Full-Vehicle Experimental Investigation of Propeller Icing on a Hovering Quadcopter

Abstract

1. Introduction

2. Proposed System Overview and Methodology

2.1. UAV Propeller Model

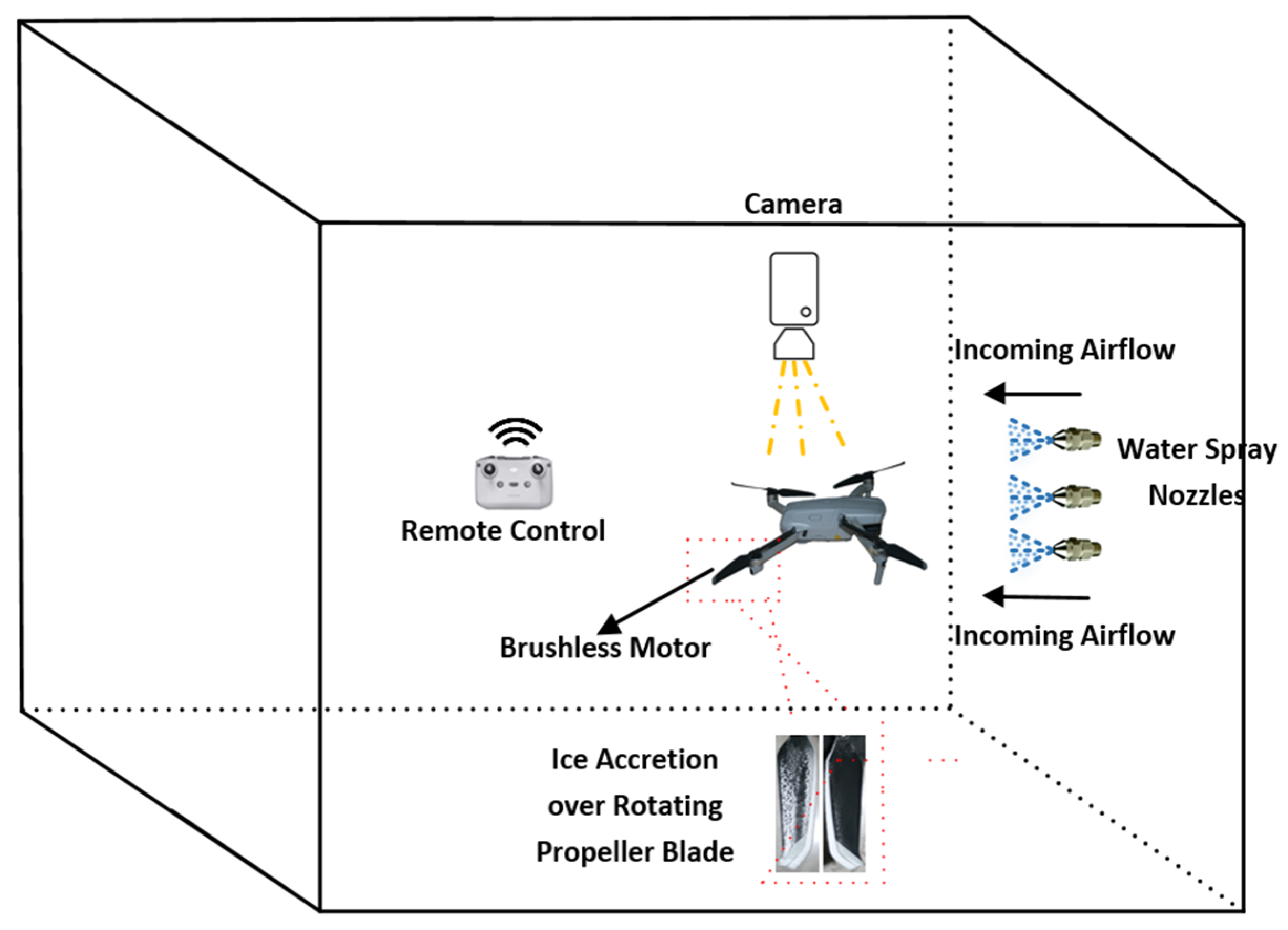

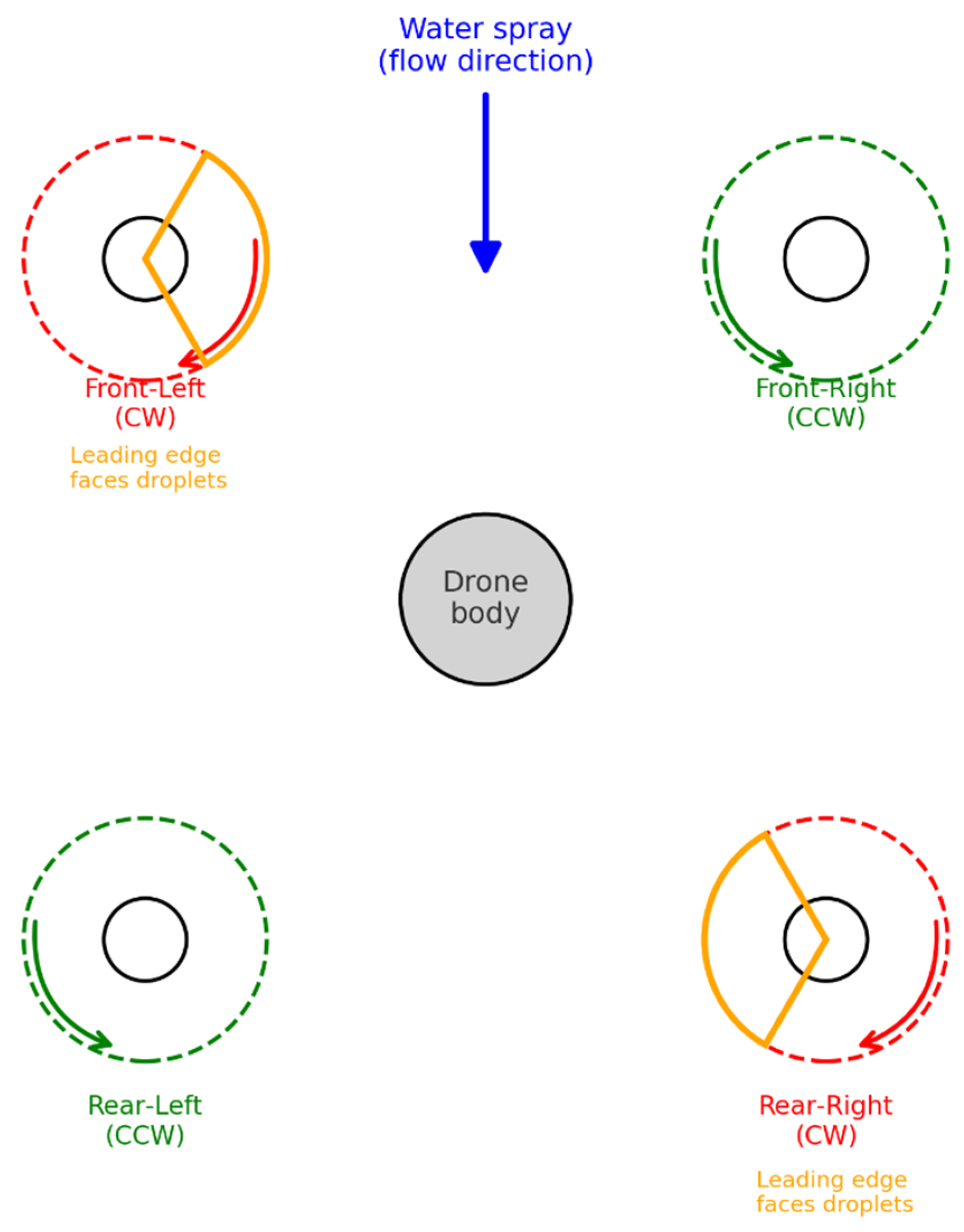

2.2. Experimental Setup

2.3. Analysis of Key Aerodynamic and Icing Parameters

3. Measurement Results and Discussion

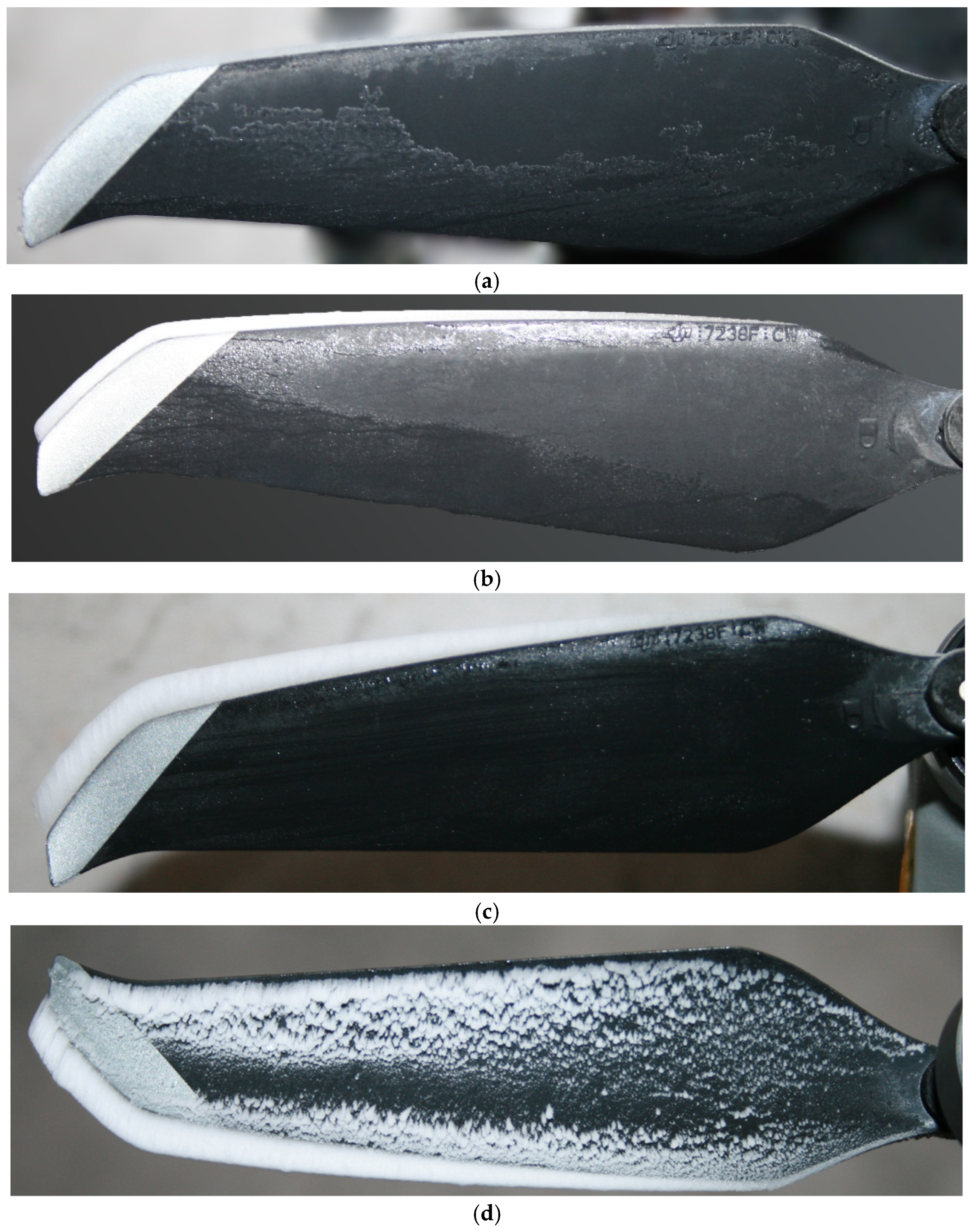

3.1. Analysis of Rime Ice Accretion on Rotating Propeller Surfaces

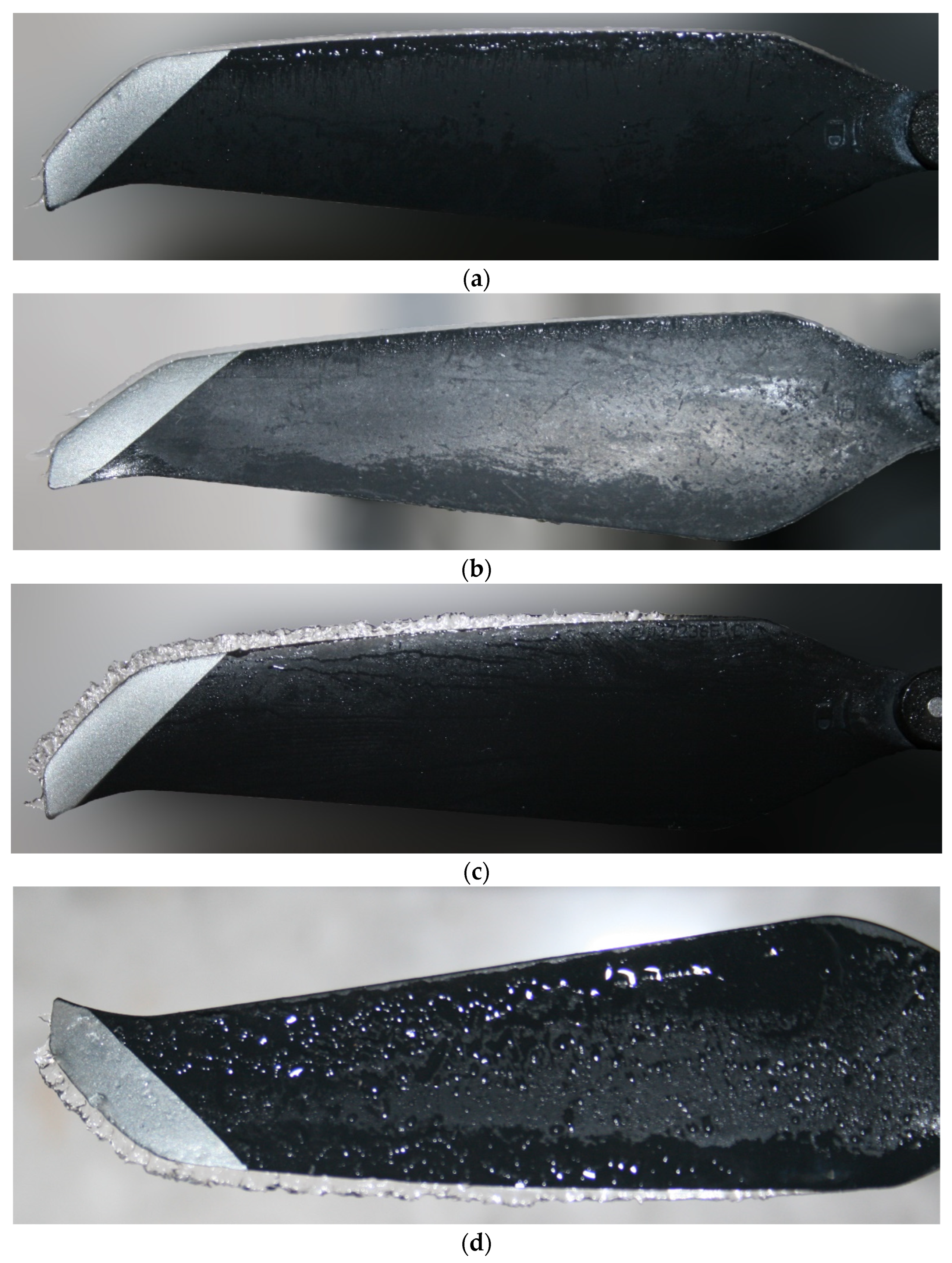

3.2. Analysis of Glaze Ice Accretion on Rotating Propeller Surfaces

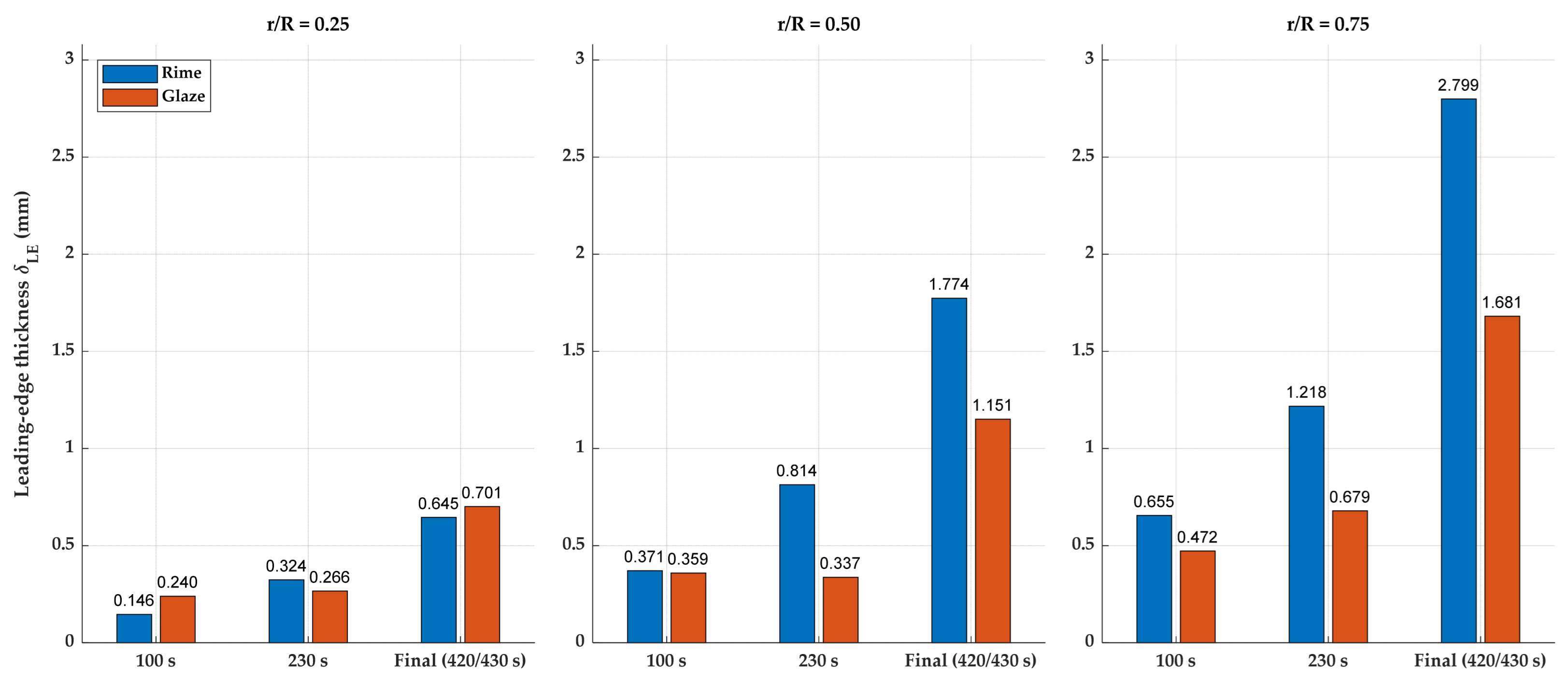

3.3. Image-Based Leading-Edge Ice Thickness

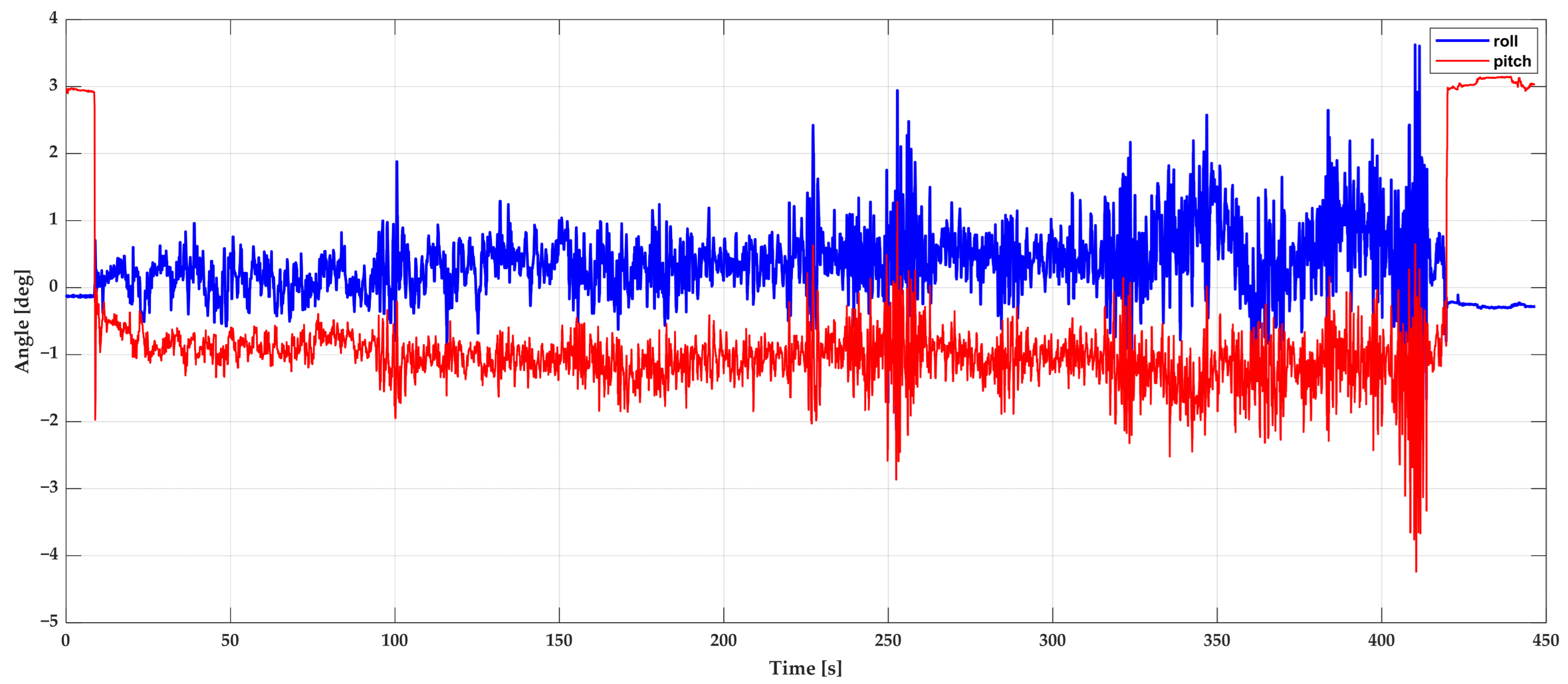

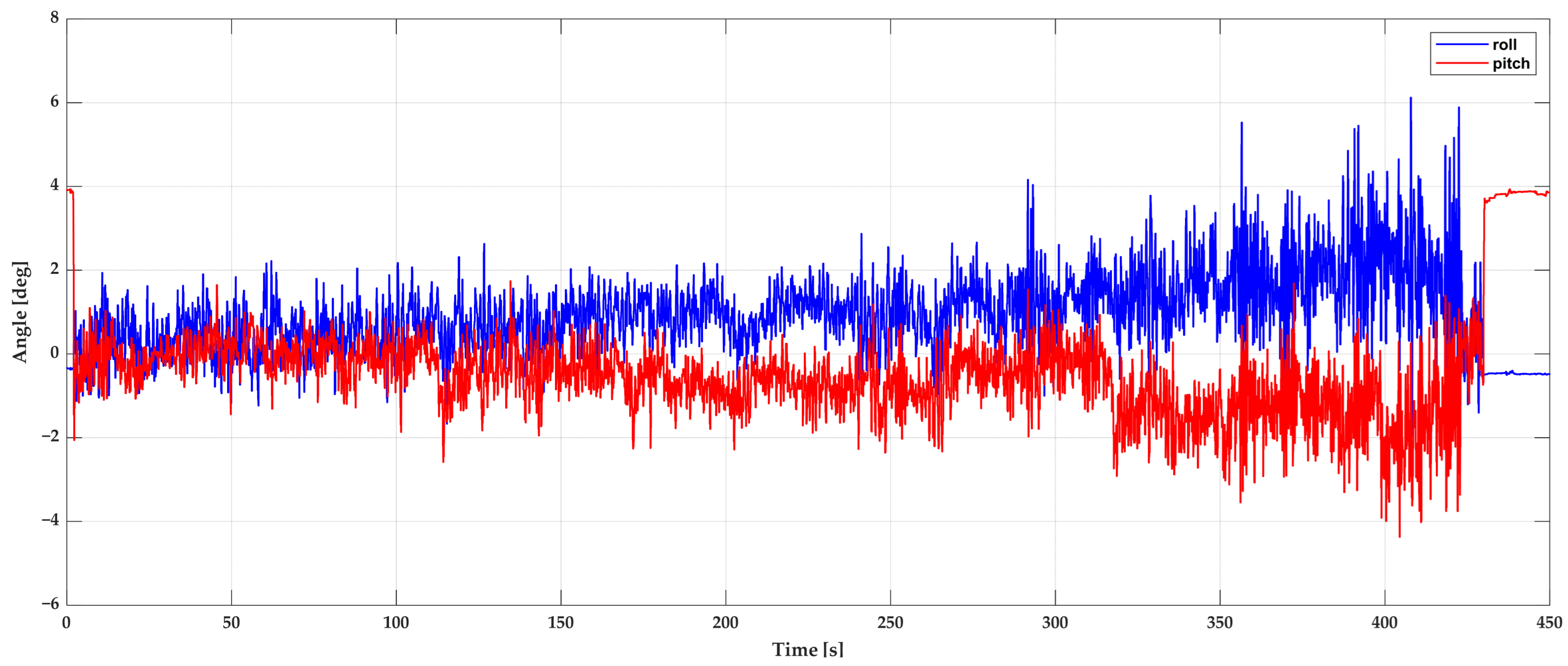

3.4. Attitude Response Under Icing (Pitch/Roll Angles)

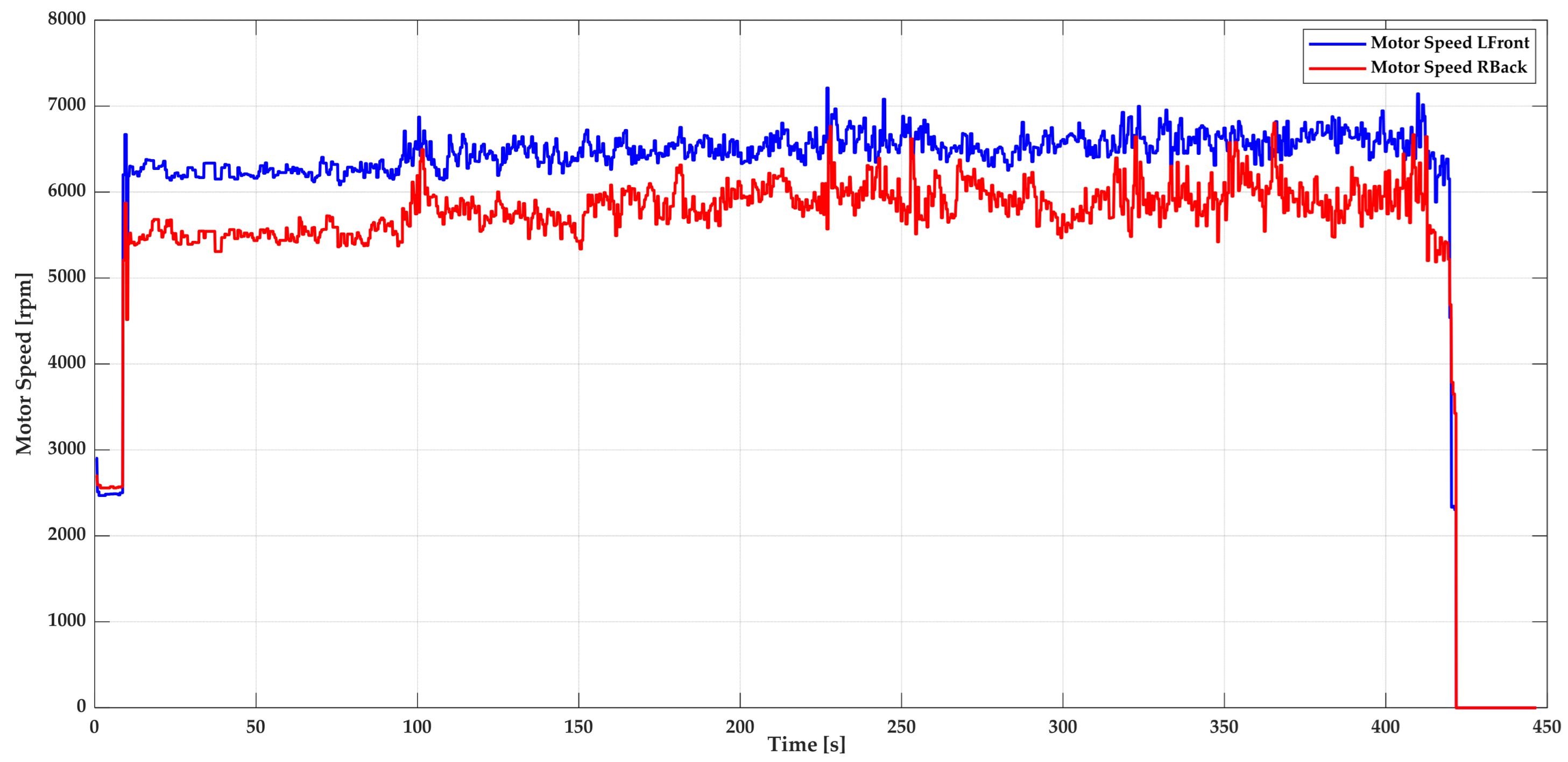

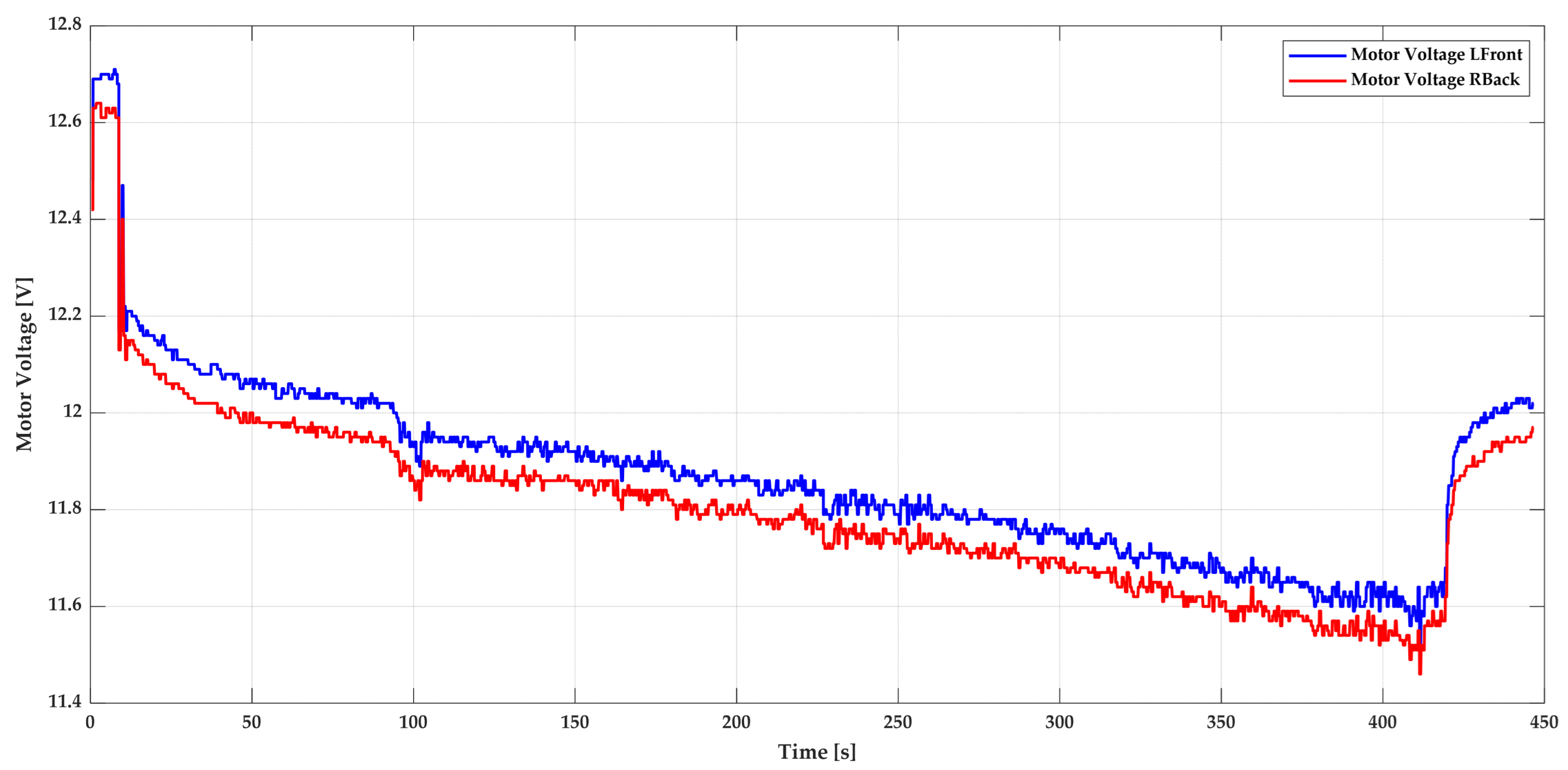

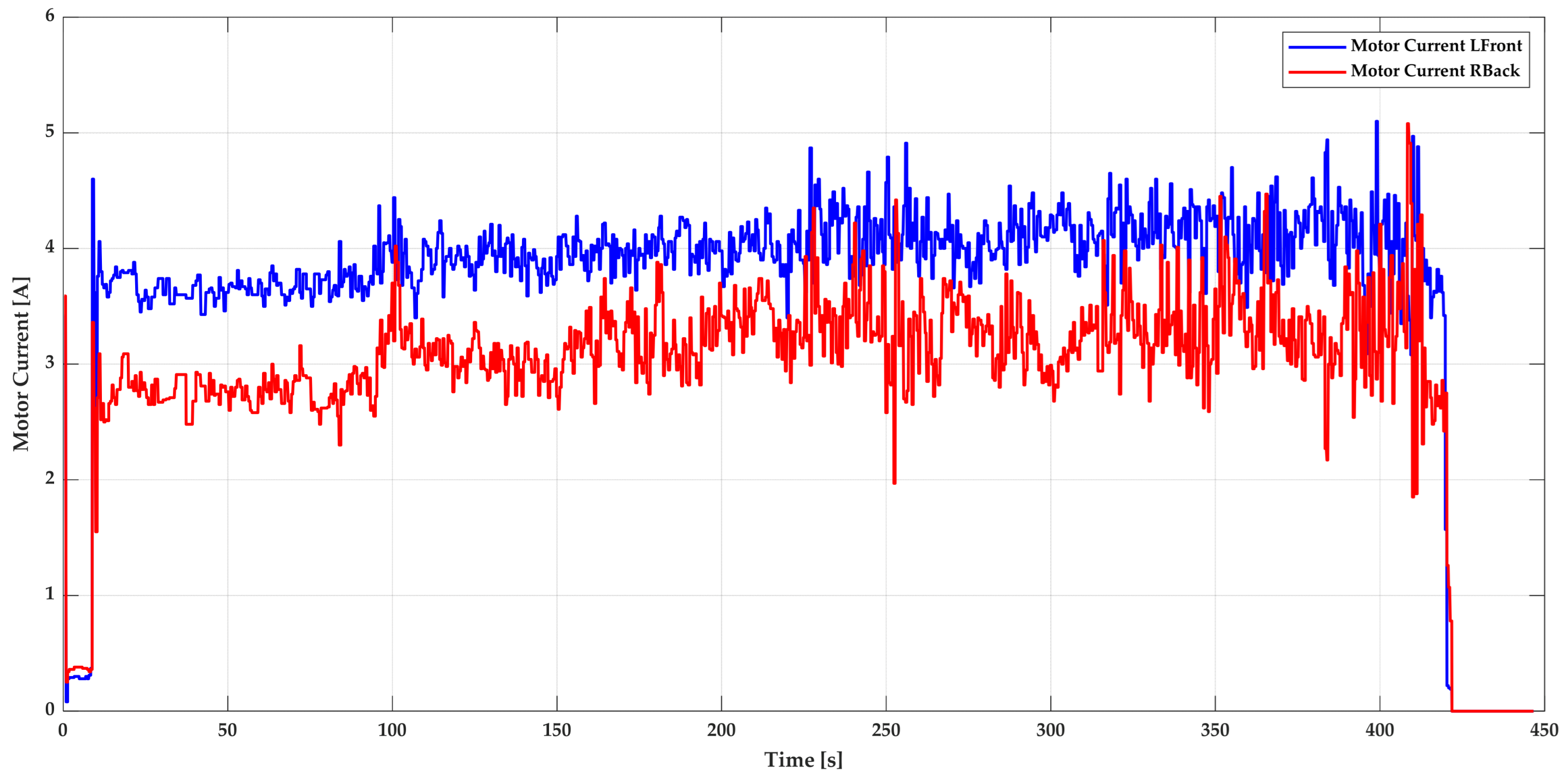

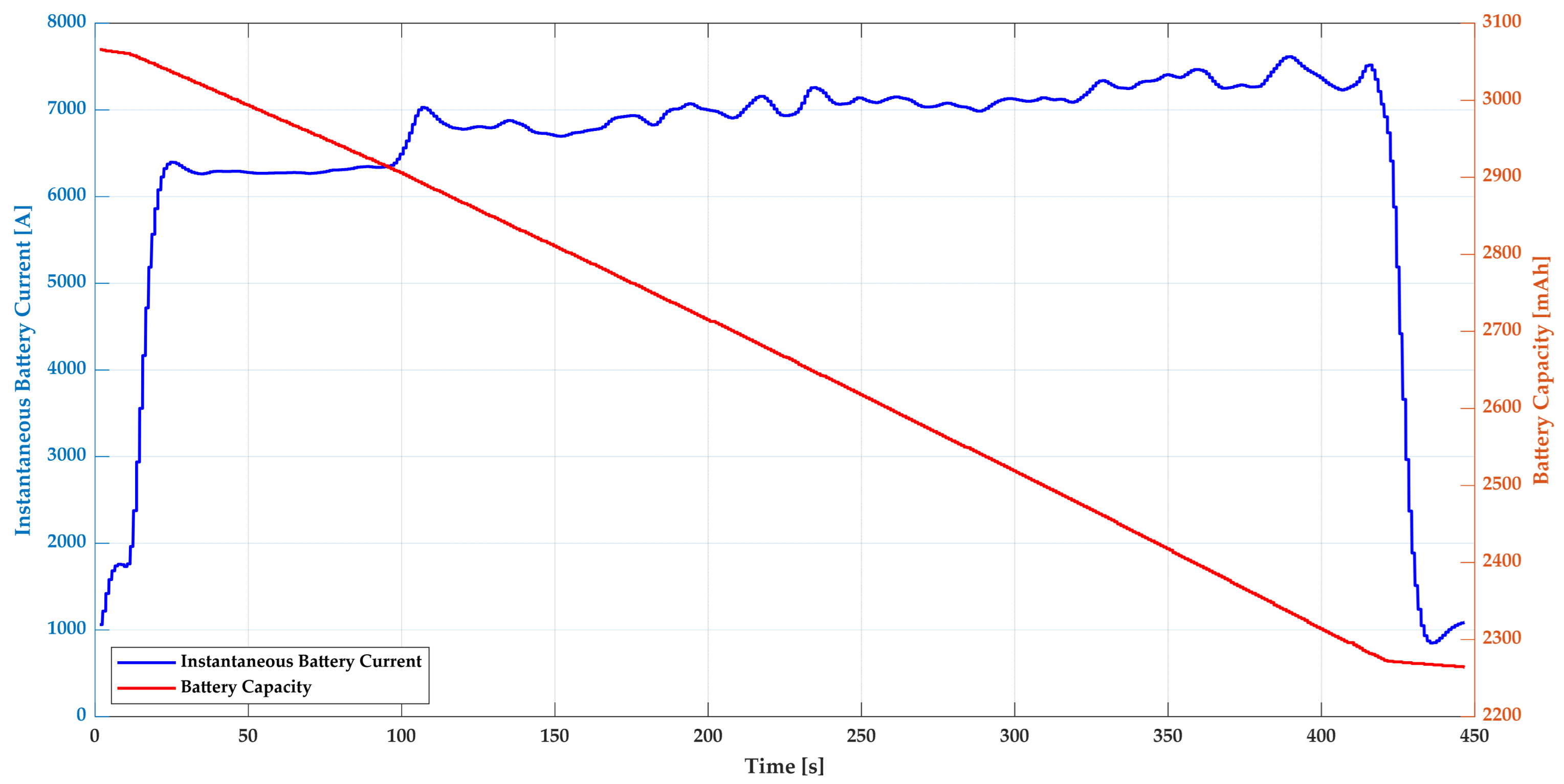

3.5. Impact of Rime Icing Condition on UAV Performance

3.6. Impact of Glaze Icing Condition on UAV Performance

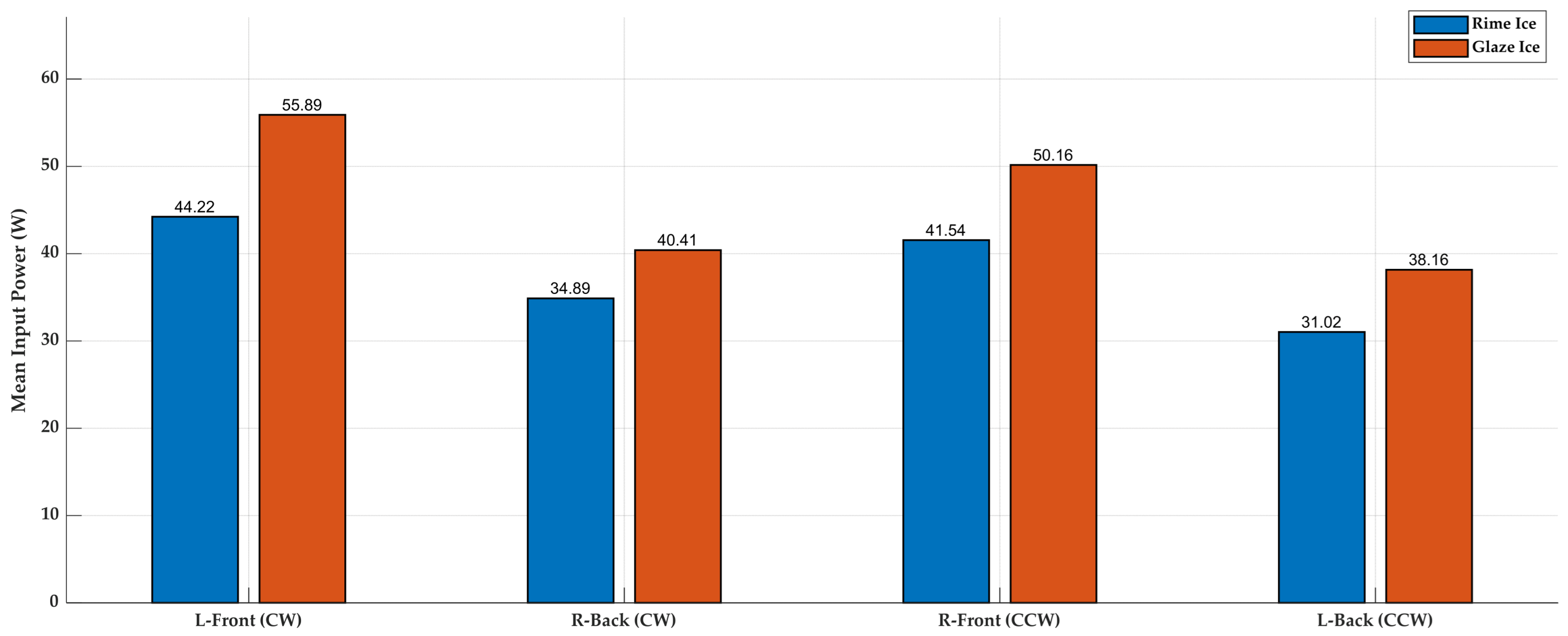

3.7. Comparison of Quadcopter Performance Under Rime Ice and Glaze Ice Conditions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| UAV | Unmanned Aerial Vehicle |

| LWC | Liquid Water Content |

| MVD | Median Volume Diameter |

| RPM | Revolution per Minute |

| DIP | Digital Image Projection |

| IMU | Inertial Measurement Unit |

| GPS | Global Positioning System |

| GNSS | Global Navigation Satellite System |

| APAS | Advanced Pilot Assistance System |

| VPS | Vision Positioning System |

| CW | Clockwise |

| CCW | Counterclockwise |

| PWM | Pulse Width Modulation |

| ESC | Electronic Speed Controller |

| BLDC | Brushless Direct Current Motor |

| SOC | State of Charge |

References

- Han, N.; Hu, H.; Hu, H. An experimental investigation on the dynamic ice accretion process over the blade surface of a rotating UAV propeller. In Proceedings of the AIAA Scitech 2022 Forum, San Diego, CA, USA, 3–7 January 2022. [Google Scholar]

- González-Jorge, H.; Martínez-Sánchez, J.; Bueno, M.; Arias, P. Unmanned aerial systems for civil applications: A review. Drones 2017, 1, 2. [Google Scholar] [CrossRef]

- Gao, M.; Hugenholtz, C.H.; Fox, T.A.; Kucharczyk, M.; Barchyn, T.E.; Nesbit, P.R. Weather constraints on global drone flyability. Sci. Rep. 2021, 11, 12092. [Google Scholar] [CrossRef] [PubMed]

- Shakhatreh, H.; Sawalmeh, A.H.; Al-Fuqaha, A.; Dou, Z.; Almaita, E.; Khalil, I.; Othman, N.S.; Khreishah, A.; Guizani, M. Unmanned aerial vehicles (UAVs): A survey on civil applications and key research challenges. IEEE Access 2019, 7, 48572–48634. [Google Scholar] [CrossRef]

- Müller, N.C.; Hann, R. UAV Icing: 3D Simulations of Propeller Icing Effects and Anti-Icing Heat Loads; SAE Technical Paper 2023-01-1383; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Szilder, K.; Yuan, W. In-flight icing on unmanned aerial vehicle and its aerodynamic penalties. Prog. Flight Phys. 2017, 9, 173–188. [Google Scholar]

- Müller, N.C.; Løw-Hansen, B.; Borup, K.T.; Hann, R. UAV icing: Development of an ice protection system for the propeller of a small UAV. Cold Reg. Sci. and Technol. 2023, 213, 103938. [Google Scholar] [CrossRef]

- Manaf, M.; Dhulipalla, A.; Sista, H.; Khawaja, H.; Virk, M.; Hu, H. An experimental investigation of transient ice accretion process on a high-lift airfoil model for UAV applications. Exp. Therm. Fluid Sci. 2025, 171, 111612. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Ning, Z.; Tian, W.; Hu, H. Experimental investigation on the dynamic icing process over a rotating propeller model. J. Propuls. Power 2018, 34, 933–946. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Li, H.; Hu, H. An experimental study of surface wettability effects on dynamic ice accretion process over a UAS propeller model. Aerosp. Sci. Technol. 2018, 73, 164–172. [Google Scholar] [CrossRef]

- Han, N.; Hu, H.; Hu, H. An experimental investigation to assess the effectiveness of various anti-icing coatings for UAV propeller icing mitigation. In Proceedings of the AIAA Aviation 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022. [Google Scholar]

- Dhulipalla, A.; Han, N.; Hu, H.; Hu, H. A Comparative Study to Characterize the Effects of Adverse Weathers on the Flight Performance of an Unmanned-Aerial-System. In Proceedings of the AIAA Aviation 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022. [Google Scholar]

- Dhulipalla, A.; Han, N.; Hu, H.; Hu, H. An experimental study to characterize the effects of ice accretion on the performance of a UAV propeller. In Proceedings of the AIAA Aviation 2023 Forum, San Diego, CA, USA, 12–16 June 2023. [Google Scholar]

- Miller, A.J.; Fuchs, C.; Omanovic, N.; Ramelli, F.; Seifert, P.; Spirig, R.; Zhang, H.; Fons, E.; Lohmann, U.; Henneberger, J. Multirotor UAV icing correlated to liquid water content measurements in natural supercooled clouds. Cold Reg. Sci. Technol. 2024, 225, 104262. [Google Scholar] [CrossRef]

- Harvey, D.; Villeneuve, E.; Béland, M.; Lapalme, M. Wind tunnel investigation of the icing of a drone rotor in forward flight. Drones 2024, 8, 380. [Google Scholar] [CrossRef]

- Suurnäkki, P.; Tiihonen, M.; Jokela, T. UAV icing: Low Reynolds number drone propeller performance during dynamic icing process. In Proceedings of the AIAA Aviation 2021 Forum, Virtual Event, USA, 2–6 August 2021. [Google Scholar]

- Kozomara, D.; Neubauer, T.; Puffing, R.; Bednar, I.; Breitfuss, W. Experimental investigation on the effects of icing on multicopter UAS operation. In Proceedings of the AIAA Aviation 2021 Forum, Virtual Event, USA, 2–6 August 2021. [Google Scholar]

- Kozomara, D.; Neubauer, T.; Puffing, R. Experimental investigation of a quadcopter UAS with a fluid-based de-icing system in Appendix C icing conditions. In Proceedings of the AIAA Aviation Forum and Ascent 2024 Forum, Las Vegas, NV, USA, 29 July–2 August 2024. [Google Scholar]

- Neubauer, T.; Oztekin, E.S. Characterization of propeller icing from 3D laser scan data. In Proceedings of the AIAA Aviation Forum and Ascent 2024 Forum, Las Vegas, NV, USA, 29 July–2 August 2024. [Google Scholar]

- Müller, N.C.; Hann, R. UAV Icing: A Performance model for a UAV propeller in icing conditions. In Proceedings of the AIAA Aviation 2022 Forum, Chicago, IL, USA, 27 June–1 July 2022. [Google Scholar]

- Samad, A.; Dhulipalla, A.; Hu, H. A hybrid anti-/de-icing strategy for UAV propeller icing protection. In Proceedings of the AIAA Aviation Forum and Ascent 2024 Forum, Las Vegas, NV, USA, 29 July–2 August 2024. [Google Scholar]

- Tu, J.; Tian, W.; Wang, X.; Tian, L. Experimental study on the effects of substrate hydro-/icephobicity on ice mitigation and ice shedding during the dynamic icing process over the rotating propeller of an unmanned-aerial-vehicle. Aerosp. Sci. Technol. 2024, 155, 109610. [Google Scholar] [CrossRef]

- Rotondo, D.; Cristofaro, A.; Johansen, T.A.; Nejjari, F.; Puig, V. Diagnosis of icing and actuator faults in UAVs using LPV unknown input observers. J. Intell. Robot. Syst. 2018, 91, 651–665. [Google Scholar] [CrossRef]

- López-Estrada, F.R.; Theilliol, D.; Astorga-Zaragoza, C.M.; Ponsart, J.C.; Valencia-Palomo, G.; Camas-Anzueto, J. Fault diagnosis observer for descriptor Takagi–Sugeno systems. Neurocomputing 2019, 331, 10–17. [Google Scholar] [CrossRef]

- DJI Mavic Air 2 User Manual v1.4: Technical Specifications; SZ DJI Technology Co., Ltd.: Shenzhen, China, 2020; Available online: https://dl.djicdn.com/downloads/Mavic_Air_2/Mavic_Air_2_User_Manual_v1.4_en.pdf (accessed on 21 October 2025).

- Frey, M.; Müller, N.C.; Wallisch, J.; Hann, R. UAV Icing: Experimental investigation and numerical CHT simulations of a propeller ice protection system. In Proceedings of the AIAA Scitech 2024 Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar]

- Karpen, N.; Diebald, S.; Dezitter, F.; Bonaccurso, E. Propeller-integrated airfoil heater system for small multirotor drones in icing environments: Anti-icing feasibility study. Cold Reg. Sci. Technol. 2022, 201, 103616. [Google Scholar] [CrossRef]

- Løw-Hansen, B.; Müller, N.; Coates, E.; Johansen, T.; Borup, K.T. Identification of an Electric UAV Propulsion System in Icing Conditions; SAE Technical Paper 2023-01-1378; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Hunt, B.; Rawlins, C.; Hill, B. An analysis of blade deicing techniques for Multi-Rotor UAV propellers. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 6–13 March 2021. [Google Scholar]

- Muhammed, M.; Virk, M.S. Ice accretion on rotary-wing unmanned aerial vehicles—A review study. Aerospace 2023, 10, 261. [Google Scholar] [CrossRef]

- Hann, R.; Müller, N.C.; Wallisch, J. UAV icing: Impact testing of ice fragments on a propeller. In Proceedings of the AIAA Aviation Forum and Ascent 2024 Forum, Las Vegas, NV, USA, 29 July–2 August 2024. [Google Scholar]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 6th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Anderson, D.N.; Tsao, J.-C. Overview of Icing Physics Relevant to Scaling. In Proceedings of the FAA In-Flight Icing/Ground De-Icing International Conference, Chicago, IL, USA, 16–20 June 2003. [Google Scholar]

- Veerakumar, R.; Tian, L.; Hu, H.; Liu, Y.; Hu, H. An experimental study of dynamic icing process on an Aluminum-Conductor-Steel-Reinforced power cable with twisted outer strands. Exp. Therm. Fluid Sci. 2022, 142, 110823. [Google Scholar] [CrossRef]

- Palacios, J.L.; Han, Y.; Brouwers, E.W.; Smith, E.C. Icing environment rotor test stand liquid water content measurement procedures and ice shape correlation. J. Am. Helicopter Soc. 2012, 57, 29–40. [Google Scholar] [CrossRef]

- Samad, A.; Dhulipalla, A.; Hu, H. Comparative Study of Various Strategies for Multirotor UAV Propeller Icing Mitigation. AIAA J. 2025, 63, 2892–2907. [Google Scholar] [CrossRef]

- Samad, A.; Dhulipalla, A.; Bowers, K.; Rodriguez, J.; Hu, H. An Experimental Investigation of the Dynamic Icing Process on a Multirotor UAV Rotor in Forward Flight. In Proceedings of the AIAA Scitech 2024 Forum, Orlando, FL, USA, 8–12 January 2024. [Google Scholar]

- Bragg, M.B.; Broeren, A.P.; Blumenthal, L.A. Iced-airfoil aerodynamics. Prog. Aerosp. Sci. 2005, 41, 323–362. [Google Scholar] [CrossRef]

- Savoye, F.; Venet, P.; Millet, M.; Groot, J. Impact of Periodic Current Pulses on Li-Ion Battery Performance. IEEE Trans. Ind. Electron. 2012, 59, 3481–3488. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Dimensions (Folded) | 180 × 97 × 84 mm |

| Dimensions (Unfolded) | 183 × 253 × 77 mm |

| Weight | 570 g |

| Max. speed | 19 m/s (S Mode), 12 m/s (N Mode), 5 m/s (T Mode) |

| Max. flight time | 34 min |

| Operating Temperature | −10° to 40 °C (14° to 104°F) |

| GNSS | GPS + GLONASS |

| Max. Transmission Distance | 10 km (FCC), 6 km (CE/SRRC/MIC) |

| Battery Capacity | 3500 mAh |

| Battery Voltage | 11.55 V |

| Max. Charging Power | 38 W |

| Remote Controller Battery | 5200 mAh |

| Intelligent Flight Features | Active Track 3.0, Spotlight 2.0, Point of Interest 3.0 |

| Air Velocity (m/s) | LWC (g/m3) | Temperature (°C) | Ice Type |

|---|---|---|---|

| 5 | 0.5 | −10 | Rime |

| 5 | 1.5 | −5 | Glaze |

| Condition | Time [s] | δLE @ r/R = 0.75 mm (75%) | δLE @ r/R = 0.50 mm (50%) | δLE @ r/R = 0.25 mm (25%) |

|---|---|---|---|---|

| Rime | 100 | 0.655 | 0.371 | 0.146 |

| Rime | 230 | 1.218 | 0.814 | 0.324 |

| Rime | 420 | 2.799 | 1.774 | 0.645 |

| Glaze | 100 | 0.472 | 0.359 | 0.240 |

| Glaze | 230 | 0.679 | 0.337 | 0.266 |

| Glaze | 430 | 1.681 | 1.151 | 0.701 |

| Motor | Vmean (Rime) [V] | Imean (Rime) [A] | Pmean (Rime) [W] | Vmean (Glaze) [V] | Imean (Glaze) [A] | Pmean (Glaze) [W] | ΔP [W] |

|---|---|---|---|---|---|---|---|

| Lfront | 11.855 | 3.7298 | 44.22 | 11.872 | 4.7076 | 55.89 | +11.67 |

| Rback | 11.788 | 2.9599 | 34.89 | 11.802 | 3.4244 | 40.41 | +5.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ercan, H.; Dalkın, A. Full-Vehicle Experimental Investigation of Propeller Icing on a Hovering Quadcopter. Drones 2025, 9, 729. https://doi.org/10.3390/drones9110729

Ercan H, Dalkın A. Full-Vehicle Experimental Investigation of Propeller Icing on a Hovering Quadcopter. Drones. 2025; 9(11):729. https://doi.org/10.3390/drones9110729

Chicago/Turabian StyleErcan, Hamdi, and Ahmet Dalkın. 2025. "Full-Vehicle Experimental Investigation of Propeller Icing on a Hovering Quadcopter" Drones 9, no. 11: 729. https://doi.org/10.3390/drones9110729

APA StyleErcan, H., & Dalkın, A. (2025). Full-Vehicle Experimental Investigation of Propeller Icing on a Hovering Quadcopter. Drones, 9(11), 729. https://doi.org/10.3390/drones9110729