Coupling Dynamics Study on Multi-Body Separation Process of Underwater Vehicles

Abstract

1. Introduction

2. Coupling Dynamics Modeling of UUV and TMV

2.1. Definition of Coordinate System and Rotation Transformation

2.2. Preparation for Dynamics Modeling

2.3. System Dynamics Model

3. Fitting of Hydrodynamic Approximation Formulas and Coordinate Transformations of Hydrodynamics

3.1. UUV Velocity Coordinate System

3.2. Hydrodynamic Drag, Lift, and Moment Equations Fitted from Empirical Data

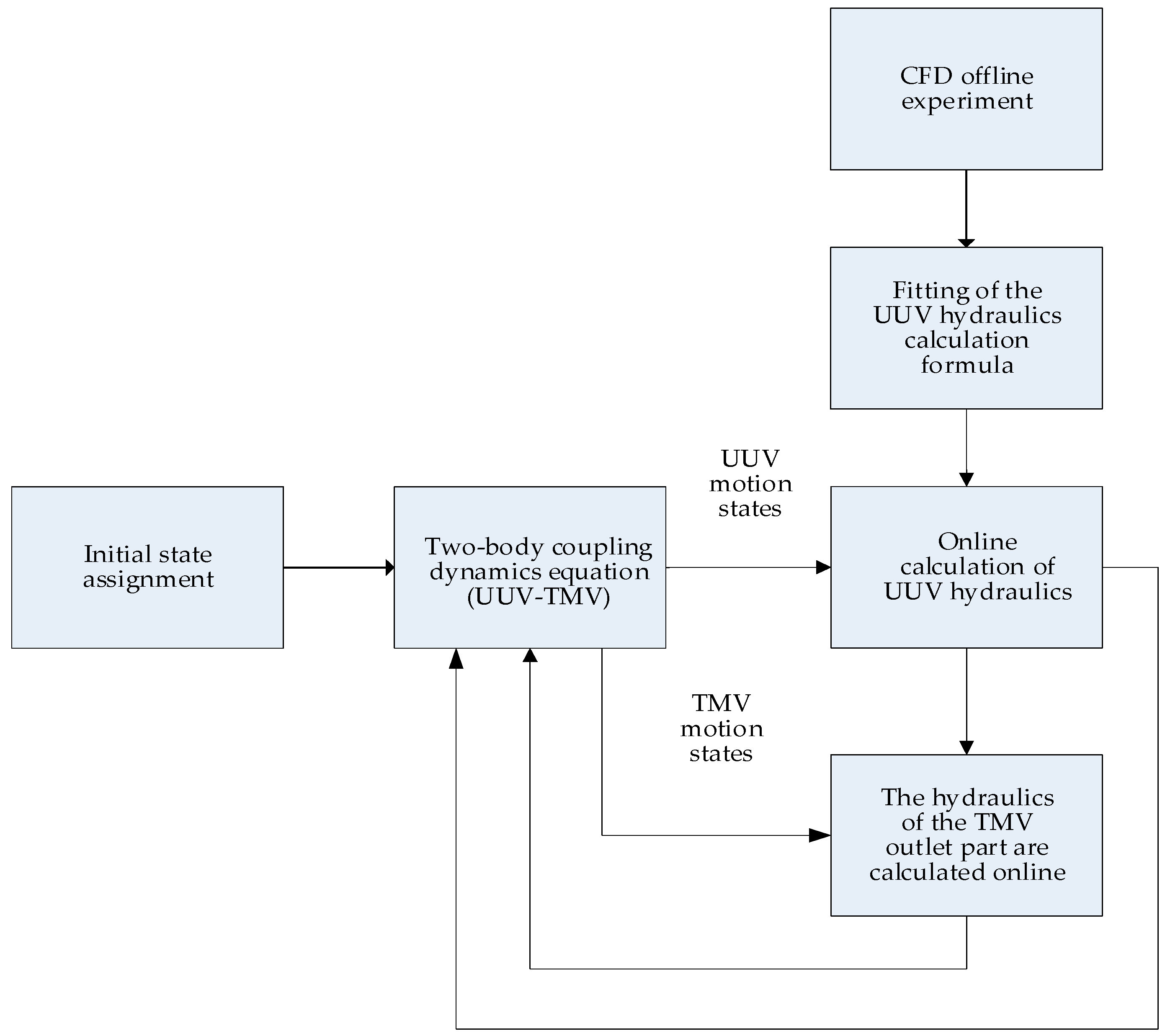

3.3. Hydrodynamic Calculation and Transformation for UUV and TMV in Coupling Simulation

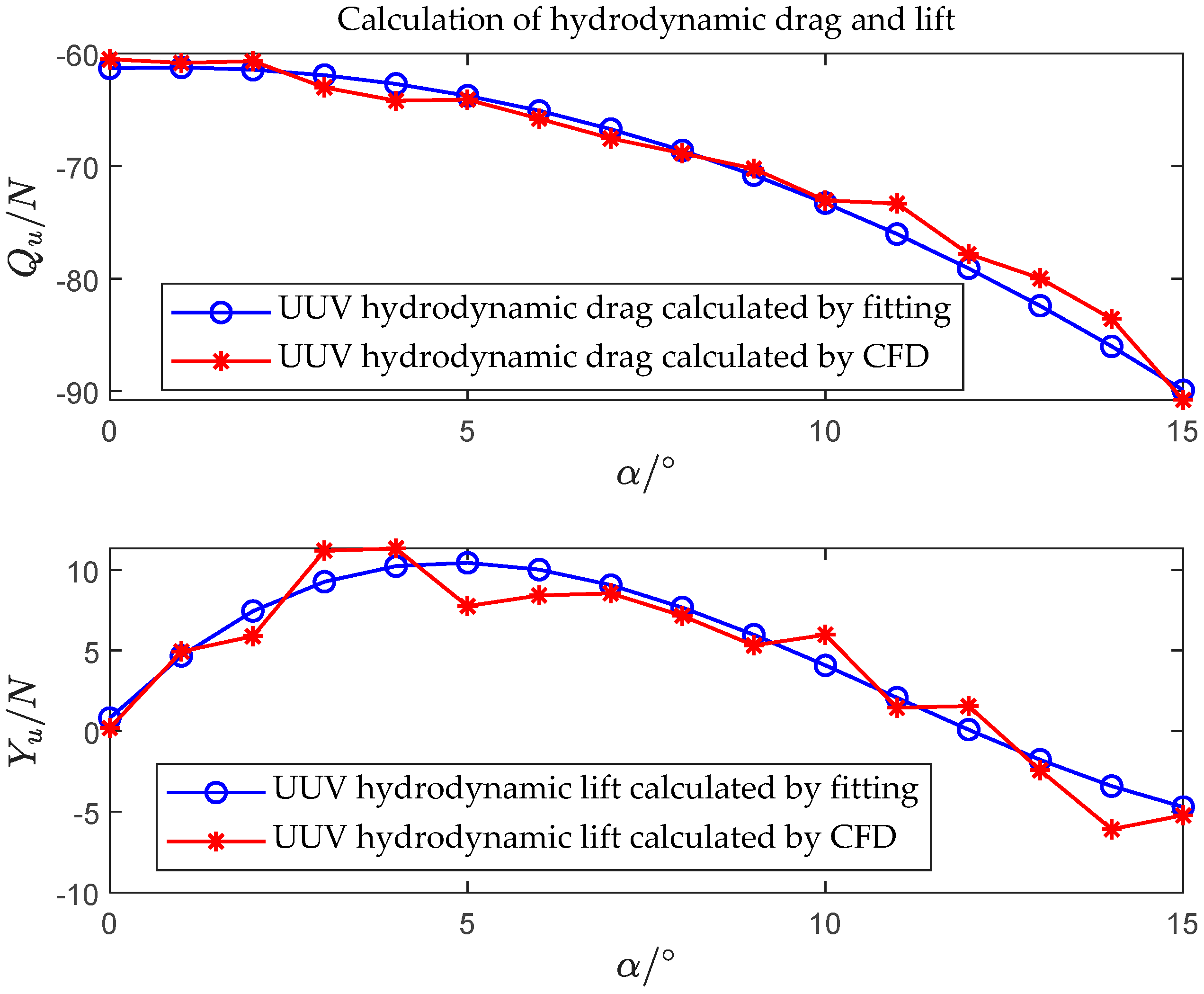

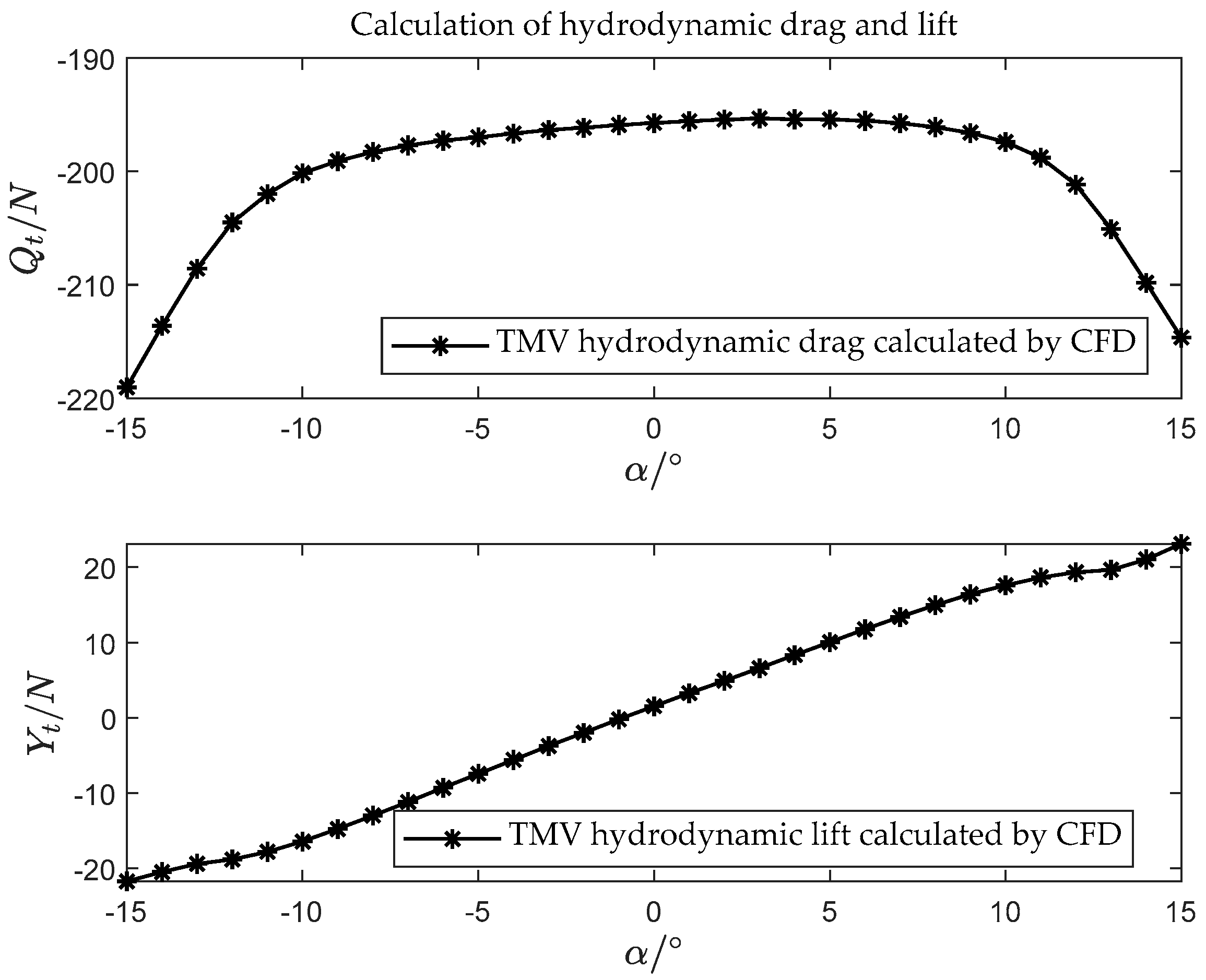

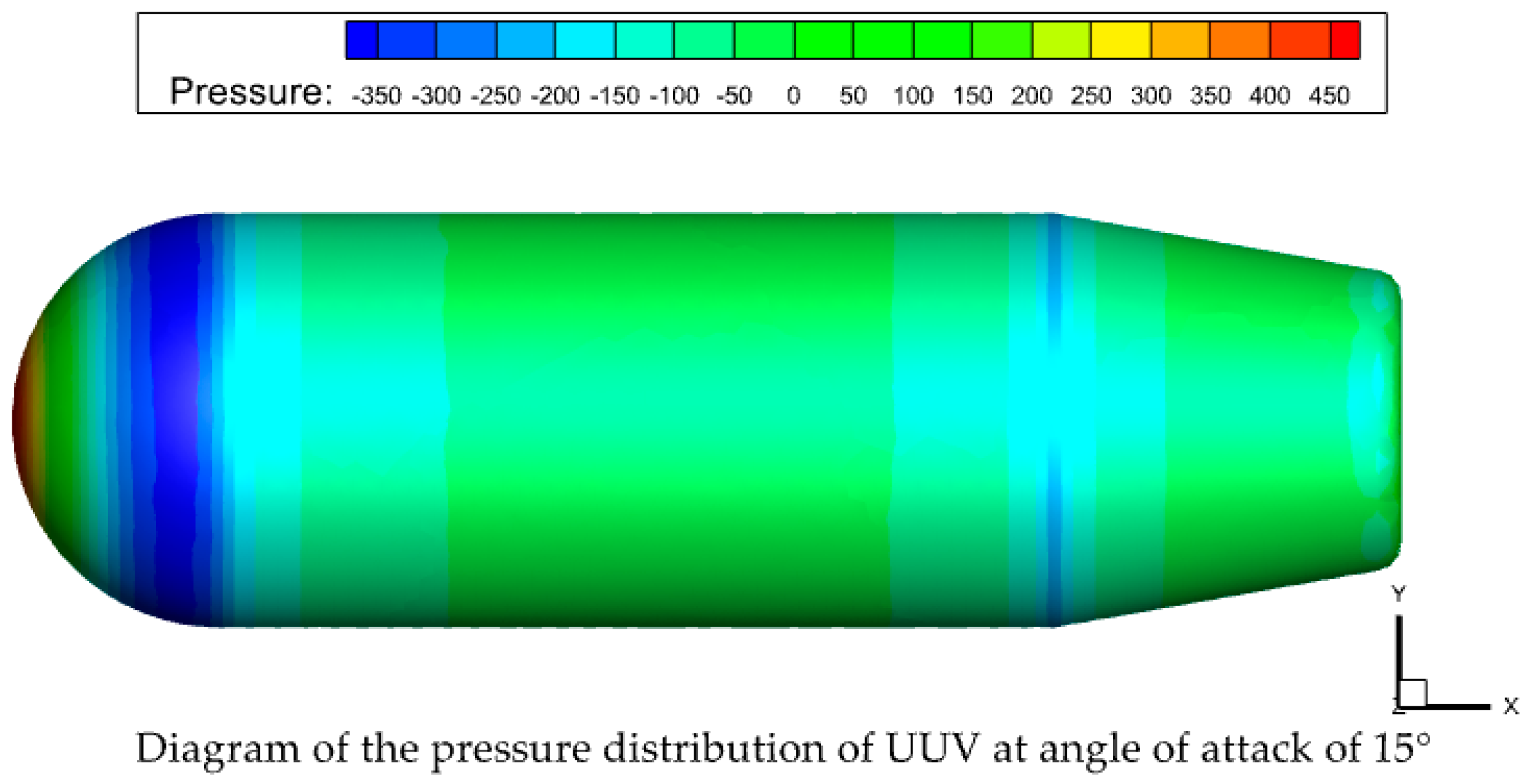

3.4. CFD Simulations and Hydrodynamic Fitting Results

4. Numerical Simulation of the Underwater Separation Process

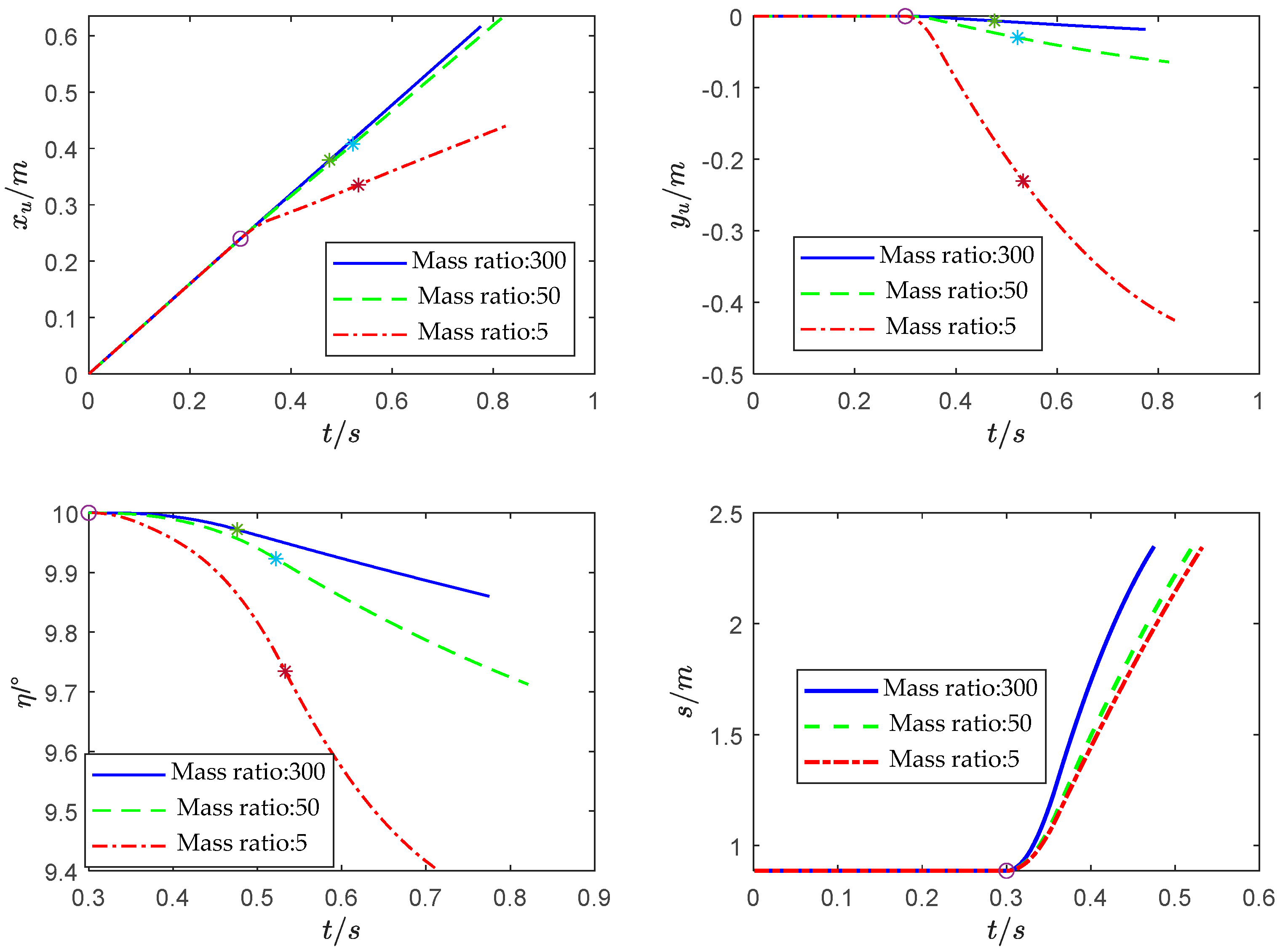

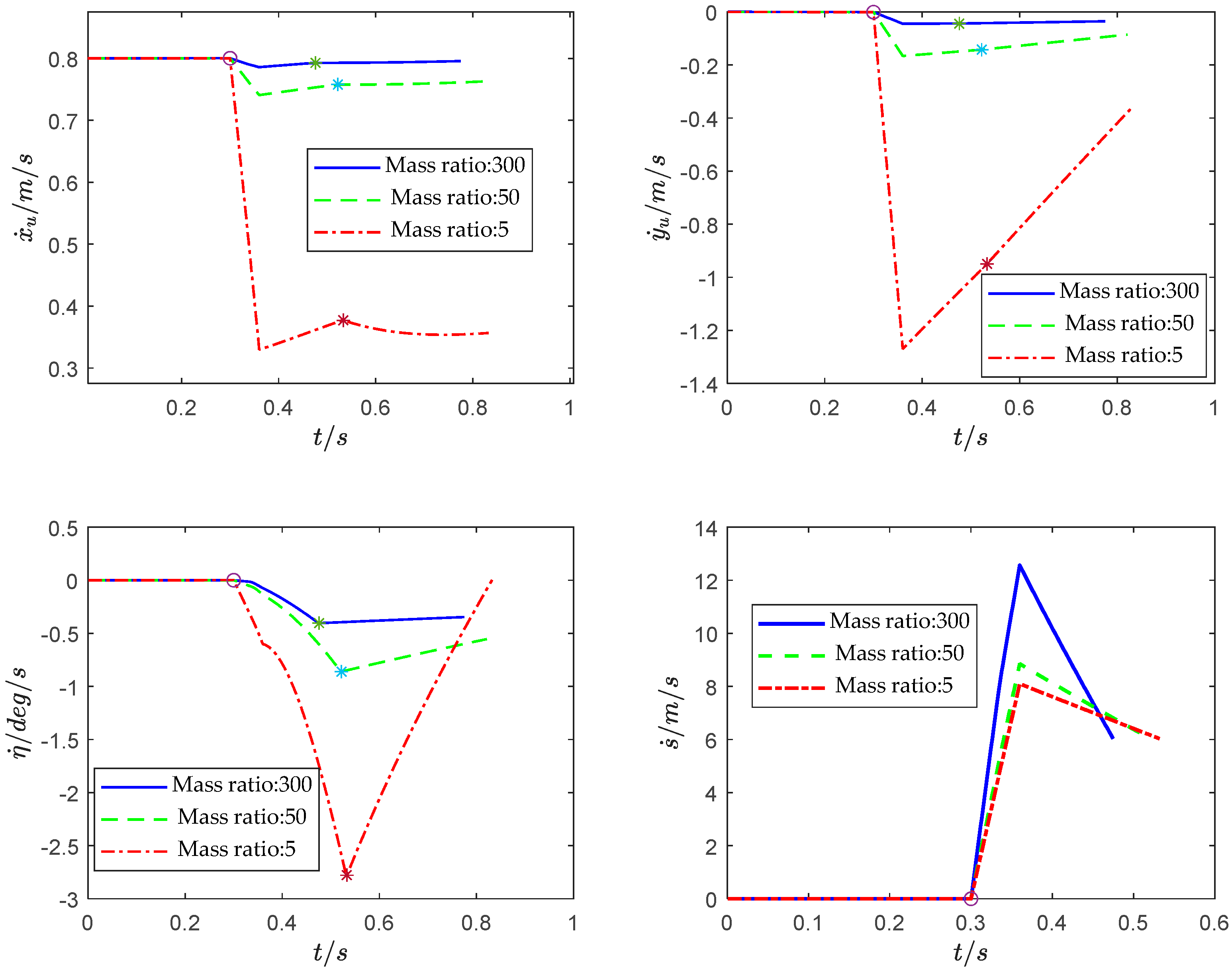

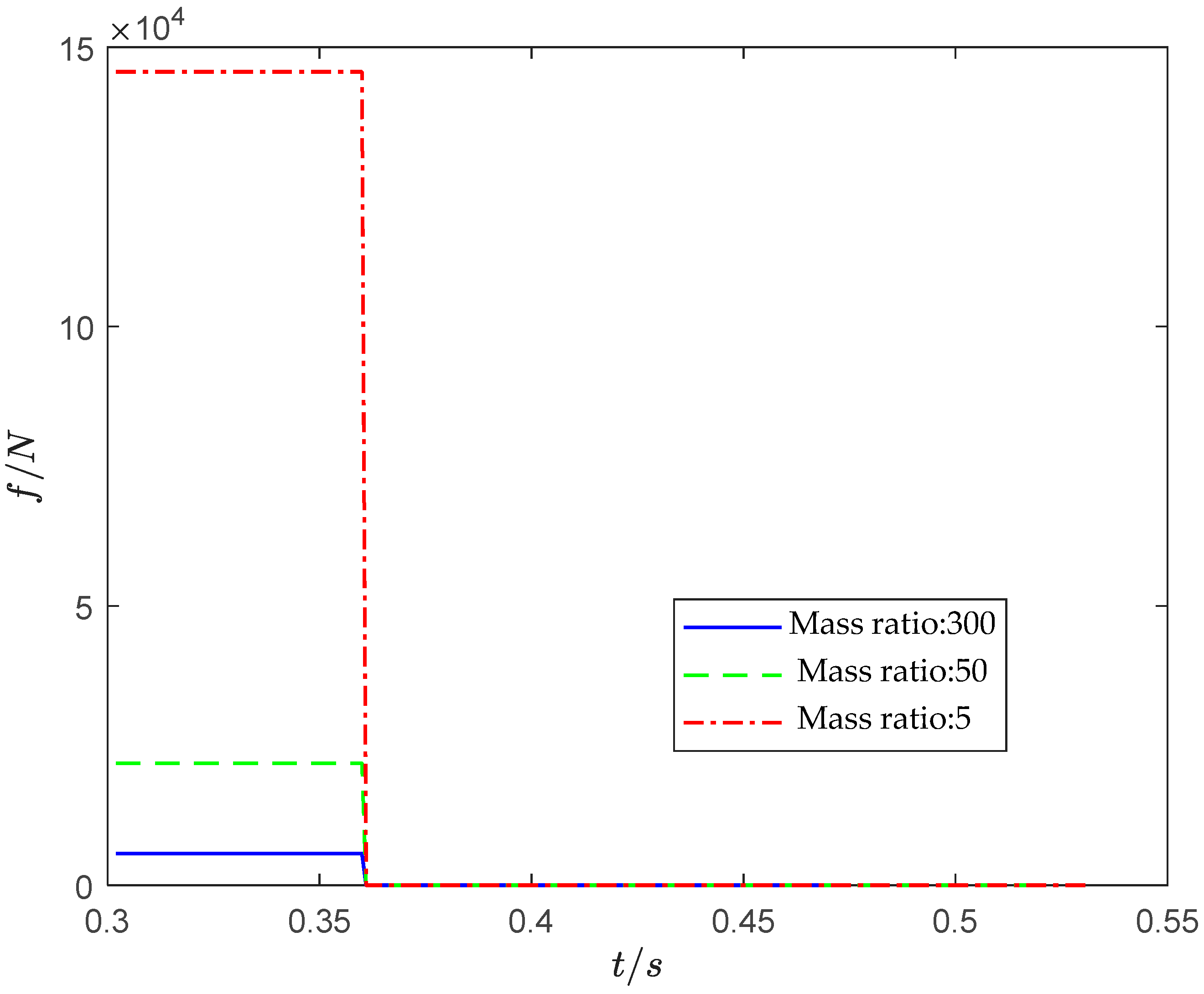

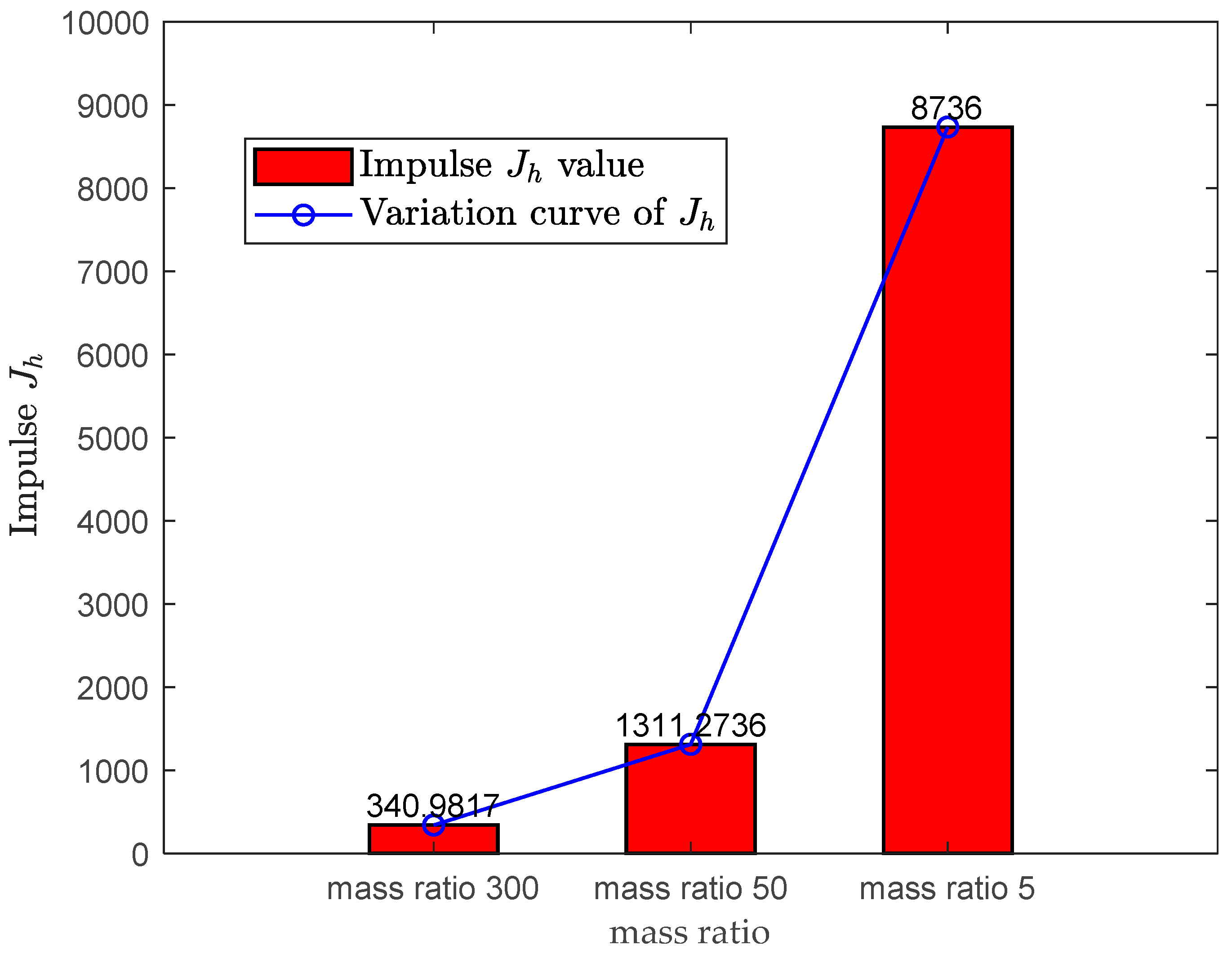

4.1. Simulation Experiment and Analysis

4.2. Simulation Conclusion

- Through numerical simulation experiments, it was found that when the mass ratio of UUV to TMV is small, the separation of the TMV will have a significant impact on the motion state of the UUV. When the TMV has completely exited the UUV, the UUV cannot automatically return to the initial cruising state, so in order to keep the UUV in a stable motion state before and after the separation of the TMV, it is necessary to study the two rigid bodies’ coupling dynamics during the process of theTMV separating from the UUV.

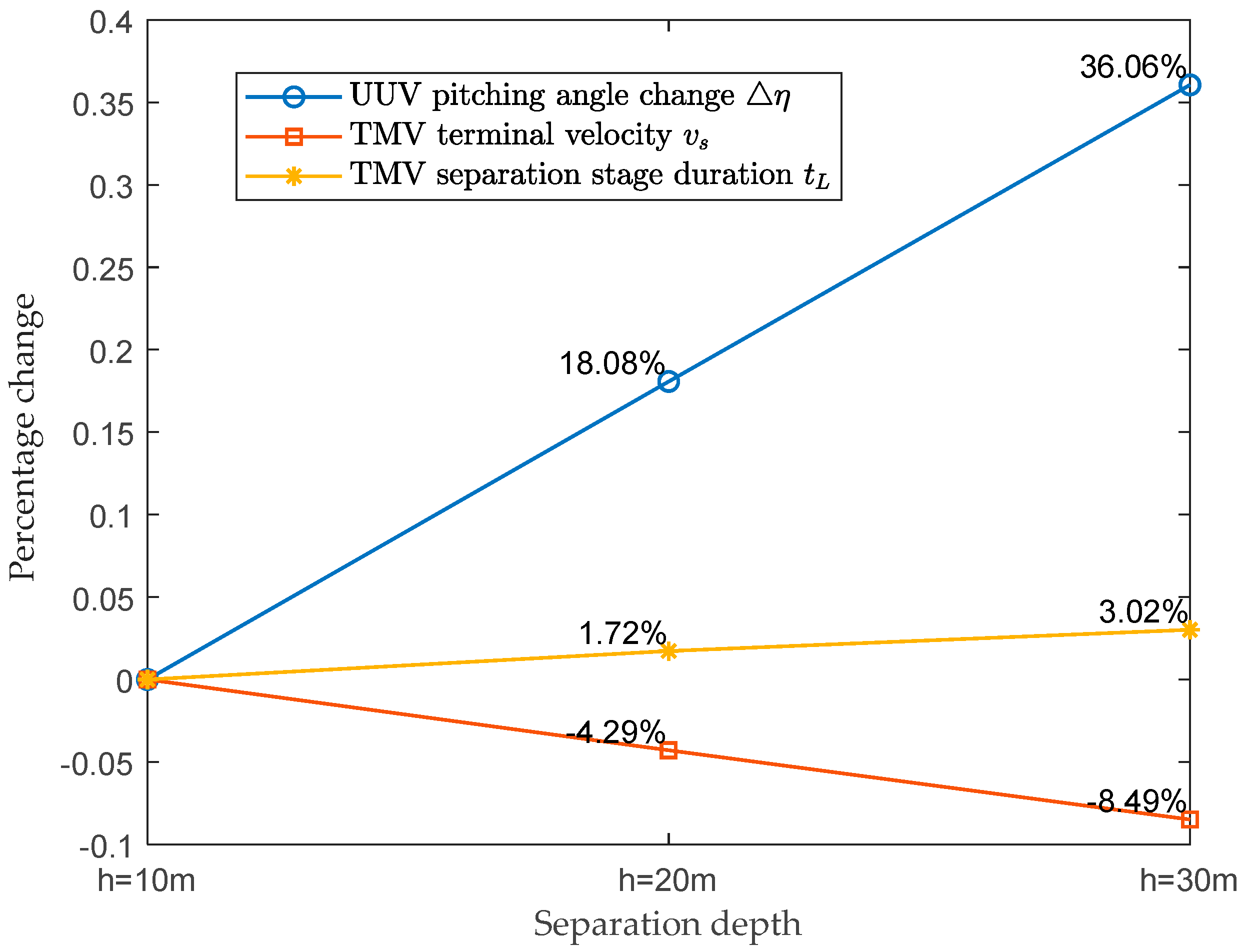

- When the TMV separates from the UUV in deep water, as the separation depth increases, the “water pressure” on the TMV’s exit section increases, so the separation resistance of the TMV increases. When the separation propulsion force parameters and other initial simulation conditions are the same, the greater the separation depth of TMV, the more severe the impact on the UUV’s motion state. In the case where the mass ratio of the UUV and TMV system is different and the terminal velocity of the TMV is basically the same, the system with a larger mass ratio consumes much less impulse during the separation process than the system with a smaller mass ratio. At the same time, when the system has a larger mass ratio, the entire separation process takes less time. That is, when the mass ratio is low, the coupling effect of the TMV on the UUV is greater.

- When a TMV separates from a UUV underwater, it is often necessary for the TMV to have a large terminal velocity, so that it can fly out of the water’s surface relying on inertia. At the same time, it is also required that the impact on the UUV’s motion state during this process is small. Therefore, the separation strategy we can adopt is to increase the mass ratio of the UUV and TMV, reduce the separation depth of the TMV, or increase the impulse acting on the TMV during the separation process.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, Y.; Pan, X.; Wang, X.; Ye, J.; Yin, X.; Dai, D. Research on unmanned underwater vehicle technology development and combat application. Ship Sci. Technol. 2023, 45, 104–109. [Google Scholar]

- Weiland, C.J.; Vlachos, P.P.; Yagla, J.J. Concept analysis and laboratory observations on a water piercing missile launcher. Ocean Eng. 2010, 37, 959–965. [Google Scholar] [CrossRef]

- Pan, G.; Shi, Y.; Wang, P.; Du, X. Study on the Control Law for Water Trajectory of Unpowered Carrier Under Wave Force. In Proceedings of the 3rd International Conference on Frontiers of Manufacturing Science and Measuring Technology (ICFMM 2013), Lijiang, China, 30–31 July 2013; pp. 525–530. [Google Scholar]

- Liu, Y.; Ma, Z. The Research on Trajectory and Hot Separation of a Vertical Submarine Launched Missile. Ship Eng. 2005, 27, 6–9. [Google Scholar]

- Liu, Y.; Zhang, Y.; Hu, D. Simulation on Capsule’s Trajectory Control of Submarine Launched Missile and Stability Studies of Capsule Moving Near the Free Surface. J. Proj. Rocket. Missiles Guid. 2005, 3, 190–191+197. [Google Scholar]

- Li, J.; Lu, C.; Chen, X.; Cao, J. Analysis on Influence of Attached Cavity on the Trajectory of Submarine Launched Missile. J. Ballist. 2014, 26, 54–58. [Google Scholar]

- Jiang, B.; Liu, Y.; Wang, C.; Liu, B. The Modeling and Research on Underwater Motion of Submarine Vertical Launched Cruise Missile. Tactical Missile Technol. 2013, 3, 30–34. [Google Scholar] [CrossRef]

- Li, D.; Zhang, Y.; Dang, J.; Luo, K. Numerical Solution for Outlet Attitude of the Missile Vertical Launched from a Submarine. J. Proj. Rocket. Missiles Guid. 2009, 29, 171–173+178. [Google Scholar]

- Shang, S.-C.; Sun, J.-Z. Research on the Affection of the Underwater Missile Launching Process. In Proceedings of the 3rd International Conference on Mechanical and Electronics Engineering (ICMEE 2011), Hefei, China, 23–25 September 2011; pp. 2594–2599. [Google Scholar]

- Wang, Y.; Lin, T.; Jiang, H. Numerical Analysis for Water-Exit Trajectory of Submarine-launched UUV. In Proceedings of the 2018 International Conference on Mathematics, Modelling, Simulation and Algorithms (MMSA 2018), Chengdu, China, 25–26 March 2018. [Google Scholar]

- You, T.; Wang, C.; Cao, W.; Wei, Y.; Zhang, J. Dynamic Analysis of Underwater Launched Vehicle During Water Exit. Adv. Sci. Lett. 2011, 4, 2907–2910. [Google Scholar] [CrossRef]

- Zahid, M.Z.; Nadeem, M.; Ismail, M. Numerical Study of Submarine Launched Underwater Vehicle. In Proceedings of the 17th International Bhurban Conference on Applied Sciences and Technology (IBCAST), Islamabad, Pakistan, 14–18 January 2020; pp. 472–476. [Google Scholar]

- Zhang, D.; Wang, C.; Shen, Y.; Wei, Y.; Xu, H. Dynamic modeling and motion prediction of two projectiles launched successively underwater. Ocean Eng. 2024, 292, 116551. [Google Scholar] [CrossRef]

- Cheng, Y.s.; Liu, H. A Coupling Model of Water Flows and Gas Flows in Exhausted Gas Bubble on Missile Launched Underwater. J. Hydrodyn. 2007, 19, 403–411. [Google Scholar] [CrossRef]

- Hu, K.; Ding, F. Simulation research of submarine ballistic missile launching movement modeling and manoeuvre control. Ship Sci. Technol. 2013, 35, 109–114. [Google Scholar]

- Tan, D. Modeling and Simulation for Underwater Trajectory of the Submarine Horizontal Launched Vehicle on the Condition of Ignition Failure. J. Ordnance Equip. Eng. 2018, 39, 16–20. [Google Scholar]

- Bian, X.; Zhao, X.; Zhu, C.; Li, X. Study on the Influence of Launch Parameters on the Safety of Vehicle Trajectory. J. Ordnance Equip. Eng. 2017, 38, 40–45. [Google Scholar]

- Lv, B.; Huang, B.; Peng, L. Research on the uncertain factors to the control of submarine during missile launching process. Ship Sci. Technol. 2017, 39, 185–189+193. [Google Scholar]

- Liu, B.; Luo, Y.; Li, F. Correlation Analysis on the Ejecting Velocity of Submarine-launched Missile. Ordnance Ind. Autom. 2020, 39, 63–64+78. [Google Scholar]

- Li, J. Navigation Safety Analysis of Submarine after Underwater Vehicle Launching. Master’s Thesis, Harbin Engineering University, Harbin, China, 2022. [Google Scholar]

| Calculation Settings | UUV | TMV |

|---|---|---|

| Magnitude of the incoming flow velocity | ||

| Range of attack angle of incoming flow | ||

| Turbulence Model | SST K-Omega model | SST K-Omega model |

| Solver settings | Pressure-based and Steady | Pressure-based and Steady |

| Monitoring conditions for convergence calculation | Residual Continuity: When Continuity < 0.0001 and the hydrodynamic force acting on the UUV remains approximately unchanged, the calculation is considered to converge | Residual Continuity: When Continuity < 0.0001 and the hydrodynamic force acting on the TMV remains approximately unchanged, the calculation is considered to converge |

| Maximum iterations | 2000 | 2000 |

| Parameter | |||

|---|---|---|---|

| 7146.2 | 7029 | 5975 | |

| 23.8 | 140 | 1195 | |

| 11,359 | 10,174 | 9497.4 | |

| 35.07 | 294.73 | 2050 |

| Parameter | |||

|---|---|---|---|

| 47.6496 | 47.6496 | 47.6496 | |

| −37.6007 | 84.5602 | 525.7601 | |

| 10 | 10 | 10 | |

| 5683.0 | 21,855.0 | 145,600.0 | |

| 0.06 | 0.06 | 0.06 | |

| 340.98 | 1311.30 | 8736.0 |

| Parameter | Value |

|---|---|

| 0 | |

| 0 | |

| 10 | |

| 0.8866 | |

| 0.8 | |

| 0 | |

| 0 | |

| 0 | |

| 1.7671 | |

| 5 | |

| 7.169 | |

| 60 |

| Parameter | Value |

|---|---|

| 0.26 | |

| 6.03 | |

| 0.232 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Han, Y.; Li, R.; Zhang, Y.; He, Z. Coupling Dynamics Study on Multi-Body Separation Process of Underwater Vehicles. Drones 2024, 8, 533. https://doi.org/10.3390/drones8100533

Chen J, Han Y, Li R, Zhang Y, He Z. Coupling Dynamics Study on Multi-Body Separation Process of Underwater Vehicles. Drones. 2024; 8(10):533. https://doi.org/10.3390/drones8100533

Chicago/Turabian StyleChen, Jiahui, Yanhua Han, Ruofan Li, Yong Zhang, and Zhenmin He. 2024. "Coupling Dynamics Study on Multi-Body Separation Process of Underwater Vehicles" Drones 8, no. 10: 533. https://doi.org/10.3390/drones8100533

APA StyleChen, J., Han, Y., Li, R., Zhang, Y., & He, Z. (2024). Coupling Dynamics Study on Multi-Body Separation Process of Underwater Vehicles. Drones, 8(10), 533. https://doi.org/10.3390/drones8100533