Integrated Optimization of Ground Support Systems and UAV Task Planning for Efficient Forest Fire Inspection

Abstract

1. Introduction

- A comprehensive mixed planning model is established, comprising the GSS site selection model, generation device capacity allocation model, inspection area division model, inspection route planning model for each inspection area, and multi-UAV collaborative task planning model. This model aims to optimize the overall efficiency of UAV inspection tasks and enhance the economic benefits of resource allocation within the energy assurance system.

- A hybrid solving strategy is proposed, employing an integer programming algorithm to address the upper-layer site selection and capacity determination problem formulated as an integer linear programming model, while k-means clustering, the boundary function, and the Douglas–Peucker algorithm are used to address the inspection area division problem. A goal-driven greedy algorithm (GDGA) is applied to tackle the multi-UAV collaborative task planning issue.

- Extensive simulation experiments are conducted to verify the effectiveness of the proposed model. Additionally, comparative algorithm experiments are executed to demonstrate the enhanced solution achieved through the proposed algorithm.

2. Problem Description

3. Mathematical Model

3.1. First Stage Planning Model

3.2. Second Stage Planning Model

3.3. Third Stage Planning Model

4. Optimization Methodology

4.1. Optimization Method for Area Partitioning

| Algorithm 1 Inspection Zone Partitioning Algorithm |

|

4.2. Optimization Method for Inspection Direction Selection

4.3. Optimization Method for UAV Task Planning

| Algorithm 2 Goal-Driven Greedy Algorithm for UAV Inspection (GDGA) |

|

5. Case Study

5.1. Parameter Setting

5.2. Simulation Result

5.2.1. Analysis of Model Effectiveness

5.2.2. Analysis of Algorithm Performance

5.3. Discussion

6. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, K.; Xu, R.; Li, J.; Lv, Y.; Lin, H.; Liu, Y. A vision-based detection and spatial localization scheme for forest fire inspection from UAV. Forests 2022, 13, 383. [Google Scholar] [CrossRef]

- Namburu, A.; Selvaraj, P.; Mohan, S.; Ragavanantham, S.; Eldin, E.T. Forest fire identification in uav imagery using x-mobilenet. Electronics 2023, 12, 733. [Google Scholar] [CrossRef]

- Chen, G.; Cheng, R.; Lin, X.; Jiao, W.; Bai, D.; Lin, H. LMDFS: A lightweight model for detecting forest fire smoke in UAV images based on YOLOv7. Remote Sens. 2023, 15, 3790. [Google Scholar] [CrossRef]

- Shamta, I.; Demir, B.E. Development of a deep learning-based surveillance system for forest fire detection and monitoring using UAV. PLoS ONE 2024, 19, e0299058. [Google Scholar] [CrossRef] [PubMed]

- Aibin, M.; Li, Y.; Sharma, R.; Ling, J.; Ye, J.; Lu, J.; Zhang, J.; Coria, L.; Huang, X.; Yang, Z.; et al. Advancing forest fire risk evaluation: An integrated framework for visualizing area-specific forest fire risks using uav imagery, object detection and color mapping techniques. Drones 2024, 8, 39. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, M.; Ding, Y.; Wan, T.; Qi, B.; Pang, Y. FBC-ANet: A semantic segmentation model for UAV forest fire images combining boundary enhancement and context awareness. Drones 2023, 7, 456. [Google Scholar] [CrossRef]

- Bamisile, O.; Acen, C.; Cai, D.; Huang, Q.; Staffell, I. The environmental factors affecting solar photovoltaic output. Renew. Sustain. Energy Rev. 2025, 208, 115073. [Google Scholar] [CrossRef]

- Chen, H.; Wu, W.; Li, C.; Lu, G.; Ye, D.; Ma, C.; Ren, L.; Li, G. Ecological and environmental effects of global photovoltaic power plants: A meta-analysis. J. Environ. Manag. 2025, 373, 123785. [Google Scholar] [CrossRef]

- Ghamry, K.A.; Kamel, M.A.; Zhang, Y. Multiple UAVs in forest fire fighting mission using particle swarm optimization. In Proceedings of the 2017 International Conference on Unmanned Aircraft Systems (ICUAS), Miami, FL, USA, 13–16 June 2017; pp. 1404–1409. [Google Scholar]

- De Sousa, J.V.R.; Gamboa, P.V. Aerial forest fire detection and monitoring using a small UAV. KnE Eng. 2020, 2020, 242–256. [Google Scholar]

- Xiao, J.; Yuan, G.; Xue, Y.; He, J.; Wang, Y.; Zou, Y.; Wang, Z. A deep reinforcement learning based distributed multi-UAV dynamic area coverage algorithm for complex environment. Neurocomputing 2024, 595, 127904. [Google Scholar] [CrossRef]

- Chen, J.; Du, C.; Zhang, Y.; Han, P.; Wei, W. A clustering-based coverage path planning method for autonomous heterogeneous UAVs. IEEE Trans. Intell. Transp. Syst. 2021, 23, 25546–25556. [Google Scholar] [CrossRef]

- Hu, W.; Yu, Y.; Liu, S.; She, C.; Guo, L.; Vucetic, B.; Li, Y. Multi-UAV coverage path planning: A distributed online cooperation method. IEEE Trans. Veh. Technol. 2023, 72, 11727–11740. [Google Scholar] [CrossRef]

- Bushnaq, O.M.; Chaaban, A.; Al-Naffouri, T.Y. The role of UAV-IoT networks in future wildfire detection. IEEE Internet Things J. 2021, 8, 16984–16999. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, C.; Wei, Z.; Pan, C.; Zhang, H.; Ren, Y. Joint UAV hovering altitude and power control for space-air-ground IoT networks. IEEE Internet Things J. 2018, 6, 1741–1753. [Google Scholar] [CrossRef]

- Li, M.; Li, H.; Ma, P.; Wang, H. Energy maximization for ground nodes in UAV-enabled wireless power transfer systems. IEEE Internet Things J. 2023, 10, 17096–17109. [Google Scholar] [CrossRef]

- Alladi, T.; Bansal, G.; Chamola, V.; Guizani, M. SecAuthUAV: A novel authentication scheme for UAV-ground station and UAV-UAV communication. IEEE Trans. Veh. Technol. 2020, 69, 15068–15077. [Google Scholar] [CrossRef]

- Panahi, F.H.; Panahi, F.H. Reliable and energy-efficient UAV communications: A cost-aware perspective. IEEE Trans. Mob. Comput. 2023, 23, 4038–4049. [Google Scholar] [CrossRef]

- Guan, H.; Sun, X.; Su, Y.; Hu, T.; Wang, H.; Wang, H.; Peng, C.; Guo, Q. UAV-lidar aids automatic intelligent powerline inspection. Int. J. Electr. Power Energy Syst. 2021, 130, 106987. [Google Scholar] [CrossRef]

- Tan, Y.; Li, S.; Liu, H.; Chen, P.; Zhou, Z. Automatic inspection data collection of building surface based on BIM and UAV. Autom. Constr. 2021, 131, 103881. [Google Scholar] [CrossRef]

- Erdelj, M.; Saif, O.; Natalizio, E.; Fantoni, I. UAVs that fly forever: Uninterrupted structural inspection through automatic UAV replacement. Ad Hoc Netw. 2019, 94, 101612. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Q.; Chu, L.; Zhou, Y.; Xu, C. Real-time detection and spatial localization of insulators for UAV inspection based on binocular stereo vision. Remote Sens. 2021, 13, 230. [Google Scholar] [CrossRef]

- Bolourian, N.; Hammad, A. Path planning of LiDAR-equipped UAV for bridge inspection considering potential locations of defects. In Proceedings of the Advances in Informatics and Computing in Civil and Construction Engineering: Proceedings of the 35th CIB W78 2018 Conference: IT in Design, Construction, and Management, Chicago, IL, USA, 1–3 October 2018; Springer: Cham, Switzerland, 2018; pp. 545–552. [Google Scholar]

- Matlekovic, L.; Juric, F.; Schneider-Kamp, P. Microservices for autonomous UAV inspection with UAV simulation as a service. Simul. Model. Pract. Theory 2022, 119, 102548. [Google Scholar] [CrossRef]

- Hu, M.; Liu, W.; Lu, J.; Fu, R.; Peng, K.; Ma, X.; Liu, J. On the joint design of routing and scheduling for vehicle-assisted multi-UAV inspection. Future Gener. Comput. Syst. 2019, 94, 214–223. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, C.; Xu, C.; Xiong, F.; Zhang, Y.; Umer, T. Energy-efficient industrial internet of UAVs for power line inspection in smart grid. IEEE Trans. Ind. Inform. 2018, 14, 2705–2714. [Google Scholar] [CrossRef]

- Ivić, S.; Crnković, B.; Grbčić, L.; Matleković, L. Multi-UAV trajectory planning for 3D visual inspection of complex structures. Autom. Constr. 2023, 147, 104709. [Google Scholar] [CrossRef]

- Liang, H.; Lee, S.C.; Bae, W.; Kim, J.; Seo, S. Towards UAVs in construction: Advancements, challenges, and future directions for monitoring and inspection. Drones 2023, 7, 202. [Google Scholar] [CrossRef]

- Takaya, K.; Ohta, H.; Kroumov, V.; Shibayama, K.; Nakamura, M. Development of UAV system for autonomous power line inspection. In Proceedings of the 2019 23rd International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 9–11 October 2019; pp. 762–767. [Google Scholar]

- Zhang, Y.; Yuan, X.; Li, W.; Chen, S. Automatic power line inspection using UAV images. Remote Sens. 2017, 9, 824. [Google Scholar] [CrossRef]

- Lopez Lopez, R.; Batista Sanchez, M.J.; Perez Jimenez, M.; Arrue, B.C.; Ollero, A. Autonomous uav system for cleaning insulators in power line inspection and maintenance. Sensors 2021, 21, 8488. [Google Scholar] [CrossRef]

- Zeng, Y.; Xu, J.; Zhang, R. Energy minimization for wireless communication with rotary-wing UAV. IEEE Trans. Wirel. Commun. 2019, 18, 2329–2345. [Google Scholar] [CrossRef]

| Parameters | Definition | Setting |

|---|---|---|

| Installed quantities of PV | [0, 10] | |

| Installed quantities of ES | [0, 8] | |

| Installed quantities of DG | [0, 8] | |

| , | Investment and operation cost of PV (USD) | 6150,0.11 |

| , | Investment and operation cost of ES (USD) | 12,100,0.89 |

| , | Investment and operation cost of DG (USD) | 9600,0.53 |

| , | Upper and lower bounds of SOC for the ES | 0.2, 0.8 |

| , | Maximum charging and discharging power (kW) | 10 |

| Maximum generation power of DG (kW) | 15 | |

| , a, b, c | correlation coefficient of load calculation | 0.121, 1.879, 0.157, 0.186 |

| Discount rate | 0.06 | |

| Service life cycle of equipment (year) | 6 | |

| Area of photovoltaic panels (m2) | 10 | |

| the reference temperature | 25 °C | |

| Conversion coefficient of PV at | 17% | |

| Conversion coefficient of DG | 36.4% | |

| the calorific value (kWh/m3) | 9.78 | |

| Maximum ramp-up power of DG (kW) | 5 | |

| the profile drag coefficient | 0.012 | |

| s | the rotor solidity of UAV | 0.16 |

| R | the rotor radius of UAV (m) | 0.81 |

| the swept area of UAV (km2) | 2.061 | |

| the power correction factor of UAV | 0.1 | |

| W | the Weight of the UAV (N) | 64.7 |

| Air density (kg/m3) | 1.225 | |

| the maximum flight range (km) | 26.4 |

| Model (Type) | Annual Total Cost (USD) | Annual Planning Cost (USD) | Annual Operation Cost (USD) | Penetration Rate of Renewable Energy |

|---|---|---|---|---|

| A (Proposed) | 68.71% | |||

| B (Take-Only) | 37.23% | |||

| C (Renewable-Only) | 55.96% |

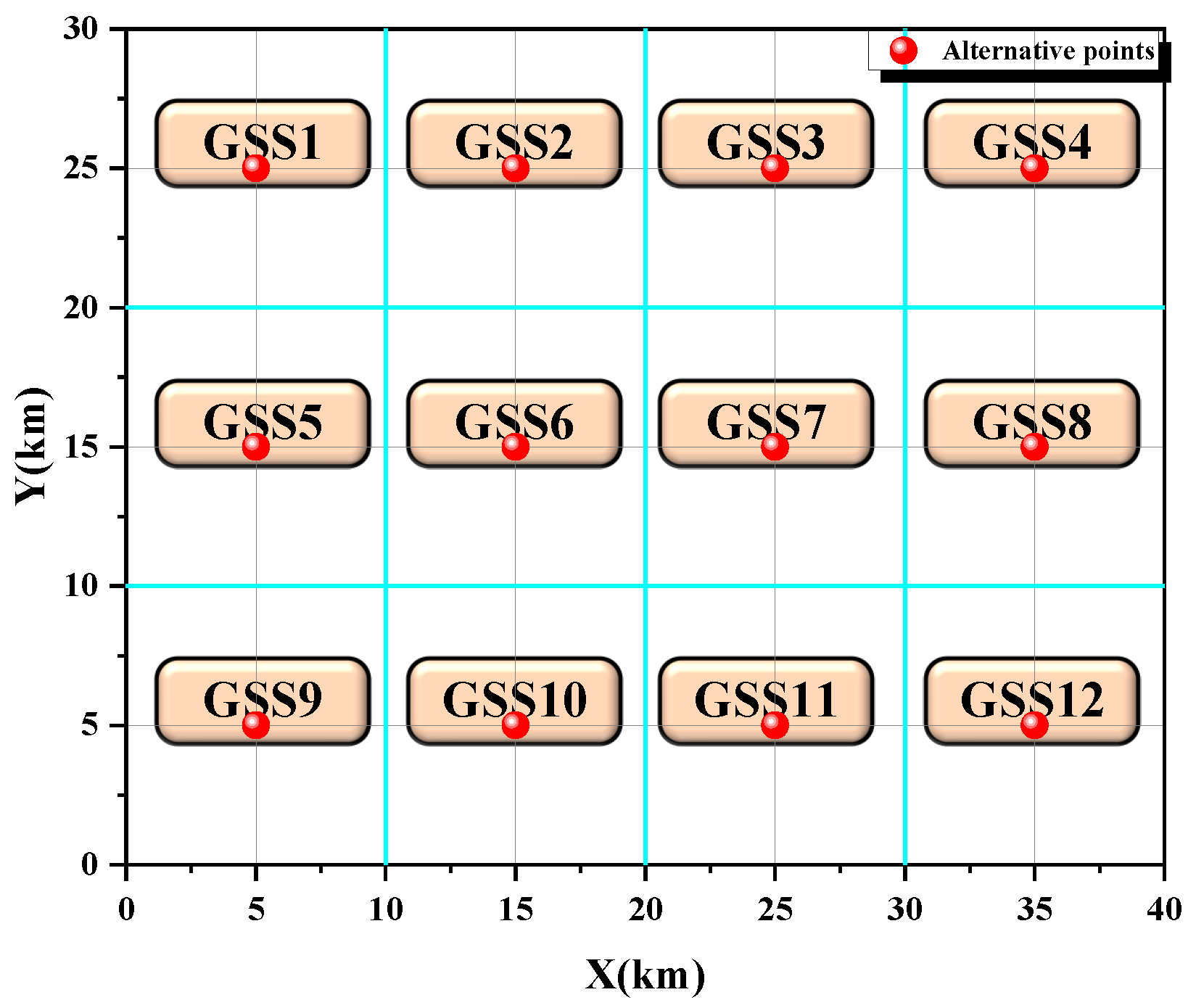

| Model (Type) | Site Selection | Capacity Planning (PV, ES, DG) |

|---|---|---|

| A (Proposed) | GSS2 GSS4 GSS9 GSS11 | GSS2: [4 1 3] GSS4: [6 2 2] |

| GSS9: [5 2 2] GSS11: [3 0 3] | ||

| B (Take-Only) | GSS5 GSS6 GSS7 GSS8 | GSS5: [4 0 5] GSS6: [5 3 3] |

| GSS7: [4 0 5] GSS8: [3 0 6] | ||

| C (Renewable-Only) | GSS4 GSS5 GSS6 GSS9 | GSS4: [4 1 1] GSS5: [5 1 1] |

| GSS6: [10 0 4] GSS9: [5 2 3] |

| Rotation Angle | Distance from Greedy Algorithm (km) | Distance from Goal-Driven Greedy Algorithm (km) |

|---|---|---|

| 0° | 29.9893 | 27.873 |

| 30° | 54.9226 | 52.4558 |

| 60° | 65.9073 | 59.9575 |

| 90° | 32.9951 | 29.9679 |

| 120° | 7.9921 | 6.9991 |

| 150° | 20.009 | 17.9853 |

| UAV Flight Distance (km) | Solution Time of Greedy Algorithm (s) | Solution Time of Goal-Driven Greedy Algorithm (s) | Solution Time of GA Algorithm (s) |

|---|---|---|---|

| 10 | 0.0165 | 0.0138 | 3.2406 |

| 20 | 0.8082 | 0.6657 | 5.7323 |

| 50 | 1.5473 | 1.1369 | 11.2110 |

| 100 | 3.4201 | 3.5760 | 16.2035 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Shi, Z.; Liu, W.; Zhang, L.; Wang, R. Integrated Optimization of Ground Support Systems and UAV Task Planning for Efficient Forest Fire Inspection. Drones 2025, 9, 684. https://doi.org/10.3390/drones9100684

Liu Z, Shi Z, Liu W, Zhang L, Wang R. Integrated Optimization of Ground Support Systems and UAV Task Planning for Efficient Forest Fire Inspection. Drones. 2025; 9(10):684. https://doi.org/10.3390/drones9100684

Chicago/Turabian StyleLiu, Ze, Zhichao Shi, Wei Liu, Lu Zhang, and Rui Wang. 2025. "Integrated Optimization of Ground Support Systems and UAV Task Planning for Efficient Forest Fire Inspection" Drones 9, no. 10: 684. https://doi.org/10.3390/drones9100684

APA StyleLiu, Z., Shi, Z., Liu, W., Zhang, L., & Wang, R. (2025). Integrated Optimization of Ground Support Systems and UAV Task Planning for Efficient Forest Fire Inspection. Drones, 9(10), 684. https://doi.org/10.3390/drones9100684