Abstract

High-temperature gas sensors are often affected by non-constant ambient conditions, especially with respect to mass flow variations. Steady operation conditions are essential for attaining stable results. So, appropriate protection caps must provide an optimum level of gas access to the sensors’ functional structures to allow for a sufficient response but also maximal homogeneity. Therefore, cap design was carried out through modelling and simulations. For verification, we used a specially developed sensor structure with screen-printed thermocouples to measure temperature homogeneity inside individually designed caps, which were created via additive manufacturing.

1. Introduction

Obtaining reliable measurement results from gas sensors presupposes stable operation conditions on the one hand and most likely unhindered contact with measuring ambience on the other [1]. For high-temperature atmospheres with high dynamic varying gas flow characteristics, gas sensors must be protected by appropriate caps to prevent the sensors’ functional structures from affecting the gas flow to retain its temperature homogeneity and—at the same time—allow enough gas access for a fast and direct response. The optimum in this regard can be found using finite-element calculations. Several degrees of freedom can be used when additive manufacturing is utilized for the creation of protection caps.

2. Materials and Methods

Typical sensor elements are based on ceramic substrates covered with different functional thick-film layers. So, the basis for our product was a reverse-side heated alumina substrate (50.8 × 6.35 mm; thickness: 635 µm). Its front side should hold a constant temperature (600 °C) homogeneously in the area of the sensor tip where the functional gas-sensing elements will be located later on.

Simulations were carried out using COMSOL Multiphysics. Here, the (digital) sensing element was mounted vertically with its tip inside a tube where gas affects the sensors’ front side in a 3-D-model. Varying designs of protection caps surrounding the sensing element were investigated. Modelling comprised heating of the ceramic substrate, gas mass flow variations, aspects of heat transfer and sensor cooling, etc. The cap design was optimized to maximize the gas stream flowing through the cap by simultaneously minimizing the temperature gradients on the sensors’ surfaces.

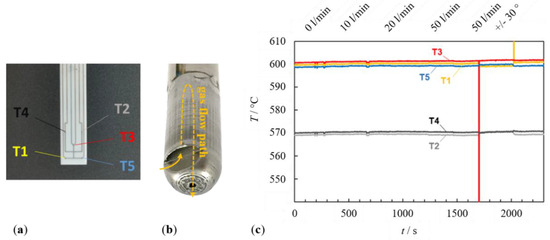

To verify the calculations experimentally and measure the temperature distribution inside the cap, a special transducer with screen-printed Au-Pt thermocouples was used [2]. Five measuring points were distributed in the heated area of the sensor tip (Figure 1a). The optimized design of the protection cap was realized via additive manufacturing (metal filament 3D-printing; Figure 1b).

Figure 1.

Example of a verification measurement: Sensor transducer (a) with screen-printed Pt-Au-thermocouples protected by individual modelled and additive-manufactured cap (b). Temperature characteristics on the sensors surface were measured under varying gas flows (c). The temperatures were even unaffected by twisting the sensor orientation.

3. Discussion

We found a kind of protection cap where the gas flow is diverted inside the cap so that it is heated first and then passes the sensing element from bottom to top before leaving the cap through its hole in the tip to be beneficial (Figure 1b). Such an individual design can easily be manufactured using additive technologies. Measurements were conducted by mounting the sensor inside the cap vertically in a tube setup (40 mm diameter) under varying gas streams from 0 to 50 l/min. The temperatures on the sensors’ front surfaces remain constant, even when the sensors are twisted 30°. These findings correlate well with simulations. Test gas measurements with functional layers (hydrocarbon sensing based on [3]) showed a little lower sensitivity with a cap but, compared to measurements without a cap, much more stable signals without signal noise.

Author Contributions

Conceptualization, G.H.; methodology, J.H. and T.W.; validation, J.H., T.W. and T.K.; investigation, T.K.; writing—original draft preparation, G.H.; writing—review and editing, J.H., T.W. and R.M.; supervision, G.H. and R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All relevant data presented in the article are stored according to institutional requirements and as such are not available online. However, all data used in this paper can be made available upon request to the authors.

Acknowledgments

The authors thank Tobias Rosnitschek (Department of Engineering Design and CAD, University of Bayreuth) for creating the prototype caps using additive manufacturing.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hagen, G.; Harsch, A.; Moos, R. A pathway to eliminate the gas flow dependency of a hydrocarbon sensor for automotive exhaust applications. J. Sens. Sens. Syst. 2018, 7, 79–84. [Google Scholar] [CrossRef]

- Wöhrl, T.; Herrmann, J.; Kita, J.; Hagen, G.; Moos, R. Methods for investigating the temperature distribution of heated ceramic sensor elements for high-temperature applications. J. Sens. Sens. Syst. 2023, 12, 205–214. [Google Scholar] [CrossRef]

- Wiegärtner, S.; Hagen, G.; Kita, J.; Reitmeier, W.; Hien, M.; Grass, P.; Moos, R. Thermoelectric hydrocarbon sensor in thick-film technology for on-board-diagnostics of a diesel oxidation catalyst. Sens. Actuators B Chem. 2015, 214, 234–240. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).