Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions

Abstract

1. Introduction

2. Design of UAV Model

2.1. Preliminary Design

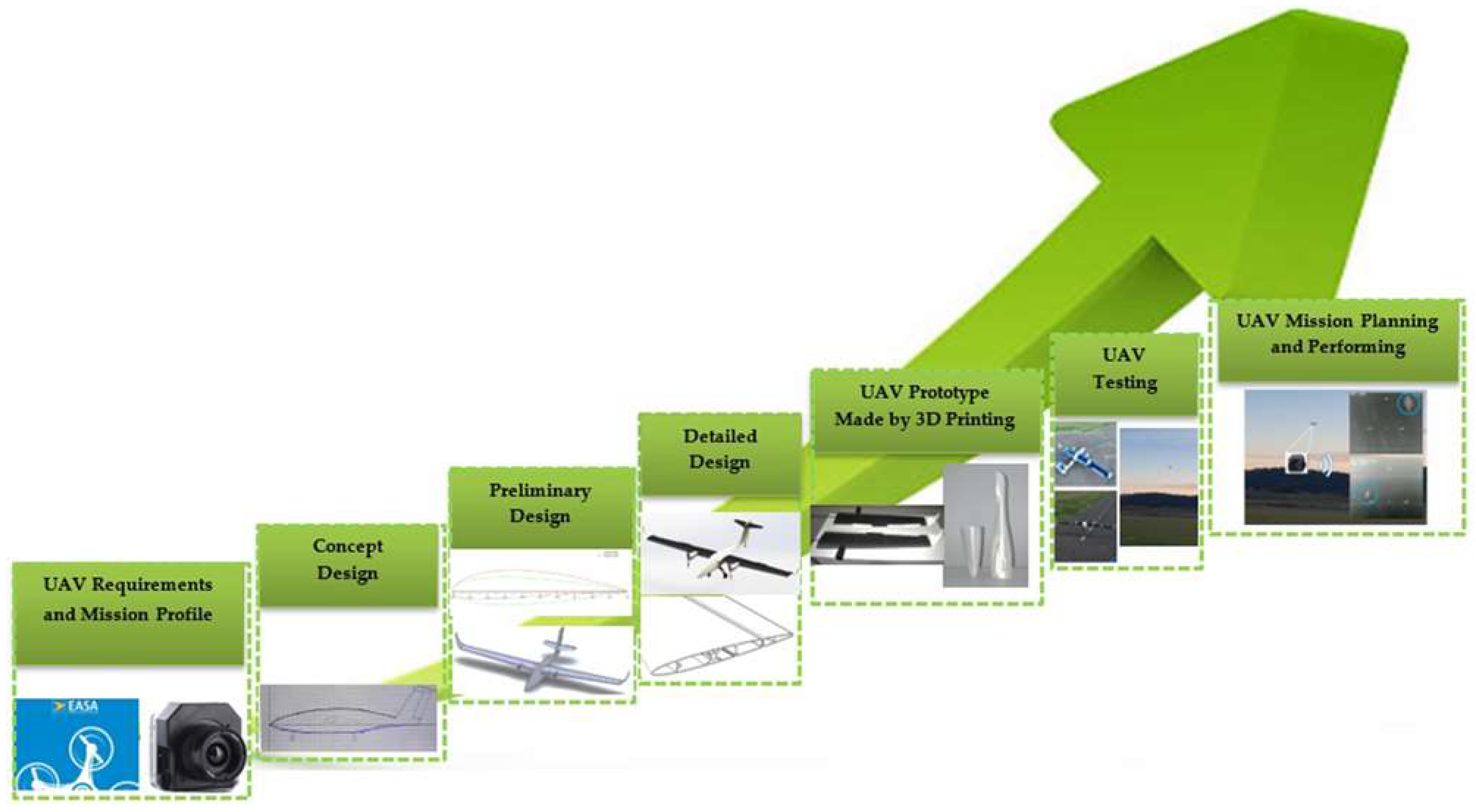

- Following the design process depicted in Figure 1, the starting point for the UAV model is to comprehend its purpose and flight mission to determine the appropriate design requirements for the aircraft. Since this study involved design and physical creation of a fixed-wing, twin-engine aircraft for search-and-rescue missions utilizing a thermal module controlled by a ground control station, both flight mission planning and design requirements had to be individually satisfied and concurrently addressed [67]. The UAV model is intended for use in mountainous areas to locate pilots and passengers after aviation accidents, wildlife tracking, and detecting illegal hunting. The selection of these missions for the UAV model was not arbitrary; it was based on studies that highlight significant deficiencies in finding economically and technically efficient solutions for aviation accident response and anti-poaching efforts in mountainous regions.

- The conceptual design stage of the UAV model involves analyzing current concepts and designs based on the defined design requirements to visualize the desired UAV configuration. This initial design investigation is crucial, since the entire design phase, up to detailed design, relies on this preliminary analysis [68] and the proposed concept. During this stage, the project team engages in brainstorming sessions that result in a predimensioned sketch of the UAV model. These sessions evaluate the advantages and disadvantages of each proposed idea, taking into consideration specifications, flight mission, manufacturing costs, and the fabrication process [69].

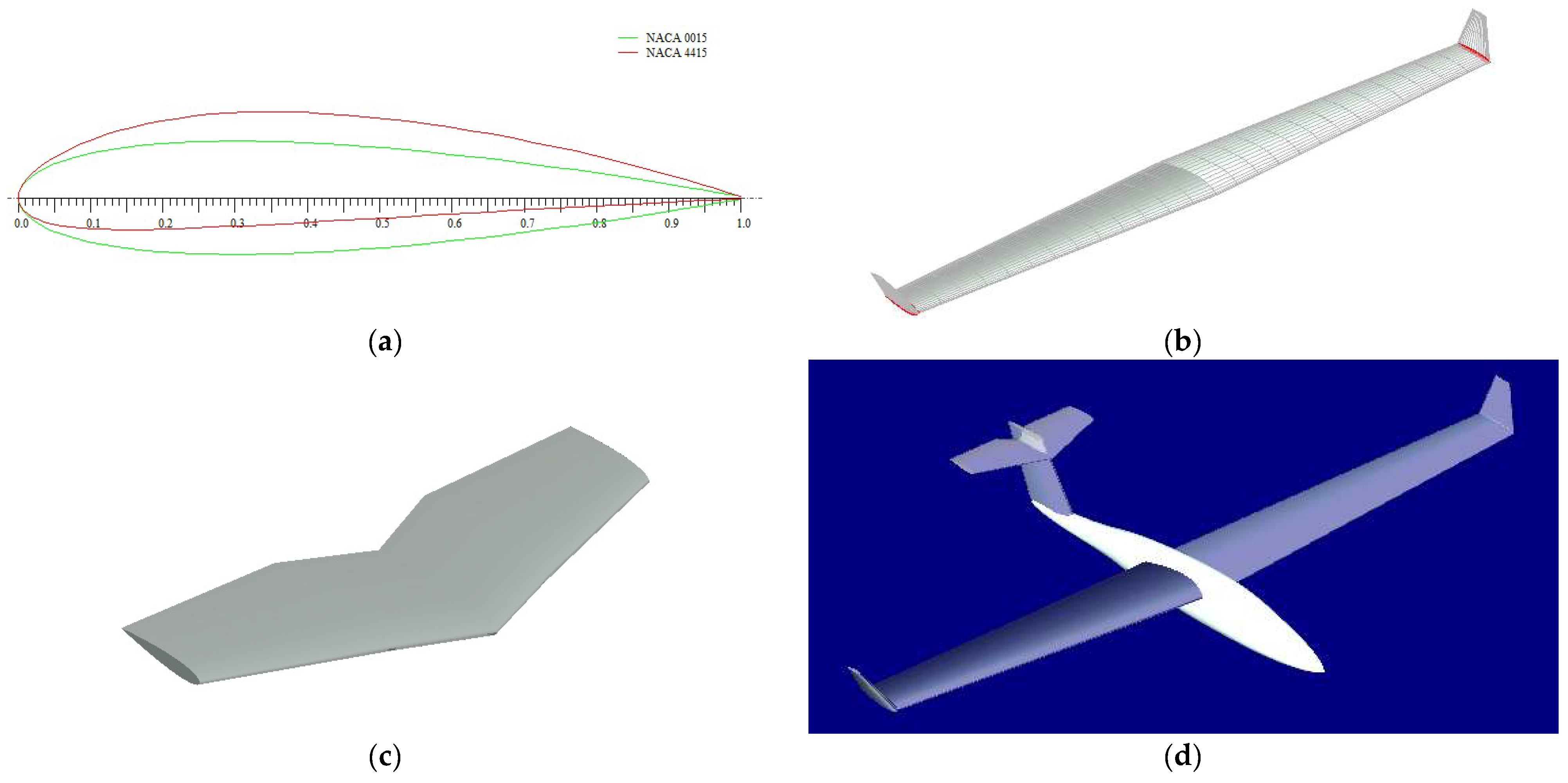

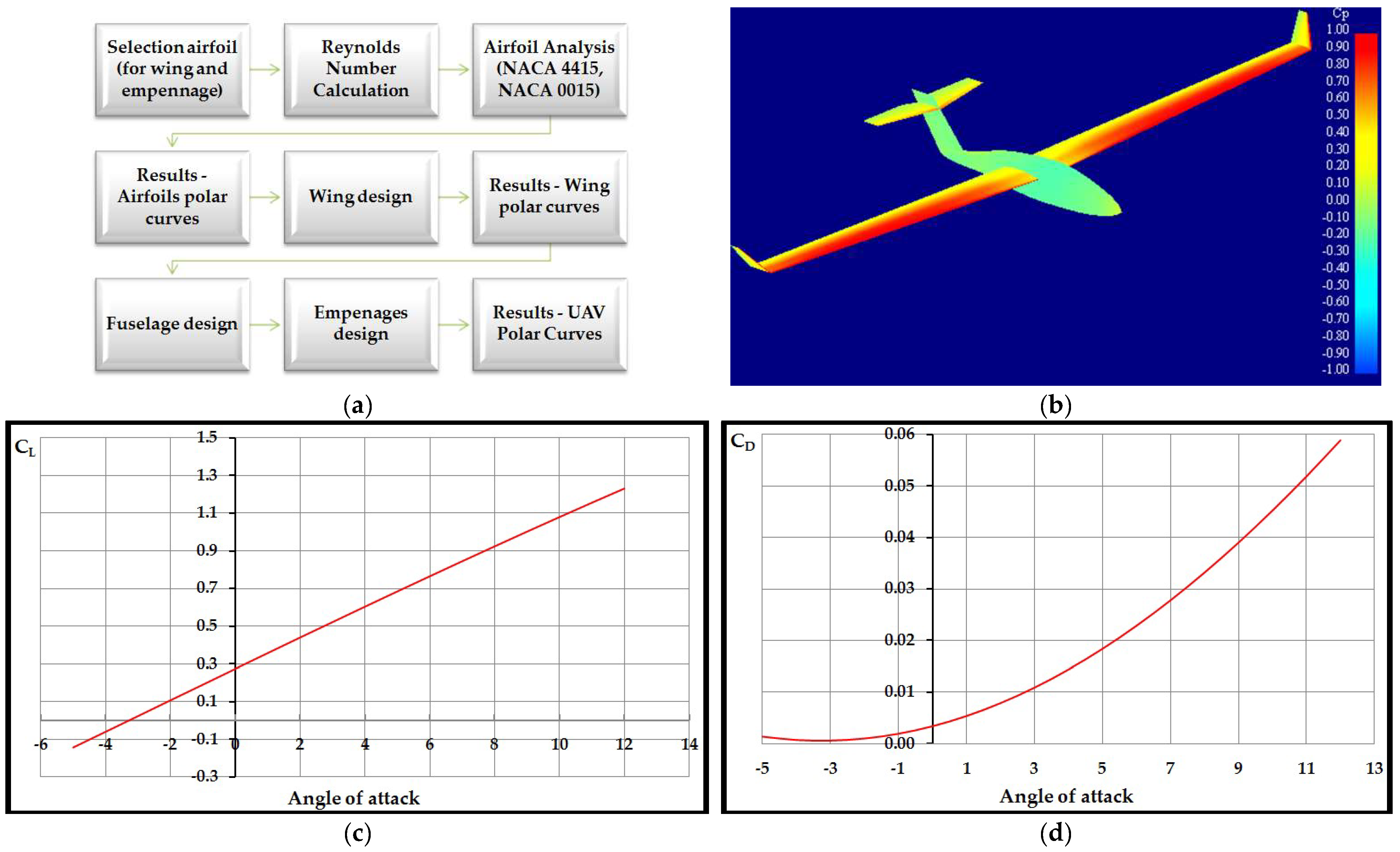

- In the preliminary design stage, the initial UAV model will be expanded and developed in much greater detail. Optimization compromises within the project will be made to maximize the performances of the aircraft for its intended operational roles and flight mission. In this stage, decisions will be made about which UAV components will be fabricated in-house and which ones will be purchased, involving a cost–benefit analysis. Utilizing specific Computer Aided Design (CAD) software systems, the preliminary UAV model was designed based on the previously established basic dimensions. Additionally, in this stage, estimates of the masses of the main components will be made from the CAD model of the aircraft, along with establishing aerodynamic profiles (for the wing and empennage) and obtaining initial results regarding the aerodynamic performance of the UAV model [70].

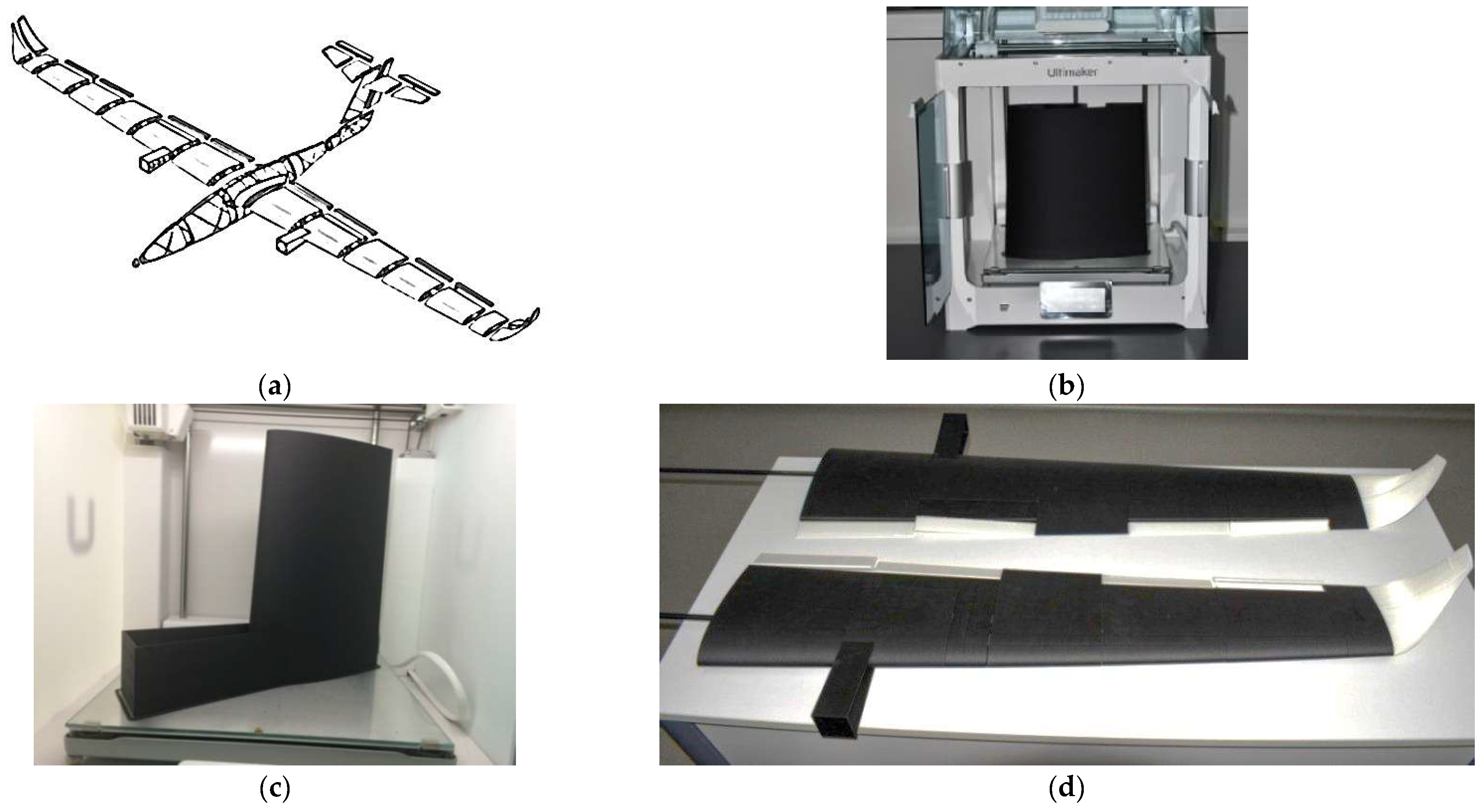

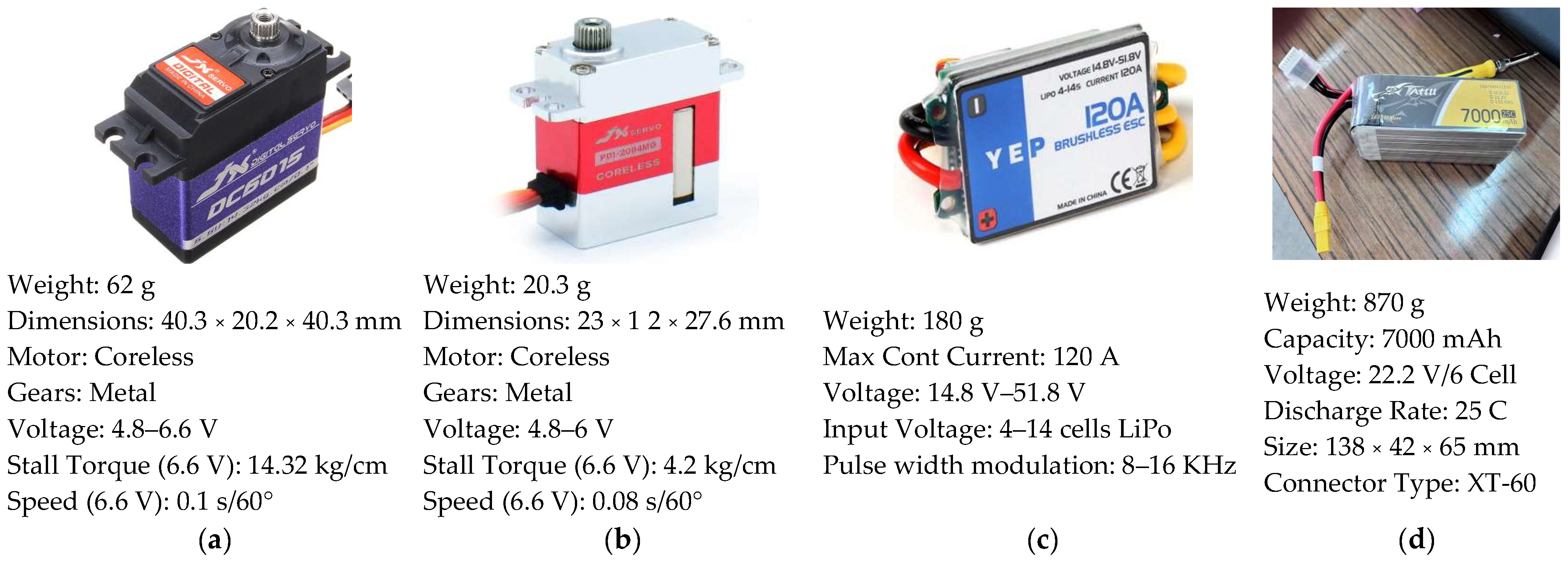

- In the subsequent detailed design stage [71] of the UAV model, computerized methods for design, calculations, simulations (virtual development), and detailed aerodynamic analyses (wing analysis, aircraft analysis) were employed. Furthermore, full characterization (mechanical and thermal) of the two types of materials used in 3D printing the UAV model [72,73] was performed in this stage. The detailed design for the additive manufacturing of the UAV components was also included, considering the 3D printing volume of the equipment used and the method of support structure application and removal for certain parts. In this stage, aspects of performance (autonomy, flight speed, ceiling) of the UAV model were obtained as the components to be used on the aircraft (electric motors, ESC, battery) were determined.

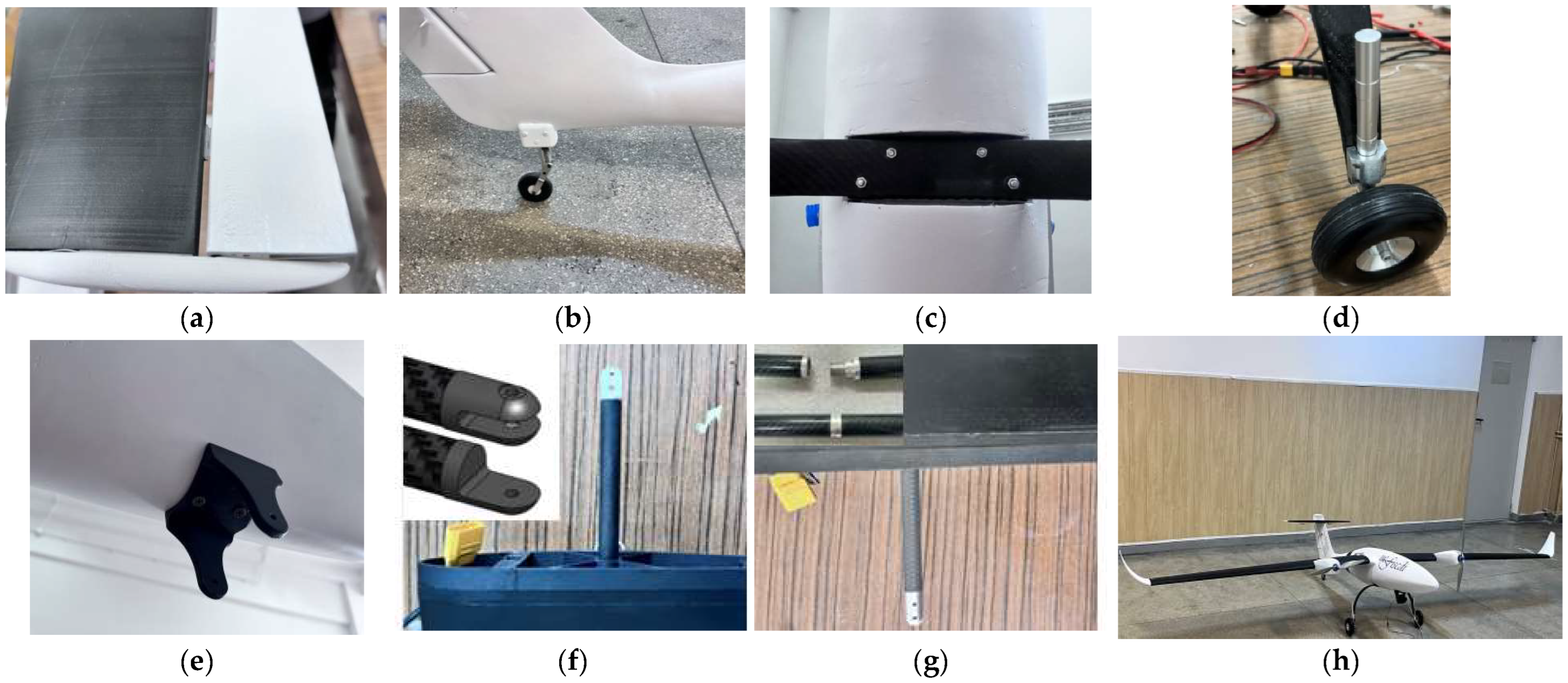

- During the 3D printing phase of the UAV prototype, detailed CAD models and manufacturing parameters from the previous stage were used to produce segments of all UAV model components. An important aspect of this phase was testing the mechanical performance of the wing [74], fuselage [73], and landing gear [75]. Following mechanical testing, the wing and fuselage proved capable of withstanding flight loads; however, a solution in the form of CFRP material was chosen for the landing gear to ensure safer takeoff and landing. Also at this stage, detailed tests were carried out on the motors manufactured through the SLS (Selective Laser Sintering) process [76] to determine their performance. This stage concludes with the simultaneous assembly of aircraft components and electronic elements, resulting in the final physical UAV model.

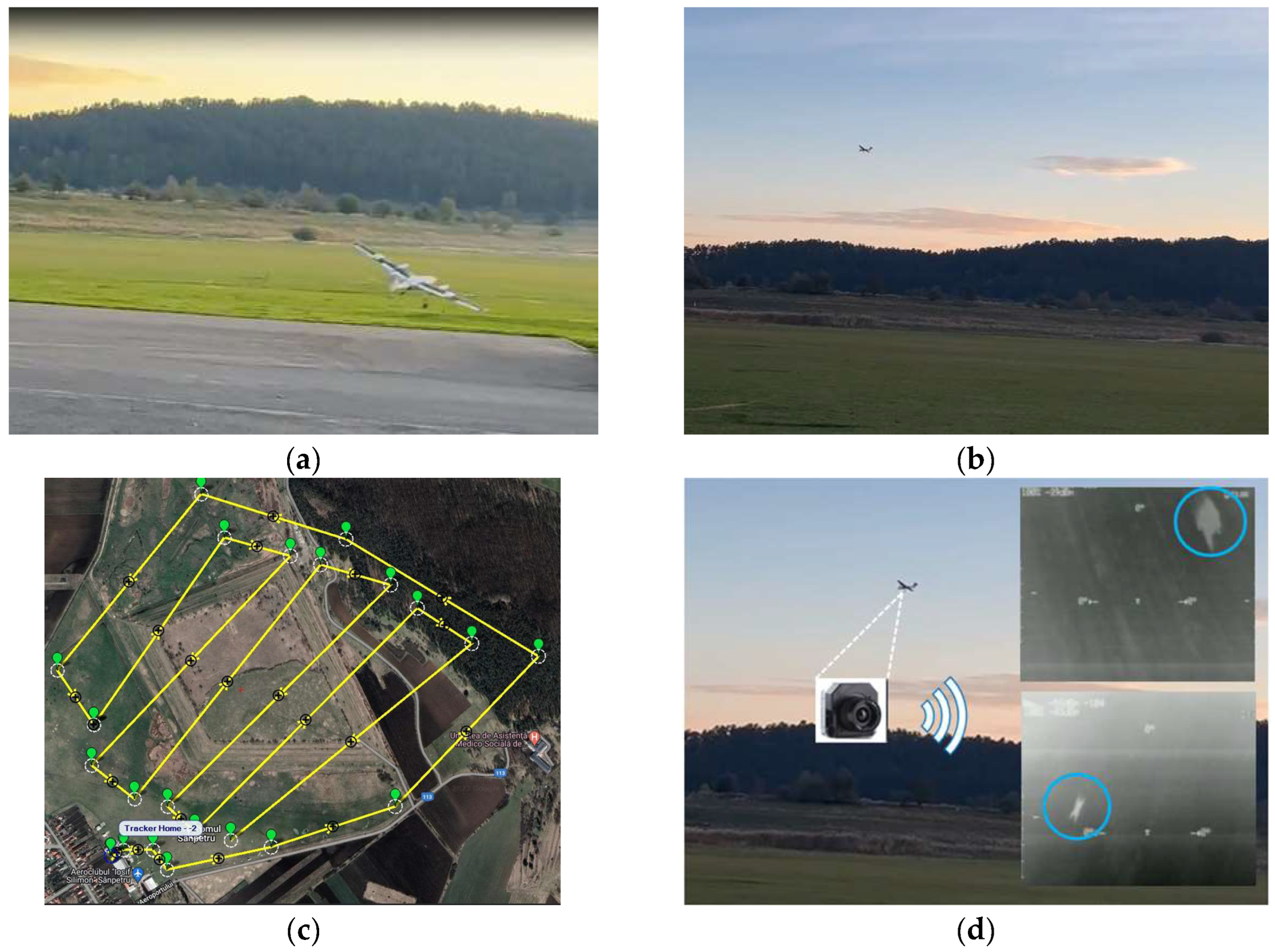

- Within the testing stage, initial ground tests of the UAV model were conducted, monitoring the correct functioning of controls, motors, and electronic systems (thermal module and ground control station). Ground rolling tests of the UAV model were also conducted during this testing stage. Following these preliminary tests, the final stage involved testing the UAV model in flight using the ground control station and thermal module.

- The final stage in the development of the UAV model included the flight mission, namely search and rescue using the thermal module. At this stage, the proposed UAV model was validated by successfully completing the specified mission outlined during the flight mission profile establishment phase. The fixed-wing UAV model with a medium altitude is capable of performing search and rescue, surveillance missions, and emergency interventions, serving as a versatile and efficient solution with reduced operating costs. Moreover, the UAV model offers an approximate flight time of 50 min and can cover large search areas rapidly (around 100 km) by thermal imaging capture. Another important aspect of the UAV model is its real-time video transmission capability, providing rescue teams with a clear and detailed view of the operational area, enabling rapid decision-making and a timely response.

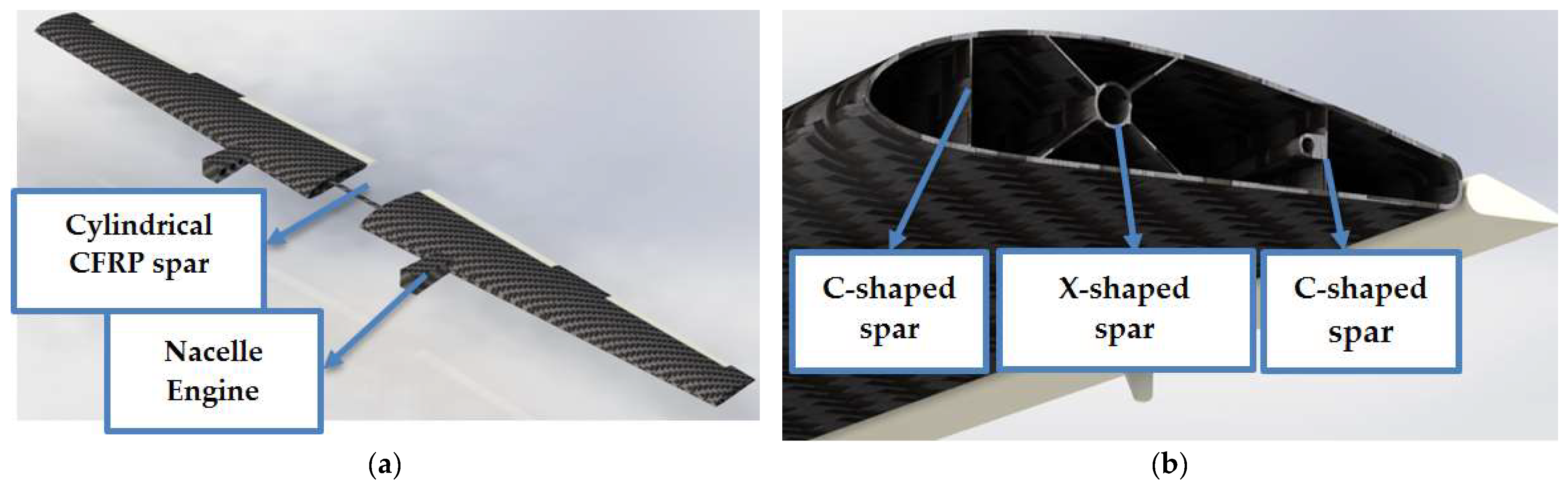

2.2. UAV Model Wing Design

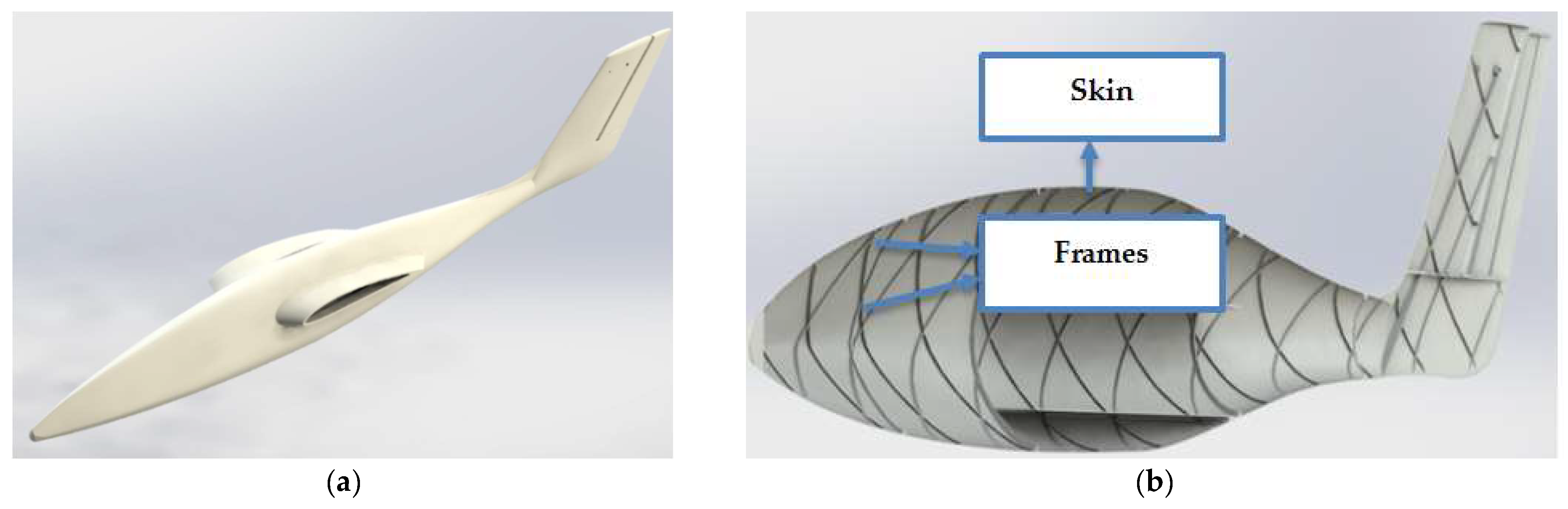

2.3. UAV Model Fuselage Design

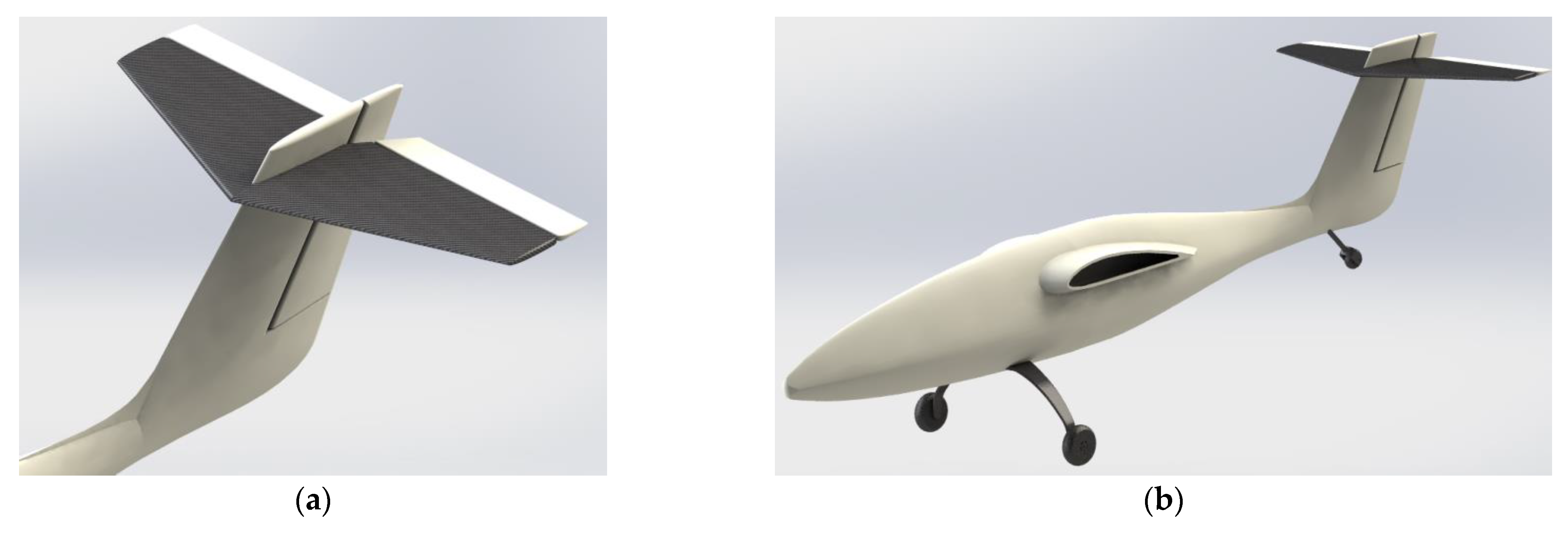

2.4. Design of Empennages and Landing Gear

2.5. Digital Assembly of the UAV Model

3. Preliminary Aerodynamic Analysis

4. Manufacturing of the UAV Model Components Using FFF Process

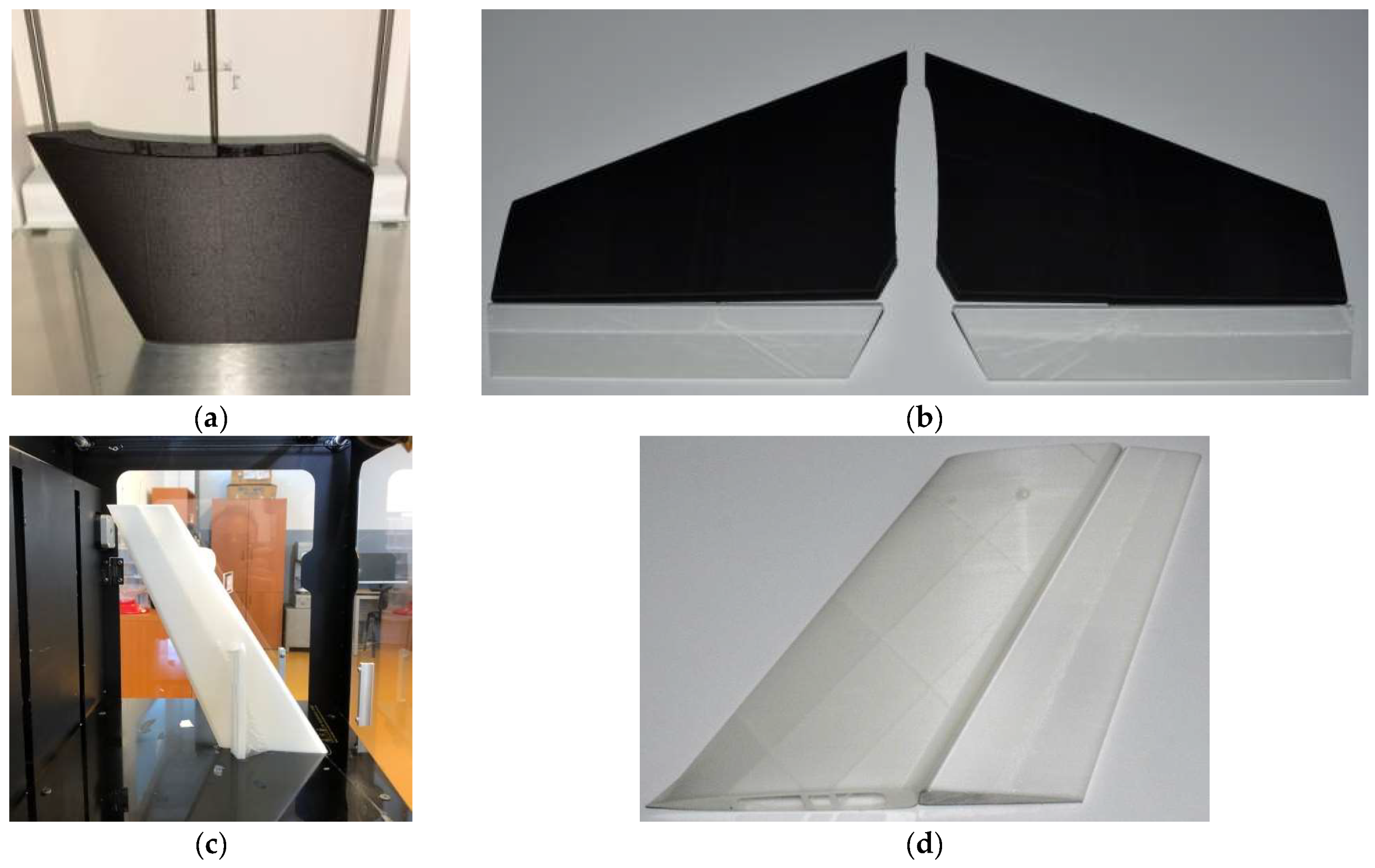

4.1. Fabrication of the Wing Structure Using the FFF Process

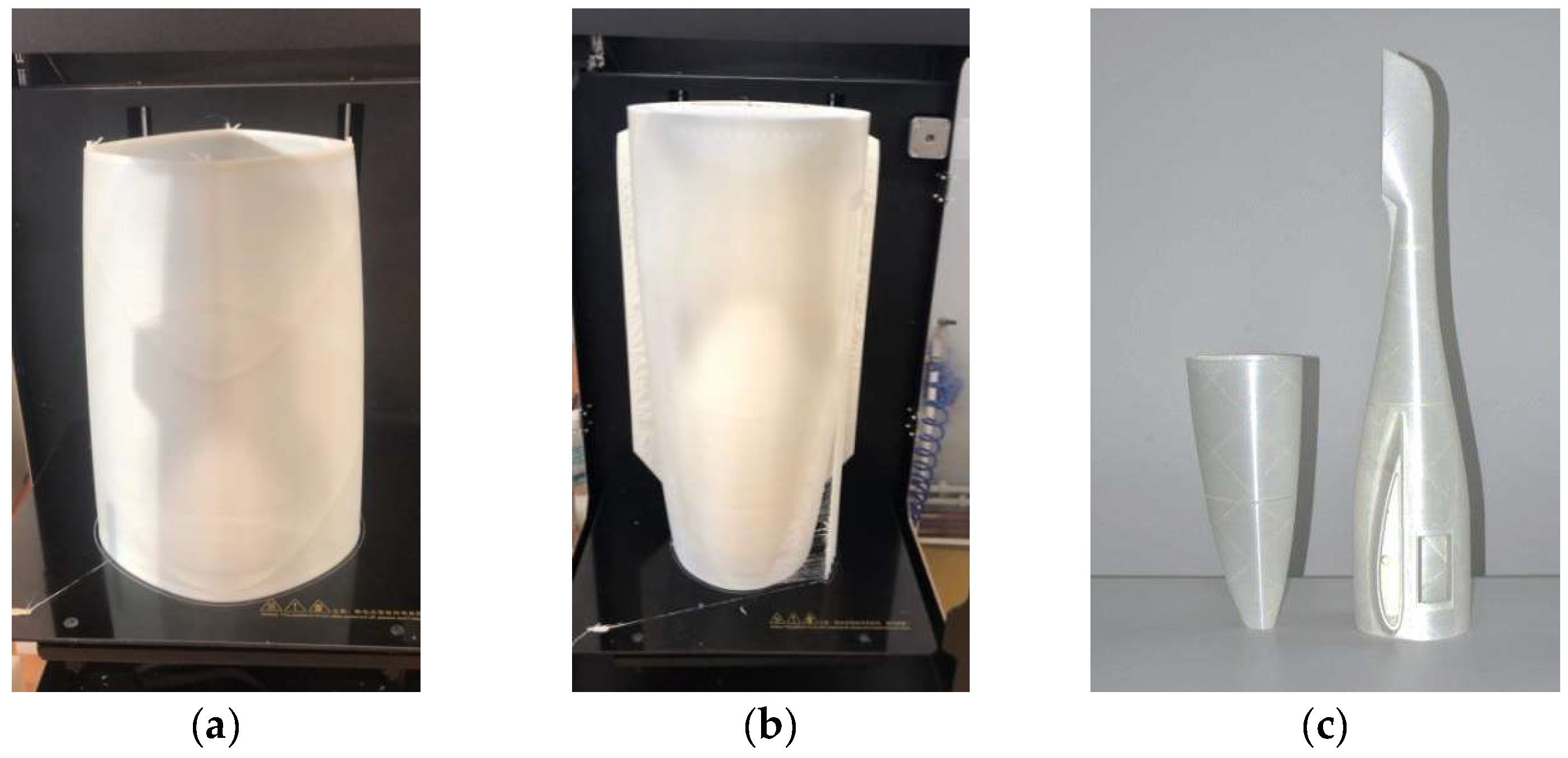

4.2. Additive Manufacturing of the UAV Fuselage

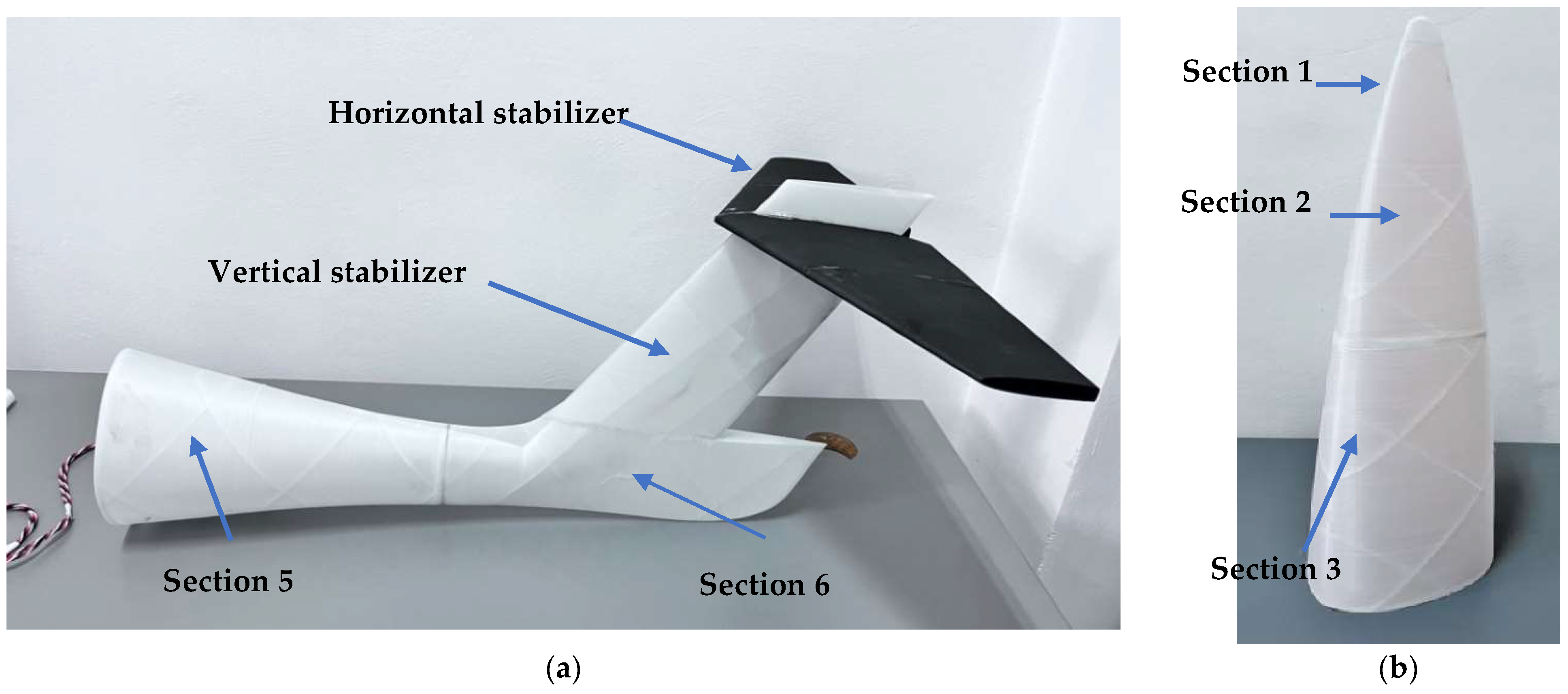

4.3. Additive Manufacturing of the UAV Empennage

4.4. Additive Manufacturing of the UAV Landing Gear

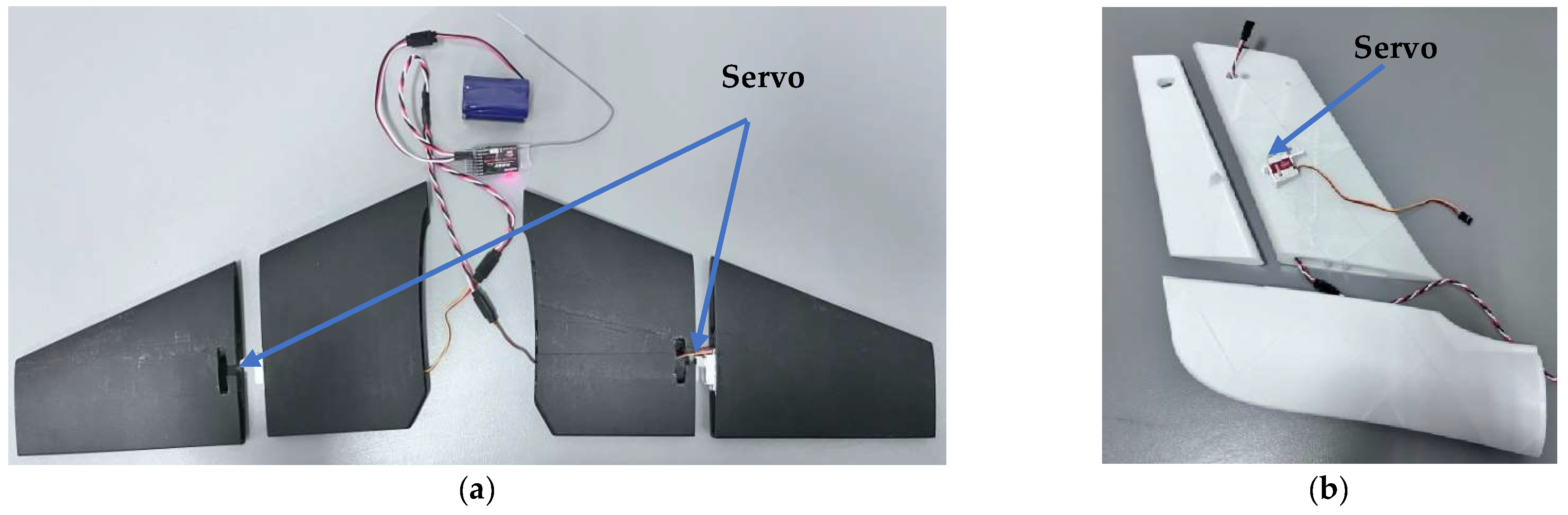

5. Assembly of the UAV Model

5.1. Assembly of the UAV Model Components

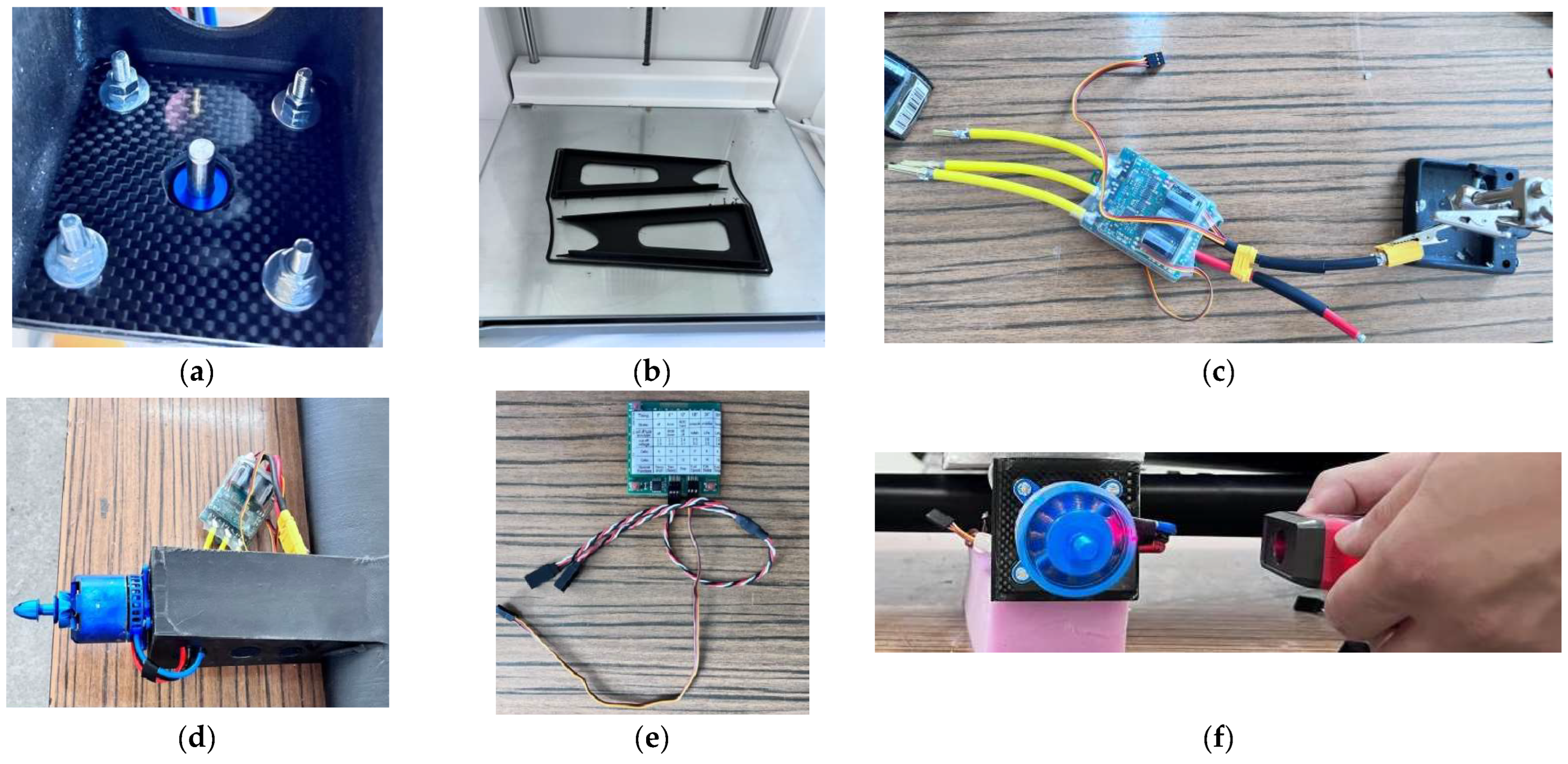

5.2. Testing the Electronic Systems of the UAV Model

5.3. Final Assembly of the UAV Model

6. Testing and Verifying the Mission of the UAV Model

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chamola, V.; Kotesh, P.; Agarwal, A.; Naren; Gupta, N.; Guizani, M. A Comprehensive Review of Unmanned Aerial Vehicle Attacks and Neutralization Techniques. Ad Hoc Netw. 2021, 111, 102324. [Google Scholar] [CrossRef] [PubMed]

- Konert, A.; Balcerzak, T. Military autonomous drones (UAVs)—From fantasy to reality. Legal and Ethical implications. Transp. Res. Procedia 2021, 59, 292–299. [Google Scholar] [CrossRef]

- Schneiderman, R. Unmanned drones are flying high in the military/aerospace sector. IEEE Signal Process. Mag. 2012, 29, 8–11. [Google Scholar] [CrossRef]

- Nyaaba, A.A.; Ayamga, M. Intricacies of medical drones in healthcare delivery: Implications for Africa. Technol. Soc. 2021, 66, 101624. [Google Scholar] [CrossRef]

- Nedelea, P.L.; Popa, T.O.; Manolescu, E.; Bouros, C.; Grigorasi, G.; Andritoi, D.; Pascale, C.; Andrei, A.; Cimpoesu, D.C. Telemedicine System Applicability Using Drones in Pandemic Emergency Medical Situations. Electronics 2022, 11, 2160. [Google Scholar] [CrossRef]

- Poljak, M.; Šterbenc, A.J.C.M. Infection, Use of drones in clinical microbiology and infectious diseases: Current status, challenges and barriers. Clin. Microbiol. Infect. 2020, 26, 425–430. [Google Scholar] [CrossRef] [PubMed]

- Rejeb, A.; Abdollahi, A.; Rejeb, K.; Treiblmaier, H. Drones in Agriculture: A Review and Bibliometric Analysis. Comput. Electron. Agric. 2022, 198, 107017. [Google Scholar] [CrossRef]

- Rahman, M.F.F.; Fan, S.; Zhang, Y.; Chen, L. A Comparative Study on Application of Unmanned Aerial Vehicle Systems in Agriculture. Agriculture 2021, 11, 22. [Google Scholar] [CrossRef]

- Hodgson, J.C.; Baylis, S.M.; Mott, R.; Herrod, A.; Clarke, R.H. Precision wildlife monitoring using unmanned aerial vehicles. Sci. Rep. 2016, 6, 22574. [Google Scholar] [CrossRef]

- Kabir, R.H.; Lee, K. Wildlife Monitoring Using a Multi-UAV System with Optimal Transport Theory. Appl. Sci. 2021, 11, 4070. [Google Scholar] [CrossRef]

- Ivanova, S.; Prosekov, A.; Kaledin, A. A Survey on Monitoring of Wild Animals during Fires Using Drones. Fire 2022, 5, 60. [Google Scholar] [CrossRef]

- Martinez-Alpiste, I.; Golcarenarenji, G.; Wang, Q.; Alcaraz-Calero, J.M. Search and rescue operation using UAVs: A case study. Expert Syst. Appl. 2021, 178, 114937. [Google Scholar] [CrossRef]

- Półka, M.; Ptak, S.; Kuziora, Ł. The use of UAV’s for search and rescue operations. Procedia Eng. 2017, 192, 748–752. [Google Scholar] [CrossRef]

- Greenwood, W.W.; Lynch, J.P.; Zekkos, D. Applications of UAVs in civil infrastructure. J. Infrastruct. Syst. 2019, 25, 04019002. [Google Scholar] [CrossRef]

- Ham, Y.; Han, K.K.; Lin, J.J.; Golparvar-Fard, M. Visual monitoring of civil infrastructure systems via camera-equipped Unmanned Aerial Vehicles (UAVs): A review of related works. Vis. Eng. 2016, 4, 1. [Google Scholar] [CrossRef]

- Lei, B.; Wang, N.; Xu, P.; Song, G. New crack detection method for bridge inspection using UAV incorporating image processing. J. Aerosp. Eng. 2018, 31, 04018058. [Google Scholar] [CrossRef]

- She, R.; Ouyang, Y. Efficiency of UAV-based last-mile delivery under congestion in low-altitude air. Transp. Res. Part C Emerg. Technol. 2021, 122, 102878. [Google Scholar] [CrossRef]

- Gu, Q.; Fan, T.; Pan, F.; Zhang, C. A vehicle-UAV operation scheme for instant delivery. Comput. Ind. Eng. 2020, 149, 106809. [Google Scholar] [CrossRef]

- Miranda, V.R.; Rezende, A.; Rocha, T.L.; Azpúrua, H.; Pimenta, L.C.; Freitas, G.M. Autonomous navigation system for a delivery drone. J. Control Autom. Electr. Syst. 2022, 33, 141–155. [Google Scholar] [CrossRef]

- Li, Y.; Liu, M.; Jiang, D. Application of Unmanned Aerial Vehicles in Logistics: A Literature Review. Sustainability 2022, 14, 14473. [Google Scholar] [CrossRef]

- Ahmed, F.; Mohanta, J.C.; Keshari, A.; Yadav, P.S. Recent Advances in Unmanned Aerial Vehicles: A Review. Arab. J. Sci. Eng. 2022, 47, 7963–7984. [Google Scholar] [CrossRef] [PubMed]

- Valoriani, F.; Esposito, M.; Gherlone, M. Shape Sensing for an UAV Composite Half-Wing: Numerical Comparison between Modal Method and Ko’s Displacement Theory. Aerospace 2022, 9, 509. [Google Scholar] [CrossRef]

- ElFaham, M.M.; Mostafa, A.M.; Nasr, G. Unmanned aerial vehicle (UAV) manufacturing materials: Synthesis, spectroscopic characterization and dynamic mechanical analysis (DMA). J. Mol. Struct. 2020, 1201, 127211. [Google Scholar] [CrossRef]

- Liang, Y.-C.; Chin, P.-C.; Sun, Y.-P.; Wang, M.-R. Design and Manufacture of Composite Landing Gear for a Light Unmanned Aerial Vehicle. Appl. Sci. 2021, 11, 509. [Google Scholar] [CrossRef]

- Boyer, R.R.; Cotton, J.D.; Mohaghegh, M.; Schafrik, R.E. Materials considerations for aerospace applications. MRS Bull. 2015, 40, 1055–1066. [Google Scholar] [CrossRef]

- Hoa, S.V. Principles of the Manufacturing of Composite Materials; DEStech Publications Inc.: Lancaster, PA, USA, 2009. [Google Scholar]

- Autonomous Unmanned Aerial Vehicles Condor 300. Available online: https://www.optimumsolution.com/item14.html (accessed on 31 August 2023).

- Applied Aeronautics, Albatross UAV. Available online: https://www.appliedaeronautics.com/albatross-uav (accessed on 31 August 2023).

- Silent Falcon™ Small Unmanned Aircraft System. Available online: https://www.homelandsecurity-technology.com/projects/silent-falcon-small-unmanned-aircraft-system/ (accessed on 31 August 2023).

- Vector VTOL Fixed Wing UAS. Available online: https://bssholland.com/product/vector-vtol-fixed-wing-uas/ (accessed on 31 August 2023).

- Aiactive Technologies, Penguin BE UAV. Available online: https://www.aiactive.com/pages/homeland-security-public-safety/uav-home-land-security/penguin-be-uav.html (accessed on 31 August 2023).

- Klippstein, H.; Diaz De Cerio Sanchez, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Fused deposition modeling for unmanned aerial vehicles (UAVs): A review. Adv. Eng. Mater. 2018, 20, 1700552. [Google Scholar] [CrossRef]

- Brischetto, S.; Ferro, C.G.; Maggiore, P.; Torre, R. Compression Tests of ABS Specimens for UAV Components Produced via the FDM Technique. Technologies 2017, 5, 20. [Google Scholar] [CrossRef]

- Rubies, E.; Palacín, J. Design and FDM/FFF Implementation of a Compact Omnidirectional Wheel for a Mobile Robot and Assessment of ABS and PLA Printing Materials. Robotics 2020, 9, 43. [Google Scholar] [CrossRef]

- Przekop, R.E.; Kujawa, M.; Pawlak, W.; Dobrosielska, M.; Sztorch, B.; Wieleba, W. Graphite Modified Polylactide (PLA) for 3D Printed (FDM/FFF) Sliding Elements. Polymers 2020, 12, 1250. [Google Scholar] [CrossRef]

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A review on voids of 3D printed parts by fused filament fabrication. J. Mater. Res. Technol. 2021, 15, 4860–4879. [Google Scholar] [CrossRef]

- Baechle-Clayton, M.; Loos, E.; Taheri, M.; Taheri, H. Failures and Flaws in Fused Deposition Modeling (FDM) Additively Manufactured Polymers and Composites. J. Compos. Sci. 2022, 6, 202. [Google Scholar] [CrossRef]

- Bochnia, J.; Blasiak, M.; Kozior, T. A Comparative Study of the Mechanical Properties of FDM 3D Prints Made of PLA and Carbon Fiber-Reinforced PLA for Thin-Walled Applications. Materials 2021, 14, 7062. [Google Scholar] [CrossRef] [PubMed]

- Comelli, C.A.; Davies, R.; van der Pol, H.; Ghita, O. PEEK filament characteristics before and after extrusion within fused filament fabrication process. J. Mater. Sci. 2022, 57, 766–788. [Google Scholar] [CrossRef]

- El Magri, A.; Vanaei, S.; Vaudreuil, S. An overview on the influence of process parameters through the characteristic of 3D-printed PEEK and PEI parts. High Perform. Polym. 2021, 33, 862–880. [Google Scholar] [CrossRef]

- Rodzeń, K.; Sharma, P.K.; McIlhagger, A.; Mokhtari, M.; Dave, F.; Tormey, D.; Sherlock, R.; Meenan, B.J.; Boyd, A. The Direct 3D Printing of Functional PEEK/Hydroxyapatite Composites via a Fused Filament Fabrication Approach. Polymers 2021, 13, 545. [Google Scholar] [CrossRef]

- Pascariu, I.S.; Zaharia, S.M. Design and testing of an unmanned aerial vehicle manufactured by fused deposition modeling. J. Aerosp. Eng. 2020, 33, 06020002. [Google Scholar] [CrossRef]

- Skawiński, I.; Goetzendorf-Grabowski, T. FDM 3D printing method utility assessment in small RC aircraft design. Aircr. Eng. Aerosp. Technol. 2019, 91, 865–872. [Google Scholar] [CrossRef]

- de Oliveira, T.L.; de Carvalho, J. Design and numerical evaluation of quadrotor drone frame suitable for fabrication using fused filament fabrication with consumer-grade ABS. J Braz. Soc. Mech. Sci. Eng. 2021, 43, 436. [Google Scholar] [CrossRef]

- Palomba, G.; Crupi, V.; Epasto, G. Additively manufactured lightweight monitoring drones: Design and experimental investigation. Polymer 2022, 241, 124557. [Google Scholar] [CrossRef]

- Yap, Y.L.; Toh, W.; Giam, A.; Yong, F.R.; Chan, K.I.; Tay, J.W.S.; Teong, S.S.; Lin, R.; Ng, T.Y. Topology optimization and 3D printing of micro-drone: Numerical design with experimental testing. Int. J. Mech. Sci. 2023, 237, 107771. [Google Scholar] [CrossRef]

- Zhu, W. Models for wind tunnel tests based on additive manufacturing technology. Prog. Aerosp. Sci. 2019, 110, 100541. [Google Scholar] [CrossRef]

- Junka, S.; Schröder, W.; Schrock, S. Design of additively manufactured wind tunnel models for use with UAVs. Procedia CIRP 2017, 60, 241–246. [Google Scholar] [CrossRef]

- Szwedziak, K.; Łusiak, T.; Bąbel, R.; Winiarski, P.; Podsędek, S.; Doležal, P.; Niedbała, G. Wind Tunnel Experiments on an Aircraft Model Fabricated Using a 3D Printing Technique. JMMP 2022, 6, 12. [Google Scholar] [CrossRef]

- Fasel, U.; Keidel, D.; Baumann, L.; Cavolina, G.; Eichenhofer, M.; Ermanni, P. Composite additive manufacturing of morphing aerospace structures. Manuf. Lett. 2020, 23, 85–88. [Google Scholar] [CrossRef]

- Bishay, P.L.; Burg, E.; Akinwunmi, A.; Phan, R.; Sepulveda, K. Development of a new span-morphing wing core design. Designs 2019, 3, 12. [Google Scholar] [CrossRef]

- Parancheerivilakkathil, M.S.; Haider, Z.; Ajaj, R.M.; Amoozgar, M. A Polymorphing Wing Capable of Span Extension and Variable Pitch. Aerospace 2022, 9, 205. [Google Scholar] [CrossRef]

- Parancheerivilakkathil, M.S.; Ajaj, R.M.; Khan, K.A. A compliant polymorphing wing for small UAVs. Chin. J. Aeronaut. 2015, 33, 2575–2588. [Google Scholar] [CrossRef]

- Belei, C.; Joeressen, J.; Amancio-Filho, S.T. Fused-Filament Fabrication of Short Carbon Fiber-Reinforced Polyamide: Parameter Optimization for Improved Performance under Uniaxial Tensile Loading. Polymers 2022, 14, 1292. [Google Scholar] [CrossRef]

- Yang, D.; Zhang, H.; Wu, J.; McCarthy, E. Fibre flow and void formation in 3D printing of short-fibre reinforced thermoplastic composites: An experimental benchmark exercise. Addit. Manuf. 2021, 37, 101686. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N.B. Compressive Behaviour of 3D-Printed PETG Composites. Aerospace 2022, 9, 124. [Google Scholar] [CrossRef]

- Goh, G.D.; Agarwala, S.; Goh, G.L.; Dikshit, V.; Sing, S.L.; Yeong, W.Y. Additive manufacturing in unmanned aerial vehicles (UAVs): Challenges and potential. Aerosp. Sci. Technol. 2017, 63, 140–151. [Google Scholar] [CrossRef]

- Zeng, C.; Liu, L.; Bian, W.; Leng, J.; Liu, Y. Compression Behavior and Energy Absorption of 3D Printed Continuous Fiber Reinforced Composite Honeycomb Structures with Shape Memory Effects. Addit. Manuf. 2021, 38, 101842. [Google Scholar] [CrossRef]

- Kepenekci, M.; Gharehpapagh, B.; Yaman, U.; Özerinç, S. Mechanical performance of carbon fiber-reinforced polymer cellular structures manufactured via fused filament fabrication. Polym. Compos. 2023, 44, 4654–4668. [Google Scholar] [CrossRef]

- Condruz, M.-R.; Paraschiv, A.; Badea, T.-A.; Useriu, D.; Frigioescu, T.-F.; Badea, G.; Cican, G. A Study on Mechanical Properties of Low-Cost Thermoplastic-Based Materials for Material Extrusion Additive Manufacturing. Polymers 2023, 15, 2981. [Google Scholar] [CrossRef] [PubMed]

- Tutar, M. A Comparative Evaluation of the Effects of Manufacturing Parameters on Mechanical Properties of Additively Manufactured PA and CF-Reinforced PA Materials. Polymers 2023, 15, 38. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Zhang, D.; Li, B.; Wan, G.; Zhao, G.; Zhang, A. Strong and thermal-resistance glass fiber-reinforced polylactic acid (PLA) composites enabled by heat treatment. Int. J. Biol. Macromol. 2019, 129, 448–459. [Google Scholar] [CrossRef] [PubMed]

- Shulga, E.; Karamov, R.; Sergeichev, I.S.; Konev, S.D.; Shurygina, L.I.; Akhatov, I.S.; Shandakov, S.D.; Nasibulin, A.G. Fused Filament Fabricated Polypropylene Composite Reinforced by Aligned Glass Fibers. Materials 2020, 13, 3442. [Google Scholar] [CrossRef]

- Li, X.; Ni, Z.; Bai, S.; Lou, B. Preparation and Mechanical Properties of Fiber Reinforced PLA for 3D Printing Materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 322, 022012. [Google Scholar] [CrossRef]

- Sadraey, M. Unmanned aircraft design: A review of fundamentals. Synth. Lect. Mech. Eng. 2017, 1, 1–193. [Google Scholar]

- Roskam, J. Airplane Design Part I: Preliminary Sizing of Airplanes, 1st ed.; DARcorporation: Lawrence, KS, USA, 1986; ISBN 978-1-884885-42-6. [Google Scholar]

- Dantsker, O.D.; Theile, M.; Caccamo, M. A Cyber-Physical Prototyping and Testing Framework to Enable the Rapid Development of UAVs. Aerospace 2022, 9, 270. [Google Scholar] [CrossRef]

- Ong, W.; Srigrarom, S.; Hesse, H. Design methodology for heavy-lift unmanned aerial vehicles with coaxial rotors. In Proceedings of the AIAA SciTech Forum, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Elmeseiry, N.; Alshaer, N.; Ismail, T. A Detailed Survey and Future Directions of Unmanned Aerial Vehicles (UAVs) with Potential Applications. Aerospace 2021, 8, 363. [Google Scholar] [CrossRef]

- Sekimoto, S.; Fujii, K.; Anyoji, M.; Miyakawa, Y.; Ito, S.; Shimomura, S.; Nishida, H.; Nonomura, T.; Matsuno, T. Flow Control around NACA 0015 Airfoil Using a Dielectric Barrier Discharge Plasma Actuator over a Wide Range of the Reynolds Number. Actuators 2023, 12, 43. [Google Scholar] [CrossRef]

- Austin, R. Unmanned Aircraft Systems: UAVs Design, Development and Deployment; American Institute of Aeronautics and Astronautics: Reston, VA, USA; Chichester, UK, 2010. [Google Scholar]

- Chicos, L.-A.; Pop, M.A.; Zaharia, S.-M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.-M. Infill Density Influence on Mechanical and Thermal Properties of Short Carbon Fiber-Reinforced Polyamide Composites Manufactured by FFF Process. Materials 2022, 15, 3706. [Google Scholar] [CrossRef]

- Chicos, L.-A.; Pop, M.A.; Zaharia, S.-M.; Lancea, C.; Buican, G.R.; Pascariu, I.S.; Stamate, V.-M. Fused Filament Fabrication of Short Glass Fiber-Reinforced Polylactic Acid Composites: Infill Density Influence on Mechanical and Thermal Properties. Polymers 2022, 14, 4988. [Google Scholar] [CrossRef] [PubMed]

- Zaharia, S.M.; Pop, M.A.; Chicos, L.-A.; Buican, G.R.; Lancea, C.; Pascariu, I.S.; Stamate, V.-M. Compression and Bending Properties of Short Carbon Fiber Reinforced Polymers Sandwich Structures Produced via Fused Filament Fabrication Process. Polymers 2022, 14, 2923. [Google Scholar] [CrossRef] [PubMed]

- Lancea, C.; Chicos, L.-A.; Zaharia, S.-M.; Pop, M.-A.; Pascariu, I.S.; Buican, G.-R.; Stamate, V.-M. Simulation, Fabrication and Testing of UAV Composite Landing Gear. Appl. Sci. 2022, 12, 8598. [Google Scholar] [CrossRef]

- Zaharia, S.-M.; Pop, M.A.; Buican, G.R.; Chicos, L.-A.; Stamate, V.M.; Pascariu, I.S.; Lancea, C. Design and Testing of Brushless DC Motor Components of A6 Steel Additively Manufactured by Selective Laser Sintering. Aerospace 2023, 10, 60. [Google Scholar] [CrossRef]

- Dündar, Ö.; Bilici, M.; Ünler, T. Design and performance analyses of a fixed wing battery VTOL UAV. Eng. Sci. Technol. Int. J. 2020, 23, 1182–1193. [Google Scholar] [CrossRef]

- Reid, W.A.; Albayati, I.M. Design of an unmanned aircraft system for high-altitude 1 kW fuel cell power system. Aerosp. Syst. 2021, 4, 353–363. [Google Scholar] [CrossRef]

- Götten, F.; Finger, D.; Braun, C.; Havermann, M.; Bil, C.; Gómez, F. Empirical correlations for geometry build-up of fixed wing unmanned air vehicles. In Proceedings of the Asia-Pacific International Symposium on Aerospace Technology, Chengdu, China, 16–18 October 2018; Springer: Singapore, 2018; pp. 1365–1381. [Google Scholar]

- Raymer, D. Aircraft Design: A Conceptual Approach, 6th ed.; American Institute of Aeronautics and Astronautics: Washington, DC, USA, 2018. [Google Scholar]

- Barnhart, R.K.; Marshall, D.M.; Shappee, E. Introduction to Unmanned Aircraft Systems; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Anderson, J.D. Aircraft Performance and Design; McGraw-Hill: New York, NY, USA, 1999. [Google Scholar]

- Sholz, D. Empennage sizing with the tail volume complemented with a method for dorsal fin layout. INCAS Bull. 2021, 13, 149–164. [Google Scholar] [CrossRef]

- Keane, A.J.; Sóbester, A.; Scanlan, J.P. Small Unmanned Fixed-Wing Aircraft Design: A Practical Approach; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Sadraey, M.H. Aircraft Design: A Systems Engineering Approach; Aerospace Series; Wiley: Chichester, UK, 2013; ISBN 978-1-119-95340-1. [Google Scholar]

- Ahmad, M.; Hussain, Z.L.; Shah, S.I.A.; Shams, T.A. Estimation of Stability Parameters for Wide Body Aircraft Using Computational Techniques. Appl. Sci. 2021, 11, 2087. [Google Scholar] [CrossRef]

- Humphreys-Jennings, C.; Lappas, I.; Sovar, D.M. Conceptual Design, Flying, and Handling Qualities Assessment of a Blended Wing Body (BWB) Aircraft by Using an Engineering Flight Simulator. Aerospace 2020, 7, 51. [Google Scholar] [CrossRef]

- Ultrafuse PAHT CF15, Technical Data Sheet. Available online: https://www.ultrafusefff.com/wp-content/uploads/2019/06/Innofil3D_PAHT_PET_CF15_Factsheet-online.pdf (accessed on 26 March 2023).

- Filaticum Glass Reinforced. Available online: https://filaticum.com/en/product/philament-glass-reinforced/ (accessed on 26 March 2023).

- Pop, M.A.; Zaharia, S.M.; Chicos, L.A.; Lancea, C.; Stamate, V.M.; Buican, G.R.; Pascariu, I.S. Effect of the infill patterns on the mechanical properties of the carbon fiber 3D printed parts. In Proceedings of the 25th Edition of Innovative Manufacturing Engineering & Energy International Conference—IMANEE, Iasi, Romania, 21–23 October 2021. [Google Scholar]

- Ismail, K.I.; Yap, T.C.; Ahmed, R. 3D-Printed Fiber-Reinforced Polymer Composites by Fused Deposition Modelling (FDM): Fiber Length and Fiber Implementation Techniques. Polymers 2022, 14, 4659. [Google Scholar] [CrossRef] [PubMed]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Ammarullah, M.I.; Hartono, R.; Supriyono, T.; Santoso, G.; Sugiharto, S.; Permana, M.S. Polycrystalline Diamond as a Potential Material for the Hard-on-Hard Bearing of Total Hip Prosthesis: Von Mises Stress Analysis. Biomedicines 2023, 11, 951. [Google Scholar] [CrossRef] [PubMed]

- Grodzki, W.; Łukaszewicz, A. Design and manufacture of unmanned aerial vehicles (UAV) wing structure using composite materials. Mater. Werkst. 2015, 46, 269–278. [Google Scholar] [CrossRef]

- Zakaria, M.; Abdallah, M.M.; Elshafie, M.A. Design and production of small tailless unmanned aerial vehicle (SAKR 2). In Proceedings of the 15-th International Conference on Applied Mechanics and Mechanical Engineering—AMME, Cairo, Egypt, 29–31 May 2012. [Google Scholar]

- Betancourth, N.J.P.; Villamarin, J.E.P.; Rios, J.J.V.; Bravo-Mosquera, P.D.; Cerón-Muñoz, H.D. Design and manufacture of a solar-powered unmanned aerial vehicle for civilian surveillance missions. J. Aerosp. Technol. Manag. 2016, 8, 385–396. [Google Scholar] [CrossRef]

| UAV Type | Design Parameters | Performances Data | ||

|---|---|---|---|---|

| Optimum Solutions Condor 300 [27]  | MTOW [kg] | 18 | Cruise Speed [km/h] | 90 |

| Span [m] | 3.2 | Range [km] | Long range | |

| Wing Area [m2] | N/A | Endurance [hours] | 4 | |

| Type of wing | Low wing | Cruise altitude [m] | 3000 | |

| Tail | T-Tail | Payload [kg] | 6 | |

| Motor type | Twin electric motor mounted on the wings | Mission | Search and Rescue of Missing Persons | |

| Power [W] | N/A | Takeoff Requirements | Autonomous take-off and landing | |

| Battery [mAh] | N/A | Takeoff Distance [m] | 40 | |

Albatross UAV [28] | MTOW [kg] | 10 | Cruise Speed [km/h] | 68 |

| Span [m] | 3 | Range [km] | 280 | |

| Wing Area [m2] | 0.683 | Endurance [hours] | 4 | |

| Type of wing | High wing | Cruise altitude [m] | Medium | |

| Tail | Inverted v-tail | Payload [kg] | 4.4 | |

| Motor type | Electric | Mission | Surveillance, search and rescue, reconnaissance | |

| Power [W] | N/A | Takeoff Requirements | Entirely autonomous from takeoff | |

| Battery [mAh] | N/A | Takeoff Distance [m] | 50–100 | |

Silent Falcon UAS [29] | MTOW [kg] | 14.5 | Cruise Speed [km/h] | 90 |

| Span [m] | 4.4 | Range [km] | 15 | |

| Wing Area [m2] | N/A | Endurance [hours] | 5 | |

| Type of wing | High wing | Cruise altitude [m] | 6000 | |

| Tail | Conventional cruciform | Payload [kg] | 3 | |

| Motor type | 1.3-hp electric motor | Mission | Search and rescue, wildlife monitoring, agricultural survey | |

| Power [W] | N/A | Takeoff Requirements | N/A | |

| Battery [mAh] | N/A | Takeoff Distance [m] | N/A | |

Vector VTOL fixed wing UAS [30] | MTOW [kg] | 7.4 | Cruise Speed [km/h] | 70 |

| Span [m] | 2.8 | Range [km] | 25 | |

| Wing Area [m2] | N/A | Endurance [hours] | 2 | |

| Type of wing | High wing | Cruise altitude [m] | N/A | |

| Tail | T tail | Payload [kg] | 0.4 | |

| Motor type | N/A | Mission | Search and rescue, convoy protection, border patrol, traffic investigation | |

| Power [W] | N/A | Takeoff Requirements | Vertical takeoff | |

| Battery [mAh] | N/A | Takeoff Distance [m] | N/A | |

Penguin BE UAV [31] | MTOW [kg] | 21.5 | Cruise Speed [km/h] | 79.2 |

| Span [m] | 3.3 | Range [km] | 180 | |

| Wing Area [m2] | 0.79 | Endurance [hours] | 2 | |

| Type of wing | High wing | Cruise altitude [m] | 6000 | |

| Tail | V-tail splits in two parts | Payload [kg] | 6.6 | |

| Motor type | Gas/Electric engine | Mission | N/A | |

| Power [W] | 2700 | Takeoff Requirements | Runway, catapult or car-launched | |

| Battery [mAh] | N/A | Takeoff Distance [m] | 30 | |

| Component | Geometric Characteristic | Value |

|---|---|---|

| Wing | Wingspan [m] | 3.4 |

| Wing area [m2] | 0.897 | |

| Root chord [m] | 0.335 | |

| Tip chord [m] | 0.200 | |

| Taper ratio | 0.597 | |

| Aspect ratio | 12.887 | |

| Mean aerodynamic chord [m] | 0.273 | |

| Flaps | Chord [m] | 0.05 |

| Span [m] | 0.6 | |

| Aileron | Chord [m] | 0.045 |

| Span [m] | 0.65 | |

| Winglet | Root chord [m] | 0.2 |

| Tip chord [m] | 0.054 | |

| Height [m] | 0.18 | |

| Fuselage | Length [m] | 1.803 |

| Height [m] | 0.228 | |

| Width [m] | 0.200 | |

| Vertical tail | Span [m] | 0.420 |

| Root chord [m] | 0.285 | |

| Tip chord [m] | 0.200 | |

| Horizontal tail | Span [m] | 0.600 |

| Root chord [m] | 0.235 | |

| Tip chord [m] | 0.120 | |

| Landing gear | Height [m] | 0.145 |

| Wheel Track [m] | 0.315 |

| FFF Parameter | Value | Value |

|---|---|---|

| Filament | BASF Ultrafuse PAHT CF15 | Philament PLA Glass Reinforced |

| Filament diameter [mm] | 2.85 | 2.85 |

| Layer height [mm] | 0.2 | 0.2 |

| Infill density [%] | 100 | 100 |

| Print speed [mm/s] | 45 | 50 |

| Travel speed [mm/s] | 100 | 80 |

| Printing temperature [°C] | 260 | 250 |

| Building plate temperature [°C] | 95 | 60 |

| Nozzle diameter [mm] | 0.6 | 0.6 |

| Component | Weight [g] | Manufacturing Time [h] |

|---|---|---|

| Fuselage | 1330 | 155 |

| Wings | 2680 | 310 |

| Ailerons | 170 | 28 |

| Flaps | 232 | 38 |

| Winglets | 240 | 36 |

| Horizontal tail | 248 | 52 |

| Vertical tail | 190 | 34 |

| Nacelle | 240 | 46 |

| Total | 5330 | 736 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaharia, S.-M.; Pascariu, I.S.; Chicos, L.-A.; Buican, G.R.; Pop, M.A.; Lancea, C.; Stamate, V.M. Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions. Drones 2023, 7, 602. https://doi.org/10.3390/drones7100602

Zaharia S-M, Pascariu IS, Chicos L-A, Buican GR, Pop MA, Lancea C, Stamate VM. Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions. Drones. 2023; 7(10):602. https://doi.org/10.3390/drones7100602

Chicago/Turabian StyleZaharia, Sebastian-Marian, Ionut Stelian Pascariu, Lucia-Antoneta Chicos, George Razvan Buican, Mihai Alin Pop, Camil Lancea, and Valentin Marian Stamate. 2023. "Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions" Drones 7, no. 10: 602. https://doi.org/10.3390/drones7100602

APA StyleZaharia, S.-M., Pascariu, I. S., Chicos, L.-A., Buican, G. R., Pop, M. A., Lancea, C., & Stamate, V. M. (2023). Material Extrusion Additive Manufacturing of the Composite UAV Used for Search-and-Rescue Missions. Drones, 7(10), 602. https://doi.org/10.3390/drones7100602