Abstract

Resistive gas dosimeters are a novel method to accurately measure timely intervals like hourly mean values even for small gas concentrations. This measuring principle overcomes the disadvantageously low recovery times of conventional chemiresistive sensors. Applications for the detection of nitrogen oxides in ambient air in the ppb range demonstrate the feasibility.

1. Background

With conventional chemiresistive gas sensors, the conductivity of the sensitive materials depends on the actual concentration of the component to be measured (i.e., the analyte). If it is intended to measure the smallest concentrations of a gaseous analyte, the classical resistance measurement using metal oxide gas sensors reaches its limits. Although the response time may be short and the sensitivity high, the recovery time is mostly very long. The determination of hourly mean values requires a timely integration of the sensor signal over one hour, and for classical metal oxides, inaccuracies and long sensor recovery times might lead to large errors.

2. Measuring Principle

Resistive gas dosimeters could provide a remedy. A typical design consists of an alumina substrate with screen-printed interdigital electrodes (IDEs) covered with layers of the dosimeter material. Such sensors follow an integrating (accumulative) measurement principle. The sensitive material stores the gas component (it accumulates it) and changes its conductivity or electrical impedance (preferred linearly) with the amount of the stored component. Two basic application modes appear possible. Since the integration takes place directly in the material, the sensor signal is proportional to the exposed analyte amount (the dose), and its changes correlate directly to timely averages, e.g., to hourly mean values (if the integration time is one hour). Advantageously, due to the timely accumulation of the analyte, gas concentrations even in the sub-ppm or ppb range can be detected. In addition, the timely derivation of the sensor signal provides information about peak concentrations and the temporal evolution of the analyte exposure. When the material starts to saturate, a deviation from linearity occurs and the sensor material has to be regenerated (mostly thermally). Due to the linearity, the exact zero point hardly matters. Thus, zero drifts can be eliminated.

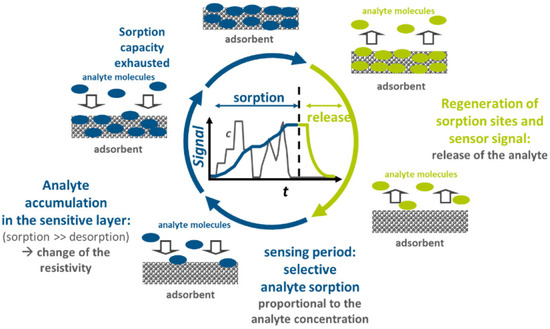

A scheme of one operation cycle with long sorption times (measuring mode) and short regeneration times is shown in Figure 1. The sensor signal, typically the resistance, is accumulative. The actual concentration can be obtained by timely derivation.

Figure 1.

Scheme of the processes that occur in a resistive gas dosimeter during one cycle consisting of a long measurement phase and a very short regeneration phase. From [1], permitted by the authors.

3. Example for a Measurement Curve

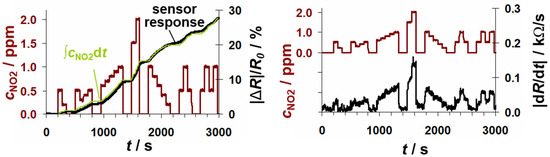

A typical example for an earlier version of the NO2 dosimeter uses a potassium-based carbonate (Figure 2). It is operated at 380 °C and can be regenerated at 600 °C. The relative resistance change |ΔR|/R0 increases in the presence of NO2 and is proportional to the timely integral of the NO2 concentration (green). The derivative |dR/dt| (right) correlates with the actual NO2 concentration. As will be shown at the conference, this method is also suitable for detecting pulses of 50 ppb accurately. Due to the operation above 300 °C, water (r.h.) variations do not affect the sensor signal. CO, CO2, or VOC also do not affect the sensor signal. A short heating pulse of a few tens of seconds (after an over one-hour measuring phase) is sufficient to regenerate the sample and to start a new measuring cycle.

Figure 2.

A typical example of an earlier sensor that demonstrates the capability to operate a dosimeter continuously for almost one hour. From [2], permitted by the authors.

Author Contributions

All authors, R.M., A.G. and D.S.-K., contributed equally to this manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received funding from several sources.

Data Availability Statement

All relevant data presented in the article are stored according to institutional requirements and as such are not available online. However, all data used in this paper can be made available upon request to the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Marr, I.; Groß, A.; Moos, R. Overview on Conductometric Solid-State Gas Dosimeters. J. Sens. Sens. Syst. 2014, 3, 29–46. [Google Scholar] [CrossRef]

- Groß, A.; Beulertz, G.; Marr, I.; Kubinski, D.J.; Visser, J.H.; Moos, R. Dual Mode NOx Sensor: Measuring Both the Accumulated Amount and Instantaneous Level at Low Concentrations. Sensors 2012, 12, 2831–2850. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).