Abstract

A simple method of obtaining 2-(1-adamantyl)furans using a smaller amount of catalyst, providing a higher yield of the target products, as well as the possibility of varying the substituents in the furan ring was developed. The result wasachieved by the adamantylation of furans with 1-adamantanol in a nitromethane medium in the presence of a Lewis acid, for which aluminum or bismuth triflate was used in an amount of 10 mol%.

1. Introduction

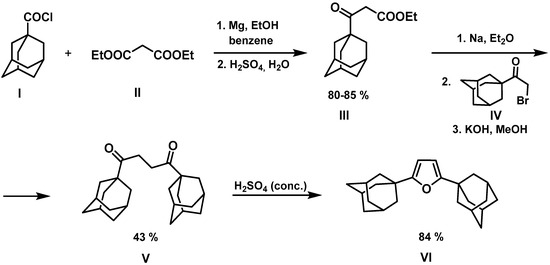

Among the first examples of preparation of furans containing the 1-adamantyl moiety wasthe method where 2,5-di(1-adamantyl)furan was prepared using 1-adamantoyl chloride and malonic ester as the starting compounds [1] (Figure 1).

Figure 1.

Synthesis of 2,5-di(1-adamantyl)furan.

At the first step, diethyl malonate II is acylated with 1-adamantoyl chloride I. Then, the resulting ethyl 3-(1-adamantyl)-3-oxopropionate III is alkylated with 1-(1-adamantyl)-2-bromoethane IV. Subsequent cyclization of 1,4-di(1-adamantyl)butane-1,4-dione V in concentrated sulfuric acid affords the target product VI in a yield of 84% (the total yield in all steps was 30%).

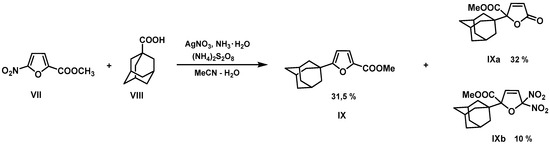

Amethod for preparation of adamantylated furans was described thatincludes the radical adamantylation of methyl 5-nitrofuran-2-carboxylic acid VII or 5-nitrofurfural. The adamantyl radical in this method isgenerated by the Ag(I)-catalyzed oxidative decarboxylation of 1-adamantanecarboxylic acid VIII [2] (Figure 2).

Figure 2.

Radical adamantylation of methyl 5-nitrofuran-2-carboxylic acid.

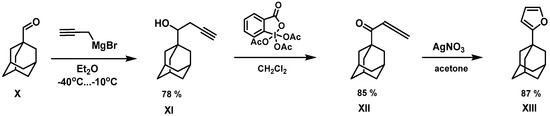

Athree-step method for preparation of 1-adamantylfuran was proposed, in whichthe starting compound was 1-adamantanecarbaldehyde X (Figure 3).

Figure 3.

Preparation of 1-adamantylfuran.

Initially, the reaction of 1-adamantanecarbaldehyde and propargyl magnesium bromide affords the corresponding homopropargyl alcohol XI, which is oxidized by the Dess–Martin periodinane into allenyl ketone XII. Its subsequent heterocyclization on exposure to silver nitrate results in the target 1-adamantylfuran XIII in atotal yield of 58% (based on three steps) [3].

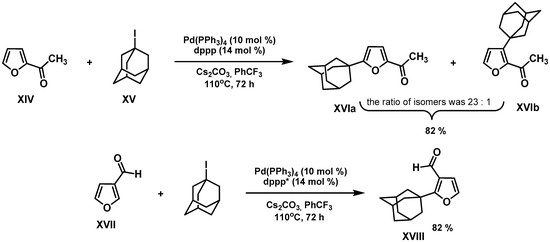

The method for 1-adamantylation of furans ring-substituted with electron-withdrawing groups (2-acetylfuran XIV, furan-3-carboxaldehyde XVII) using 1-iodoadamantane XV in the presence of 10 mol% tetrakis(triphenylphosphine)palladium(0), 14 mol% 1,3-bis(diphenylphosphino)propane (dppp), and 200 mol% cesium carbonate in trifluorotoluene is known [4] (Figure 4).

Figure 4.

Adamantylation of furans with 1-iodoadamantane.

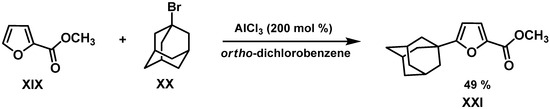

Adamantylation using 1-bromoadamantane in the presence of Lewis acid was used in the patent application: methyl furan-2-carboxylate XIX was treated with 1-bromoadamantane XX in ortho-dichlorobenzene in the presence of 200 mol% aluminum chloride. The yield of the target product XXI was 49% [5] (Figure 5).

Figure 5.

Adamantylation of furans with 1-bromoadamantane.

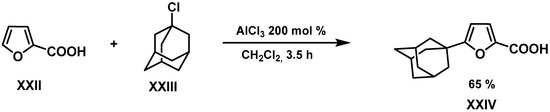

Adamantylation of 2-furancarboxylic acid XXII in dichloromethane in the presence of 200 mol% aluminum chloride proceeds similarly. The yield of the target product XIV was 65% [6] (Figure 6).

Figure 6.

Adamantylation of furans with 1-chloroadamantane.

The above-mentioned methods for the synthesis of 1-adamantylated furans have drawbacks, which includethe many steps in the synthesis scheme, the necessity for expensive palladium catalysts and specific reaction media, andthe formation of mixed reaction products. In addition, none of the methods given above was realized for a wide spectrum of furan substrates, which would allow one to talk about its versatility.

2. Materials and Methods

1H and 13C NMR spectra were recorded on an ECA 400 (JEOL) instrument in CDCl3 or (CD3)2SO (Cambridge Isotop Laboratories Inc., Tewksbury, MA, USA) using residual solvent signals as the internal standard. IR spectra were recorded on an IR Prestige instrument (Shimadzu, Kyoto, Japan) in KBr pellets. The course of the reactions was monitored by gas chromatography–mass spectrometry (GC/MS) using a GC-2010 instrument (Shimadzu) with QP-2010 Plus mass selective detector (Shimadzu): the column was a Supelko SLB-5ms, 30 m, withprogrammed heating from 60 to 265 °C at a rate of 30 °C/min. Melting points were measured in open-end capillaries on a Stuart SMP30 instrument. The reagents used were commercially available from Aldrich, Acros, or ABCR.

Example of Preparation of 2-(1-adamantyl)-5-(tert-butyl)furan (2a)

1-Adamantanol (250 mg, 1.64 mmol) and aluminum triflate (78.9 mg, 0.164 mmol) were added to nitromethane (7 mL). 2-(tert-Butyl)furan (200 mg, 1.64 mmol) was added and the resulting solution was stirred for 4 h at room temperature. The reaction mixture was transferred to a separatory funnel containing 2 M hydrochloric acid (20 mL) and chloroform (5 mL). The organic layer was separated, the aqueous layer was extracted with chloroform (3 × 5 mL), and the combined chloroform extracts were evaporated on a rotary evaporator. The residue was purified by flash chromatography using hexane–ethylacetate (20:1) as the eluent to give product 2a in yield of 83% as colorless crystals, m.p. 60–61 °C. IR (KBr), ν/cm–1: 3103 (Csp2–H), 2964, 2927, 2906, 2848 (Csp3–H), 1604, 1556 (Csp2–Csp2), 1452. MS (EI, 70 eV), m/z (Irel (%)): 258 (15, M+), 243 (100). 1H NMR (399.78 MHz, CDCl3), δ: 1.25 (s, 9H, CH3), 1.72–1.78 (m, 6H, CH2), 1.88–1.91 (m, 6H, CH2), 2.01–2.06 (m, 3H, CH), 5.76 (d, 1H, CH, 3JHH = 3.2 Hz), 5.81 (d, 1H, CH, 3JHH = 3.2 Hz). 13C NMR (CDCl3), δ: 28.2 (CH), 29.0 (CH3), 32.6 (C), 34.5 (C), 36.9 (CH2), 41.2 (CH2), 101.0 (CH), 101.4 (CH), 161.7 (C), 162.6 (C).

2-(1-Adamantyl)-5-methylfuran (2b). Yield 79%. IR (KBr), ν/cm−1: 3103 (Csp2–H), 2964, 2927, 2906, 2848 (Csp3–H), 1604, 1556 (Csp2–Csp2), 1452. MS (EI, 70 eV), m/z (Irel (%)): 216 (75, М+), 159 (100), 131 (15), 122 (34). 1H NMR (399.78 MHz, CDCl3), δ: 1.71–1.77 (m, 6H, CH2), 1.87–1.90 (m, 6H, CH2), 1.99–2.06 (m, 3H, CH), 2.25 (s, 9H, CH3), 5.76 (d, 1H, CH, 3JHH = 2.7 Hz), 5.82 (d, 1H, CH, 3JHH = 2.7 Hz). 13C NMR (CDCl3), δ: 13.5 (CH3), 28.3 (CH), 34.3 (C), 36.8 (CH2), 41.3 (CH2), 101.7 (CH), 105.4 (CH), 149.6 (C), 163.1 (C).

2-(1-Adamantyl)furan (2c). Yield 79%. Colorless oil. MS (EI, 70 eV), m/z (Irel (%)): 202 (71, М+), 159 (10), 145 (100), 117 (28), 108 (33). NMR spectrum corresponds to thatpublished in [3].

2-(1-Adamantyl)-5-(4-nitrophenyl)furan (2d). Yield 83%. Желтыекристаллы. m.p. 169–170 °C. IR (KBr), ν/cm−1: 3012 (Csp2–H), 2920, 2904, 2893, 2852 (Csp3–H), 1602, 1508 (Csp2–Csp2), 1535 (NO2as), 1332 (NO2sy). MS (EI, 70 eV), m/z (Irel (%)): 323 (100, М+), 266 (68), 229 (24), 150 (14). 1H NMR (399.78 MHz, CDCl3), δ: 1.75–1.82 (m, 6H, CH2), 1.96–1.99 (m, 6H, CH2), 2.06–2.10 (m., 3H, CH), 2.07 – 2.12 (m., 6H, CH2), 6.08 (д, 3.2 Гц, 1H, CH), 6.77 (д, 3.2 Гц, 1H, CH), 7.72 (m, 2H, CH), 8.20 (m, 2H, CH). 13C NMR (CDCl3), δ: 28.2 (CH), 34.9 (C), 36.7 (CH2), 41.2 (CH2), 104.8 (CH), 109.9 (CH), 123.3 (CH), 124.3 (CH), 137.0 (C), 145.8 (C), 149.4 (C), 167.0 (C).

2-((5-(1-Adamantyl)-2-furyl)methyl)-1H-isoindole-1,3(2H)-dione (2e). Yield 77%. IR (KBr), ν/cm−1: 3115, 3103 (Csp2–H), 2906, 2848 (Csp3–H), 1774, 1722 (C=O). MS (EI, 70 eV), m/z (Irel (%)): 361 (96, М+), 333 (21), 267 (10), 226 (44), 157 (92), 135 (100). 1H NMR (399.78 MHz, CDCl3), δ: 1.70–1.78 (m, 6H, CH2), 1.85 (уш.с, 6H, CH2), 2.00 (уш.с, 3H, CH), 4.81 (с, 2H, CH2), 5.81 (д, 3.2 Гц, 1H, CH), 6.21 (д, 3.2 Гц, 1H, CH), 7.67–7.73 (m, 2H, CH), 7.82–7.88 (m, 2H, CH). 13C NMR (CDCl3), δ: 28.2 (CH), 34.6 (CH2), 36.7 (CH2), 41.1 (CH2), 43.2 (C), 102,3 (CH), 108.9 (CH), 123.4 (CH), 132.2 (C), 134.0 (CH), 147.0 (C), 164.6 (C), 167.7 (C=O).

Ethyl 5-(1-adamantyl)-2-furoate (2f). Yield 72%. Colorless crystals. m.p. 84°C. IR (KBr), ν/cm−1: 3169, 3128 Csp2–H), 2981, 2941, 2900, 2850 (Csp3–H), 1720 (C=O). MS (EI, 70 eV), m/z (Irel (%)): 274 (100, М+), 229 (19), 217 (63), 180 (23). 1H NMR (399.78 MHz, CDCl3), δ: 1.36 (t, 7 Hz, CH3, 3H), 1.73–1.80 (m, 6H, CH2), 1.91 (s, 3H), 1.93–1.98 (m., 6H, CH2), 2.03–2.09 (m., 3H, CH), 4.33 (q, 7 Hz, 2H, CH2), 6.04 (d, 3.4 Hz, 1H, CH), 7.06 (d, 3.5 Hz, 1H, CH). 13C NMR (CDCl3), δ: 14.4 (CH3), 28.1 (CH), 35.0 (C), 36.5 (CH2), 41.8 (CH2), 60.5 (CH2), 104.2 (CH), 118.7 (CH), 142.7 (C), 159.0 (C), 169.0 (C=O).

2-(1-Adamantyl)-5-(2-nitrovinyl)furan(2g). Yield 37%. Lemon yellow crystals. IR (KBr), ν/cm−1: 3147, 3103, 3066 (Csp2–H), 2908, 2848 (Csp3–H), 1627, 1492 (Csp2–Csp2), 1523 (NO2as), 1330 (NO2sy). MS (EI, 70 eV), m/z (Irel (%)): 273 (15, М+), 230 (37), 145 (15), 135 (100). 1H NMR (399.78 MHz, CDCl3), δ: 1.73–1.81 (m, 6H, CH2), 1.91–1.93 (m., 6H, CH2), 2.07 (br.s., 3H, CH), 6.13 (d, 3.7 Hz, 1H, CH), 6.80 (d, 3.7 Hz, 1H, CH), 7.47 (d, 12.8 Hz, 1H, CH), 7.70 (d, 13.2 Hz, 1H, CH). 13C NMR (CDCl3), δ: 28.0 (CH), 35.2 (C), 36.5 (CH2), 40.8 (CH2), 106.3 (CH), 121.9 (CH), 125.7 (CH), 133.2 (C), 144.7 (C), 170.4 (C).

3. Results and Discussion

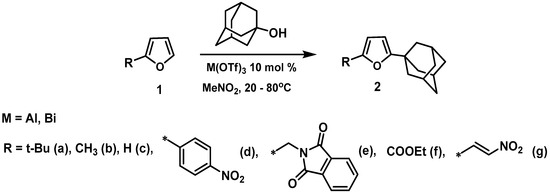

We propose performingadamantylation of furans with 1-adamantanol in nitromethane in the presence of Lewis acid, which could be aluminum or bismuth triflate in the amount of 10 mol%, according to Figure 7.

Figure 7.

Adamantylation of furans with 1-adamantanol.

Optimum conditions for the preparation of adamantylated furans were selected on the model reaction of 2-tert-butylfuran with 1-adamantanol whose course was controlled by chromatography–mass spectrometry.

The degree of conversion of 1-adamantanol into 2-(1-adamantyl)-5-(tert-butyl)furan, depending on the Lewis acid used, is shown in the figure.

As the figure shows, consumption of 1-adamantanol and accumulation of the adamantylation product occur most rapidly whenusing 10 mol% of bismuth triflate (97% conversion after 2.5 h at room temperature), while the same amount of aluminum triflate within the same time provides a conversion of 85%. Nevertheless, aluminum triflate gives a conversion of 97% upon mixing the reagents for 4 h. In the case of scandium triflate, the 82% conversion is achieved only after 22 h and, in the case of zinc triflate, the conversion within the same time was only 5%.

Depending on the nature of substituents at the furan ring, adamantylation was carried out at room temperature or upon heating to 50–80 °C.

This method can be extended to several alkyl- and arylfurans, as well as to furans containing functional groups, such as carbethoxy and β-nitrovinyl which are most promising to be used in the synthesis of bioactive substances.

4. Conclusions

A simple method of obtaining 2-(1-adamantyl)furans using aluminum or bismuth triflate in nitromethane an amount of 10 mol% was developed. This method can be extended to several alkyl- and arylfurans, as well as to furans containing functional groups, such as carbethoxy and β-nitrovinyl which are most promising to be used in the synthesis of bioactive substances.

Acknowledgments

This work was financially supported by the Russian Foundation for Basic Research (Project No. 16-43-230002 r_a) and the Administration of the Krasnodar Territory.

References

- Stetter, H.; Rauscher, E. Zurkenntnis des β-[adamantyl-(1)]-)-β-oxo-propionsaure-athylesters. Chem. Ber. 1960, 93, 2054–2057. [Google Scholar] [CrossRef]

- Cogolli, P.; Tastaferri, L.; Tiecco, M.; Tingoli, M. Factors controlling the fate of radical ipso intermediates. Homolytic alkylation of furan derivatives. J. Chem. Soc. Chem. Commun. 1979, 18, 800–801. [Google Scholar] [CrossRef]

- Hashmi, A.S.K.; Salathe, R.; Frey, W. Gold catalysis: No steric limitations in the phenol synthesis. Chem. Eur. J. 2006, 12, 6991–6996. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Wei, J.; See, T.; Xu, K.; Hirao, H.; Roger, J.; Hierso, J.-C.; Zhou, J. A general palladium-catalyzed method for alkylation of heteroarenes using secondary and tertiary alkyl halides. Angew. Chem. Int. Ed. 2014, 53, 13573–13577. [Google Scholar] [CrossRef] [PubMed]

- EP2 RECEPTOR AGONISTS, PCT/WO2005/080367 A1, IPC (7) C07D 307/68, C07D 405/04, 1 September 2005.

- Aikawa, H.; Takahira, Y.; Yamaguchi, M. Synthesis of 1,8-di(1-adamantyl)naphthalenes as single enantiomers stable at ambient temperatures. Chem. Commun. 2011, 47, 1479–1481. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).