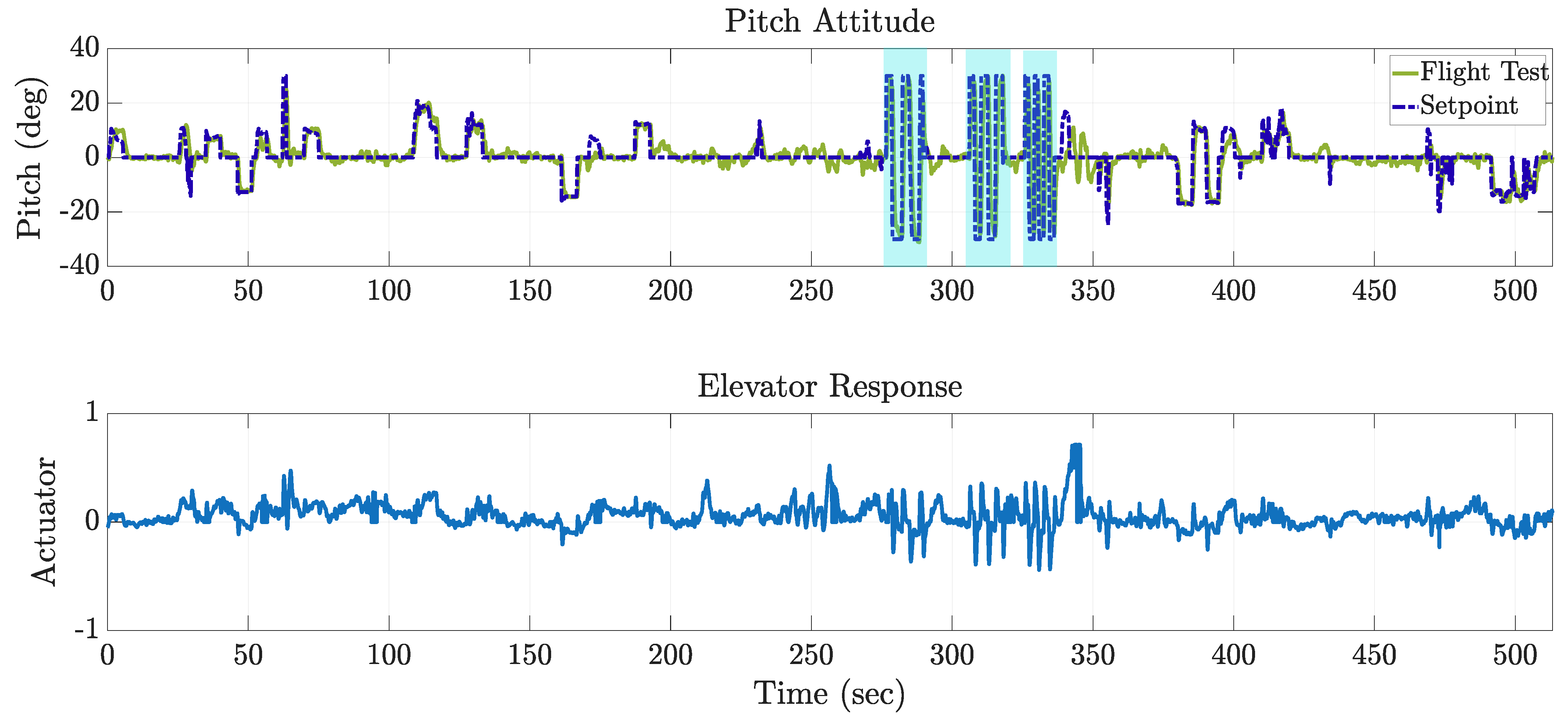

For completeness, the roll and yaw control axes are not redesigned in this study. Instead, they retain the default PX4 configurations, which provide baseline stability while allowing the focus of this work to remain on the pitch-axis controller design and validation.

2.1. UAV Dynamic Model

The controller design is based on linearized models derived from the full six-degree-of-freedom (6-DoF) UAV dynamics. The nonlinear rigid-body equations of motion were formulated following standard flight dynamics references [

19,

20], incorporating aerodynamic forces and moments, propulsion effects, and inertial coupling. The aerodynamic force and moment coefficients were obtained using the Athena Vortex Lattice (AVL) method [

21], which provided the necessary stability derivatives for the roll and pitch axes.

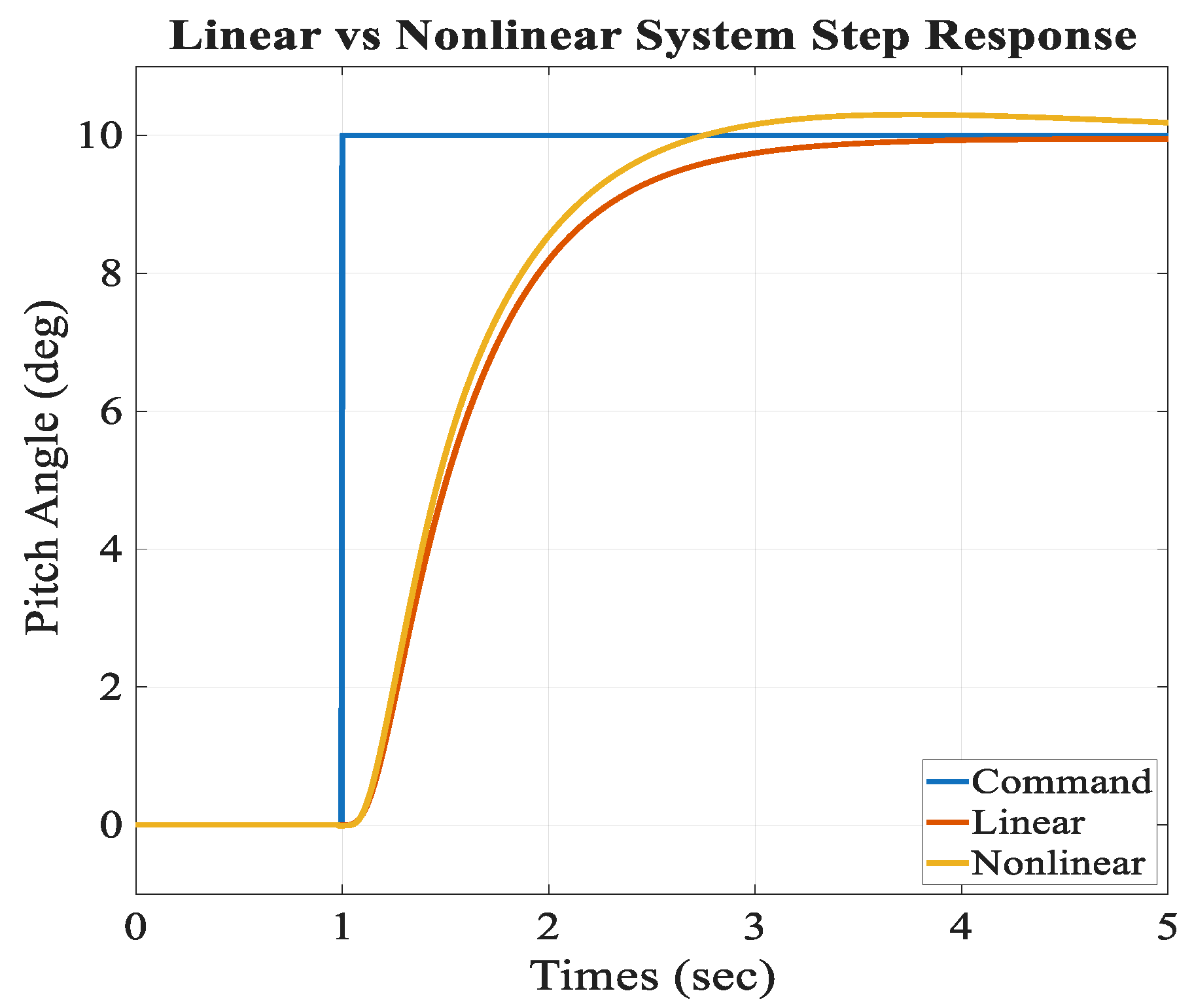

For the purposes of controller synthesis, the nonlinear model was linearized at the steady-level flight trim condition. The resulting linearized dynamics were reduced to single-input-single-output (SISO) transfer function representations between control surface deflections (aileron and elevator) and the corresponding body angular rates (roll rate , pitch rate ). These transfer functions form the basis of the loop-shaping design, enabling frequency–domain analysis using Bode plots and pole–zero placement. The yaw channel was excluded from this process and retained the default PX4 controller configuration. Final validation was conducted using the complete nonlinear 6-DoF simulation model to ensure that the linear-model-based design translates effectively to the full system dynamics.

For a practical fixed-wing UAV, a first-order actuator dynamics model was included, represented as

The final design model for the pitch rate loop was constructed as the product of the linearized UAV transfer functions and the actuator dynamics. The linearized models were obtained using the MATLAB (R2025a) Control System Toolbox, where the full nonlinear 6-DoF UAV simulation model was trimmed at a steady level-flight condition corresponding to an airspeed of approximately

. These transfer functions are summarized in

Table 1, where the first row indicates the corresponding dynamic channel (pitch), and the second row lists the respective transfer function representations derived from the high-fidelity 6-DoF model. To account for actuator effects, each dynamic model was subsequently multiplied by the actuator transfer function

. The resulting combined transfer functions served as the effective plant models for the loop-shaping controller design.

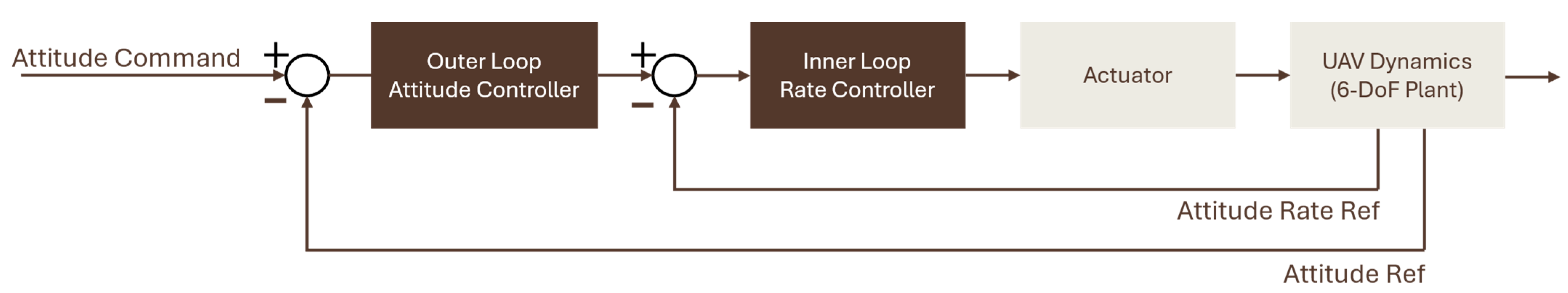

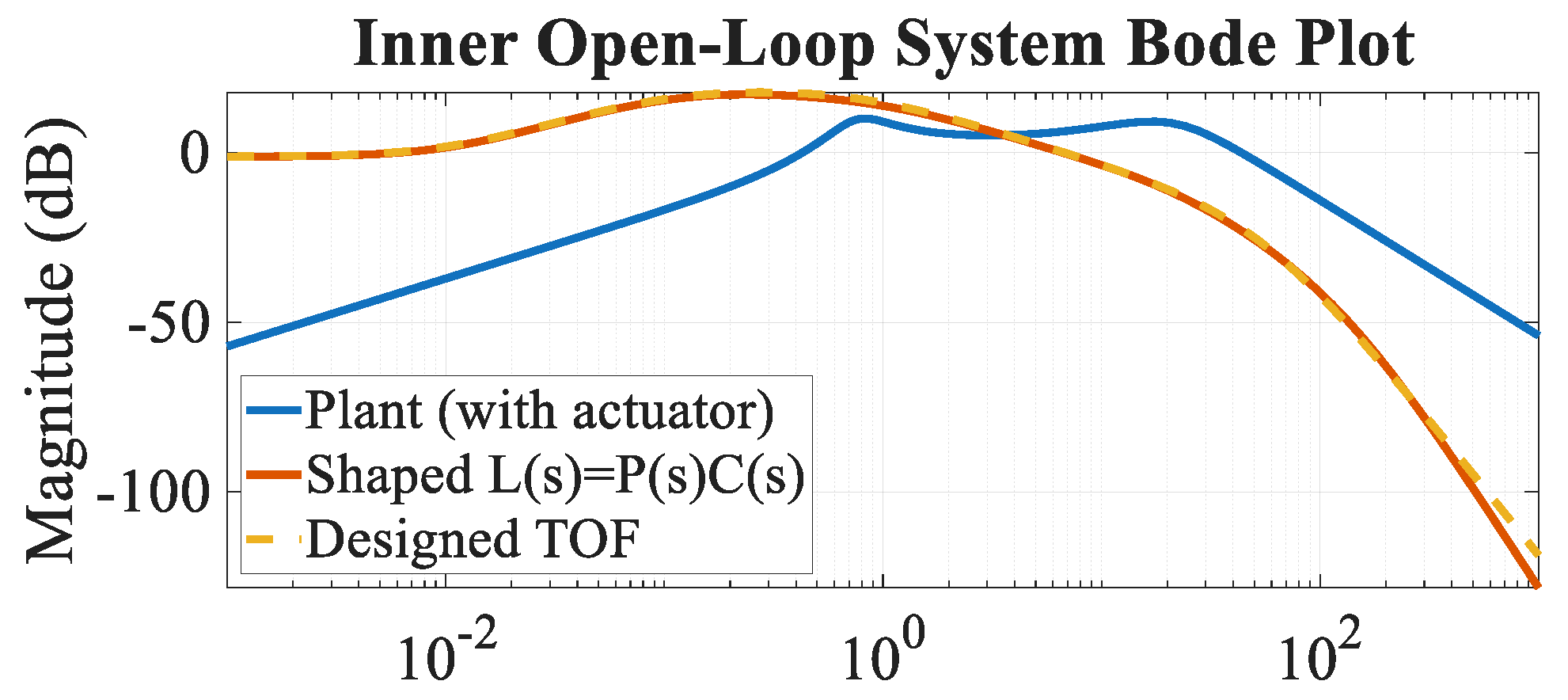

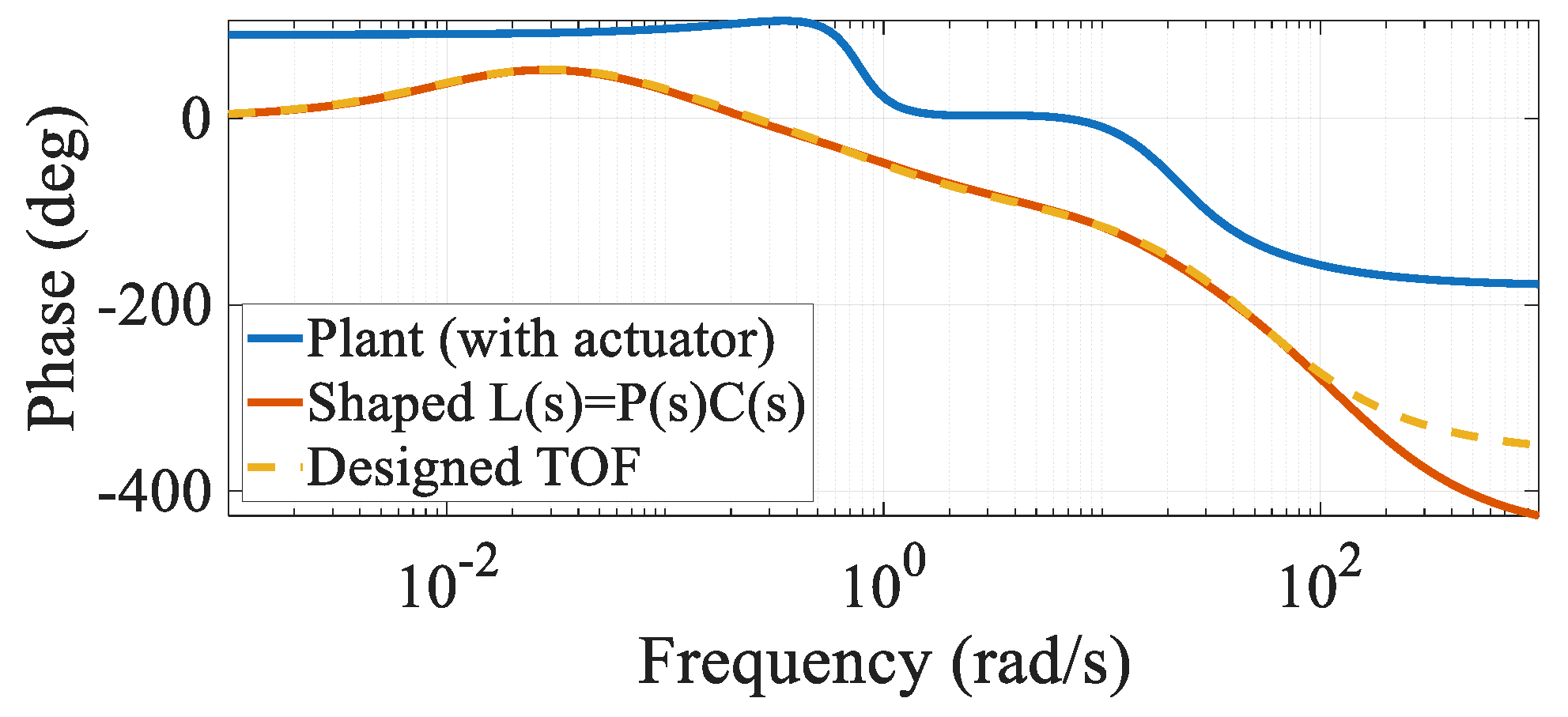

For clarity,

Figure 2 illustrates the open-loop Bode plot of the pitch rate channel, respectively, after incorporating the actuator model. This figure highlights the baseline frequency–domain characteristics of each axis, which were used as the starting point for the sequential pole-zero placement and compensator synthesis in the loop-shaping procedure.

Figure 2.

Open-loop Bode plot of the pitch channels.

Figure 2.

Open-loop Bode plot of the pitch channels.

2.3. Design Objectives

The primary objective of the controller design is to achieve stable and well-damped angular rate responses in the pitch () axis, while maintaining robustness against model uncertainties and external disturbances. To this end, three frequency–domain specifications are adopted as the main design targets:

The desired crossover frequency for the pitch rate loop is set at approximately . This provides sufficiently fast angular rate responses while remaining within the bandwidth limits of the actuator and sensor dynamics.

- 2.

Outer-loop close-loop bandwidth.

The pitch attitude loops employ simple proportional controllers with a target bandwidth of approximately

. According to conventional flight control design practice, the bandwidth of the inner rate loops should be about three to five times higher than that of the outer loops [

20,

22,

23,

24]. This ensures adequate loop separation and prevents dynamic coupling between the cascaded loops.

- 3.

Phase and gain margins.

A minimum phase margin of

and a gain margin exceeding

are specified. These values provide adequate robustness to modeling errors and parameter uncertainties, and are consistent with flying-quality guidelines for small UAVs [

20,

25,

26].

- 4.

Disturbance rejection.

At low frequency, the loop must provide high gain to suppress steady-state disturbances such as gusts and trim errors. Conversely, high-frequency gain is required to decay rapidly to attenuate sensor noise and unmodeled high-frequency dynamics.

The specification is deliberately conservative because this study reports a first deployment of the workflow on a real platform; focusing on a single axis reduces implementation risk while preserving generality. And by adopting cautious bandwidth and stability-margin targets, the design ensures robust flight stability during early testing, thereby reducing implementation risks while still providing sufficient performance for practical evaluation.

2.4. Construct Target Open-Loop Transfer Function

The design objective is expressed through a target open-loop transfer function, denoted , which specifies the desired crossover frequency, disturbance-rejection capability, and high-frequency roll-off. The controller is then synthesized to shape the actual plant dynamics so that the resulting open-loop transfer function approximates .

In general, each design element can be represented in the form of the following transfer functions.

where the numerator and denominator terms correspond to controller zeros and poles, respectively. The parameter

specifies the associated gain adjustment in decibels, while

and

denote the break frequencies of the zero and pole, respectively. A single first-order pole is obtained when only the denominator is present, whereas a single zero is represented by omitting the denominator. By combining such elements in sequence, the target open-loop transfer function can be flexibly shaped to meet multiple objectives, including bandwidth, phase margin, and disturbance rejection.

The crossover frequency

is selected based on the desired closed-loop bandwidth. In well-damped systems, the gain crossover frequency is closely related to the closed-loop bandwidth. To impose this behavior, a first-order lag was introduced with a pole at

:

The gain compensates for the magnitude drop at the intended crossover frequency caused by the lag pole.

To improve low-frequency performance and reduce steady-state error, a second low-frequency pole is added at

:

The additional gain flattens the magnitude curve at low frequencies, increasing DC gain for better disturbance rejection.

We still need to achieve the required phase margin

, a zero is placed at

. The final target transfer function becomes:

The gain factor was selected to normalize the magnitude such that the crossover frequency settled at approximately .

To suppress sensor noise and attenuate unmodeled dynamics, a third-order pole cluster was introduced at approximately

. This frequency corresponds to roughly seven times the crossover frequency (

), which ensures that the roll-off is sufficiently separated from the control bandwidth to avoid degrading stability margins, while remaining low enough to provide effective attenuation of high-frequency disturbances. This placement follows common control design practices, where roll-off dynamics are typically placed at 5–10 times the crossover frequency to balance robustness and noise rejection [

27]. The resulting target open-loop function is

This placement enforces an asymptotic slope of in the high-frequency region, while preserving the desired phase characteristics within the bandwidth of interest. To finalize the design, a scalar gain of was applied so that the open-loop magnitude intersected the axis at the intended crossover frequency of . The resulting closed-loop response exhibited an effective bandwidth of approximately , aligning with the design objective of achieving a fast yet practically realizable angular rate response.

The final target open-loop transfer function thus incorporates (i) a specified crossover near , (ii) enhanced low-frequency gain for disturbance rejection, (iii) sufficient phase margin, and (iv) high-frequency roll-off for noise attenuation. The corresponding closed-loop system exhibits an effective bandwidth of approximately . This frequency–domain profile serves as the reference model that the actual plant dynamics are shaped to approximate during controller synthesis.

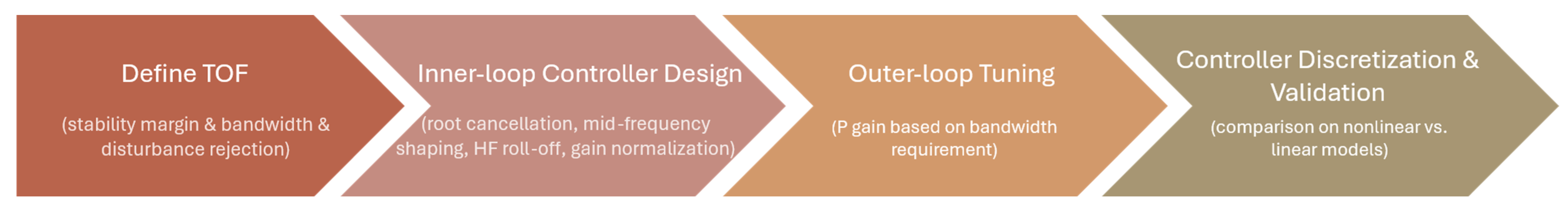

The target open-loop transfer function (TOF) was shaped by sequentially introducing poles and zeros, with the detailed placements summarized in

Table 2. First, a lag pole was introduced at low frequency to help establish the desired bandwidth, since the crossover frequency typically lies close to the closed-loop bandwidth, and to suppress steady-state drift while retaining integral-like behavior. A second low-frequency pole was then placed to improve robustness against actuator dynamics and constant biases. A zero was added near the crossover frequency to provide phase lead and increase stability margin. At high frequency, a third-order roll-off was applied to attenuate sensor noise and prevent excitation of unmodeled dynamics. Finally, the overall loop gain was adjusted to achieve the target bandwidth while maintaining sufficient gain and phase margins. This step-by-step shaping procedure ensures that the TOF construction directly reflects the intended design objectives.

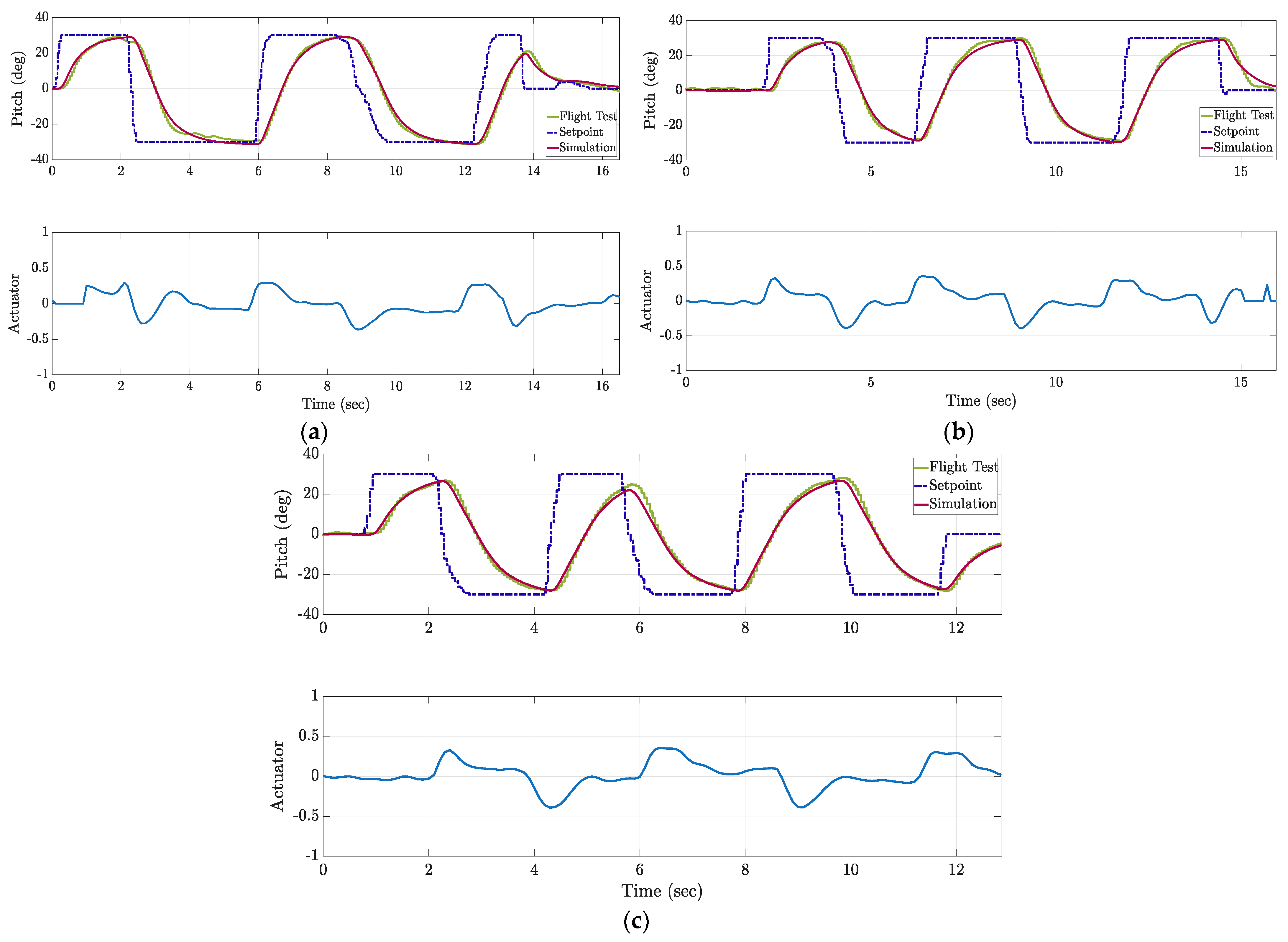

To aid interpretation,

Figure 4a illustrates the open-loop Bode plots after each construction step, showing the progressive shaping of the magnitude and phase response toward the final target. The corresponding closed-loop responses are shown in

Figure 4b, confirming that the final design achieves the intended bandwidth and stability margins.

Figure 4.

Frequency response characteristics of the target function: (a) sequential construction of the target open-loop transfer function , the green dot indicate the crossover frequency of the corresponding open-loop response. (b) closed-loop Bode plots corresponding to the constructed target transfer functions.

Figure 4.

Frequency response characteristics of the target function: (a) sequential construction of the target open-loop transfer function , the green dot indicate the crossover frequency of the corresponding open-loop response. (b) closed-loop Bode plots corresponding to the constructed target transfer functions.

2.5. Loop Shaping Controller Design Methodology

The loop-shaping design procedure aims to adjust the open-loop frequency response of the aircraft dynamics such that it conforms to a predefined target transfer function, thereby ensuring that the prescribed design objectives are satisfied. The design process is carried out in a structured sequence of steps, as outlined below. For clarity of presentation, the detailed step-by-step design is illustrated using the pitch channel as a representative example.

We consider the longitudinal inner-loop plant

where the open-loop poles

and zeros

are shown in

Table 3.

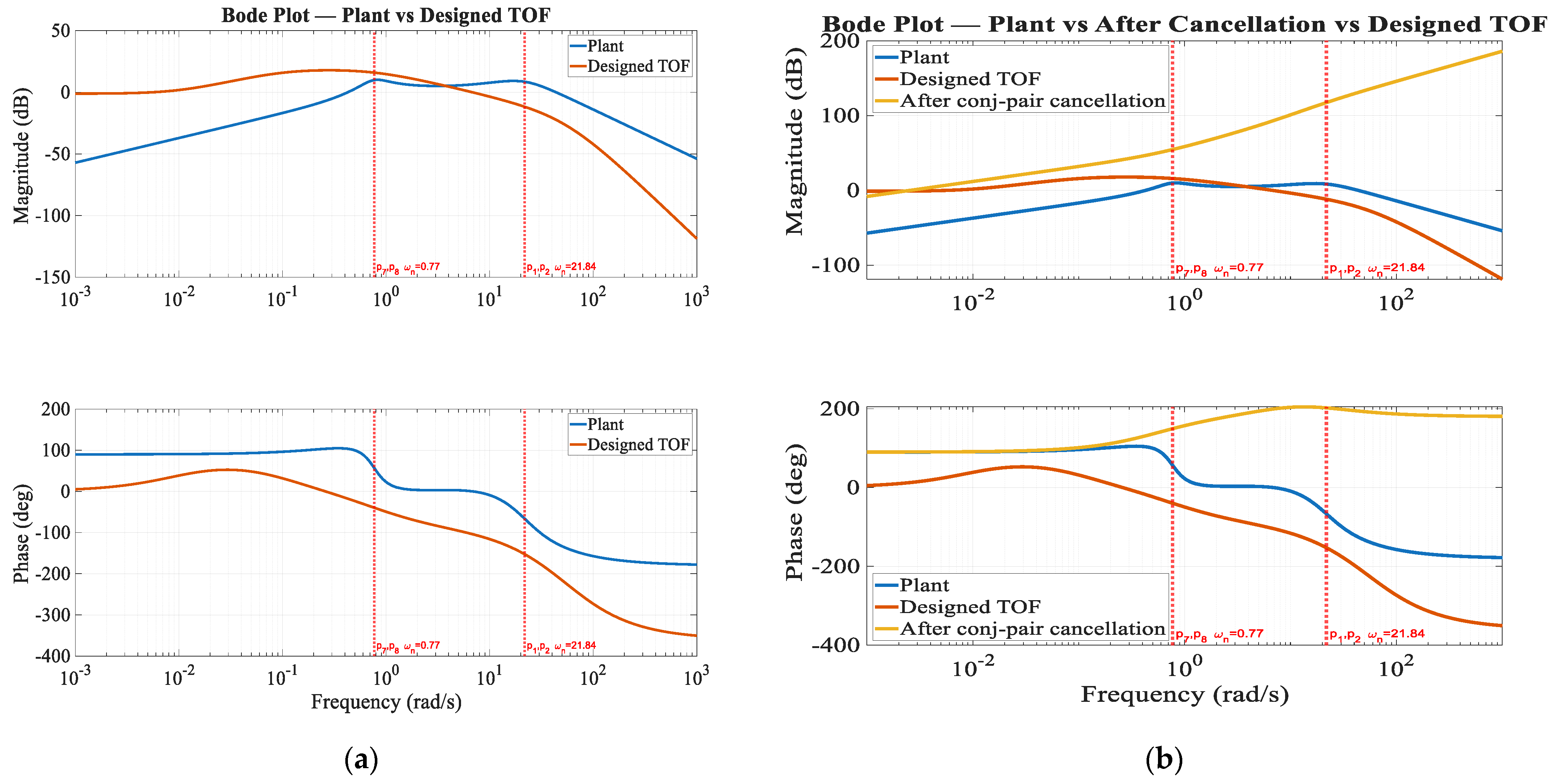

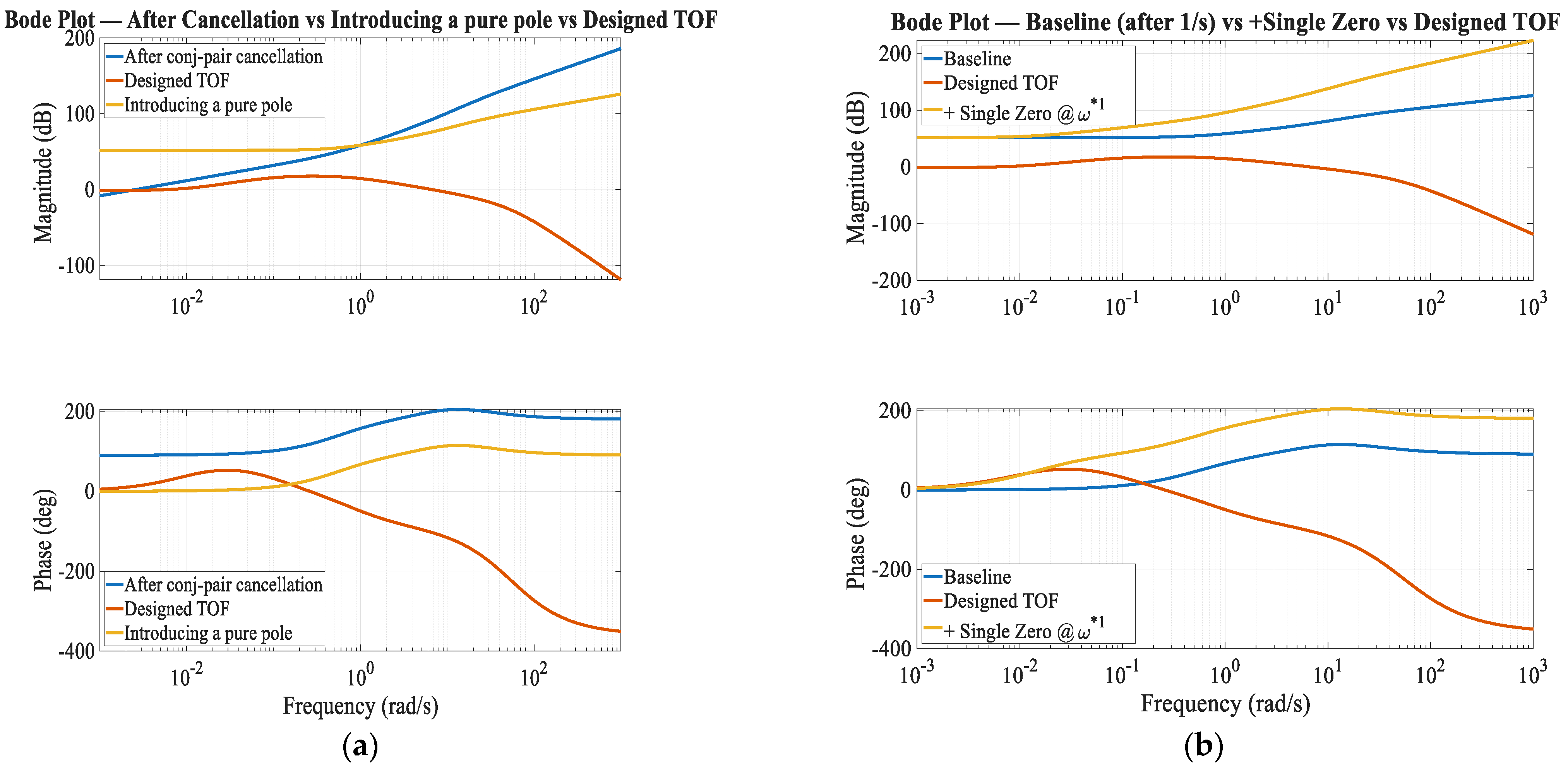

To initiate the controller synthesis, the first step is to eliminate the pronounced phase distortions caused by the dominant complex conjugate poles of the plant. As illustrated in

Figure A1a, located in Stepwise Bode Plots of the Pitch Rate Loop-Shaping Design Procedure Section in

Appendix A, the Bode plots of the original plant and the target closed-loop guideline (TOF) are compared. Two prominent resonant regions can be identified: the low-frequency pair (

) at a natural frequency of approximately

, and the high-frequency pair (

) located at about

. These poles introduce sharp phase variations in the open-loop response, which hinder the attainment of the desired phase margin. To mitigate this effect, conjugate zeros were introduced at the same locations, forming the cancelation polynomial

This cancelation provides a smoother baseline upon which subsequent shaping actions can be performed, thereby aligning the system response with the target TOF specification. The resulting compensated response is shown in

Figure A1b, located in Stepwise Bode Plots of the Pitch Rate Loop-Shaping Design Procedure Section in

Appendix A, where the mid- and high-frequency phase distortions are significantly reduced, allowing the Bode plot to more closely follow the target guideline.

Remark 1. The choice of which poles to cancel in this study was based on graphical considerations—specifically, the locations where cancelation yielded the most effective shaping of the Bode plot. This selection is not unique; alternative choices may also be valid depending on design priorities and implementation constraints.

- 2.

Low-frequency phase correction.

After canceling the dominant conjugate poles in Step 1, the next objective is to align the open-loop phase response with the target TOF over a wide frequency range. This is achieved by progressively introducing poles and zeros from low to high frequency.

In the low-frequency region, a discrepancy of approximately

was observed. To address this, a pure pole was introduced in the controller, represented by

This pole provides a continuous phase lag starting from the lowest frequencies, thereby reducing the excessive phase lead of the original system. By attenuating the low-frequency gain while shaping the phase trajectory downward, the pure pole not only enhances the fidelity of the phase alignment with the target function but also improves robustness by mitigating potential amplification of low-frequency disturbances. As shown in

Figure A2, the Bode plot confirms that the insertion of

effectively reduces the low-frequency phase offset, establishing a more suitable foundation for subsequent zero-pole placements at higher frequencies.

- 3.

Mid-frequency shaping

Following the insertion of the pure pole to correct the low-frequency offset, a residual phase deficit of approximately

was observed at

. Since the phase error is not constant across the band but accompanied by an insufficient magnitude slope, a single controller zero is introduced to raise the local slope and supply the required phase:

This placement aligns the phase at

without imposing a platform-like phase plateau, and simultaneously transitions the magnitude slope towards

in the surrounding decade. As shown in

Figure A2, the open-loop Bode after adding

conforms closely to the target TOF around

.

To further align the phase response, a single pole is introduced to lower the local slope and supply the required negative phase at

. Using the first-order phase relation

, the pole is placed at

such that

. This placement simultaneously yields a moderate magnitude attenuation of

at

, which helps suppress high-frequency components (See

Figure A3 for the after overlay)

Between the previously placed zero and pole, the phase error remains nearly constant. At

, the deficit is

; hence, a lead compensator is introduced to provide a platform-like phase lift around

with minimal side effects:

with

gives

,

, and

.

This placement delivers

at

while altering the magnitude only mildly, which is subsequently absorbed by the final gain normalization. As shown in

Figure A3, the compensated loop aligns closely with the target phase over the crossover neighborhood without disturbing the low- or high-frequency shaping established in earlier steps.

By iteratively adding zero, pole, and Lead/Lag compensators in increasing frequency order, the open-loop response is shaped to closely track the TOF across the entire design band, while ensuring smooth accumulation of phase correction and avoiding over-adjustment in previously matched regions.

- 4.

High-frequency roll-off.

After the mid-frequency adjustments (omitted here for brevity), the design proceeds to the high-frequency region where the target TOF exhibits a steep magnitude roll-off. To replicate this decay trend and suppress high-frequency noise, higher-order poles are introduced.

For example, a second-order pole is placed at frequency

:

Or equivalently, a third-order pole at

:

These higher-order poles steepen the slope of the magnitude response while introducing the necessary phase lag to align with the TOF. The break frequency or is selected to coincide with the onset of rapid decay in the target TOF.

The target TOF specifies a rapid decay to suppress unmodeled dynamics and sensor noise in the high-frequency region, with an asymptotic slope of and a corresponding phase lag approaching . To reproduce this behavior within the loop-shaping framework, a third-order real pole cluster was introduced.

Unlike simply adopting the TOF pole location, the design in this study employs a phase requirement back-solve method. Specifically, the compensator break frequency is determined such that the pole cluster contributions require additional phase lag at the designated frequency . At , the open-loop response exhibited a phase discrepancy of approximately , which was selected as the design target.

From the third-order pole phase relation,

The break frequency is back-solved as

This approach guarantees that the phase alignment is enforced directly at the critical frequency of interest, while still preserving the robustness benefits of a third-order asymptotic decay. The resulting compensated loop matches the TOF in both slope and phase trend in the high-frequency band, as shown in

Figure A4.

- 5.

Gain normalization.

A final scalar gain is applied to align the open-loop magnitude with the unity condition at the target crossover. Specifically, a proportional factor of is introduced after the high-frequency third-order roll-off. This adjustment vertically shifts the open-loop magnitude curve so that it intersects the line at the chosen crossover frequency, without altering the phase-shaping or slope characteristics already achieved through pole–zero placement.

The final controller

:

where consists of a structured combination of pole-zero elements and a scalar gain, synthesized through the loop-shaping procedure. The design process began with cancelation of dominant plant poles to reduce phase distortion, followed by sequential pole and zero placements from low to mid frequency to align the open-loop response with the target transfer function. Lead–lag compensators were introduced in frequency regions where nearly constant phase deficits were identified, and a third-order high-frequency pole cluster was employed to enforce the desired

roll-off. Finally, a scalar gain normalization was applied to ensure that the open-loop crossover frequency was located at approximately

, yielding a closed-loop bandwidth of about

. A summary of all compensator pole and zero placements, together with the corresponding gain values used in the loop-shaping design, is provided in

Table 4.

The synthesis was focused on the frequency range of interest for aircraft dynamics, approximately , which encompasses the dominant rigid-body modes of fixed-wing aircraft. Within this band, the controller was shaped to satisfy bandwidth, robustness margin, and disturbance-rejection requirements. Beyond , precise alignment with the target profile was not pursued, as this region is dominated by actuator and sensor dynamics as well as unmodeled high-frequency effects. Instead, the third-order roll-off ensures sufficient attenuation to suppress noise and avoid undesired high-frequency amplification.

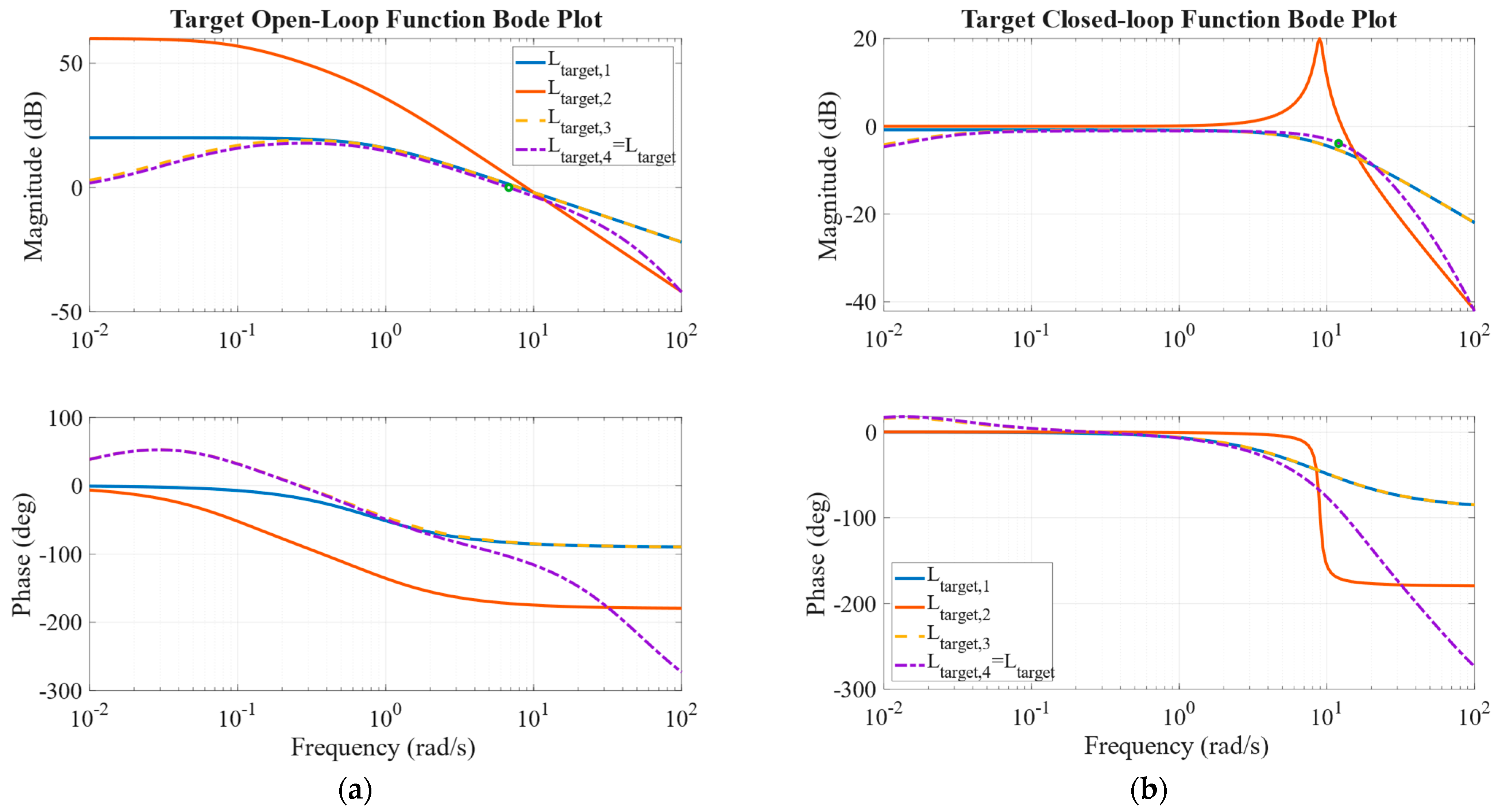

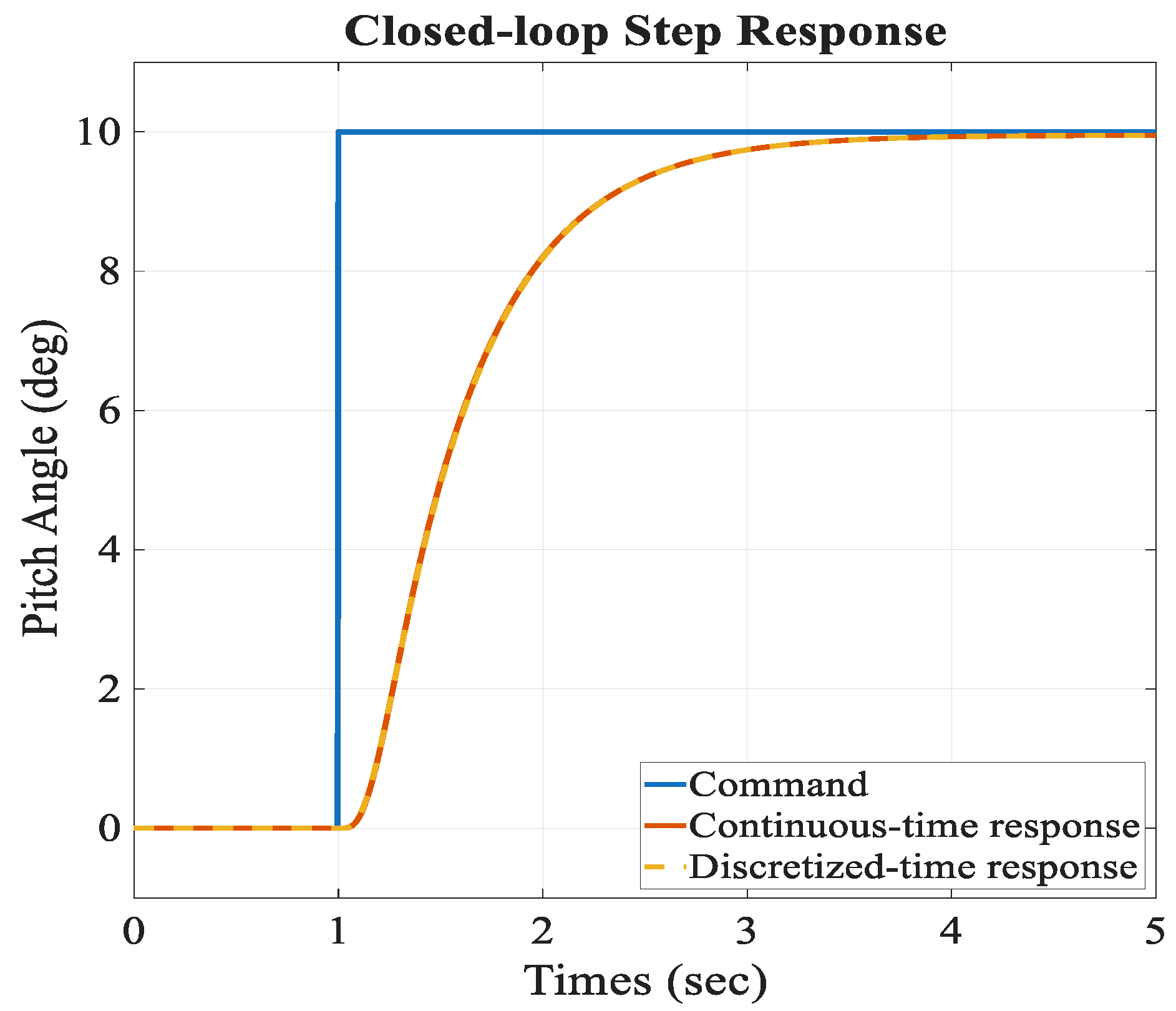

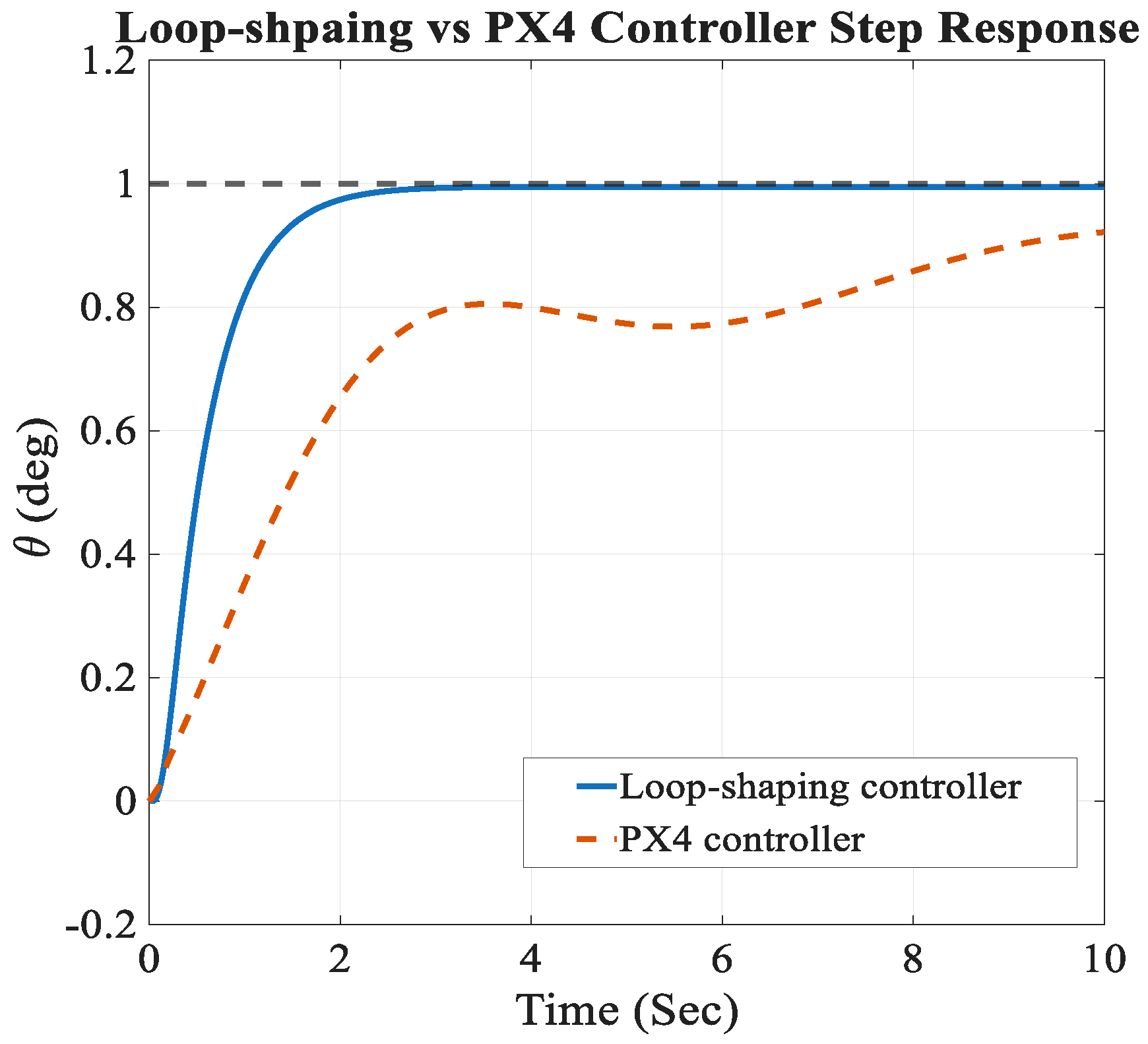

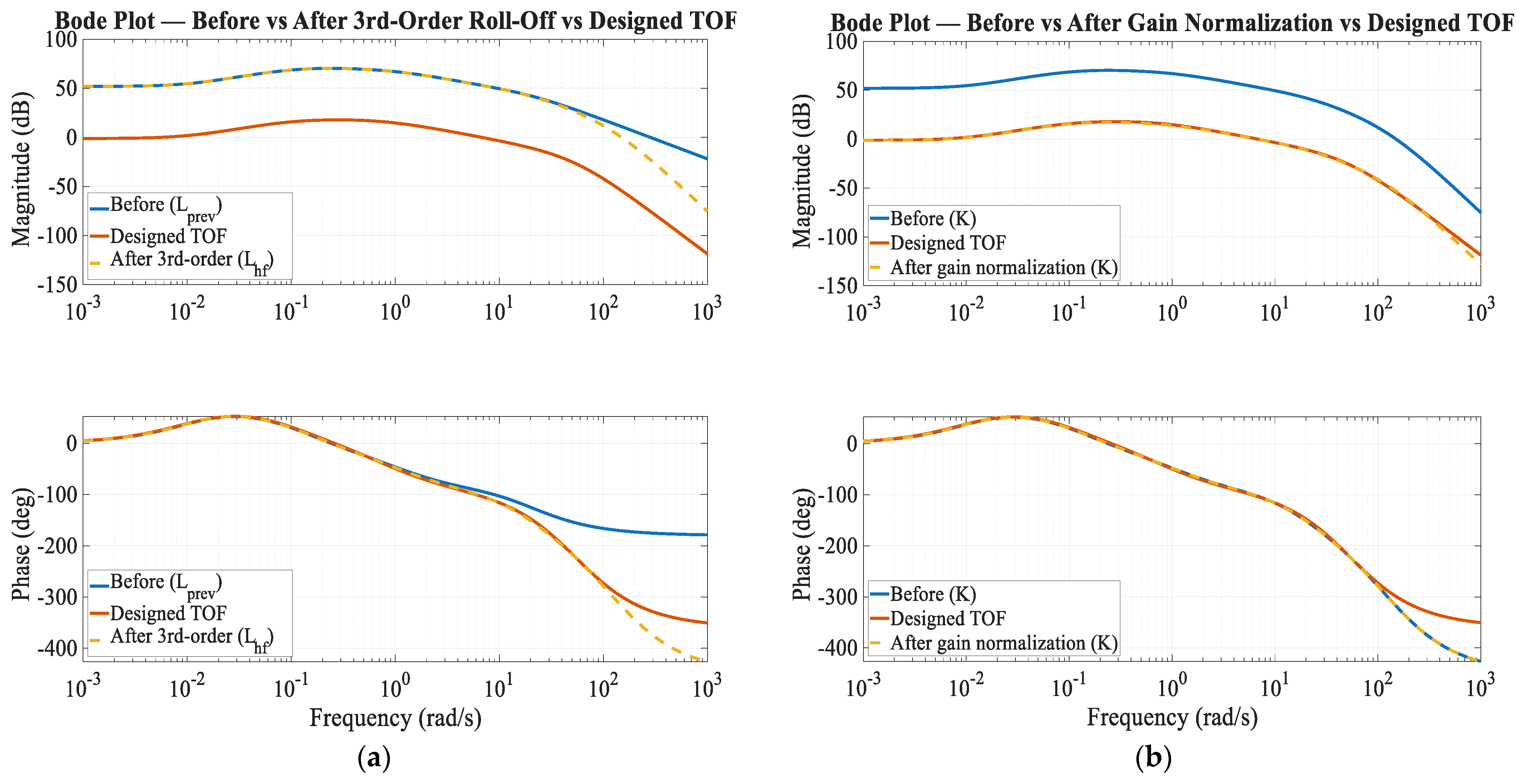

To further validate the effectiveness of the controller, closed-loop step responses of the pitch angular rate loops are presented in

Figure 5, demonstrating that the frequency–domain design translates into satisfactory time–domain performance with fast rise, limited overshoot, and well-damped behavior.

Figure 5.

Open-loop Bode plots comparing the actuator-augmented plant , the shaped loop , and the target open-loop function .

Figure 5.

Open-loop Bode plots comparing the actuator-augmented plant , the shaped loop , and the target open-loop function .