Robust Predictive Functional Control for Quadrotor Flight Systems

Abstract

1. Introduction

2. Control Theory

2.1. Problem Statement

2.2. Predictive Functional Control (PFC)

2.3. Robust Predictive Functional Control (RPFC)

2.4. Stability of RPFC

3. Flight Control System Design

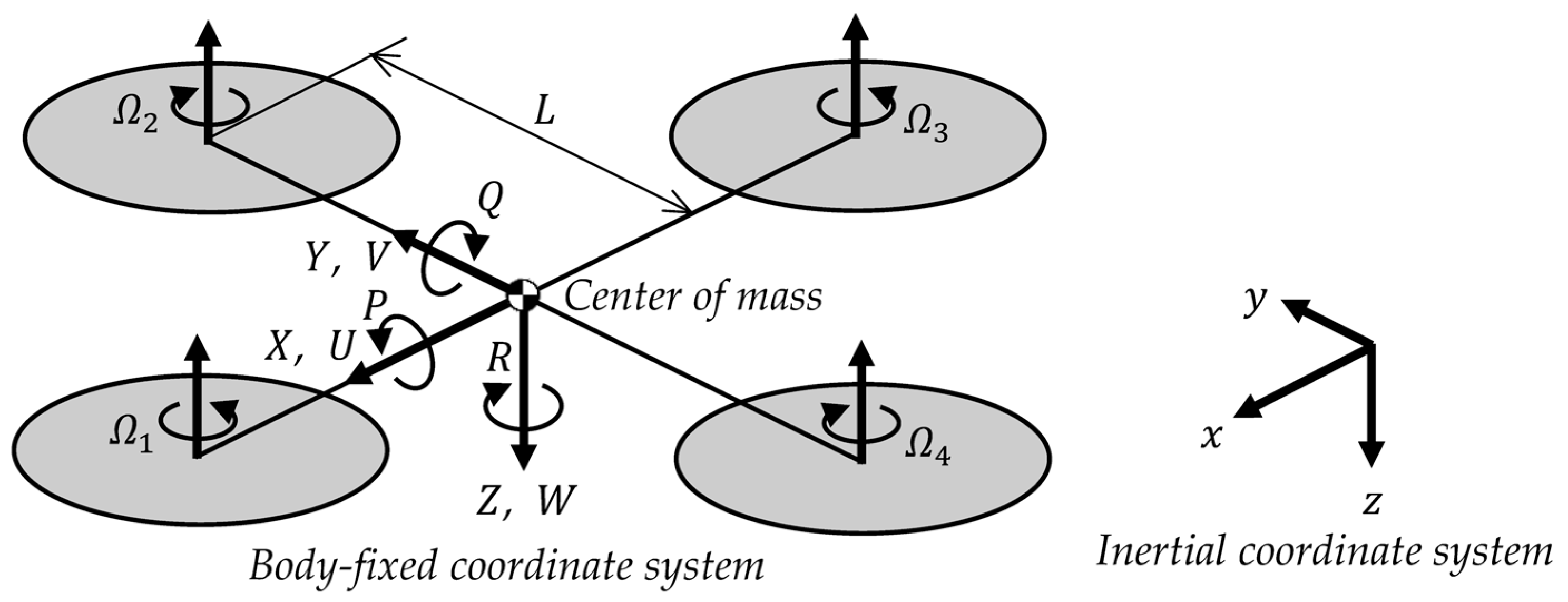

3.1. Nonlinear Dynamics of a Quadrotor

3.2. Linearization of Equations of Motion

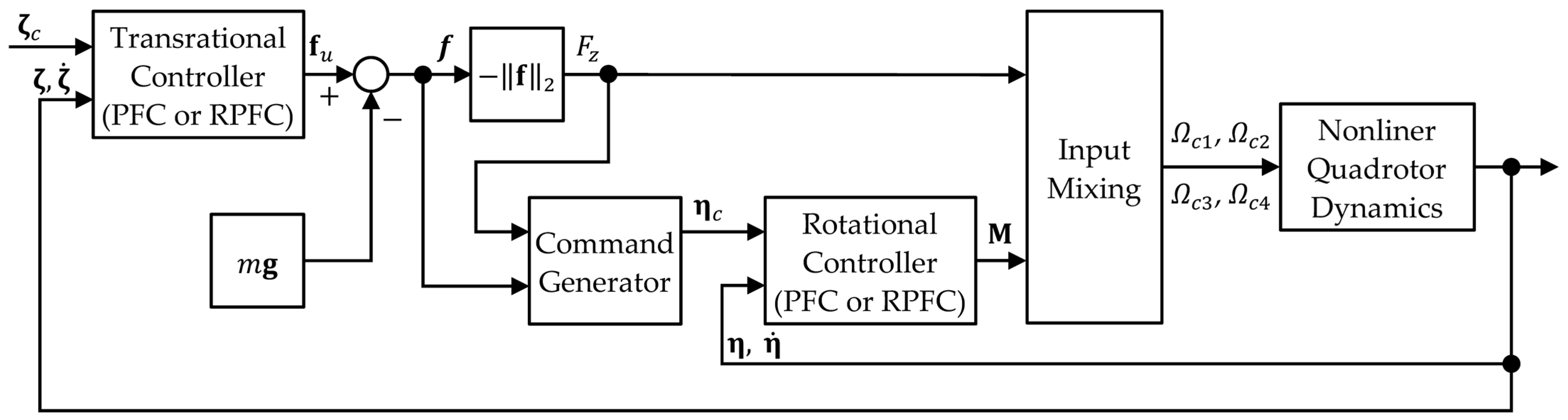

3.3. Flight Control System of the Quadrotor

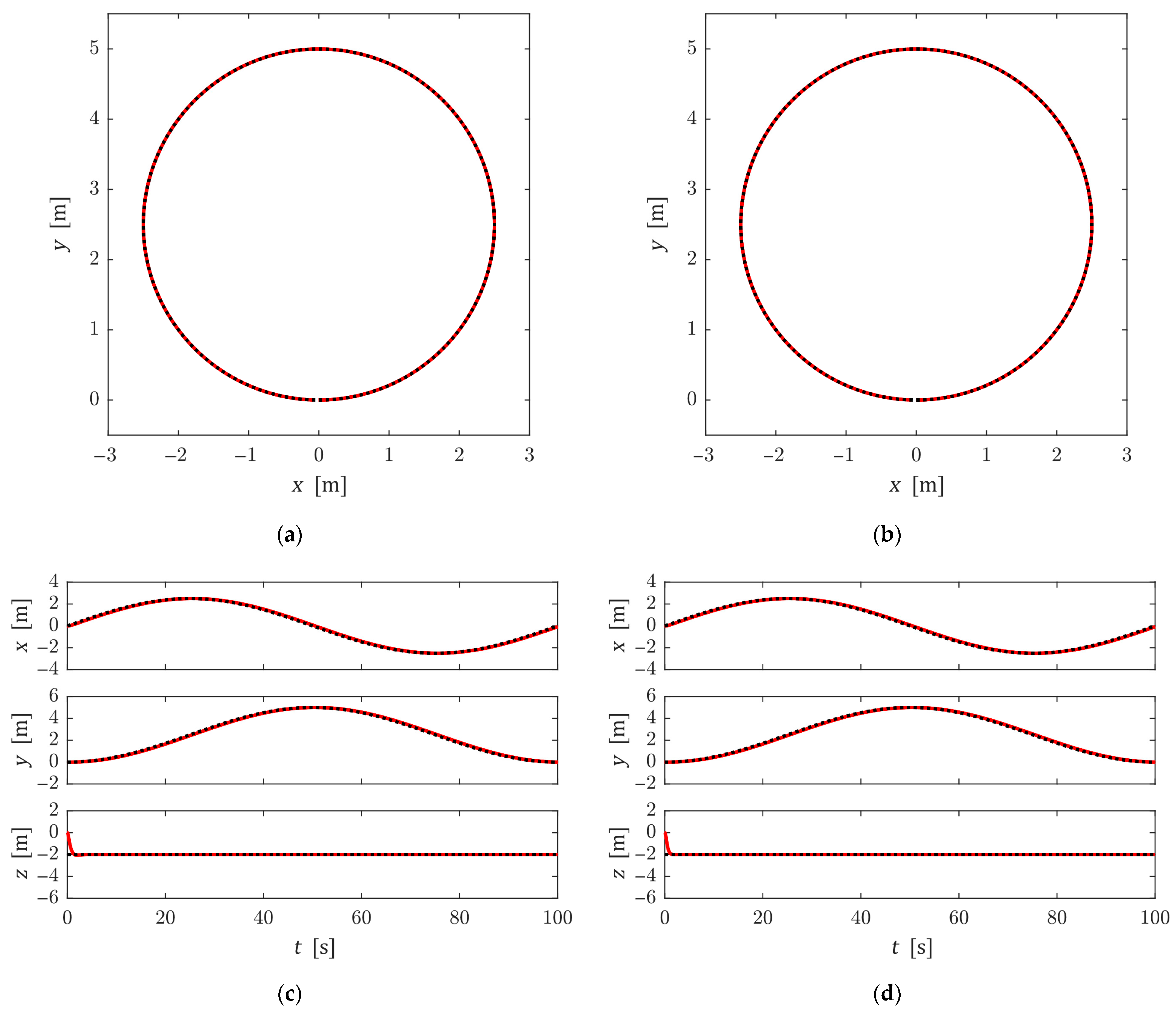

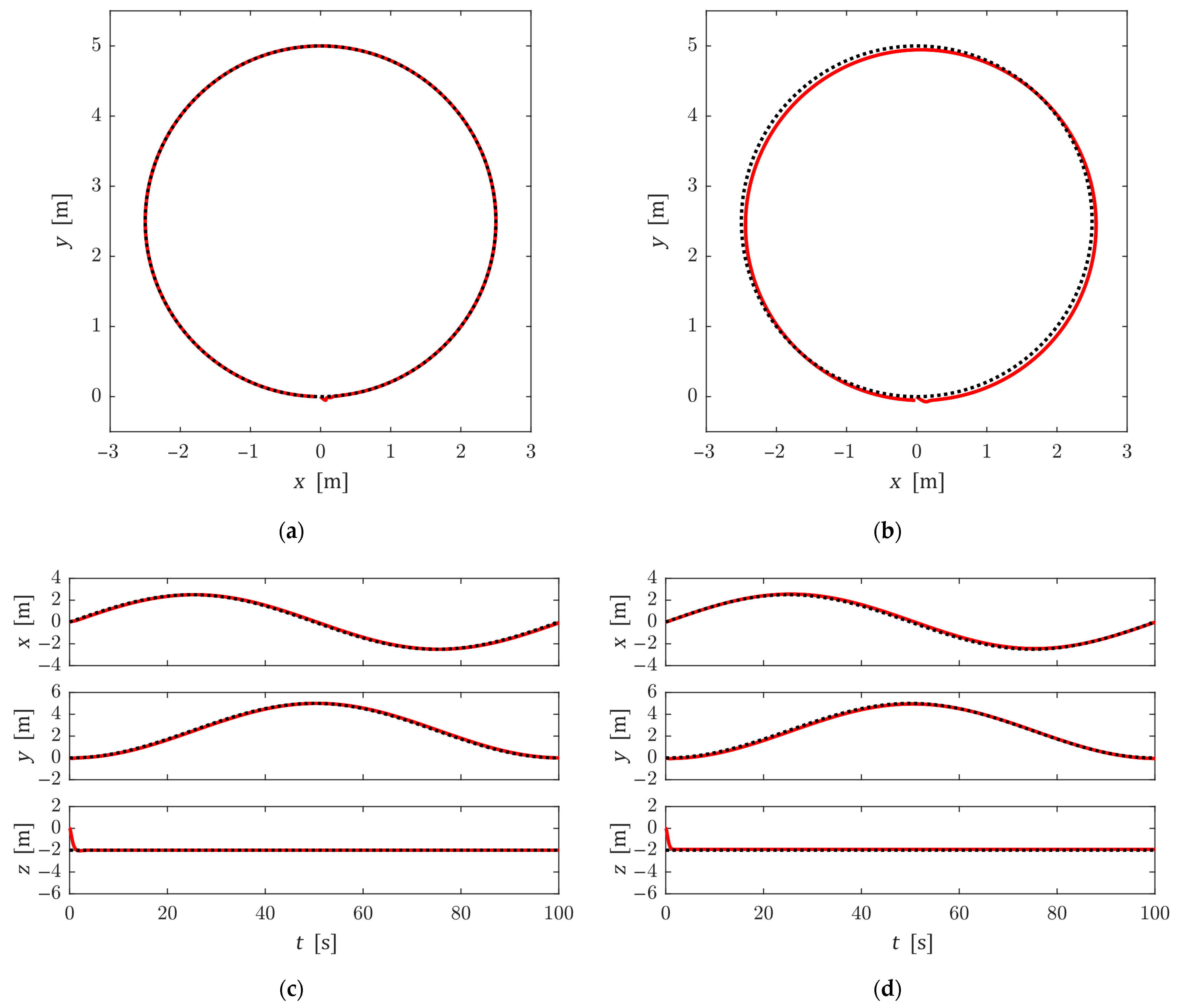

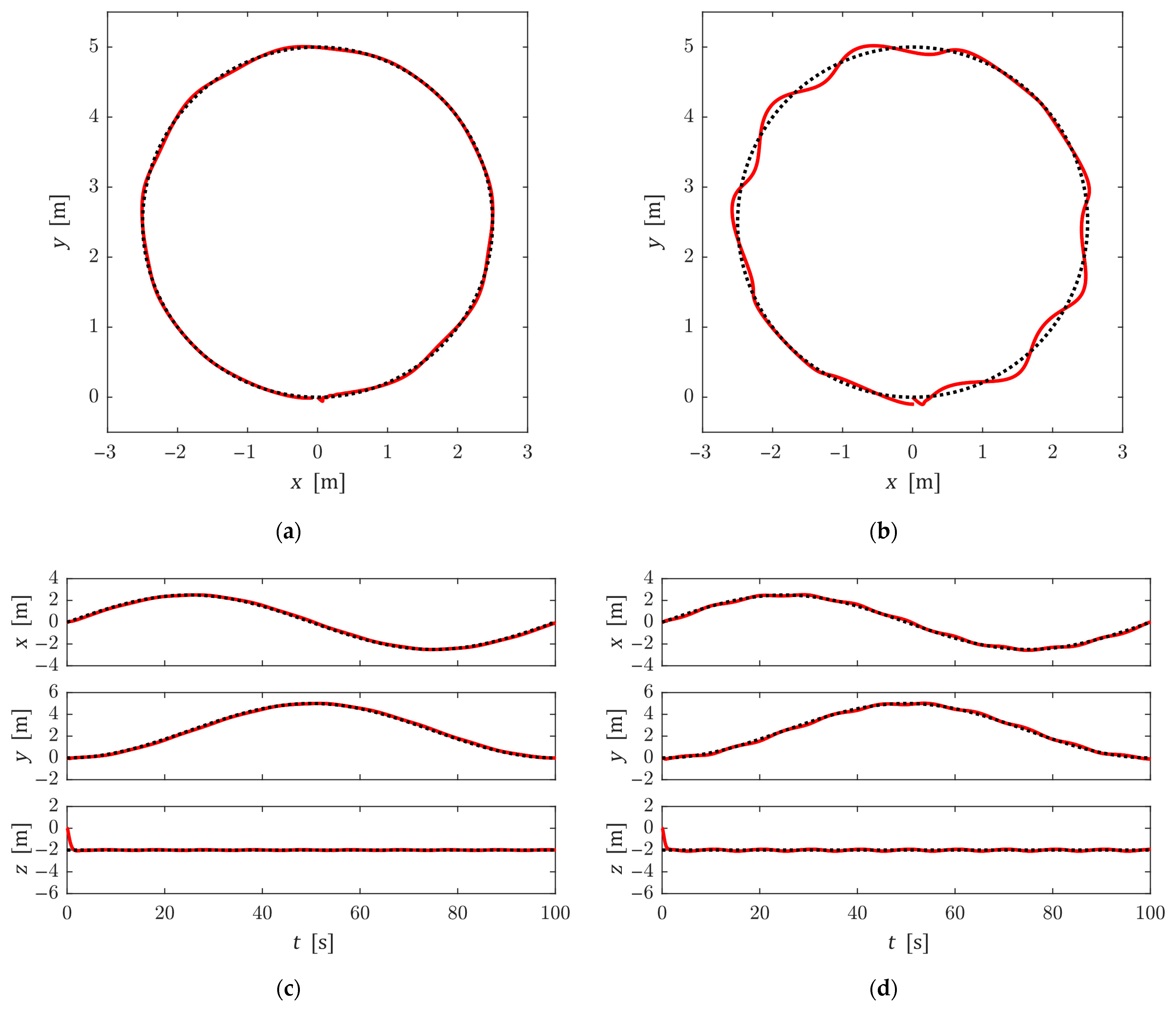

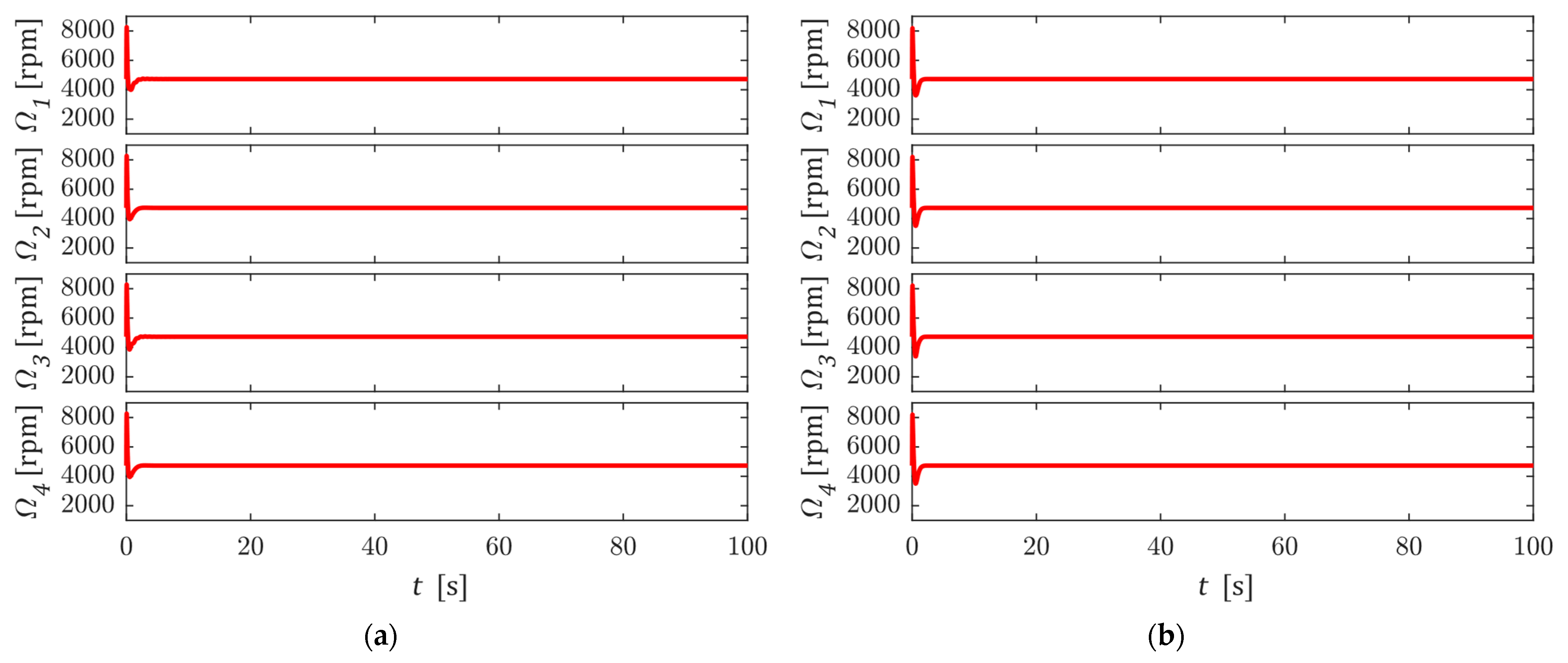

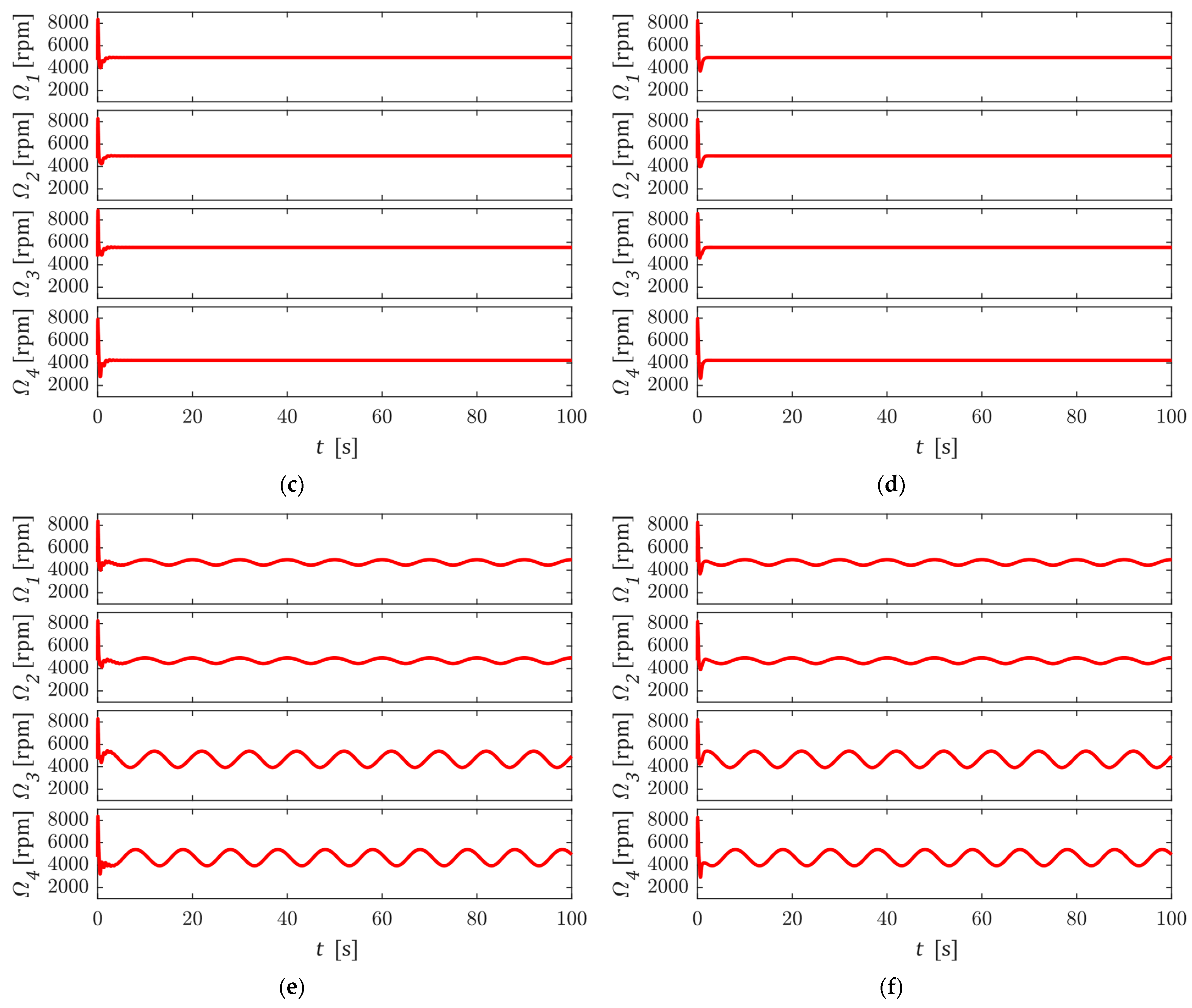

4. Numerical Simulation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Maciejowski, J.M. Predictive Control: With Constraints; Prentice Hall Press: Hoboken, NJ, USA, 2000. [Google Scholar]

- Morari, M.; Lee, J.H. Model Predictive Control: Past, Present and Future. J. Comput. Appl. Chem. Eng. 1999, 23, 667–682. [Google Scholar] [CrossRef]

- Qin, S.J.; Badgwell, T.A. A Survey of Industrial Model Predictive Control Technology. IFAC Control. Eng. Pract. 2003, 11, 733–764. [Google Scholar] [CrossRef]

- Nguyen, H.; Kamel, M.; Alexis, K.; Siegwart, R. Model Predictive Control for Micro Aerial Vehicles: A Survey. In Proceedings of the European Control Conference (ECC), Delft, The Netherlands, 29 June–2 July 2021; pp. 1556–1563. [Google Scholar] [CrossRef]

- Eren, U.; Prach, A.; Kocer, B.B.; Rakovic, S.V.; Kayacan, E.; Acikmese, B. Model Predictive Control in Aerospace Systems: Current State and Opportunities. AIAA J. Guid. Control. Dyn. 2017, 40, 1541–1566. [Google Scholar] [CrossRef]

- Oh, D.D.; Byun, J.; Lee, D. Real-Time Trajectory Generation of a Quadrotor UAV with Load Suspended from a Pulley. In Proceedings of the International Conference on Control, Automation and Systems (ICCAS), Jeju, Republic of Korea, 27 November–1 December 2022; pp. 1309–1314. [Google Scholar] [CrossRef]

- Islam, M.; Idres, M.M. Dynamics and Control of Quadcopter Using Linear Model Predictive Control Approach. IOP Conf. Ser. Mater. Sci. Eng. 2017, 270, 012007. [Google Scholar] [CrossRef]

- Koo, S.; Kim, S.; Suk, J. Model Predictive Control for UAV Automatic Landing on Moving Carrier Deck with Heave Motion. IFAC-PapersOnLine 2015, 48, 59–64. [Google Scholar] [CrossRef]

- Romero, A.; Sun, S.; Foehn, P.; Scaramuzza, D. Model Predictive Contouring Control for Time-Optimal Quadrotor Flight. IEEE Trans. Robot. 2022, 38, 3340–3356. [Google Scholar] [CrossRef]

- Mao, S.; Tan, W.K.; Low, K.H. Autonomous Formation Flight of Indoor UAVs Based on Model Predictive Control. In Proceedings of the AIAA Science and Technology (SciTech) Forum, San Diego, CA, USA, 3–7 January 2016; p. 0515. [Google Scholar] [CrossRef]

- Richalet, J.; Ata-Doss, S.E.; Arber, C.; Kuntze, H.; Jacubasch, A.; Schill, W. Predictive Functional Control-Application to Fast and Accurate Robots. IFAC Proc. Vol. 1987, 20, 251–258. [Google Scholar] [CrossRef]

- Richalet, J.; O’Donovan, D. Predictive Functional Control: Principles and Industrial Applications, 2009th ed.; Springer: Berlin, Germany, 2009. [Google Scholar]

- Vivas, A.; Poignet, P. Model Based Predictive Control of a Fully Parallel Robot. In Proceedings of the 7th IFAC Symposium on Robot Control, Wroclaw, Poland, 1–3 September 2003; pp. 279–284. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Satoh, T.; Nagase, J.; Saga, N. Comparison between PFC and PID Control Systems for a Pneumatic Cylinder. IEEJ Trans. Electr. Electron. Eng. 2015, 10, 605–607. [Google Scholar] [CrossRef]

- Nagase, J.; Satoh, T.; Saga, N.; Suzumori, K. Predictive Functional Control of Tendon-Driven Actuator Using Pneumatic Balloon. J. Adv. Mech. Des. Syst. Manuf. 2013, 7, 752–762. [Google Scholar] [CrossRef]

- Satoh, T.; Kaneko, K.; Saito, N. Performance Improvement of Predictive Functional Control: A Disturbance Observer Approach. In Proceedings of the 37th Annual Conference of the IEEE Industrial Electronics Society, Victoria, Australia, 7–10 November 2011; pp. 279–284. [Google Scholar] [CrossRef]

- Hara, H.; Satoh, T.; Saito, N.; Nagase, J.; Saga, N. Disturbance Observer-Based Predictive Functional Control Using Zero Phase Error Tracking Controller. In Proceedings of the World Congress on Industrial Control Systems Security, London, UK, 14–16 December 2015; pp. 19–20. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, H.; Jiang, Z.; Hu, F.; Zhang, W. Robust Predictive Functional Control for Flight Vehicles Based on Nonlinear Disturbance Observer. Int. J. Aerosp. Eng. 2015, 2015, 1–16. [Google Scholar] [CrossRef][Green Version]

- Utkin, V.I. Sliding Mode Control in Mechanical Systems. In Proceedings of the Annual Conference of IEEE Industrial Electronics, Bologna, Italy, 5–9 September 1994; pp. 1429–1431. [Google Scholar] [CrossRef]

- Utkin, V.I. Sliding Modes in Control and Optimization, 1st ed.; Springer: Berlin, Germany, 1992; pp. 1–73. [Google Scholar]

- Utkin, V.I. Integral Sliding Mode in Systems Operating under Uncertainty Conditions. In Proceedings of the IEEE Conference on Decision and Control (CDC), Kobe, Japan, 11–13 December 1996; pp. 4591–4596. [Google Scholar] [CrossRef]

- Rubagotti, M.; Estrada, A.; Castanos, F.; Ferrara, A.; Fridman, L. Integral Sliding Mode Control for Nonlinear Systems With Matched and Unmatched Perturbations. IEEE Trans. Autom. Control. 2011, 56, 2699–2704. [Google Scholar] [CrossRef]

- Pan, Y.; Yang, C.; Pan, L.; Yu, H. Integral Sliding Mode Control: Performance, Modification, and Improvement. IEEE Trans. Ind. Inform. 2018, 14, 3087–3096. [Google Scholar] [CrossRef]

- Woodham, C.A.; Zinober, A.S.I. Eigenvalue Placement in a Specified Sector for Variable Structure Control Systems. Int. J. Control. 1993, 57, 1021–1037. [Google Scholar] [CrossRef]

- Castillo, I.; Fridman, L. MATLAB Toolbox for Singular LQ Based Sliding Mode Control Design. In Proceedings of the IEEE Conference on Decision and Control, Firenze, Italy, 10–13 December 2013; pp. 4242–4247. [Google Scholar] [CrossRef]

- Bhattacharjee, D.; Subbarao, K. Robust Control Strategy for Quadcopters using Sliding Mode Control and Model Predictive Control. In Proceedings of the AIAA Science and Technology (SciTech) Forum, Orlando, FL, USA, 6–10 January 2020; pp. 2020–2071. [Google Scholar] [CrossRef]

- Rubagotti, M.; Raimondo, D.M.; Ferrara, A.; Magni, L. Robust Model Predictive Control With Integral Sliding Mode in Continuous-Time Sampled-Data Nonlinear Systems. IEEE Trans. Autom. Control. 2011, 56, 556–570. [Google Scholar] [CrossRef]

- Xiao, H.; Zhao, D.; Gao, S.; Spurgeon, S.K. Sliding Mode Predictive Control: A Survey. Annu. Rev. Control. 2022, 54, 148–166. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, W.; Tomizuka, M.; Alsuwaidan, B.N. Model Predictive Sliding Mode Control: For Constraint Satisfaction and Robustness. In Proceedings of the Dynamic Systems and Control Conference, Palo Alto, CA, USA, 21–23 October 2013. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Z.; Pei, R. Sliding Mode Model Predictive Control with Terminal Constraints. In Proceedings of the 3rd World Congress on Intelligent Control and Automation, Hefei, China, 26 June–2 July 2000; pp. 2791–2795. [Google Scholar] [CrossRef]

- Masuda, K.; Uchiyama, K. Extended Model Predictive Control: Robust Controller with Matching Condition. Trans. JSME 2020, 86, 19-00300. (In Japanese) [Google Scholar] [CrossRef]

- Masuda, K.; Uchiyama, K. Control System Design by using Extended Model Predictive Control for The Quadrotor. In Proceedings of the AIAA Science and Technology (SciTech) Forum, San Diego, CA, USA, 3–7 January 2022; p. 2022-0753. [Google Scholar] [CrossRef]

- Masuda, K.; Uchiyama, K. Attitude Control System for Quadrotor Using Robust Monte Carlo Model Predictive Control. Actuators 2024, 13, 443. [Google Scholar] [CrossRef]

- Franklin, G.F.; Powell, J.D.; Workman, M.L. Digital Control of Dynamic Systems, 3rd ed.; Prentice Hall Press: Hoboken, NJ, USA, 1997. [Google Scholar]

| Physical Significance | Symbol | Value |

|---|---|---|

| Mass of quadrotor | ||

| Distance from the center of mass to each rotor | ||

| Moments of inertia | ||

| Lift coefficient of the propellers | ||

| Drag coefficient of the propellers | ||

| Time constant of the propellers | ||

| Sampling time | ||

| Simulation time | ||

| Sample size | ||

| Amplitudes of the target position | ||

| Angular frequency of the target position | ||

| Magnitudes of the disturbances | ||

| Magnitudes of the disturbances | ||

| Angular frequency of the disturbance |

| Physical Significance | Symbol | Value |

|---|---|---|

| Coincidence point for output | ||

| Coincidence point for switching function | ||

| Time constant of the reference trajectory | ||

| Time constant of the reference trajectory | ||

| Coefficient matrix of the hypersurface |

| Physical Significance | Symbol | Value |

|---|---|---|

| Coincidence point for output | ||

| Coincidence point for switching function | ||

| Time constant of the reference trajectory | ||

| Time constant of the reference trajectory | ||

| Coefficient matrix of the hypersurface |

| Condition | Disturbance | Disturbance |

|---|---|---|

| 1 | ||

| 2 | ||

| 3 |

| Condition | Output | RPFC | Difference (vs. PFC) | PFC |

|---|---|---|---|---|

| 1 | 33.080 | +2.747% | 32.195 | |

| 33.276 | +2.445% | 32.482 | ||

| 149.206 | +6.991% | 139.457 | ||

| 0.000 | 0.000% | 0.000 | ||

| 0.051 | +65.273% | 0.031 | ||

| 0.000 | 0.000% | 0.000 | ||

| 2 | 32.633 | −50.616% | 66.080 | |

| 33.429 | −45.906% | 61.798 | ||

| 152.078 | −23.536% | 198.890 | ||

| 0.635 | −96.716% | 19.341 | ||

| 0.449 | −97.058% | 15.249 | ||

| 0.001 | −99.973% | 5.464 | ||

| 3 | 35.078 | −52.805% | 74.326 | |

| 35.746 | −53.222% | 76.418 | ||

| 154.495 | −14.351% | 180.381 | ||

| 1.372 | −90.201% | 14.001 | ||

| 1.066 | −90.638% | 11.391 | ||

| 0.008 | −99.718% | 2.732 |

| Condition | Input | RPFC | Difference (vs. PFC) | PFC |

|---|---|---|---|---|

| 1 | 245,167 | 0.0000% | 245,167 | |

| 245,167 | 0.0000% | 245,167 | ||

| 245,167 | 0.0000% | 245,167 | ||

| 245,167 | 0.0000% | 245,167 | ||

| 2 | 267,610 | +0.0035% | 267,601 | |

| 267,607 | +0.0026% | 267,600 | ||

| 337,607 | +0.0022% | 337,599 | ||

| 197,604 | +0.0030% | 197,598 | ||

| 3 | 243,909 | +0.0064% | 243,893 | |

| 243,901 | +0.0046% | 243,890 | ||

| 243,903 | +0.0057% | 243,890 | ||

| 243,897 | +0.0040% | 243,887 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masuda, K.; Uchiyama, K. Robust Predictive Functional Control for Quadrotor Flight Systems. Drones 2025, 9, 506. https://doi.org/10.3390/drones9070506

Masuda K, Uchiyama K. Robust Predictive Functional Control for Quadrotor Flight Systems. Drones. 2025; 9(7):506. https://doi.org/10.3390/drones9070506

Chicago/Turabian StyleMasuda, Kai, and Kenji Uchiyama. 2025. "Robust Predictive Functional Control for Quadrotor Flight Systems" Drones 9, no. 7: 506. https://doi.org/10.3390/drones9070506

APA StyleMasuda, K., & Uchiyama, K. (2025). Robust Predictive Functional Control for Quadrotor Flight Systems. Drones, 9(7), 506. https://doi.org/10.3390/drones9070506