Lightweight Multipurpose Three-Arm Aerial Manipulator Systems for UAV Adaptive Leveling after Landing and Overhead Docking

Abstract

1. Introduction

2. Concept

2.1. Resting on Horizontal Surfaces

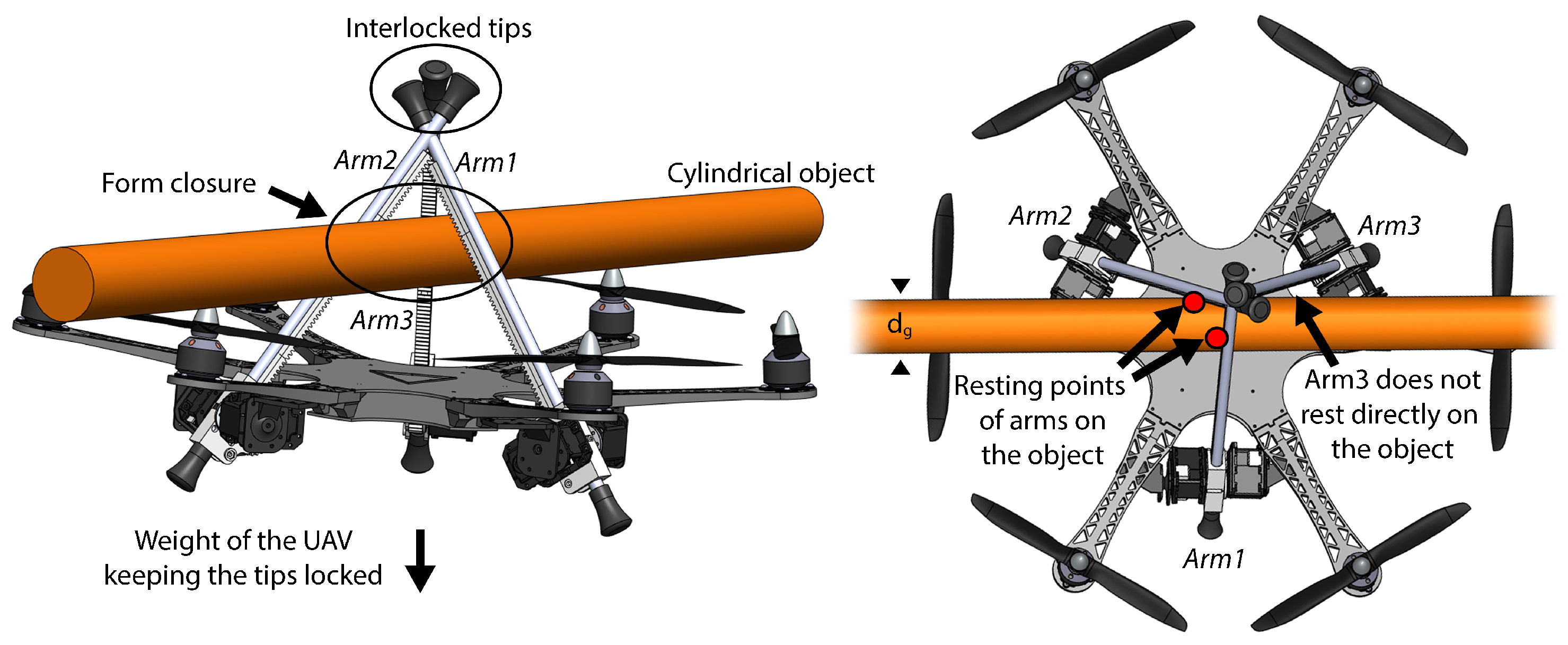

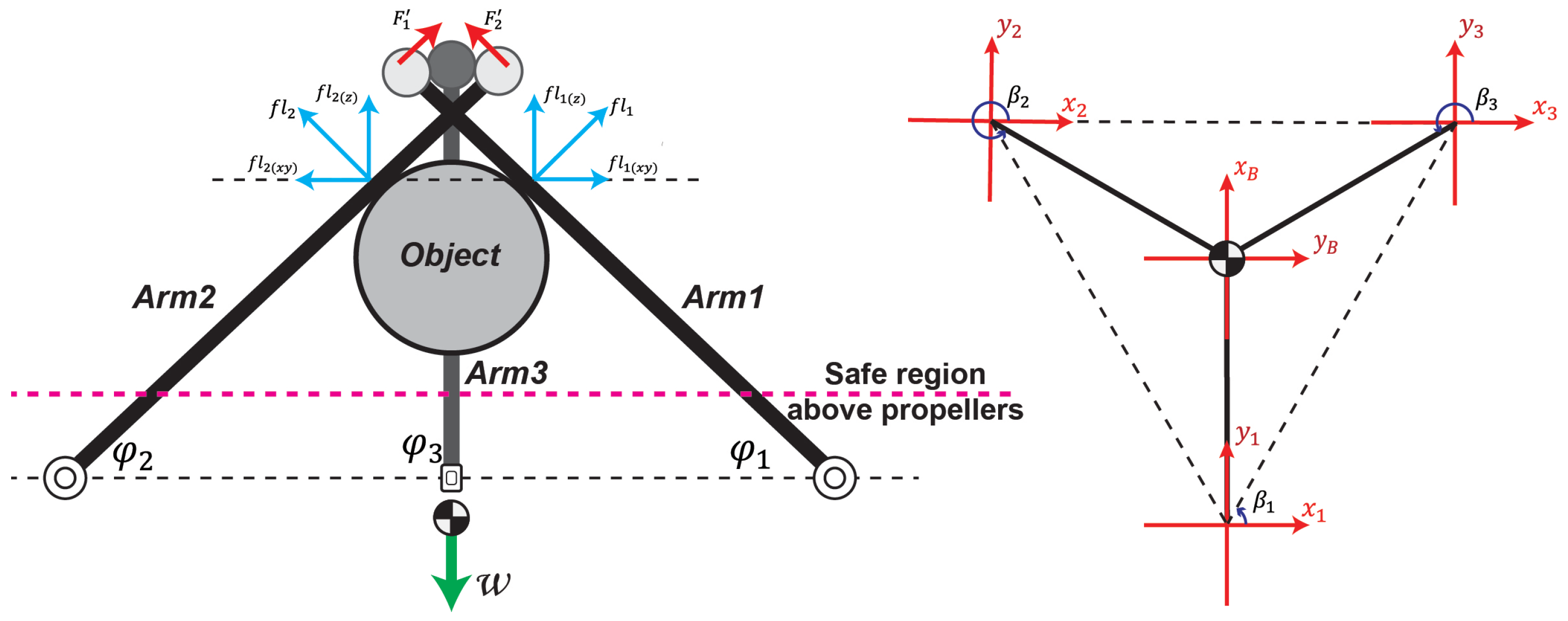

2.2. Suspending from Horizontal Objects

2.3. Real Deployment Case

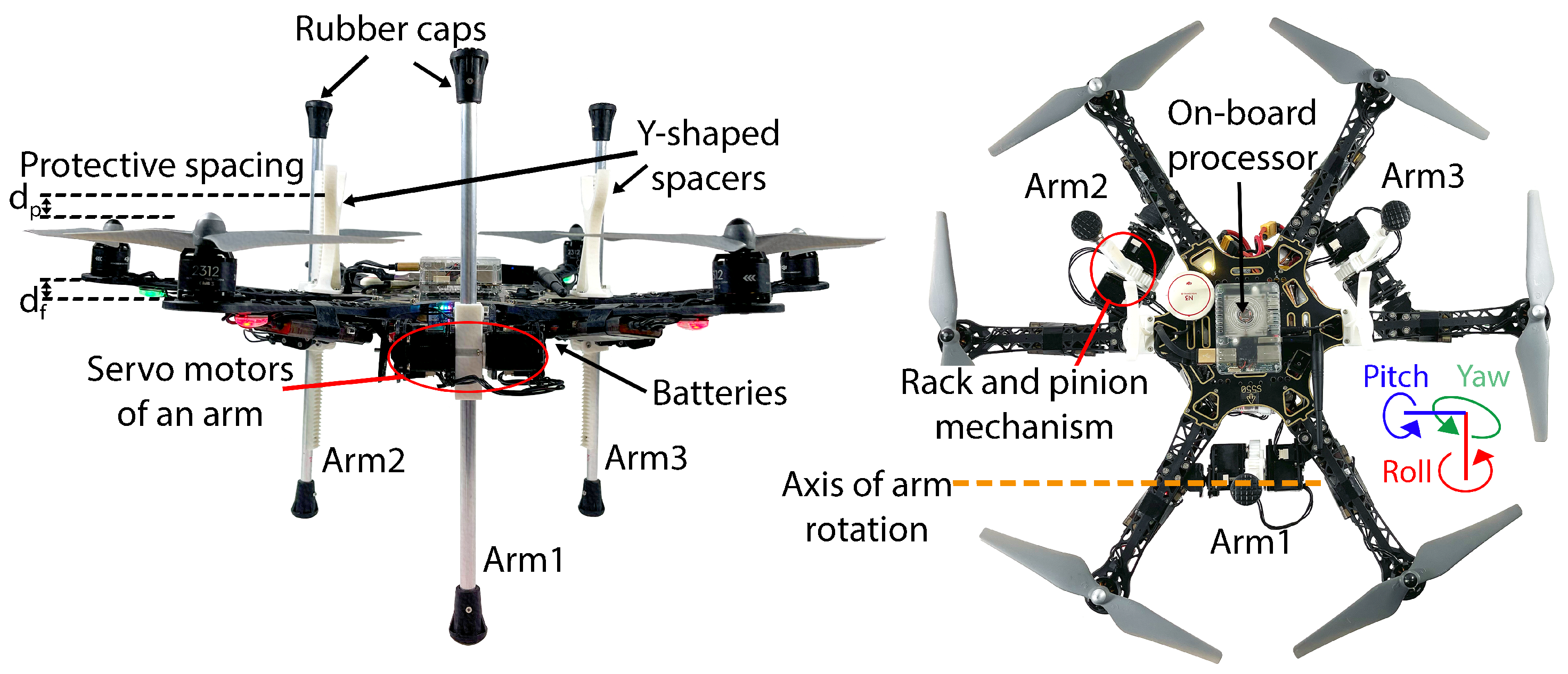

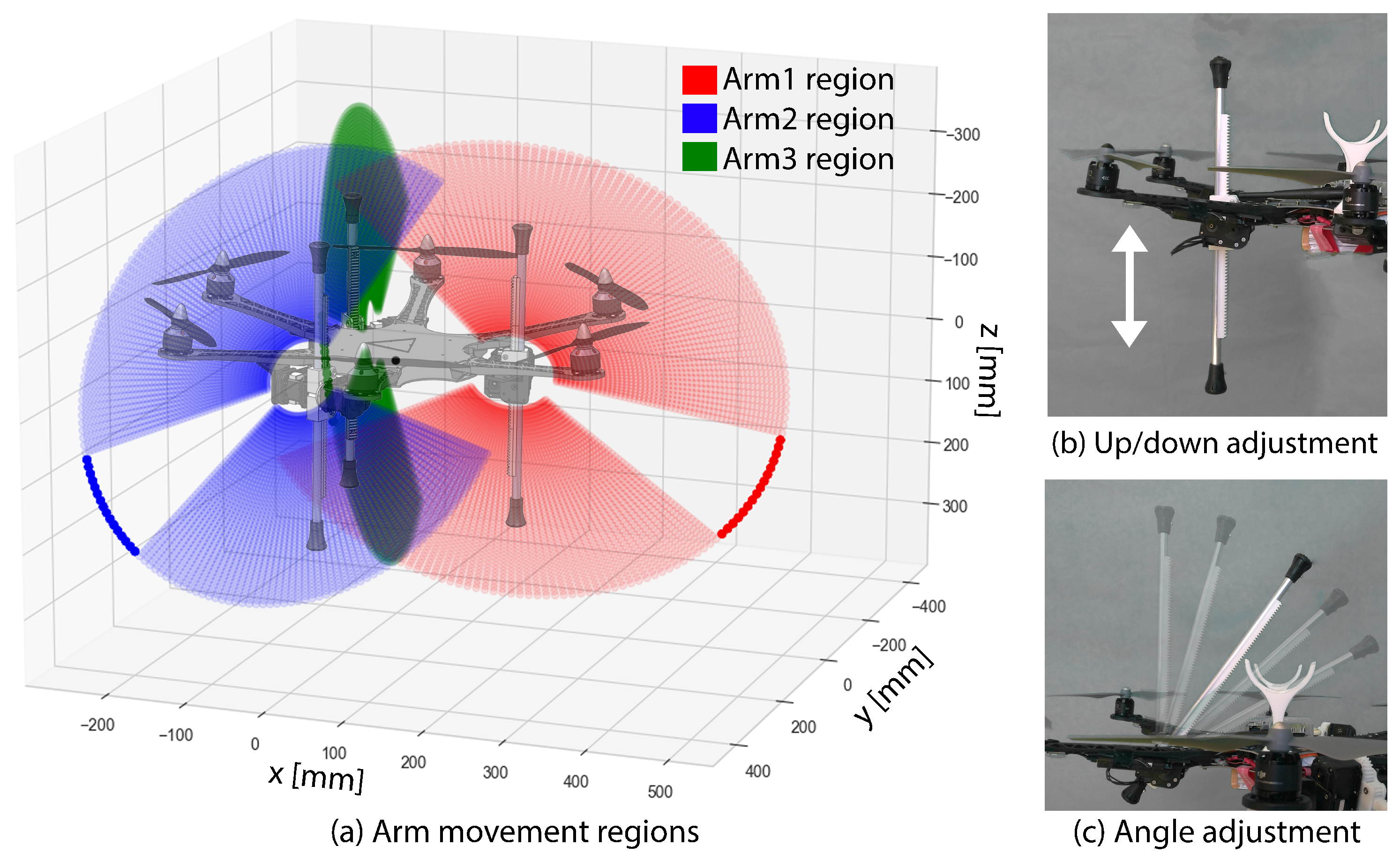

3. Hardware Description

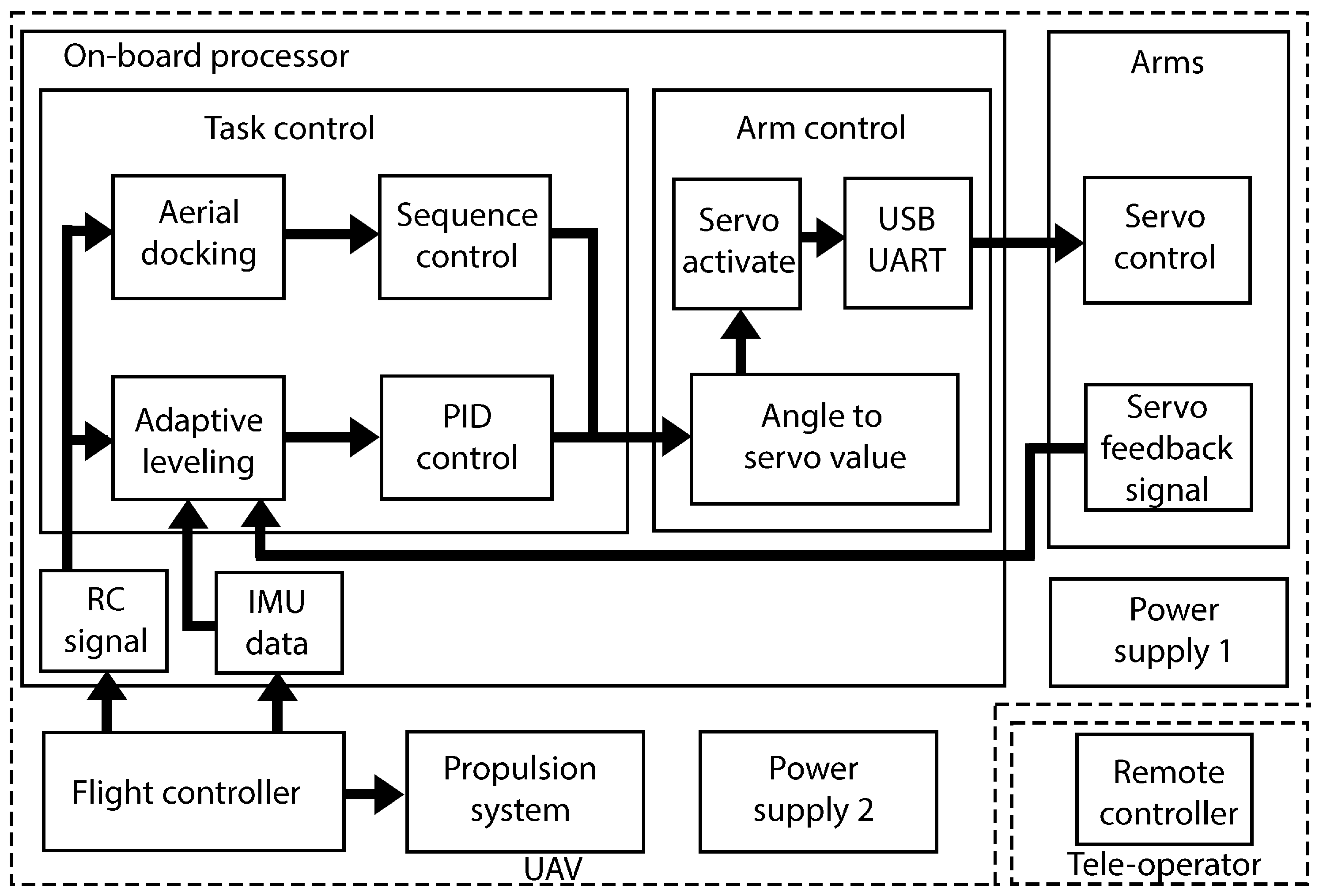

4. Algorithms of the Focused Tasks

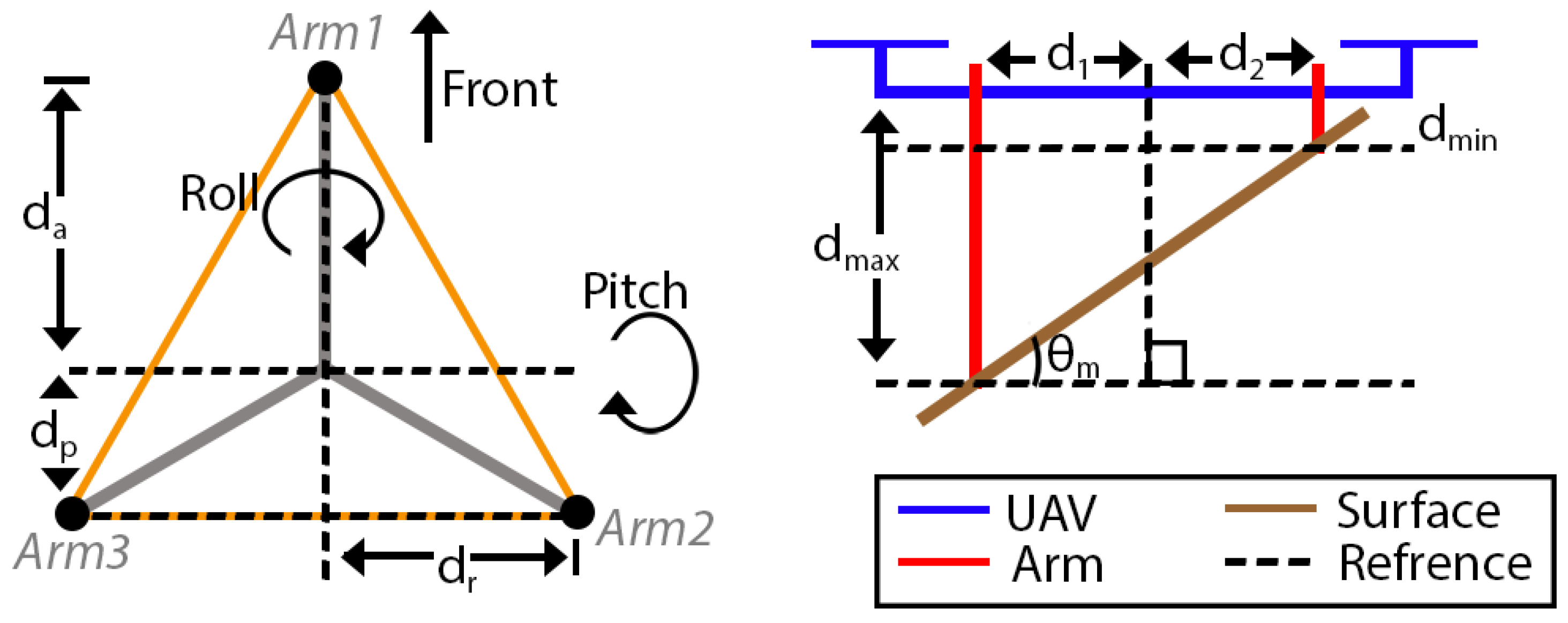

4.1. Adaptive Leveling

4.2. Aerial Docking

5. Experiments

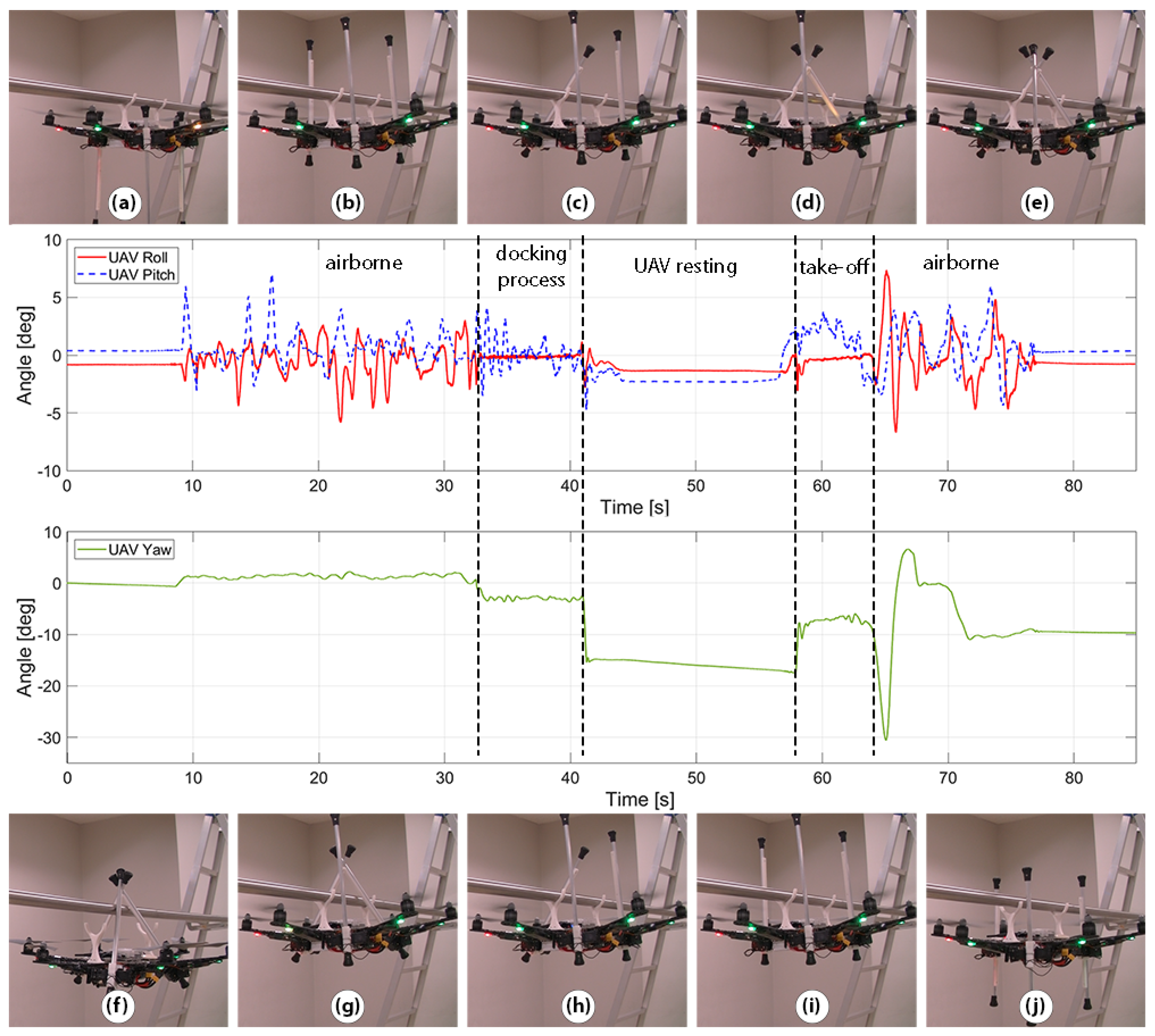

5.1. Aerial Docking Experiment

5.2. Adaptive Airframe Leveling

6. Discussion and Future Works

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ollero, A.; Tognon, M.; Suarez, A.; Lee, D.; Franchi, A. Past, present, and future of aerial robotic manipulators. IEEE Trans. Robot. 2021, 38, 626–645. [Google Scholar] [CrossRef]

- Ruggiero, F.; Lippiello, V.; Ollero, A. Aerial manipulation: A literature review. IEEE Robot. Autom. Lett. 2018, 3, 1957–1964. [Google Scholar] [CrossRef]

- Ladig, R.; Paul, H.; Miyazaki, R.; Shimonomura, K. Aerial manipulation using multirotor UAV: A review from the aspect of operating space and force. J. Robot. Mechatron. 2021, 33, 196–204. [Google Scholar] [CrossRef]

- Jimenez-Cano, A.; Braga, J.; Heredia, G.; Ollero, A. Aerial manipulator for structure inspection by contact from the underside. In Proceedings of the 2015 IEEE/RSJ international conference on intelligent robots and systems (IROS), Hamburg, Germany, 28 September–3 October 2015; pp. 1879–1884. [Google Scholar]

- Suarez, A.; Caballero, A.; Garofano, A.; Sanchez-Cuevas, P.J.; Heredia, G.; Ollero, A. Aerial manipulator with rolling base for inspection of pipe arrays. IEEE Access 2020, 8, 162516–162532. [Google Scholar] [CrossRef]

- Bartelds, T.; Capra, A.; Hamaza, S.; Stramigioli, S.; Fumagalli, M. Compliant aerial manipulators: Toward a new generation of aerial robotic workers. IEEE Robot. Autom. Lett. 2016, 1, 477–483. [Google Scholar] [CrossRef]

- Kristensen, A.S.; Ahsan, D.; Mehmood, S.; Ahmed, S. Rescue Emergency Drone for fast response to medical emergencies due to traffic accidents. Int. J. Health Med. Eng. 2017, 11, 637–641. [Google Scholar]

- Van de Voorde, P.; Gautama, S.; Momont, A.; Ionescu, C.M.; De Paepe, P.; Fraeyman, N. The drone ambulance [A-UAS]: Golden bullet or just a blank? Resuscitation 2017, 116, 46–48. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Seo, H.; Kim, H.J. Operating an unknown drawer using an aerial manipulator. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 5503–5508. [Google Scholar]

- Suarez, A.; Jimenez-Cano, A.; Vega, V.; Heredia, G.; Rodriguez-Castaño, A.; Ollero, A. Lightweight and human-size dual arm aerial manipulator. In Proceedings of the 2017 international conference on unmanned aircraft systems (ICUAS), Miami, FL, USA, 13–16 June 2017; pp. 1778–1784. [Google Scholar]

- Paul, H.; Miyazaki, R.; Ladig, R.; Shimonomura, K. TAMS: Development of a multipurpose three-arm aerial manipulator system. Adv. Robot. 2021, 35, 31–47. [Google Scholar] [CrossRef]

- Paul, H.; Ono, K.; Ladig, R.; Shimonomura, K. A multirotor platform employing a three-axis vertical articulated robotic arm for aerial manipulation tasks. In Proceedings of the 2018 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM), Auckland, New Zealand, 9–12 July 2018; pp. 478–485. [Google Scholar]

- Lee, D.; Ryan, T.; Kim, H.J. Autonomous landing of a VTOL UAV on a moving platform using image-based visual servoing. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, St. Paul, MN, USA, 14–18 May 2012; pp. 971–976. [Google Scholar]

- Sarkisov, Y.S.; Yashin, G.A.; Tsykunov, E.V.; Tsetserukou, D. Dronegear: A novel robotic landing gear with embedded optical torque sensors for safe multicopter landing on an uneven surface. IEEE Robot. Autom. Lett. 2018, 3, 1912–1917. [Google Scholar] [CrossRef]

- Paul, H.; Miyazaki, R.; Ladig, R.; Shimonomura, K. Landing of a multirotor aerial vehicle on an uneven surface using multiple on-board manipulators. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 1926–1933. [Google Scholar]

- Paul, H.; Miyazaki, R.; Kominami, T.; Ladig, R.; Shimonomura, K. A Versatile Aerial Manipulator Design and Realization of UAV Take-Off from a Rocking Unstable Surface. Appl. Sci. 2021, 11, 9157. [Google Scholar] [CrossRef]

- Thomas, J.; Loianno, G.; Daniilidis, K.; Kumar, V. Visual servoing of quadrotors for perching by hanging from cylindrical objects. IEEE Robot. Autom. Lett. 2015, 1, 57–64. [Google Scholar] [CrossRef]

- Kitchen, R.; Bierwolf, N.; Harbertson, S.; Platt, B.; Owen, D.; Griessmann, K.; Minor, M.A. Design and evaluation of a perching hexacopter drone for energy harvesting from power lines. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 1192–1198. [Google Scholar]

- Popek, K.M.; Johannes, M.S.; Wolfe, K.C.; Hegeman, R.A.; Hatch, J.M.; Moore, J.L.; Katyal, K.D.; Yeh, B.Y.; Bamberger, R.J. Autonomous grasping robotic aerial system for perching (agrasp). In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 1–9. [Google Scholar]

- Hang, K.; Lyu, X.; Song, H.; Stork, J.A.; Dollar, A.M.; Kragic, D.; Zhang, F. Perching and resting—A paradigm for UAV maneuvering with modularized landing gears. Sci. Robot. 2019, 4, eaau6637. [Google Scholar] [CrossRef] [PubMed]

- Wopereis, H.W.; Van Der Molen, T.; Post, T.; Stramigioli, S.; Fumagalli, M. Mechanism for perching on smooth surfaces using aerial impacts. In Proceedings of the 2016 IEEE international symposium on safety, security, and rescue robotics (SSRR), Lausanne, Switzerland, 23–27 October 2016; pp. 154–159. [Google Scholar]

| Component | Specification | Value |

|---|---|---|

| One arm | Material | Aluminum and PLA |

| Width × height | 10 mm × 370 mm | |

| Slider displacement | 60 mm (min), 350 mm (max) | |

| Weight | 0.28 kg | |

| Airframe | Rotors | 6 |

| Weight | 1.2 kg | |

| Entire robot | Arms | 3 |

| Width × height (min) | 590 mm × 310 mm | |

| Weight including 2 batteries | 3.0 kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paul, H.; Martinez, R.R.; Ladig, R.; Shimonomura, K. Lightweight Multipurpose Three-Arm Aerial Manipulator Systems for UAV Adaptive Leveling after Landing and Overhead Docking. Drones 2022, 6, 380. https://doi.org/10.3390/drones6120380

Paul H, Martinez RR, Ladig R, Shimonomura K. Lightweight Multipurpose Three-Arm Aerial Manipulator Systems for UAV Adaptive Leveling after Landing and Overhead Docking. Drones. 2022; 6(12):380. https://doi.org/10.3390/drones6120380

Chicago/Turabian StylePaul, Hannibal, Ricardo Rosales Martinez, Robert Ladig, and Kazuhiro Shimonomura. 2022. "Lightweight Multipurpose Three-Arm Aerial Manipulator Systems for UAV Adaptive Leveling after Landing and Overhead Docking" Drones 6, no. 12: 380. https://doi.org/10.3390/drones6120380

APA StylePaul, H., Martinez, R. R., Ladig, R., & Shimonomura, K. (2022). Lightweight Multipurpose Three-Arm Aerial Manipulator Systems for UAV Adaptive Leveling after Landing and Overhead Docking. Drones, 6(12), 380. https://doi.org/10.3390/drones6120380