Abstract

Trichogramma-based biological control technology is of great significance to the development of green agriculture. Agricultural drones have the advantages of low-altitude and high-speed operations and have been well applied and widely recognized in the field of Trichogramma delivery. Drone-based Trichogramma ball delivery not only utilizes the efficiency and flexibility of drones but also enables remote precision control. However, existing delivery devices are relatively rudimentary, leading to reliability and precision issues. It is necessary to develop an efficient and accurate drone delivery device to improve the effect of drone delivery of Trichogramma. In this study, a device consisting of a rotary storage mechanism and a rotating hammer-type delivery mechanism was developed. The delivery port of the delivery device should be set in the airflow outlet area 50 cm below the drone’s body. The storage mechanism is equipped with eight storage tube units with a diameter of Φ38 mm, capable of delivering a total of 56 balls in a single mission. The reliable delivery speed ranges from 2 to 6 m/s, with the remote position of the lever serving as the optimal starting position. The release test results showed that 3 m/s flight speed and 4 m/s delivery speed resulted in a small coefficient of variation for the delivery deviation (29%), making it the best operating parameter set. The performance of the developed UAV-based Trichogramma delivery device meets the requirements of field delivery when the appropriate operating parameters are optimized. This study provides reference for further optimization and design of this delivery device prototype.

1. Introduction

Biological control technology refers to the technology of using beneficial organisms or other organisms (including microorganisms, parasitic natural enemies, predatory natural enemies, etc.) to control harmful organisms [1,2]. This technology can effectively avoid a series of problems caused by chemical control and provide an eco-friendly alternative for the control of pests and diseases [3,4]. Trichogramma is the most widely applicable natural enemy of Lepidoptera pests in the world, and it is widely used in the field of biological control [5]. Research on biological control technology based on the parasitic wasp has become an important part of the development of modern green agriculture in China [6]. Agricultural drones have the advantages of small size, flexible manipulation, and no need for a special take-off runway [7]. In this context, using agricultural drones to release Trichogramma balls can effectively solve the problem of difficult operation of traditional ground-based machinery in high-stem crop fields, paddy fields, and poor terrain plots. In addition, the use of this type of technology adds efficiency and has important research significance and practical value [8,9].

The key to using drones to release Trichogramma lies in properly handling the Trichogramma host eggs, minimizing direct contact between the host eggs and the release device, and avoiding losses caused by external environmental stimulation. Trichogramma release in the field usually involves submerged release. In field releases of Trichogramma, a flooding method is commonly employed [10]. Previous studies have achieved the placement of Trichogramma egg cards [11], spraying of suspensions [12], the release of mixtures [13], or specialized carriers. Trichogramma egg cards refer to paper cards attached to Trichogramma eggs, which are small and easy to fix on the crop stems and leaves. Trichogramma egg cards have a high eclosion rate but are susceptible to rain and strong winds, and it is difficult to achieve mechanized release. Therefore, researchers have used specially designed cartons with small holes [14], paper bags [15], and other alternatives to effectively reduce the impact of the environment on the quality of Trichogramma emergence. These methods effectively ensure the survival rate of Trichogramma, but they require a large amount of labor, the work environment is harsh, and the release speed and quality are limited [16]. Sun Mujun et al. demonstrated the feasibility of using the spraying system of agricultural drones to spray Trichogramma egg suspensions with the help of a peristaltic pump [17]. Experimental results showed that using crop protection drones to spray Trichogramma egg suspensions did not significantly affect their activity. However, there are many limitations to spraying Trichogramma egg suspensions, such as the type and concentration of the solute, the soaking time of the Trichogramma eggs, and the temperature during spraying operations, all of which can affect the uniform distribution and emergence rate of Trichogramma eggs.

Compared to spraying Trichogramma egg suspensions, the use of Trichogramma egg carriers eliminates these limitations. Italic Entobot biological release aircraft can deploy a mixture of Trichogramma eggs and vermiculite or dedicated capsule carriers [18]. The device consists of a Trichogramma egg storage container, a deployment rate regulation and measurement device, and a gravity-assisted deployment system located at the bottom of the storage container. The accompanying ground station and flight control system transport the biological release device to the corresponding locations for operational tasks. The drone-based deployment system operates at a rate of 20 hectares per hour, with a single operation lasting 0.5 h, and 400,000 Trichogramma host eggs can be spread per hectare [19]. Park et al. designed a low-cost aerial biological release device for inaccessible control areas. However, this device can only accommodate eight cylindrical paper carriers, resulting in a smaller payload [20]. Furthermore, the bottom of the carrier is filled with clay, which reduces the impact force upon landing when the carrier collides with the crop canopy. This may not be sufficient to break the clay end cap at the bottom of the carrier and release the beneficial organisms, thus compromising the effectiveness of pest control.

The abovementioned delivery methods have effectively improved deployment efficiency and reduced manual labor. However, there are also some problems with the structural design and deployment accuracy of the devices used for different forms of Trichogramma. Trichogramma balls are lightweight spherical carriers made of biodegradable and environmentally friendly materials, containing cards with Trichogramma eggs [21]. These spherical carriers have small holes on the surface, facilitating the emergence of Trichogramma and ensuring advantages in achieving mechanized precision deployment and promoting Trichogramma eclosion rate [22]. Existing drone-based deployment mechanisms for Trichogramma balls mainly consist of storage devices, discharge devices, deployment devices, and corresponding control parts. The storage devices are primarily categorized into hopper type [23,24], combined cylindrical type [25], and spiral arrangement type [26]. Hopper-type storage devices typically require antiblocking mechanisms or structures, while spiral-arrangement-type and combined-cylindrical-type storage devices are less prone to clogging but have reduced storage capacity. The methods of carrier deployment include free-fall [27] and projection [28]. Projection methods increase the initial velocity of the carrier upon leaving the drone, accelerating its descent and reducing interference from environmental winds, thus bringing the carrier closer to the intended release point. Zhu J et al. designed a deployment device for beneficial organism carriers. During operation, the gear teeth rotate to sequentially release the carriers, while the stirring rod inside the container continuously rotates to prevent blockage. A counter at the bottom is used to measure the number of carriers deployed, greatly improving operational efficiency [29]. Zhan Y et al. developed a new Trichogramma carrier deployment device mounted on a drone [30]. It uses a fork to rotate and orderly discharge the carriers, incorporates a photoelectric switch for counting, and is capable of monitoring the deployment quantity and detecting blockages. Field deployment experiments have shown that the results generally meet operational requirements. The abovementioned studies achieved UAV deployment of red-eyed wasp capsules, but there is limited research on the relationship between the deployment process and influencing factors. The delivery process based on drones is inevitably influenced by both the rotor wind field generated by the drone and the natural environment during low-altitude and high-speed operations [31,32].

To improve the deployment process of Trichogramma balls and enhance the accuracy of drone-based deployment, this paper proposes a rotary-wheel-based aerial deployment device for Trichogramma balls. By utilizing a rotary wheel storage method, the device achieves sequential and quantified release of the capsules and accelerates the deployment process through the action of a rotating hammer. Through the design and simulation testing of key components, the factors affecting the descent of Trichogramma balls were analyzed, and the operational parameters of the drone-based deployment device were optimized.

2. Design of Structures of the Delivery Device

2.1. Overall Structure and Working Principle

The overall structure of the rotary Trichogramma ball dispensing device based on a drone is shown in Figure 1. Each arm of the drone has a length of 78 cm, and the height of the drone body is 71 cm. The drone platform is assembled with a DJI A3 flight control system and a lightbridge2 system for autonomous route planning. The maximum takeoff weight is 15 kg, and the maximum flight height is 30 m. The dispensing device is installed 50 cm below the drone. The device mainly consists of a rotary storage mechanism, a turntable, upper and lower support plates, and a delivery mechanism. The upper and lower support plates, along with support rods, form the basic framework of the device. The rotary storage mechanism is fixed between the upper and lower support plates and mainly includes ball storage tubes and gripping mechanisms. The ball storage tubes are radially mounted on the gripping plate, which is connected to the rotation shaft of the rotary motor through a shaft fixing device, enabling the circular motion of multiple ball storage tubes. When a ball storage tube rotates to align with the drop hole on the lower support plate, the Trichogramma ball falls by gravity. The delivery mechanism is installed at the bottom of the lower support plate and mainly consists of a ball-receiving frame and a projection lever. The ball-receiving frame is used to catch the Trichogramma balls that fall through the drop hole. The Trichogramma balls are then accelerated and ejected at a certain initial velocity through the acceleration channel of the ball-receiving frame under the action of the driving lever.

Figure 1.

Schematic diagram of the Trichogramma ball delivery device of agricultural drone. 1. Support lever; 2. wheel motor; 3. upper support plate; 4. ball storage tube; 5. rotary shaft fixing part; 6. clamping disc; 7. lower support plate; 8. driving lever; 9. motor seat; 10. ball holder; 11. driving lever motor.

The working principle of the delivery device is as follows. Firstly, the ball storage tubes are filled with Trichogramma balls. When the drone reaches the designated release point, the control system receives the signal and controls the rotary motor to turn on. The rotary motor drives the ball storage tubes to rotate to the position of the drop hole. Once the Trichogramma balls fall into the ball-receiving frame, the ejection motor is activated. The ejection lever strikes the Trichogramma balls, propelling them along the acceleration channel of the ball-receiving frame to leave the delivery device.

2.2. Design of the Storage Mechanism

As illustrated in Figure 2, the Trichogramma balls (manufacturer: Guangzhou Yufeng Biological Pest Control Services Co., Ltd., Guangzhou, China) selected in this study are mainly composed of two half-circular cavities, an inner partition, and an exit opening. The upper half-circular cavity and the inner partition have an opening for the Trichogrammas to emerge, while the lower half-circular cavity is filled with a certain quantity of Trichogramma eggs or egg cards. The outer diameter of the Trichogramma ball is 35 mm, and it weighs 5.5 g. Each ball contains approximately 1000 Trichogrammas internally.

Figure 2.

Schematic diagram of the structure and composition of Trichogramma balls.

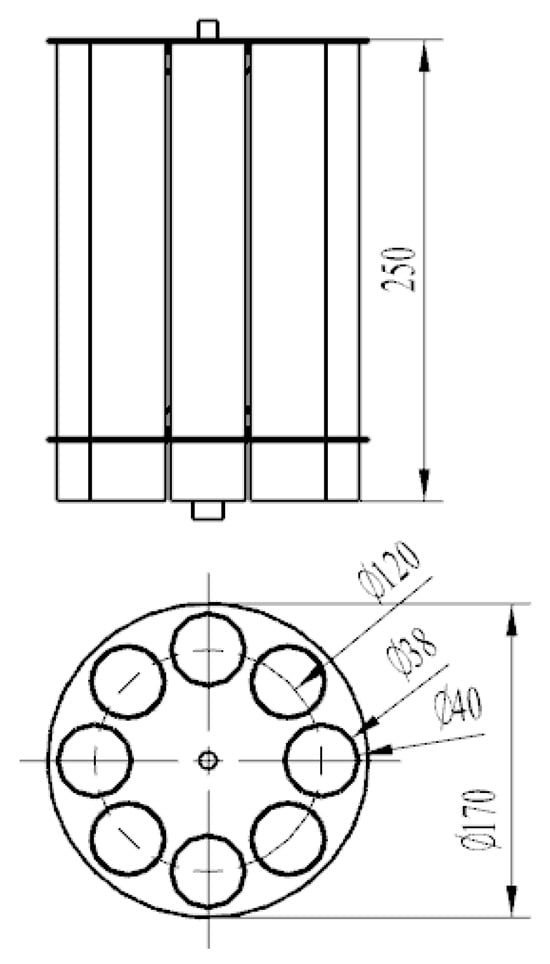

As illustrated in Figure 3, a rotating storage device used in this study consists of multiple storage tubes arranged evenly along the center of the upper and lower clamping discs. The number and length of the storage tubes increase with the target payload. However, this also leads to an increase in the diameter of the clamping disc. When the total payload is fixed, a larger number of storage tubes results in a smaller height of the storage device, while a higher payload per individual storage tube leads to a taller storage device.

Figure 3.

Structural parameters of the wheel storage device.

According to the Trichogramma delivery requirements in the Shandong province [33], the adjacent delivery interval for the Trichogramma balls is approximately 20 m, with a delivery quantity of 120 per hectare. Assuming a drone flight speed of 2 m/s and a duration of 600 s for the Trichogramma ball deployment operation, the approximate payload of Trichogramma balls is around 60 balls. Considering the single endurance time of the drone platform and the limited space at the bottom of the drone body, storage tubes with an outer diameter of 40 mm, a wall thickness of 1 mm, a length of 250 mm, and a quantity of 8 tubes were selected. Thus, the actual payload capacity for Trichogramma balls was 56 balls.

2.3. Design of Delivery Mechanism

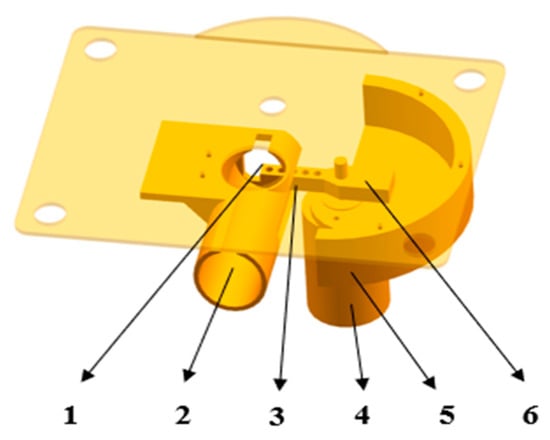

According to the design requirements, the delivery mechanism needs to have adjustable speed and deliver Trichogramma balls at a certain frequency. As shown in Figure 4, a hammering-type delivery mechanism was adopted in this study. During operation, the driving lever is driven by a DC motor to rotate around the pivot point. At the rotation outlet, the driving lever strikes the Trichogramma ball, providing it with kinetic energy. The Trichogramma ball is then launched along the acceleration channel of the ball receptacle. To facilitate smooth ejection of the Trichogramma balls, the diameter of the acceleration channel in the ball receptacle is 5 mm larger than the diameter of the Trichogramma balls, and it has been lengthened accordingly.

Figure 4.

Schematic diagram of delivery mechanism. 1. Fall hole; 2. acceleration channel; 3. rotary port; 4. lever motor; 5. motor seat; 6. driving lever.

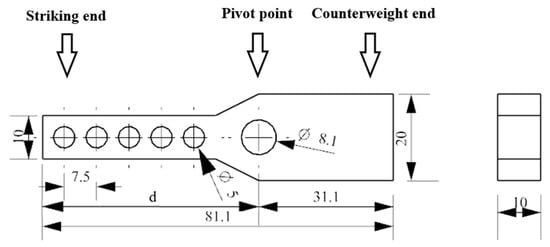

The structure of the driving lever shown in Figure 5 mainly consists of a striking end, a pivot point, and a counterweight end. In order to optimize the static balance of the lever, the lever designed in this study includes holes at the striking end to reduce the mass of the lever, and a counterweight end is used to adjust the lever’s center of mass to be as close as possible to the rotation center. In order to improve the delivery speed, the angle between the starting position of the striking end of the driving lever and the striking point is set to 270°. According to the structure of the Trichogramma ball and the ball receptacle, the radius of rotation for the driving lever is taken as d = 50 mm. The radius of rotation d (mm), the rotation speed of the driving lever n (r/min), and the projection velocity of the Trichogramma ball V (m/s) have the following functional relationship formula:

Figure 5.

Structure of the driving lever.

To ensure that the Trichogramma ball achieves a velocity higher than the initial flight speed of the drone, the required rotation speed of the driving lever should be higher than 382 r/min. The rotation speed of the driving lever is controlled by the lever motor, so the adjustable voltage range is 2–6 V.

3. Optimization of Operational Parameters for Delivery Device

3.1. Simulation of Rotor Wind

The Trichogramma ball is small and lightweight, making the delivery process susceptible to interference from the rotor downwash of the drone. Therefore, the position and delivery direction of the delivery device mounted on the drone have a significant impact on the delivery results. In this study, the fluid simulation software (Ansys Workbench) was used to simulate the rotor downwash airflow of the drone, and the airflow distribution around the lower region of the drone was analyzed. This analysis provides valuable insights for the installation and optimization design of the dispensing device.

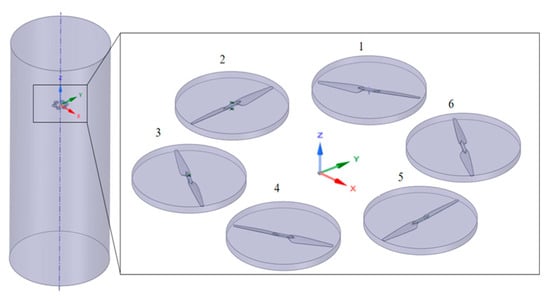

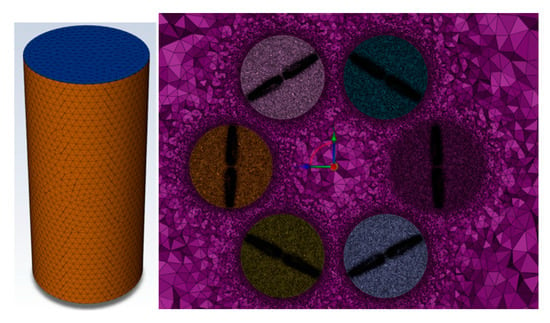

To reduce computational complexity and processing difficulty, the simulation neglected the influence of the drone body and only considered factors such as the wheelbase, relative positions of the propellers, and their rotation directions. As shown in Figure 6, assuming the positive Z-axis direction is above the drone body and the positive Y-axis direction is in front of the drone body, the external flow field was established based on the actual layout of the propellers. The computational domain was divided into an outer large region and six small regions corresponding to the six propellers. The entire computational domain was set as a cylinder coaxial with the centers of the six propellers, with a diameter of 13 m and a height of 28 m. The distance from the inlet to the propeller region was 8 m, and the distance from the outlet to the propeller region was 20 m. The six propellers were arranged counterclockwise. The six small regions were circular rotating areas that included the propeller surfaces. Due to their complex geometry and significant flow field changes, a higher mesh quality was obtained using volume refinement. The external region was a stationary area, and a relatively sparse unstructured mesh was used (Figure 7). The simulation parameters were designed as follows. The inlet was set as a velocity inlet with a value of zero. The turbulence intensity at the inlet was 5%, and the turbulent viscosity ratio was 10. The outlet boundary condition was set as a pressure outlet, where the static pressure at the outlet was zero. The wall was treated with a no-slip boundary condition. The standard k-ε turbulence model was selected (the equations are as shown in Equations (2) and (3)). Each small region corresponding to a propeller was set as a sliding mesh with an input rotation speed of 4500 r/min based on preliminary measurements. The pressure–velocity coupling scheme adopted the SIMPLE algorithm, the convective option used a first-order upwind differencing scheme, and the diffusive term used a first-order central differencing scheme. The calculation used a fixed time step of 1% of the propeller rotation speed to avoid divergence with a simulation time of 3 s.

where ρ is fluid density; p is downwind pressure; u is velocity; u’ is pulsation velocity; μ is dynamical viscosity; Si is the generalized source term of the momentum equation; −ρ is the Reynolds stress term; and , where Gk is the generation term of turbulent kinetic energy k due to the influence of buoyancy; is the turbulent viscosity; is the pulsation expansion term in compressible turbulence; , , and are empirical constants; and are the Prandtl numbers corresponding to the turbulent dissipation rate ɛ and turbulence energy k, respectively; and are user-defined source terms. For incompressible fluids, = 0, = 0, = 0.

Figure 6.

Simulation calculation domain. The six small regions were circular rotating areas that included the propeller surfaces.

Figure 7.

Mesh division.

3.2. Simulation of Delivery Progress

The process of delivering the Trichogramma balls is influenced by the flight parameters of the drones and the motion state of the Trichogramma balls after delivery. To study the deviation between the actual landing point and the delivery point of the Trichogramma balls, three main factors were selected as the research objects: drone flight speed (DFS), flight height (FH), and initial delivery speed (IDS) of the Trichogramma balls. The CFD simulation technology based on grid overlap was used to simulate the delivery process of the Trichogramma balls. Through simulation, the falling trajectories of the particles under different conditions were modeled and the coordinates at different moments were acquired. The effects of various factors on the falling process of the Trichogramma balls were analyzed to optimize the parameters. The factors and levels are shown in Table 1.

Table 1.

Overall variables table.

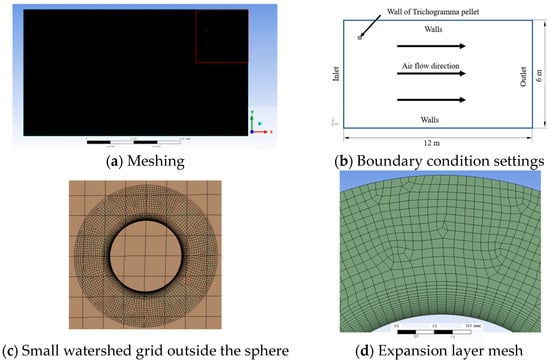

As shown in Figure 8, this study only simulated the motion process of the Trichogramma balls in the vertical plane. A geometric model was created in ANSYS SCDM, and the computational domain was set as a two-dimensional plane simulation area with a rectangular shape (dimensions of 6 × 12 m). In the simulation, the Trichogramma balls were treated as homogeneous spheres. To simplify the simulation process, the delivery point of the Trichogramma balls was fixed, and the entrance velocity of the simulation computational domain was set to represent the forward velocity of the drone. The initial position of the Trichogramma balls was set in the upper-left corner of the computational domain with an area reserved on the right side for the ball to fall into. The left side of the computational domain was set as the velocity inlet, with the inlet velocity being equal in magnitude but opposite in direction to the flight speed of the drone. The top and bottom edges of the computational domain were set as walls, while the right edge was set as a pressure outlet. ANSYS MESH was used for mesh generation, and the external boundaries of the Trichogramma ball’s outer small domain were defined as overset interfaces. The mesh of the outer small domain was refined, and the edges of the small domain’s ball were set with an inflation layer to achieve higher computational accuracy. During the simulation, the fluid type was air, and its parameter table is shown in Table 2.

Figure 8.

Simulation calculation area and boundary condition settings.

Table 2.

Air parameters.

Under standard atmospheric pressure and normal temperature, the variation in air density is less than 5%. Therefore, a pressure-based solver type was chosen in the study. First, a steady-state calculation was performed with the velocity set at the outlet. The large domain and the outer small domain of the Trichogramma balls were set with overlapping grid interfaces. In the simulation, a steady-state solution was obtained first to achieve a converged airflow field, followed by a transient solution to simulate the falling process of the Trichogramma balls. The simulation time was 4 s, and postprocessing was carried out in CFD-POST after the simulation was completed.

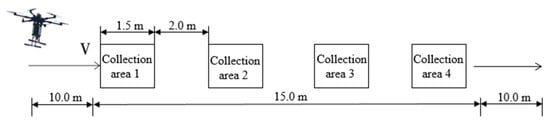

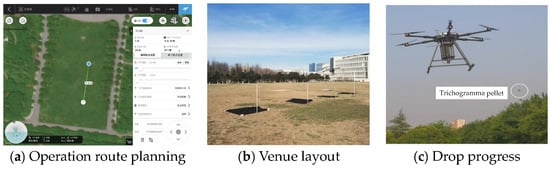

3.3. Validation Test for Delivery Effect

The test was conducted on the lawn south of the library at Shandong University of Technology. The wind speed on the day of the test ranged from 0.5 to 1.5 m/s, and the temperature was 8 °C. As shown in Figure 9, the flight route of the drone was planned using DJI GS Pro software. The total length of the route was approximately 35 m with 10 m buffer zones at both ends. The length of the test area was approximately 15 m, and within this area, four collection zones were set along the flight route with a 2 m interval. Four carpet squares with a side length of 1.5 m were placed at the target points in the collection zones for easy observation and measurement.

Figure 9.

Layout of the test area.

As illustrated in Figure 10, to prevent the Trichogramma balls from bouncing or rolling off the carpet after landing, a layer of adhesive was applied to the carpet to ensure immediate adhesion upon impact. To accurately record the landing positions of the Trichogramma balls, markers were placed at the center points of the carpets. To accurately observe the drone above the center of the carpets when delivering the Trichogramma ball, calibration poles were placed at the center points along the edges of the carpets for observers to make judgments.

Figure 10.

Delivery test.

To avoid interference from the ground effect generated by the drone’s rotor airflow, the flight height of the drone during testing was set to 2.5 m. The remaining parameters were set as follows: flight speeds of 2, 3, and 4 m/s and delivery speeds of 2, 3, and 4 m/s. By changing the flight speed and delivery speed, the distance between the landing point of the Trichogramma balls and the center of the carpet was recorded under different conditions, and the deviation was calculated. Each test was repeated three times, and the average value was taken.

4. Results and Analysis

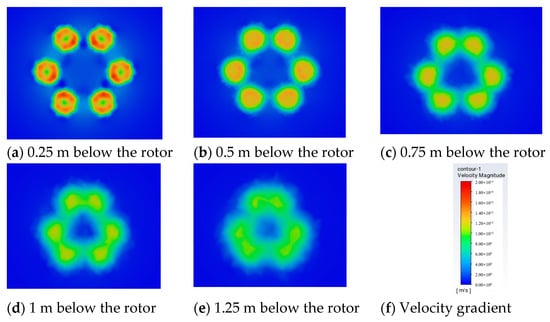

4.1. The Simulation Results and Analysis of Rotor Wind

To clearly demonstrate the wind field below the drone, five horizontal planes were set within the range of 0–2 m below the rotor. Figure 11 shows the velocity distribution contour maps of these five planes. From the figure, it can be observed that in a hovering state, the wind field of a multirotor drone is symmetrically distributed along the z-axis. Below the drone body, the wind field in the vicinity of each rotor was relatively independent and concentrated, gradually expanding and eventually converging downwards. The airflow disturbance generated by the rotors increased in size and decreased in velocity as the distance from the rotors increased. At 1 m below the drone body, the disturbance airflow from different rotors intersected, and the horizontal velocity gradually increased. Based on the above analysis, if the Trichogramma balls enter an area with strong airflow disturbance after being released, their trajectory will be significantly affected by the disturbance. Therefore, it is important to ensure that the delivery location is within 1 m below the drone rotor. In the actual design, 50 cm below the rotor was chosen as the location for Trichogramma ball delivery.

Figure 11.

Cloud map of velocity distribution at different heights.

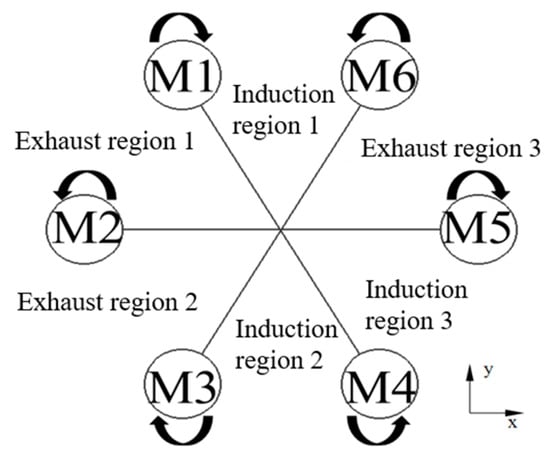

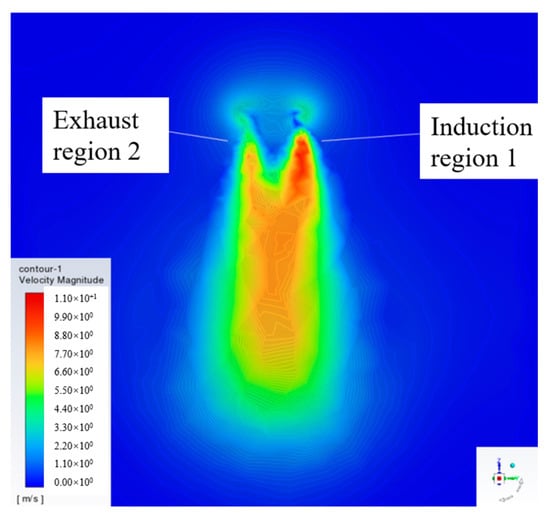

In a hovering state, adjacent rotors of the drone had opposite rotational speeds, resulting in the phenomenon of alternating “induction regions” and “exhaust regions” in the downwash airflow distribution (Figure 12). The velocity contour map on the y-o-z plane is shown in Figure 13. From the figure, it can be observed that the wind speed in the exhaust region 2 was significantly lower than the wind speed in the induction region 1. The wind field in the exhaust region tended to flow outward, which was beneficial for the delivery of Trichogramma balls. On the other hand, the wind field in the induction region tended to flow inward, which was unfavorable for the outward delivery of Trichogramma balls. Overall, the delivery outlet for Trichogramma balls should be positioned directly below the drone and facing the exhaust region 2.

Figure 12.

“Airflow inlet” and “airflow outlet” region sketch map.

Figure 13.

Velocity nephogram of wind field in y-o-z section.

4.2. The Simulation Results and Analysis of Delivery Progress

Figure 14 shows the velocity contour plot of the converged flow field in the steady-state solution (the inlet velocity was 2 m/s). From the figure, it can be observed that the velocity in local regions of the flow field varied due to the influence of the walls. The air velocities in most areas ranged from 1.70 to 2.27 m/s, which satisfied the computational conditions.

Figure 14.

Steady-state computing speed cloud map.

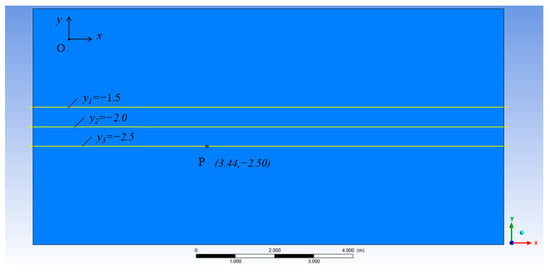

The simulation process of the Trichogramma ball’s falling process is shown in Figure 15. The initial position of the Trichogramma ball is the coordinate origin in the coordinate system. The three horizontal lines depicted correspond to y1 = −1.5 m, y2 = −2.0 m, and y3 = −2.5 m. In this Figure, the point P (3.44, −2.5) indicates that at a height of −2.5 m, the Trichogramma ball had a horizontal displacement of 3.44 m.

Figure 15.

Transient calculation results.

In Figure 15, the corresponding computational step at that moment is denoted as N, the number of time steps in the transient calculation is denoted as t (s), and the simulated flight velocity (i.e., inlet velocity) of the drone is denoted as v (m/s). The theoretical formula for calculating the relative displacement s′ (m) between the Trichogramma ball and the drone in the horizontal direction is as follows:

The calculation value of the relative displacement s (m) between the Trichogramma ball and the drone in the horizontal direction, with the abscissa of point P, was used to calculate the deviation value S of the landing point using the following formula:

The deviation reflects the accuracy of the delivery, with smaller values indicating closer proximity to the theoretical delivery point. The simulation data results for different delivery speeds, flight speeds, and heights are shown in Table 3. The impact of these three variables on the deviation of the Trichogramma ball’s descent was analyzed using SPSS software, and the variance regression analysis table is presented in Table 4. In the table, the dependent variable is the deviation value (Y), and the independent variables are the delivery speed (XT), flight speed (XF), and height (XH). According to the analysis results, the impact of flight speed and delivery speed on the deviation value was highly significant, while the impact of flight height on the delivery deviation value was significant. Because all three variables had a significant impact on the delivery deviation value, a linear equation could be established.

Table 3.

Delivery deviation value.

Table 4.

Regression analysis of variance.

The regression coefficients of the three variables in the deviation regression equation were 0.048, −0.074, and 0.039, with a constant term (C) of 0.126. Therefore, the relationship model between the deviation value (Y) and the delivery speed (XT), flight speed (XF), and height (XH) can be expressed as follows:

Y = 0.126 + 0.048XT − 0.074XF + 0.039XH

From the above equation, it can be observed that the magnitude of the deviation value is negatively correlated with the delivery speed and positively correlated with the flight speed and flight height. Therefore, it can be concluded that lower flight speeds, lower flight heights, and higher delivery speeds result in smaller deviation values, indicating more accurate delivery.

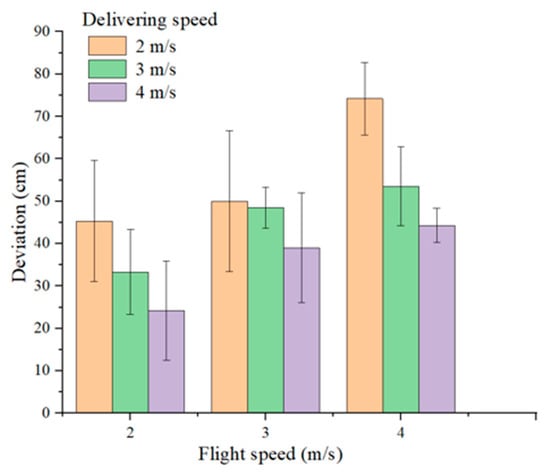

4.3. The Overall Delivery Performance

The results of the deviation in the distance of the Trichogramma ball during the delivery experiment are shown in Figure 16. The influence of flight height and delivery speed on the distance deviation was consistent with the simulation results. The statistical analysis showed that the calculated values and test values had an error within 10% of the center point of the collection area, which verified the accuracy of the calculation results. The correlation analysis results indicated that the correlation coefficients between the delivery speed, flight speed, and distance deviation were −0.640 and 0.715, respectively. The significance levels were 0.063 and 0.030, respectively, indicating that the delivery speed was negatively correlated with the distance deviation, while the flight speed was positively correlated with the distance deviation. The impact of flight speed on distance deviation was significant. The coefficient of variation for distance deviation is shown in Table 5. As shown in the table, the flight speed of the drone was 2 m/s. The dispersion of the Trichogramma ball’s delivery position from the center point was the highest, while at flight speeds of 3 and 4 m/s, the delivery range was more concentrated, resulting in an overall better performance. Therefore, it can be concluded that the smallest deviation in the landing point where the Trichogramma ball is closest to the intended delivery point is achieved when the flight speed is 3 m/s and the delivery speed is 4 m/s.

Figure 16.

Results of field placement test.

Table 5.

Analysis of launch distance at different flight speeds.

5. Discussion

The delivery mechanism designed in this study includes a cylindrical acceleration channel and a driving lever. To ensure accurate and stable delivery speed, it is crucial for the Trichogramma ball to be positioned correctly in the acceleration channel and for the driving lever to strike at the right point. If the striking position is incorrect, the force direction of the Trichogramma ball may not align with the axis of the acceleration channel, resulting in collisions between the Trichogramma ball and the inner wall of the channel, energy loss, and changes in the trajectory. As a result, it becomes difficult to maintain a stable velocity vector as the Trichogramma ball exits the acceleration channel, ultimately affecting the landing position. Therefore, a relatively stable voltage range of 2–6 V was chosen. Furthermore, due to the light weight of the Trichogramma ball, it is susceptible to the influence of the wind generated by the rotors of drones. The drive lever is controlled by a DC motor, and the kinetic energy when striking a Trichogramma ball is positively correlated with the output voltage of the motor, so a larger voltage can be used in practice before avoiding interference from the rotor wind field. According to the principles of mechanics, when a rotating component rotates at a constant speed, the inertial forces generated by the mass of different parts of the rotating component converge at the center of rotation, forming a resultant force system. If the resultant force system is unbalanced, the resultant force of the system will not be zero, causing additional dynamic pressure and periodic mechanical vibrations within the bearings of the center of rotation [34]. To address the stability issues of the driving lever’s rotational motion, this study specifically utilized Solidworks software to optimize the centroid position, ensuring that the distance between the striking end and the counterweight end from the center of rotation is consistent. This optimization enables smooth and stable rotational motion of the driving lever.

In this study, a simulation-based approach was employed to analyze the distribution of the drone’s rotor wind field, particularly the airflow generated by the rotors at the bottom of the drone, and to optimize the installation position of the delivery device. A proper installation position not only reduces the impact of airflow on the delivery process of Trichogramma balls but also utilizes the rotor airflow to accelerate the movement of the projectiles, resulting in improved trajectories and landing positions.

Furthermore, this study analyzed the effects of drone flight height, flight speed, and delivery speed on the delivery effectiveness. Under the premise of considering both efficiency and effectiveness, the operational parameters were optimized, providing scientific guidance for the practical application of the delivery system. The study tested flight parameters of 1.5–2.5 m in height and 2–4 m/s in speed, which are relatively small compared to the operational parameters in other drone applications. One reason for this is that individual Trichogramma balls have a larger effective control range, so there is no need to consider a wide swath and dispersion of Trichogramma balls [35]. Another reason is that Trichogramma balls need to be spaced at certain distances for individual delivery, and the drone requires time to determine the delivery points. High flight speed would intensify the drone’s abrupt stops and accelerations; shorten the response time of the delivery system, thus negatively affecting flight stability and accuracy of judgment; and cause disturbances in the rotor airflow, thereby affecting the descent of the Trichogramma ball. Therefore, when using drones for delivering Trichogramma balls, it is necessary to analyze the critical factors and select appropriate operational parameters to achieve the best match between the drone platform and the delivery system, regardless of the delivery structure and principles used.

This study proposes a rotary delivery device designed specifically for multirotor drones. Compared to conventional material boxes, this device achieves the separation of Trichogramma balls within the ball storage mechanism, ensuring sequential and individual release of Trichogramma balls. However, limitations in the drone’s body structure restrict the capacity of the ball storage tube, and the time-consuming process of filling the Trichogramma ball somewhat compromises the operational efficiency of this delivery device. Further optimization in the structural design is necessary.

Additionally, when the agricultural drone delivery device operates in the field, different crops will also have an effect on the landing effect of ruderalis pellets. This study only conducted the test on the ground with carpet and did not consider the effect of the crops and natural environment on the delivery deviation. It is necessary to study this aspect as a next step, and the results of the study can provide an effective guide for actual field applications.

6. Conclusions

To improve the mechanized delivery technique of Trichogramma balls and enhance the effectiveness of biological control, a Trichogramma ball delivery device was designed based on a multirotor agricultural drone. The device utilizes a rotating wheel storage mechanism and a hammer-type delivery mechanism to achieve precise delivery of Trichogramma balls. Through the design of key components, simulation of the delivery process, and practical verification experiments, the following conclusions were drawn:

- (1)

- Based on the investigation of the conventional parameters of Trichogramma balls and the agronomic requirements for field delivery and considering the characteristics of drone platform and its endurance, it was determined that the airflow outlet area of the delivery device should be located about 50 cm below the drone to facilitate accelerated delivery using the airflow. The storage mechanism consists of eight storage tubes with an inner diameter of 38 mm and a length of 250 mm, providing a total loading capacity of 56 Trichogramma balls. To ensure smooth delivery, the diameter of the acceleration channel in the delivery mechanism is 5 mm larger than the diameter of the Trichogramma balls. The radius of rotation of the driving lever is set to d = 50 mm, with the hitting end 50 mm away from the rotation center and the counterweight end 31.1 mm away from the rotation center. The thickness of the lever is 10 mm, and its rotational speed needs to be higher than 382 r/min. The reliable delivery speed range of the device is 2–6 m/s, with the remote position of the driving lever serving as the optimal starting position.

- (2)

- The parameters of delivery speed, flight speed, and flight height have a significant impact on the deviation of Trichogramma ball landing points. The variance regression analysis results indicate that the size of the deviation is negatively correlated with the delivery speed and positively correlated with the flight speed and flight height. The influence of the delivery speed, flight speed, and flight height on the deviation is significant. There exists a certain functional relationship between the deviation (Y) and the delivery speed (XT), flight speed (XF), and flight height (XH).

- (3)

- The experimental results showed that the group with a flight speed of 3 m/s and a delivery speed of 4 m/s had a smaller coefficient of variation for the delivery deviation (29%), making it the optimal operating parameter set.

In conclusion, the designed rotating wheel Trichogramma ball delivery device can achieve targeted and quantified delivery, and optimal delivery results can be obtained under suitable operating parameters. However, the automation level of the delivery control system can be further improved to adapt to different operational scenarios. In addition, the Trichogramma ball sphere selected in this study is an eccentric sphere. The influence of its eccentric state on delivery accuracy and the impact of the surface characteristics of Trichogramma balls on the falling process have not been clearly defined and require further research.

Author Contributions

Methodology, C.S.; investigation, Q.W.; resources, G.W.; data curation, T.Z., J.H.; writing—original draft preparation, L.L.; visualization, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Shandong Natural Science Foundation Project (ZR2021QC154).

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the companies that applied the Trichogramma balls and provided technological suggestions. They also wish to thank fellows and participators from their cooperative department for their assistance during the test.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lahlali, R.; Ezrari, S.; Radouane, N.; Kenfaoui, J.; Esmaeel, Q.; Hamss, H.; Belabess, Z.; Barka, E.A. Biological control of plant pathogens: A global perspective. Microorganisms 2022, 10, 596. [Google Scholar] [CrossRef] [PubMed]

- Ratto, F.; Bruce, T.; Chipabika, G.; Mwamakamba, S.; Mkandawire, R.; Khan, Z.R.; Mkindi, A.; Pittchar, J.; Chidawanyika, F.; Sallu, S.M.; et al. Biological control interventions and botanical pesticides for insect pests of crops in sub-Saharan Africa: A mapping review. Front. Sustain. Food Syst. 2022, 6, 883975. [Google Scholar]

- Kumar, K.K.; Arthurs, S. Recent advances in the biological control of citrus nematodes: A review. Biol. Control 2022, 157, 104593. [Google Scholar] [CrossRef]

- Hou, Z. Application of biological control technology in forest pest control. South. Agric. 2019, 13, 79–80. [Google Scholar]

- Del, P.M.; Cabello, T.; Hernández-Suárez, E. Biological Control Options for the Golden Twin-Spot Moth, Chrysodeixis chalcites (Esper) (Lepidoptera: Noctuidae) in Banana Crops of the Canary Islands. Insects 2022, 13, 516. [Google Scholar]

- Huang, N.; Jaworski, C.; Desneux, N.; Zhang, F.; Yang, P.; Wang, S. Long-term and large-scale releases of Trichogramma promote pesticide decrease in maize in northeastern China. Entomol. Gen. 2022, 40, 331–335. [Google Scholar] [CrossRef]

- Chen, S.; Wu, C.; Chen, L.; Chang, K.; Qian, S.; Chen, W.; Lan, Y. Design and test of aerial broadcast device for agricultural granular materials. Int. J. Precis. Agric. Aviat. 2020, 3, 44–50. [Google Scholar] [CrossRef]

- Yang, S.; Zheng, Y.; Liu, X. Research status and trends of downwash airflow of spray UAVs in agriculture. Int. J. Precis. Agric. Aviat. 2019, 2, 1–8. [Google Scholar] [CrossRef][Green Version]

- Ji, S.; Yao, C.; Feng, Z. Path recognition of UAV based on improved super-greening algorithm and design of adaptive Trichogramma pill dispenser. Multimed. Tools Appl. 2023, 82, 17301–17320. [Google Scholar] [CrossRef]

- Cherif, A.; Mansour, R.; Grissa-Lebdi, K. The egg parasitoids Trichogramma: From laboratory mass rearing to biological control of lepidopteran pests. Biocontrol Sci. Technol. 2021, 31, 661–693. [Google Scholar] [CrossRef]

- Zhao, J.; Liang, M.; Wang, Z.; Zhao, Y.; Cheng, J.; Du, Y. Evaluation and optimization of blends for attracting Trichogramma dendrolimi based on semiochemicals mediating tritrophic interactions in the orchard habitat. Biol. Control 2022, 173, 104998. [Google Scholar]

- Gauthier, P.; Khelifi, M.; Dionne, A.; Todorova, S. Technical Feasibility of Spraying Trichogramma ostriniae Pupae to Control the European Corn Borer in Sweet Corn Crops. Appl. Eng. Agric. 2019, 35, 185–192. [Google Scholar] [CrossRef]

- Canopée Dronautique, Inc. Canopée—Système D’épandage D’insectes par Drone (2050 dans Votre Assiette-Segment) [EB/OL]. Available online: https://www.youtube.com/watch?v=nbHqQSyZDc0&t=2s.htm (accessed on 30 January 2019).

- Wang, Z.; Huang, B.; Zhou, W.; Yang, W.; Mao, Y. A Kind of Releasing Device for Noctuid Black Trichogramma Egg. China Patent CN215873144U, 17 August 2021. [Google Scholar]

- Xie, C.; Zheng, H.; Xu, M.; Liu, Y.; Gao, Y.; Xu, L. A New Type of Bee-Bag for Chow’s Gnats. China Patent CN214282840U, 19 January 2019. [Google Scholar]

- Tabebordbar, F.; Formisano, G.; Shishehbor, P.; Ebrahimi, E.; Giorgini, M.; Sørensen, J. Variation among populations of Trichogramma euproctidis (Hymenoptera: Trichogrammatidae) revealed by life table parameters: Perspectives for biological control. J. Econ. Entomol. 2023, 116, 1119–1127. [Google Scholar] [PubMed]

- Sun, M.; Peng, Z.; Li, J.; Fan, Y.; Yu, F.; Ma, H. Preliminary study on control effect of Trichogramma released by UAV against rice Chilo suppressalis. China Plant Prot. 2021, 2, 10. [Google Scholar]

- Canopée Dronautique, Inc. Application of Trichogramma [EB/OL]. 2021. Available online: http://canopee.io/en/innovations.htm/#spreading (accessed on 3 June 2021).

- Martel, V.; Johns, R.C.; Jochems-Tanguay, L.; Jean, F.; Maltais, A.; Trudeau, S.; St-Onge, M.; Cormier, D.; Smith, S.M.; Boisclair, J. The use of UAS to release the egg parasitoid Trichogramma spp. (Hymenoptera: Trichogrammatidae) against an agricultural and a forest pest in Canada. J. Econ. Entomol. 2021, 114, 1867–1881. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.L.; Gururajan, S.; Thistle, H.; Chandran, R.; Reardon, R. Aerial release of Rhinoncomimus latipes (Coleoptera: Curculionidae) to control Persicaria perfoliata (Polygonaceae) using an unmanned aerial system. Pest Manag. Sci. 2018, 74, 141–148. [Google Scholar] [CrossRef]

- Liu, X. A Trichogramma Egg Card Hanger. Chinese Patent CN104798733B, 21 November 2017. [Google Scholar]

- Lan, Y.; Zhan, Y.; Chen, S.; Ouyang, F.; Chen, P.; Chang, K.; Qian, S. A Biomass Ball Delivery System Delivery Method for UAV. Chinese Patent CN110733642A, 31 January 2020. [Google Scholar]

- Wang, G.; Song, C.; Zhang, W.; Liu, L.; Lan, Y. An Air-Blown Spiral Launching Type of Trichogramma Delivery UAV and a Delivery Method. CN115610658A, 5 November 2022. [Google Scholar]

- Zhu, H.; Huang, Y.; Li, H.; Pei, S. A UAV for Biological Control of Trichogramma. Chinese Patent CN209454998U, 1 October 2019. [Google Scholar]

- Cheng, H.; Cheng, G.; Wang, H.; Wang, N.; Han, Q.; Chi, X. Drone Biological Control Dispenser. China Patent CN212423484U, 29 January 2021. [Google Scholar]

- Wang, C. Design and Experimental Study of Natural Enemy Carrier Release Device for Aircraft; Jiangsu University: Zhenjiang, China, 2018. [Google Scholar]

- Cheng, G.; Lei, J.; Wang, H.; Gao, Y.; Lu, X.; Mao, G. Biological Dropper. China Patent CN206851877U, 9 January 2018. [Google Scholar]

- Chen, H.; Zhai, Y.; Dai, X.; Zheng, L.; Cao, G.; Yu, Y. A Field Trichogramma Dropping Drones. Chinese Patent CN110771574A, 11 February 2020. [Google Scholar]

- Zhu, J.; Fu, W.; Li, D.; Lin, S. A Kind of Releasing Device and UAV for Releasing Ball of Pest Natural Enemy. Chinese Patent CN210168793U, 24 March 2020. [Google Scholar]

- Zhan, Y.; Chen, S.; Wang, G.; Fu, J.; Lan, Y. Biological control technology and application based on agricultural unmanned aerial vehicle (UAV) intelligent delivery of insect natural enemies (Trichogramma) carrier. Pest Manag. Sci. 2021, 77, 3259–3272. [Google Scholar] [CrossRef]

- Ji, S.; Gong, J.; Cui, K.; Zhang, Y.; Mostafa, K. PerformanceTest and Parameter Optimization of Trichogramma Delivery System. Micromachines 2022, 13, 1996. [Google Scholar] [CrossRef]

- Zhan, Y.; Chen, P.; Xu, W.; Chen, S.; Han, Y.; Lan, Y.; Wang, G. Influence of the downwash airflow distribution characteristics of a plant protection UAV on spray deposit distribution. Biosyst. Eng. 2022, 216, 32–45. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, X.; Wang, L.; Liu, Y.; Lan, Y.; Liu, Y.; Han, Y.; Wang, L. Research on the technology of using unmanned aerial vehicle to release the Trichogramma japonicum to control rice Stem Borer. J. Anhui Agric. Sci. 2023, 1, 136–138. [Google Scholar]

- Li, L.; Chen, K.; Gao, J.; Gao, J.; Liu, J.; Gao, Z. Research on optimizing-assembly and optimizing-adjustment technologies of aero-engine fan rotor blades. Adv. Eng. Inform. 2022, 51, 101506. [Google Scholar] [CrossRef]

- Shen, X.; Liu, M.; Luo, C.; Tang, D.; Zhou, W. Field effect evaluation of rice pest control-Control of rice leaf roller and Borer based on Trichogramma released by plant protection drone. Guangxi Plant Prot. 2019, 34, 6–8. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).