Inverted Docking Station: A Conceptual Design for a Battery-Swapping Platform for Quadrotor UAVs

Abstract

:1. Introduction

- Propose a novel concept of inverted docking;

- Present design guidelines and a mathematical model of a w-shaped positioning design for quadrotor UAVs with experimental landing error data;

- Develop a 3D CAD model of the inverted docking station with detailed motion steps;

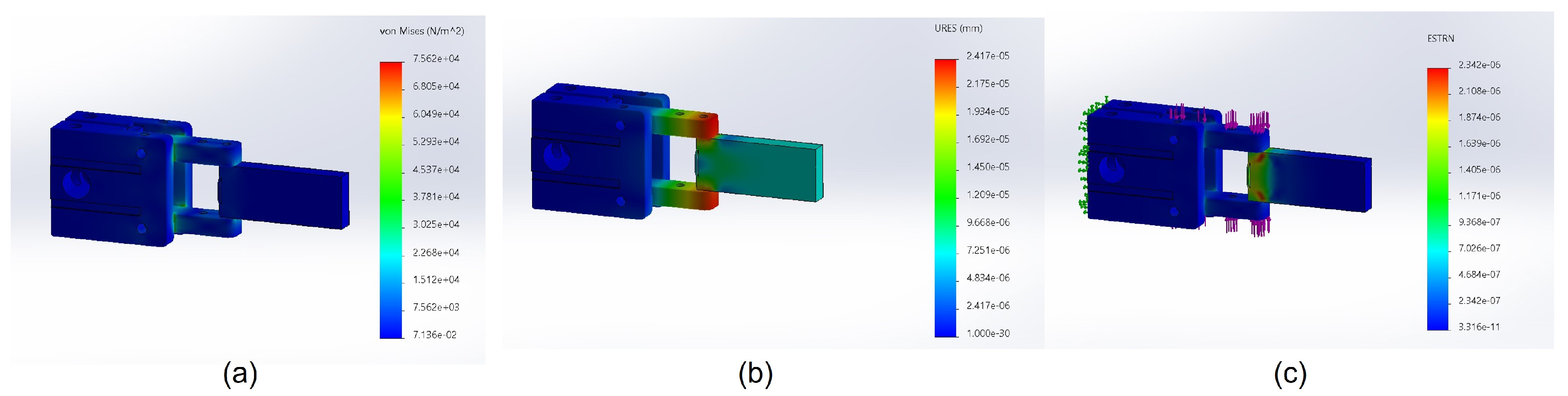

- Simulate a motion study and Finite Element Analysis (FEA) of the designed 3D model.

2. Literature Review

2.1. Landing Platforms of UAVs

2.2. Positioning Mechanisms

2.2.1. Active Positioning Mechanisms

2.2.2. Passive Positioning Mechanisms

2.3. Battery-Charging Techniques for UAVs

2.4. Battery-Swapping Stations for UAVs

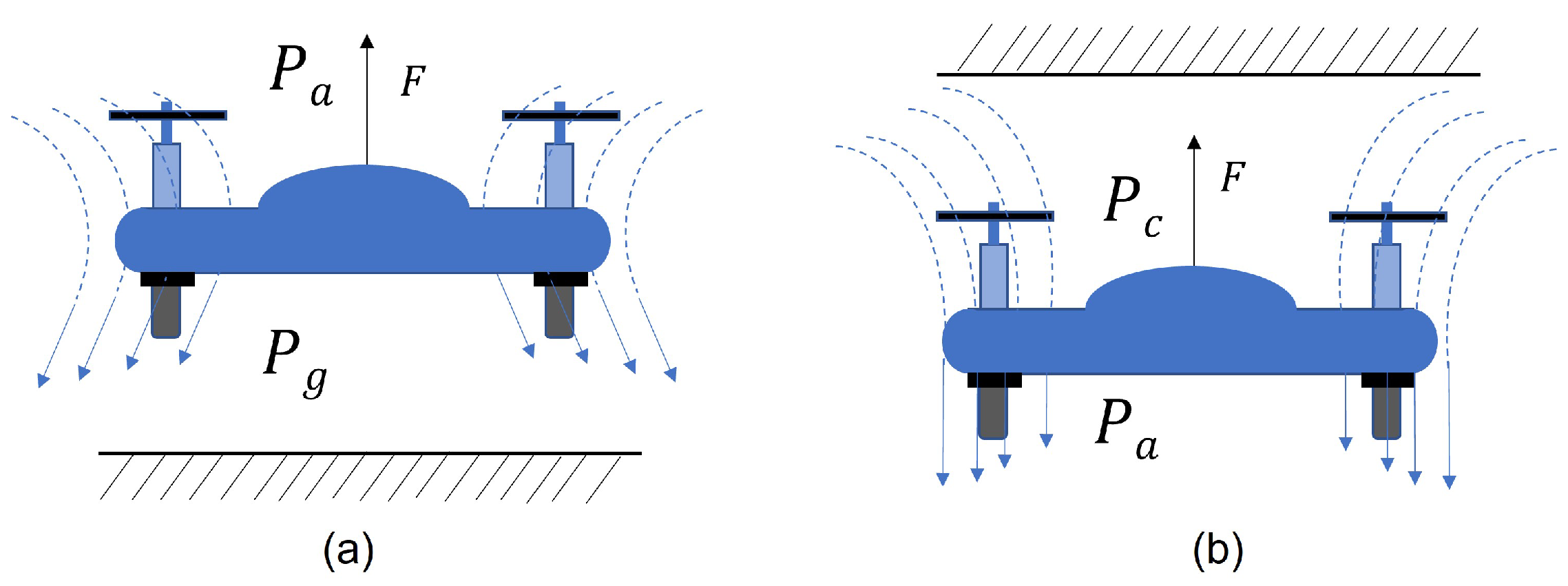

2.5. Ground and Ceiling Effects

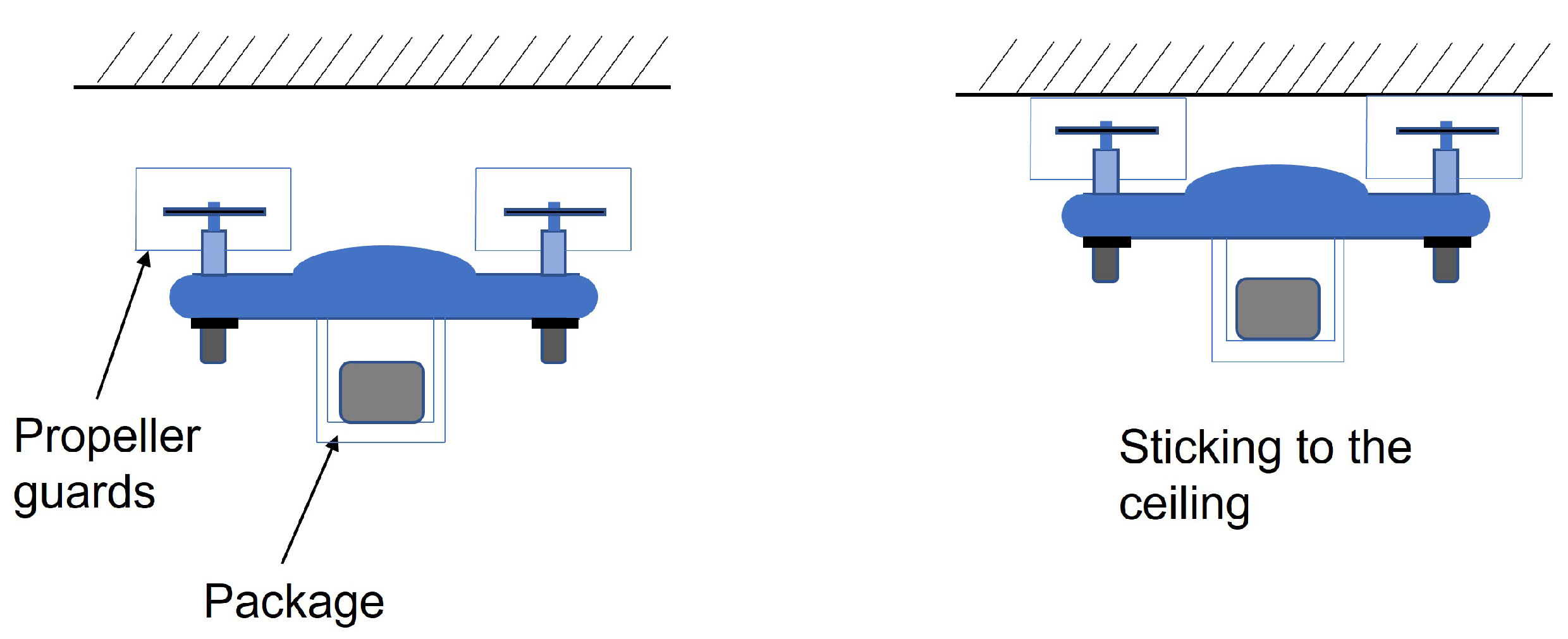

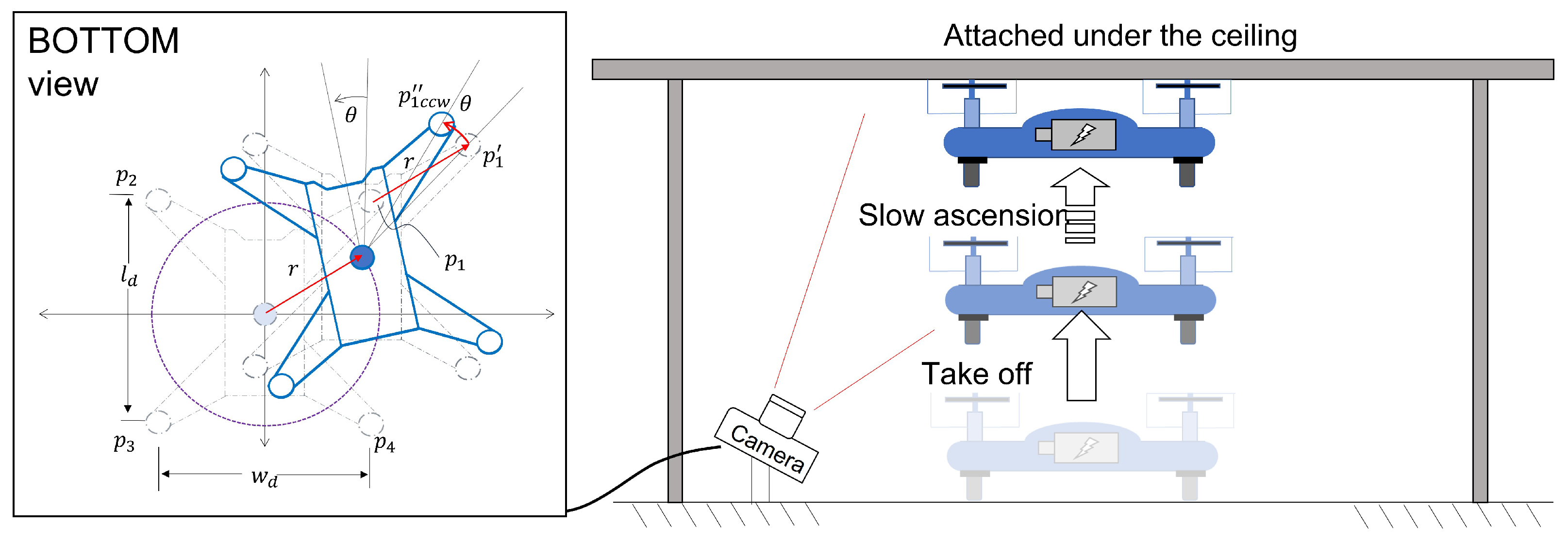

3. Concept of Inverted Docking Station

3.1. Overview of the Research

- Calculating the error of landing;

- Designing the landing platform and the positioning mechanism based on the calculations;

- Analyzing the gripping mechanism to achieve the loading and unloading of the battery from the quadrotor;

- Creating a customized secondary gripping mechanism to change the orientation of the battery;

- Identifying design limitations.;

- Preparing a movable battery charging unit.

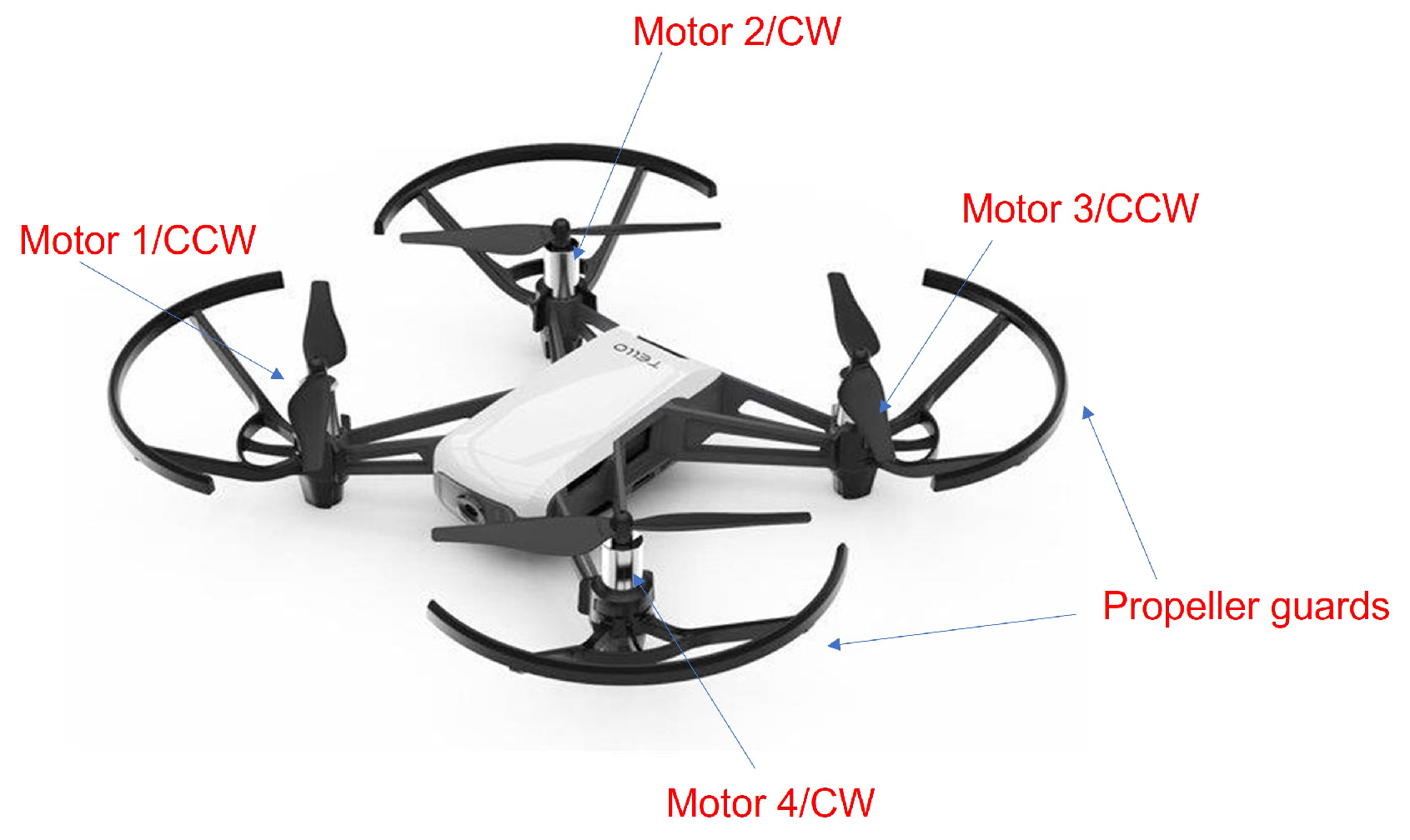

3.2. Scope of the Research

3.3. Design Considerations and Guidelines

3.3.1. Error of Inverted Landing

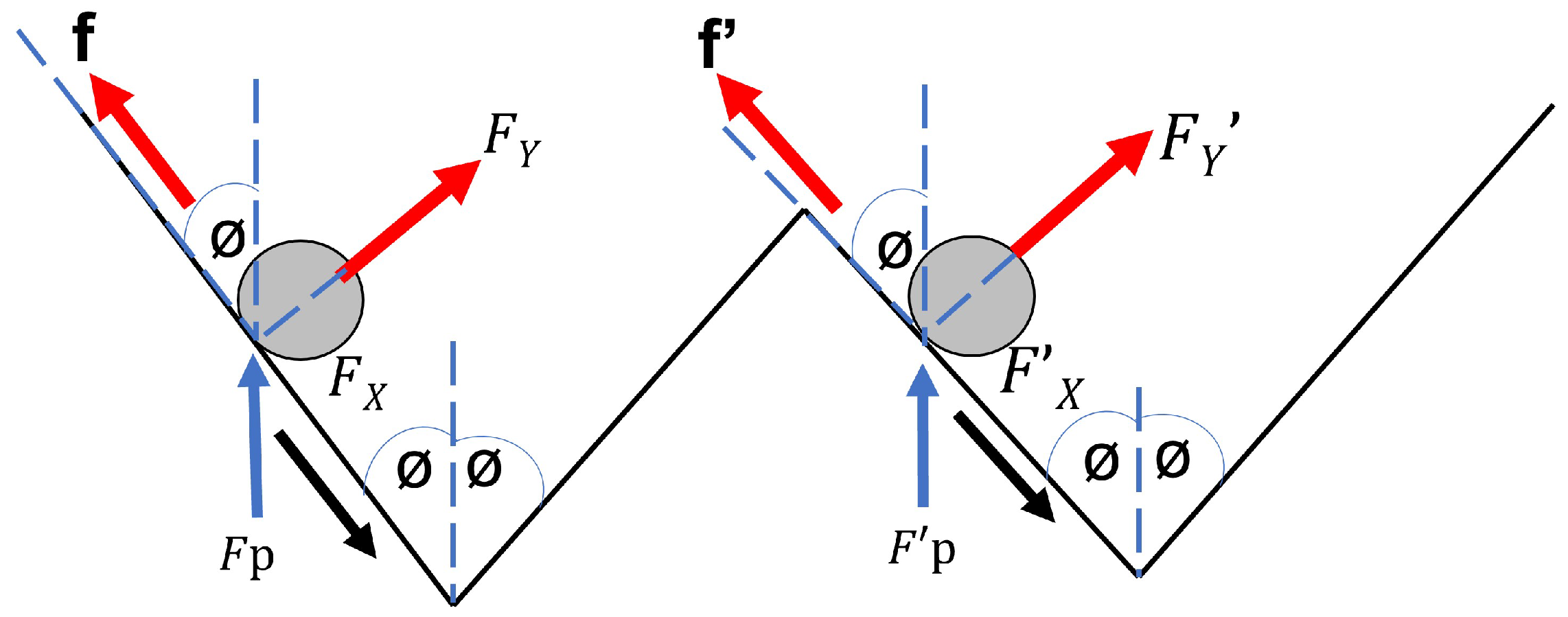

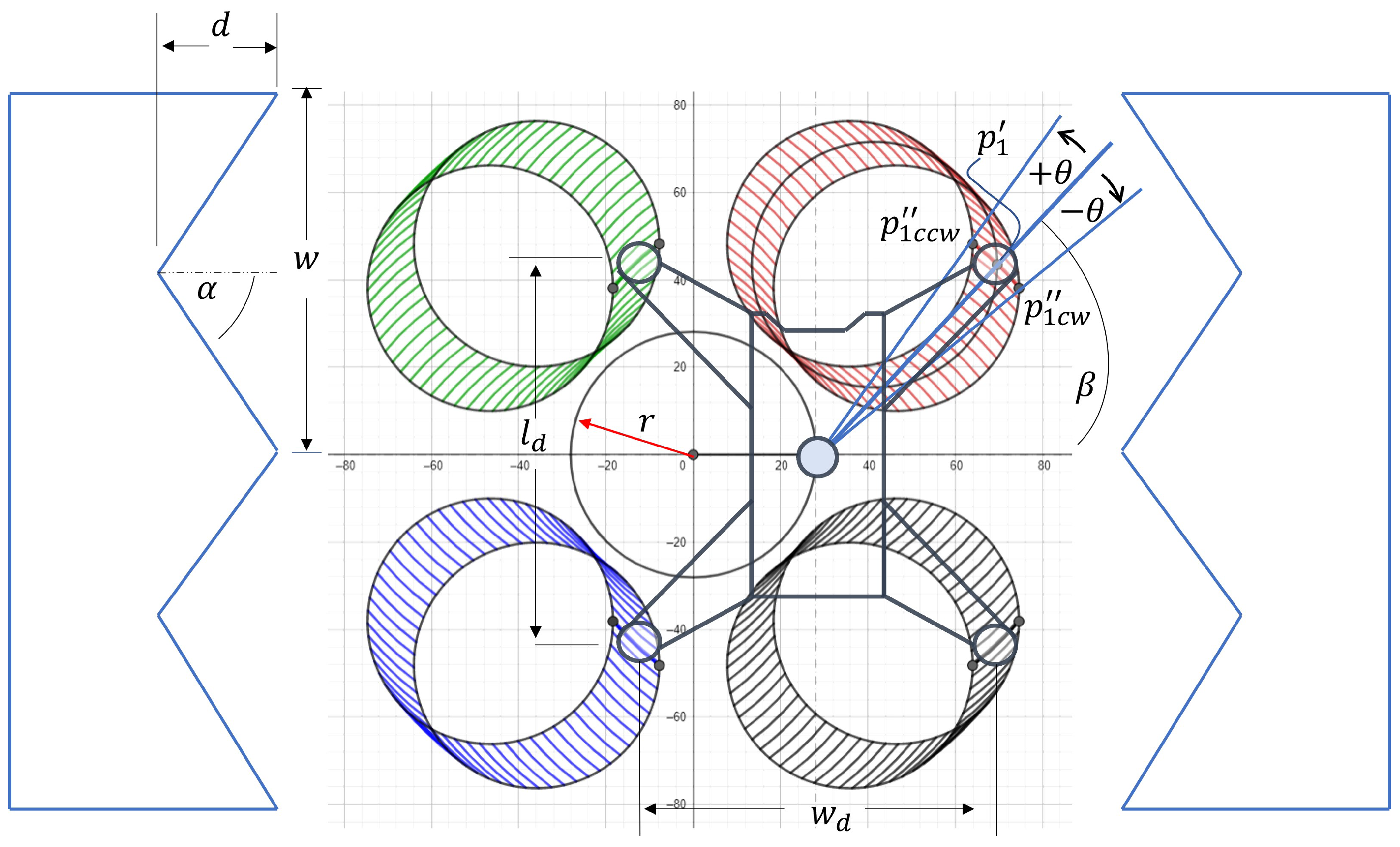

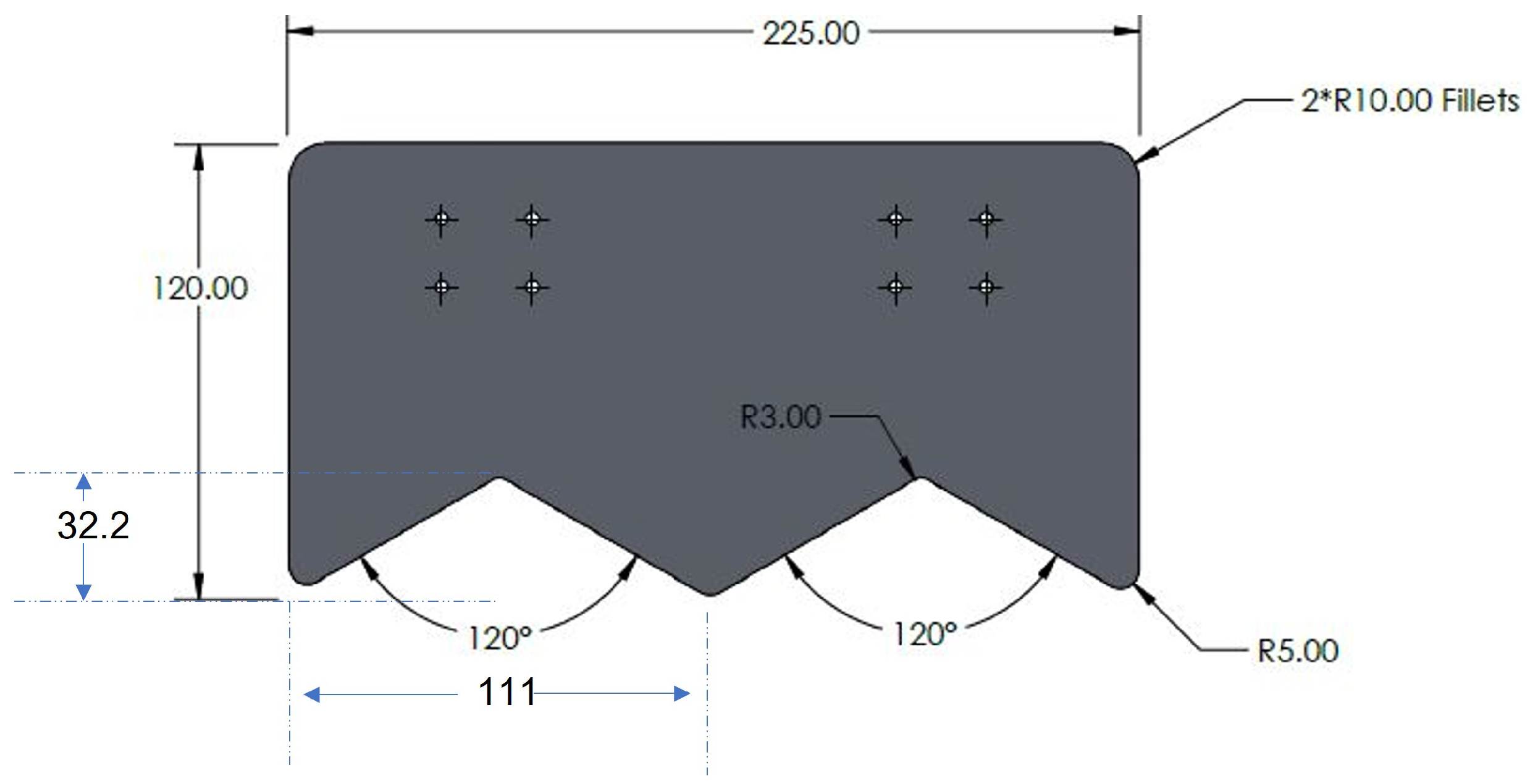

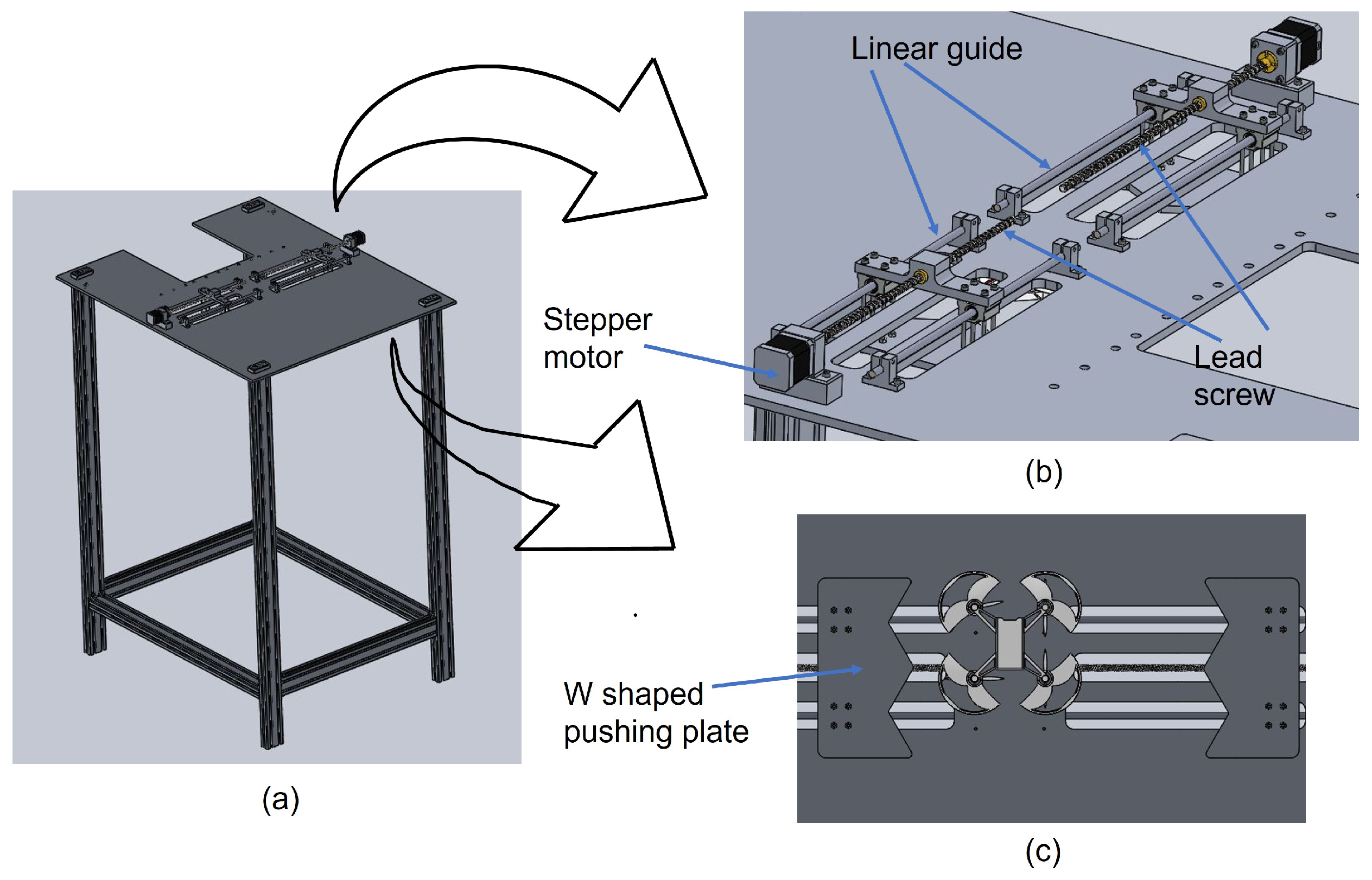

3.3.2. Designing the Positioning Plate

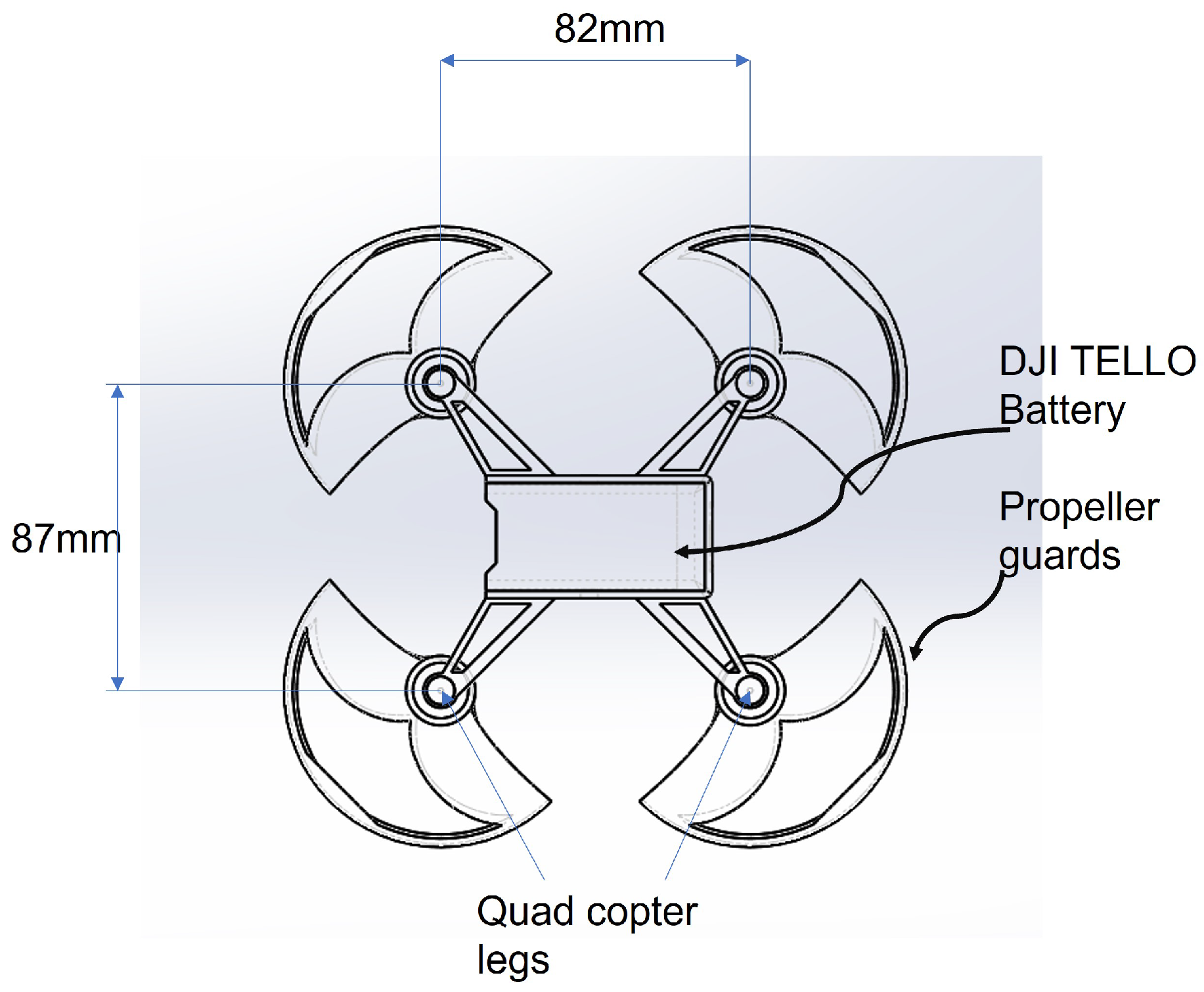

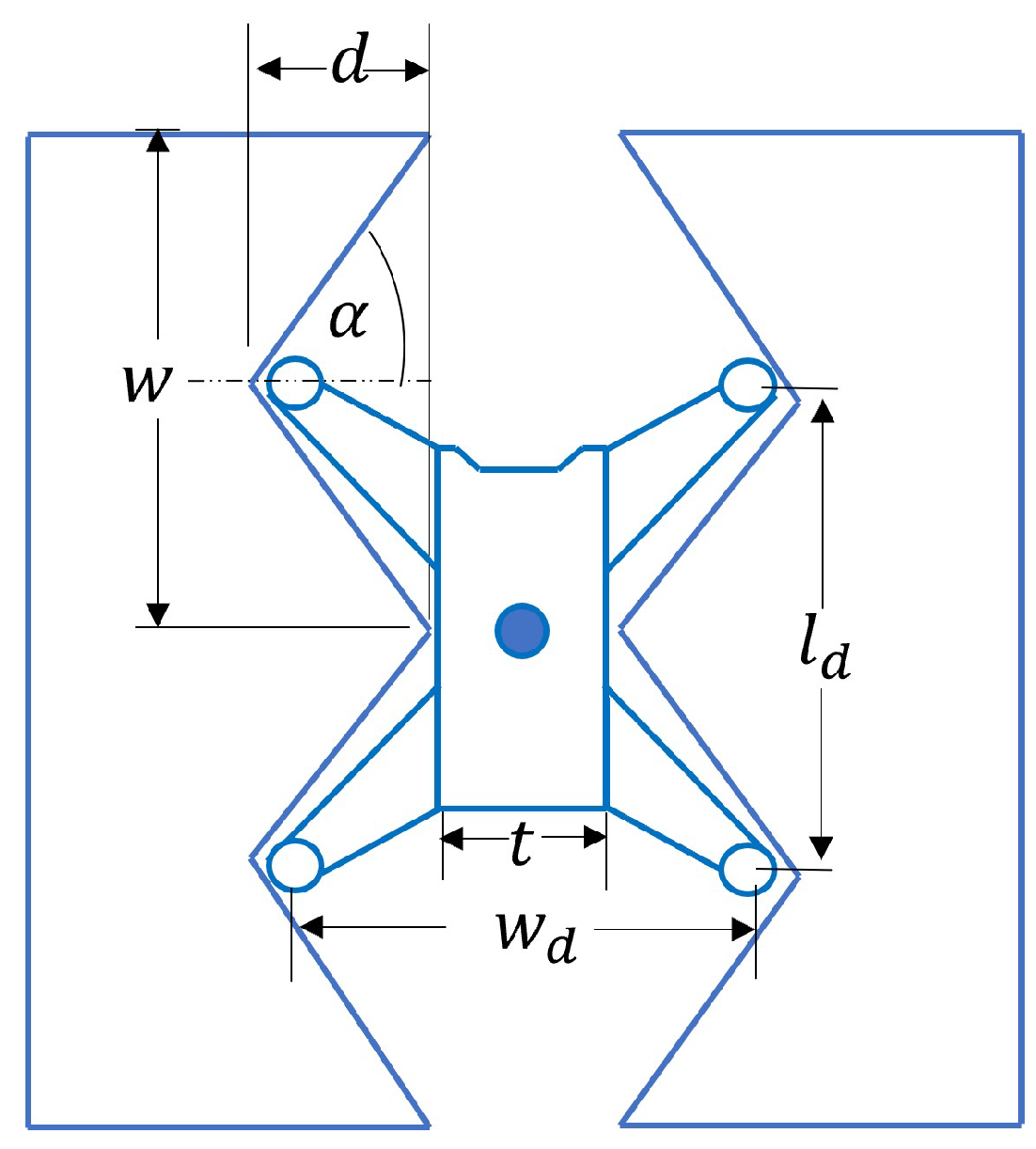

- UAV size measured from the leg centers , ;

- Possible landing position of the legs;

- Width of the positioning plate w;

- Depth of the positioning plate d.

- Choose proper width w according to landing errors;

- Choose plate angle as small as possible to reduce contact friction;

- Check the depth d to prevent collision.

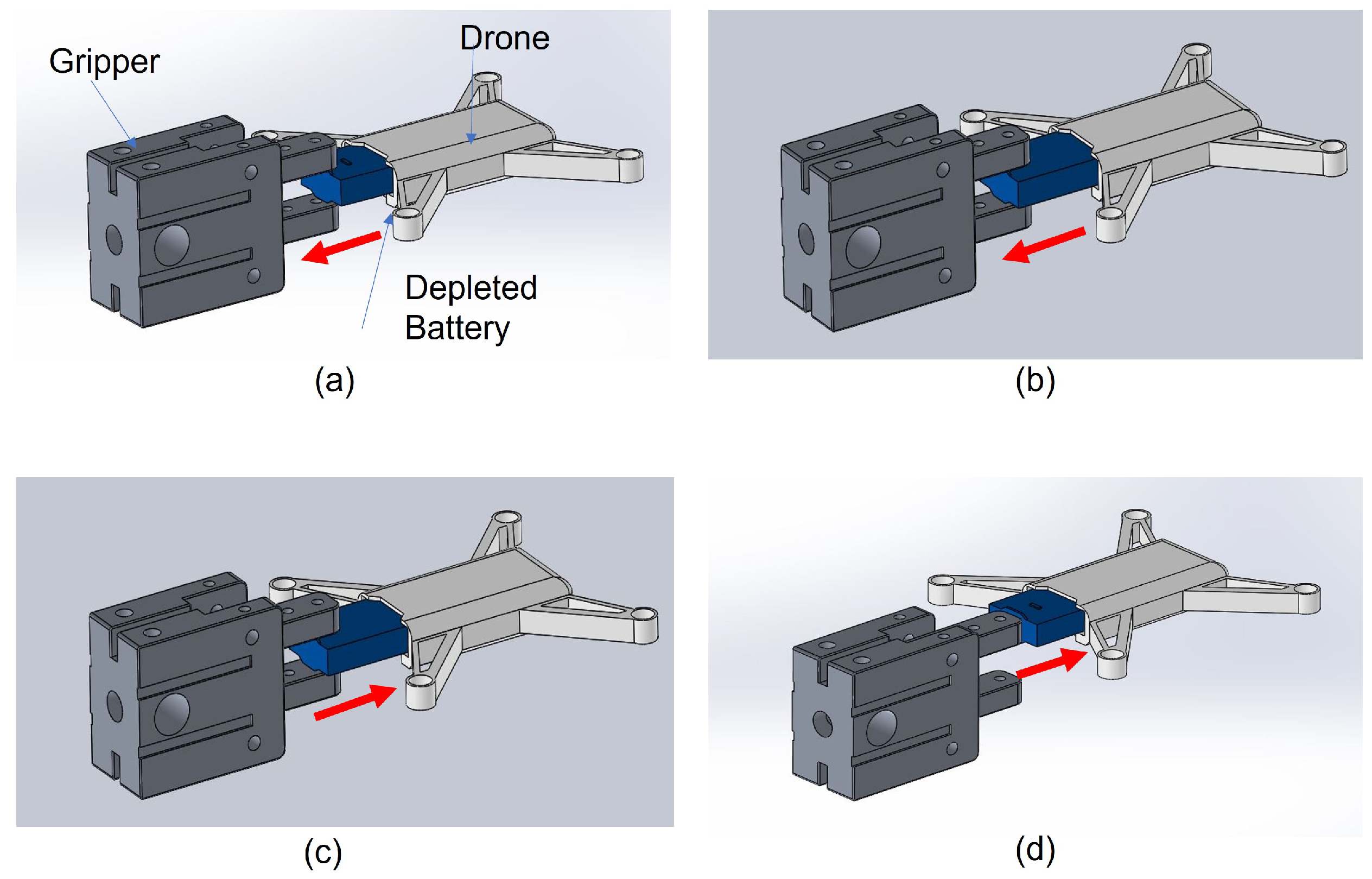

3.3.3. Analyzing the Gripping Mechanism

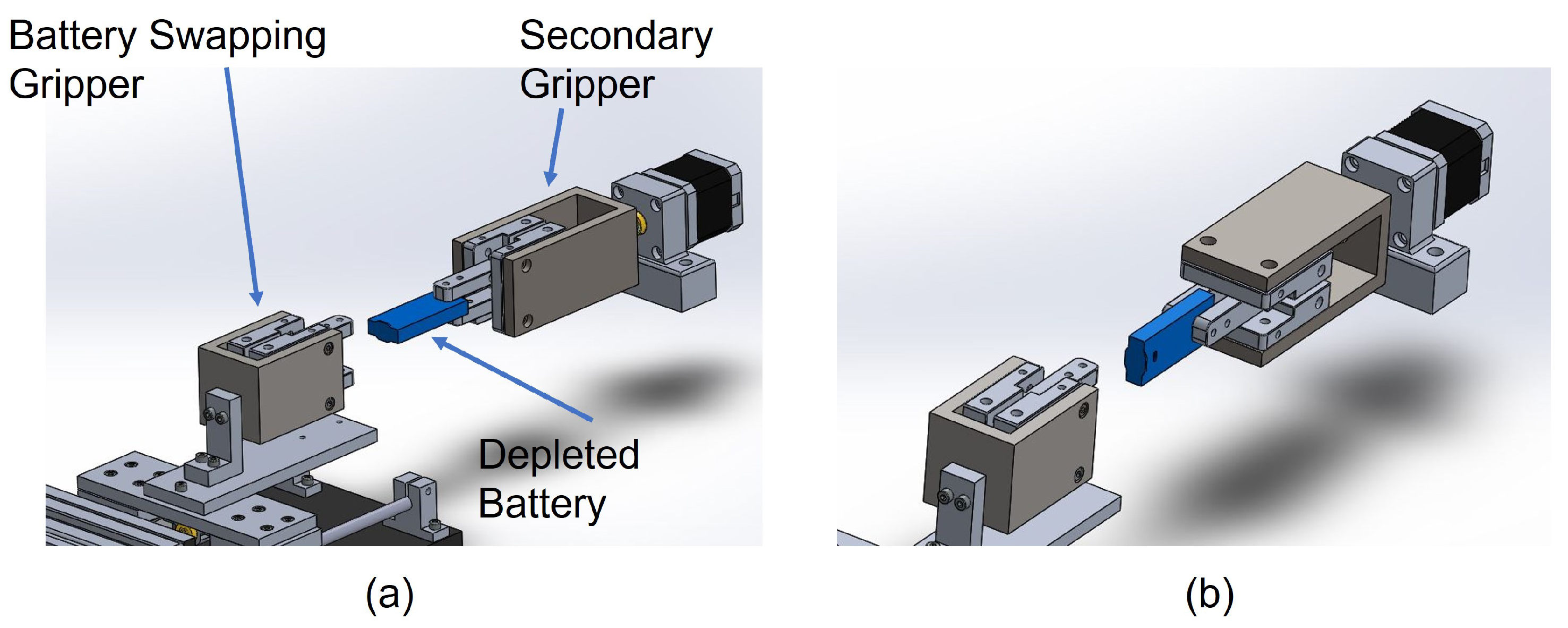

3.3.4. Need of a Secondary Gripper

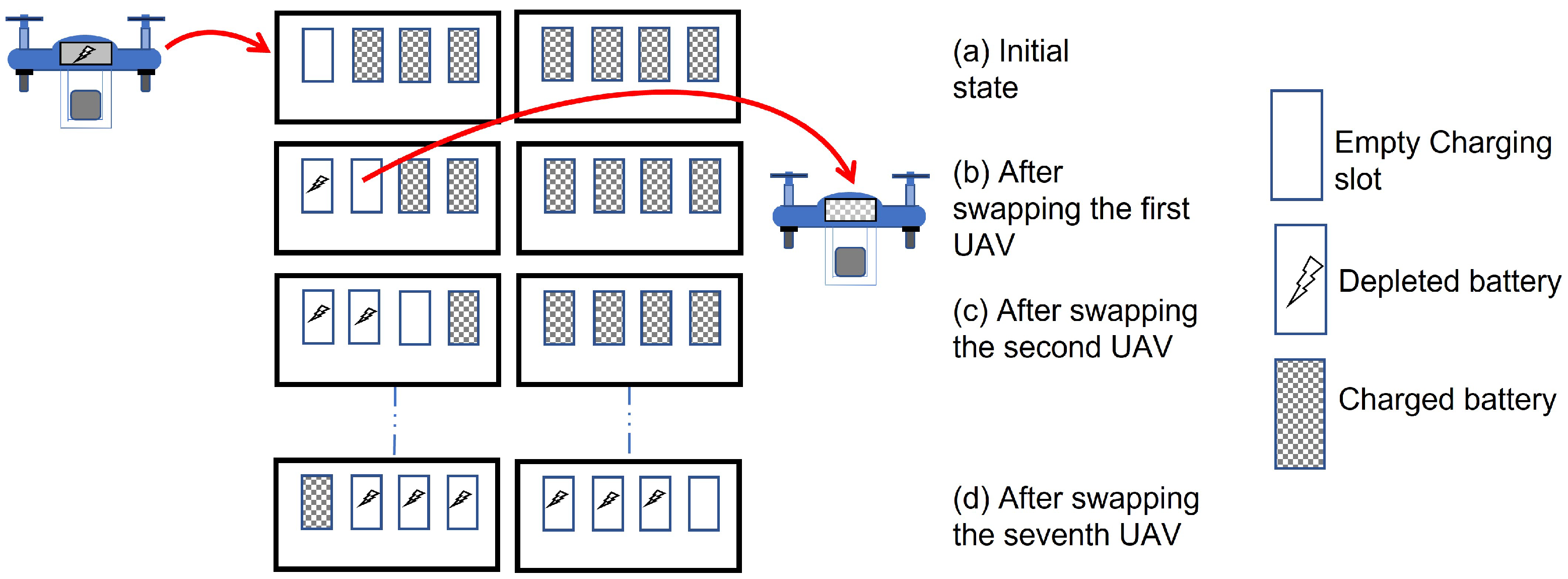

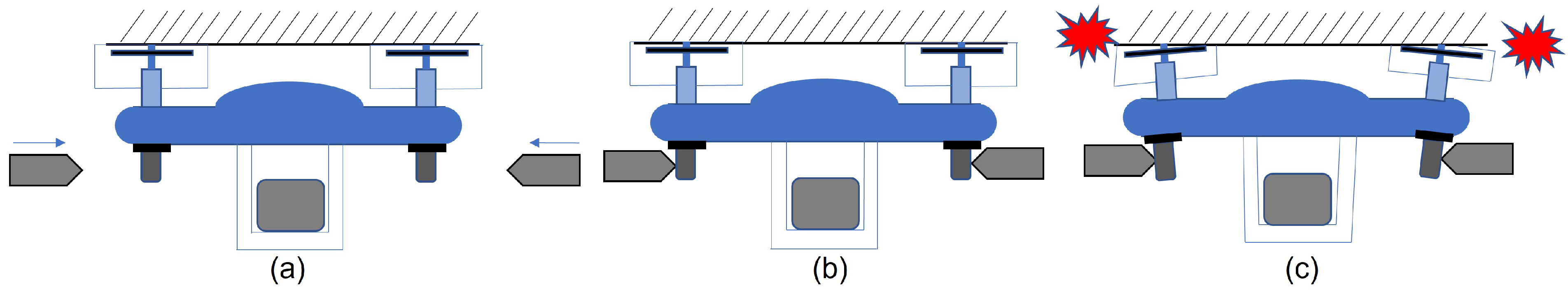

3.4. Definition of Working Sequence for the System

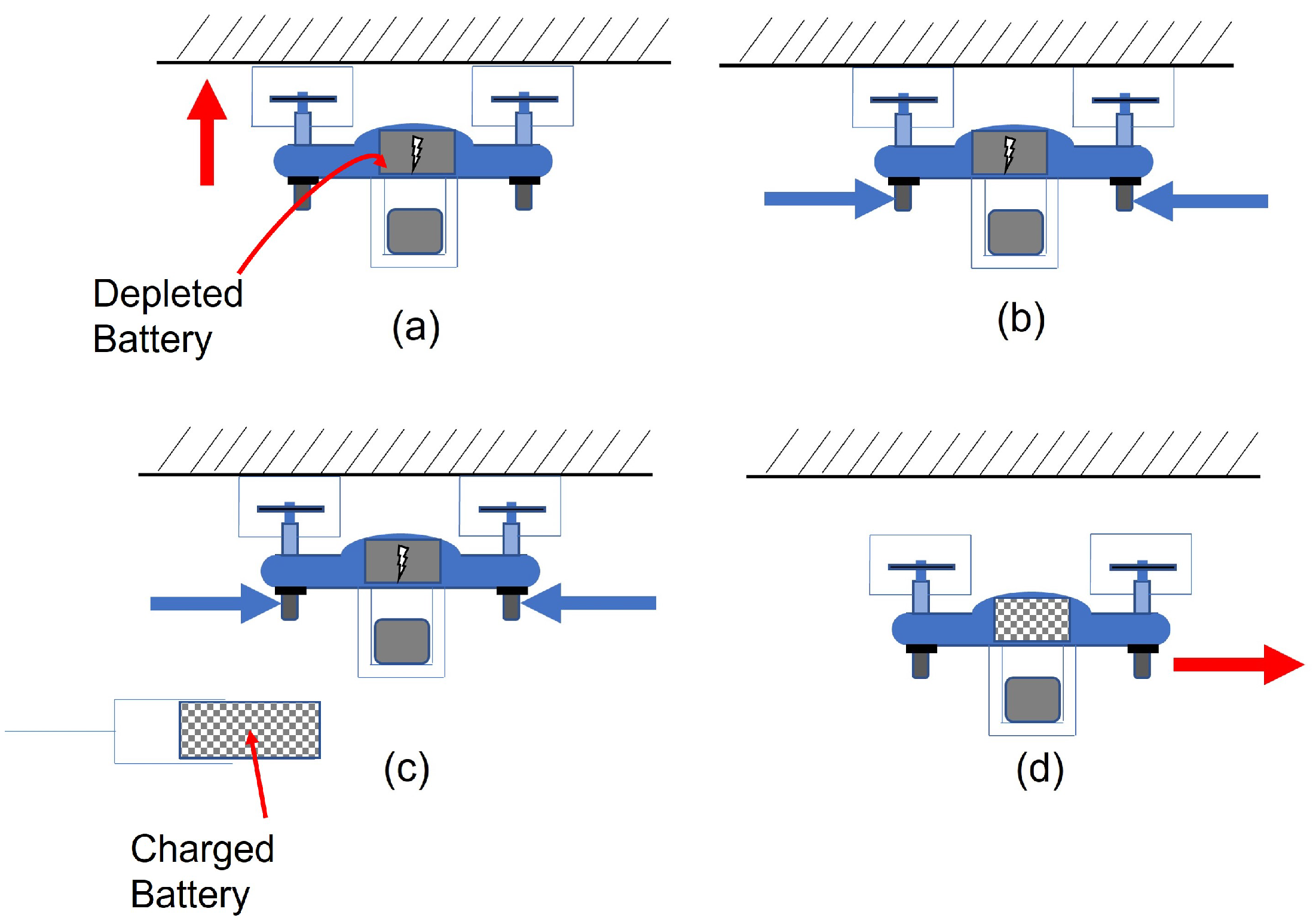

- Docking: The UAV is inversely docked under the ceiling with the help of the ceiling effect;

- Positioning: The UAV is then centered and locked by w-shaped positioning plates;

- Battery swapping: The depleted battery should be removed, and a new battery is installed by the battery-swapping gripper;

- Unlocking: The positioning plate releases the UAV from its locked position;

- Flight: The UAV is now free to fly out from the station.

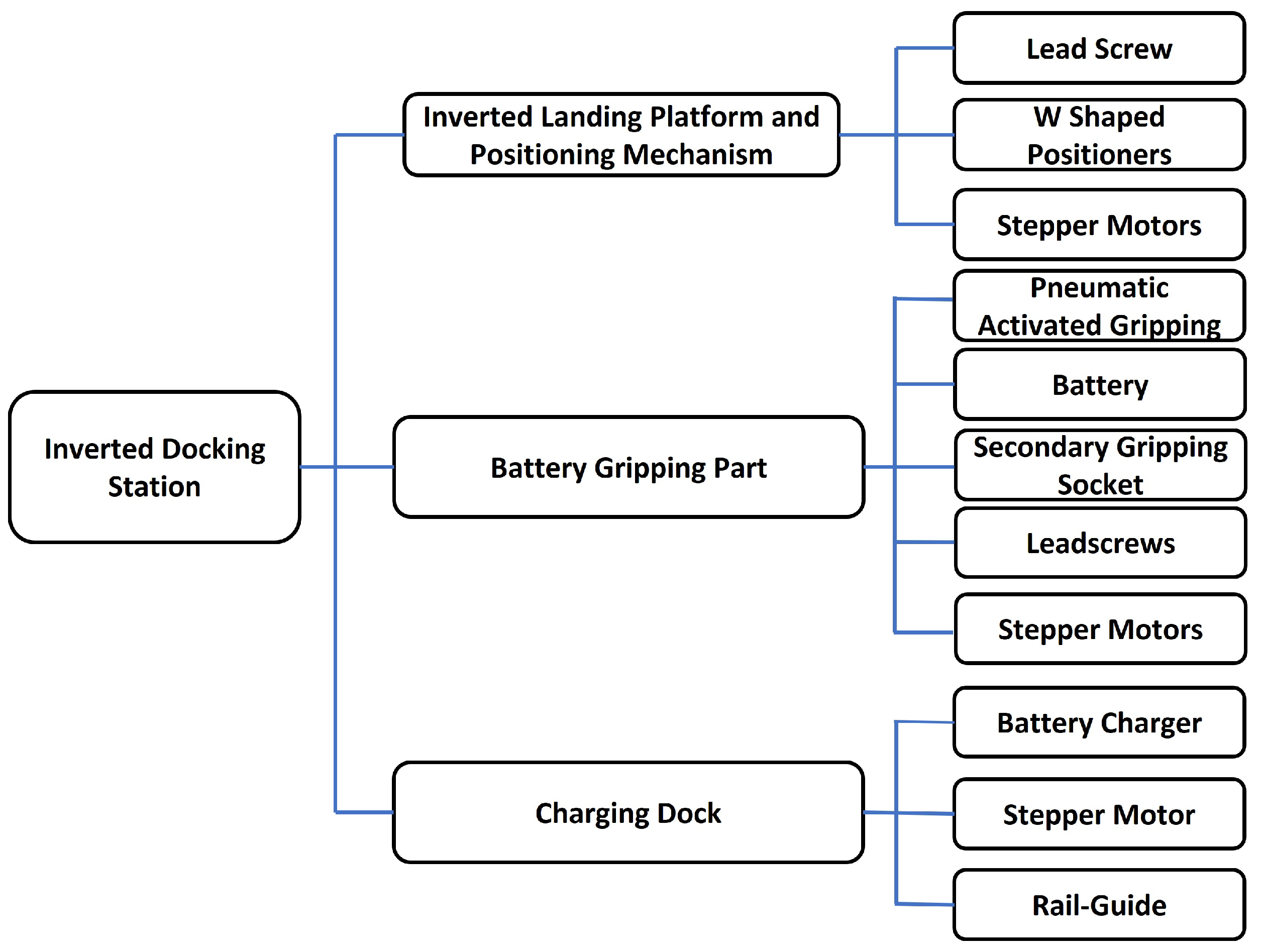

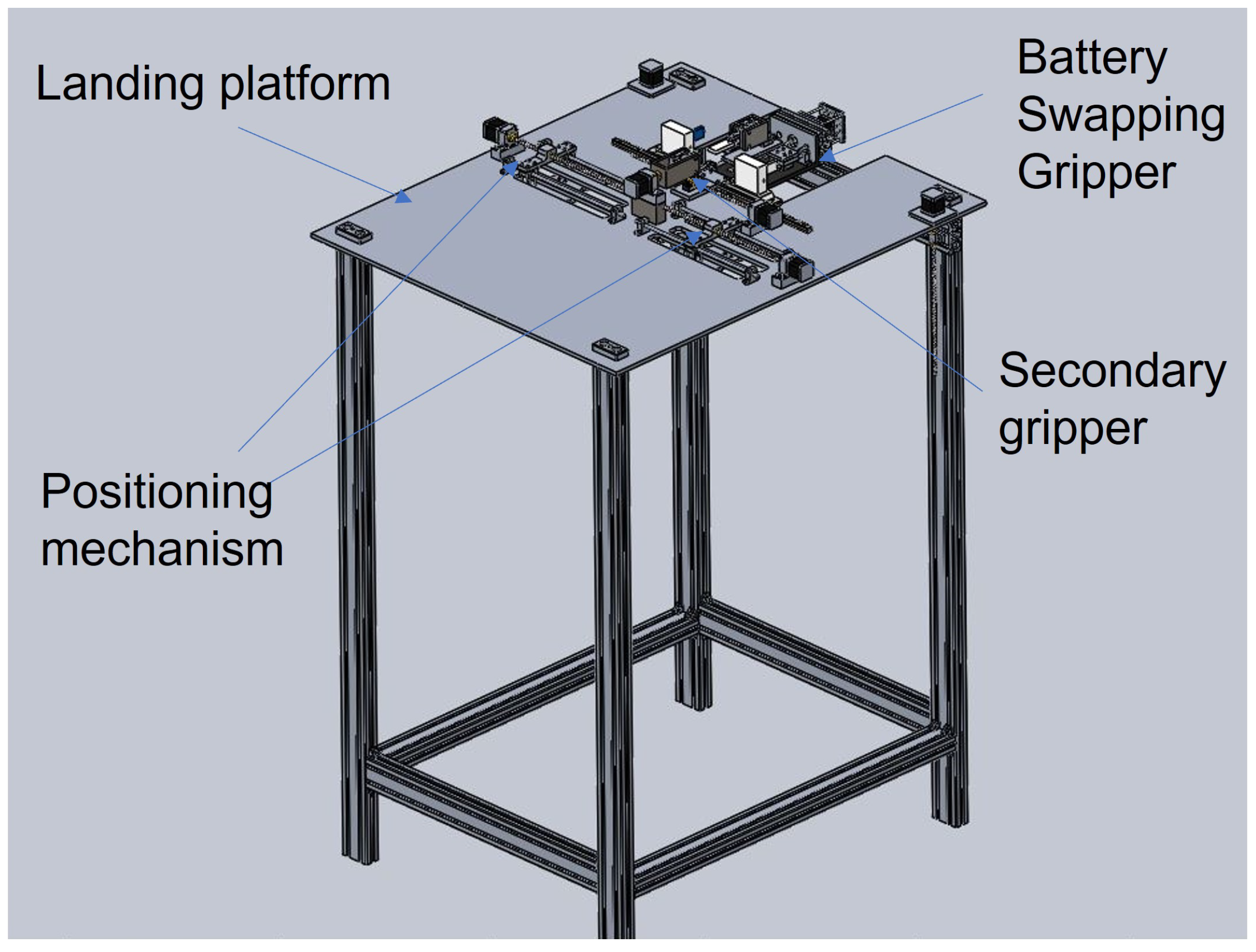

4. Design of the System

4.1. Designing of the Landing Platform and Positioning Mechanism

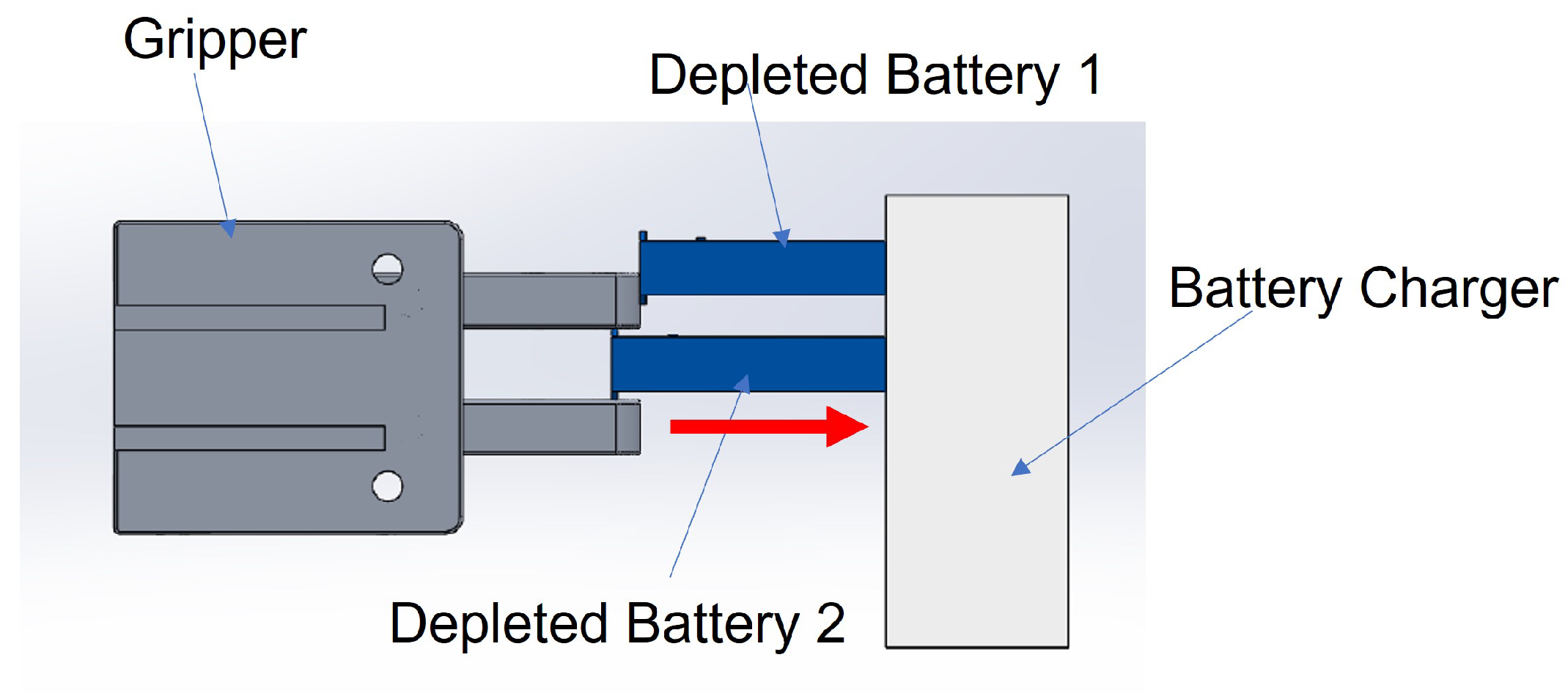

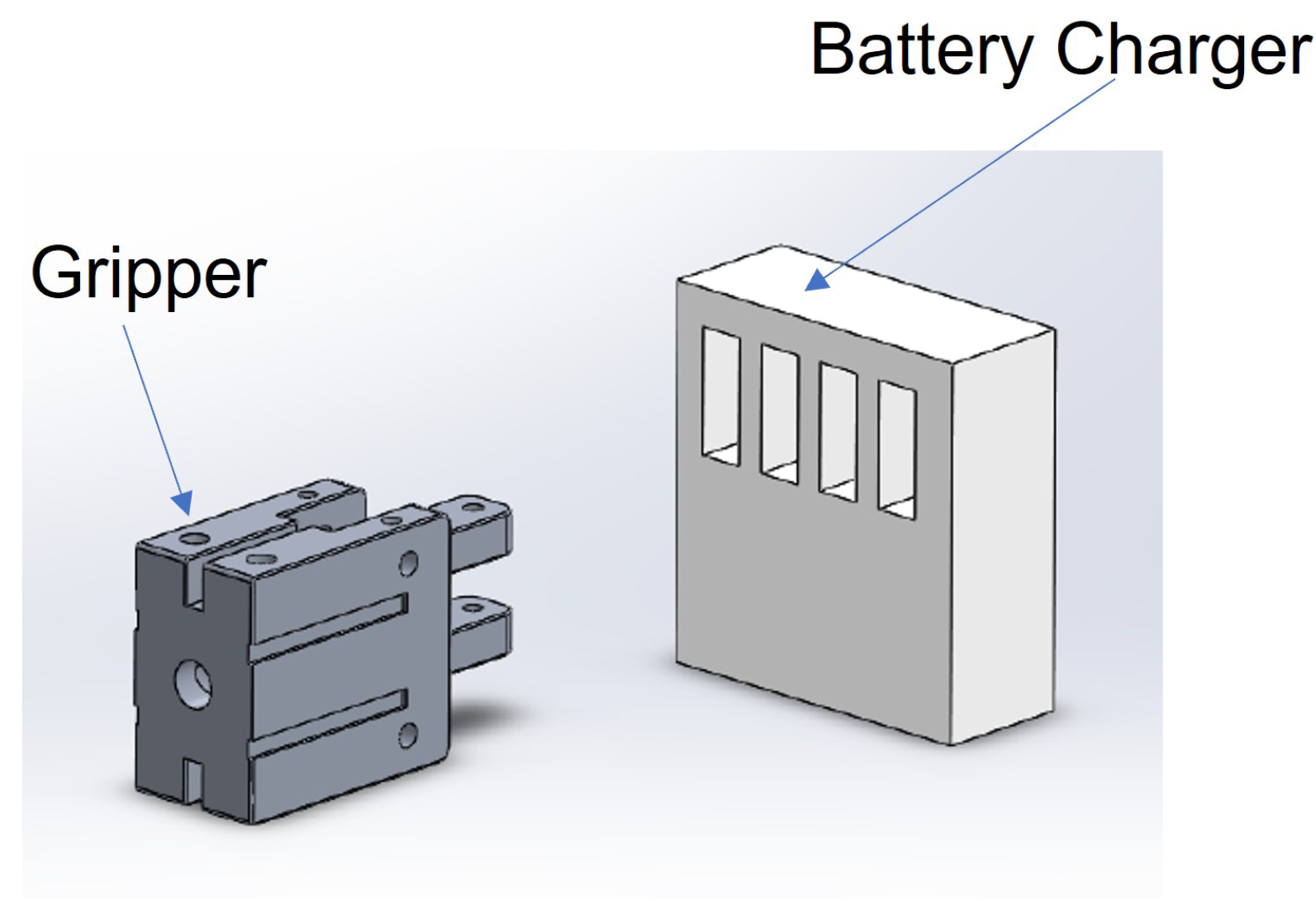

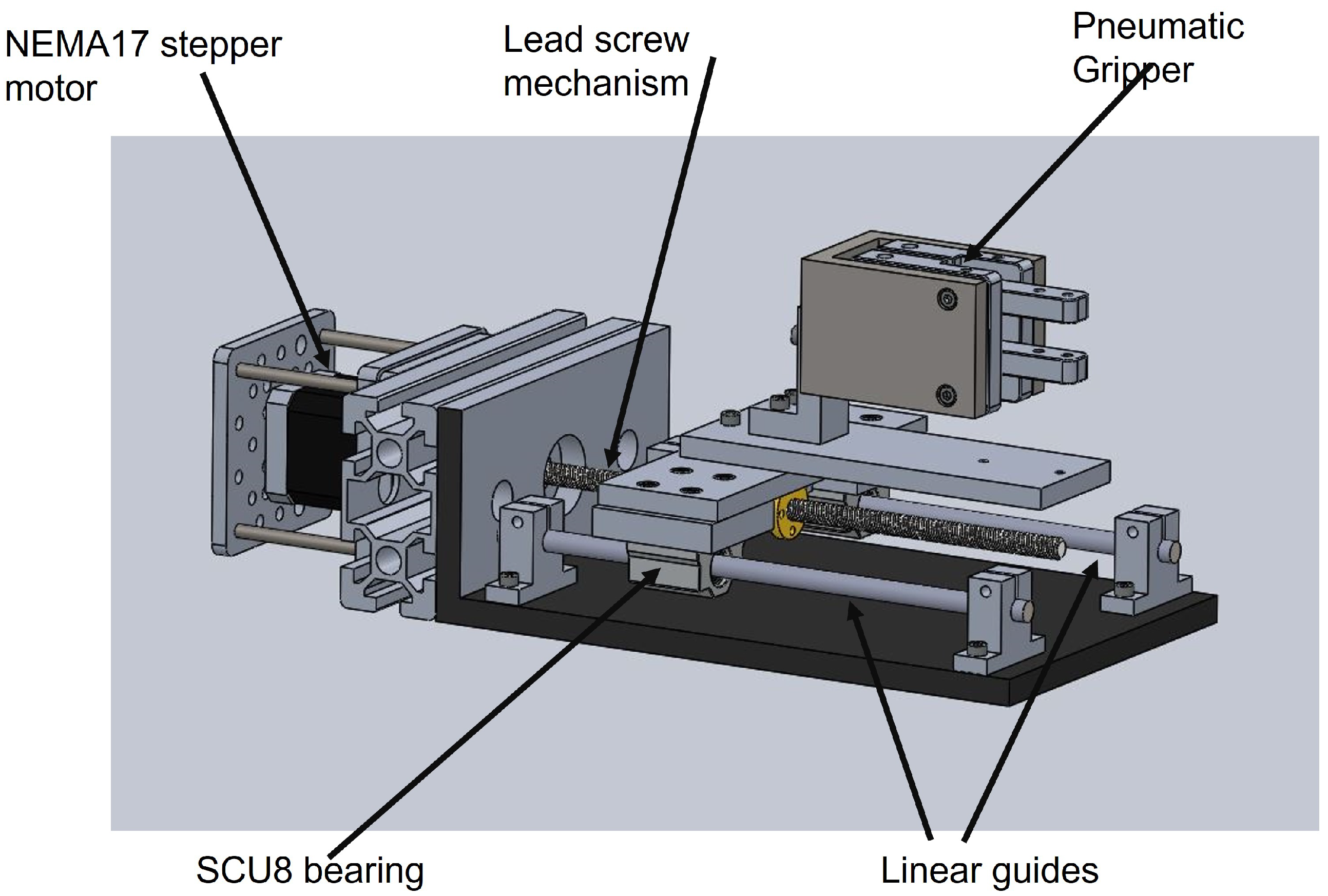

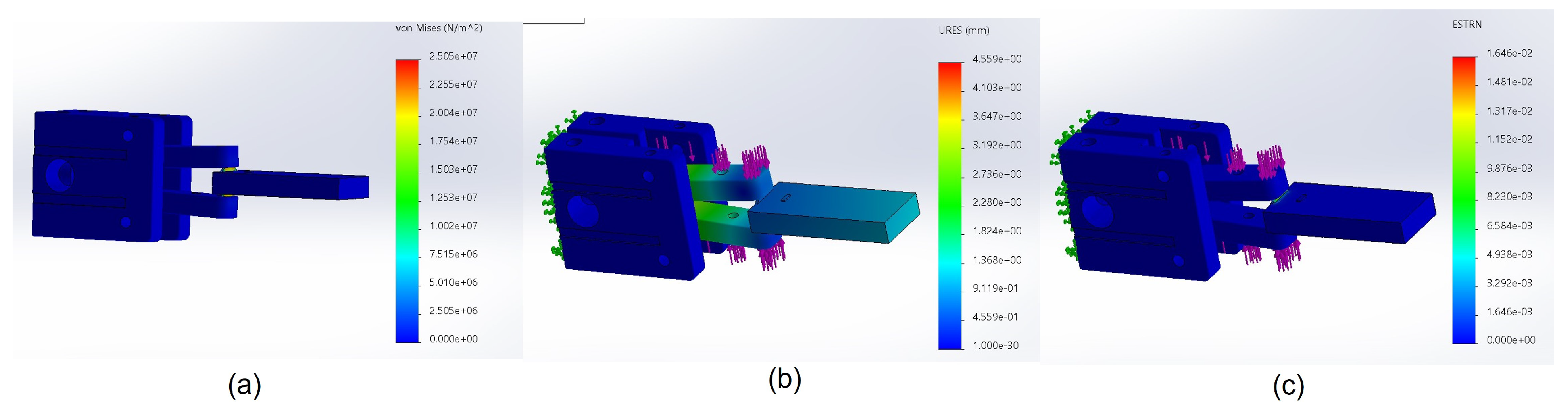

4.2. Battery Gripper

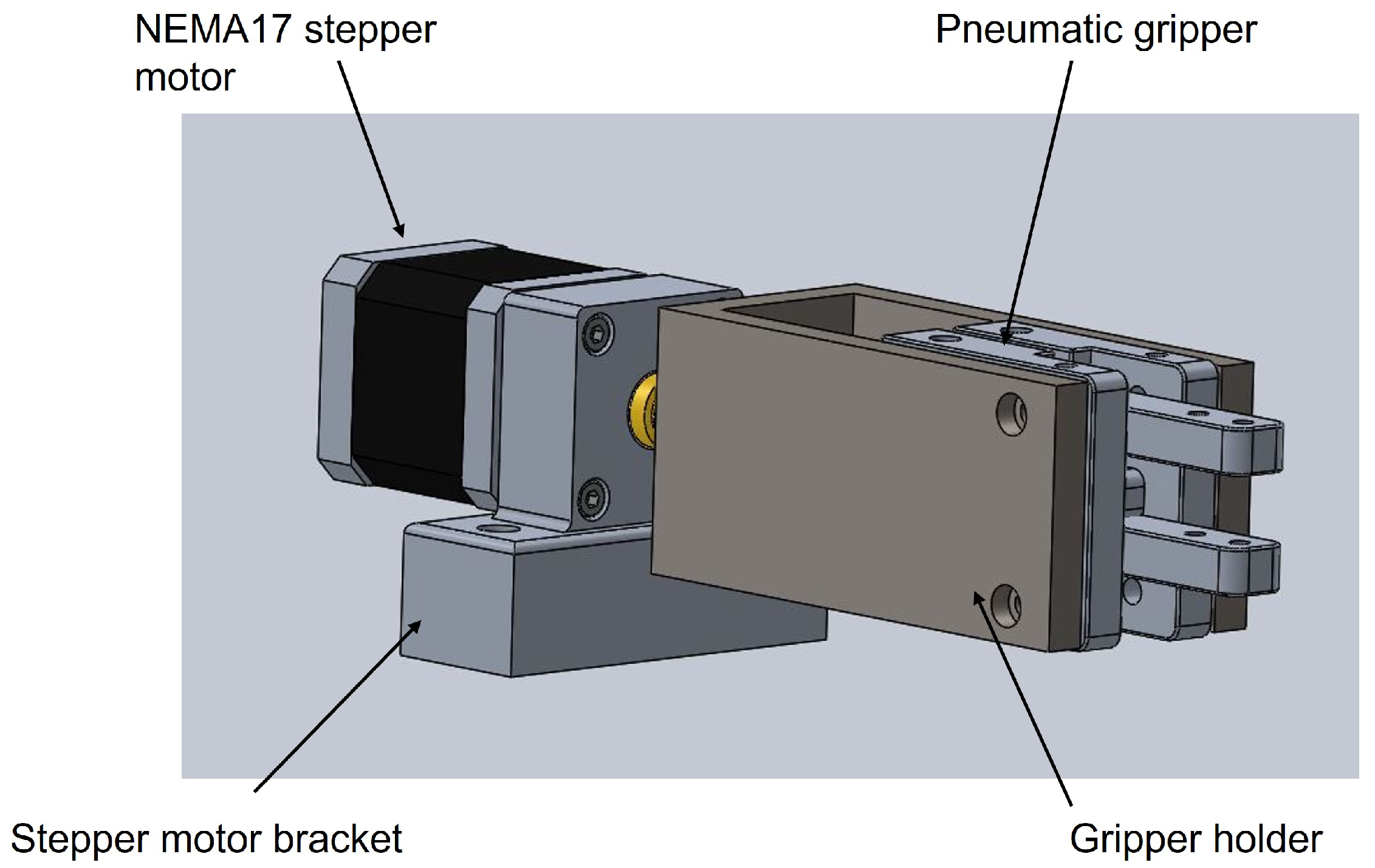

4.3. Secondary Battery Gripper

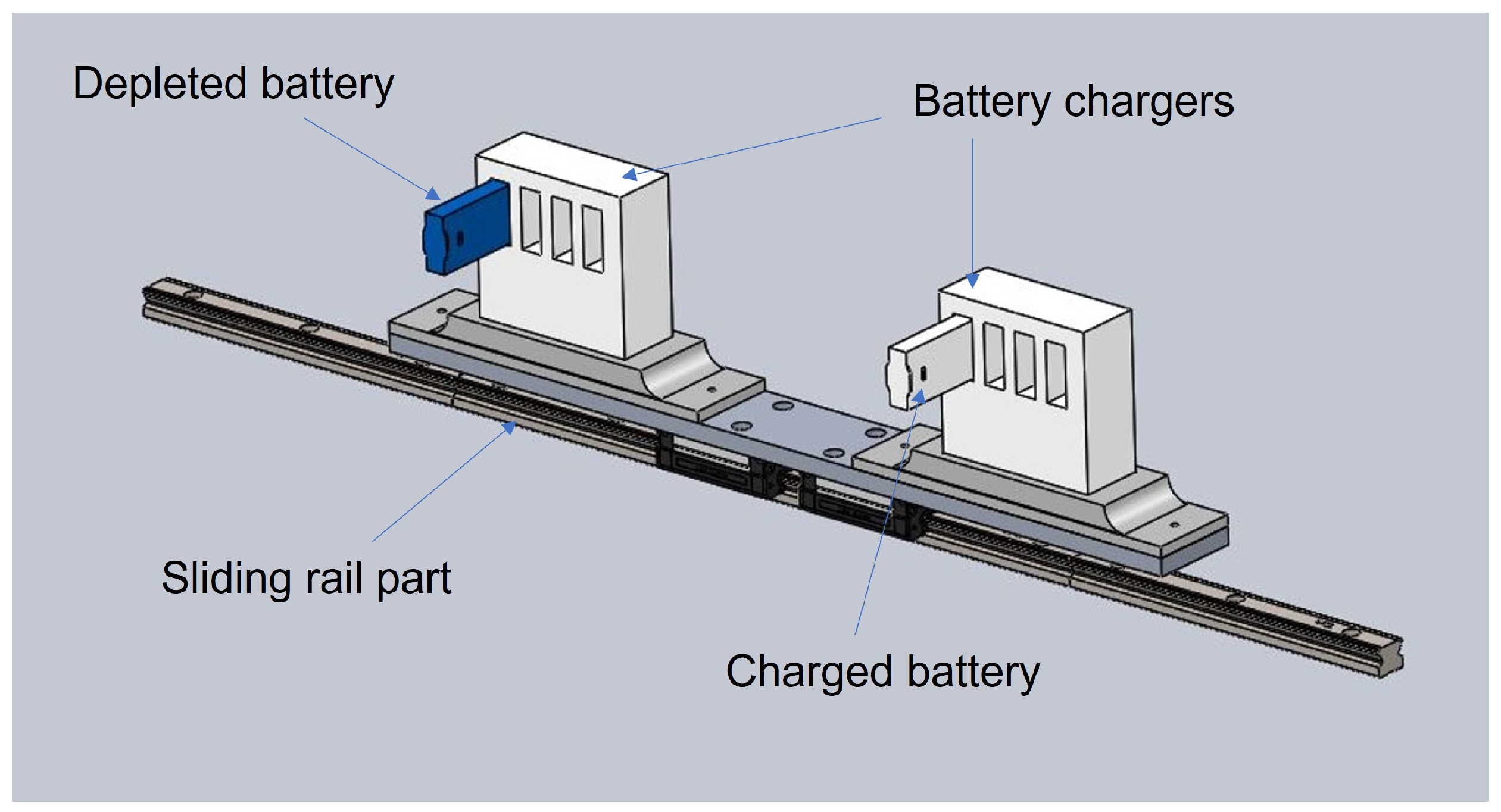

4.4. Battery Storage and Charging Unit

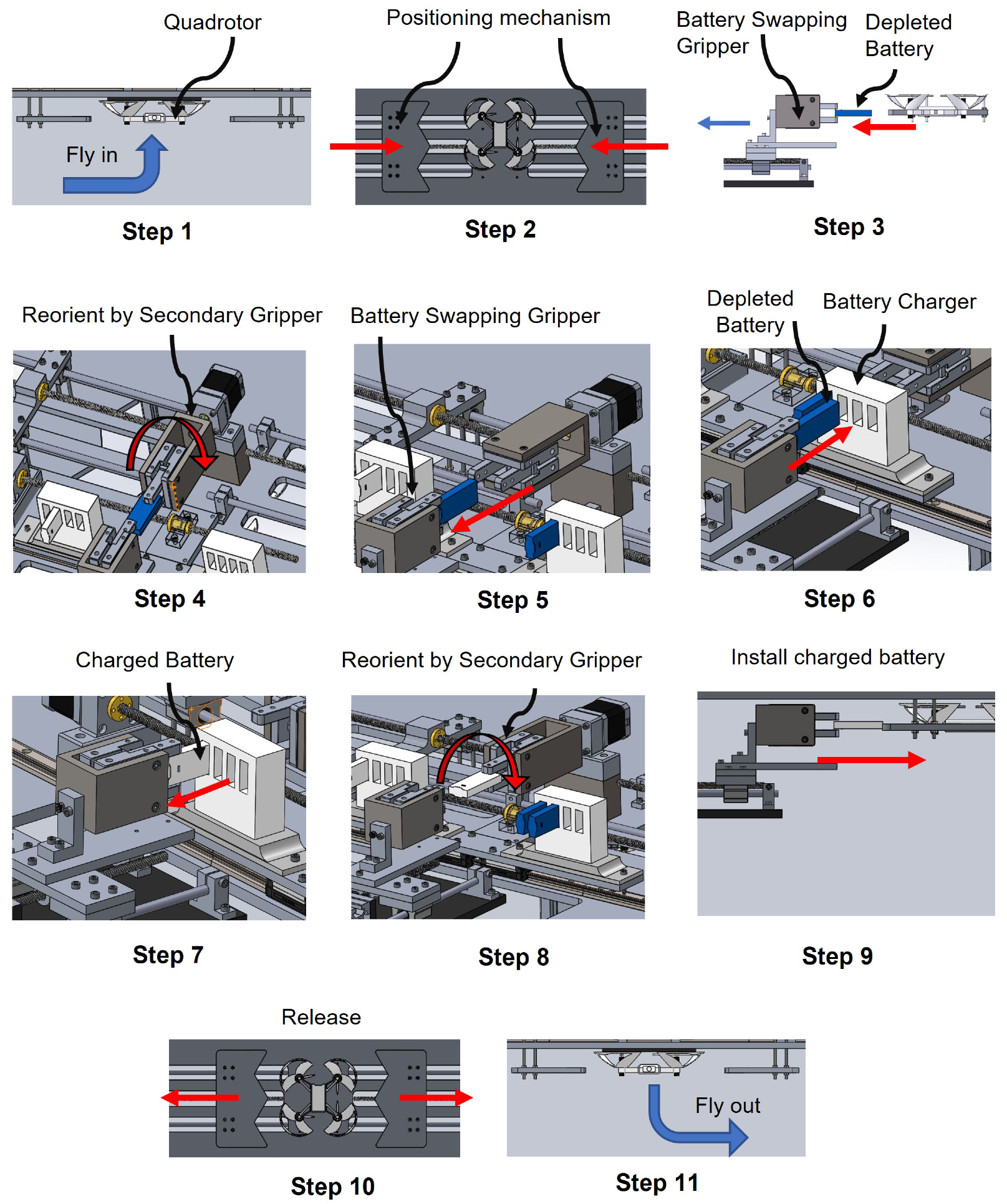

5. Motion Simulation of the Landing Platform Using CAD

- Step 1: The quadrotor docks under the ceiling in an inverted manner by using the ceiling effect;

- Step 2: The positioning plates clamp and center the UAV, keeping it still;

- Step 3: The battery-swapping gripper removes the depleted battery using the method discussed in Section 3.3.3;

- Step 4: The depleted battery orientation is changed after it is inserted into the secondary gripper as discussed in Section 3.3.4;

- Step 5: The battery-swapping gripper takes out the reoriented depleted battery;

- Step 6: The depleted battery is inserted to the battery charger after the charger aligned with the gripper;

- Step 7: The swapping gripper takes a charged battery out of the charger unit. The in–out sequence of the battery was discussed in Section 3.3.3;

- Step 8: The charged battery is reoriented by the secondary gripper;

- Step 9: The battery-swapping gripper installs the charged battery to the quadrotor after the gripper is aligned with the battery socket of the UAV. The insertion steps were discussed in Section 3.3.3;

- Step 10: The quadrotor is unlocked as the w-shaped positioning plates move back to initial state;

- Step 11: The quadrotor flies out of the station.

6. Results and Discussion

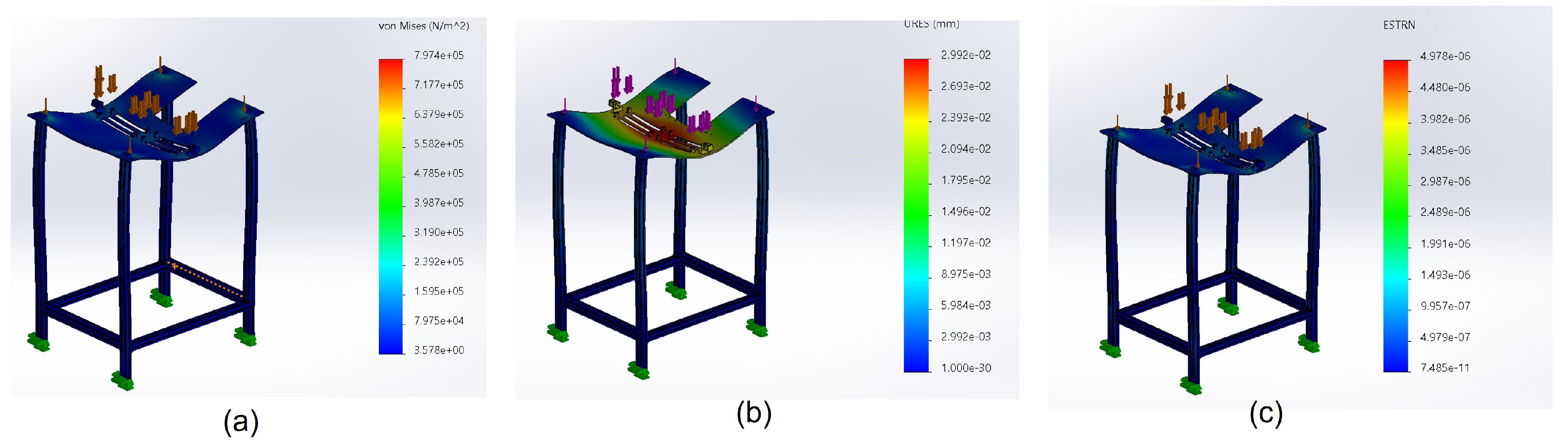

6.1. Results: Finite Element Analysis of the Landing Platform

6.2. Results: Expected Battery Swapping Time Calculation

- Rounds per second (RPS) =

- Angular velocity of the motor =

- Linear velocity of the motor(v) =

- All charging ports of the charger will be filled with charged batteries;

- The motor will be working with full power capacity;

- Zero friction was assumed.

6.3. Discussion: No Tilting Feature of the UAV While Battery Swapping

7. Conclusions and Future Works

7.1. Conclusions

7.2. Significance of the Research and Limitation

7.3. Future Work and Suggestion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Radiansyah, S.; Kusrini, M.D.; Prasetyo, L.B. Quadcopter applications for wildlife monitoring. IOP Conf. Ser. Earth Environ. Sci. 2017, 54, 012066. [Google Scholar] [CrossRef] [Green Version]

- Townsend, A.; Jiya, I.N.; Martinson, C.; Bessarabov, D.; Gouws, R. A comprehensive review of energy sources for unmanned aerial vehicles, their shortfalls and opportunities for improvements. Heliyon 2020, 6, e05285. [Google Scholar] [CrossRef] [PubMed]

- Hassija, V.; Saxena, V.; Chamola, V. Scheduling drone charging for multi-drone network based on consensus time-stamp and game theory. Comput. Commun. 2020, 149, 51–61. [Google Scholar] [CrossRef]

- Mostafa, T.M.; Muharam, A.; Hattori, R. Wireless battery charging system for drones via capacitive power transfer. In Proceedings of the 2017 IEEE PELS Workshop on Emerging Technologies: Wireless Power Transfer (WoW), Chongqing, China, 20–22 May 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Junaid, A.B.; Lee, Y.; Kim, Y. Design and implementation of autonomous wireless charging station for rotary-wing UAVs. Aerosp. Sci. Technol. 2016, 54, 253–266. [Google Scholar] [CrossRef]

- Junaid, A.B.; Konoiko, A.; Zweiri, Y.; Sahinkaya, M.N.; Seneviratne, L. Autonomous Wireless Self-Charging for Multi-Rotor Unmanned Aerial Vehicles. Energies 2017, 10, 803. [Google Scholar] [CrossRef]

- Yang, C.; He, Y.; Qu, H.; Wu, J.; Hou, Z.; Lin, Z.; Cai, C. Analysis, design and implement of asymmetric coupled wireless power transfer systems for unmanned aerial vehicles. AIP Adv. 2019, 9, 025206. [Google Scholar] [CrossRef] [Green Version]

- Campi, T.; Dionisi, F.; Cruciani, S.; De Santis, V.; Feliziani, M.; Maradei, F. Magnetic field levels in drones equipped with Wireless Power Transfer technology. In Proceedings of the 2016 Asia-Pacific International Symposium on Electromagnetic Compatibility (APEMC), Shenzhen, China, 17–21 May 2016; Volume 1, pp. 544–547. [Google Scholar] [CrossRef]

- Mourgelas, C.; Kokkinos, S.; Milidonis, A.; Voyiatzis, I. Autonomous drone charging stations: A survey. In Proceedings of the PCI 2020: 24th Pan-Hellenic Conference on Informatic, Athens Greece, 20–22 November 2020; pp. 233–236. [Google Scholar] [CrossRef]

- Mulgaonkar, Y.; Kumar, V. Autonomous charging to enable long-endurance missions for small aerial robots. In Micro- and Nanotechnology Sensors, Systems, and Applications VI; George, T., Islam, M.S., Dutta, A.K., Eds.; International Society for Optics and Photonics, SPIE: Bellingham, WA, USA, 2014; Volume 9083, pp. 404–418. [Google Scholar] [CrossRef]

- Cocchioni, F.; Pierfelice, V.; Benini, A.; Mancini, A.; Frontoni, E.; Zingaretti, P.; Ippoliti, G.; Longhi, S. Unmanned Ground and Aerial Vehicles in extended range indoor and outdoor missions. In Proceedings of the 2014 International Conference on Unmanned Aircraft Systems (ICUAS), Orlando, FL, USA, 27–30 May 2014; pp. 374–382. [Google Scholar] [CrossRef]

- Song, B.D.; Kim, J.; Kim, J.; Park, H.; Morrison, J.R.; Shim, D.H. Persistent UAV service: An improved scheduling formulation and prototypes of system components. In Proceedings of the 2013 International Conference on Unmanned Aircraft Systems (ICUAS), Atlanta, GA, USA, 28–31 May 2013; pp. 915–925. [Google Scholar] [CrossRef]

- Leahy, K.; Zhou, D.; Vasile, C.I.; Oikonomopoulos, K.; Schwager, M.; Belta, C. Persistent surveillance for unmanned aerial vehicles subject to charging and temporal logic constraints. Auton. Robot. 2016, 40, 1363–1378. [Google Scholar] [CrossRef]

- Kemper, F.; Suzuki, K.; Morrison, J. UAV Consumable Replenishment: Design Concepts for Automated Service Stations. J. Intell. Robot. Syst. 2011, 61, 369–397. [Google Scholar] [CrossRef]

- Ahmad Shah, S.; Hamid, S.; Liyana, N.; Norhashim, N.; Sahwee, Z.; Rafael, A.; Zolkifli, I. Experimental evaluation of solar charge controller installed in a solar-powered Unmanned Aerial Vehicle (UAV). Def. S T Tech. Bull. 2021, 14, 198–210. [Google Scholar]

- Swieringa, K.A.; Hanson, C.B.; Richardson, J.R.; White, J.D.; Hasan, Z.; Qian, E.; Girard, A. Autonomous battery swapping system for small-scale helicopters. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 3335–3340. [Google Scholar] [CrossRef]

- Grlj, C.G.; Krznar, N.; Pranjić, M. A Decade of UAV Docking Stations: A Brief Overview of Mobile and Fixed Landing Platforms. Drones 2022, 6, 17. [Google Scholar] [CrossRef]

- Cokyasar, T.; Dong, W.; Jin, M.; Verbas, İ.Ö. Designing a drone delivery network with automated battery swapping machines. Comput. Oper. Res. 2021, 129, 105177. [Google Scholar] [CrossRef]

- Simic, M.; Bil, C.; Vojisavljevic, V. Investigation in Wireless Power Transmission for UAV Charging. Procedia Comput. Sci. 2015, 60, 1846–1855. [Google Scholar] [CrossRef] [Green Version]

- Belmonte, N.; Staulo, S.; Fiorot, S.; Luetto, C.; Rizzi, P.; Baricco, M. Fuel cell powered octocopter for inspection of mobile cranes: Design, cost analysis and environmental impacts. Appl. Energy 2018, 215, 556–565. [Google Scholar] [CrossRef]

- Ucgun, H.; Yuzgec, U.; Bayilmis, C. A review on applications of rotary-wing unmanned aerial vehicle charging stations. Int. J. Adv. Robot. Syst. 2021, 18, 17298814211015863. [Google Scholar] [CrossRef]

- Galkin, B.; Kibilda, J.; Dasilva, L. UAVs as Mobile Infrastructure: Addressing Battery Lifetime. IEEE Commun. Mag. 2019, 57, 132–137. [Google Scholar] [CrossRef] [Green Version]

- Choi, C.; Jang, H.; Lim, S.; Lim, H.; Cho, S.; Gaponov, I. Automatic wireless drone charging station creating essential environment for continuous drone operation. In Proceedings of the 2016 International Conference on Control, Automation and Information Sciences (ICCAIS), Ansan, Korea, 27–29 October 2016; pp. 132–136. [Google Scholar] [CrossRef]

- Park, C.W. A Study on Drone Charging System Using Wireless Power Transmission. Master’s Thesis, Busan University of Foreign Studies Graduate School, Busan, Korea, 2016. [Google Scholar]

- Xuan-Mung, N.; Hong, S.K.; Nguyen, N.P.; Ha, L.N.N.T.; Le, T.L. Autonomous Quadcopter Precision Landing Onto a Heaving Platform: New Method and Experiment. IEEE Access 2020, 8, 167192–167202. [Google Scholar] [CrossRef]

- Cabecinhas, D.; Naldi, R.; Silvestre, C.; Cunha, R.; Marconi, L. Robust Landing and Sliding Maneuver Hybrid Controller for a Quadrotor Vehicle. IEEE Trans. Control. Syst. Technol. 2016, 24, 400–412. [Google Scholar] [CrossRef]

- Gonçalves, V.M.; McLaughlin, R.; Pereira, G.A.S. Precise Landing of Autonomous Aerial Vehicles Using Vector Fields. IEEE Robot. Autom. Lett. 2020, 5, 4337–4344. [Google Scholar] [CrossRef]

- Saripalli, S.; Sukhatme, G. An Experimental Study of the Autonomous Helicopter Landing Problem. In Experimental Robotics VIII; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Ryan, T.; Kim, H.J. Autonomous landing of a VTOL UAV on a moving platform using image-based visual servoing. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 971–976. [Google Scholar] [CrossRef]

- Cui, E.; Zhang, X. Ground Effect Aerodynamics. In Encyclopedia of Aerospace Engineering; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Enrique, J.C.M.; David, E.C.; David, S.J.; Ivan, M.; Fernando, C. Device and Method for Use with Unmanned Aerial Vehicles. U.S. Patent 9,481,458, 1 November 2016. [Google Scholar]

- Godzdanker, R.; Valavanis, K.P.; Rutherford, M.J. Intelligent Self-Leveling Docking System. W.O. Patent 2012,0648,91A3, 12 July 2012. [Google Scholar]

- Fox, Y.; Meir, K.; Krauss, R. Positioning and Locking System and Method for Unmanned Vehicles. U.S. Patent 2019,0202,578A1, 4 July 2019. [Google Scholar]

- Lushizou, D.; Ren, Y.; Jie, T.; Sun, Q. A Kind of Unmanned Plane Relay. U.S. Patent 2064,855,85U, 12 September 2017. [Google Scholar]

- Krauss, R.; Kliner, M. Unmanned Aerial Vehicle Charging Station with Centering Mechanism. W.O. Patent 2017,130,181A1, 3 August 2017. [Google Scholar]

- Çakici, F.; Leblebicioğlu, M.K. Control System Design of a Vertical Take-off and Landing Fixed-Wing UAV. IFAC-PapersOnLine 2016, 49, 267–272. [Google Scholar] [CrossRef]

- Antonini, R.; Fici, G.P.; Gaspardone, M. Landing Platform for Unmanned Aerial Vehicles. W.O. Patent 2015,117,216A1, 13 August 2015. [Google Scholar]

- Kim, J.; Song, C.-U. Three-Phase Wireless Power Transfer System And Three-Phase Wireless Chargeable Unmanned Aerial Vehicle System Based On The Same. U.S. Patent 2018,0056,794A1, 25 September 2018. [Google Scholar]

- A.R.Gabdullin, M.M.Galimov, A. Landing Place for Drone. R.U. Patent 27,1088,7c1, 14 January 2020.

- Alhadi, S.; Rianmora, S.; Phlernjai, M. Conceptual Design and Analysis of Small Power Station for Supporting Unmanned Aerial Vehicle (UAV) Deployment. Eng. J. 2021, 25, 51–71. [Google Scholar] [CrossRef]

- Barbasov, K.B.V. System of Landing of Unmanned Aerial Vehicle and Landing Vehicle of Verticle Take-off and Landing. RU Patent RU26,669,75c1, 13 September 2018. [Google Scholar]

- Miyazaki, R.; Jiang, R.; Paul, H.; Ono, K.; Shimonomura, K. Airborne Docking for Multi-Rotor Aerial Manipulations. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 4708–4714. [Google Scholar] [CrossRef]

- Liu, Z.N.; Liu, X.Q.; Yang, L.J.; Leo, D.; Zhao, H.W. An Autonomous Dock and Battery Swapping System for Multirotor UAV. 2018; preprint. [Google Scholar] [CrossRef]

- Lee, D.; Zhou, J.; Lin, W.T. Autonomous battery swapping system for quadcopter. In Proceedings of the 2015 International Conference on Unmanned Aircraft Systems (ICUAS), Denver, CO, USA, 9–12 June 2015; pp. 118–124. [Google Scholar] [CrossRef]

- Toksoz, T.; Redding, J.; Michini, M.; Michini, B.; How, J.; Vavrina, M.; Vian, J. Automated Battery Swap and Recharge to Enable Persistent UAV Missions. In Proceedings of the Infotech@Aerospace 2011, St. Louis, MO, USA, 29–31 March 2011. [Google Scholar] [CrossRef] [Green Version]

- Suzuki, K.; Filho, P.; Morrison, J. Automatic Battery Replacement System for UAVs: Analysis and Design. J. Intell. Robot. Syst. 2012, 65, 563–586. [Google Scholar] [CrossRef]

- Ure, N.K.; Chowdhary, G.; Toksoz, T.; How, J.P.; Vavrina, M.A.; Vian, J. An Automated Battery Management System to Enable Persistent Missions With Multiple Aerial Vehicles. IEEE/ASME Trans. Mechatron. 2015, 20, 275–286. [Google Scholar] [CrossRef]

- Matus-Vargas, A.; Gómez, G.; Martinez-Carranza, J. Ground effect on rotorcraft unmanned aerial vehicles: A review. Intell. Serv. Robot. 2021, 14, 1–20. [Google Scholar] [CrossRef]

- Wang, X.; Du, S.; Liu, Y. Research on Ceiling Effect of Quadrotor. In Proceedings of the 2017 IEEE 7th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Honolulu, HI, USA, 31 July–4 August 2017; pp. 846–851. [Google Scholar] [CrossRef]

- Hsiao, Y.; Chirarattananon, P. Ceiling Effects for Hybrid Aerial-Surface Locomotion of Small Rotorcraft. IEEE/ASME Trans. Mechatronics 2019, 24, 2316–2327. [Google Scholar] [CrossRef] [Green Version]

- Cabas, R.; Balaguer, C. Design and development of a light weight embodied robotic hand activated with only one actuator. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 2369–2374. [Google Scholar] [CrossRef]

- Ali Abotiheen, M.H. Finite Element Analysis is A Powerful Approach To Predictive Manufacturing Parameters. J. Univ. Babylon 2017, 26, 229–238. [Google Scholar]

| Positioning Mechanism | Activation Type | Pros | Cons |

|---|---|---|---|

| Parallel pushing [31,32]. | Supports a wide range of UAV sizes. Can position the drone at any desired point. | Limited to even number of legs. Separated 2-DOF pusher control. |

| V- and W-shaped pushing [33,34]. | Simple control with 1-DOF. | Limited to symmetrical leg structure. Cannot easily change clamping positions. |

| Aligned by rotating [35]. | Simple control with 1-DOF. | The rotation center may obstruct the landing and limit UAV size. Can be looser than other types. |

| Iris Diaphragm [36]. | Support wide range of UAV sizes. | Complex and harder to maintain. No orientation lock. |

| Positioning Mechanism | Type of Positioning | Pros | Cons |

|---|---|---|---|

| Funnels used for each leg [37]. | No moving devices or mechanisms. Clamping can be done easily. | Limited to lower number of legs. |

| One funnel used for all legs [38,39]. | Clamping can be done easily. | However, the clamping is poor compared to previous method. |

| One funnel used for the whole body of the UAV [38,39]. | Simple landing compared to previous two methods. | Clamping is poor compared to previous two methods. |

| Overhead funnel positioning [41]. | Size of the UAV does not matter. | Requires a more-advanced technology than others. |

| Landing Platforms Using “Active” Positioners | Landing Platforms Using “Passive” Positioners |

|---|---|

| The drone will be fixed to a particular position. | Deviation can happen due to wind condition. |

| Landing precision is not compulsory. | Landing precision is compulsory. |

| Proper controlling strategies should be used. | Only gravitational force will be used to land and position. |

| Trial | Radius of Shift r [mm] | Angle of Rotational Error [degrees] |

|---|---|---|

| Initial | 0.0 | 0.0 |

| 1 | 1.0 | 17.4 |

| 2 | 3.0 | 12.1 |

| 3 | 1.4 | −59.1 |

| 4 | 70.7 | −12.1 |

| 5 | 65.6 | 30.0 |

| 6 | 60.8 | 28.2 |

| 7 | 63.2 | 30.2 |

| 8 | 20.6 | 22.6 |

| 9 | 20.6 | −1.0 |

| 10 | 22.6 | −2.0 |

| Average | 30.3 | 6.6 |

| Standard Deviation | 22.8 | 27.4 |

| Motor | NEMA17 Closed Loop Stepper |

|---|---|

| Motor Torque (T) | 200 steps/Rev |

| Step Angle () | 1.8 degrees |

| Operation Frequency (f) | 1500 Hz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Silva, S.C.; Phlernjai, M.; Rianmora, S.; Ratsamee, P. Inverted Docking Station: A Conceptual Design for a Battery-Swapping Platform for Quadrotor UAVs. Drones 2022, 6, 56. https://doi.org/10.3390/drones6030056

De Silva SC, Phlernjai M, Rianmora S, Ratsamee P. Inverted Docking Station: A Conceptual Design for a Battery-Swapping Platform for Quadrotor UAVs. Drones. 2022; 6(3):56. https://doi.org/10.3390/drones6030056

Chicago/Turabian StyleDe Silva, Sudam Chamikara, Maroay Phlernjai, Suchada Rianmora, and Photchara Ratsamee. 2022. "Inverted Docking Station: A Conceptual Design for a Battery-Swapping Platform for Quadrotor UAVs" Drones 6, no. 3: 56. https://doi.org/10.3390/drones6030056

APA StyleDe Silva, S. C., Phlernjai, M., Rianmora, S., & Ratsamee, P. (2022). Inverted Docking Station: A Conceptual Design for a Battery-Swapping Platform for Quadrotor UAVs. Drones, 6(3), 56. https://doi.org/10.3390/drones6030056