% of the total costs. The recycling rate should reach ≥80%;

- System-level reliability: The battery system must comply with communication protocols such as ISO 21895 [27] to ensure interoperability. Mission support requires a power response time of ≤100 ms to meet rapid takeoff and landing demands. Module consistency means a voltage deviation of ≤50 mV and a temperature difference of ≤3 °C.

Figure 2.

Six-dimensional radar chart for unmanned aerial vehicle battery reliability evaluation.

In summary, the reliability of unmanned aerial vehicle battery systems is defined as the system’s ability to consistently maintain the designed performance, safe operation, and economic viability throughout its lifecycle under specified environmental conditions and flight scenarios. This multifaceted concept encompasses five core dimensions: performance reliability, covering capacity, power, and lifespan metrics; operational reliability, which includes environmental adaptability, dynamic response, and availability; safety reliability, which includes redundancy design, thermal runaway protection, and electromagnetic compatibility; economic reliability, which is reflected in the flight costs, maintenance expenses, and recycling efficiency; and system-level reliability, which involves interoperability, mission support, and module consistency. Furthermore, reliability distinctions include inherent reliability, operational reliability, and environmental reliability, extending to emerging aspects such as cybersecurity, the interpretability of state prediction models, and sustainability. Together, these form an integrated assurance system that balances performance, safety, and economic considerations.

2.2. Indicators of UAV Battery Reliability

To comprehensively evaluate the stability and availability of unmanned aerial vehicle battery systems across diverse flight scenarios, the multidimensional reliability metrics framework is essential. As shown in Table 1, Table 2, Table 3, Table 4, Table 5 and Table 6, this framework encompasses five core dimensions—performance reliability, operational reliability, safety reliability, economic reliability, and system-level reliability—while extending to emerging requirements such as cybersecurity, artificial intelligence interpretability, and sustainability. The performance dimension reflects the battery’s sustained capabilities in terms of its capacity, power output, cycle life, and calendar life. The operational dimension addresses its adaptability to external conditions, including temperature, humidity, high altitudes, and vibration, as well as its stability in high-frequency missions. The safety dimension emphasizes fault tolerance, thermal runaway protection, and electromagnetic compatibility to ensure safe operation under extreme conditions. The economic dimension evaluates the lifecycle cost-effectiveness through metrics such as the per-flight cost, maintenance expenses, and material recycling rate. The system-level dimension focuses on inter-module communication compatibility, mission support capabilities, and cell consistency to ensure efficient system coordination. This comprehensive metrics system aligns with standards such as IEC 62619, IEEE P2836 [28], and China’s GB/T 34131, providing quantitative benchmarks and decision-making support for UAV battery design optimization, reliability assessment, and lifecycle management.

Table 1.

Performance reliability indicators.

Table 2.

Operational Reliability Indicators.

Table 3.

Safety Reliability Indicators.

Table 4.

Economic Reliability Indicators.

Table 5.

System Reliability Indicators.

Table 6.

Emerging Trends in Reliability Indicators.

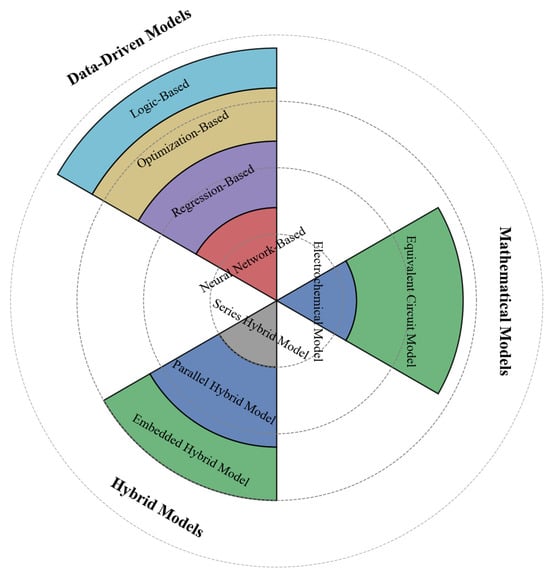

3. Reliability Modeling Methods for UAV Batteries

As UAV batteries are the core component responsible for ensuring endurance and flight safety, their performance, lifespan, and safety status require accurate prediction and control, which depend critically on appropriate modeling and simulation. Battery modeling aims to describe dynamic processes such as electrochemical reactions, thermal behavior, and degradation mechanisms through mathematical or physical representations. With the rapid expansion of UAV applications in fields such as logistics, surveying, and emergency response, battery models are required to simultaneously achieve high accuracy, low computational complexity, and scalability so that they can adapt to dynamic flight scenarios. As illustrated in Figure 3, which is based on modeling principles and levels of fidelity, the mainstream battery modeling approaches can be broadly classified into three categories: mathematical models (white-box models), data-driven models (black-box models), and hybrid models (grey-box models).

Figure 3.

Comparison of drone battery reliability modeling methods.

3.1. Mathematical Models

Mathematical models are constructed based on the multi-physical processes that occur within UAV energy storage batteries, including electrochemical reactions, thermal conduction, mechanical stress, and aging mechanisms. These models aim to accurately capture the intrinsic behavior of batteries during UAV operations. Mathematical models offer strong interpretability and predictive capability, playing a critical role in battery structural design, flight performance evaluation, safety analysis, and lifespan prediction. According to modeling approaches and levels of data dependence, battery models can be classified into three main types:

- Mathematical models, such as the Newman electrochemical model, equivalent circuit models, and thermal models, which are based on physical mechanisms and emphasize mechanistic interpretability;

- Data-driven models, which rely on extensive operational data (e.g., voltage, current, and temperature) collected during flight missions and are constructed using machine learning or statistical methods, which makes them suitable for complex, nonlinear scenarios;

- Hybrid models, which integrate the mechanistic foundation of mathematical models with the adaptability of data-driven models and thereby balance interpretability and predictive accuracy.

These models can be employed individually or coupled together to form multi-physics or multi-method frameworks, which enables their adaptation to varying precision and computational complexity requirements for UAV applications across different flight missions.

3.1.1. Electrochemical Models

- Pseudo-Two-Dimensional Model

For unmanned aerial vehicle systems that operate under highly dynamic flight conditions, the pseudo-two-dimensional (P2D) model enables the detailed simulation of internal electrochemical processes within the battery and thereby provides a theoretical foundation for optimizing battery performance under high-rate discharge and frequent load fluctuations.

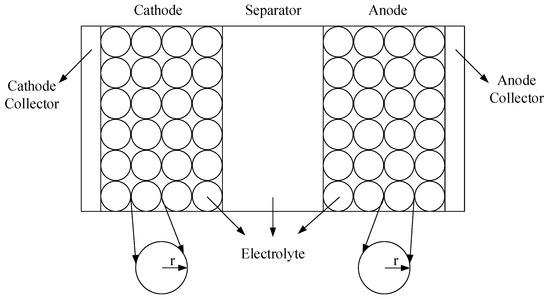

The pseudo-two-dimensional model of lithium-ion batteries, as illustrated in Figure 4, was proposed by Newman, M. Doyle, and co-workers. This model describes key physical and chemical processes, including lithium-ion diffusion in the electrolyte, electrode reaction kinetics, ohmic behavior, charge conservation, and mass conservation [30].

Figure 4.

Pseudo-two-dimensional (P2D) model.

The P2D model is capable of simultaneously describing both the internal and external characteristics of lithium-ion batteries. M. Rosas et al. developed a P2D model for lithium manganese oxide (LMO) batteries and validated it under dynamic conditions [31]. Zhang Q. et al. employed the P2D model to simulate the charge distribution in lithium cobalt oxide (LCO) electrodes and introduced a semi-empirical treatment of the symmetry factor in the reaction kinetics equations, demonstrating the model’s applicability for the electrode analysis of LCO materials [32]. T. T. Sara et al. proposed a model based on the particle radii of both the anode and cathode, and established a P2D model for 18650-format lithium iron phosphate (LFP) batteries [33]. The parameters in the P2D model have clear physical significance, allowing the model to capture the internal states of lithium-ion batteries during charge and discharge processes. Therefore, the P2D model is particularly well-suited for the micro-scale investigation of lithium-ion battery behavior.

In unmanned aerial vehicle systems, the pseudo-two-dimensional model can be employed to thoroughly analyze the impacts of dynamic variations on internal battery reactions, such as lithium-ion concentration gradients, intensified polarization, and thermal accumulation. By simulating the electrochemical behavior of batteries during acceleration, hovering, and prolonged flight, the P2D model facilitates the optimization of thermal management and state-of-health assessment, thereby providing theoretical support for the enhancement of UAV endurance and flight safety.

- 2.

- SP Model

The P2D model consists of partial differential equations and nonlinear parameters, and results in a high number of iterations, lengthy computation times, and numerous parameters. Due to differences in computational efficiency and parameter identification, the application of the P2D model is limited. As a result, many researchers have been continuously exploring reasonable and effective simplification methods for the P2D model, among which the most widely used is the single particle (SP) model. The SP model was proposed by B. S. Haran et al. [34]. In this model, it is assumed that the lithium-ion concentration in the liquid phase is uniform throughout the battery, and the electromotive force of the solid phase is uniform within the electrode. The SP model neglects the non-uniform distribution of the lithium-ion diffusion potential in the liquid phase and, therefore, the entire electrode can be represented by a single active particle.

Based on the P2D model, the SP model introduces the following assumptions, which significantly simplify the computational process of the model.

Compared to the P2D model, the SP model has fewer equations, fewer parameters, and higher computational efficiency. Therefore, it is an electrochemical model that is applicable to real-time systems and has been employed by some researchers for the real-time monitoring of lithium-ion concentrations in lithium-ion batteries [35].

To meet the real-time control requirements of unmanned aerial vehicle systems, the single particle model is particularly well-suited for embedded battery management systems due to its simplified structure and computational efficiency. By employing a reduced-order particle-based representation, the SP model enables the rapid prediction of batteries’ state of charge and voltage variations during flight, and thereby provides low-latency support for energy scheduling and remaining range estimation during mission execution.

- 3.

- Extended SP Model

Due to its excessive simplification of electrochemical processes, the SP model suffers from reduced accuracy and is only suitable for low-rate charge and discharge conditions. To address the limitations of the SP model, many researchers have proposed extended SP models. To address the challenges of high-rate charge–discharge and rapid operational transitions in unmanned aerial vehicles (UAVs), the extended single particle (SP) model was developed, which enhances the SP model’s capability to capture battery dynamic behavior by incorporating electrolyte-phase diffusion and heterogeneous reactions. This improvement makes the model more suitable for meeting the demands of flight safety and performance optimization. Luo W, Lyu C, and others introduced the effects of liquid-phase diffusion and heterogeneous reaction distribution into the SP model, proposing an extended SP model capable of charge and discharge modelling at 4C rates [36]. Han X and Ouyang M, among others, approximated the solid-phase diffusion of lithium ions using multiple first-order processes and used parabolic fitting to handle liquid-phase concentration distribution, which resulted in an extended SP model that is applicable to battery management systems [37]. S. K. Rahimian and S. Rayman incorporated a liquid-phase potential and material balance into the SP model [38]. I. Goto and H. Ohkuma included the concentration distribution of lithium electrolyte ions into the SP model [39]. In the extended SP model, the electrode is simplified to a single active particle, and the electrochemical processes omitted in the SP model are approximated and solved.

The extended single particle model offers enhanced electrochemical modeling accuracy, enabling the more precise representation of phenomena such as lithium-ion concentration polarization and potential hysteresis. By coupling the extended SP model with flight control data, it becomes possible to dynamically predict battery performance degradation and thermal accumulation during flight, and thereby to provide critical decision-making support for safe UAV landing and an early warning of battery degradation.

3.1.2. Equivalent Circuit Model

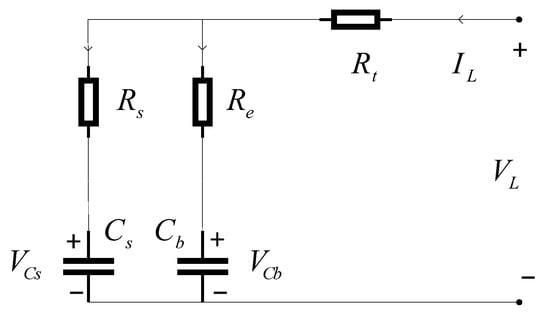

In UAV battery management, equivalent circuit models have become a core tool for battery state estimation and energy management within flight control systems, owing to their computational simplicity and fast real-time response. The equivalent circuit model of a battery is developed based on its operational principles, in which a circuit network is utilized to characterize the performance of lithium-ion batteries. These models are thus applicable to a broader range of battery types. To meet the demands of simulation techniques, various equivalent circuit models for lithium-ion batteries have been developed. Reference [40] categorizes the existing methods for constructing equivalent circuit models into two types: time-domain and frequency-domain analysis models. Time-domain analysis models primarily utilize voltage and current data of lithium-ion batteries, whereas frequency-domain analysis models rely on impedance measurements, such as Nyquist and Bode plots. The most commonly used equivalent circuit models are established through time-domain analysis. This review primarily focuses on the RC, PNGV, Thevenin, and modified Thevenin models [41].

- RC Model

The RC model consists of two capacitors and three resistors, as illustrated in Figure 5. The large capacitor represents the charge storage capacity of the lithium-ion battery, while the small capacitor accounts for the surface capacitance and diffusion effects of the battery. Resistor denotes the terminal resistance, represents the surface resistance, and corresponds to the terminal resistance.

Figure 5.

RC model.

The voltages across the two capacitors, and , serve as state variables, the terminal current as the input variable, and the terminal voltage as the output variable. Equation (2) is formulated based on Kirchhoff’s laws, from which the state-space equations of the RC model can be derived.

The RC model features a simple structure and parameters with clear physical interpretations, which makes it suitable for rapid state estimation in embedded systems. In UAV applications, this model can be integrated into the flight control system to enable real-time battery voltage prediction and health state estimation during flight, which ensures energy continuity throughout the execution of missions.

- 2.

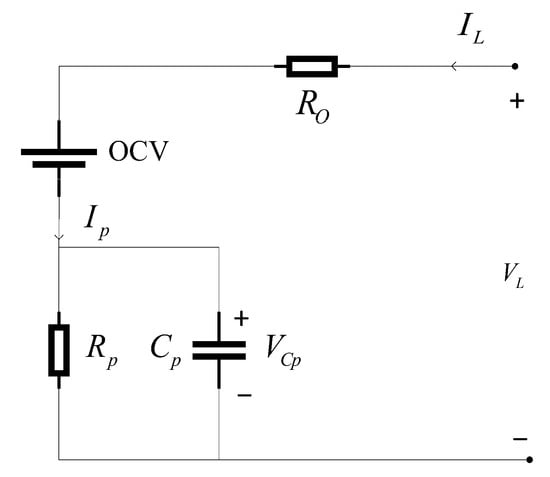

- Thevenin Model

The Thevenin model, as shown in Figure 6, is a widely used model. This model employs an ideal voltage source to represent the open-circuit voltage of a lithium-ion battery and incorporates a series resistor and a parallel RC network to predict the battery’s response to transient loads at a specific state of charge.

Figure 6.

Thevenin model.

The voltage across capacitor , denoted as , serves as the state variable, the terminal current as the input variable, and the terminal voltage as the output variable. Equations (4) and (5) are formulated based on Kirchhoff’s laws, from which the state-space equations of the Thevenin model are derived.

Due to its simplicity and ability to meet the basic requirements of lithium-ion batteries, the Thevenin model has been widely adopted. However, if the open-circuit voltage does not vary with the state of charge, this model is limited to describing the transient response of lithium-ion batteries at a specific SOC. Consequently, it is incapable of capturing steady-state voltage variations or predicting the runtime of the battery. Additionally, the model cannot describe the relationship between the OCV and SOC, nor can it predict the battery’s runtime or manage its charge–discharge processes.

In sudden high-current scenarios that are commonly encountered during UAV flights, such as takeoff or emergency obstacle avoidance, the Thevenin model enables the efficient evaluation of voltage drop and transient response characteristics with a low computational cost. It is widely used in flight control systems to support decision-making for energy-performance trade-offs.

- 3.

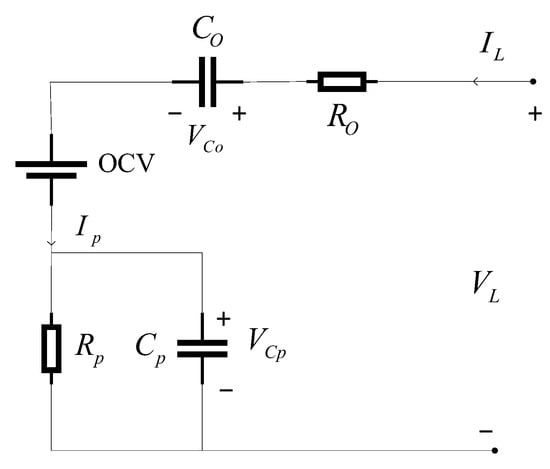

- PNGV Model

As depicted in Figure 7, the PNGV model is derived by incorporating an additional capacitor into the Thevenin model. The PNGV model enhances the dynamic tracking capability between the battery voltage and state of charge by introducing a polarization capacitor and thereby enabling more accurate endurance prediction during long-duration flight missions in unmanned aerial vehicles. This model possesses clear physical significance, with the ideal voltage source representing the OCV of the lithium-ion battery. Resistor denotes the battery’s ohmic internal resistance, resistor represents the polarization internal resistance, and capacitor corresponds to the polarization capacitance. denotes the load current, represents the polarization current, is the terminal voltage, and capacitor accounts for the OCV variation caused by the time integral of the load current . When the lithium-ion battery is in a charging or discharging state, the accumulation of current over time alters the SOC, which further modifies the battery’s OCV and is manifested as a voltage change across capacitor . In this model, capacitor not only represents the capacity of the lithium-ion battery but also its DC response, and thereby addresses the limitations of the Thevenin model.

Figure 7.

PNGV model.

The voltages across capacitors and , denoted as and , serve as state variables, the terminal current as the input variable, and the terminal voltage as the output variable. Equations (6) and (7) are developed based on Kirchhoff’s laws, from which the state-space equations of the PNGV model are derived.

The PNGV model, proposed by the Partnership for a New Generation of Vehicles in the United States, is significantly influenced by the Freedom CAR hybrid electric vehicle initiative. Owing to its systematic parameter identification methods and relatively high model accuracy, the PNGV model facilitates straightforward parameter identification experiments. Consequently, it is one of the most commonly adopted models.

Additionally, for medium- to high-power UAV platforms, the PNGV model can accurately characterize the evolution of the state of charge and voltage during long-endurance flights. This facilitates the development of mission-oriented endurance prediction systems and thereby enhances the robustness of flight mission planning and improves energy utilization efficiency.

- 4.

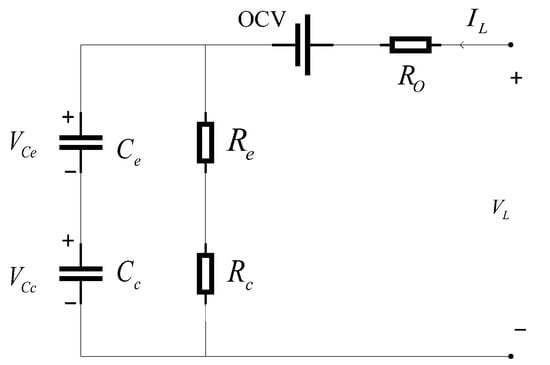

- Modified Thevenin Model

Single-pole models of lithium-ion batteries do not always meet the requirements for dynamic performance. Consequently, researchers have introduced various bipolar and multipolar models [42]. Among these, the modified Thevenin model, as depicted in Figure 8, is frequently utilized. In this model, an ideal voltage source represents the open-circuit voltage of the lithium-ion battery. Resistor denotes the ohmic internal resistance, resistor represents the electrochemical polarization internal resistance, and capacitor corresponds to the electrochemical polarization capacitance. Resistor is associated with the concentration polarization capacitance, capacitor represents the concentration polarization capacitance, denotes the electrochemical polarization voltage, represents the concentration polarization voltage, is the load current, and is the terminal voltage.

Figure 8.

Modified Thevenin model.

The electrochemical polarization voltage and the concentration polarization voltage serve as state variables, the terminal current as the input variable, and the terminal voltage as the output variable. Equations (8) and (9) are derived based on Kirchhoff’s laws, from which the state-space equations of the modified Thevenin model are obtained.

The polarization in the modified Thevenin model enables a precise representation of the battery’s dynamic characteristics. As the performance requirements for lithium-ion batteries continue to increase, the application of this model has become increasingly widespread. The frequent dynamic load variations encountered during UAV missions impose higher demands on battery performance evaluation. The modified Thevenin model incorporates concentration polarization processes to more accurately characterize the dynamic voltage response of the battery, which aids in voltage drop risk prediction and the dynamic correction of the remaining energy during flight state transitions. However, similar to its original version, the modified Thevenin model cannot account for OCV variations caused by the time integration of the load current . If the OCV in the Thevenin model is treated as a variable, the equivalent relationship between the lithium-ion battery’s OCV and its SOC can replace the capacitor in the PNGV model. Despite its limitations, the modified Thevenin model retains significant practical importance.

3.2. Data-Driven Models

Data-driven models represent an approach that leverages extensive operational data to model and predict the dynamic behavior of energy storage battery systems using methods such as statistical learning, machine learning, or deep learning. In contrast to white-box modeling, which relies on the physicochemical mechanisms within the battery, data-driven models fall into the “black-box” or “gray-box” category. Their core principle is to forego explicit physical model construction and instead utilize the inherent relationships within the data to map and predict battery performance metrics. This approach is particularly suitable for scenarios where physical processes cannot be accurately modeled or where abundant data are available but the structural information is incomplete. Data-driven models offer advantages such as low modeling costs, high deployment efficiency, and strong adaptability.

In real-world operational environments, unmanned aerial vehicle battery systems are exposed to complex and dynamic working conditions such as frequent takeoffs and landings, rapid load switching, strong electromagnetic interference, and pressure fluctuations at high altitudes. Data-driven approaches can leverage historical flight data—such as data on the voltage, current, temperature, and load power—to rapidly adapt to variations in flight missions and environmental conditions. This enables the real-time, online estimation of key indicators such as the state of charge, state of health, and remaining useful life within complex urban airspace, and thereby enhances flight safety and mission success rates.

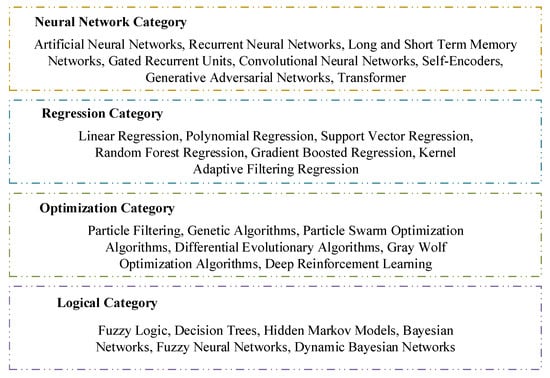

As illustrated in Figure 9, data-driven models are primarily categorized into four types: neural network-based, regression-based, optimization-based, and logic-based models, with the classification being based on the core algorithms and data processing methods used by the model. Neural network-based models rely on artificial neural networks, employing multilayer nonlinear mapping to learn complex data relationships, which makes them suitable for high-dimensional nonlinear problems. Regression-based models utilize statistical regression techniques to focus on fitting mathematical relationships between inputs and outputs and are applicable to scenarios with clear data patterns. Optimization-based models employ optimization algorithms to identify optimal parameters or structures and are commonly used for system parameter identification or control strategy optimization. Logic-based models, which are grounded in logical reasoning or rules, emphasize rule-driven decision-making and are well-suited for systems with discrete or well-defined conditions. These four types of data-driven models reflect the differences in modeling objectives, complexity, and applicable scenarios among various algorithms.

Figure 9.

Classification of data-driven models for UAV batteries.

3.2.1. Neural Network-Based Models

Neural network-based models represent a significant branch of data-driven models for unmanned aerial vehicle battery systems, being constructed using artificial neural networks (ANNs) and excelling in handling complex nonlinear relationships and high-dimensional data. Their core mechanism involves simulating the dynamic characteristics of UAV batteries—such as their capacity degradation, voltage response, and internal resistance variations—through a multilayer structure comprising input, hidden, and output layers. During training, the model adjusts weights using experimental or flight data, including current, voltage, and temperature data, to optimize its prediction accuracy. Common types include feedforward neural networks, recurrent neural networks (RNNs), and long short-term memory (LSTM) networks, with LSTM networks being particularly suitable for UAV battery state estimation due to their ability to capture long-term dependencies in time-series data. Neural network-based models do not require in-depth knowledge of internal battery mechanisms, offering strong generalization capabilities. However, they demand substantial high-quality data and computational resources, which results in longer training times. In recent years, the integration of deep learning and transfer learning has expanded their applications in UAV battery life prediction and fault diagnosis, significantly enhancing flight safety and the precision and robustness of battery management.

Artificial neural networks were among the earliest neural networks to be applied to battery modeling [43]. Utilizing a multilayer perceptron (MLP) structure with fully connected layers, ANNs fit nonlinear relationships between battery operational data and state metrics. Their training typically employs the backpropagation algorithm with a mean squared error (MSE) loss function, which makes ANNs suitable for static mapping tasks such as capacity degradation prediction or voltage–current relationship modeling. ANNs achieve high accuracy without requiring a detailed understanding of battery mechanisms, outperforming methods like open-circuit voltage estimation in lead-acid battery state-of-charge applications. Their advantages include their structural simplicity and ease of implementation. However, ANNs struggle to handle time-series data, which limits their ability to capture dynamic behaviors in charge–discharge cycles, and their generalization to complex datasets is constrained, often requiring extensive feature engineering. Although enhanced by deep networks and optimization algorithms (e.g., Adam), ANNs remain valuable in simple scenarios but are gradually being supplanted by more sophisticated models.

Recurrent neural networks (RNNs) [44] are applied to battery modeling due to their ability to process time-series data. By retaining historical information through a recurrent structure, RNNs take sequential inputs such as the voltage and current to predict battery states. They are well-suited for capturing short-term dynamic behaviors, such as changes during charge–discharge processes. However, RNNs suffer from the vanishing gradient problem, which limits their ability to model long-term dependencies and results in reduced accuracy under complex operating conditions. Their strength lies in sequence modeling, but their training is sensitive to hyperparameters and their computational costs are high. Due to gradient-related limitations, traditional RNNs have gradually faded from mainstream application, although they laid the foundation for dynamic system modeling.

Long short-term memory networks [45], an advanced variant of RNNs, incorporate memory cells and gating mechanisms (input, forget, and output gates) to retain long-term historical information, which makes them particularly suitable for modeling slow battery degradation processes. LSTMs excel in online SOC estimation and their combination with Kalman filtering further enhances their accuracy. Compared to traditional RNNs, LSTMs effectively capture long-term dependencies and adapt to dynamic changes in complex operating conditions. However, they require substantial data for training, have a high computational complexity, and involve intricate hyperparameter tuning. LSTMs offer high accuracy and robustness, which makes them widely used in battery life prediction, although they may be limited in scenarios that require strong real-time performance.

Gated recurrent units (GRUs) [46], another RNN variant, feature a simpler structure than LSTMs, merging the input and forget gates into an update gate, which reduces the number of parameters and the computational complexity. With inputs and outputs similar to LSTMs, GRUs are suitable for SOC, state-of-health (SOH), or remaining useful life (RUL) predictions. GRUs enable faster SOC estimation on embedded devices, which makes them ideal for real-time applications while still allowing them to retain their long-term dependency modeling capabilities. They offer higher training efficiency and simpler hyperparameter tuning. However, their modeling capacity for extremely long sequences is slightly inferior to that of LSTMs, and they still require substantial data support. Due to their balance of efficiency and accuracy, GRUs have become a popular choice for battery modeling, particularly in resource-constrained scenarios, and there is potential for their future integration with lightweight techniques for edge computing applications.

Inspired by computer vision, convolutional neural networks (CNNs) [47] have been adapted for battery modeling. Battery data, such as voltage curves and impedance spectra, exhibit local patterns that are suitable for feature extraction using convolutional kernels. CNNs capture temporal or spatial correlations through convolution operations, with pooling layers reducing the dimensionality of the output SOC, SOH, or RUL predictions. One-dimensional CNNs process time-series data, while two-dimensional CNNs analyze impedance spectra. CNNs are robust to noise, parameter-efficient, and well-suited for large-scale data processing. However, their ability to model long-term temporal dependencies is limited, which makes it challenging to capture slow changes in battery cycles. To address this, CNNs are often combined with LSTMs or GRUs to form hybrid models with enhanced dynamic modeling capabilities. The efficiency of CNNs in feature extraction makes them a valuable tool for complex battery modeling.

Autoencoders (AEs) [48] are employed in battery modeling due to their unsupervised learning capabilities. AEs consist of an encoder that compresses input data into a low-dimensional representation and a decoder that reconstructs the data, which makes them suitable for tasks such as dimensionality reduction, denoising, or anomaly detection. Variational autoencoders (VAEs) model data distributions, excelling in scenarios with scarce fault data. Denoising autoencoders (DAEs) enhance models’ robustness by handling noisy data. The primary advantage of AEs is their ability to operate without labeled data, which makes them ideal for preprocessing or feature extraction. However, their direct modeling capacity for high-dimensional time-series data is limited, and they often require integration with networks like LSTMs. AEs typically serve as auxiliary tools in battery modeling, but their potential in multimodal data fusion is significant, particularly in data-scarce scenarios.

Generative adversarial networks (GANs) [49] are utilized in battery modeling for their data augmentation capabilities. Comprising a generator that produces realistic battery data and a discriminator that distinguishes between real and synthetic data, GANs are effective for expanding training datasets or detecting anomalies. Conditional GANs (CGANs) generate data for specific operating conditions and have found wide applications in SOC estimation and fault detection. The strength of GANs lies in their mitigating data scarcity and enhancing models’ generalization. However, their training is often unstable, requiring carefully designed loss functions. GANs that incorporate physical constraints are emerging as a research focus, promising to improve the authenticity of generated data. GANs hold substantial potential for small-sample learning and fault diagnosis, with their future applications likely extending to full-lifecycle data simulation.

Transformer models, known for their powerful sequence modeling capabilities, have been applied to battery modeling [50]. Their self-attention mechanism assigns weights to each time step, capturing both short- and long-term dependencies. With multidimensional time-series inputs, the encoder extracts features, and the decoder generates predictions for the SOC or RUL. Transformers achieve high accuracy in life prediction under complex operating conditions, benefiting from their ability to process long sequences in parallel, which makes them suitable for large-scale datasets. However, their high computational complexity demands substantial data and computational resources. Lightweight transformers (e.g., Informer) and pre-training techniques are being explored to reduce costs. Transformers show immense potential in multi-battery collaborative management and full-lifecycle modeling. Although their application is still in the early stages, their parallel processing and accuracy advantages position them as a future mainstream direction.

From simple artificial neural networks to complex transformer models, neural networks have significantly advanced battery modeling techniques. ANNs established a foundation for static modeling through nonlinear mapping, while RNNs, LSTMs, and GRUs addressed dynamic sequence modeling challenges. CNNs and AEs optimized feature extraction, and GANs and transformers overcame limitations in data scarcity and long-sequence modeling. The primary strength of neural networks lies in their robust nonlinear fitting capabilities and adaptability to complex operating conditions, which enable the precise prediction of battery state parameters such as the SOC, SOH, and RUL. However, their training requires substantial data and computational resources, and their interpretability is limited, which constrains real-time applications. Recent developments in hybrid modeling and lightweight designs have improved the real-time performance of battery modelling, while transfer learning has reduced data requirements. In the future, hybrid models that integrate physical knowledge, multimodal data fusion, and enhanced interpretability will be key research directions that offer new opportunities for efficient battery management.

3.2.2. Regression-Based Models

Regression-based, data-driven models rely on statistical regression techniques to model battery behavior by fitting mathematical relationships between inputs (e.g., voltage, current, temperature) and outputs (e.g., battery state parameters). Their core premise assumes that battery behavior can be described by parameterized functions. Common methods include linear regression, polynomial regression, support vector regression (SVR), random forest regression (RFR), gradient boosting regression (GBR), and kernel adaptive filtering regression (KAF). These models typically aim to minimize prediction errors, optimizing parameters through algorithms such as gradient descent or least squares. In battery modeling, regression-based models excel in scenarios with clear data patterns, such as capacity degradation trend prediction or state parameter estimation under static conditions. Their advantages include algorithmic simplicity, high computational efficiency, and strong interpretability, which make them suitable for use with small-scale datasets or real-time applications. However, their limitations lie in their restricted ability to model nonlinear, high-dimensional, or dynamic data, as they struggle to capture long-term temporal dependencies or complex degradation patterns. Recent advancements that have combined feature selection and ensemble learning have kept regression-based models competitive in specific scenarios, although they often require integration with neural networks or other methods to enhance their accuracy.

Linear regression [51], rooted in statistics, is the most fundamental regression method. It assumes a linear relationship between battery operational data (e.g., voltage, current) and state metrics, optimizing parameters via the least squares method. Widely applied in simple conditions, such as open-circuit voltage (OCV)-SOC estimation for lead-acid batteries, it is valued for its computational simplicity. Its strengths include its ease of implementation, strong interpretability, and suitability for small-scale datasets and rapid deployment, particularly for beginners. Linear regression serves as a baseline model, providing a reference for more complex methods. However, its capacity to model nonlinear relationships is limited, which makes it inadequate for capturing dynamic behaviors like nonlinear capacity loss during cycling, and it is sensitive to noise, requiring high-quality data. In modern complex scenarios, linear regression is often used as a component of hybrid models or for validating simple hypotheses.

Polynomial regression [52] extends linear regression by incorporating higher-order terms to fit nonlinear relationships. Commonly used for fitting voltage–current curves or predicting capacity degradation trends, it is prevalent in lithium-ion battery research. Polynomial regression retains the simplicity and interpretability of linear regression while capturing moderately nonlinear patterns, has low computational costs, and is suitable for small-to-medium-scale datasets. Its limitations include the risk of overfitting with higher-order terms, particularly with limited data, which leads to poor generalization. Additionally, it struggles with dynamic time-series modeling, failing to address long-term dependencies in battery cycling. When combined with regularization techniques, polynomial regression remains valuable in simple scenarios but typically requires integration with other methods to improve its accuracy.

Support vector regression (SVR) [53], based on support vector machine principles, maps data to a high-dimensional space using kernel functions to fit nonlinear relationships, with the aim of minimizing the structural risk. SVR performs exceptionally in lithium-ion battery state parameter estimation. Its strengths include robustness to noise and outliers, suitability for small-to-medium-scale datasets, and flexibility in adapting to various nonlinear patterns through kernel functions. However, SVR is sensitive to kernel and regularization parameters, requiring complex tuning, and its computational cost escalates with the use of large-scale data. While effective for static state predictions, SVR requires enhancements for dynamic sequence modeling and is often combined with sequential models. SVR’s strong generalization capabilities ensure its continued importance in battery modeling.

Random forest regression (RFR) [54], an ensemble method based on decision trees, constructs multiple trees through random sampling and feature selection, averaging its predictions to enhance its accuracy. Widely applied in battery life prediction, such as estimating the SOH from voltage curves, RFR achieves accuracy comparable to that of neural networks. Its advantages include robustness to noise, a low risk of overfitting, and the ability to assess feature importance, and it is often used to guide feature engineering. However, its predictions are discrete averages, and the training time increases with the number of trees. RFR excels in complex condition state estimation but requires improvements for dynamic sequence modeling, often being paired with sequential models to enhance its dynamic capabilities. RFR’s potential in multivariable scenarios remains significant.

Gradient boosting regression (GBR) [55] iteratively optimizes weak learners to fit residuals, constructing high-accuracy models. In battery life prediction, GBR achieves superior precision, effectively capturing complex nonlinear patterns. It is highly adaptable to imbalanced or noisy data, which makes it suitable for multivariable battery state parameter estimation. GBR’s strengths include high accuracy and flexibility, with a performance that is tunable through learning rate and tree depth adjustments. However, it is sensitive to hyperparameters, has long training times, and risks overfitting due to its complexity. GBR is commonly used for high-precision state predictions, and its efficiency can be further improved with automated hyperparameter tuning. GBR’s potential to rival deep learning models in complex conditions makes it a key choice for high-accuracy modeling.

Kernel adaptive filtering regression (KAF) [56] integrates kernel methods with adaptive filtering, allowing the dynamic adjustment of parameters through online learning to adapt to changing battery data. It is well-suited for real-time applications and resource-constrained scenarios, such as state estimation under dynamic conditions. KAF’s advantages include a low computational cost and online learning capabilities, which enable it to rapidly adapt to condition changes, and it has significant potential in battery management systems (BMSs). However, KAF is sensitive to initial parameters, and its long-term prediction accuracy may lag behind that of deep learning models. KAF offers a novel approach for real-time scenarios, with future integration with edge computing likely to expand its applications, particularly in high-response-demand environments.

Regression-based methods have evolved from the simple linear fitting of linear regression to the nonlinear modeling of polynomial regression, SVR, and RFR, and further to the high-precision dynamic predictions of GBR and KAF. Linear and polynomial regression provide straightforward baselines, SVR and RFR enhance robustness, while GBR, KAF, and advanced methods address complex scenarios. The strengths of regression-based models lie in their simplicity, computational efficiency, and interpretability, with SVR and RFR offering noise robustness and KAF enabling online learning. Their limitations include restricted nonlinear modeling capabilities and weak dynamic sequence processing. Recent advancements in ensemble learning and online optimization have improved the performance of these models. In the future, integrating physical constraints, multimodal data fusion, and lightweight designs will address interpretability challenges, enabling reliable battery management.

3.2.3. Optimization-Based Models

Optimization-based data-driven models address parameter identification and control strategy design by seeking optimal solutions to target functions, such as minimizing prediction errors or maximizing system efficiency. Their core approach involves using global or local search algorithms to fit complex relationships between battery operational data and state parameters. Common methods include particle filtering (PF), genetic algorithms (GAs), particle swarm optimization (PSO), differential evolution (DE), grey wolf optimization (GWO), deep reinforcement learning (DRL), and hybrid optimization. These models do not require in-depth knowledge of battery mechanisms and excel in handling nonlinear, high-dimensional problems, which makes them widely used for equivalent circuit model parameter estimation and charging strategy optimization. Their strengths include robust global search capabilities and adaptability to complex operating conditions, particularly in dynamic scenarios.

Particle filtering (PF) [57], based on Monte Carlo sampling, estimates the posterior distribution of battery states by generating numerous particles, which makes it suitable for nonlinear, non-G MSM systems. PF uses data such as the voltage and current to approximate the SOC or SOH, excelling in handling dynamic uncertainties and commonly being applied in real-time state tracking. Its advantages include strong adaptability to nonlinear systems and the ability to integrate multi-source information (e.g., temperature, cycle counts) to enhance its accuracy, which make it ideal for online battery state estimation. However, PF suffers from particle degradation, which can lead to bias, and its computational complexity increases with the number of particles, which reduces its efficiency in large-scale systems. Improved resampling strategies are critical to mitigate these issues. PF performs reliably on small-scale datasets and is often combined with Kalman filtering to form hybrid methods, which enhances its robustness and accuracy, with this combination serving as a benchmark for battery state estimation.

Genetic algorithms (GAs) [58] emulate biological evolution, using selection, crossover, and mutation operations to search for optimal solutions in the parameter space and thus optimize battery model parameters. With the objective of minimizing errors, GAs are well-suited for parameter identification in ECMs, as they are capable of handling complex nonlinear optimization problems. Their strengths include robust global search capabilities, the ability to escape local optima, and a low dependence on initial conditions, which ensure broad adaptability. However, GAs converge slowly and incurs high computational costs, particularly in high-dimensional parameter spaces. To improve their convergence, GAs are often combined with local optimization algorithms to form more efficient search strategies. While their standalone use has decreased, GAs remain a cornerstone of hybrid optimization frameworks, being applicable to parameter estimation and multi-objective optimization scenarios, such as balancing energy efficiency and battery lifespan.

Particle swarm optimization (PSO) [59], inspired by collective behaviors, optimizes target functions through collaborative particle searches, and is commonly used for ECM parameter estimation or control strategy design. PSO offers advantages such as minimal parameters, ease of implementation, and superior global search capabilities compared to traditional gradient-based methods, which makes it suitable for small-to-medium-scale optimization problems. Its limitations include the risk of converging to local optima in high-dimensional or multimodal problems and its sensitivity to velocity update parameters, which necessitate careful tuning. To enhance its performance, PSO is often integrated with deep models to improve its adaptability in complex conditions. Widely applied in SOH prediction and charging optimization, PSO’s efficiency and flexibility make it a classic method in battery modeling.

Differential evolution (DE) [60] optimizes parameters through differential mutation, crossover, and selection operations, which makes it suitable for parameter identification in complex battery models, such as electrochemical models. DE offers strong exploration capabilities and faster convergence than GAs, with a low dependence on initial conditions. Its advantages include a simple algorithmic structure, suitability for high-dimensional nonlinear optimization, and efficiency in handling multi-objective tasks, such as balancing accuracy and efficiency. However, DE is sensitive to mutation factors and crossover rates, and improper tuning can degrade its performance. Adaptive parameter adjustment strategies are increasingly explored to address this issue. DE excels in SOC estimation and lifespan prediction, and its recent use in multivariable optimization scenarios, coupled with dynamic tuning, enhances its potential for real-time modeling applications.

Grey wolf optimization (GWO) [61], inspired by wolf pack hunting behaviors, optimizes target functions by simulating leadership and collaboration mechanisms, which makes it suitable for battery model or control parameter adjustments. GWO is simple, gradient-free, and converges quickly. Its strengths include a hierarchical structure that balances exploration and exploitation, offering superior robustness compared to traditional swarm intelligence algorithms. This makes it suitable for small-to-medium-scale optimization tasks. However, GWO may converge prematurely in ultra-high-dimensional problems, in which case it requires improved diversity mechanisms to maintain its search capabilities. With an accuracy surpassing that of PSO and GWO, when combined with multi-objective optimization, its applicability in complex conditions is broad, and this method is emerging as a promising choice for efficient modeling.

Deep reinforcement learning (DRL) [62], integrating deep learning and reinforcement learning, optimizes BMS control or parameter adjustments by enabling agents to learn optimal strategies. Targeting long-term reward maximization, DRL adapts to high-dimensional dynamic systems. Its strengths include leveraging deep networks to extract features and handle nonlinear behaviors in complex conditions, which make it suitable for adaptive SOC estimation or charging optimization. However, DRL requires substantial data and computational resources for training, and its strategy convergence may be unstable, with limited interpretability. Transfer learning, to reduce costs, is a growing research focus. DRL holds immense potential in dynamic optimization scenarios, such as designing strategies to extend batteries’ lifespan.

Hybrid optimization methods integrate multiple algorithms, combining the strengths of global and local searching to optimize complex battery model parameters or control strategies. For instance, combining GAs with PSO significantly improves their accuracy [63]. Targeting multi-objective optimization (e.g., balancing accuracy and efficiency), hybrid optimization overcomes the limitations of single methods, offering strong robustness. Its advantages include balancing convergence speed and global search capabilities, which allows it to adapt to multivariable optimization in complex conditions. However, its design complexity requires tailored algorithm combinations for specific problems. Hybrid optimization excels in full-lifecycle parameter identification and can further improve models’ performance through adaptive mechanisms.

Optimization-based methods have evolved from the probabilistic estimation of particle filtering to the swarm intelligence searches of genetic algorithms, particle swarm optimization, and differential evolution, and further to the dynamic modeling of grey wolf optimization, deep reinforcement learning, and hybrid optimization. PF excels in nonlinear state estimation, GAs and PSO provide global search capabilities, DE and GWO offer faster convergence, and DRL adapts to dynamic control. The strengths of optimization-based models lie in escaping local optima, handling high-dimensional nonlinear problems, and supporting parameter identification and strategy optimization. However, they incur high computational costs, involve complex parameter tuning, and, for DRL, involve lengthy training times. Recent advancements in adaptive strategies and multi-objective optimization have improved the efficiency of these models. In the future, reducing computational demands through physical knowledge integration, multimodal data fusion, and algorithmic lightweighting will drive BMSs toward efficient, intelligent development.

3.2.4. Logic-Based Models

Logic-based models rely on rule-based reasoning or logical relationships to model battery behavior by defining explicit state transitions or decision rules. Their core approach involves utilizing logical frameworks, such as fuzzy logic, decision trees, or Markov models, to map the relationship between unmanned aerial vehicle battery operational data and states. These models are commonly applied in fault diagnosis, state classification, and flight control strategy development, particularly in scenarios with discrete or well-defined conditions. Typical methods include fuzzy logic control, decision tree classification, hidden Markov models (HMMs), Bayesian networks, fuzzy neural networks (FNNs), and dynamic Bayesian networks (DBNs). The strengths of logic-based models lie in their clear rules, strong interpretability, ability to incorporate expert knowledge, and high computational efficiency, which make them suitable for real-time UAV applications. In recent years, logic-based models have increasingly been combined with neural networks to enhance their flexibility. In the future, logic-based models that incorporate adaptive rules and multimodal data will play a greater role in intelligent decision-making and safety management for UAV battery systems.

Fuzzy logic (FL) [64] employs fuzzy sets and membership functions to model uncertainty, using expert-defined rules to infer battery states, which makes it suitable for control and diagnostic scenarios. FL maps data such as voltage and current data to fuzzy rules, generating outputs like the SOC or fault states, and is often used for tasks like overcharge detection. Its advantages include intuitive rules, strong interpretability, no requirement for precise mathematical models, and high computational efficiency, and it is ideal for real-time applications. FL effectively handles nonlinear relationships through fuzzy inference, performing reliably in simple conditions. However, its rule design relies heavily on expert experience, which limits its ability to handle high-dimensional data or dynamic sequence modeling. To enhance its flexibility, FL is often combined with adaptive algorithms to optimize its rule generation. FL is widely applied in BMSs for state classification and preliminary control strategies, as it is suitable for rapid deployment in low-complexity scenarios.

Decision trees (DTs) [65] use a tree-like structure to perform classification or regression based on feature conditions, and are used in optimizing battery state predictions. With operational data as the input, DTs split nodes based on information gain, outputting SOH or fault categories, and are commonly used in health classification tasks. Their advantages include clear logic, low computational cost, and the rapid processing of discrete data, which make them suitable for fault diagnosis. DTs reveal key variables through feature selection, offering strong interpretability and facilitating the analysis of influencing factors. However, DTs are prone to overfitting, exhibit poor generalization on small datasets, and have limited effectiveness in continuous dynamic modeling. To improve their performance, DTs are often used as components in ensemble models. DTs perform reliably in preliminary classification tasks, and combining them with automated feature engineering can enhance their applicability in complex conditions.

Hidden Markov models (HMMs) [66] model time-series data based on state transition probabilities, assuming battery states as hidden variables and inferring the SOC or SOH from observed data. They are suitable for cycle degradation prediction. Their strengths include capturing temporal dependencies, which makes them appropriate for sequential state estimation in nonlinear systems with moderate computational efficiency. HMMs handle uncertainty through probabilistic inference, meeting dynamic modeling needs. However, their assumption of Markovian state transitions limits their ability to model complex long-term dependencies, and their training requires substantial data. To improve their accuracy, HMMs are often combined with particle filtering. HMMs perform reliably in SOC estimation and fault detection, and expanding the state space can further enhance their modeling capabilities in multi-condition scenarios.

Bayesian networks (BNs) [67] model probabilistic dependencies between variables using directed graphs, optimizing the conditional distribution of battery states and generating SOH or fault probabilities. They are commonly used for anomaly detection. Their advantages include the ability to integrate multi-source data (e.g., temperature, cycle counts), handle uncertainty through probabilistic inference, and offer strong interpretability, which make them suitable for static or semi-dynamic scenarios with moderate computational complexity. BNs facilitate causal analysis but require careful network structure design, and their inference costs increase in complex scenarios, which limits their dynamic modeling capabilities. To enhance their performance, BNs are often combined with temporal models. BNs are widely applied in fault diagnosis and state classification, and automated structure learning can improve their adaptability across diverse conditions.

Fuzzy neural networks (FNNs) [68] integrate fuzzy logic and neural networks, optimizing state predictions through adaptive rules to generate SOC or RUL predictions, and are suitable for fault diagnosis. Their strengths include leveraging neural networks to automatically adjust membership functions, which reduces their reliance on expert experience and allows them to adapt to complex nonlinear relationships. FNNs combine inference and learning, offering superior accuracy and generalization compared to FL, which makes them suitable for dynamic conditions. However, their training requires substantial data, their hyperparameter tuning is complex, and their computational costs are high. For real-time applications, FNNs often adopt lightweight structures. FNNs excel in state estimation and health management, and integrating online learning can further enhance their dynamic modeling potential in BMSs.

Dynamic Bayesian networks (DBN) [69] extend BNs to time-series data, modeling battery dynamic behavior through temporal probabilities for state parameter estimation. They are suitable for full-lifecycle prediction. Their strengths include capturing long-term dependencies, integrating multisource data to improve their accuracy, and adapting to nonlinear systems in complex conditions. DBNs handle dynamic uncertainty through temporal inference, offering greater flexibility than static BNs. However, they require careful structure and parameter design, their performance is limited with insufficient data, and their computational costs are significant. To enhance their robustness, DBNs are often combined with deep models. DBNs show significant potential in dynamic state estimation, and adaptive structure design can further improve their performance in multi-scenario modeling.

Logic-based methods have evolved from the rule-based inference of fuzzy logic and decision trees to the probabilistic modeling of hidden Markov models and Bayesian networks, and further to the dynamic predictions of fuzzy neural networks and dynamic Bayesian networks. FL and DTs provide intuitive rules, HMMs and BNs excel in sequential and probabilistic inference, while FNNs and DBNs have an enhanced accuracy in complex scenarios. The strengths of logic-based models include strong interpretability, clear rules, suitability for fault diagnosis and state classification, and high computational efficiency. However, their rule design relies on experience, their dynamic modeling capabilities are limited, and FNNs and DBNs require substantial data. Recent advancements in adaptive rules and model integration have improved their flexibility. In the future, simplifying rules, integrating physical knowledge, and adopting online learning will drive the broader application of logic-based models in intelligent battery management.

3.3. Hybrid Models

Hybrid modeling integrates the interpretability of physics-based mechanistic models with the robust fitting capabilities of data-driven models, aiming to address the limitations of both pure white-box models, which heavily rely on mechanistic understanding and exhibit low inference efficiency, and black-box models, which are sensitive to data quality and lack interpretability. By achieving the complementary coupling of physical and data-driven approaches at different modeling levels, hybrid models construct high-accuracy, highly generalizable, and robust frameworks for battery behavior prediction and health assessment. These models have emerged as a research hotspot in energy storage battery system modeling.

In UAV application scenarios, it is challenging for a single modeling approach to simultaneously achieve high computational efficiency and predictive accuracy. Hybrid modeling improves the stability and responsiveness of flight state awareness by combining the real-time capabilities of mathematical models with the pattern recognition strengths of data-driven models. For example, in urban logistics drones, integrating heat conduction equations with long short-term memory networks enables the early warning of thermal runaway risks. In fixed-wing UAVs that are used for emergency rescue missions, incorporating physical priors with transformer networks enhances the robustness of remaining useful life predictions during high-altitude, long-endurance flights. Moreover, hybrid modeling supports lightweight deployment on edge computing platforms, meeting the dual requirements of real-time performance and safety in embedded battery management systems. This provides critical support for high-reliability flight missions.

3.3.1. Series Hybrid Modeling

Series hybrid modeling establishes a sequential connection between physics-based and data-driven models, with the core concept of this method being employing these models in a “pre-processing–post-learning” or “coarse prediction–fine correction” framework. Typically, the physics-based model is positioned at the front end of the system and is responsible for preliminary feature extraction or intermediate variable estimation, while the data-driven model serves as a subsequent module to compensate for errors, refine predictions, or enhance accuracy. This approach preserves the strong interpretability of physics-based models while leveraging the powerful fitting capabilities of data-driven models to improve their prediction accuracy, which makes it particularly suitable for complex system scenarios with incomplete information or features that are difficult to extract directly.

In practical applications, series hybrid modeling is commonly used for state estimation in UAV battery systems. For state-of-charge estimation, researchers often first employ an equivalent circuit model to model the battery’s voltage–current response, generating an initial SOC estimate. However, ECMs are highly condition-dependent and prone to deviations under dynamic loads. To address this, deep learning models, such as long short-term memory networks, can be introduced to model the error sequence between the initial estimate and the true value, dynamically correcting the prediction. Similarly, state-of-health estimation can adopt this structure, using electrochemical impedance characteristics or equivalent parameters to provide physical priors for neural networks and thereby enhance their generalization and interpretability.