Minimum Snap Trajectory Planning and Augmented MPC for Morphing Quadrotor Navigation in Confined Spaces

Abstract

1. Introduction

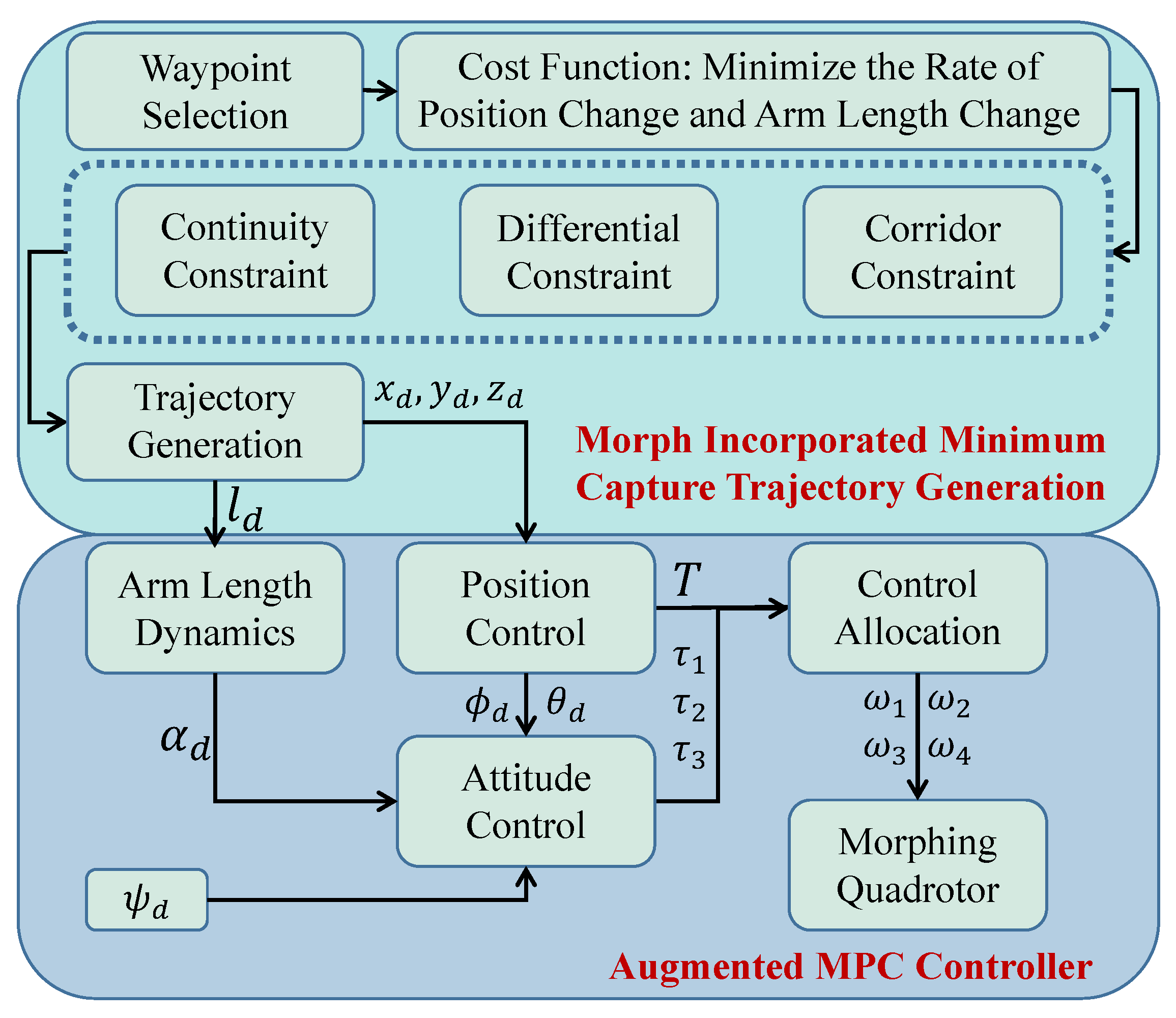

2. Dynamic Modeling and Controller Design

2.1. Dynamic Model of the Morphing Quadrotor

2.1.1. Position Dynamics

2.1.2. Attitude Dynamics

2.1.3. Identification of Arm Length Dynamics

2.2. Differential Flatness of the Morphing Quadrotor

2.3. Augmented Model Predictive Control

2.3.1. Augmented Model

2.3.2. Output Prediction

2.3.3. Constraints

2.3.4. Optimization

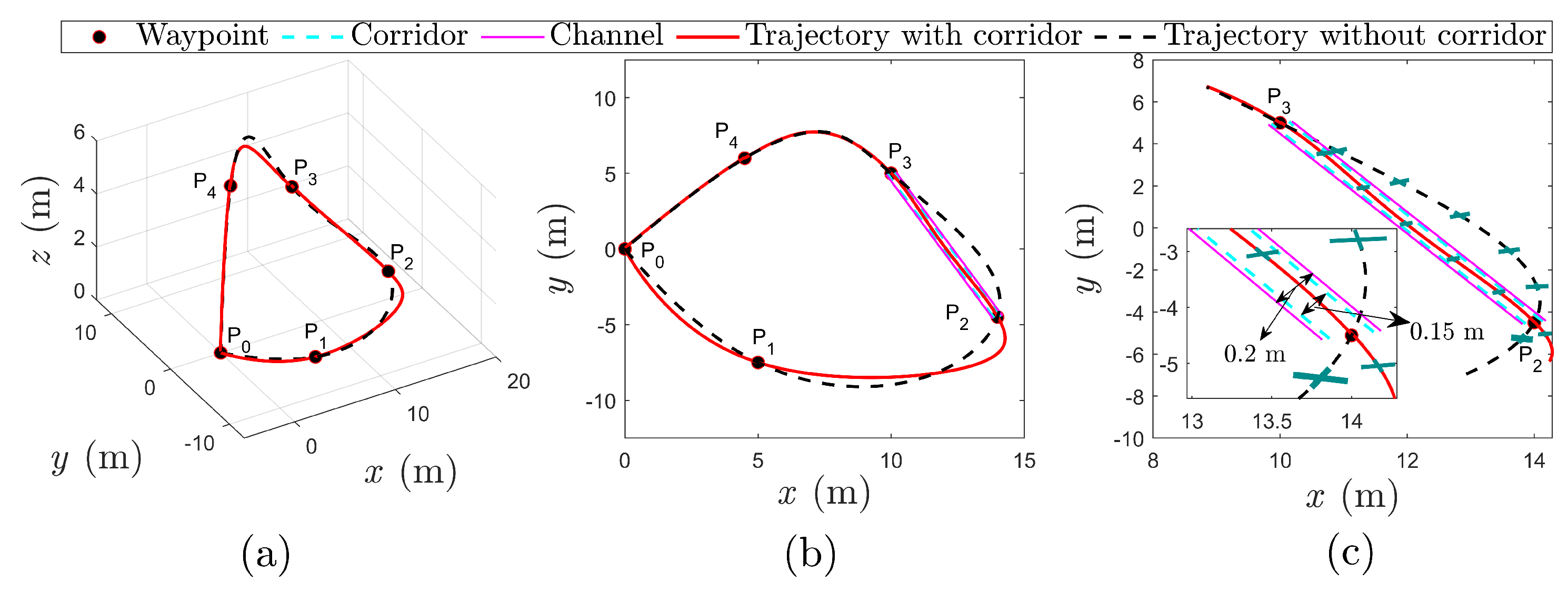

3. Trajectory Generation with Corridor Constraints

3.1. Determining Objective Function

3.2. Adding Equality Constraints

3.2.1. Waypoint Constraint

3.2.2. Continuity Constraint

3.2.3. Differential Constraint

3.3. Adding Inequality Constraint

4. Numerical Studies and Results

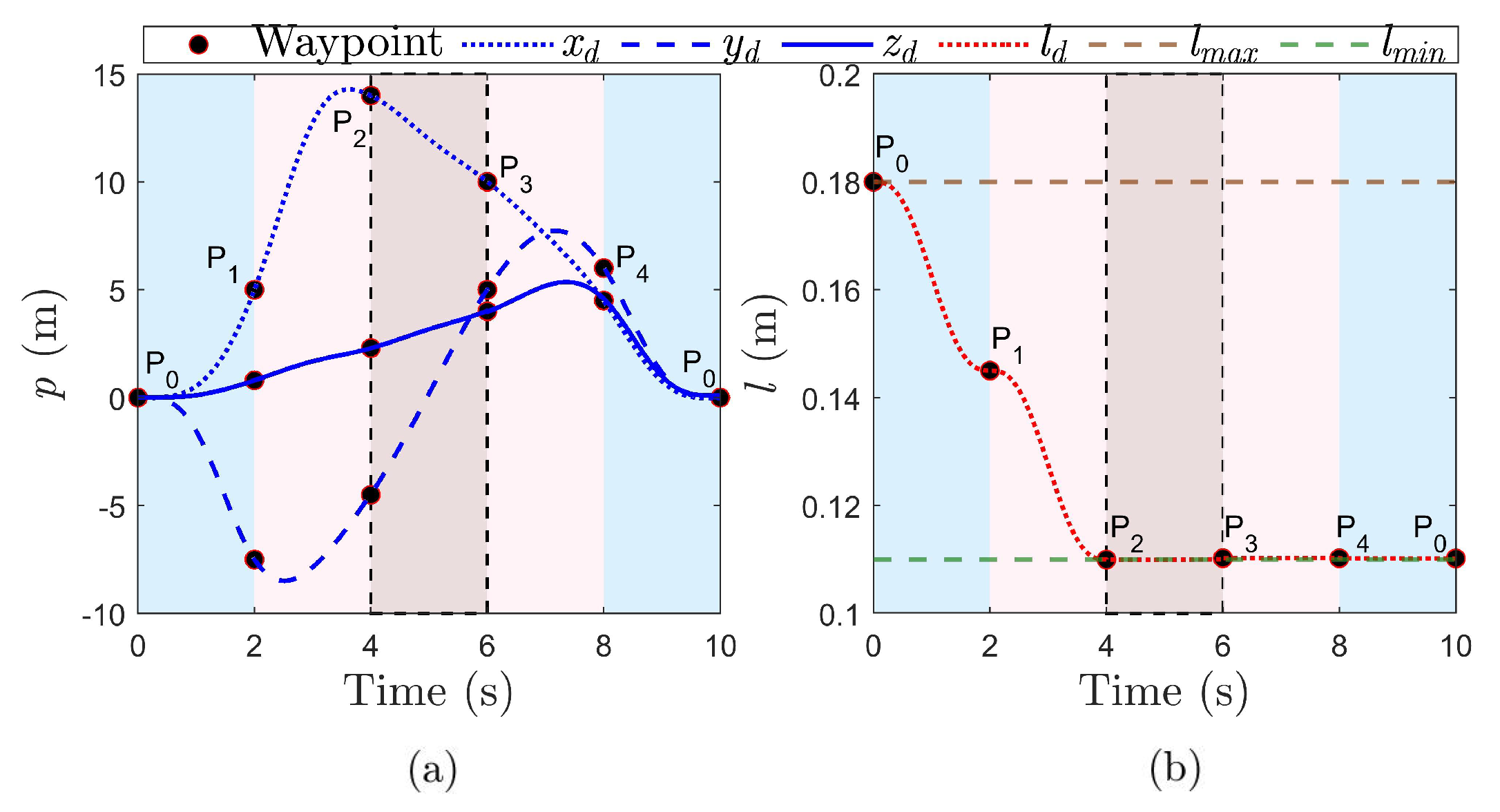

4.1. Trajectory Planning Results

4.1.1. Experimental Setup

4.1.2. Experimental Results

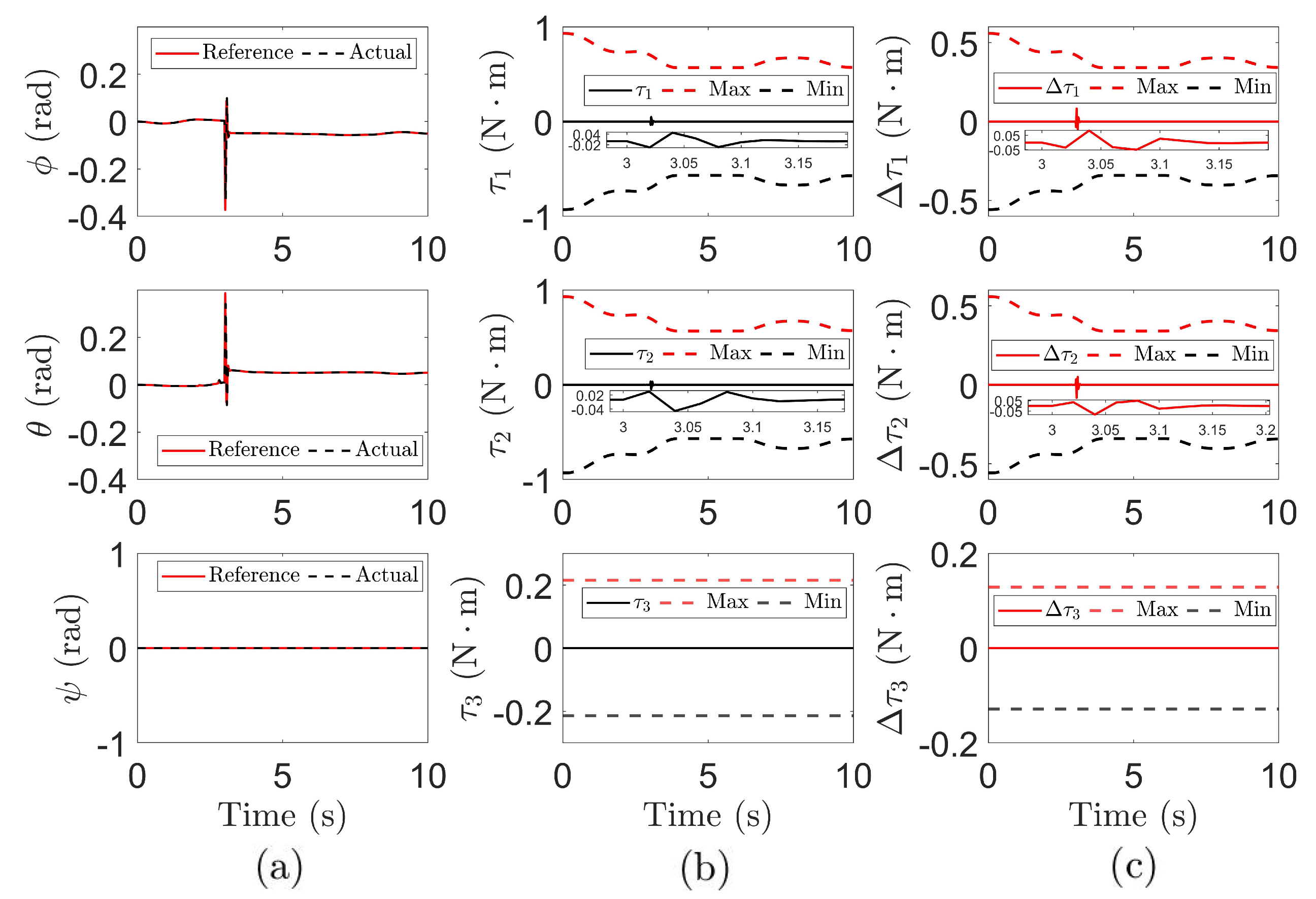

4.2. Augmented MPC-Based Controller Results

4.2.1. Experimental Setup

4.2.2. Experimental Results

4.3. Robustness Test Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PID | Proportional-Integral-Derivative |

| RRT | Rapidly Exploring Random Tree |

| LQR | Linear Quadratic Regulato |

| DOF | Degree of Freedom |

| MPC | Model Predictive Control |

| LTI | Linear Time-Invariant |

| LPV | Linear Parameter-Varying |

References

- Ollero, A.; Tognon, M.; Suarez, A.; Lee, D.; Franchi, A. Past, Present, and Future of Aerial Robotic Manipulators. IEEE Trans. Robot. 2022, 38, 626–645. [Google Scholar] [CrossRef]

- Loianno, G.; Scaramuzza, D. Special Issue on Future Challenges and Opportunities in Vision-Based Drone Navigation. J. Field Robot. 2020, 37, 1–8. [Google Scholar] [CrossRef]

- Zhao, N.; Luo, Y.; Deng, H.; Shen, Y. The Deformable Quad-Rotor: Design, Kinematics and Dynamics Characterization, and Flight Performance Validation. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 2391–2396. [Google Scholar]

- Zhao, M.; Anzai, T.; Shi, F.; Chen, X.; Okada, K.; Inaba, M. Design Modeling and Control of an Aerial Robot Dragon: A Dual-Rotor-Embedded Multilink Robot with the Ability of Multi-Degree-of-Freedom Aerial Transformation. IEEE Robot. Autom. Lett. 2018, 3, 1176–1183. [Google Scholar] [CrossRef]

- Falanga, D.; Kleber, K.; Mintchev, S.; Floreano, D.; Scaramuzza, D. The Foldable Drone: A Morphing Quadrotor That Can Squeeze and Fly. IEEE Robot. Autom. Lett. 2019, 4, 209–216. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, F.; Wang, Z.; Wang, K.; Cao, Y.; Xu, C.; Gao, F. Ring-Rotor: A Novel Retractable Ring-Shaped Quadrotor with Aerial Grasping and Transportation Capability. IEEE Robot. Autom. Lett. 2023, 8, 2126–2133. [Google Scholar] [CrossRef]

- Bucki, N.; Tang, J.; Mueller, M.W. Design and Control of a Midair-Reconfigurable Quadcopter Using Unactuated Hinges. IEEE Trans. Robot. 2023, 39, 539–557. [Google Scholar] [CrossRef]

- Xu, M.; De, Q.; Yu, D.; Hu, A.; Liu, Z.; Wang, H. Biomimetic Morphing Quadrotor Inspired by Eagle Claw for Dynamic Grasping. IEEE Trans. Robot. 2024, 40, 2513–2528. [Google Scholar] [CrossRef]

- Zhao, N.; Luo, Y.; Wang, G.; Shen, Y. A Deployable Articulated Mechanism Enabled In-Flight Morphing Aerial Gripper. Mech. Mach. Theory 2022, 167, 104518. [Google Scholar] [CrossRef]

- Patnaik, K.; Zhang, W. Adaptive Attitude Control for Foldable Quadrotors. IEEE Control Syst. Lett. 2023, 7, 1291–1296. [Google Scholar] [CrossRef]

- Xing, S.; Zhang, X.; Tian, J.; Xie, C.; Chen, Z.; Sun, J. Morphing Quadrotors: Enhancing Versatility and Adaptability in Drone Applications—A Review. Drones 2024, 8, 762. [Google Scholar] [CrossRef]

- Cui, G.; Xia, R.; Jin, X.; Tang, Y. Motion Planning and Control of a Morphing Quadrotor in Restricted Scenarios. IEEE Robot. Autom. Lett. 2024, 9, 5759–5766. [Google Scholar] [CrossRef]

- González, D.; Pérez, J.; Milanés, V.; Nashashibi, F. A Review of Motion Planning Techniques for Automated Vehicles. IEEE Trans. Intell. Transp. Syst. 2016, 17, 1135–1145. [Google Scholar] [CrossRef]

- Hart, P.E.; Nilsson, N.J.; Raphael, B. A Formal Basis for the Heuristic Determination of Minimum Cost Paths. IEEE Trans. Syst. Sci. Cybern. 1968, 4, 100–107. [Google Scholar] [CrossRef]

- Karaman, S.; Frazzoli, E. Sampling-Based Algorithms for Optimal Motion Planning. Int. J. Robot. Res. 2011, 30, 846–894. [Google Scholar] [CrossRef]

- Mellinger, D.; Kumar, V. Minimum Snap Trajectory Generation and Control for Quadrotors. In Proceedings of the 2011 IEEE International Conference on Robotics and Automation, Shanghai, China, 9–13 May 2011; pp. 2520–2525. [Google Scholar]

- Patnaik, K.; Zhang, W. Towards Reconfigurable and Flexible Multirotors: A Literature Survey and Discussion on Potential Challenges. Int. J. Intell. Robot. Appl. 2021, 5, 365–380. [Google Scholar] [CrossRef]

- Desbiez, A.; Expert, F.; Boyron, M.; Diperi, J.; Viollet, S.; Ruffier, F. X-Morf: A Crash-Separable Quadrotor That Morfs Its X-Geometry in Flight. In Proceedings of the 2017 Workshop on Research, Education and Development of Unmanned Aerial Systems (RED-UAS), Cartagena, Spain, 8–10 November 2017; pp. 222–227. [Google Scholar]

- Yang, D.; Mishra, S.; Aukes, D.M.; Zhang, W. Design, Planning, and Control of an Origami-Inspired Foldable Quadrotor. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019; pp. 2551–2556. [Google Scholar]

- Zhao, N.; Luo, Y.; Qin, C.; Luo, X.; Chen, R.; Shen, Y. Attitude Control for Morphing Quadrotor through Model Predictive Control with Constraints. In Proceedings of the 2024 IEEE International Conference on Robotics and Automation (ICRA), Yokohama, Japan, 13–17 May 2024; pp. 10489–10495. [Google Scholar]

- Rossiter, J.A. Model-Based Predictive Control: A Practical Approach; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, C.; Zhao, N.; Wang, Q.; Luo, Y.; Shen, Y. Minimum Snap Trajectory Planning and Augmented MPC for Morphing Quadrotor Navigation in Confined Spaces. Drones 2025, 9, 304. https://doi.org/10.3390/drones9040304

Qin C, Zhao N, Wang Q, Luo Y, Shen Y. Minimum Snap Trajectory Planning and Augmented MPC for Morphing Quadrotor Navigation in Confined Spaces. Drones. 2025; 9(4):304. https://doi.org/10.3390/drones9040304

Chicago/Turabian StyleQin, Chaojun, Na Zhao, Qiuyu Wang, Yudong Luo, and Yantao Shen. 2025. "Minimum Snap Trajectory Planning and Augmented MPC for Morphing Quadrotor Navigation in Confined Spaces" Drones 9, no. 4: 304. https://doi.org/10.3390/drones9040304

APA StyleQin, C., Zhao, N., Wang, Q., Luo, Y., & Shen, Y. (2025). Minimum Snap Trajectory Planning and Augmented MPC for Morphing Quadrotor Navigation in Confined Spaces. Drones, 9(4), 304. https://doi.org/10.3390/drones9040304