1. Introduction

The standard method for assessing exposure to hand-arm vibration is defined by ISO 5349-1 [

1]. The daily vibration exposure

of an operator must be derived from the vibration total value

emitted by the machine and the total daily duration of exposure

. In the field, the evaluation of

is often performed on a limited time period in order not to disturb the company’s production.

Some hand-held tools generate shocks and transient vibrations of high amplitudes [

2]. For these non-stationary signals, the vibration total value

and the total daily exposure time

may not be representative of the worker’s real exposure: irregular working task, signal splitting by the experimenter, and limited information on daily activities. The estimation of the daily vibration exposure

and its comparison with the regulatory limit values are therefore difficult [

3].

The aim of this article is to present a method for the estimation of the daily vibration exposure adapted to vibrations composed of repeated shocks. It only requires the calculation of the vibration dose received by the operator during the intervention and the estimation of the total number of daily shocks. Its mathematical formulation is presented. It is then illustrated on a real case of field measurement.

2. Materials and Methods

2.1. Daily Vibration Exposure

The daily vibration exposure

is defined as:

is the vibration total value emitted by the machine.

is the total daily duration of exposure of the operator.

is the reference duration for a working day.

The vibration total value emitted by the machine

is defined as:

is the root-mean-square value of the

weighted accelerations, measured in the directions

,

, and

.

The root-mean-square value of the

weighted accelerations

is defined as:

is the

sample value of the

weighted acceleration.

is the total number of samples.

is the sampling frequency of the signal.

2.2. Estimation from Field Measurements

, , and are the quantities related to the measurements made over a portion of the working day (measured work phase). In particular, is the sample duration over which is calculated.

, , and are the estimates of the unknown quantities , , and relative to the whole working day.

If the measured work phase is considered to be representative of the operator’s daily task, then

may be derived from Equation (1) as:

Depending on the nature of the working task, it is sometimes possible to know the numbers of shock repetitions during the measured work phase

, and during complete working task

.

is then derived from Equation (1) as:

represents the average vibration dose received per shock

of the sample. It is equal to the dose that would be received for each of the

shocks of the sample if they were all identical:

2.3. Application to Vibrations Emitted by Firearms

Vibrations emitted by a Zastava M70 AB2 automatic assault rifle were measured (

Figure 1). Five 7.62 × 39 mm M43 rounds were fired in 35.5 s during the measurements. The ballistics expert estimates that this weapon is used for 1.5 h per day. Another piece of information is that approximately 300 rounds are fired per day both in semi-automatic and full-automatic mode. A piezoelectric accelerometer was glued to the rifle (356B20-PCB Piezotronics

®). Acceleration was recorded with a R2DB front-end (DEWESOFT

®).

3. Results

3.1. Field Measurements

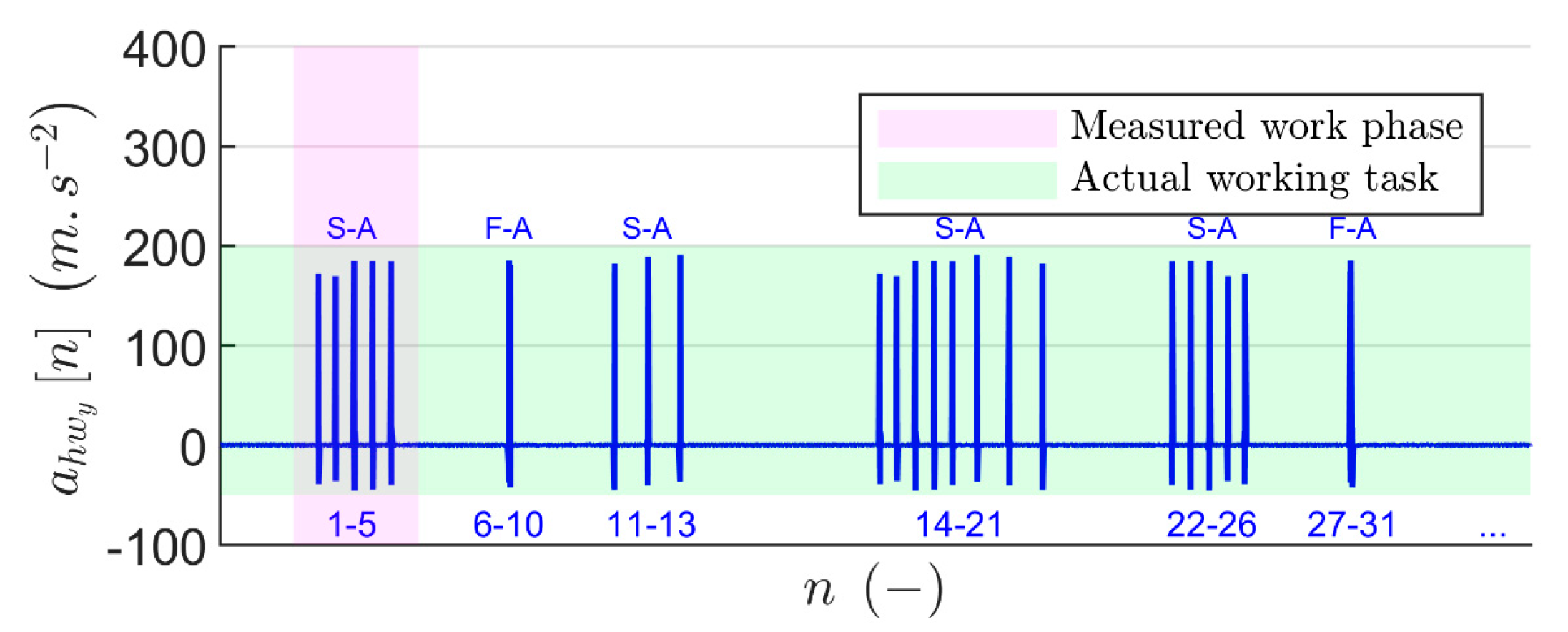

Figure 2 presents the weighted acceleration

of the measured work phase. Only one axis is shown for readability reasons. An extract of the operator’s daily working task is also presented in order to illustrate the differences that may exist with the sample. This part remains unknown during field measurements. Signals characteristics are presented in

Table 1.

3.2. Daily Vibration Exposure Estimations

Table 2 shows

values calculated from the sample depending on the available information.

4. Discussion

For non-stationary vibrations composed only of one or more successive shocks, Equations (1)–(3) show that varies with the number of points of a signal. This is not the case for .

When only the total daily duration of exposure can be determined from the daily task information, Equation (4) shows that depends on . is then particularly sensitive to the sampling conditions: the machine emission, and the regularity of the firing rate throughout the day.

When the numbers of shocks of the sample and of the whole day can be determined from task information, Equations (5) and (6) show that depends only on the dose . is then insensitive to the consistency of the firing pace outside of the sample.

In practice, the field-measurement conditions are not always controlled.

varies during the day depending on the company’s production (

Figure 2). The assumption that the sample is representative is not always satisfied (

Table 1).

is also difficult to determine as it represents the actual duration of exposure to vibration. It can be very different from the duration of use of the machine. The estimate of daily vibration exposure

is then strongly biased (

Table 2).

When possible, the estimation of the total number of shocks

is easier to perform and often more accurate than

. The average vibration dose received per shock during sampling

is often representative of the whole set of shocks (

Table 1).

is then closer to the actual daily exposure.

5. Conclusions

The estimation method for the daily exposure to vibration , which takes into account the number of shock repetitions, is often more reliable than the usual one. It also facilitates the implementation of technical prevention solutions by linking the operator’s exposure to production rather than to his work pace. It should be preferred for assessing the risk created by repeated shocks at the workplace.

Author Contributions

Conceptualization, F.M. and M.A.; methodology, F.M.; software, F.M.; validation, F.M. and M.A.; formal analysis, F.M.; investigation, F.M.; resources, F.M.; data curation, F.M.; writing—original draft preparation, F.M.; writing—review and editing, F.M.; visualization, F.M.; supervision, F.M.; project administration, F.M.; funding acquisition, F.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data not available due to legal/commercial restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- ISO 5349-1:2001; Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2001.

- Pitts, P.; Kaulbars, U.; Lindell, H.; Grétarsson, S.L.; Machens, M.; Brammer, A.J.; Yu, G.-Q.; Schenk, T.; Haas, F. Hand-Arm Vibration: Exposure to Isolated and Repeated Shock Vibrations—Review of the International Expert Workshop 2015 in Beijing; IFA Report 5/2017e; IFA: Bonn, Germany, 2015; ISBN 978-3-86423-198-8. [Google Scholar]

- Directive 2002/44/EC of the European Parliament and of the Council of 25 June 2002 on the Minimum Health and Safety Requirements Regarding the Exposure of Workers to the Risks Arising from Physical Agents (vibration). Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:546a09c0-3ad1-4c07-bcd5-9c3dae6b1668.0004.02/DOC_1&format=PDF (accessed on 1 December 2022).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).